Patents

Literature

626 results about "Plant production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

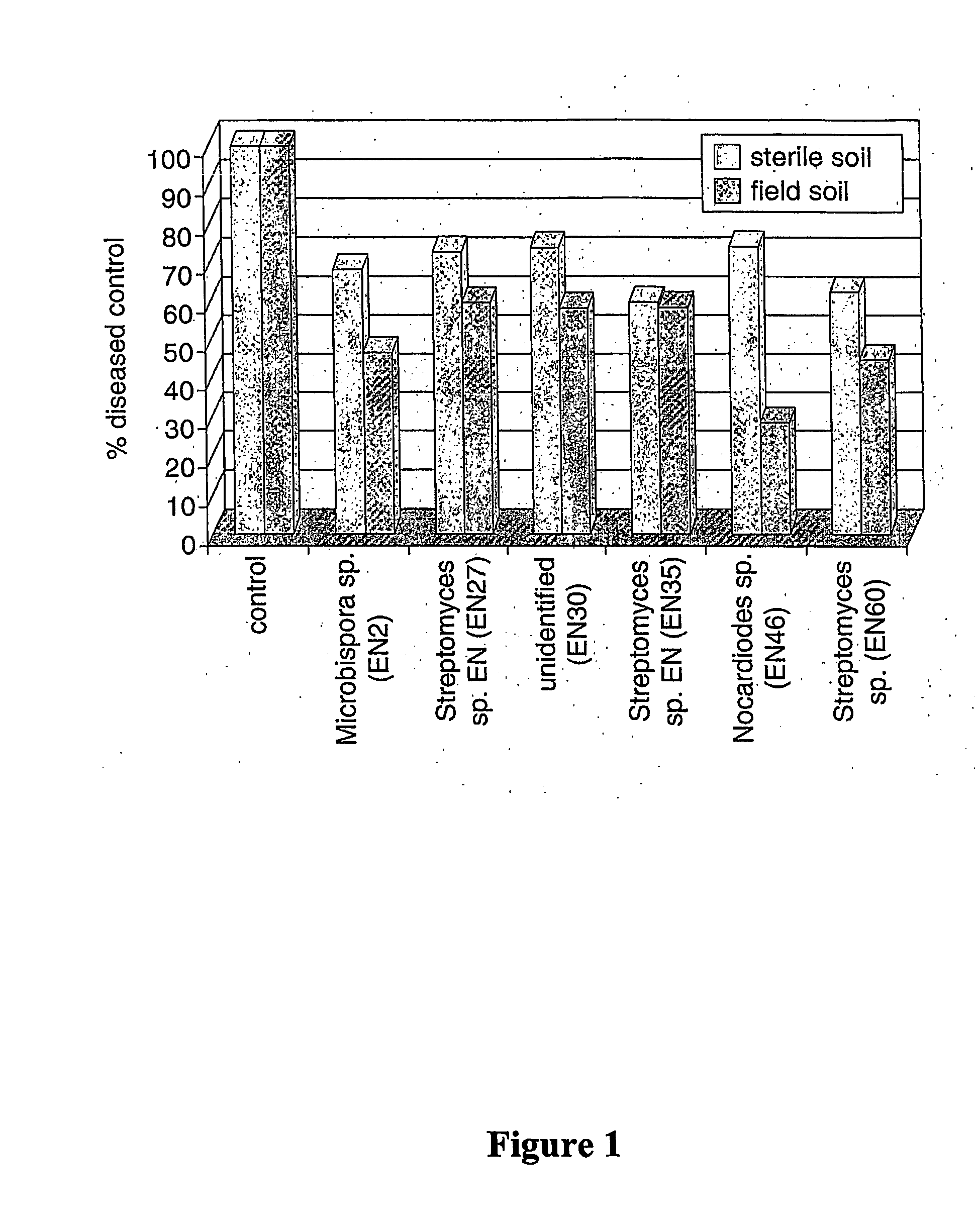

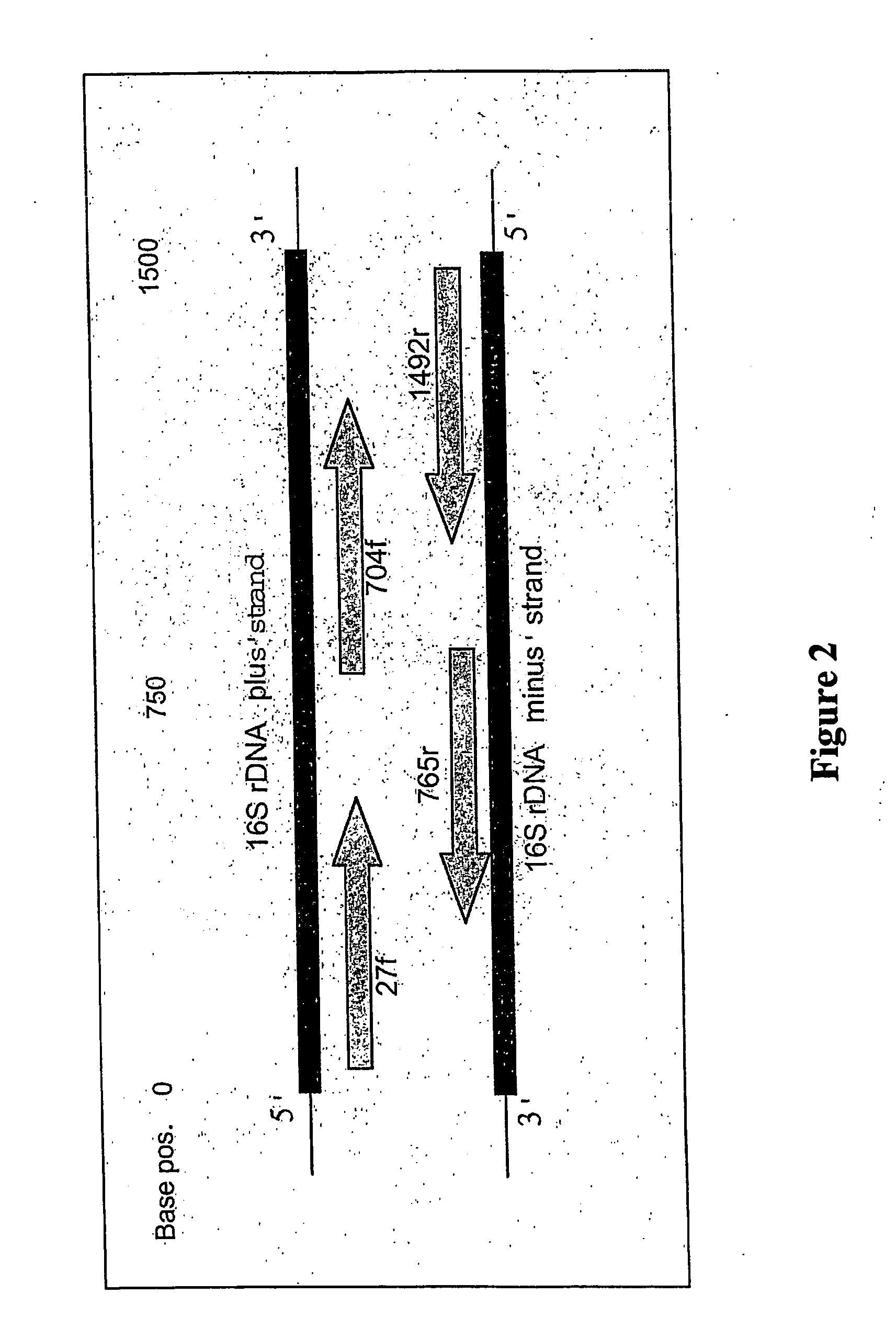

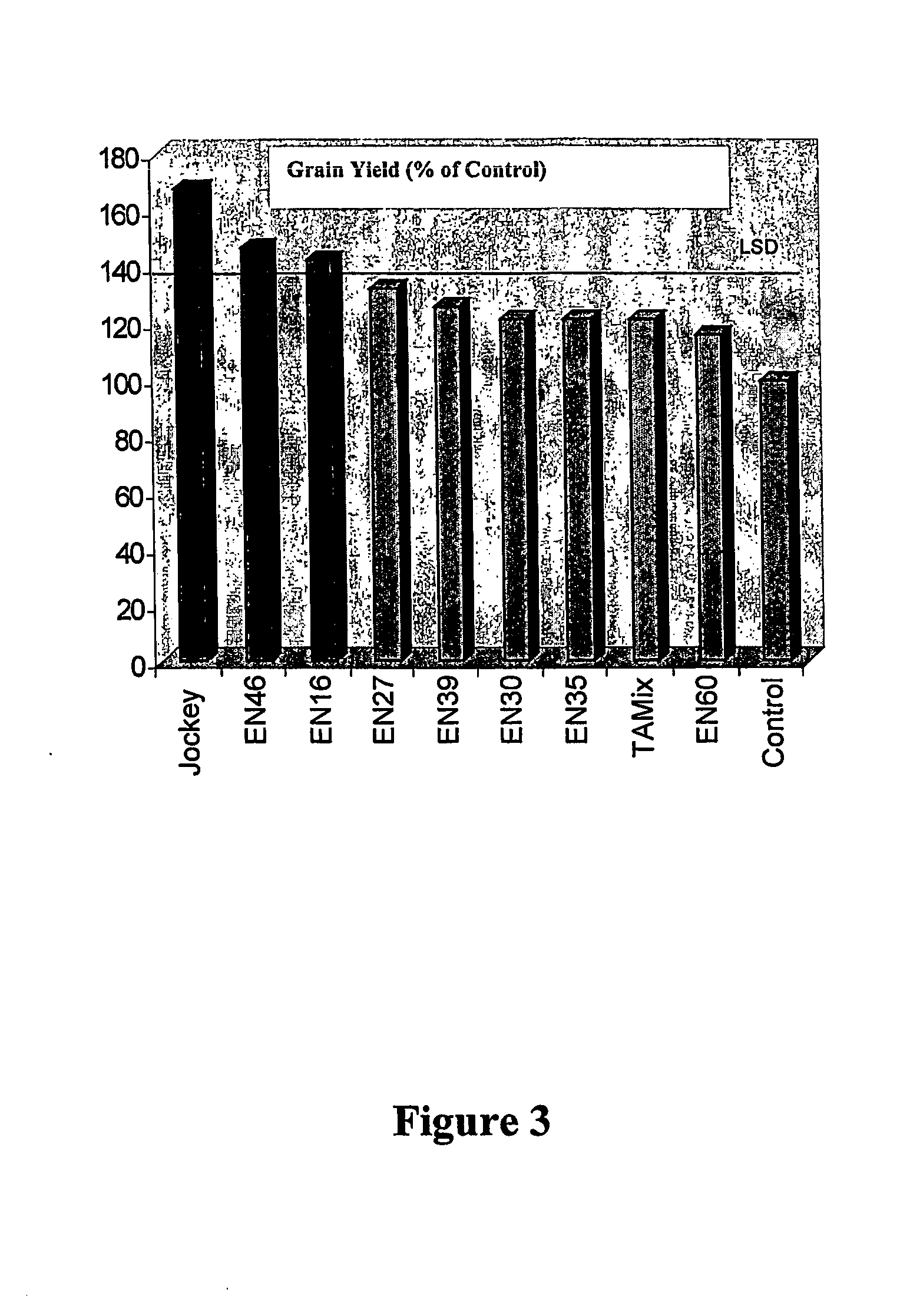

Method and agents for improving plant productivity involving endophytic actinomycetes and metabolites thereof

The present invention relates to a method for improving plant productivity, and in particular crop yields, via the introduction of an endophytic microorganism to the subject plant. More particularly, the present invention is directed to a method for improving cereal crop productivity via the introduction of an endophytic actinomycete to the subject crop. The method of the present invention facilitates the improvement of crop productivity, such as increasing germination, by, inter alia, providing the subject plant with disease bio-control capabilities and up-regulating plant growth promoting activities. The present invention is also directed to novel endophytic microorganisms and uses thereof.

