Patents

Literature

57results about How to "Reduce layer spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

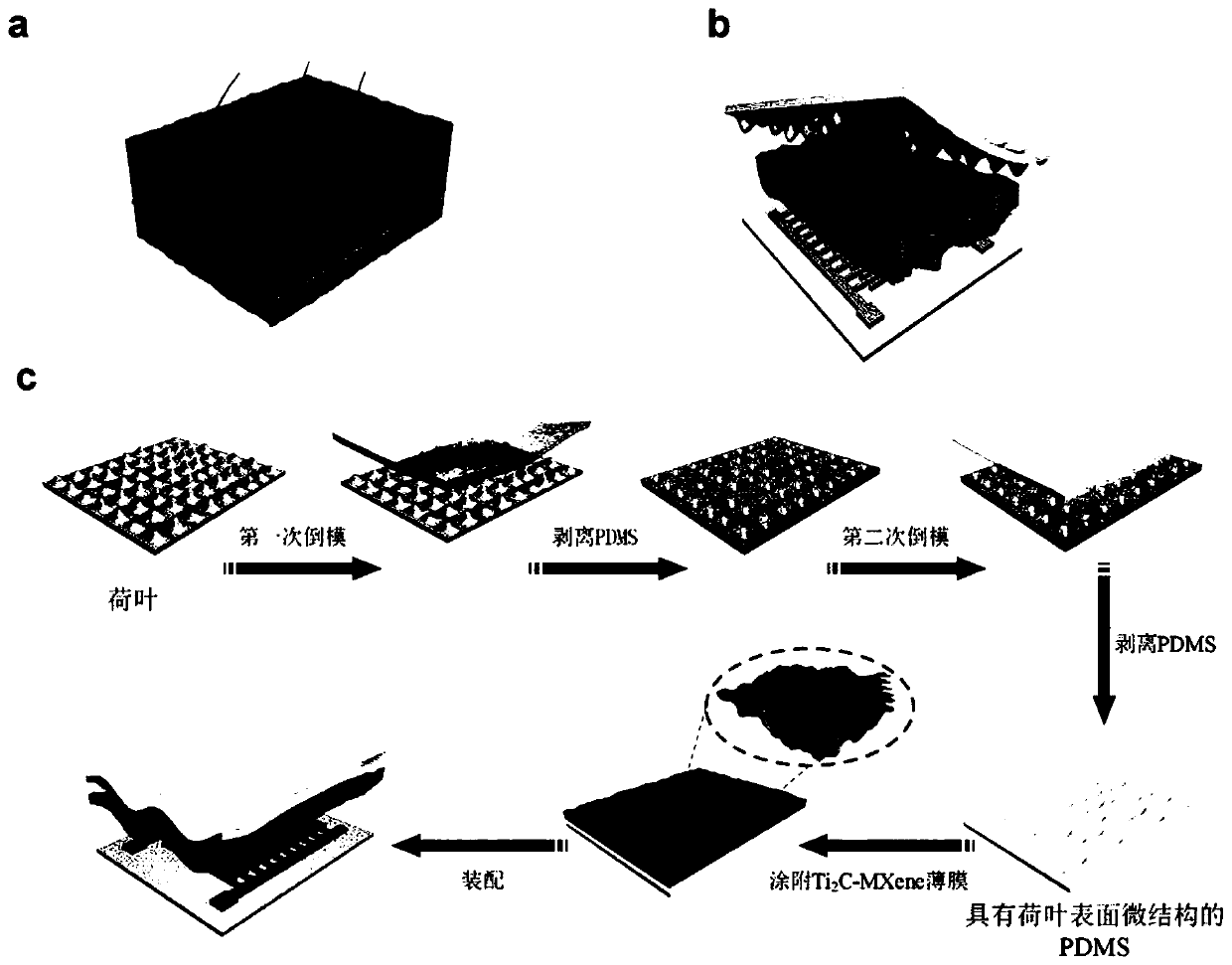

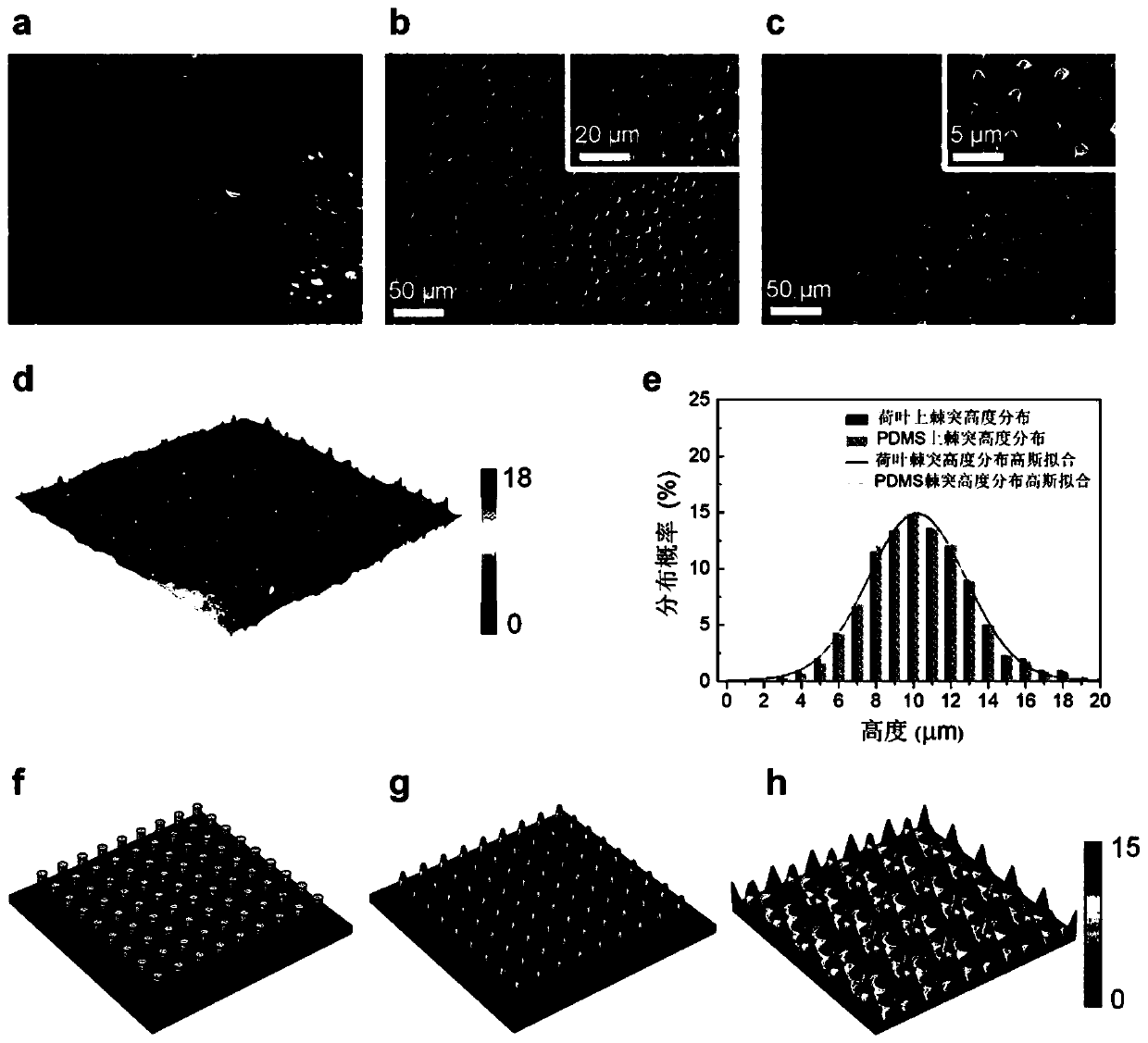

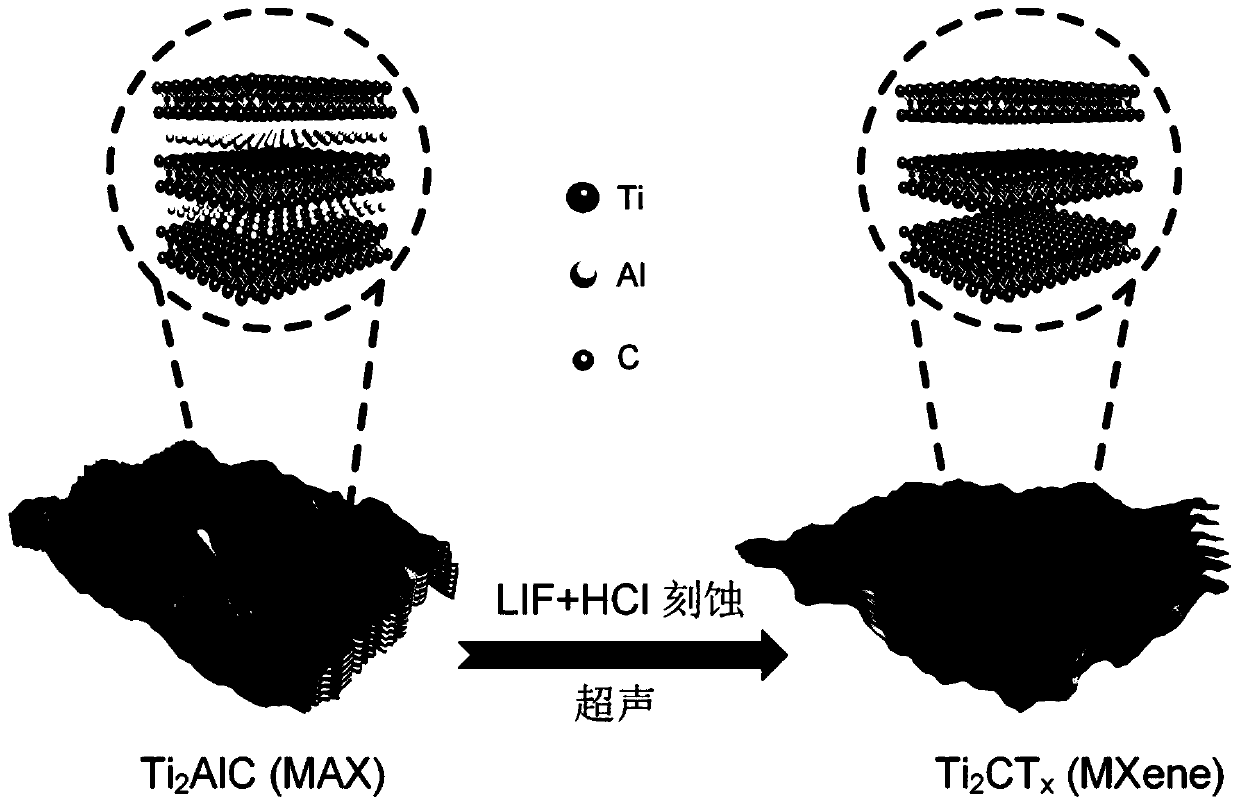

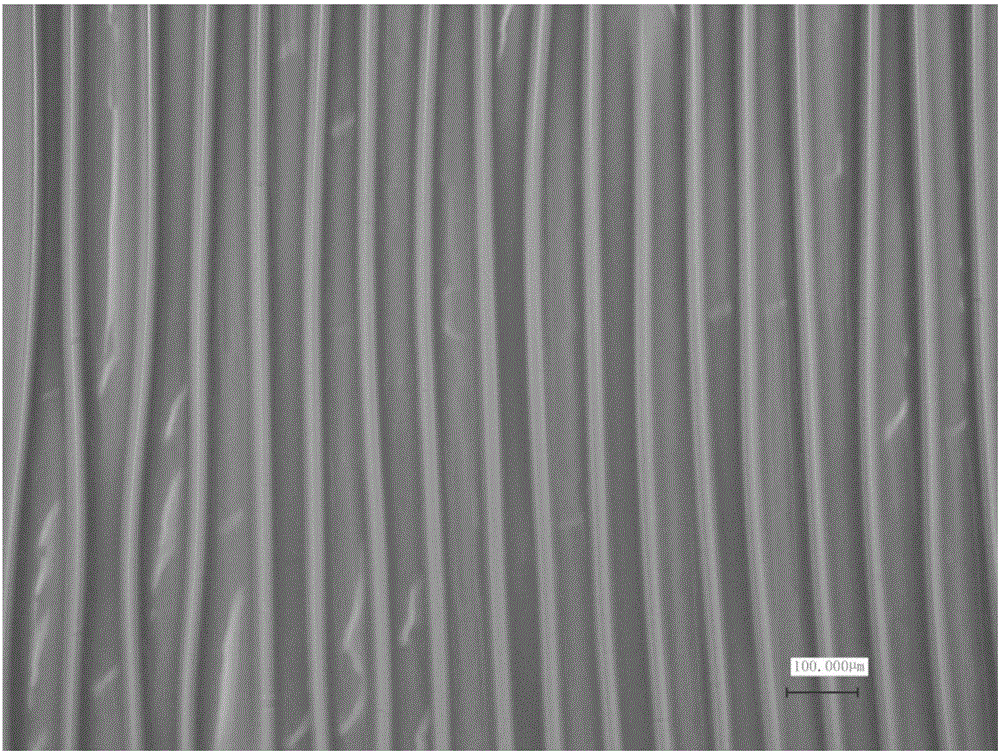

Bionic flexible pressure sensor based on lotus leaf micro-spinous-process/MXene composite structure

ActiveCN110501095AHigh sensitivityLinearity of height and widthForce measurementPressure senseEngineering

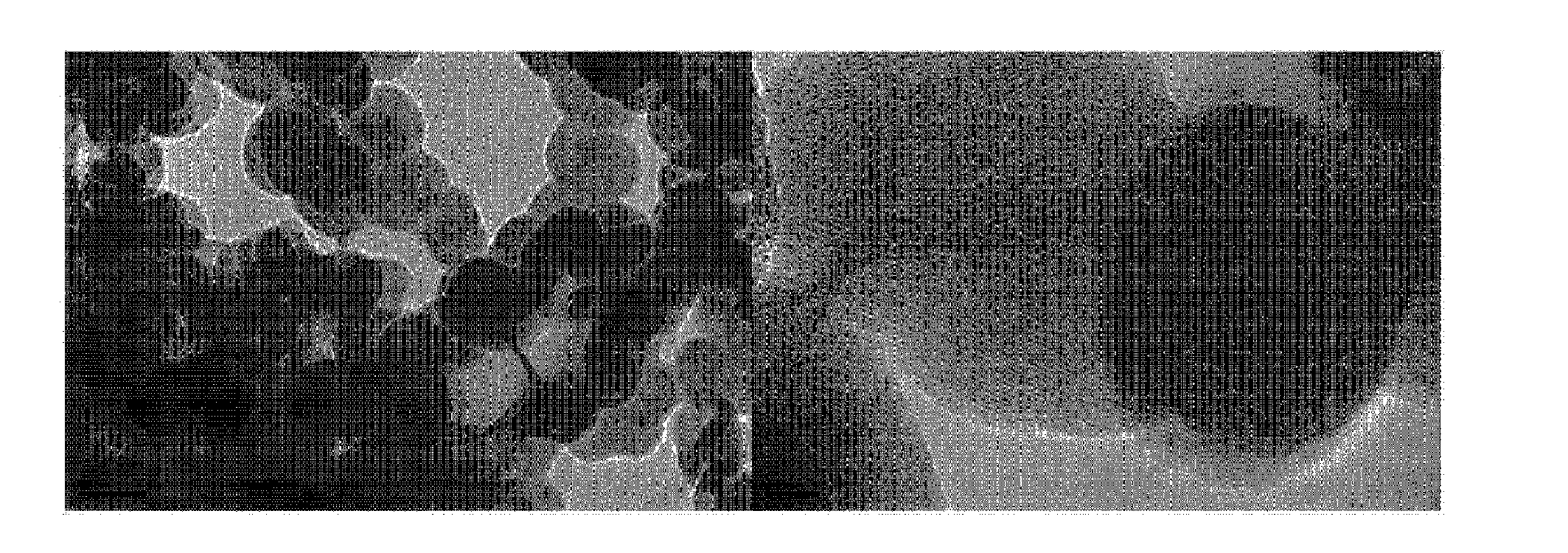

The invention discloses a bionic flexible pressure sensor based on a lotus leaf micro-spinous-process / MXene composite structure. The sensor comprises a pressure-sensing layer being polydimethylsiloxane (PDMS) with a micro-spinous-process structure on the surface of a lotus leaf, a pressure treatment layer being a multilayer Ti2C-MXene film, and a signal output layer being a flexible electrode andbeing used for supporting and protecting the Ti2C-MXene film and outputting an electrical signal converted by the pressure signal. According to the bionic flexible pressure sensor based on a lotus leaf micro-spinous-process / MXene composite structure, the sensor has excellent characteristics of high sensitivity, wide linearity, low response time, high stability and the like without the complicatedstructure design and manufacturing process.

Owner:FUDAN UNIV

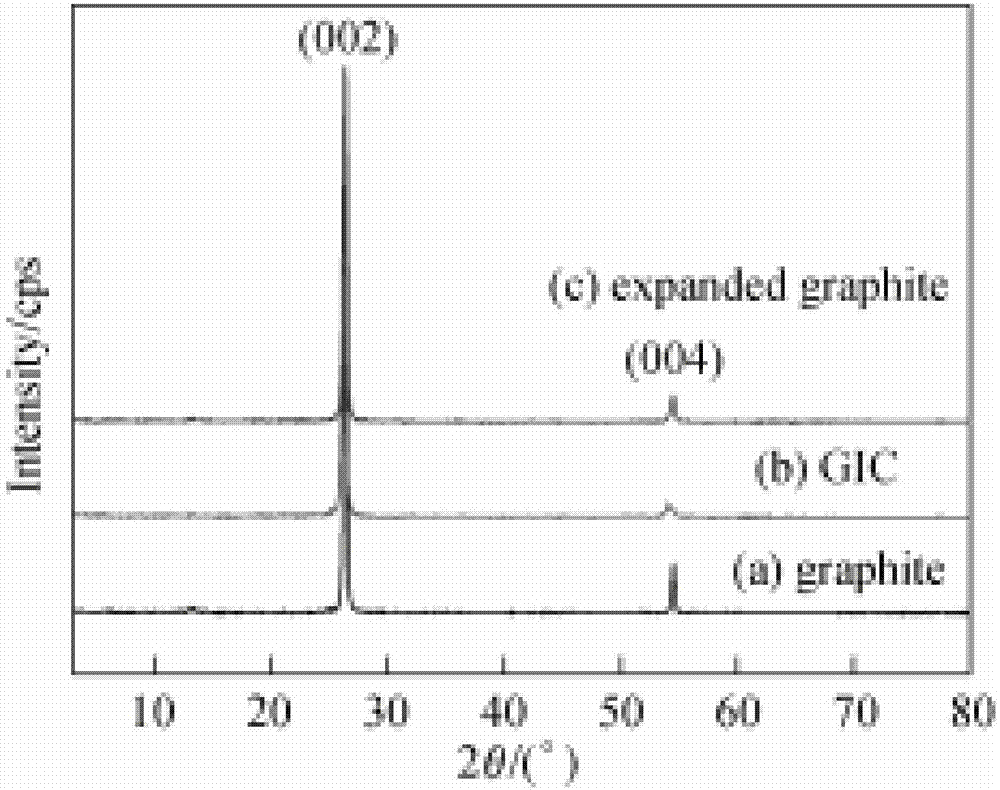

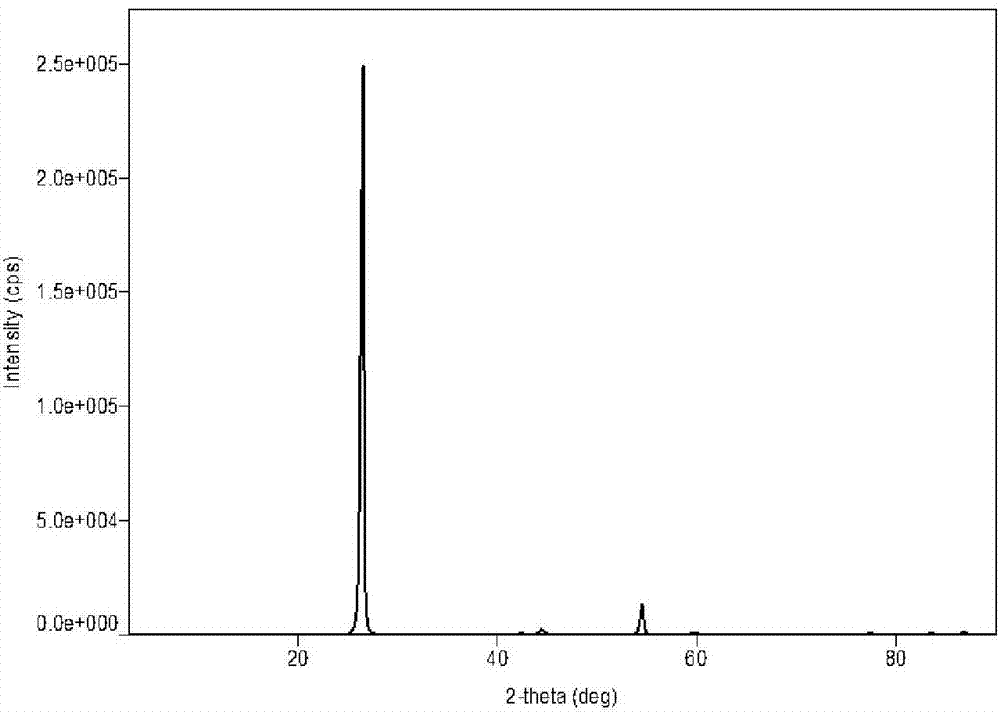

Method for preparing graphene from biomass-derived carbonaceous mesophase

ActiveUS20150133568A1Reduce layer spacingMaintain stabilityOther chemical processesMixing methodsAlcoholHydrogen atmosphere

The present invention relates to a method for preparing graphene from a biomass-derived carbonaceous mesophase, which includes: soaking a base substance into an ethanol solution of a biomass-derived carbonaceous mesophase; after a certain period of time, taking out and drying the base substance, a layer of biomass-derived carbonaceous mesophase film being attached to the surface of the base substance; subjecting the base substance to a heat treatment under the protection of a hydrogen atmosphere, then a stacked graphene film was formed on the surface of the base substance; and further subjecting the base substance to ultrasonic dispersion in an alcohol solvent to separate the graphene film and the base substance, then a graphene alcosol was formed. The preparation process of the present invention is easy to implement. The raw material biomass-derived carbonaceous mesophase has abundant sources and is low in cost. The preparation process has low energy consumption, and is applicable to mass production. The obtained graphene film and graphene alcosol can be used in solar cells, nano-electronic devices, sensors, and so on, and have broad market prospects.

