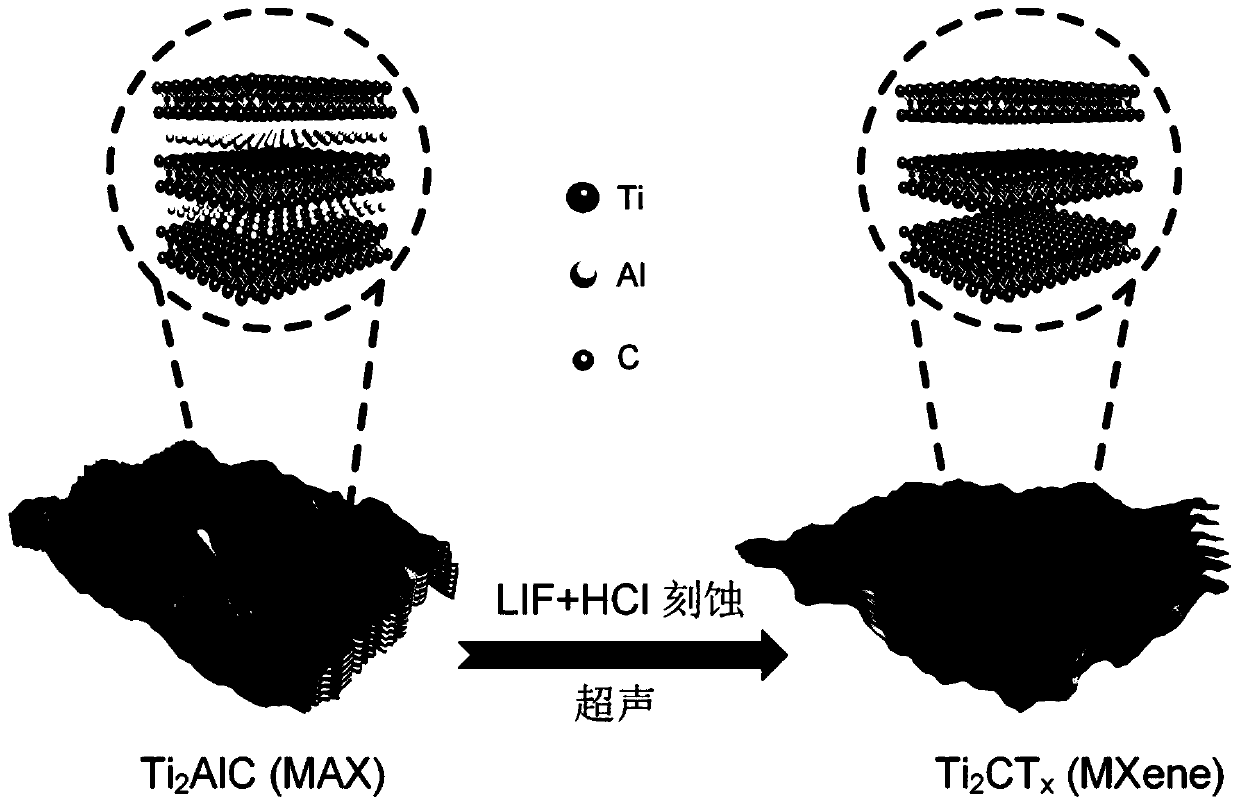

Bionic flexible pressure sensor based on lotus leaf micro-spinous-process/MXene composite structure

A technology of pressure sensor and composite structure, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of lack of wide linearity, limited mass production, high cost, etc., and achieve low response time, high stability, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

