Lithium-ion battery with high rate performance and preparation method thereof

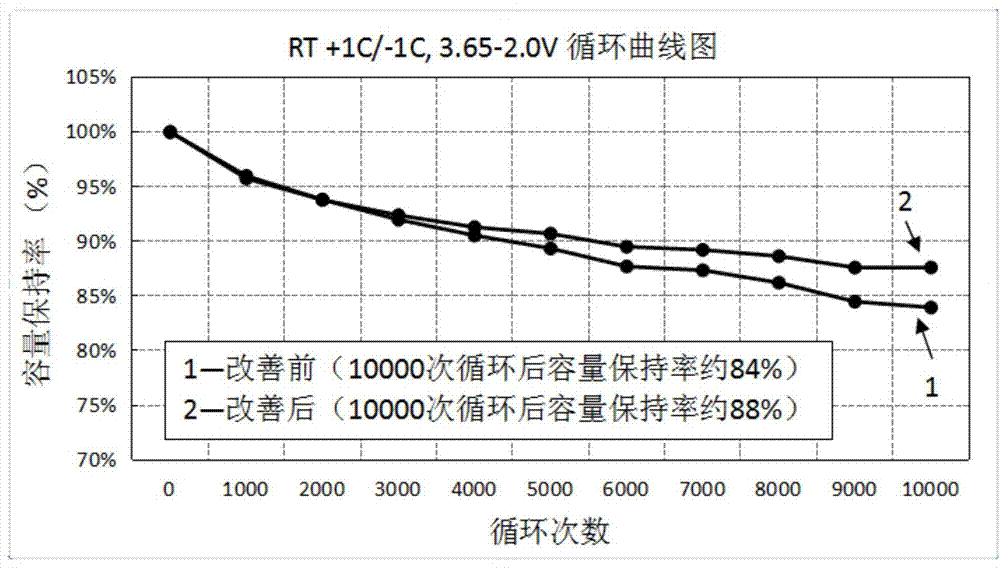

A lithium-ion battery, high-rate technology, used in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as inability to withstand high current fast charging, shorten battery life, and small charge and discharge currents, and achieve improved performance. The effect of fast charge and discharge performance, high conductivity and short charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