Owner:SHANGHAI JIAO TONG UNIV +1

Heat processing technology of high-carbon carbon steel coil rod for steel wire rope

InactiveCN102719643AImprove plasticityImprove toughnessFurnace typesHeat treatment bathsCarbon steelHeat processing

The invention discloses a heat processing technology of a high-carbon carbon steel coil rod for a steel wire rope. The heat processing technology is characterized by comprising the following steps of: carrying out hot rolling, water passing and cooling and coiling on the high-carbon carbon steel coil rod with the diameter of 6mm-16.5mm so as to obtain coil rod; when the prepared coil rod reaches the temperature range of 820 DEG C-900 DEG C, rapidly throwing the coil rod in a salt groove to keep for 2 seconds-40 seconds in salt bath lower than sorbite temperature at constant temperature; and then putting the coil rod into salt bath or lead bath with the sorbite temperature range to keep at constant temperature for 5 minutes-15 minutes, taking out and cooling naturally, thereby completing the heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope can effectively refine the sorbite clique size and interlayer spacing and can improve the uniformity of interlayer spacing; and the product has the advantages of high intensity plasticity, excellent fatigue resistance, long service and the like. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope has an obvious effect of improving the high plasticity of a coil rod wire material.

Owner:GUIZHOU UNIV

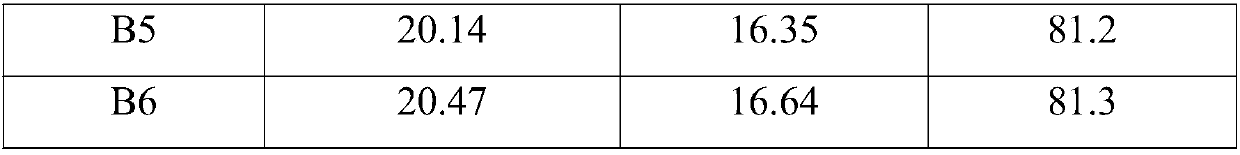

Low-temperature cycle iron phosphate lithium-ion power battery and preparation method thereof

ActiveCN107768667AHigh specific surface areaImprove conductivityFinal product manufactureCell electrodesPower batteryLithium iron phosphate

The invention relates to the technical field of lithium batteries, inp articular to a low-temperature cycle iron phosphate lithium-ion power battery and a preparation method of the low-temperature cycle iron phosphate lithium-ion power battery. The low-temperature cycle iron phosphate lithium-ion power battery comprises a positive electrode, a negative electrode and an electrolyte, the positive electrode comprises lithium iron phosphate, the average particle size distribution D50 of the volume of the lithium iron phosphate is 0.5-2 [mu]m, the tap density of the lithium iron phosphate is 0.8-1.5 g / cm<3>, the specific surface area of the lithium iron phosphate is 6-12 m<2> / g, the negative electrode comprises a green coke pulverized super-high temperature graphitized material, the particle size distribution D50 of the green coke pulverized super-high temperature graphitized material is 2-10 [mu]m, the tap density of the green coke pulverized super-high temperature graphitized material is1.2-2 g / cm<3>, and the specific surface area of the green coke pulverized super-high temperature graphitized material is 0.5-1.5 m<2> / g. The positive electrode and the negative electrode are modified,so that the low-temperature cycle performance of the lithium battery is improved.

Owner:江苏海四达电源有限公司

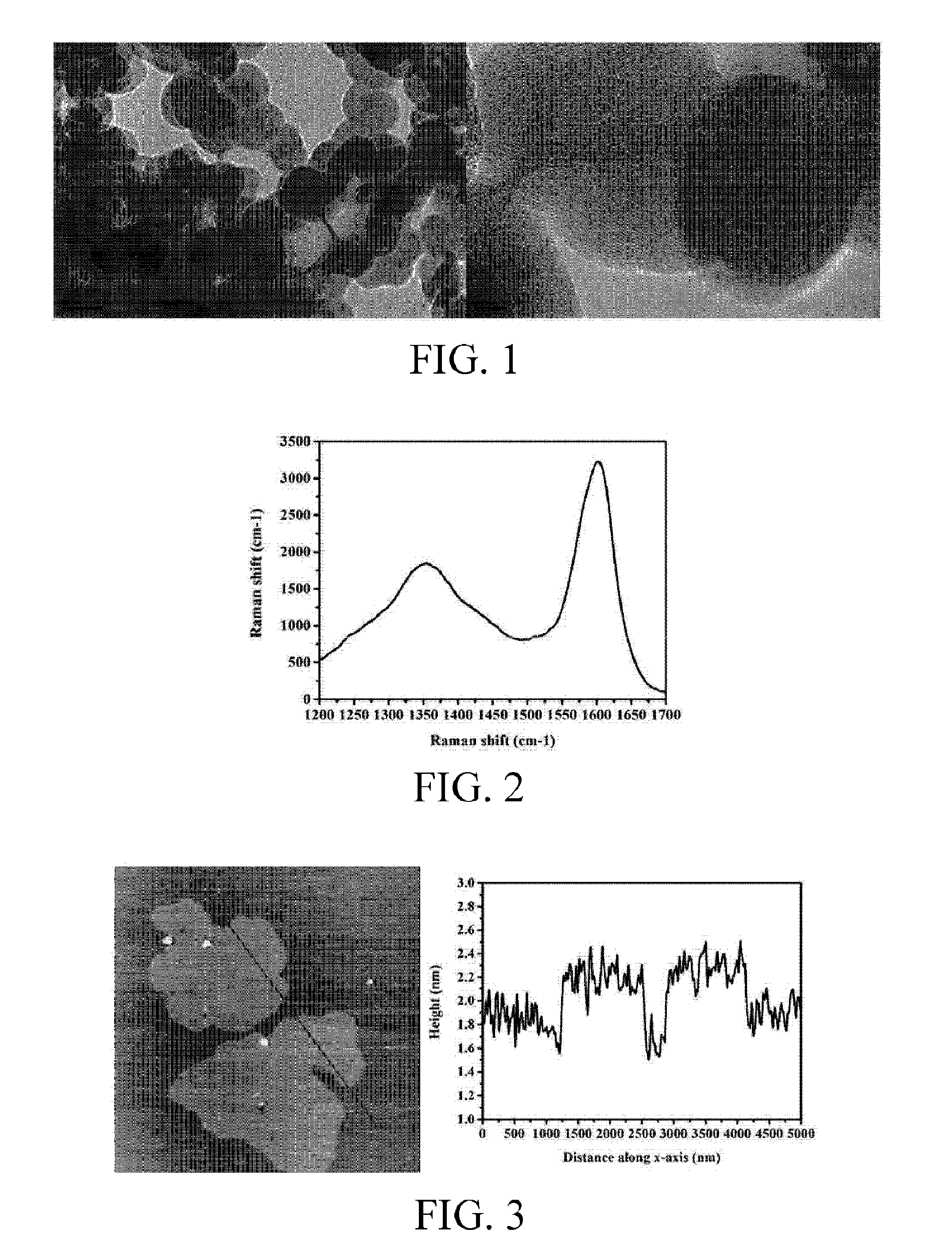

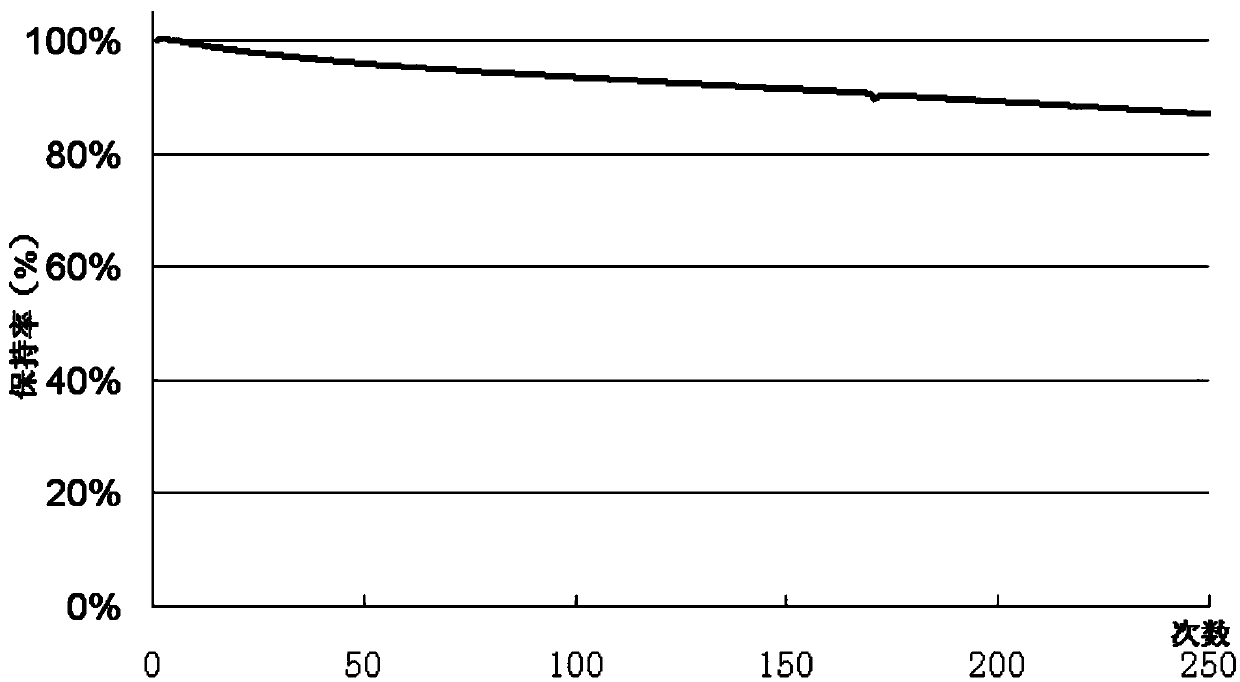

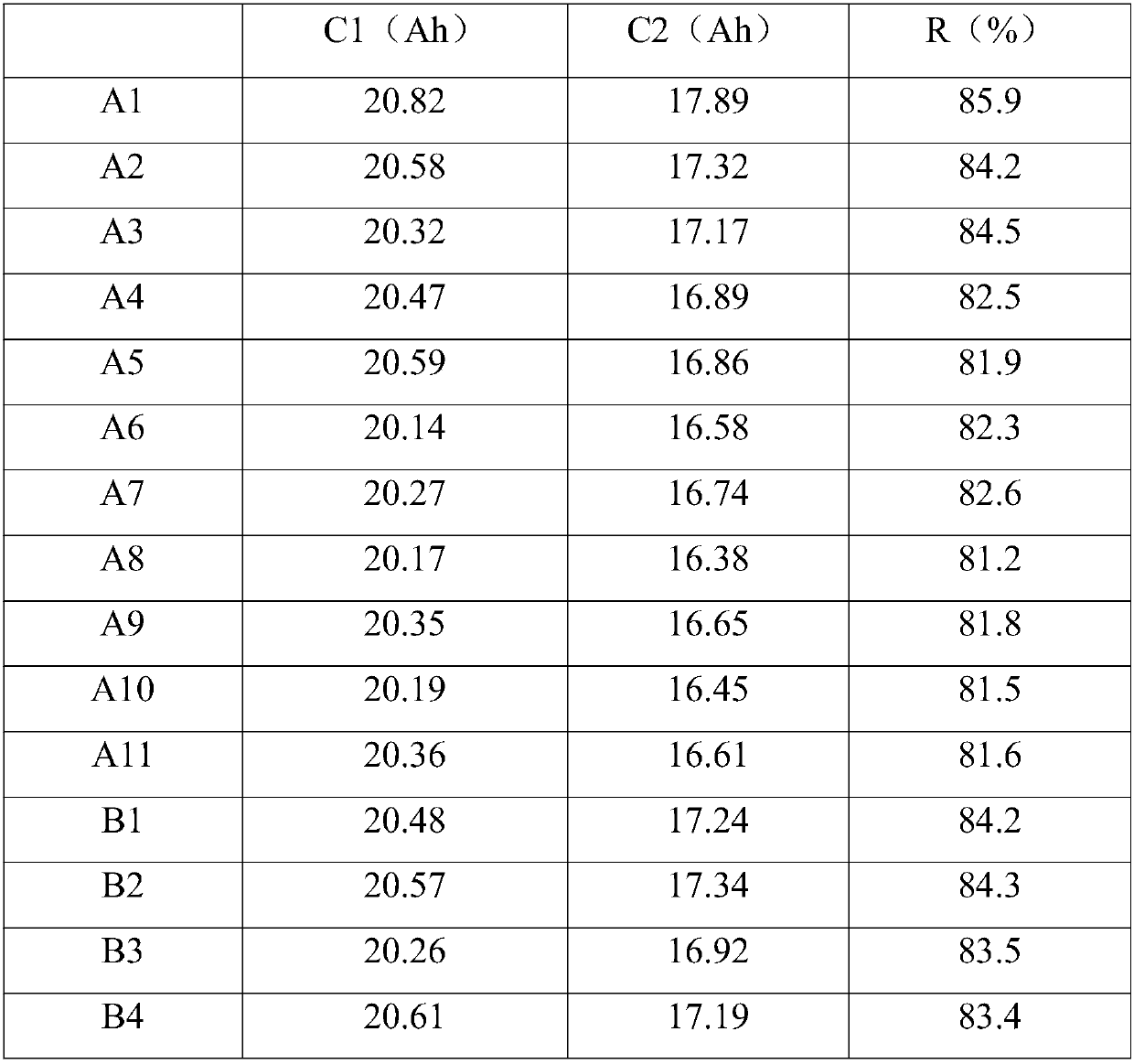

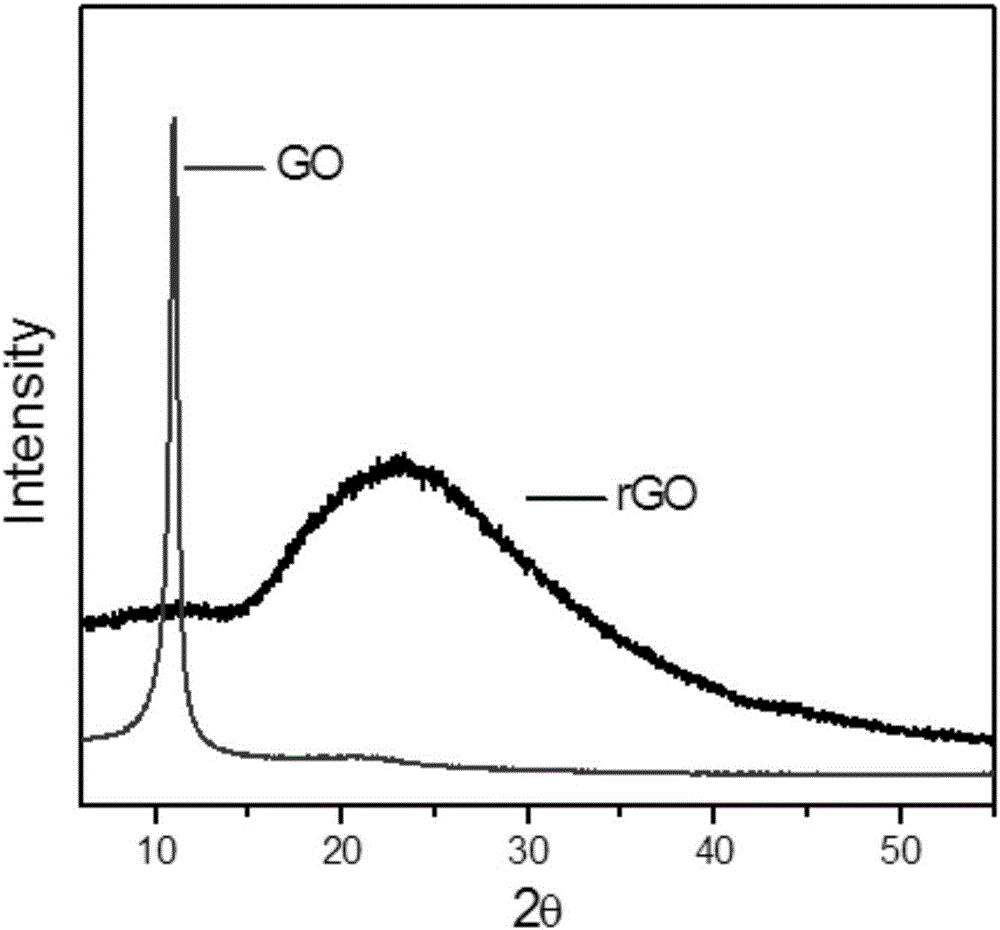

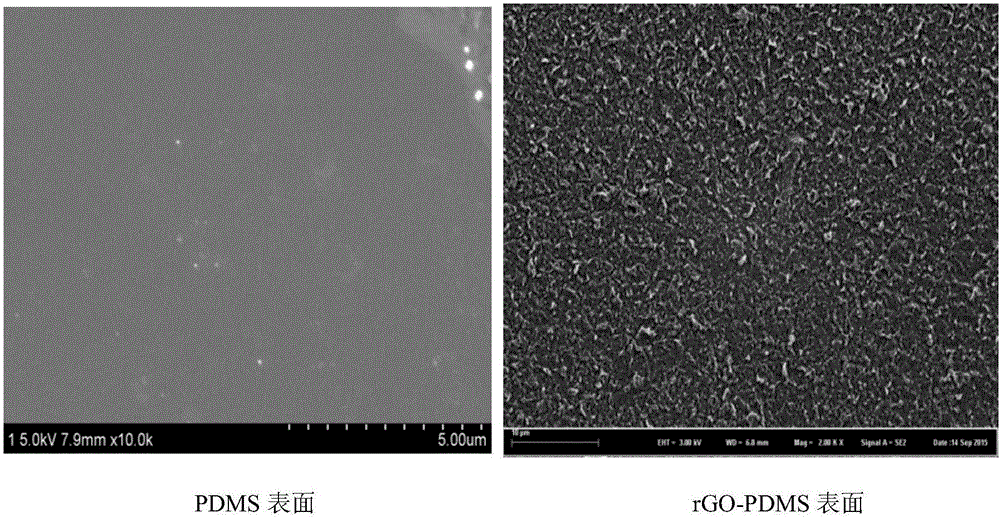

Apical impulse sensor based on reduced graphene oxide film with bilayer buckling structure

The invention provides an apical impulse sensor based on a reduced graphene oxide film with a bilayer buckling structure, belonging to the field of reduced graphene oxide sensors. A reduced graphene oxide film flexible sensor with a buckling structure is formed by carrying out suction filtration on a reduced graphene oxide water liquid to form a film, transferring reduced graphene oxide onto a flexible polydimethylsiloxane (PDMS) substrate which is pre-stretched by 30%, connecting copper wire electrodes at the two ends of reduced graphene oxide respectively, then relaxing reduced graphene oxide to return to the original state, cutting the reduced graphene oxide flexible film from the middle and folding the reduced graphene oxide flexible film in half so that the reduced graphene oxide layers come into contact with each other. The reduced graphene oxide film flexible sensor with a buckling structure has large specific surface area and excellent electrical conductivity and mechanical properties. A preparation method of the reduced graphene oxide sensor is mild in preparation conditions, controllable in technological parameters and low in cost, is simple and practicable and has high repeatability. The sensor can be attached to human skins and is used for testing the apical impulse.

