CC-NiO-CuCoS composite material as well as preparation method and application thereof

A composite material, cc-nio-cucos technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of rapid cycle performance decay, and achieve the effects of accelerating diffusion, improving stability, and improving supercapacitor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

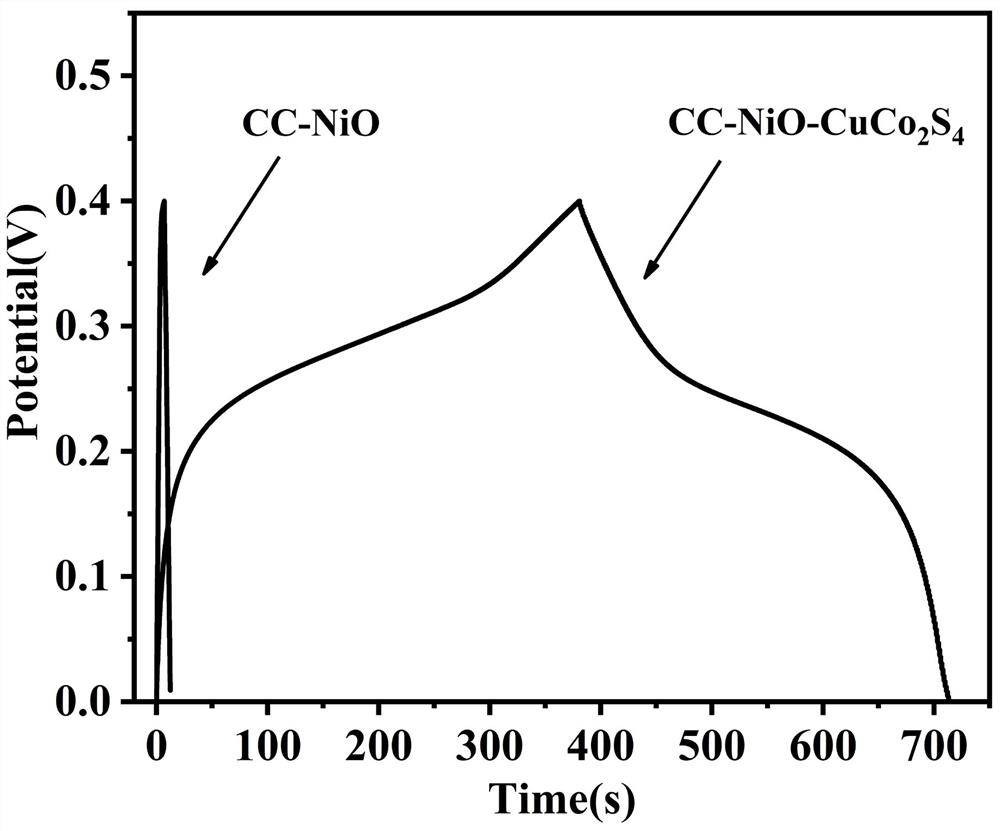

[0057] A kind of preparation method of CC-NiO-CuCoS composite material, its preparation method comprises the following steps:

[0058] Step 1) Activation of CC, the CC with a size of 2cm X 2cm was ultrasonically cleaned in 40mL of 99% ether solution, 40mL of absolute ethanol, and 40mL of deionized water for 15min, and then cleaned in 40mL of 69% concentrated Boil in nitric acid in a water bath at 80-90°C for 4 hours for activation. After the water bath is completed, wash with deionized water and absolute ethanol three times respectively, and dry at 60°C for 12 hours to obtain the activated CC;