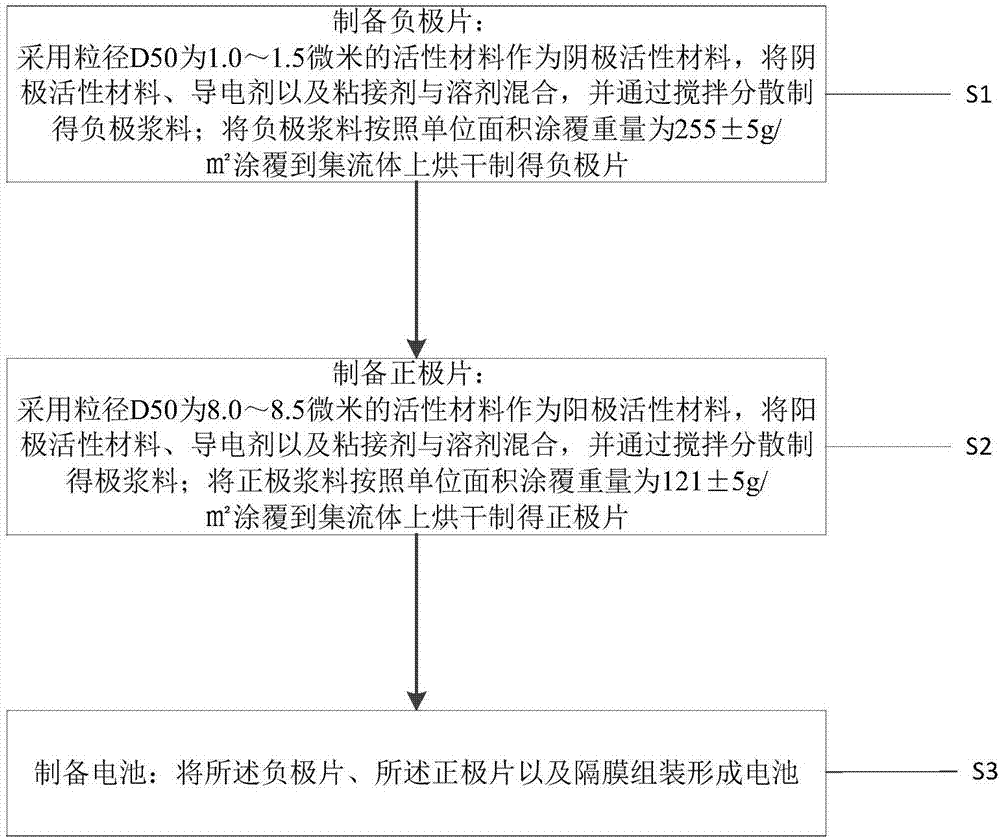

[0041] figure 1 The preparation method of the lithium ion battery with high rate performance of the present invention is shown.

[0042] like figure 1 Shown, this has the preparation method of high-rate performance lithium-ion battery, comprises the following steps:

[0043] S1. Preparation of negative electrode sheet: using an active material with a particle size D50 of 1.0 to 1.5 microns as the negative electrode active material, mixing the negative electrode active material, conductive agent, and binder with a solvent, and stirring and dispersing to prepare a negative electrode slurry; The negative electrode slurry is coated on the current collector according to the coating weight per unit area of 255±5g / ㎡ and dried to prepare the negative electrode sheet.

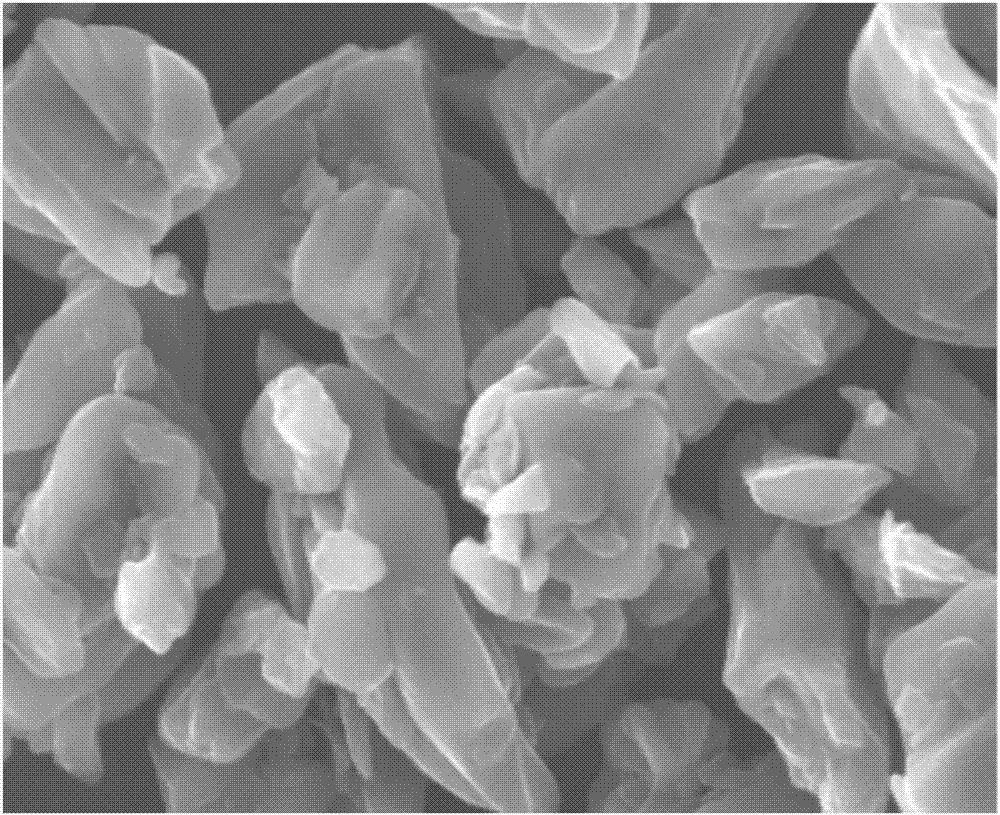

[0044] Wherein, the conductive agent includes a tube bundle conductive agent and a granular conductive agent, and the tube bundle conductive agent can be KS-6; the cathode active material can be a relatively small c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com