Plant leaf back light supply lamp panel

A technology of plant leaves and light lamps, which is applied in the direction of botany equipment and methods, light sources, and light source fixation, and can solve the problems of inability to fully develop the overall photosynthetic ability of plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in more detail below with reference to the accompanying drawings and reference numerals, so that those skilled in the art can implement it after studying this specification. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

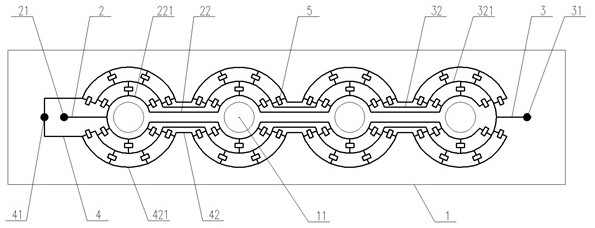

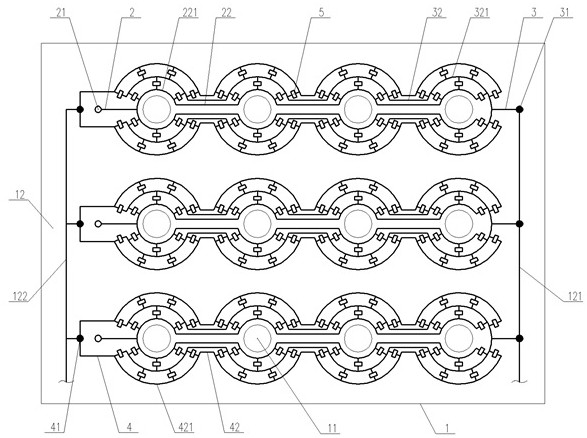

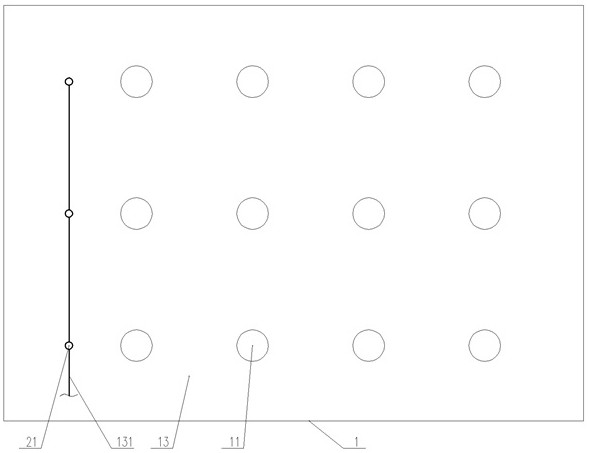

[0027] The present invention provides a figure 1 The light supply lamp board for the back of a plant leaf as shown includes a substrate 1, on which a plurality of planting holes 11 arranged in an array are arranged, and each column of planting holes 11 is provided with a group of power lines, and the power lines include the first A wiring 2, a second wiring 3 and a third wiring 4; the first wiring 2 includes a first electrode connection point 21 and a first symmetrical line 22 connected to the first electrode connection point 21, The first line of symmetry 22 includes a plurality of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com