Sealing gasket with excellent resilience performance and preparation method thereof

A technology of resilience performance and sealing gasket, applied in the field of sealing gasket and its preparation, can solve problems such as affecting the use effect of sealing gasket, deformation of sealing gasket, waste of resources, etc., so as to improve stability and hardness, and avoid displacement. , improve the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

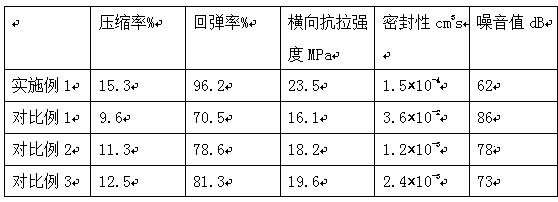

Examples

Embodiment 1

[0025] A sealing gasket with excellent resilience performance, the components by weight are as follows: 10 parts of elastic graphene particles, 40 parts of copper sulfate solution, 2 parts of molybdenum sulfide, 3 parts of carboxymethyl cellulose, 15 parts of acrylic emulsion, 5 parts of methyl silicone oil, 40 parts of polytetrafluoroethylene powder, 80 parts of terpolymer rubber, 3 parts of glass fiber, and 1 part of auxiliary crosslinking agent.

[0026] As preferably, wherein the mass fraction of the copper sulfate solution is 10%; the auxiliary crosslinking agent is selected from one or at least two of the auxiliary crosslinking agent TAIC, HVA-2 or VP-4; the acrylic acid emulsion solid The content is 28%.

[0027] As preferably, the preparation method of wherein said elastic graphene particles is as follows:

[0028] 1) Take 10 parts of dimethylol propionic acid, add it to 20 parts of N-methylpyrrolidone solution, stir to dissolve, then add 13 parts of polyester diol, 0...

Embodiment 2

[0040] A sealing gasket with excellent resilience performance, the components by weight are as follows: 13 parts of elastic graphene particles, 50 parts of copper sulfate solution, 2.5 parts of molybdenum sulfide, 3.5 parts of carboxymethyl cellulose, 20 parts of acrylic acid emulsion, 6 parts of methyl silicone oil, 50 parts of polytetrafluoroethylene powder, 100 parts of terpolymer rubber, 4 parts of glass fiber, and 1.5 parts of auxiliary crosslinking agent.

[0041] As preferably, wherein the mass fraction of the copper sulfate solution is 13%; the auxiliary crosslinking agent is selected from one or at least two of the auxiliary crosslinking agent TAIC, HVA-2 or VP-4; the acrylic acid emulsion solid The content is 30%.

[0042] As preferably, the preparation method of wherein said elastic graphene particles is as follows:

[0043] 1) Take 13 parts of dimethylol propionic acid, add it to 25 parts of N-methylpyrrolidone solution, stir to dissolve, then add 15 parts of poly...

Embodiment 3

[0055] A sealing gasket with excellent resilience performance, the components by weight are as follows: 15 parts of elastic graphene particles, 60 parts of copper sulfate solution, 3 parts of molybdenum sulfide, 4 parts of carboxymethyl cellulose, 25 parts of acrylic acid emulsion, 7 parts of methyl silicone oil, 60 parts of polytetrafluoroethylene powder, 120 parts of terpolymer rubber, 5 parts of glass fiber, and 2 parts of auxiliary crosslinking agent.

[0056] As preferably, wherein the mass fraction of the copper sulfate solution is 15%; the cross-linking agent is selected from one or at least two of the cross-linking agent TAIC, HVA-2 or VP-4; the acrylic emulsion solid The content is 32%.

[0057] As preferably, the preparation method of wherein said elastic graphene particles is as follows:

[0058] 1) Take 15 parts of dimethylol propionic acid, add it to 30 parts of N-methylpyrrolidone solution, stir to dissolve, then add 17 parts of polyester diol, 1.0 parts of dibu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com