Owner:FLINDERS TECH

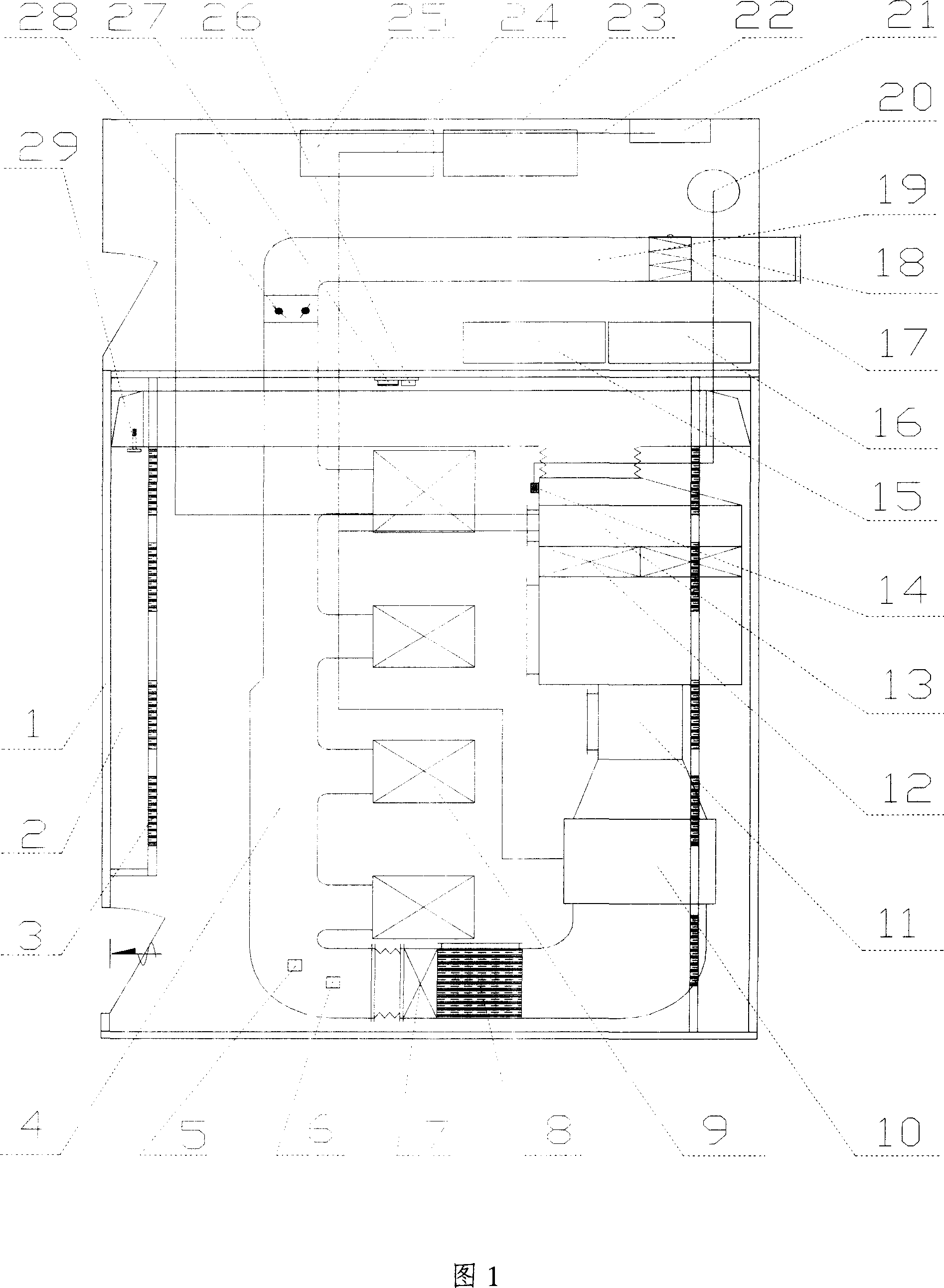

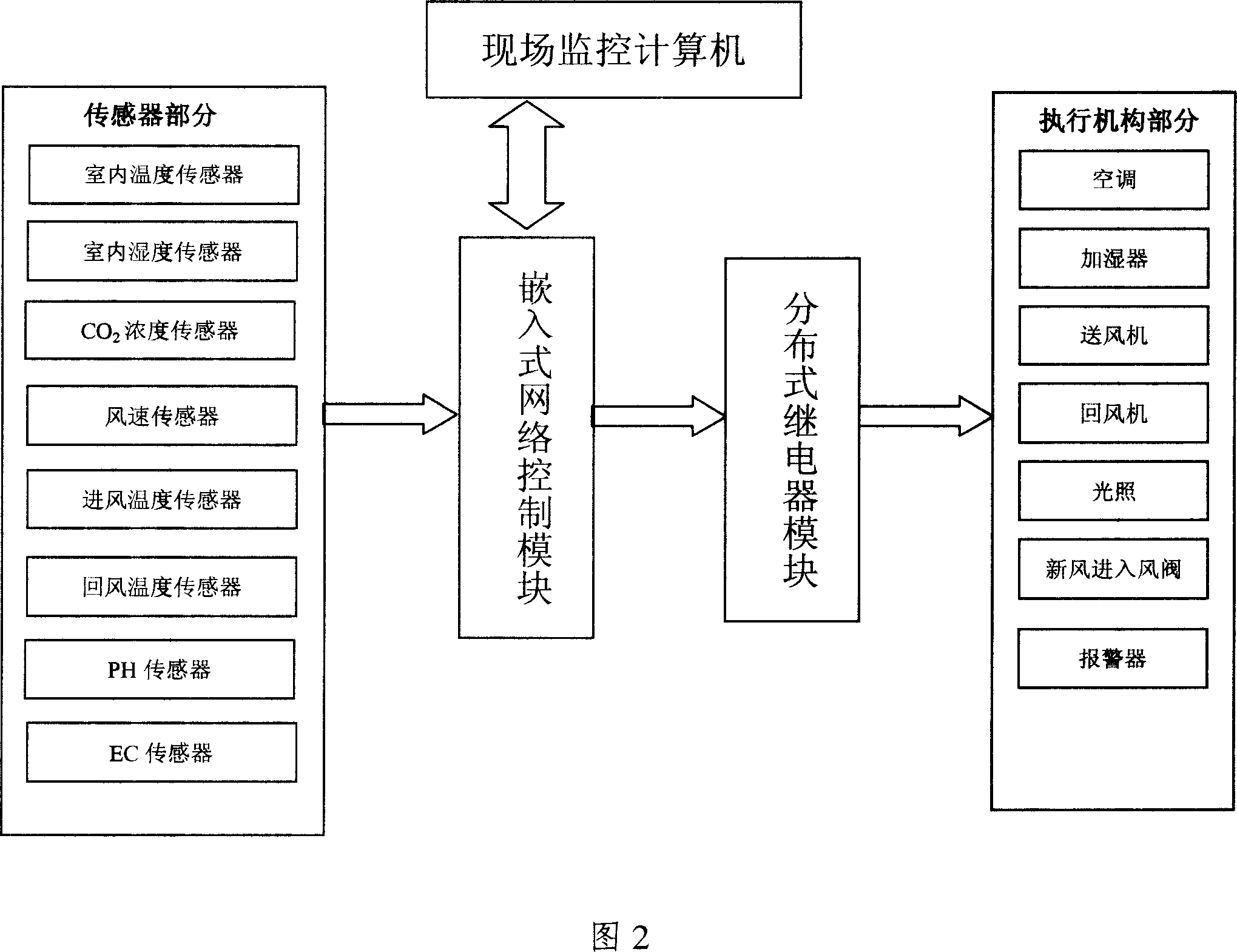

Closed type fully using artificial light environment controlled plant factory

ActiveCN101057550AControl light timeControl light intensityClimate change adaptationSaving energy measuresAir cycleEngineering

The invention discloses an environment control plant factory through seal-typed artificial light, which comprises the following parts: fender structure, air circulating system, temperature adjusting system, moisture adjusting system, CO2 supplying system, light supplying system, control system based on inserted network technique and automatic power-metering system, wherein the systems are seal, heat-proof and light-tight, which provides clean and fitful growing environment for plant. The invention saves cost and energy consumption, which realizes normalized and standardized cultivating management and planning manufacturing.