Owner:ZHEJIANG SCI-TECH UNIV

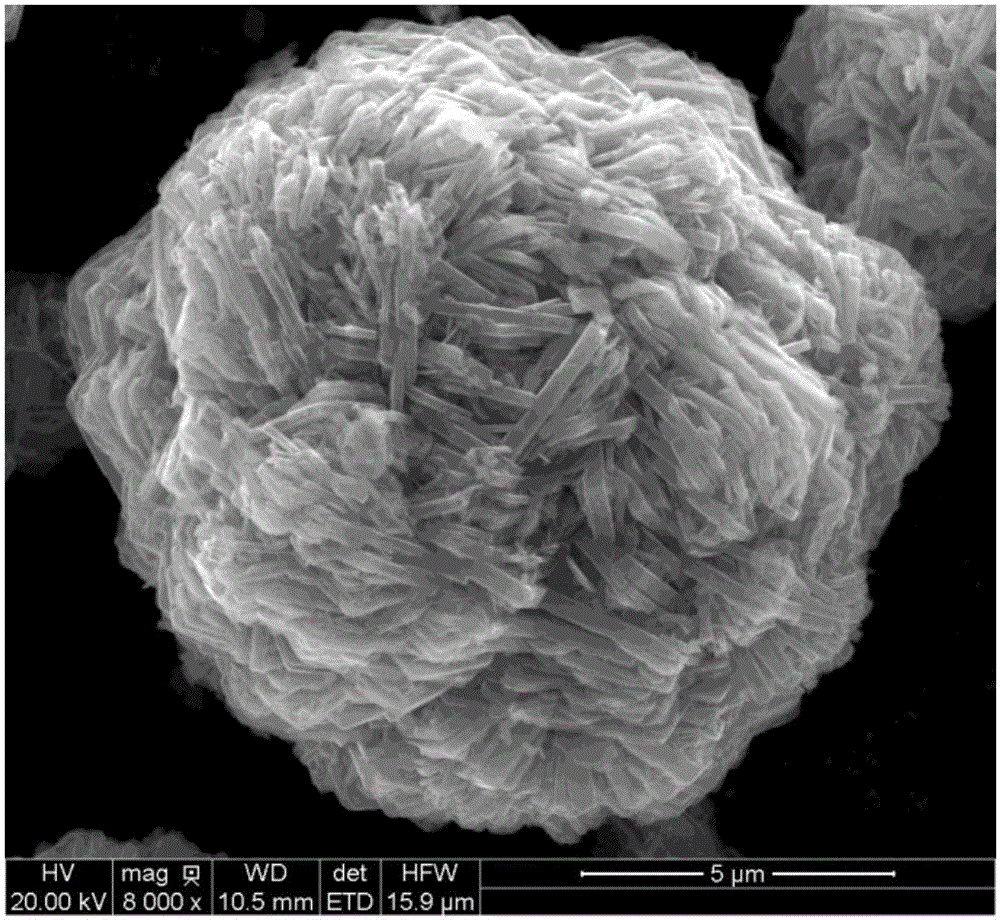

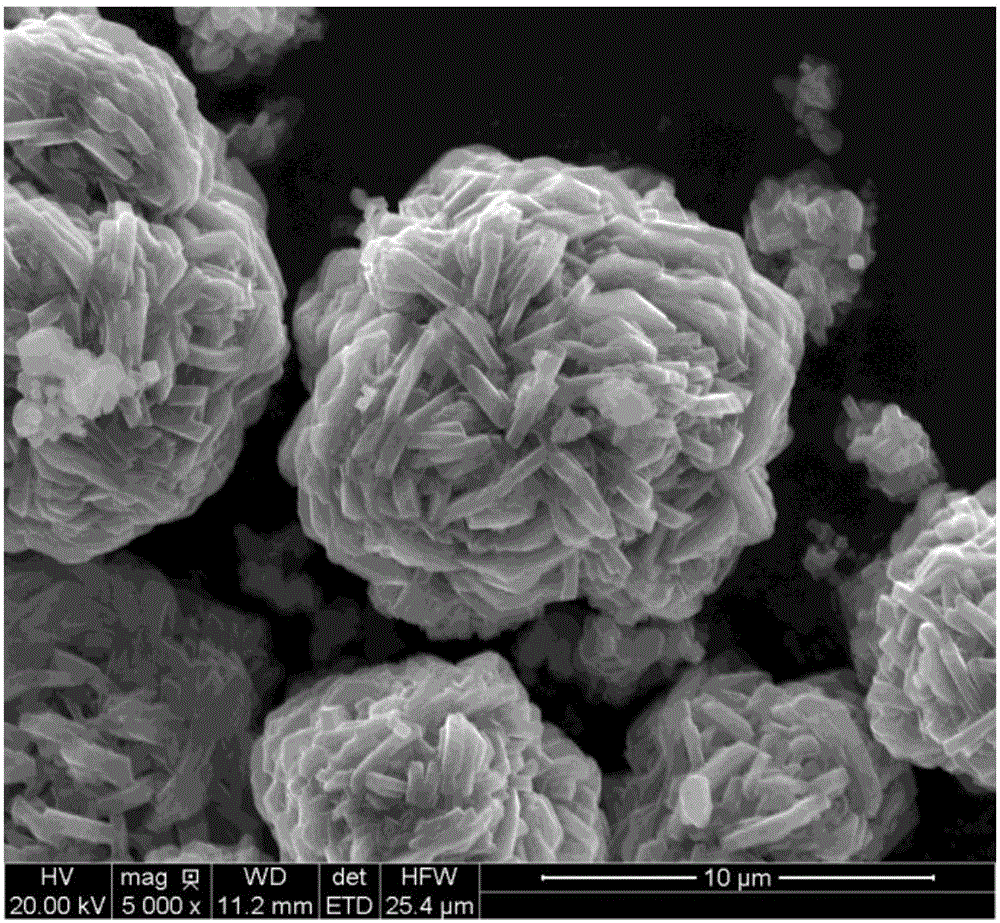

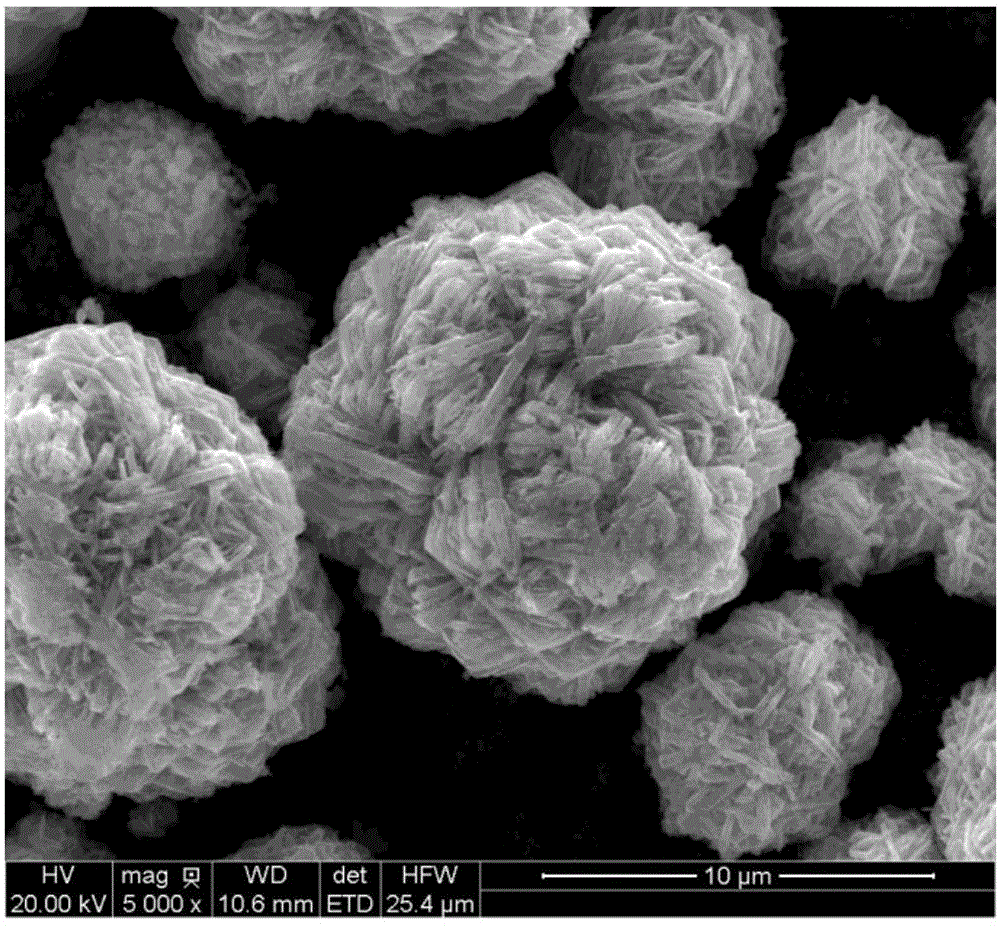

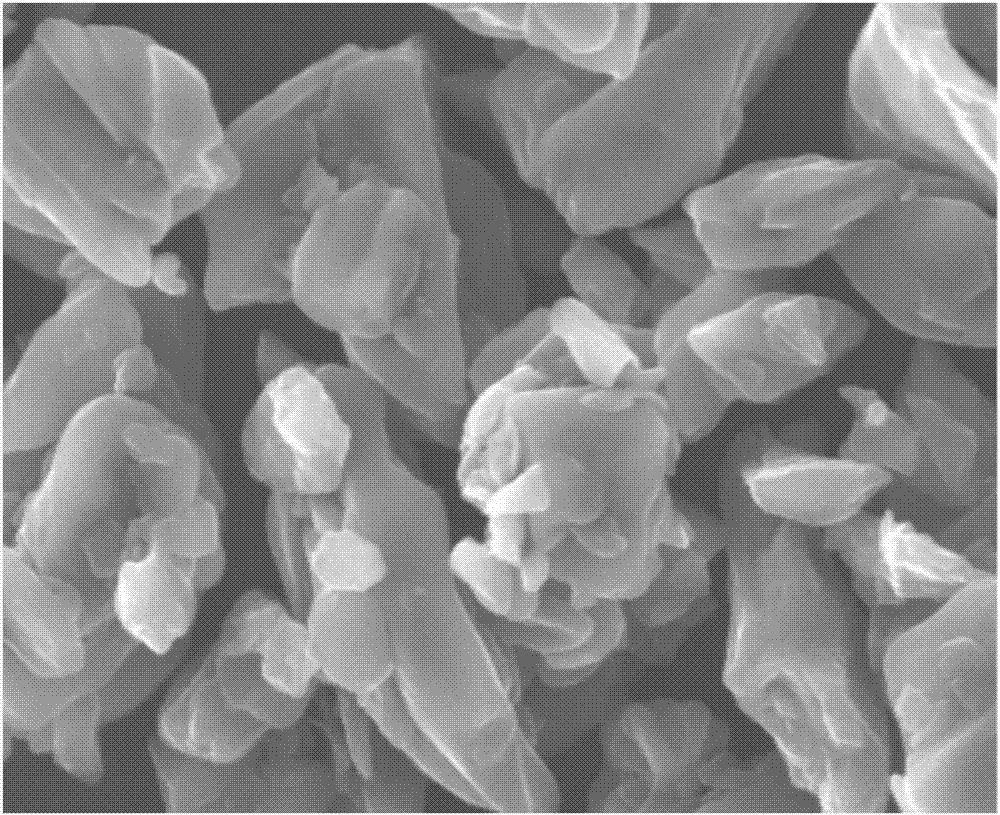

Cathode material precursor, preparation method thereof, cathode material and preparation method thereof

ActiveCN105762352AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsNickel compoundsManganese

The invention provides a preparation method of a cathode material precursor. The preparation method comprises the following steps of: mixing a nickel-containing compound, a cobalt-containing compound and a manganese-containing compound to obtain a mixed solution; mixing the mixed solution, a complexing agent, a precipitating agent and a metallic-colloid precursor, and reacting to obtain the cathode material precursor. In the process of preparing the cathode material precursor, nano metallic colloid forms double electrode layers on the surface of the precursor by co-precipitation reaction, so that the thickness increase of primary particles of the precursor is inhibited, the interlamellar spacing of a lamellar structure of the primary particles is reduced and the cathode material precursor of a lithium-ion battery aggregated by a hexagonal and lamellar structure is prepared. The application also provides a cathode material prepared by the cathode material precursor. The cathode material prepared by the application has the advantages that the hexagonal and lamellar primary particles have shorter lithium-ion migration path and better electrolyte wettability, so that the rate capacity of the cathode material can be increased, and the cathode material is especially applicable to manufacturing the lithium-ion power battery.

Owner:宁波富理电池材料科技有限公司

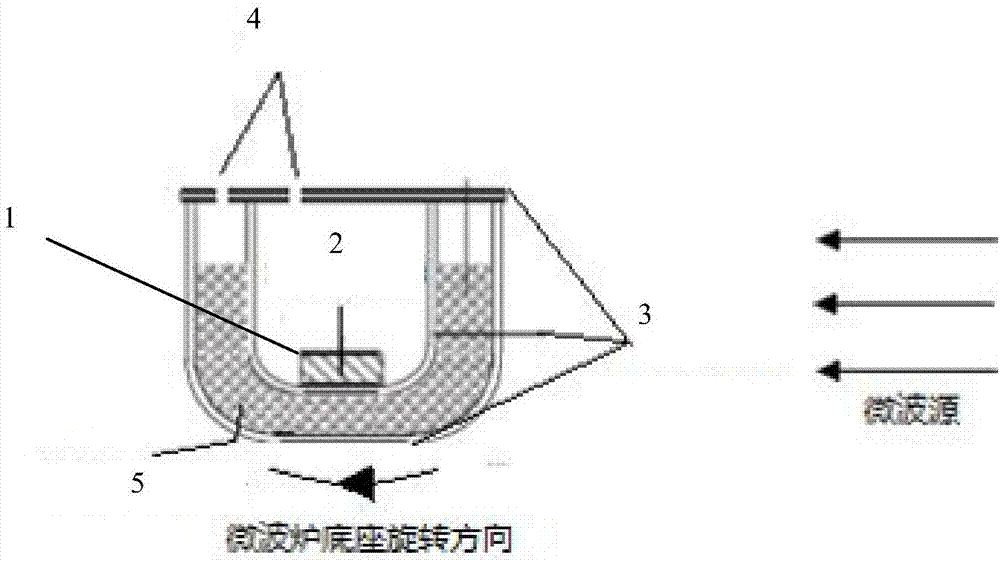

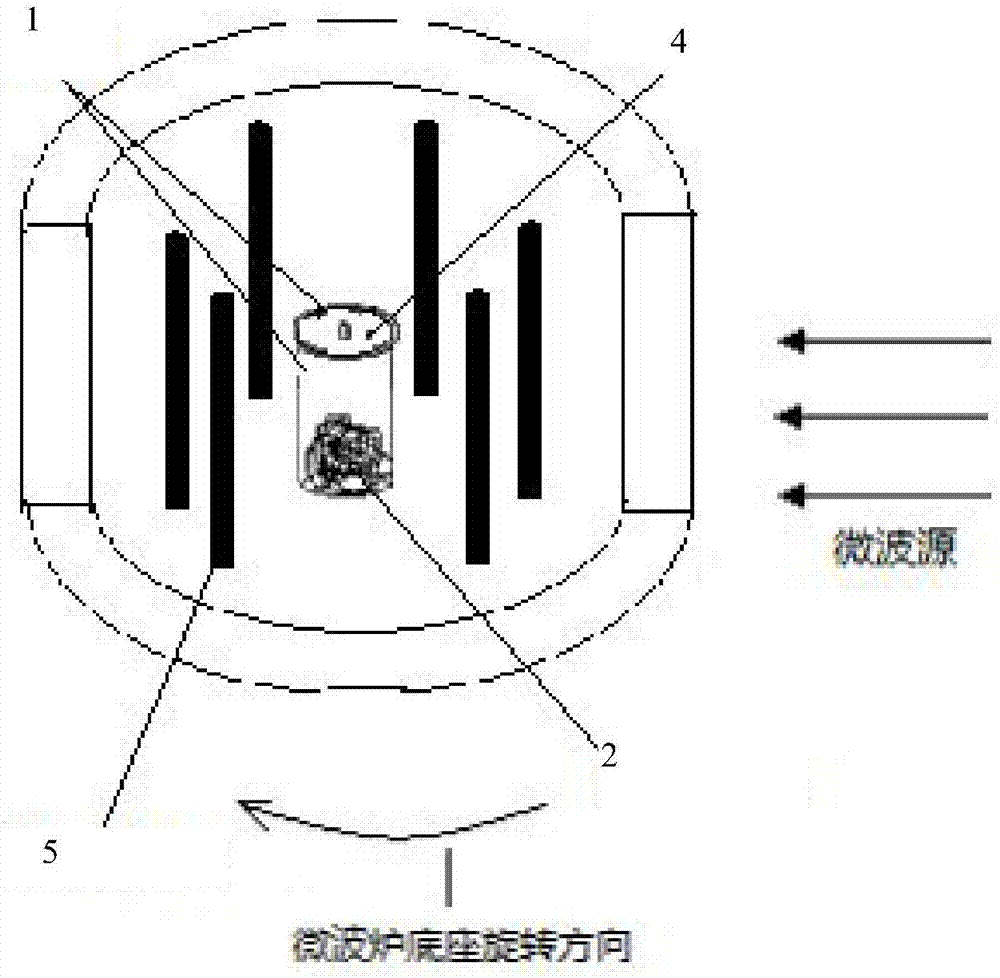

Method for preparing graphene with solid phase assisted microwaves

InactiveCN107416814AAchieve restorationIncrease temperatureCarbon compoundsChemical industryMicrowave ovenCentrifugation

The invention discloses a method for preparing graphene with solid phase assisted microwaves. The method comprises the following steps: a graphite oxide and water mixed solution is subjected to ultrasonic treatment for 10 min-1 h, then a suspension obtained after ultrasonic treatment is centrifuged under the condition of 2000-3000 rpm for 20-60 min, a supernatant liquid obtained after centrifugation is graphene oxide colloid, the graphene oxide colloid is dried, and graphene oxide is obtained; graphene oxide and an assisted wave absorbing material are placed into a reaction chamber of an industrial microwave oven and react under the power of 300-2000 W for 15-90 s with inert gas shielding, then the microwaves are stopped, and graphene is obtained after cooling to the room temperature. Any chemical reagent harmful to the human body and the environment is not required to be added in the reaction process, and safety and environmental protection are realized; the preparation process is simple, the reaction time is short, and high efficiency and energy saving are realized.

Owner:SHANGHAI INST OF TECH

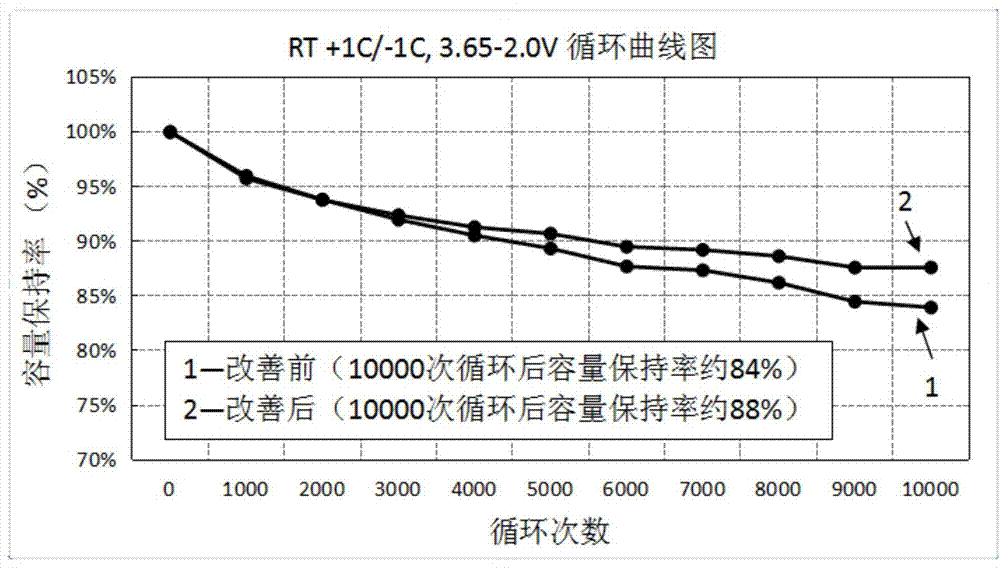

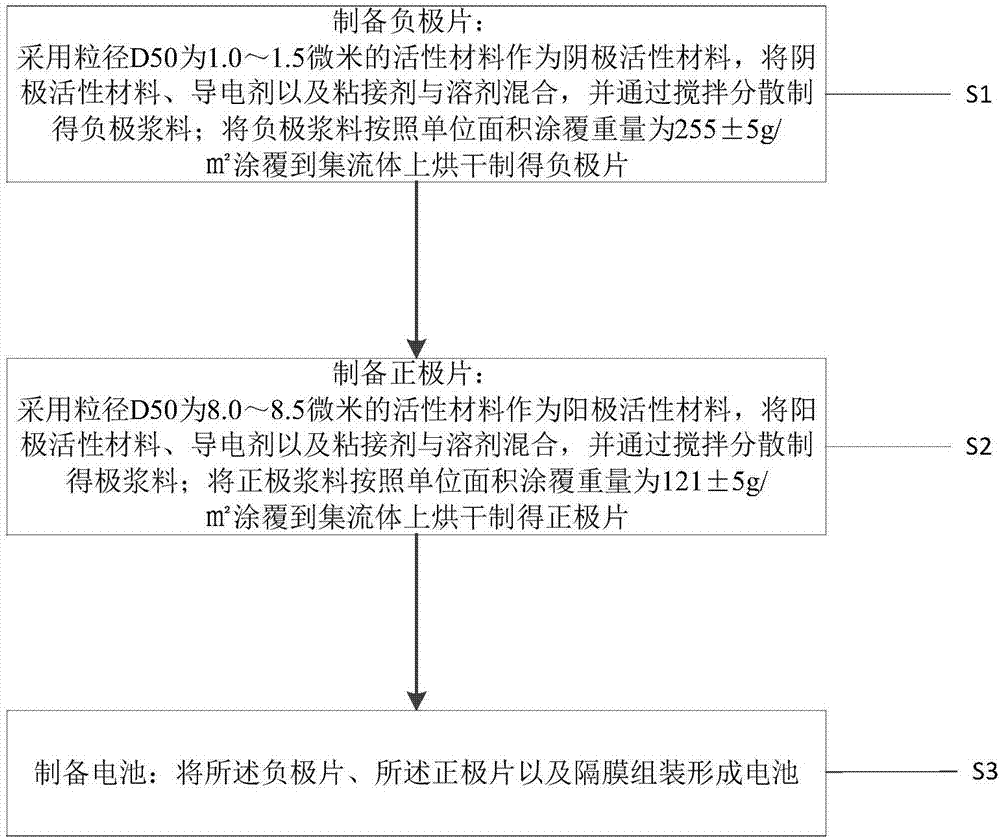

Lithium-ion battery with high rate performance and preparation method thereof

InactiveCN107394116AIncrease migration rateImprove migration abilityFinal product manufactureCell electrodesHigh rateSolvent

The invention relates to a preparation method of a lithium-ion battery with high rate performance. The preparation method comprises the steps of adopting an active material with the particle size D50 of 1.0-1.5 microns as a cathode active material; mixing the cathode active material, a conductive agent and a binder with a solvent, and mixing and dispersing to obtain negative electrode paste; coating the negative electrode paste on a current collector according to a coating weight per unit area of 255+ / -5 g / m2 and drying to obtain a negative electrode piece; adopting an active material with the particle size D50 of 8.0-8.5 microns as an anode active material, mixing the anode active material, the conductive agent and the binder with the solvent, and mixing and dispersing to obtain active electrode paste; coating the active electrode paste on the current collector according to a coating weight per unit area of 121+ / -5 g / m2 and drying to obtain a positive electrode piece, wherein the conductive agent comprises a tube bundle conductive agent and a granular conductive agent; and assembling the negative electrode piece, the positive electrode piece and a diaphragm to form a battery. The battery prepared by the preparation method has the advantages such as short charging time and excellent rate performance.