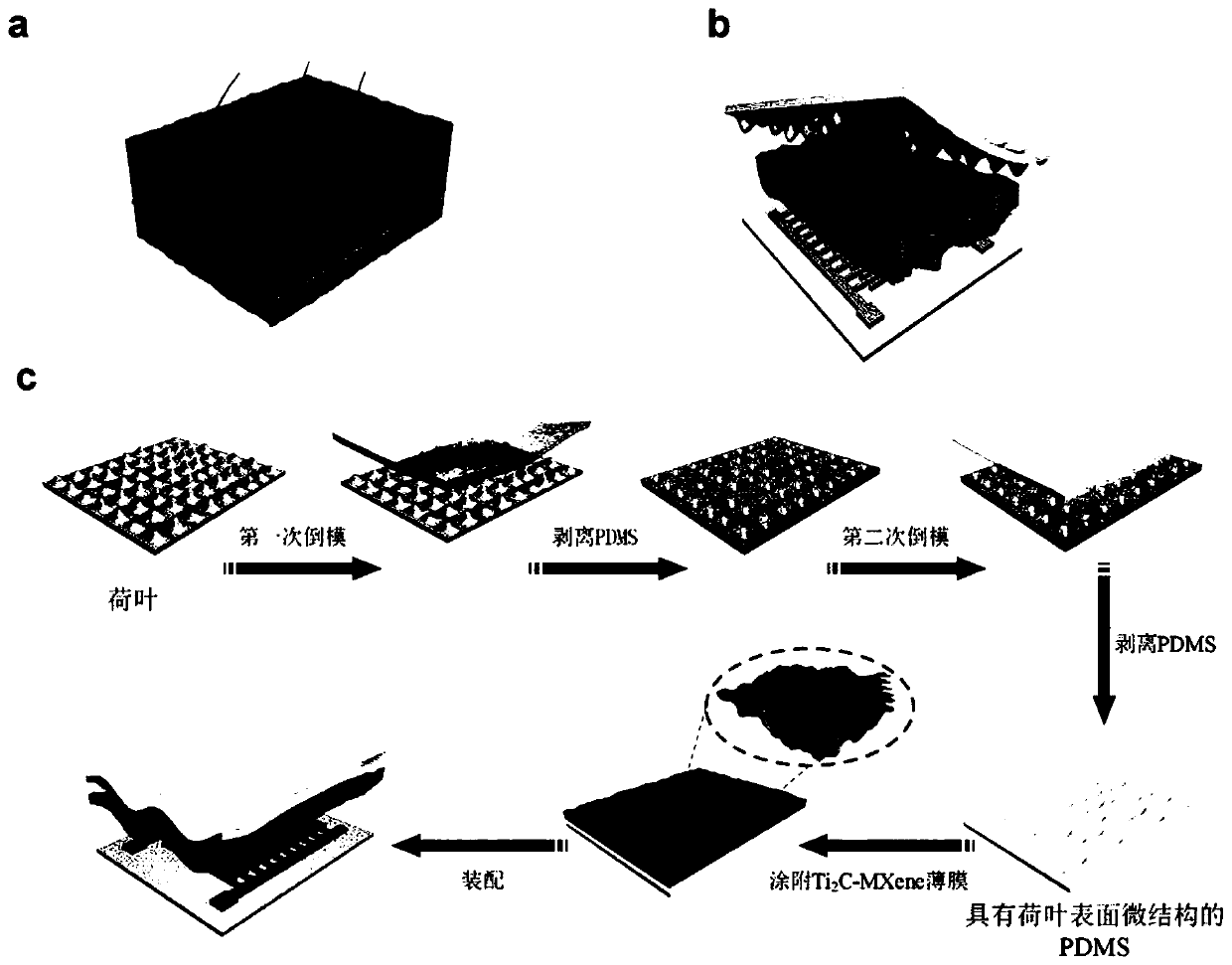

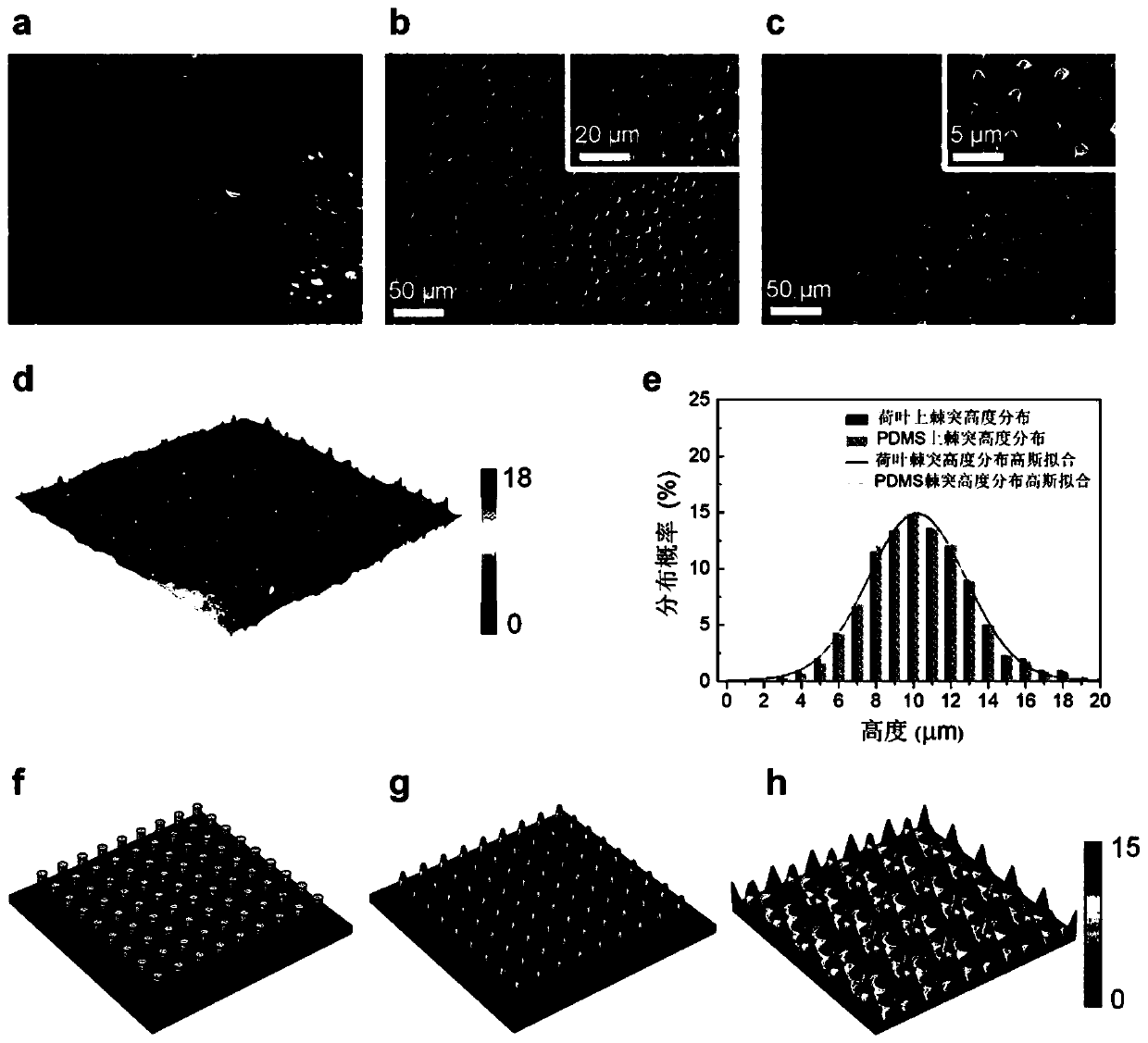

[0033] The micro spinous process structure of PDMS lotus leaf is based on lotus leaf, using SLYGARD 184 PDMS material produced by Dow Corning, which is composed of main agent and curing agent, to prepare PDMS prepolymer for secondary soft lithography inversion molding. The preparation method comprises the following steps:

[0034] a. Cut fresh Wagyu leaves into squares (5mm×5mm), wash three times with deionized water;

[0035] b. After nitrogen drying, fix the lotus leaves on the 4-inch silicon wafer substrate with double-sided adhesive tape;

[0036] c. Use PDMS for the first pour: curing agent = 5:1 prepolymer. After the prepolymer is configured, stir evenly until it is completely mixed, and degas it in a vacuum drying oven at room temperature for 20 minutes to Remove air bubbles at room temperature;

[0037] d. Spin-coat a certain amount of PDMS prepolymer on the silicon wafer with the lotus leaf attached, and perform the uniform glue process. The speed of gear I is 300r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com