Modularized drawer-type multilayer vibrating screen and manufacture method thereof

A multi-layer vibration and drawer-type technology, which is applied in the field of vibrating screening machinery and multi-layer vibrating screen manufacturing, can solve the problems of wasting the distance between vibrating screen layers, labor and time, etc., and achieve investment saving, simplification of screening equipment and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

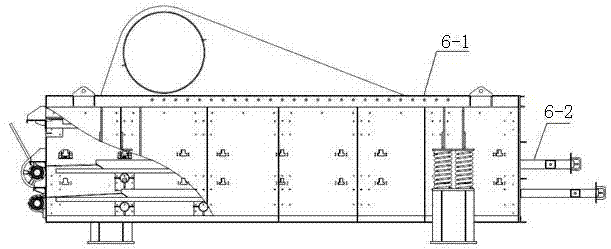

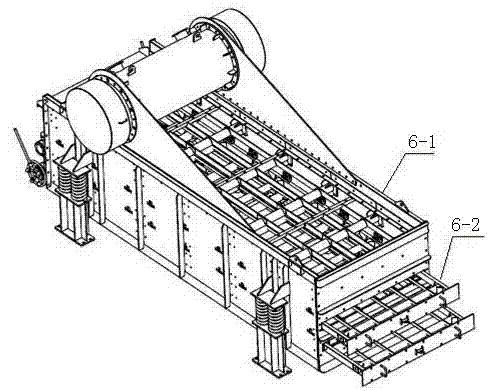

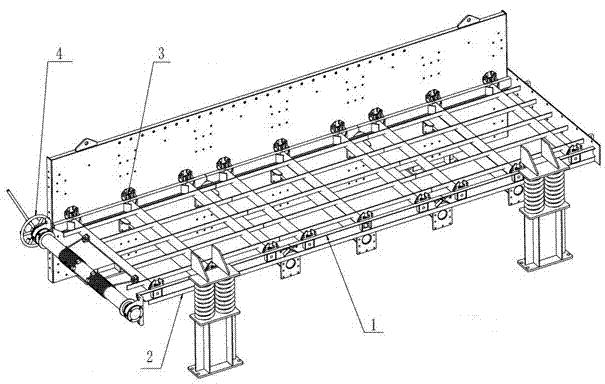

[0022] Embodiment 1: with reference to attached Figure 1-10 . A modular drawer-type multi-layer vibrating screen, comprising a multi-layer vibrating screen, the sieve plate in the multi-layer vibrating screen is a modular drawer-type vibrating screen 6-2, and the modular drawer-type vibrating screen 6-2 is connected with the box The bodies 6-1 are drawn together; the modular drawer vibrating screen 6-2 consists of a modular screen bracket device 1, a bracket slide rail 2, a screen bracket pressing device 3 and a bracket traction device. 4 components, two bracket slide rails 2 are fixedly installed on the side wall of the vibrating screen, the modular combined screen bracket device 1 is located on the surface of the two bracket slide rails 2, and the screens are respectively installed on the modular combined screen On the bracket device 1, the bracket traction device 4 is located at the end of the side wall of the vibrating screen, the modular combined screen bracket device 1...

Embodiment 2

[0034] Embodiment 2: A method for manufacturing a modular drawer-type multi-layer vibrating screen. First, the qualified screens of the required specifications are respectively fixed on the modular combined screen bracket device 1, and the wire rope in the bracket traction device 4 4-2 Stretch to a suitable ground, and assemble with the two fixed pulleys 1-2 in the modular combined tail screen bracket device with the sieve plate installed, and then connect with other parts of the modular combined screen bracket The screen bracket soft connection devices 1-4 between the racks are connected and fastened to each other, and then the bracket traction device 4 is twisted, and the combined bracket group is dragged to the inlet end of the bracket slide rail 2. When the type screen bracket device 1 is close to the bracket slide rail 2, it is assisted by the fixed pulley previously fixed on the head of the feed conveyor belt, and is first sent into the modular combined tail screen bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com