Owner:SHENZHEN TOPBAND CO LTD

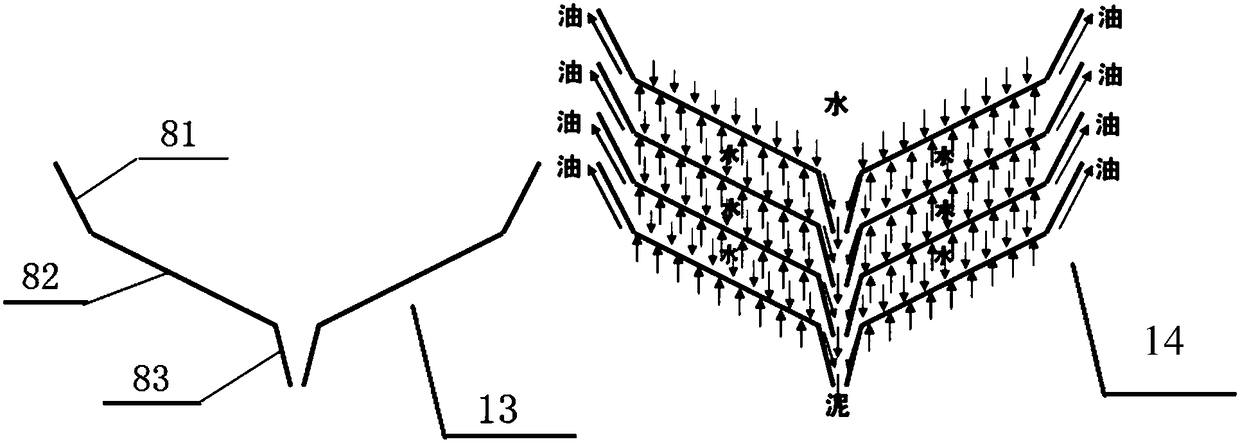

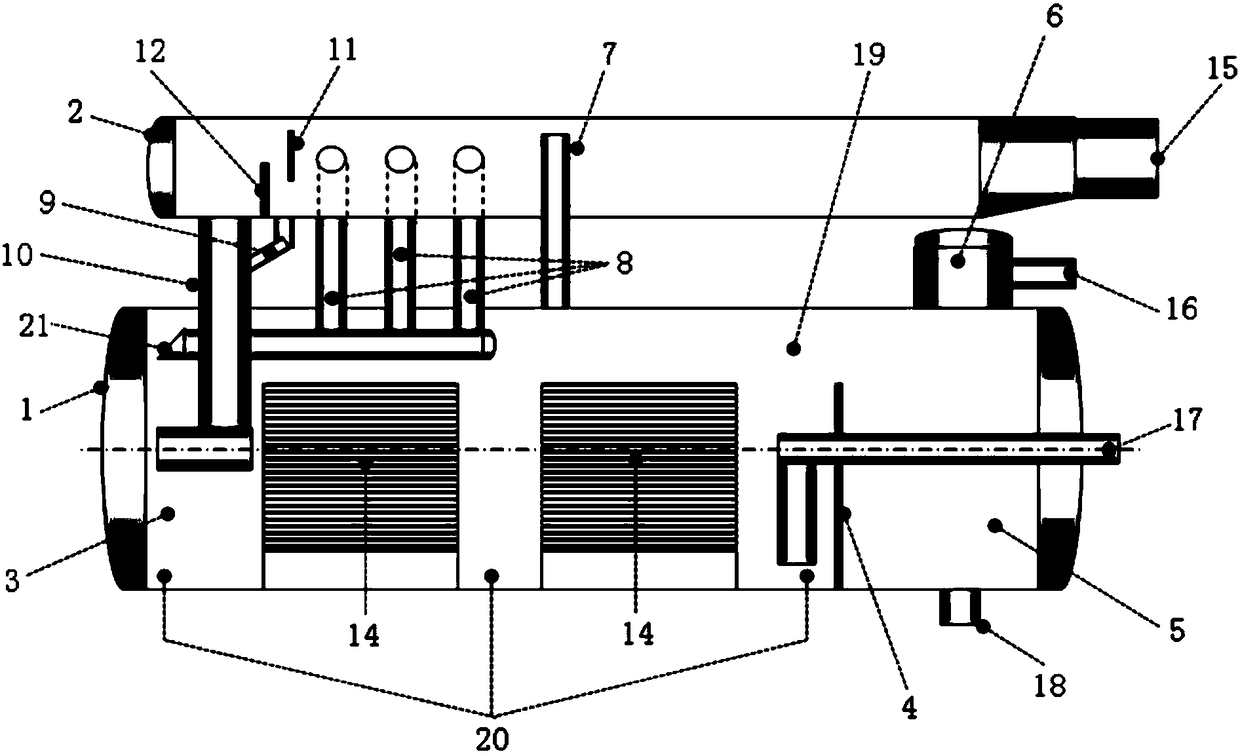

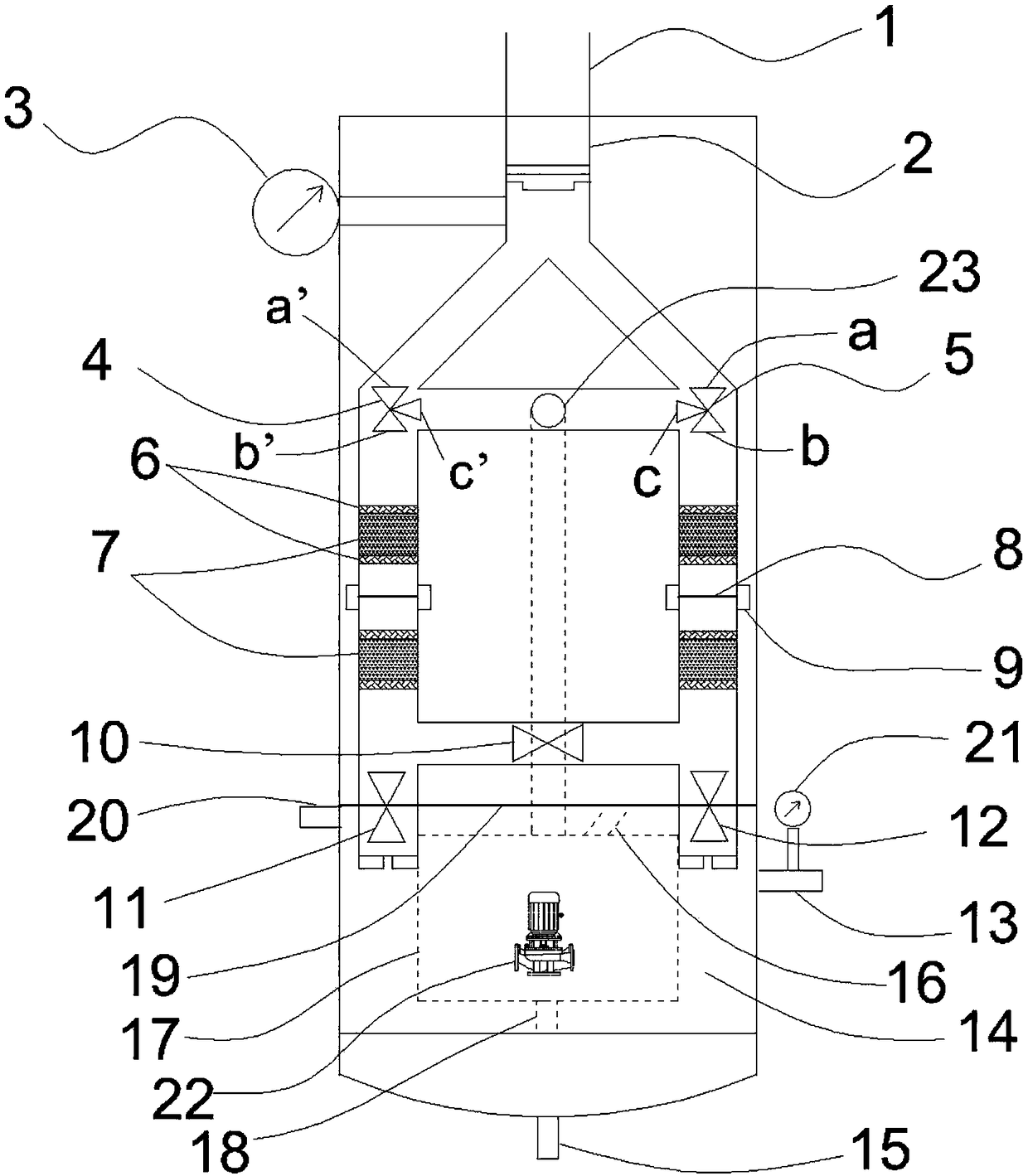

Horizontal three-phase separation device and separation method thereof

The invention discloses a wing-plate horizontal three-phase separation device and a separation method thereof. The wing-plate horizontal three-phase separation device comprises a pre-separation tube and a separation dehydration container; the lower part of the separation dehydration container is partitioned into an oil-water separation chamber and an oil chamber by an oil overflow weir plate, andthe upper part is a gas phase space, and a large dip angle folio wing plate body is arranged in the oil-water separation chamber. After processing the three-compound combination flooding ultra-high water-containing oil-gas-water mixture by adopting the wing-plate horizontal three-phase separation device and the separation method disclosed by the invention, the water content of the outlet oil doesnot exceed 10%, and the oil content of the outlet water does not exceed 1000mg / L, the processing capacity and the efficiency are about doubled in comparison with the conventional three-phase separator; the processing effect is much better than the conventional three-phase separator, the equipment cost of the unit processing liquid volume is reduced by 30-70%, the sediment deposition is avoided, and the separation device can be efficiently used for a long time.

Owner:PETROCHINA CO LTD +2

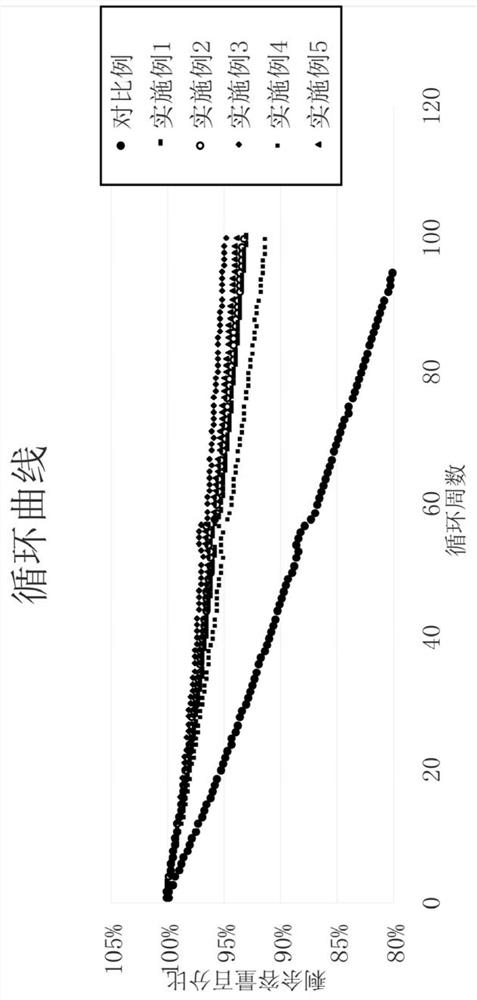

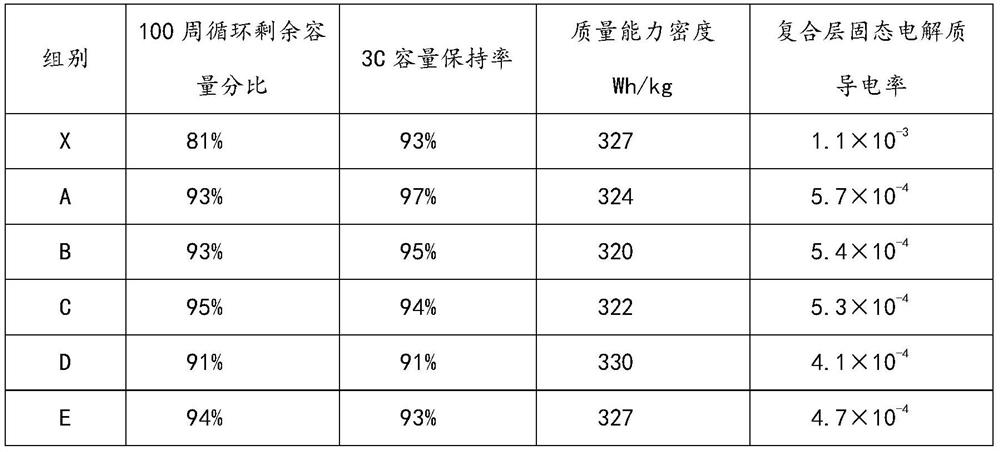

Composite electrolyte and application thereof

ActiveCN111613830AGood chemical stabilityImprove conductivitySolid electrolytesSecondary cellsSolid state electrolyteElectrolytic agent

The invention discloses a composite electrolyte and application thereof, the composite electrolyte comprises a gel electrolyte coated on a lithium negative electrode and a quasi-solid electrolyte coated on a positive electrode, and the gel electrolyte is in contact with the quasi-solid electrolyte; electrolyte is adsorbed in the quasi-solid electrolyte; both the gel electrolyte and the quasi-solidelectrolyte contain the same conductive lithium salt; the invention also discloses application of the composite electrolyte to a lithium ion battery. According to the invention, through cooperation of the two electrolytes, lithium dendrites are inhibited, and the composite electrolyte is ensured to have good conductivity.

Owner:南通赛得能源有限公司

Negative electrode material and negative electrode of lithium battery, lithium battery and preparation methods thereof

InactiveCN107658427AIncrease compaction densityHigh tap densityCell electrodesSecondary cellsInternal resistanceMicrometer

The invention relates to the technical field of lithium batteries, in particular to a negative electrode material and a negative electrode of a lithium battery, the lithium battery and preparation methods thereof. The negative electrode material of the lithium battery comprises a negative electrode active material, a conductive agent and a binder, wherein the negative electrode active material comprises an ultra-high-temperature graphitized material of smashed green cokes, wherein the particle size distribution D50 of the ultra-high-temperature graphitized material of the smashed green cokes is 2-10 micrometers, the tap density thereof is 1.2-2 g / cm<3>, and the specific surface area is 0.5-1.5 m<2> / g. The ultra-high-temperature graphitized material of the smashed green cokes serves as thenegative electrode active material, and the compaction density and the tap density of the ultra-high-temperature graphitized material of the smashed green cokes are enhanced to decrease its interlayerspacing, increase space utilization rate and reduce interlayer spacing, so that the low-temperature charge and discharge performance and the cycle performance of the negative electrode material are improved.

Owner:江苏海四达电源有限公司

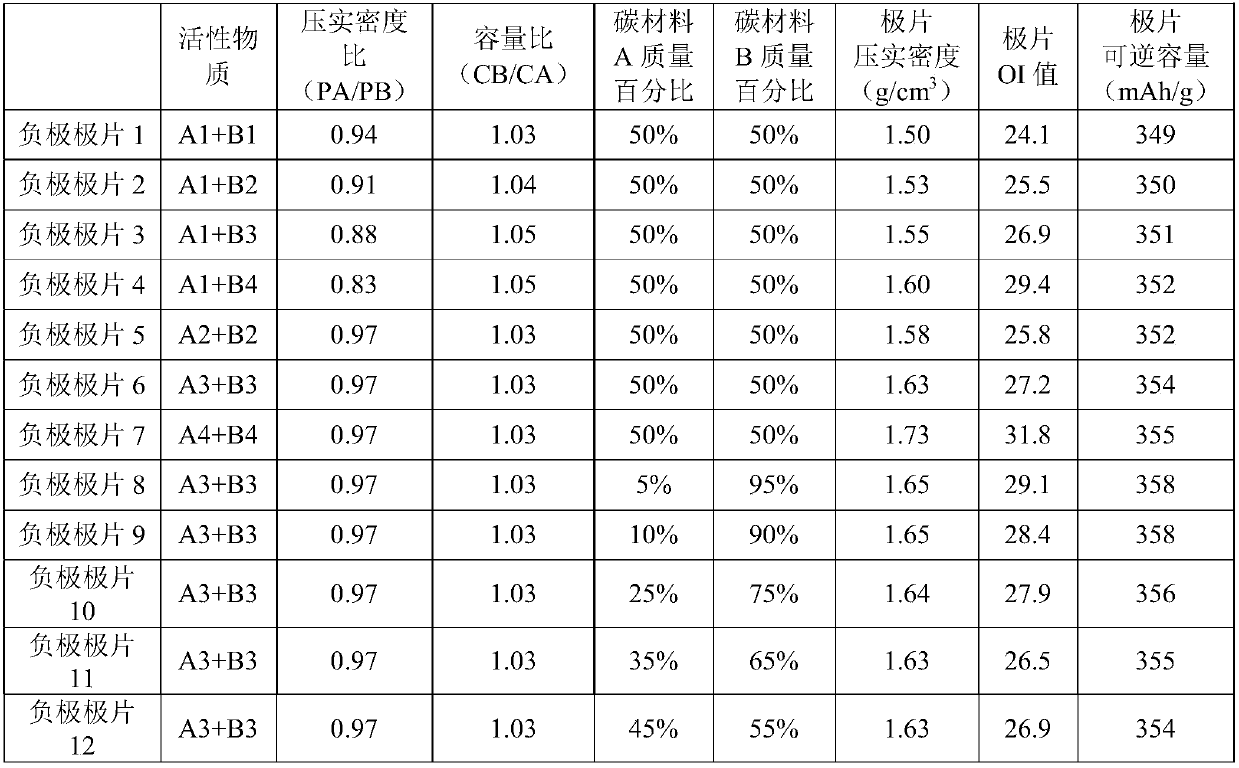

Secondary battery

ActiveCN110148714AImprove structural stabilityImprove cycle lifeNegative electrodesSecondary cellsGramPole piece

The invention relates to a secondary battery including a positive electrode pole piece, a negative electrode pole piece, an isolating membrane and an electrolyte. The positive electrode pole piece includes a positive active material layer containing a ternary positive electrode material. The negative electrode pole piece includes a negative active material layer, and active materials contain a carbon material A and a carbon material B. The carbon material B has a high reversible capacity and cooperates with the ternary positive electrode material to achieve a high gram capacity of the battery.Compared with the carbon material B, the carbon material A has a low degree of graphitization, a relatively large interlayer spacing and higher mechanical strength. The combination of the two carbonmaterials ensures that the negative electrode pole piece has both high reversible capacity and good pressure resistance, and the cycle life of the battery is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

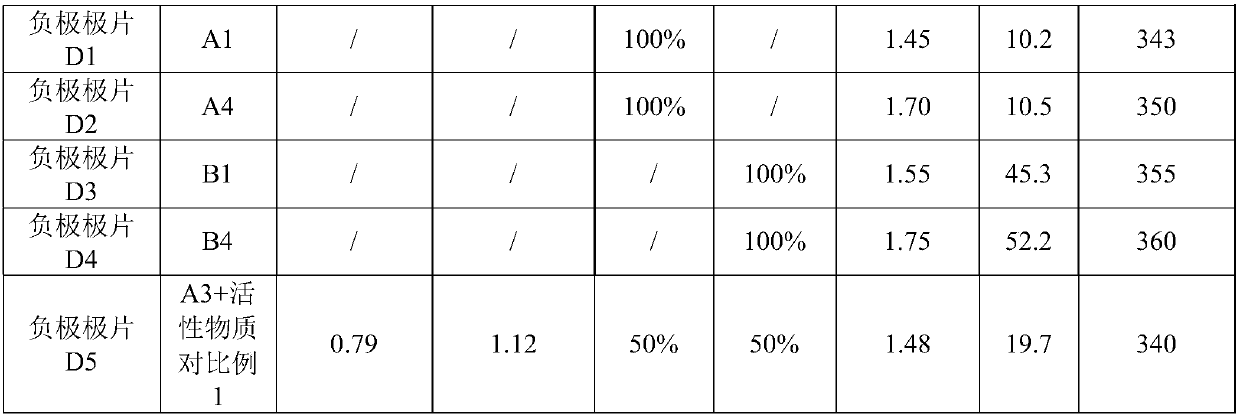

Formation method for improving K value of soft-package battery cell

PendingCN110649339AImprove internal activityControl thicknessFinal product manufactureSecondary cells charging/dischargingEngineeringBattery cell

The invention discloses a formation method for improving the K value of a soft-package battery cell, which solves the problems of poor film formation of an SEI film formed by normal pressure formationof the soft-package battery cell, deformation and insufficient hardness of a battery cell main body, black spots on an interface, lithium precipitation and the like, and also solves the problem of high K value reject ratio caused by the formation of a high-temperature and high-pressure clamp of the soft-package battery cell. According to the invention, in the formation step operation process, theinterlayer spacing between the positive electrode and the diaphragm and the interlayer spacing between the negative electrode and the diaphragm can be reduced by applying a small surface pressure tothe surface of the battery cell, and the migration path of lithium ions in the formation process is further reduced, so that the film forming quality is improved, the internal activity of the batterycell can be improved by controlling the temperature of a clamping plate, and the migration difficulty of the lithium ions is reduced. The method has the advantages that the SEI film forming quality ishigh, the main body of the battery cell is not easy to deform, and the K value of the battery cell is stable.