Owner:CHINA AGRI UNIV

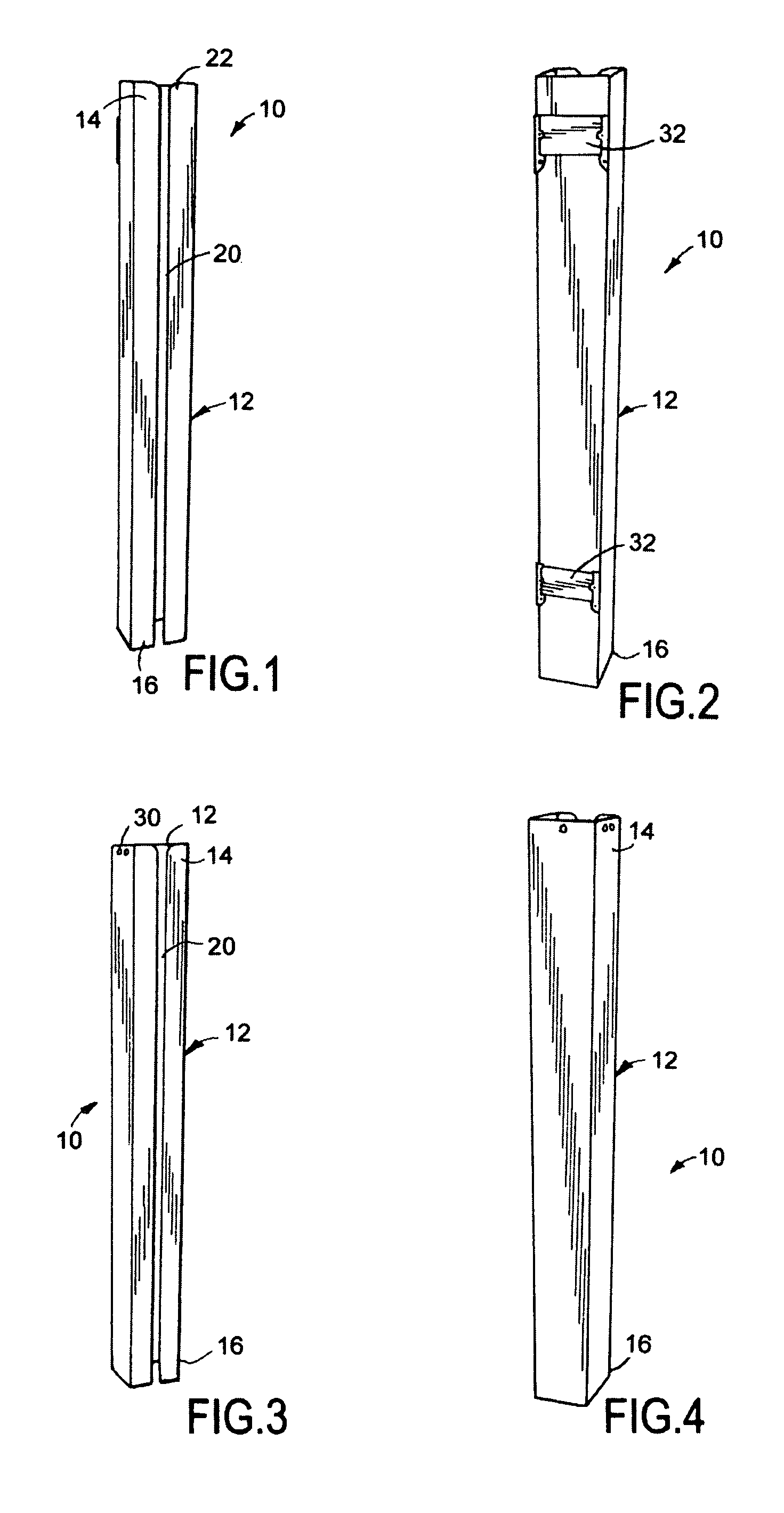

