Horizontal three-phase separation device and separation method thereof

A three-phase separation, horizontal technology, used in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of reduced processing efficiency, difficult maintenance operations, high costs, improved processing capacity and efficiency, accelerated oil-water separation, and prevented silt silting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

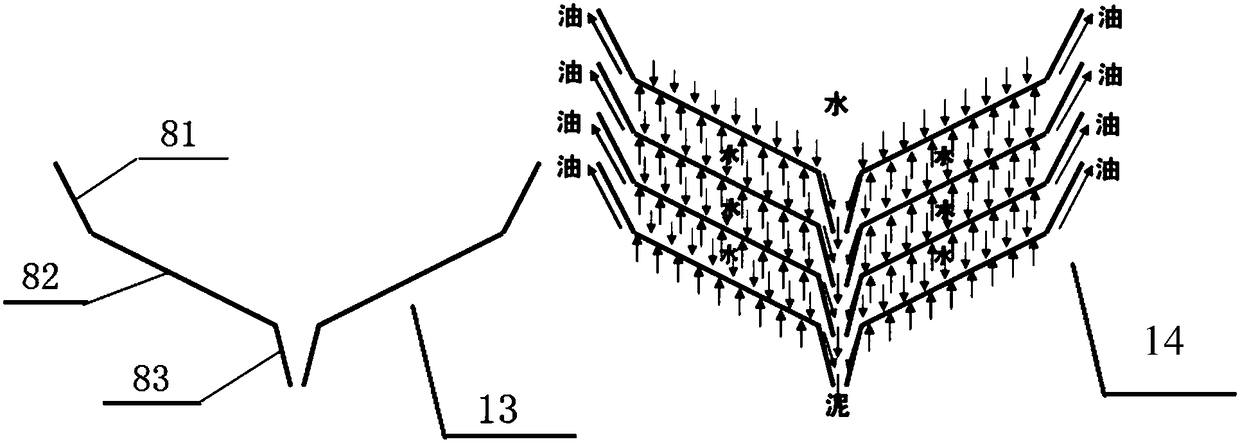

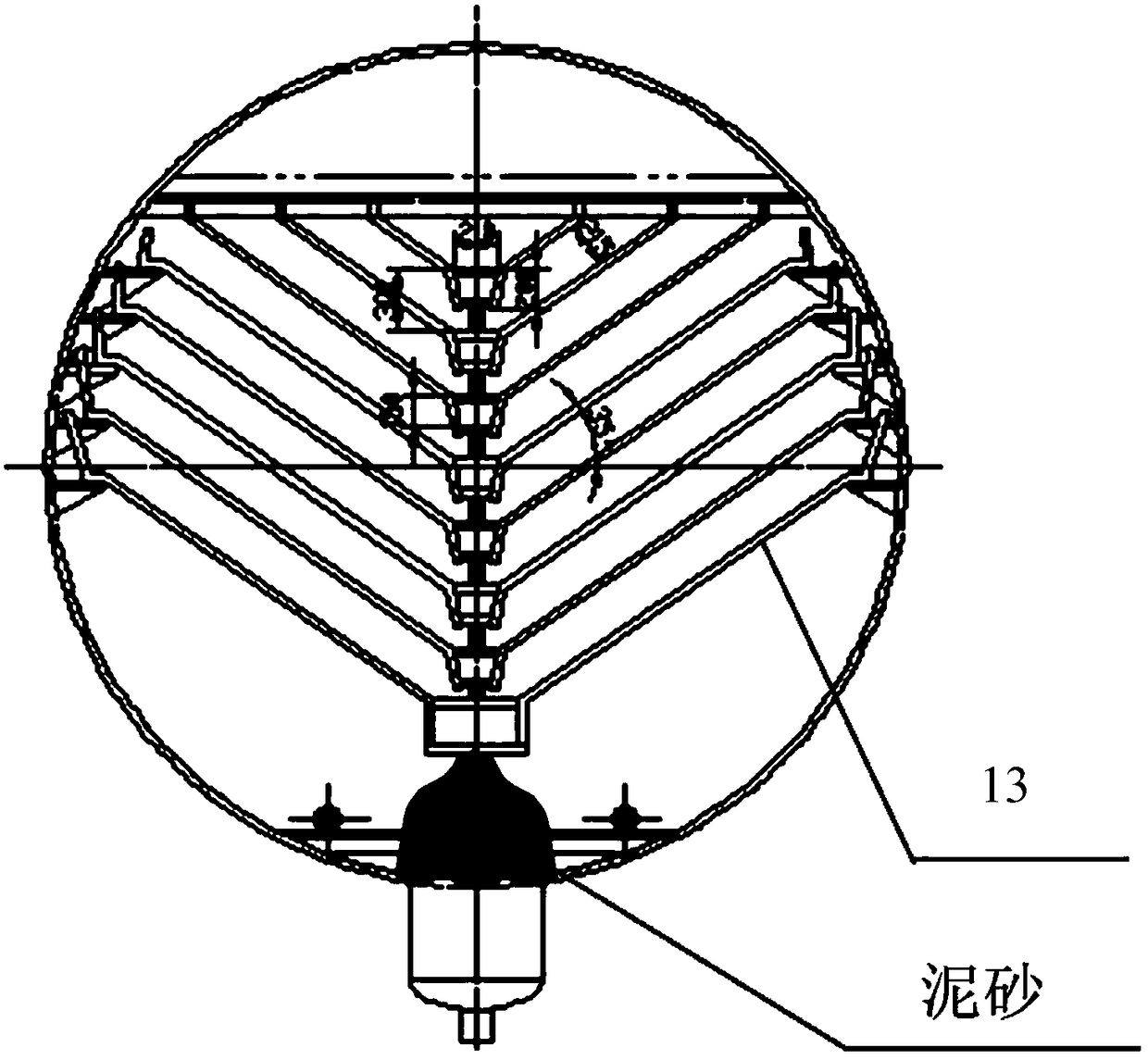

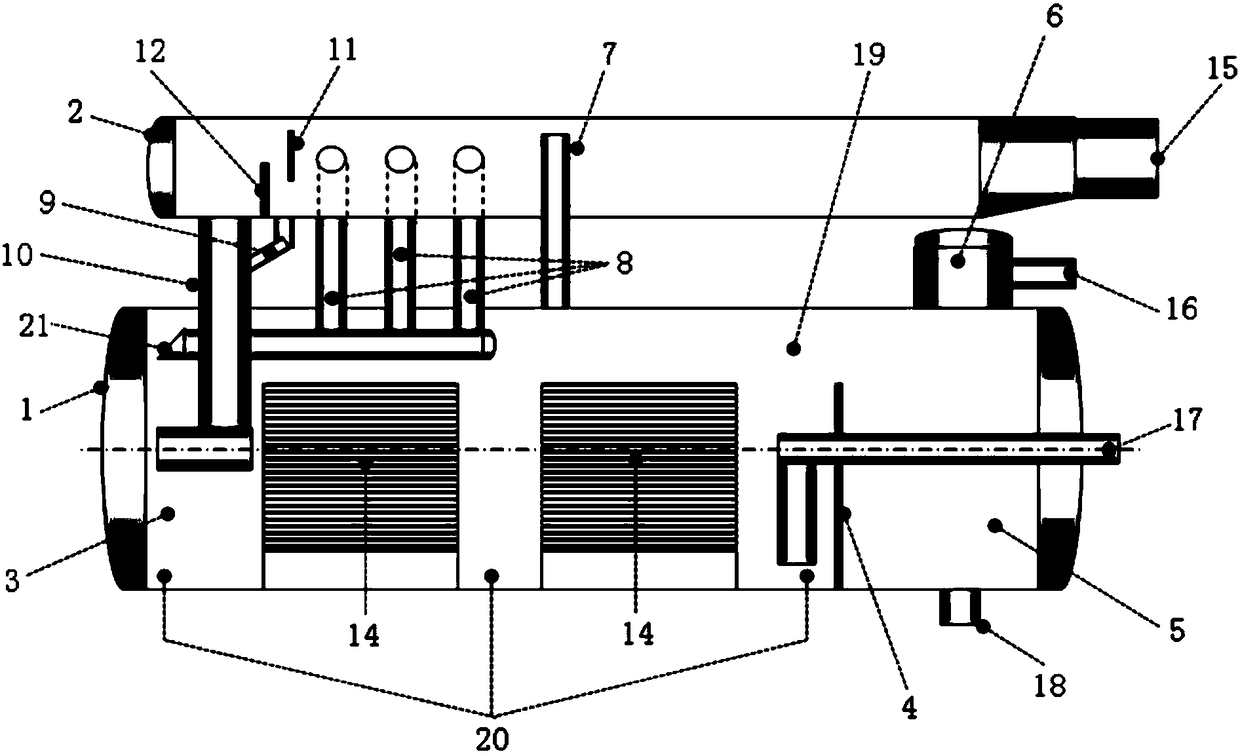

[0049] The original design intention and working principle of the wing plate horizontal three-phase separation device provided by the present invention and the separation method of oil-gas-water multiphase medium realized by the separation device are as follows:

[0050] (1) High-efficiency oil-water separation components with open airfoils with large oblique angles

[0051] Since the diameter of the horizontal three-phase separator commonly used in the oil field is mostly 3-4m, its cross-sectional area is large, and the medium flow rate is low, the mud and sand in the oil well production fluid are easy to deposit inside the container, and various coalescing fillers installed inside it All of them fail after being silted up by mud and sand. In order to overcome this problem, the inclination angle of the large oblique angle split wing plate in the present invention is between 25-45 degrees, such as figure 1 As shown, the mud and sand settled down from the oil-water medium fall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com