Owner:成都格力钛新能源有限公司 +1

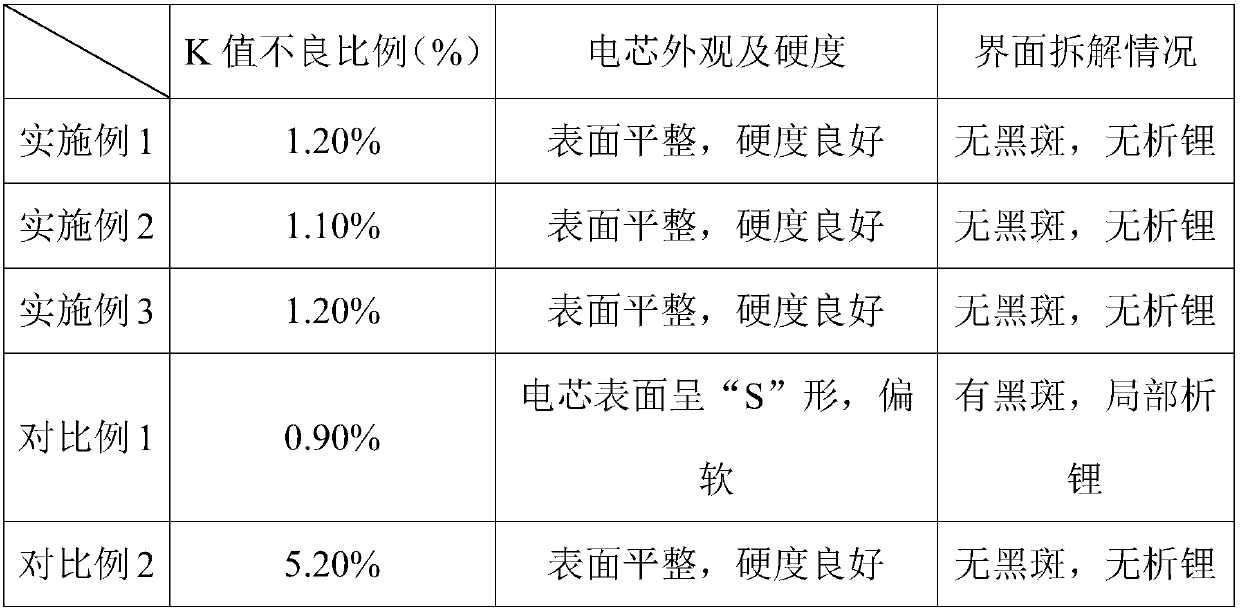

Preparation method of organic bentonite gel adsorbents

InactiveCN105214619AIncrease layer spacingReduce layer spacingOther chemical processesCross-linkCarboxymethyl cellulose

The invention discloses a preparation method of bentonite composite gel adsorbents and relates to a preparation method of bentonite adsorbents. According to the method, firstly, sodium-based bentonite is modified with cetyl pyridinium chloride (CPC) as a modifying agent; after cetyl pyridinium chloride organic bentonite (CPC-B) is prepared, the CPC-B is secondarily modified through sodium carboxymethyl cellulose (CMC) with AlCl3 as a cross-linking agent, and cetyl pyridinium chloride / sodium carboxymethyl cellulose organic bentonite gel adsorbents (CPC / CMC-B) are prepared. The cetyl pyridinium chloride / sodium carboxymethyl cellulose organic bentonite gel adsorbents (CPC / CMC-B) prepared through the method are good in adsorbing performance and obvious in removing effect, adsorbing operation is easy and convenient, losses are few, the recovery rate is high, and the adsorbents are environment-friendly forming adsorbents with good application prospects.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

General short needle and micro needle clamp

InactiveCN105424984AImprove test yieldReduce layer spacingPrinted circuit testingMeasurement instrument housingFiberCopper

The invention provides a general short needle and micro needle clamp. The general short needle and micro needle clamp comprises a composite fiber board in a multi-layer structure, fixing copper columns, steel needles and sponge, wherein the composite fiber board comprises a top fiber board, a middle fiber board and a lower fiber board which are sequentially laminated, the top fiber board, the middle fiber board and the lower fiber board each comprise multi-layer fiber boards, a preset gap is further arranged between two adjacent fiber boards, a preset gap scope is 0.01-4mm, the composite fiber boards are each provided with through holes and penetration needle holes, the fixing copper columns are arranged in the through holes, the steel needles are mounted in the needle holes, two ends of the steel needles are respectively exposed out of surfaces of the fiber boards, diameters of the steel needles are greater than or equal to 0.08mm, the sponge is arranged on the surface of one of the fiber boards, so the steel needles are not easy to generate deformation when the steel needles having relatively small diameters are utilized to test, the loss rate is reduced, the test yield of the clamp is improved, and thereby detection on PCBs with smaller bonding pads are convenient for users.

Owner:HANS LASER TECH IND GRP CO LTD +1

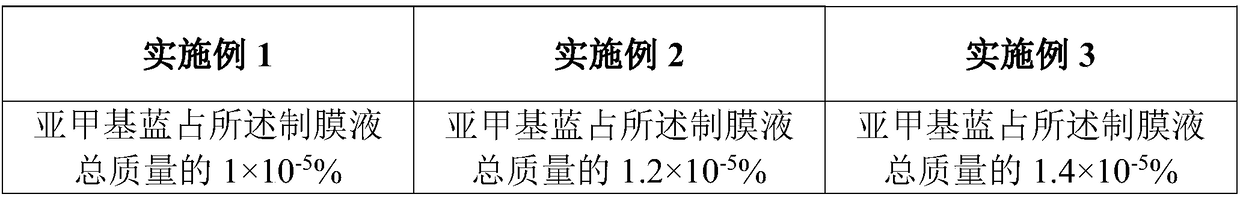

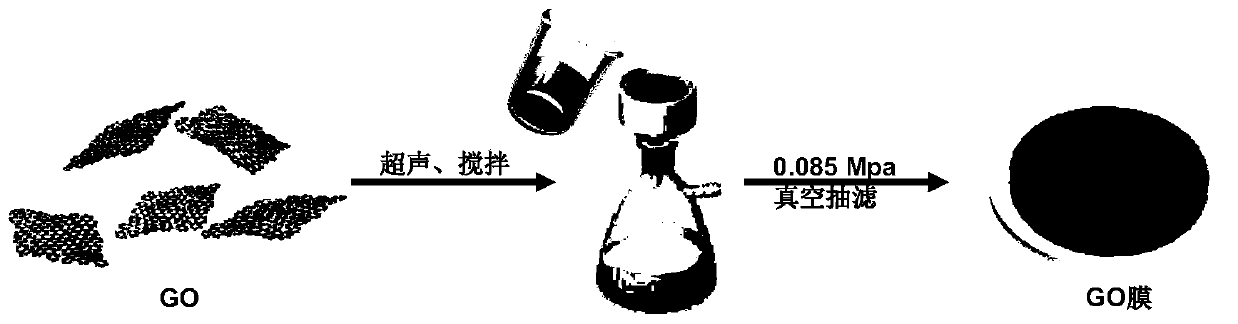

Graphene oxide/methylene blue composite film and preparation method thereof

ActiveCN109304097AReduce layer spacingImprove stabilityWater contaminantsUltrafiltrationComposite filmFiltration

The invention discloses a graphene oxide / methylene blue composite film and a preparation method thereof. The graphene oxide / methylene blue composite film is composed of a base film and a filtering layer attached to the base film, wherein the main components of the filtering layer are graphene oxide and methylene blue. The preparation method comprises the following steps: adding graphene oxide to pure water, grinding the graphene oxide until particles are dispersed uniformly, adding pure water under a stirring condition to dilute the product to 5-20mu g / mL, and performing continuous stirring; then performing ultrasonic treatment for 1-30min at 200-600w; adding methylene blue to be stirred and mixed uniformly to obtain a film forming solution; adding a proper amount of film forming solutionto a sand core funnel, wherein the base film is paved in the sand core funnel in advance; and performing vacuum suction filtration and drying to obtain the graphene oxide / methylene blue composite film. The preparation method is simple, efficient, low in cost and high in repeatability; and the obtained product can greatly increase the interception rate of dyes.

Owner:TIANJIN POLYTECHNIC UNIV

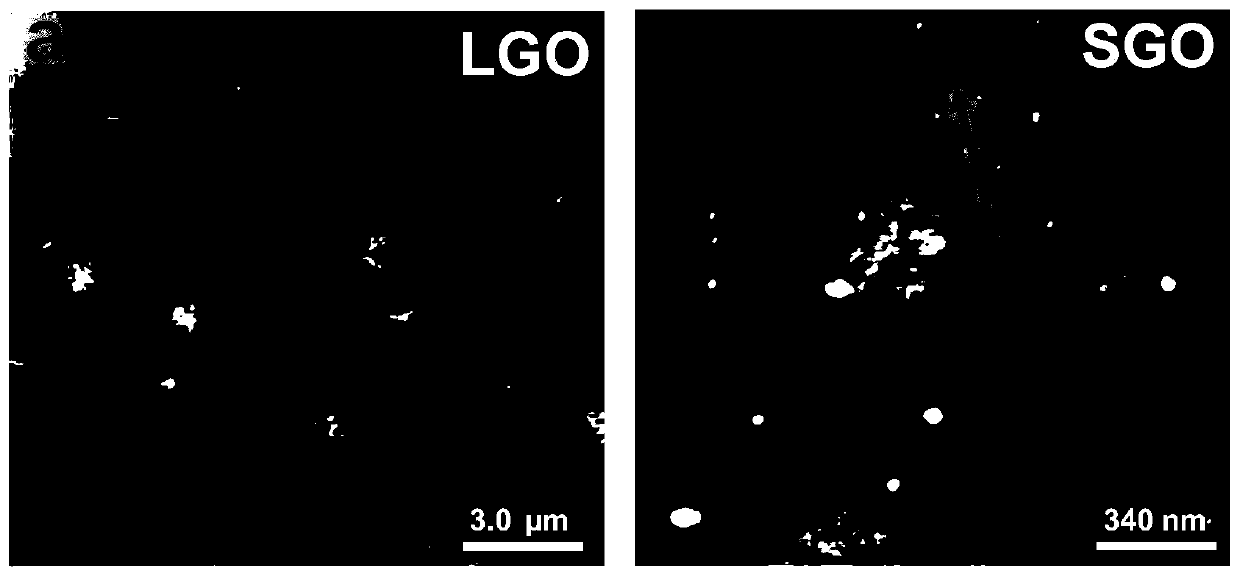

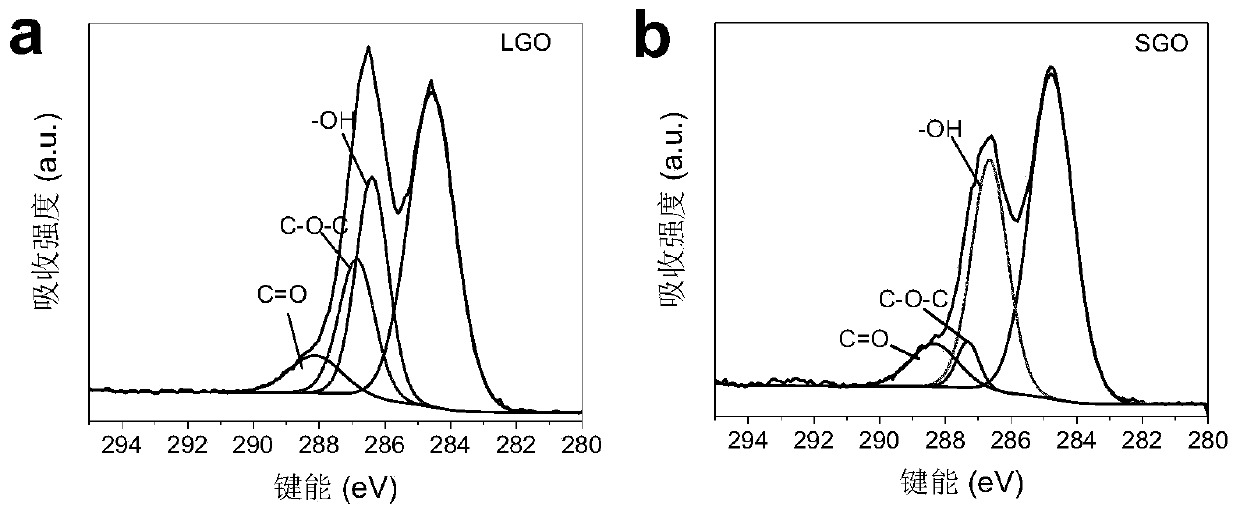

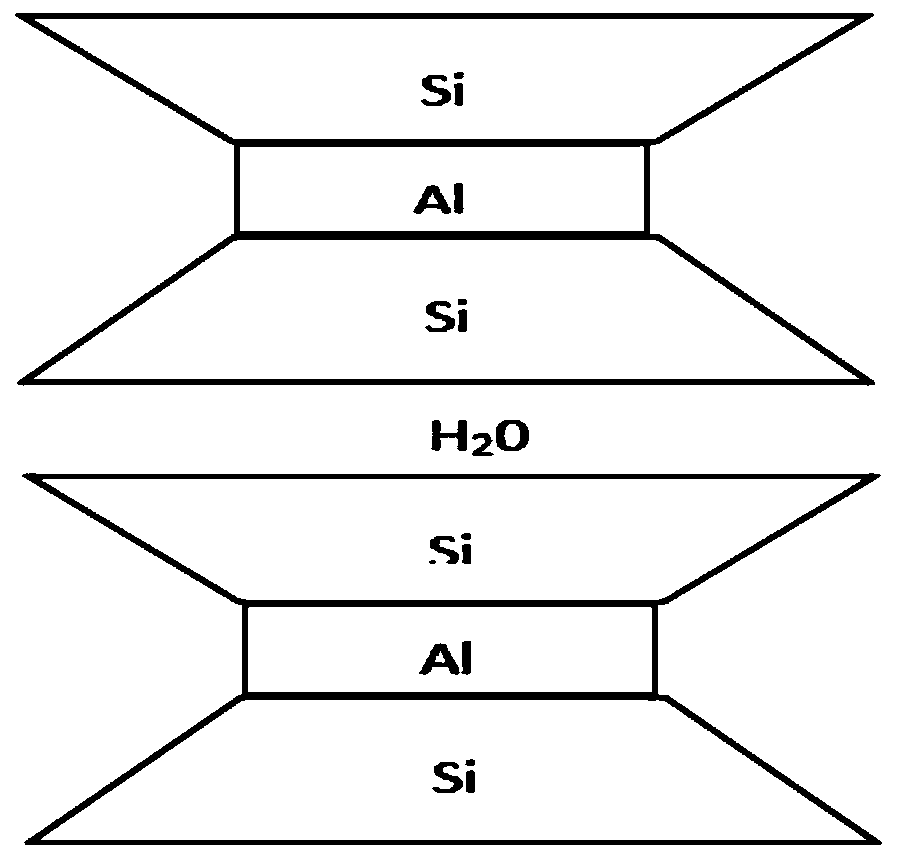

Mixed graphene oxide nanofiltration membrane and preparation method and application thereof

ActiveCN110772994ASpecial structureReduce layer spacingMembranesReverse osmosisPhysical chemistryEngineering

The invention provides a preparation method of a mixed graphene oxide nanofiltration membrane. The preparation method comprises the following steps: dispersing and centrifuging graphene oxide, takinga liquid supernatant, and drying and quantifying the liquid supernatant to obtain small-size graphene oxide; re-dispersing a precipitate at the bottom, carrying out centrifuging, and drying and quantifying the obtained precipitate to obtain large-size graphene oxide; preparing a large-size graphene oxide dispersion liquid from the large-size graphene oxide and pure water; preparing a small-size graphene oxide dispersion liquid from the small-size graphene oxide and pure water; preparing a mixed graphene oxide dispersion liquid from the large-size graphene oxide dispersion liquid and the small-size graphene oxide dispersion liquid; and subjecting the mixed graphene oxide dispersion liquid to suction filtration onto a polyvinylidene fluoride support membrane under a vacuum condition to obtain the mixed graphene oxide nanofiltration membrane. According to the prepared mixed graphene oxide nanofiltration membrane, interlayer spacing is effectively reduced, a water flow path is prolonged, and salt interception efficiency is greatly improved; meanwhile, the membrane has high mechanical stability, and the interception capacity and long-term stability of dye small molecules are enhanced.

Owner:成都石大力盾科技有限公司

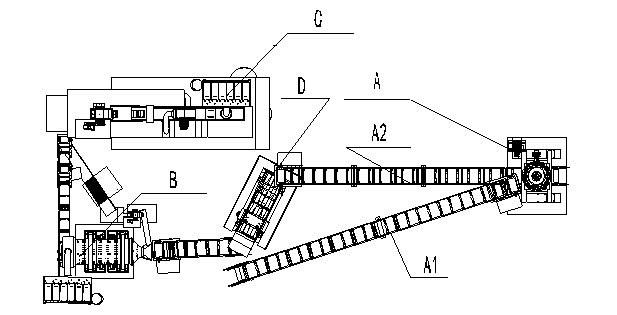

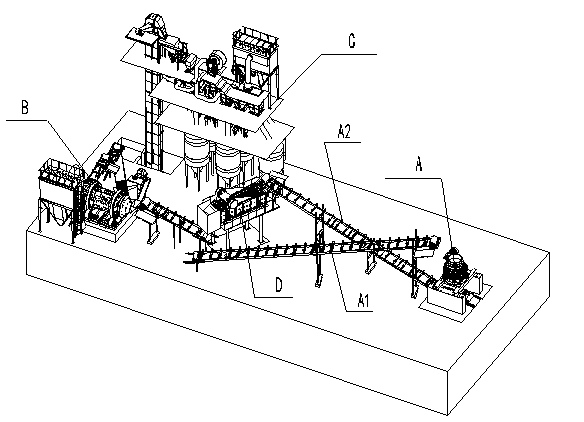

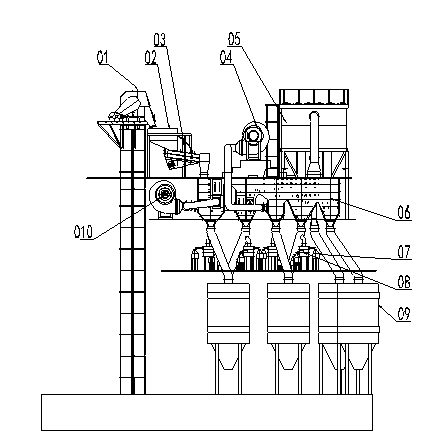

Dust-free machine-made natural sand manufacturing separation system and method

ActiveCN103357481ALight weightShorten the timeSievingGas current separationProgrammable logic controllerBucket elevator

The invention relates to a machine-made sand wind power winnowing system and a machine-made sand wind power winnowing method capable of realizing the selection of machine-made sand of different grain sizes through wind power and capable of realizing the dust-free performance of the machine-made sand. The system comprises a programmable logic controller (PLC), wherein a discharging hole of a mixed finished product bucket elevator faces an inlet of a buffer bin; a discharging hole of the buffer bin faces an inlet of a feeder; an outlet of the feeder is communicated with a charging hole of a cabin body of a machine-made sand wind power winnower; a plurality of stages of discharging holes of the cabin body of the machine-made sand wind power winnower are communicated with inlets of self grading storage tanks through conveying pipes respectively; a wind outlet of a main fan is communicated with a main wind port in the cabin body of the machine-made sand wind power winnower; a wind outlet of an auxiliary fan is communicated with an auxiliary wind port in the cabin body of the machine-made sand wind power winnower; a dust removal port in the cabin body of the machine-made sand wind power winnower is communicated with an inlet of a dust remover.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

