Formation method for improving K value of soft-package battery cell

A chemical formation method and cell technology, applied in the field of lithium-ion batteries, can solve problems such as poor K value, increase in the distance between the positive and negative electrodes of the cell, and the deformation of the main body of the cell, so as to improve internal activity, save formation time, The effect of stabilizing the K value of the battery cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

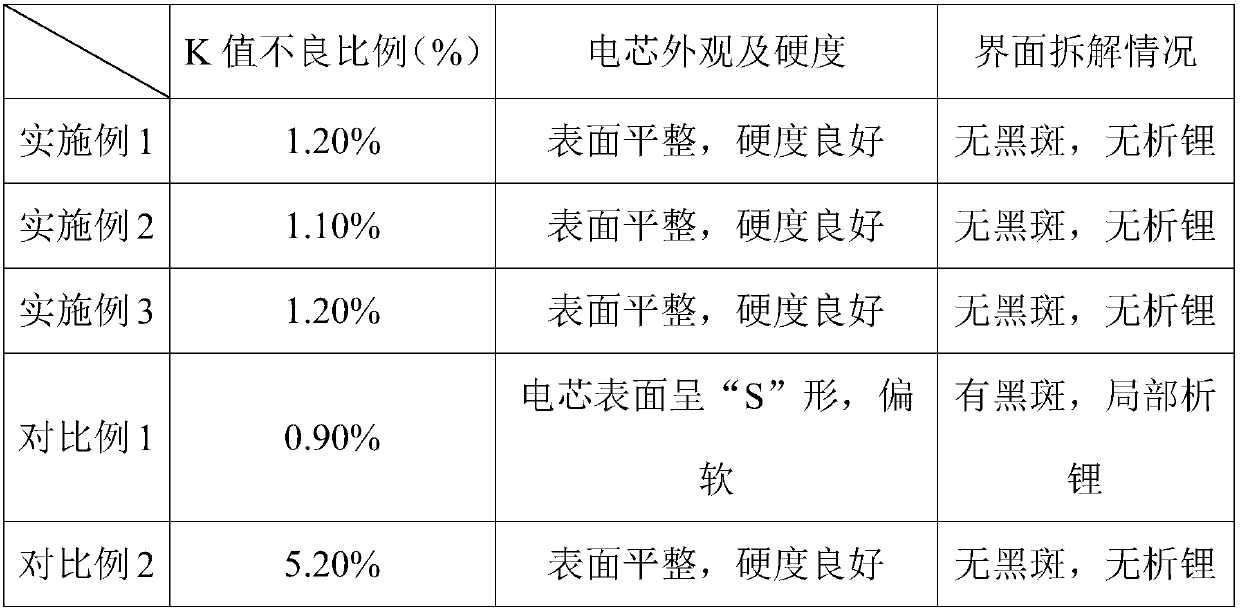

Examples

Embodiment 1

[0028] Step 1, use the battery cell of model 415879 after liquid injection and capacity of 3000mAh for formation, place the soft-packed battery cell between the splints of the fixture formation cabinet, place 4 on each layer, set the temperature of the splint to 45°C, Apply a cell surface pressure of 0.01Mpa to the surface of the cell, control the layer spacing between the positive and negative electrodes of the cell and the diaphragm to decrease, and obtain the first cell;

[0029] Step 2. Put the first battery cell obtained in step 1 in the jig forming cabinet and let it stand for 20 minutes. Set the forming step to carry out the forming. The specific forming step is as follows: First, the first stage of charging and discharging uses the size of 0.02 times the battery capacity value The current constant current charging to 3.3V, the charging cut-off time is 80min; then, the second stage of charging and discharging is charged to 3.5V with a current of 0.1 times the battery cap...

Embodiment 2

[0033] Step 1, use the battery cell of model 415879 after liquid injection and capacity of 3000mAh for formation, place the soft-packed battery cell between the splints of the fixture formation cabinet, place 4 on each layer, set the temperature of the splint to 45°C, Apply a cell surface pressure of 0.05Mpa to the surface of the cell, and control the layer spacing between the positive and negative electrodes of the cell and the separator to decrease to obtain the first cell;

[0034]Step 2. Put the first battery cell obtained in step 1 in the jig forming cabinet and let it stand for 20 minutes. Set the forming step to carry out the forming. The specific forming step is as follows: First, the first stage of charging and discharging uses the size of 0.02 times the battery capacity value The current constant current charging to 3.3V, the charging cut-off time is 80min; then, the second stage of charging and discharging is charged to 3.5V with a current of 0.1 times the battery ca...

Embodiment 3

[0038] Step 1. Use the battery cell with the model number 415879 and a capacity of 3000mAh after liquid injection for formation. Place the soft-packed battery cell between the splints of the fixture formation cabinet, place 4 on each layer, and set the temperature of the splint to 55°C. Apply a cell surface pressure of 0.01Mpa to the surface of the cell, control the layer spacing between the positive and negative electrodes of the cell and the diaphragm to decrease, and obtain the first cell;

[0039] Step 2. Put the first battery cell obtained in step 1 in the jig forming cabinet and let it stand for 20 minutes. Set the forming step to carry out the forming. The specific forming step is as follows: First, the first stage of charging and discharging uses the size of 0.02 times the battery capacity value The current constant current charging to 3.3V, the charging cut-off time is 80min; then, the second stage of charging and discharging is charged to 3.5V with a current of 0.1 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com