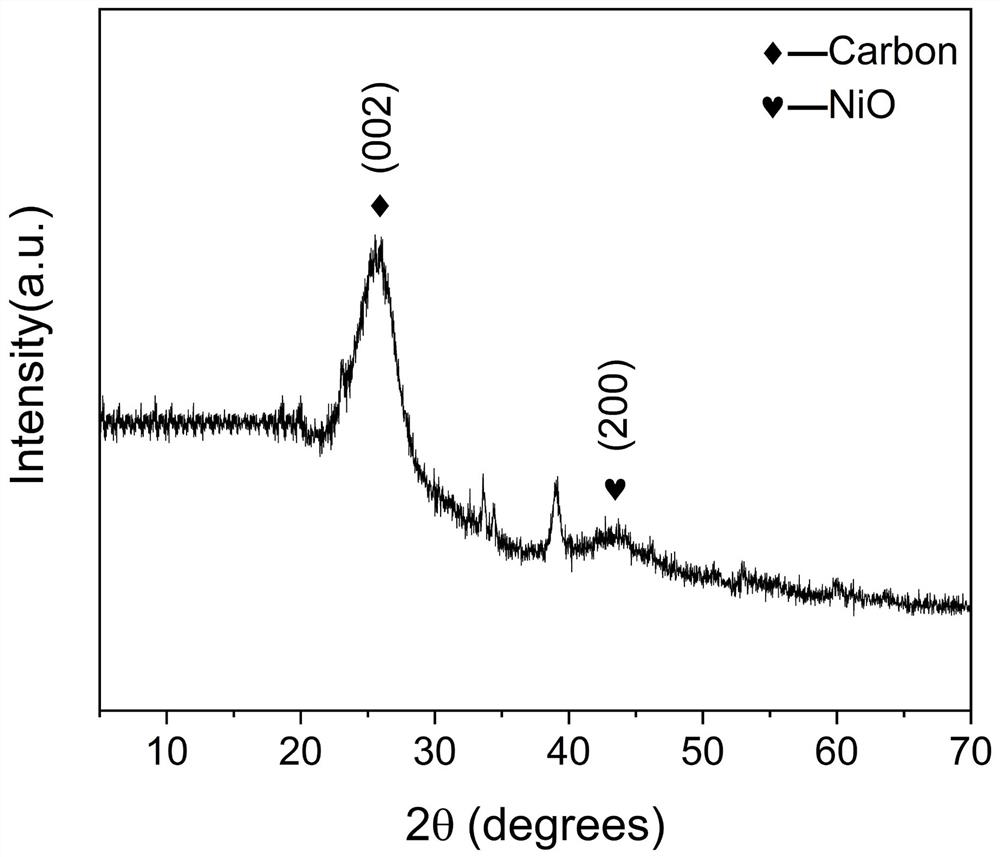

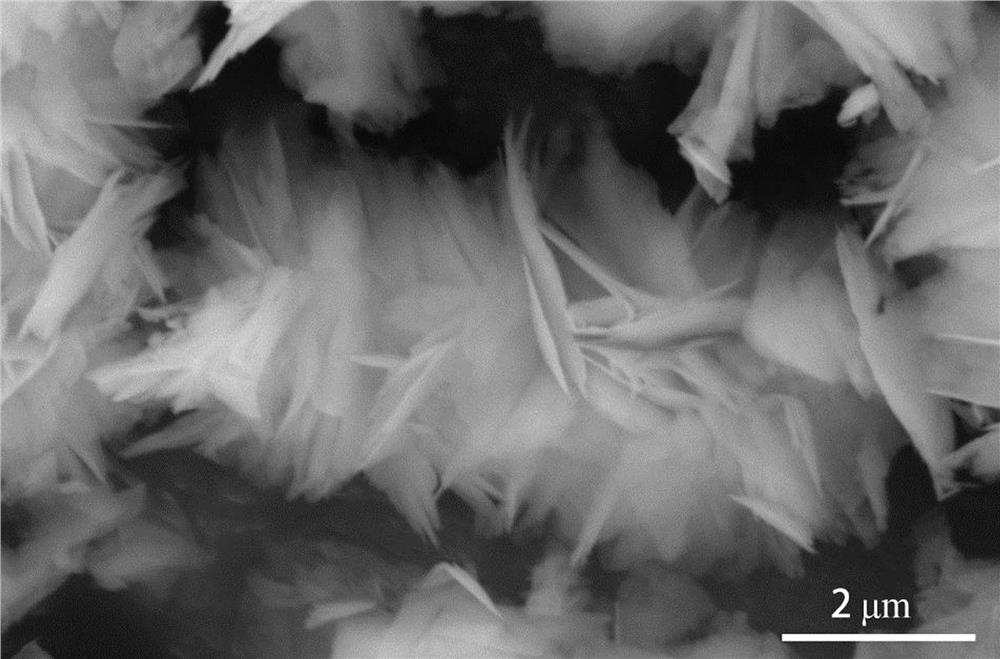

[0059] Step 2) The preparation of CC-NiO composite material, the ratio of the amount of nickel nitrate hexahydrate, ammonium fluoride, and urea is 1:6:12, and the activated CC obtained in step 1 is mixed with nickel nitrate hexahydrate, fluorine Put ammonium chloride and urea into 60mL water together, and carry out hydrothermal reaction in an autoclave under the condition of reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com