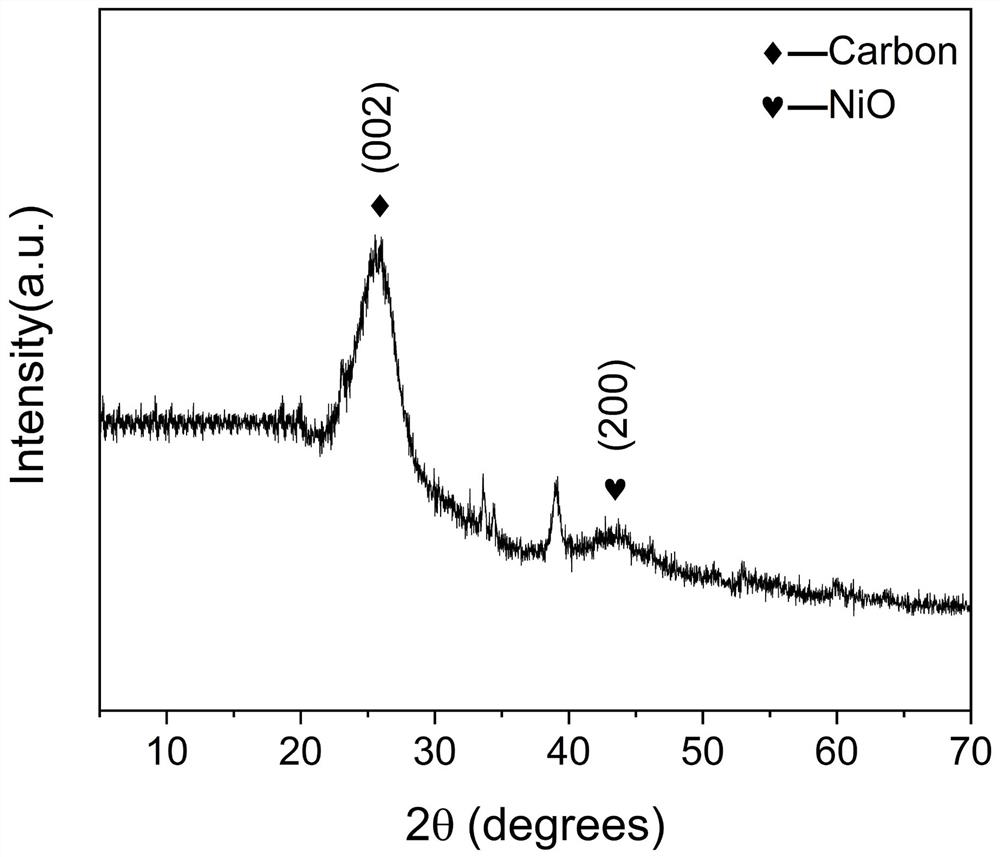

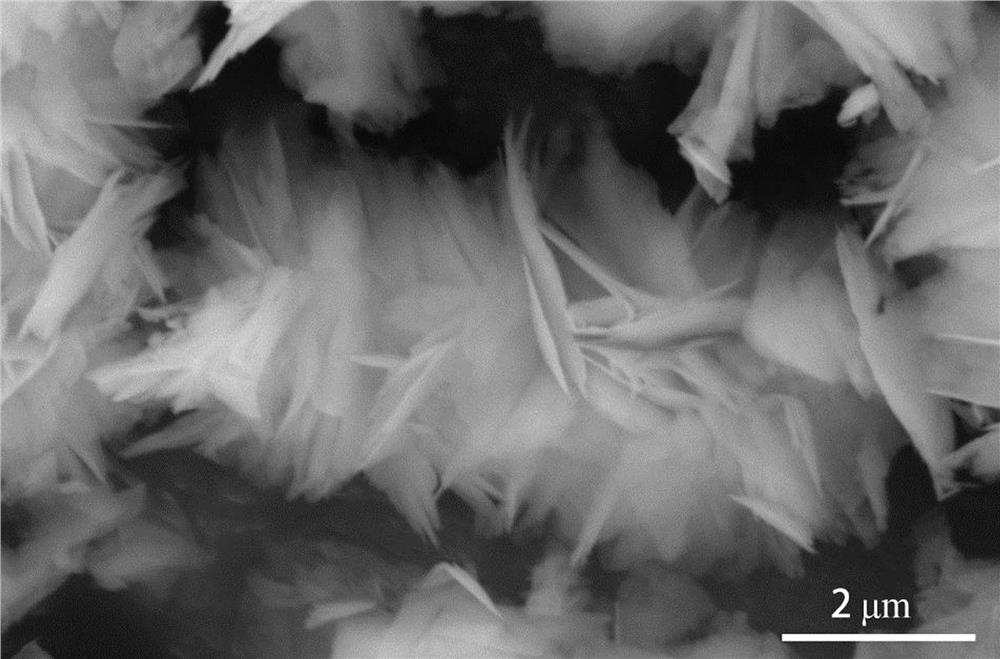

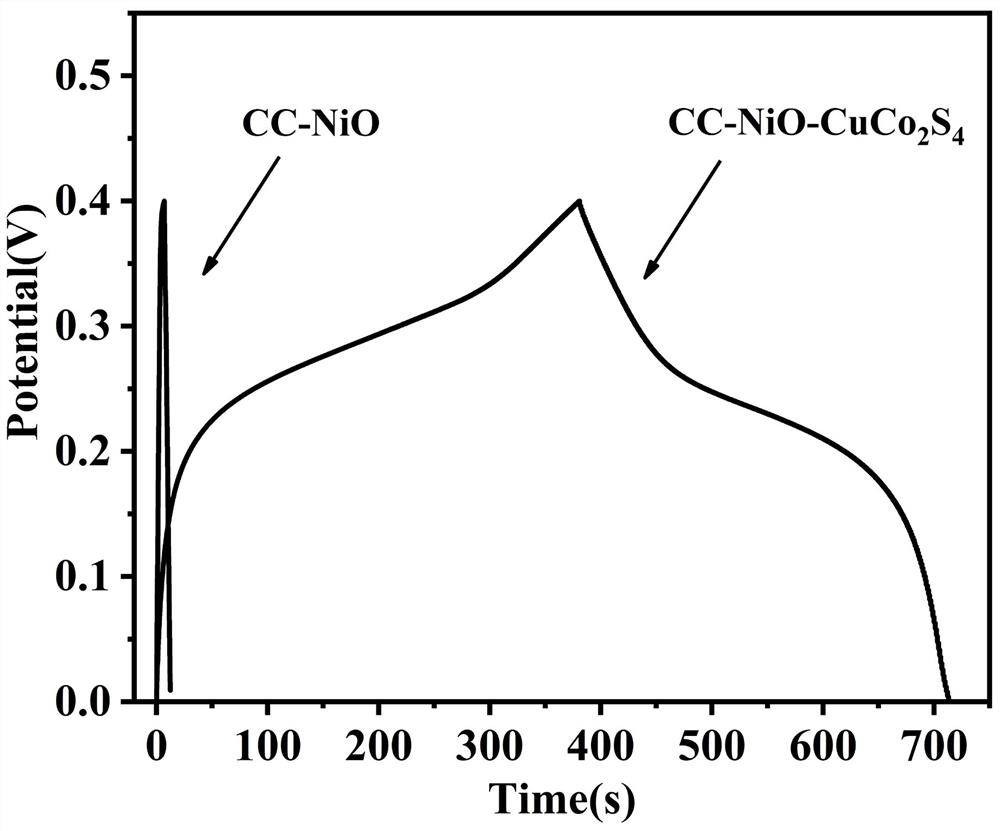

CC-NiO-CuCoS composite material as well as preparation method and application thereof

The invention discloses a CC-NiO-CuCoS composite material. The CC-NiO-CuCoS composite material is composed of CC, NiO and CuCo2S4, wherein CC is a base material, the microstructure of CC is of a fibrous structure, and CC is used for providing a substrate, so NiO nanosheets cannot be stacked, and the conductive substrate is beneficial to ultra-high-speed transportation of electrons; the microstructure of NiO is a nanosheet structure, and NiO is loaded on the surface of CC and is used for providing extra pseudocapacitance; and the microstructure of CuCo2S4 is a nano-particle structure, and CuCo2S4 is attached to the surfaces of the CC and NiO nanosheets, and is used for stabilizing the sheet structure of NiO and covering a part of exposed CC. According to the invention, the CC-NiO-CuCoS composite material is prepared from CC, nickel nitrate hexahydrate, ammonium fluoride, urea, cupric acetate monohydrate, cobalt acetate tetrahydrate and thiourea are used as initial raw materials throughtwo-step hydrothermal preparation. The preparation method comprises the following steps of (1) cleaning and activation of CC; (2) preparation of a CC-NiO composite material; and (3) preparation of theCC-NiO-CuCo2S4 composite material. When the composite material is used as a supercapacitor electrode material, specific capacitance is 840 F g<-1>, and cycling stability after 3000 cycles is 100%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

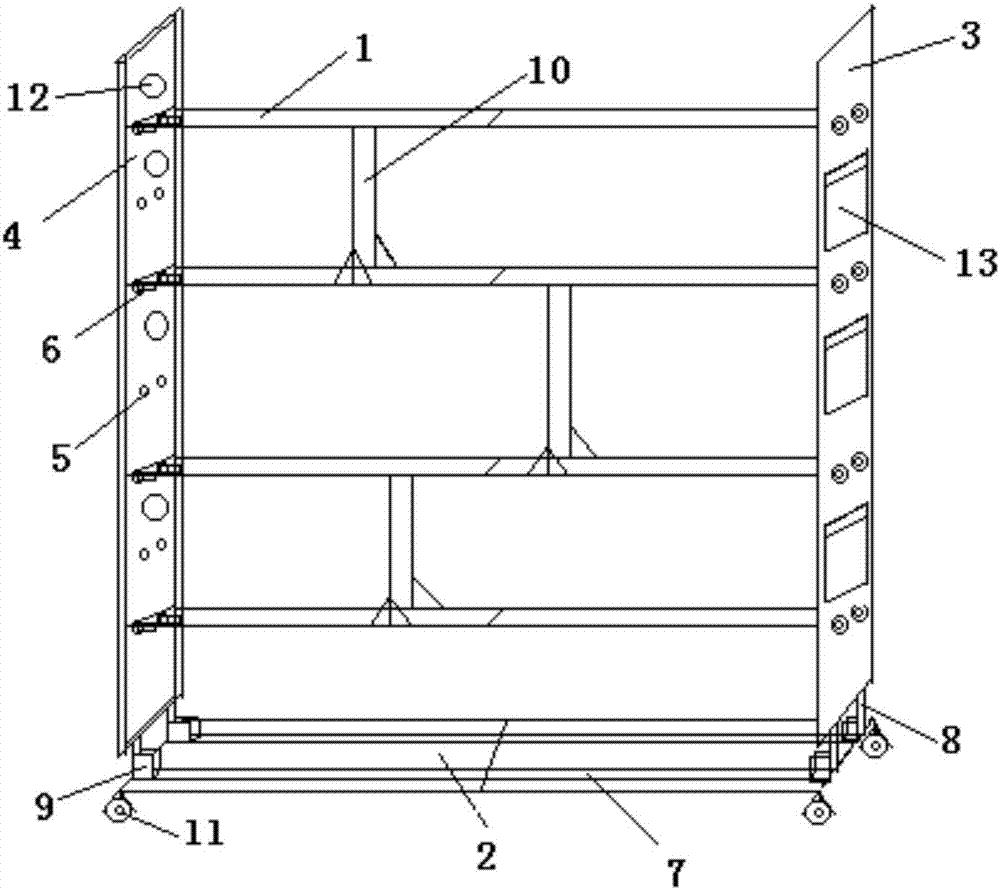

Interlayer-spacing-adjustable bookshelf

InactiveCN107157148AImprove applicabilityIncrease profitBook cabinetsFurniture partsStructural engineeringEngineering

The invention discloses a bookshelf with adjustable layer spacing, comprising a partition, a bottom plate and a side plate, two side plates are symmetrically fixed on the bottom plate, and each side plate is provided with a chute, and each At least two insertion holes are opened in each of the sliding grooves along the vertical direction, and the insertion holes in the two sliding grooves are arranged horizontally symmetrically, and the two ends of the partition plate are horizontally fixed to the two sides by inserting rods. The invention solves the problem that slightly larger books cannot be neatly placed on the bookshelf due to the fixed layer spacing of the existing bookshelf, and has simple design and convenient use.

Owner:王会战

Oxidation modification method of graphite negative electrode material, graphite negative electrode material and lithium ion battery

InactiveCN107487770AImprove conductivityImprove cycle stabilityGraphiteCell electrodesAluminium-ion batteryBromine

The invention belongs to the technical field of a lithium ion battery, and relates to an oxidation modification method of a graphite negative electrode material, the graphite negative electrode material and a lithium ion battery. The oxidation modification method of the graphite negative electrode material comprises the following steps: mixing a graphite matrix material and liquid bromine uniformly and performing oxidation modification on the graphite matrix material to obtain an intermediate; calcining and grinding the intermediate to obtain the graphite negative electrode material. The graphite is subjected to oxidation modification treatment by taking efficient liquid bromine as an oxidizing agent, so that the electric conductivity and the cycling stability of the graphite material can be effectively improved; moreover, the method is convenient in production operation and easy to control.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

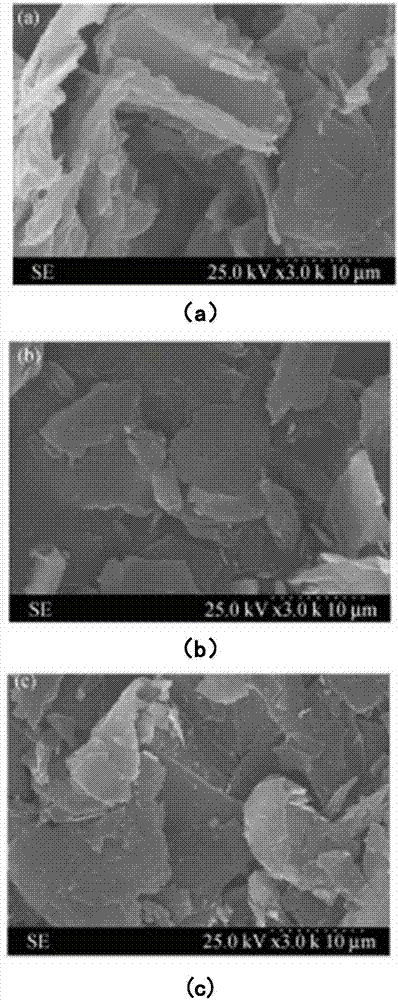

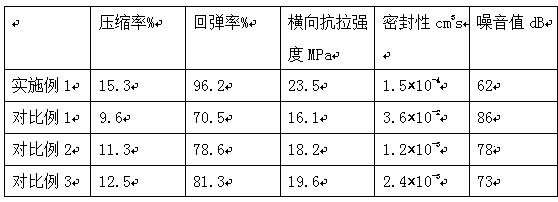

Sealing gasket with excellent resilience performance and preparation method thereof

The invention discloses a sealing gasket with excellent resilience performance and a preparation method thereof. The sealing gasket comprises the following raw materials including 10-15 parts of elastic graphene microparticles, 40-60 parts of a copper sulfate solution, 2-3 parts of molybdenum sulfide, 3-4 parts of carboxymethylcellulose, 15-25 parts of an acrylic emulsion, 5-7 parts of methylsilicone oil, 40-60 parts of polytetrafluoroethylene powder, 80-120 parts of ternary ethylene rubber, 3-5 parts of glass fibers and 1-2 parts of a crosslinking additive. The preparation method includes thefollowing steps that 1, the elastic graphene microparticles are added into the copper sulfate solution and subjected to pulse current treatment and pulse electromagnetic treatment to obtain modifiedelastic graphene microparticles; 2, the modified elastic graphene microparticles, the molybdenum sulfide and the carboxymethyl cellulose are mixed, then the acrylic emulsion and the methylsilicone oilare added, and ball milling and drying are carried out; 3, the remaining raw materials are mixed and cooled and then added into a product obtained in step 2 for stirring, compression molding and vulcanization treatment, and the sealing gasket can be prepared. The sealing gasket has excellent resilience performance, shock absorption and sound attenuation performance and sealing performance, can beused for a long time in the field of chemical pumps, and has a broad application and popularization prospect.

Owner:刘东

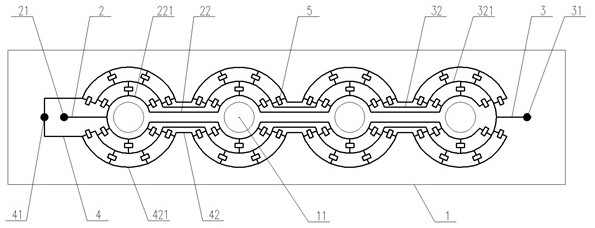

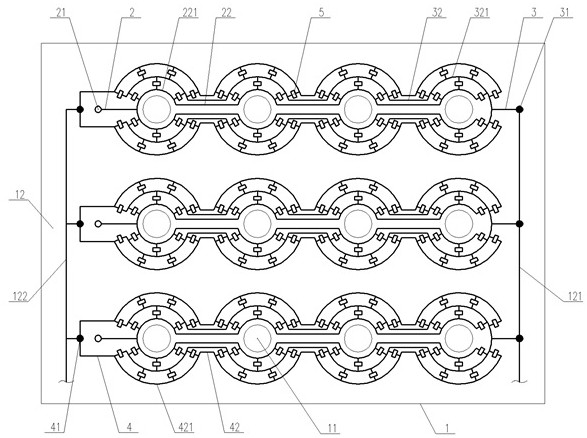

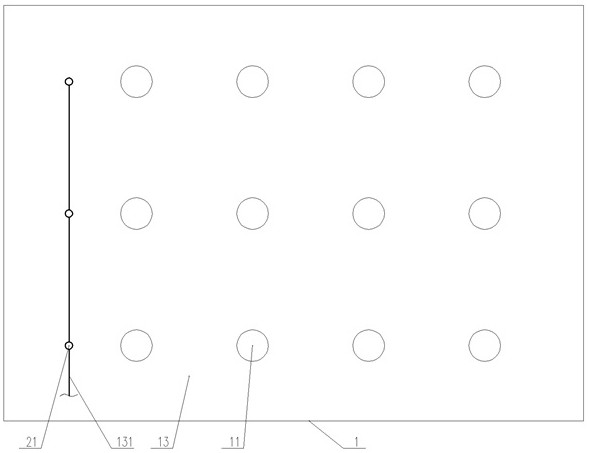

Plant leaf back light supply lamp panel

InactiveCN111853717AImprove photosynthesis efficiencySolve the problem of insufficient light intensityElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringPlantlet

The invention provides a plant leaf back light supply lamp panel, and relates to the technical field of plant planting. According to the technical scheme, the plant leaf back light supply lamp panel comprises a substrate, wherein a plurality of planting holes arranged in an array mode are formed in the substrate; each row of planting holes is provided with a set of power lines; the power lines comprise first wires, second wires and third wires. Each planting hole corresponds to one plant, a plurality of LED elements are evenly distributed around the planting holes, each plant can obtain uniform bottom light supply, the photosynthesis capacity of the bottom faces of leaves is developed, the overall photosynthesis efficiency of the plants is improved, and the purpose of increasing the yieldis achieved. The planting holes are distributed in the substrate in an array mode, the circuit structure and the circuit width of the first wires, the second wires, the third wires and the like on thesubstrate for supplying power to the LED elements are optimized, crossing, winding and wire jumping are avoided, the length of a power supply circuit is reduced as much as possible, enough width is guaranteed so as to reduce resistance, and the current carrying capacity is guaranteed.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

Functionalized graphene/polyaniline composite filter membrane and preparation method thereof

PendingCN110559870AHas a reducing effectHigh retention rateSemi-permeable membranesWater contaminantsAnilinePolyaniline composite

The invention discloses a functionalized graphene / polyaniline composite filter membrane and a preparation method thereof, and aims to provide a membrane material used for water treatment. The grapheneoxide / polyaniline composite membrane comprises a matrix, functionalized graphene oxide and polyaniline grafted on the surface of a functionalized graphene oxide membrane. The preparation method comprises the following steps: functionalizing the graphene oxide, preparing a membrane on the matrix, immersing the matrix with the membrane in a mixed acid solution of aniline and ammonium persulfate, performing a reaction for a certain time, taking out the obtained material, and removing the polyaniline on the surface to obtain the functionalized graphene oxide / polyaniline composite filter membrane.The functionalized graphene oxide / polyaniline composite filter membrane has the advantages of simple preparation process, low cost and good purification effect.

