Graphene oxide/methylene blue composite film and preparation method thereof

A methylene blue and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as shedding, unstable GO membrane, and low rejection rate of graphene oxide membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

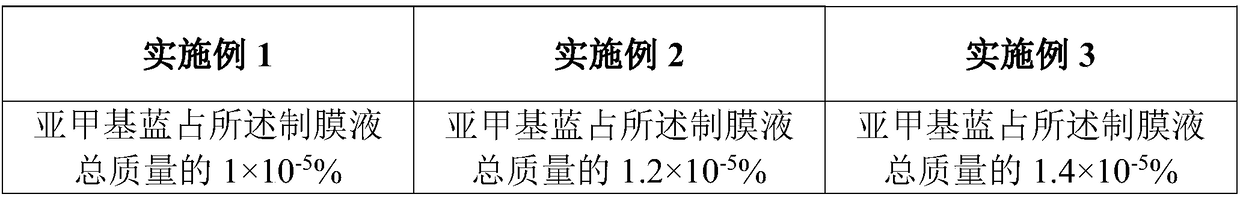

Embodiment 1~3

[0018] A preparation method of graphene oxide / methylene blue composite film, comprising the steps of:

[0019] Take 0.005g sheet-layer graphene oxide and put it into a mortar, add 1mL of pure water dropwise and grind for 5min, transfer it to a 500mL round-bottomed flask, dilute to 300mL with pure water, and mechanically stir at 20°C for 3.5h, then sonicate to After complete dispersion, it is sealed and stored in a low temperature room to obtain a uniformly dispersed graphene oxide aqueous solution;

[0020] Add different amounts of methylene blue powder to the graphene oxide aqueous solution, and magnetically stir for 24 hours to obtain a film-forming solution;

[0021] Pre-lay the mixed cellulose microfiltration membrane in the sand core funnel as the base membrane, vacuum filter 100mL of the membrane-making solution under the condition of -0.1Mpa to form a membrane, and then dry it at room temperature for 2 days to obtain the graphene oxide / methylene blue composite membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com