Owner:YANCHENG ZENGCAI SCI & TECH

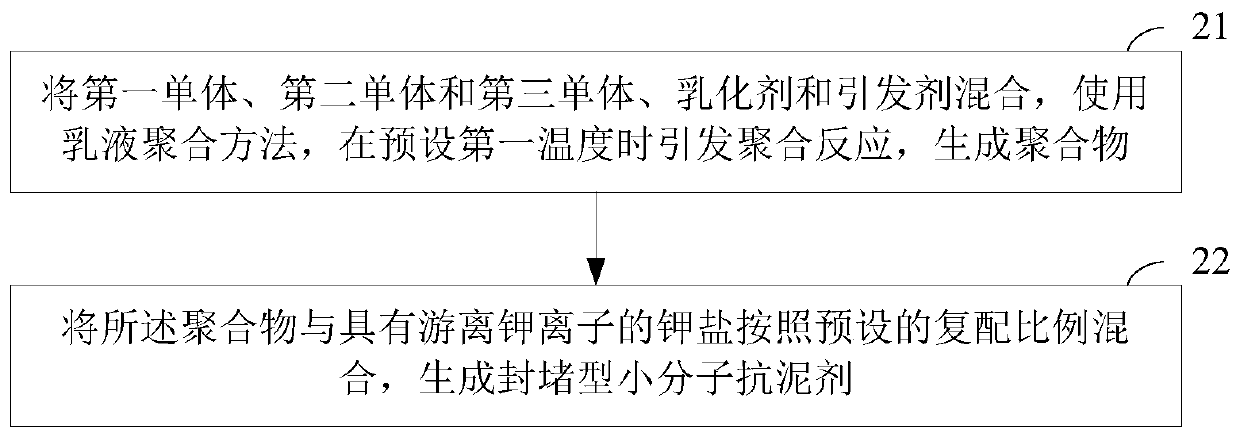

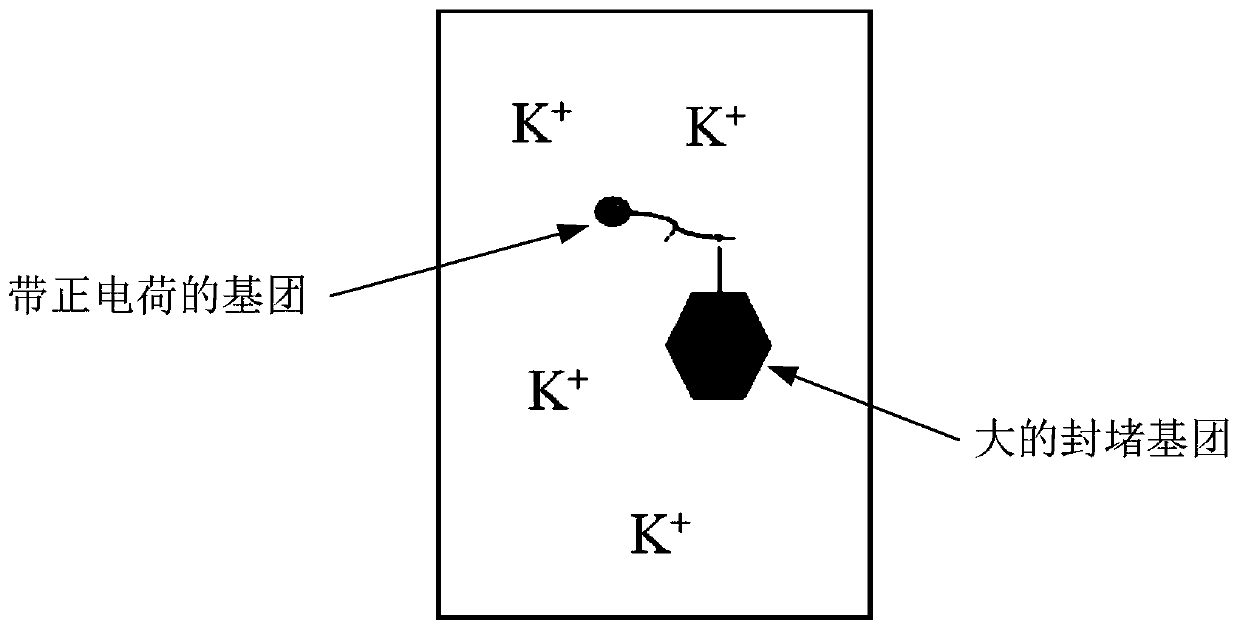

Anti-mud agent and preparation method thereof

The invention provides an anti-mud agent and a preparation method thereof. The anti-mud agent is prepared from the following raw materials: a polymer and sylvite with free potassium ions, wherein a weight ratio of the polymer to the sylvite is 1:1, the polymer is prepared from the following raw materials in parts by weight: 17% of a water-soluble cationic polymeric monomer, 17% of a water-solublepolymeric small monomer, 17% of a polymeric monomer with a large group, 2% of an emulsifier, 0.1% of an initiator and 46.9% of water. By applying the anti-mud agent, the mixing amount of the anti-mudagent can be reduced, so that the production cost is reduced.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

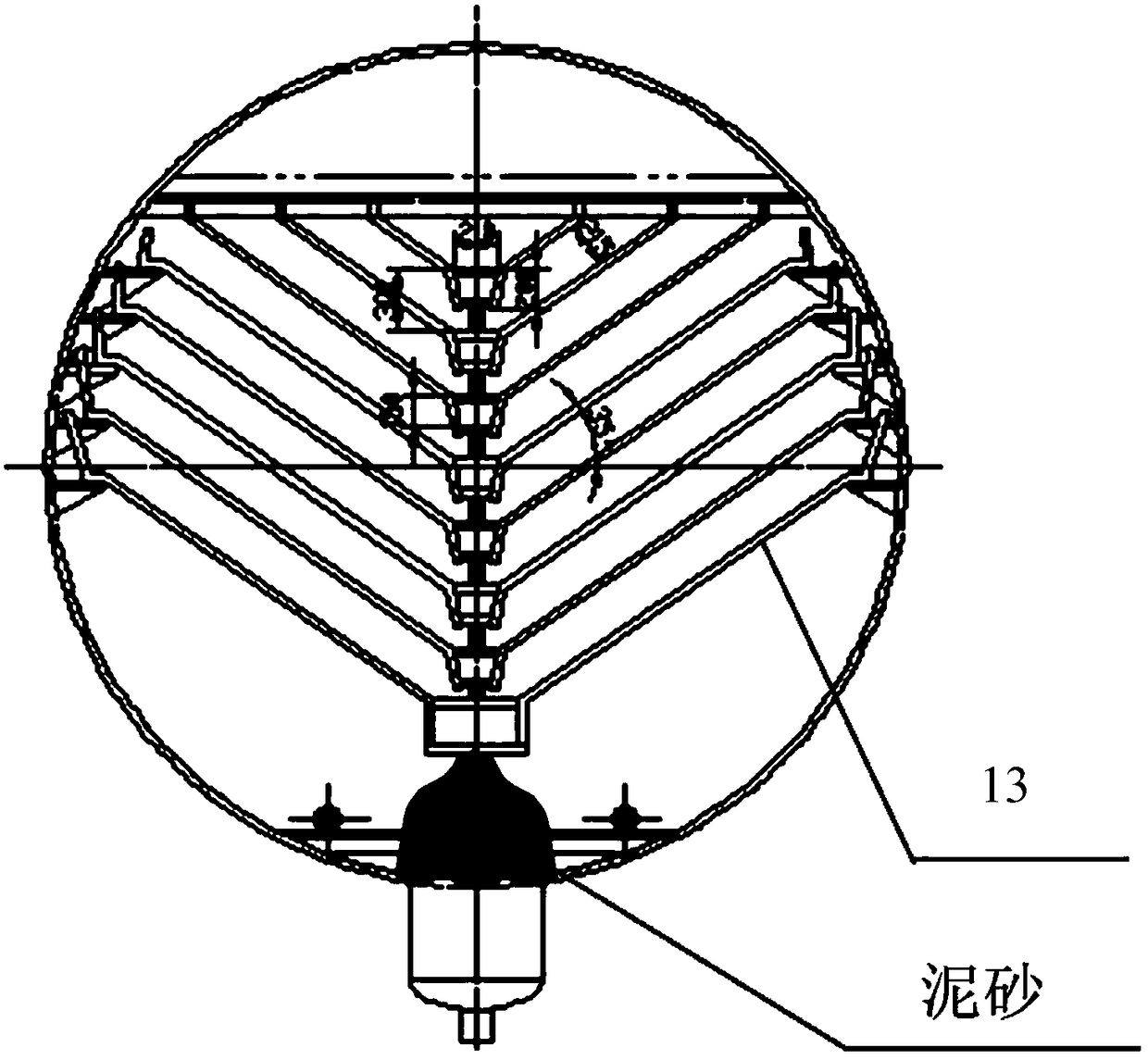

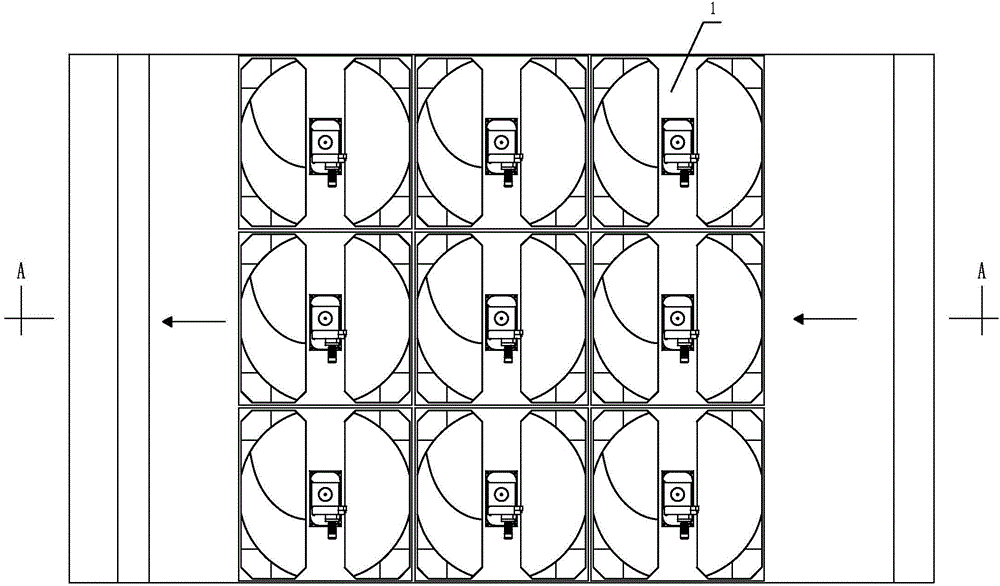

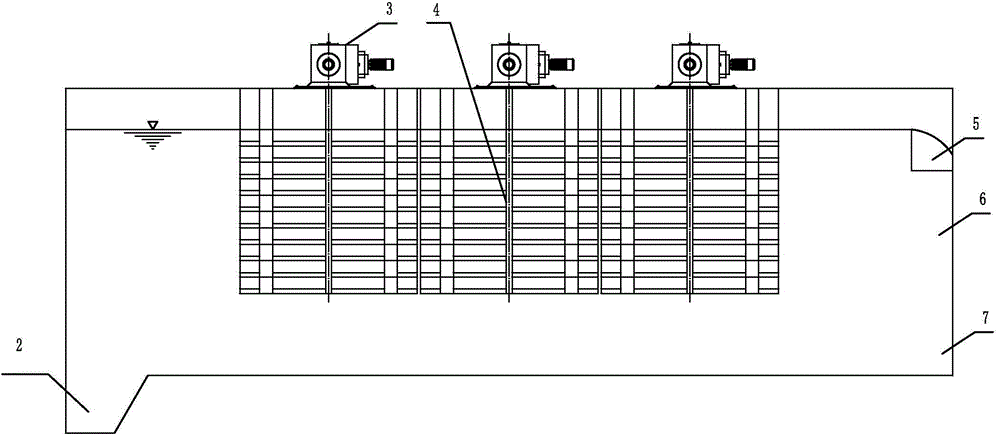

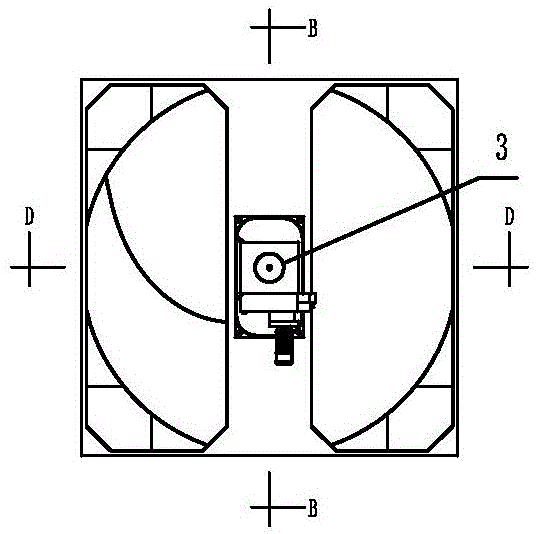

Compound flat plate settling unit and settling process using same

ActiveCN104826370AIncrease the sedimentation areaImprove precipitation effectWater/sewage treatment by flocculation/precipitationSedimentation settling tanksSludgeWater quality

The invention discloses a compound flat plate settling unit, which comprises multiple circular flat plates arranged on a bracket in parallel, wherein a flange is formed in the outer periphery of each flat plate, a sewage storage chamber is arranged at the outside of the flange and is communicated with a flat plate through the groove opening of the flange; a sludge channel is formed between each two adjacent sewage storage chambers in the bracket; and a rotary mud scrapping part is arranged in each flat plate and is connected with a driving device through a transmission part. The invention further relates to the setting process using the compound flat plate settling unit. By adopting the method, the settling area is effectively increased; the surface hydraulic load is reduced; the sludge-water separation effect is improved; the discharged water quality is improved; the highly concentrated active sludge of the system is maintained and the occupied area of a settling pool is remarkably saved.

Owner:中国市政工程西南设计研究总院有限公司

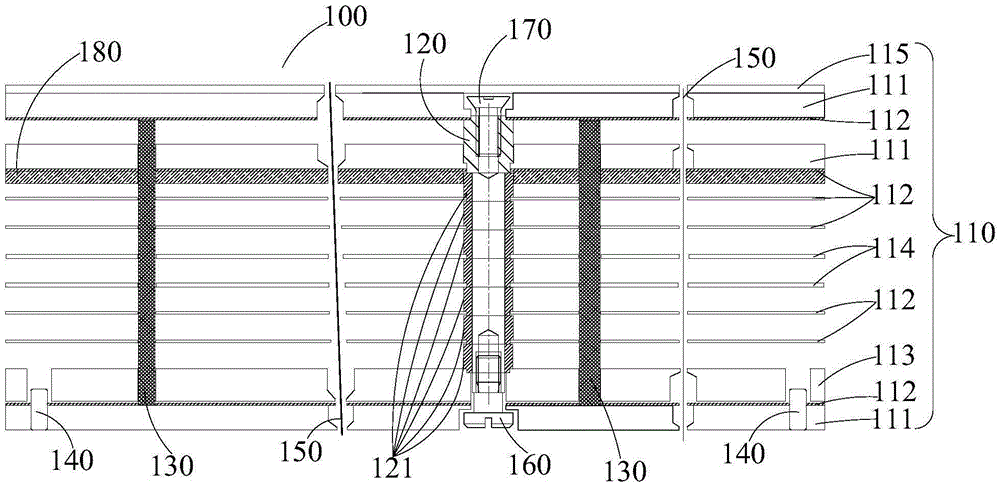

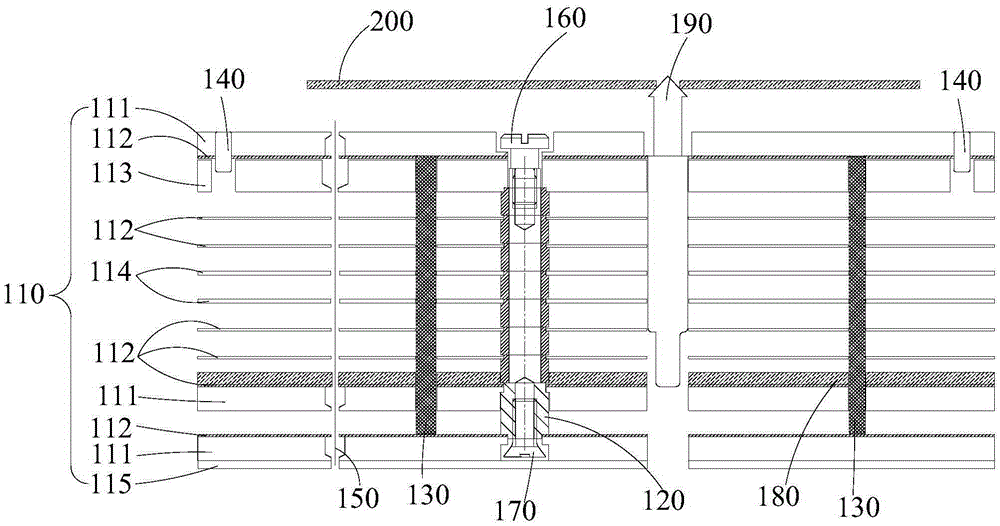

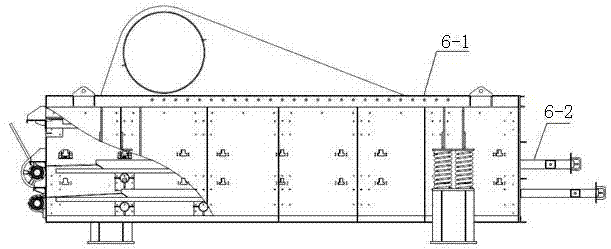

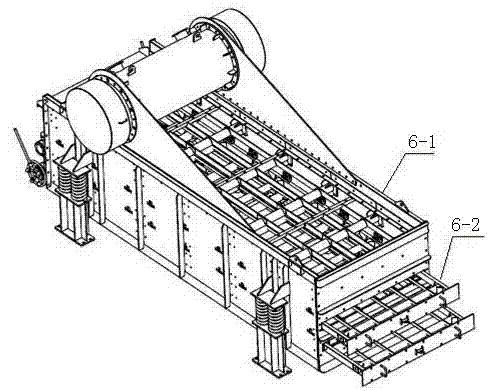

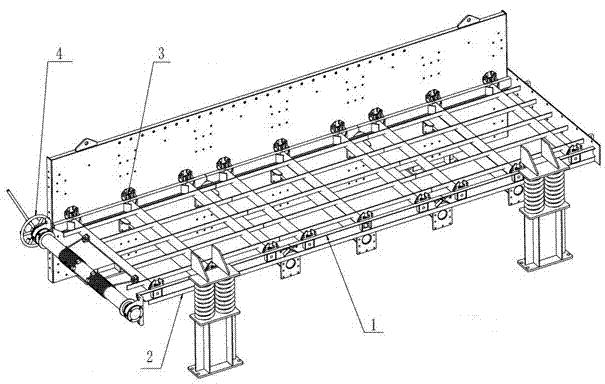

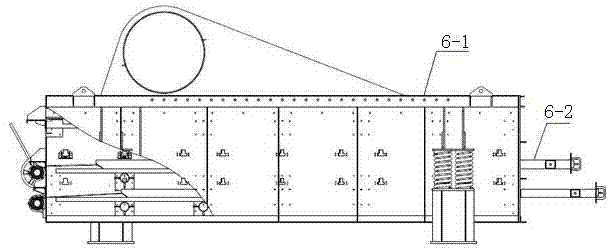

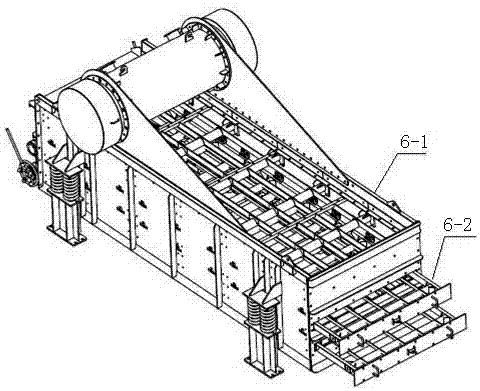

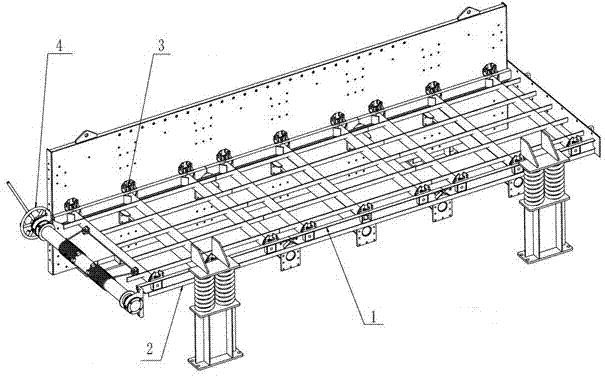

Modularized drawer-type multilayer vibrating screen and manufacture method thereof

The invention relates to the field of vibratory screening machinery, and mainly relates to rapid replacement of a screen surface of a multilayer vibrating screen from a second layer to below and realization of a modularized drawer-type multilayer vibrating screen of the multilayer screening modularization and a manufacture method thereof in the production of the vibrating screens. The modularized drawer-type multilayer vibrating screen comprises a multilayer vibrating screen body, a sieve plate of the multilayer vibrating screen body is the modularized drawer-type multilayer vibrating screen, and the modularization drawer-type multilayer vibrating screen is in pull-draw match with a case body; the modularized drawer-type multilayer vibrating screen comprises module-combined type screen bracket devices, bracket sliding rails, a screen bracket hold-down gear and a bracket drawing device; two bracket sliding rails are fixedly arranged on the sidewall panel of the vibrating screen; the module-combined type screen bracket devices are arranged on the surface of each of the two bracket sliding rails; screens are respectively arranged on the module-combined type screen bracket devices; the bracket drawing device is arranged at top end of the sidewall panel of the vibrating screen; and the module-combined type screen bracket devices are connected with load cables of the bracket drawing device.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

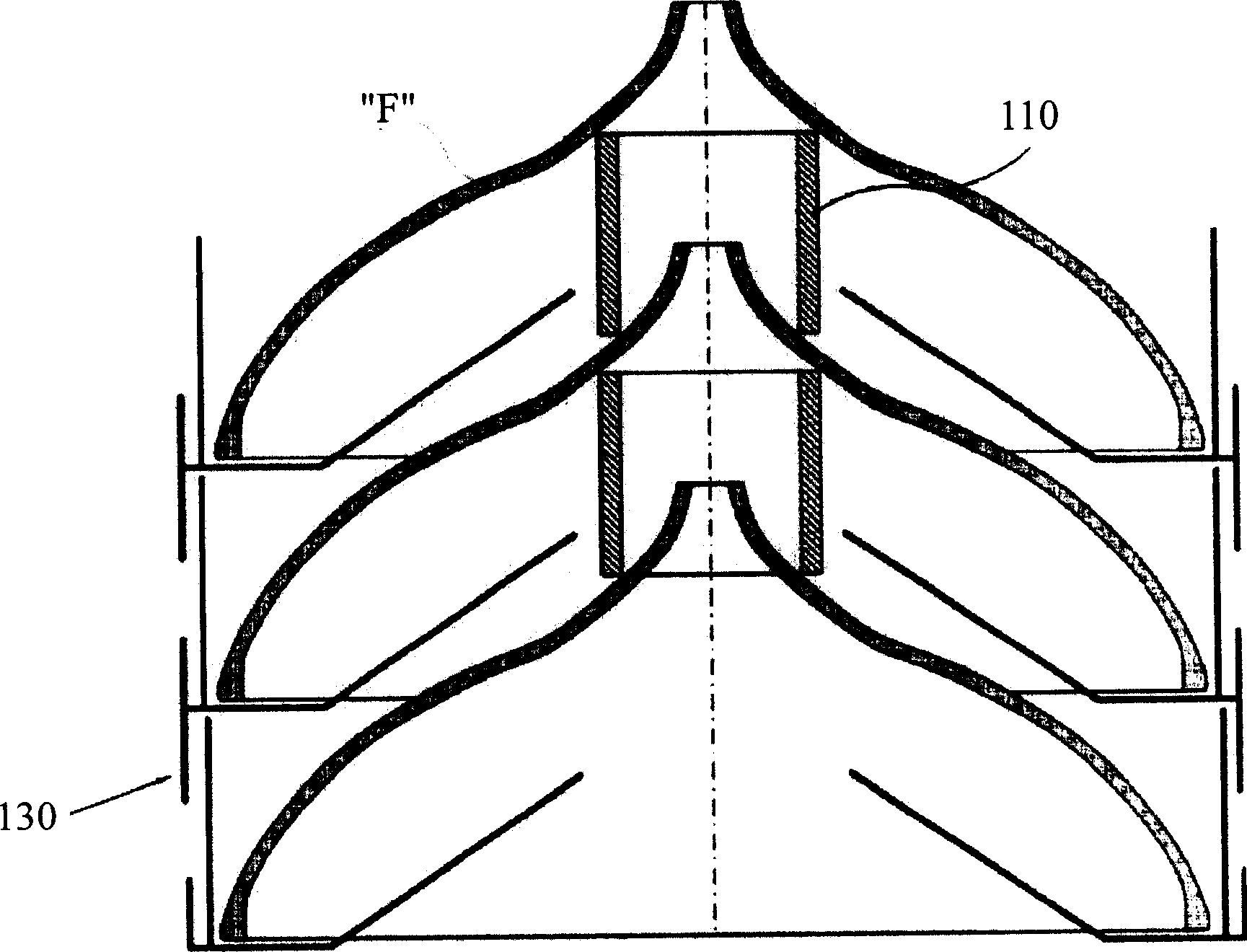

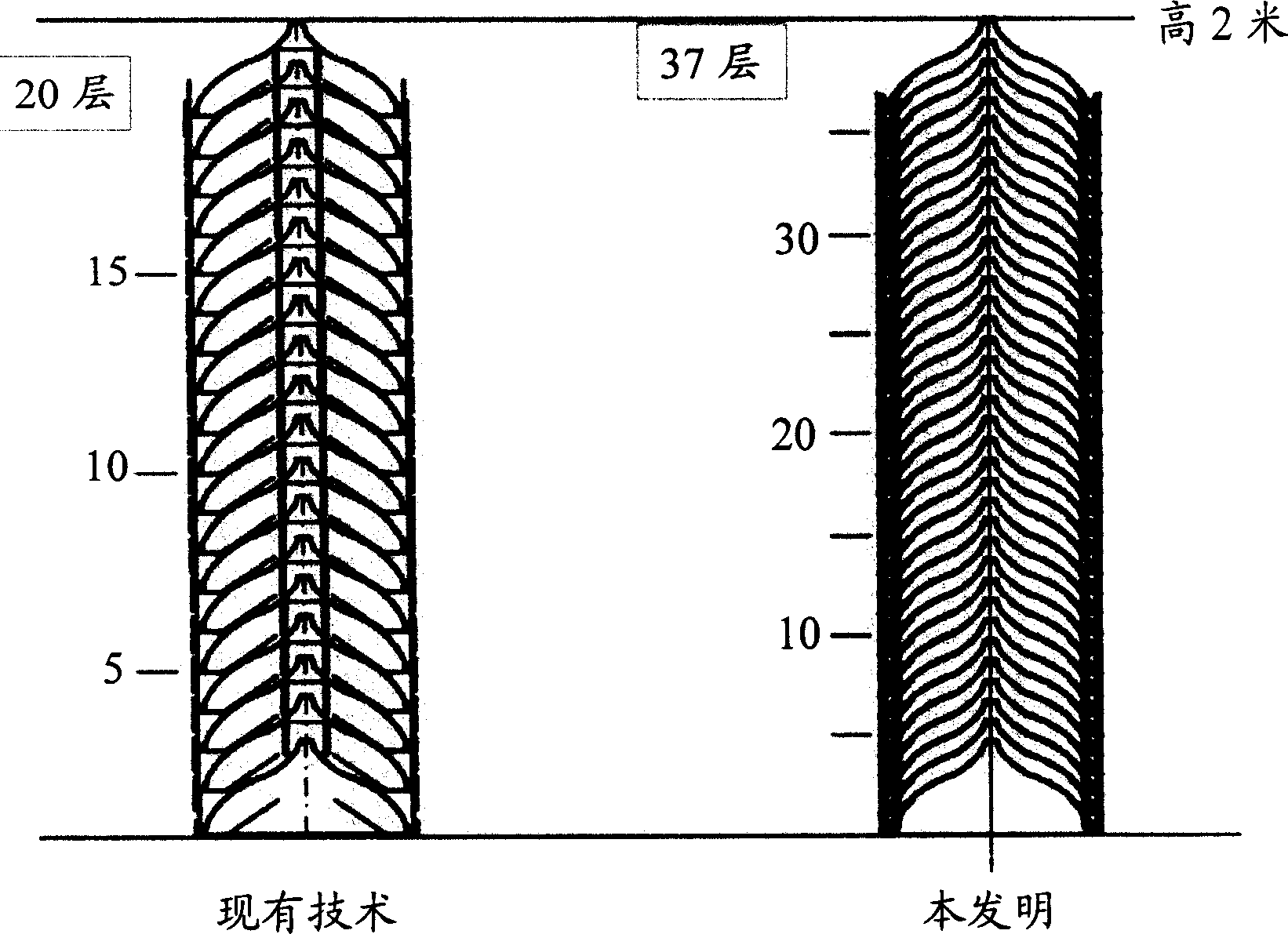

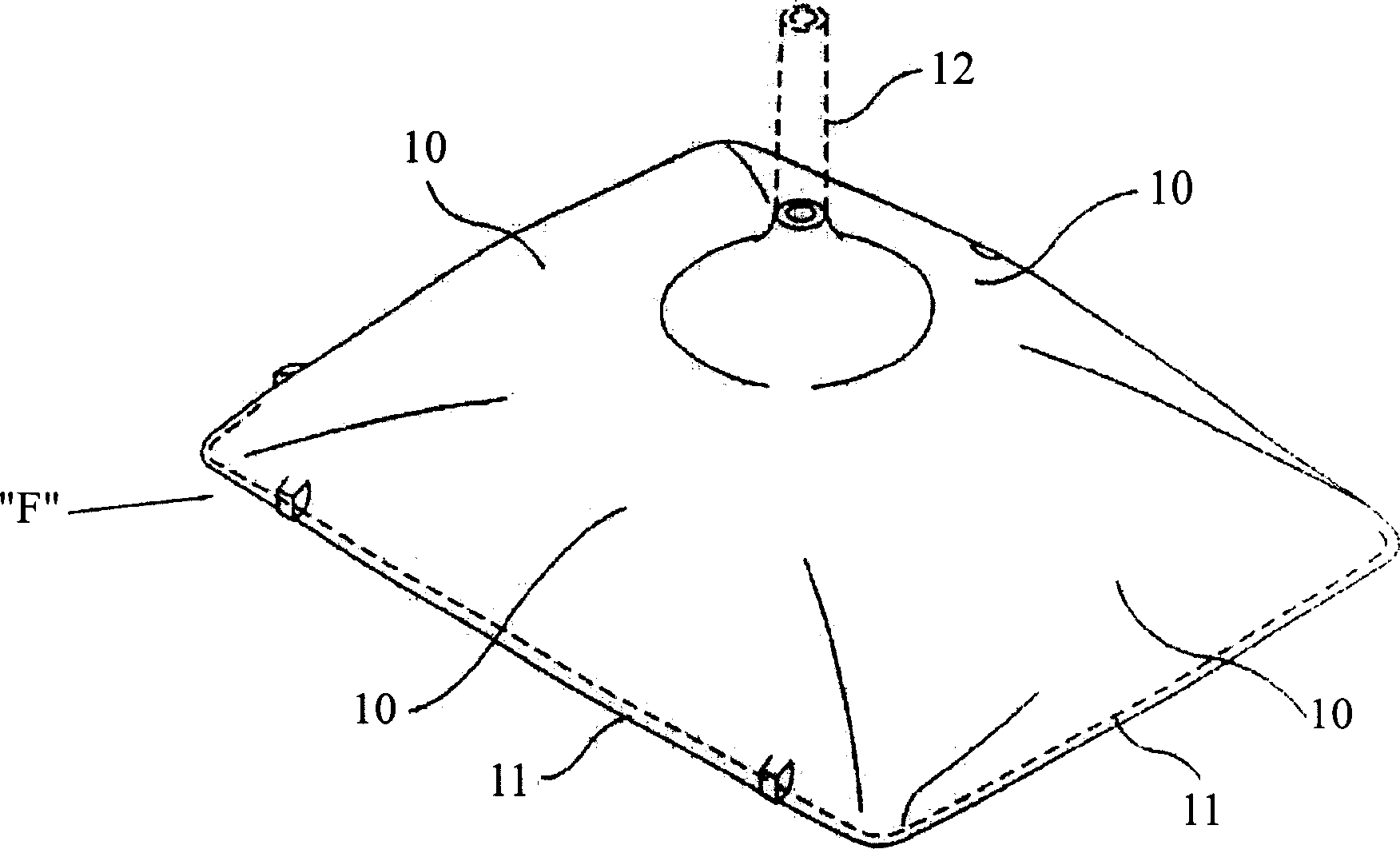

Cathode-ray tube hopper package

InactiveCN1597463AReduce layer spacingConvenient verticalCathode-ray/electron-beam tube vessels/containersInternal framesMechanical engineeringCathode Ray Tube Display

The packaging material is provided with a bottom part to support the bottom face of the funnel, a side wall part 1 which is bent upward from the outer end of the bottom part to form a side wall, at least a pair of stacking-connection projections which are extended upward along the side wall part from the bottom part in order to detachably connect adjacent packaging materials and a contact prevention part which is extended aslant along the slop surface of the funnel from the inner end of the bottom part in order to prevent the stacked funnels from coming in contact with each other and has an opening to partially expose the funnel formed at the center part. In this way, it can provide a packaging material for a funnel for a cathode-ray tube, with which the funnel can be loaded easily in the height direction while the height between layers is decreased as much as possible so that more funnel can be loaded per unit height and the supporting rigidity in the height direction of which is increased so that the funnel can be loaded vertically without an inclination.

Owner:郑志源 +1

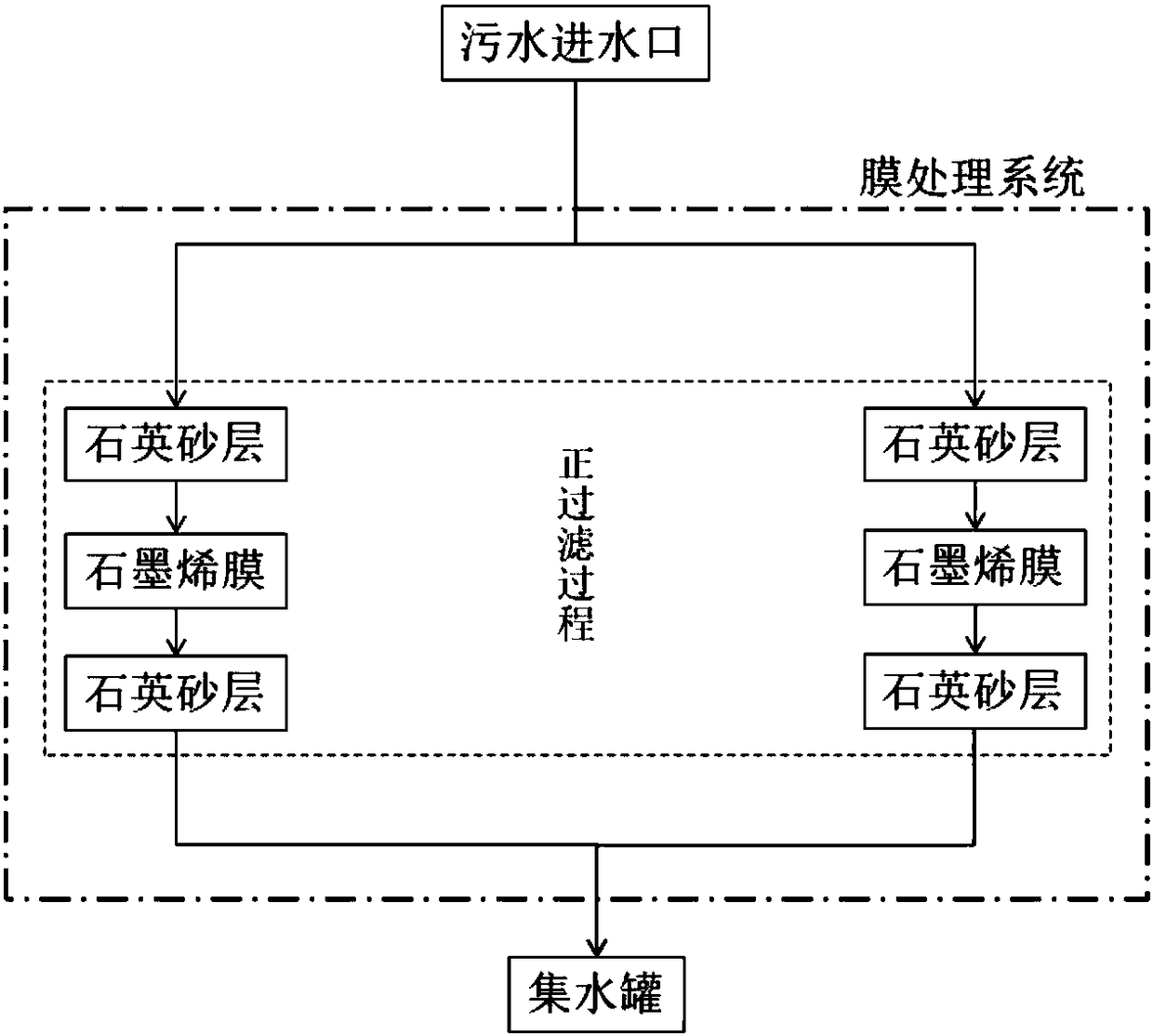

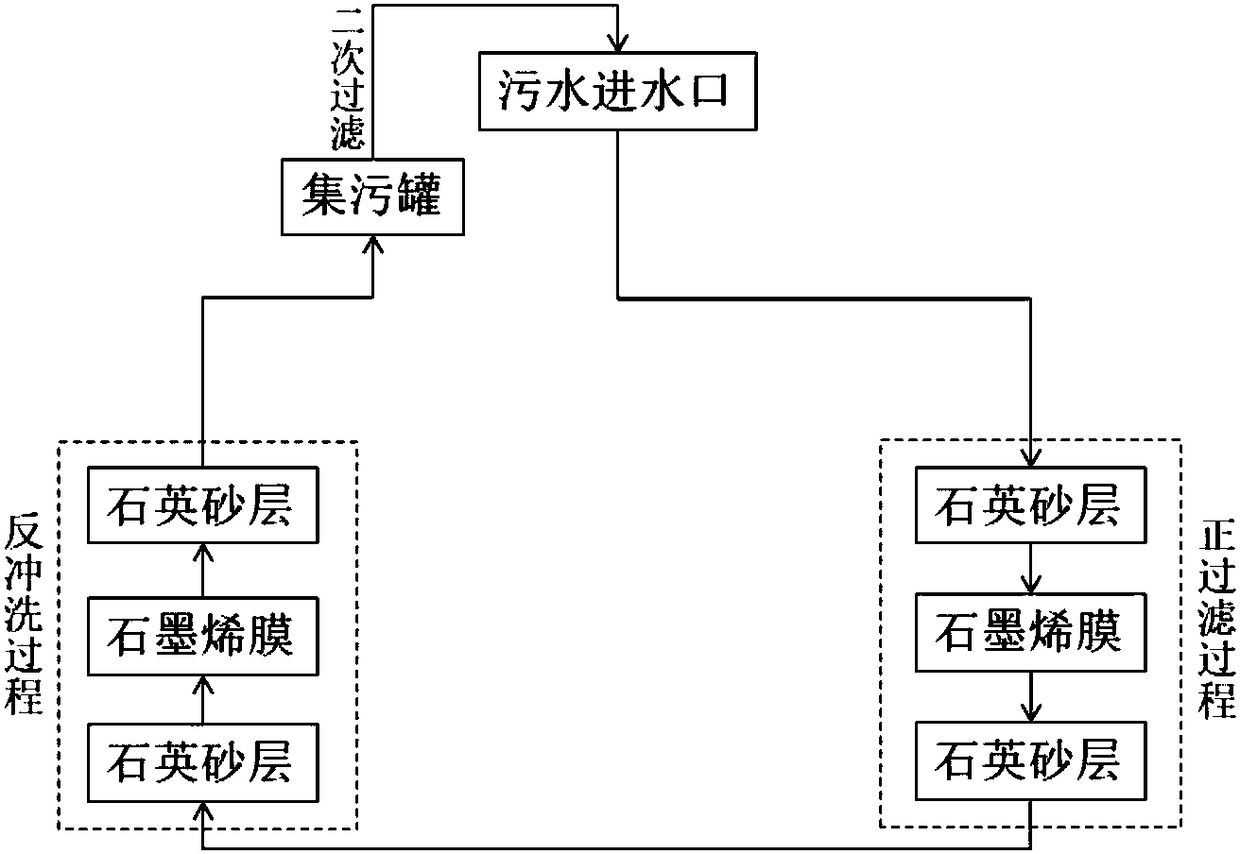

Graphene membrane continuous sewage filtering device and filtering method

PendingCN108328698AImprove processing efficiencyControllabilitySemi-permeable membranesMembranesSolenoid valveSewage

The invention discloses a graphene membrane continuous sewage filtering device and a filtering method and belongs to the technical field of sewage treatment. The graphene membrane continuous sewage filtering device disclosed by the invention comprises a sewage water inlet, a membrane treatment system, a dirt collection tank and a water collection tank. According to the graphene membrane continuoussewage filtering device, a pipeline in a membrane treatment system and a solenoid valve pipeline control part are arranged, so that sewage continuously enters from the sewage water inlet; the sewageis filtered through the membrane treatment system; when a filtering membrane in the system reaches a certain adsorption amount and needs to be subjected to backwashing, water input of sewage does notneed to be interrupted; a solenoid valve is regulated to control filtered water to carry out the backwashing directly along the movement direction of water in the pipeline, so that a positive filtering process and a backwashing process of the sewage are mutually independent and does not interfere with each other. By adopting the graphene membrane continuous sewage filtering device and the filtering method, the sewage can be continuously filtered; the filtering membrane has high permeability, long service life and high sewage treatment efficiency.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Modularized drawer-type multilayer vibrating screen and manufacture method thereof

The invention relates to the field of vibratory screening machinery, and mainly relates to rapid replacement of a screen surface of a multilayer vibrating screen from a second layer to below and realization of a modularized drawer-type multilayer vibrating screen of the multilayer screening modularization and a manufacture method thereof in the production of the vibrating screens. The modularized drawer-type multilayer vibrating screen comprises a multilayer vibrating screen body, a sieve plate of the multilayer vibrating screen body is the modularized drawer-type multilayer vibrating screen, and the modularization drawer-type multilayer vibrating screen is in pull-draw match with a case body; the modularized drawer-type multilayer vibrating screen comprises module-combined type screen bracket devices, bracket sliding rails, a screen bracket hold-down gear and a bracket drawing device; two bracket sliding rails are fixedly arranged on the sidewall panel of the vibrating screen; the module-combined type screen bracket devices are arranged on the surface of each of the two bracket sliding rails; screens are respectively arranged on the module-combined type screen bracket devices; the bracket drawing device is arranged at top end of the sidewall panel of the vibrating screen; and the module-combined type screen bracket devices are connected with load cables of the bracket drawing device.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com