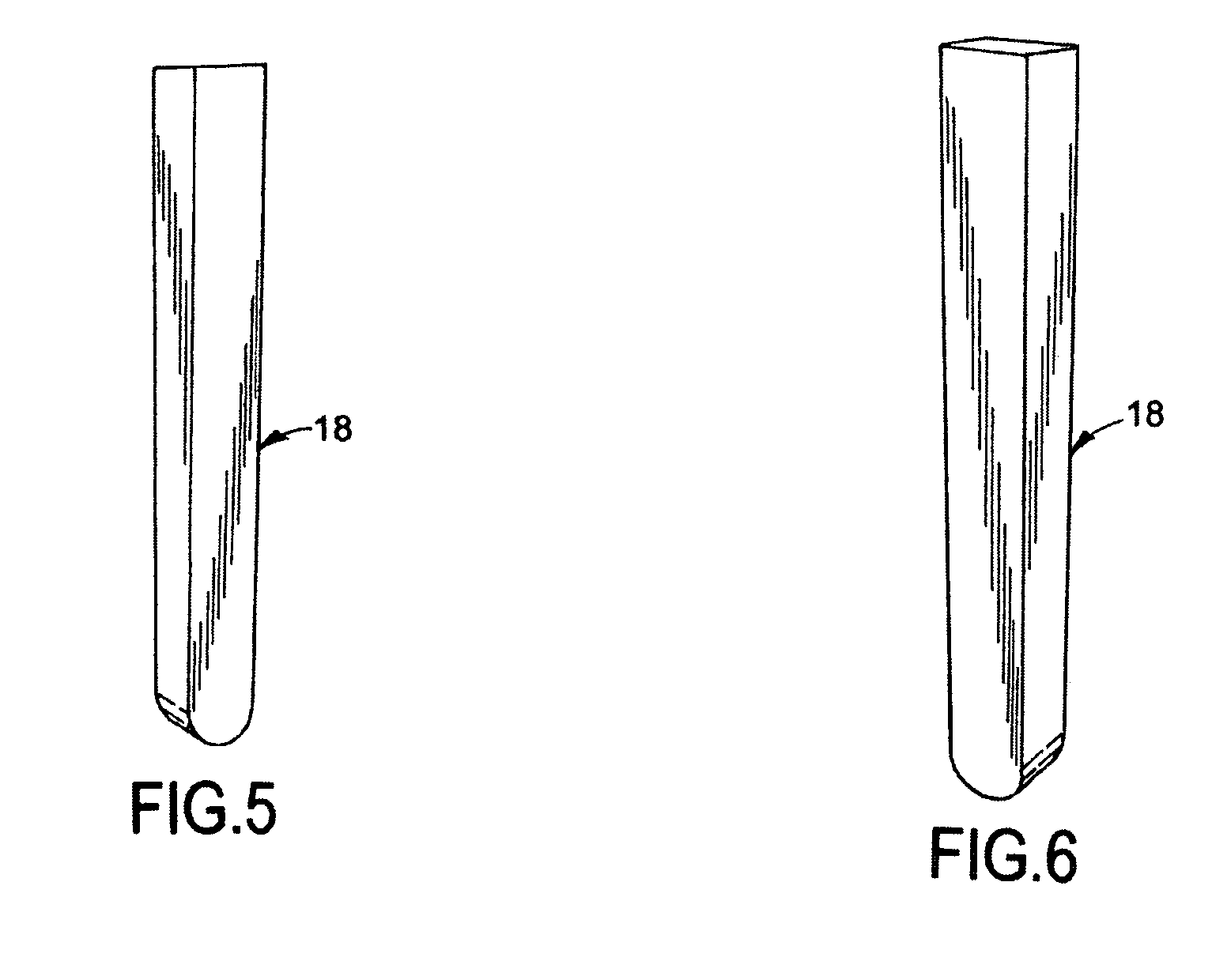

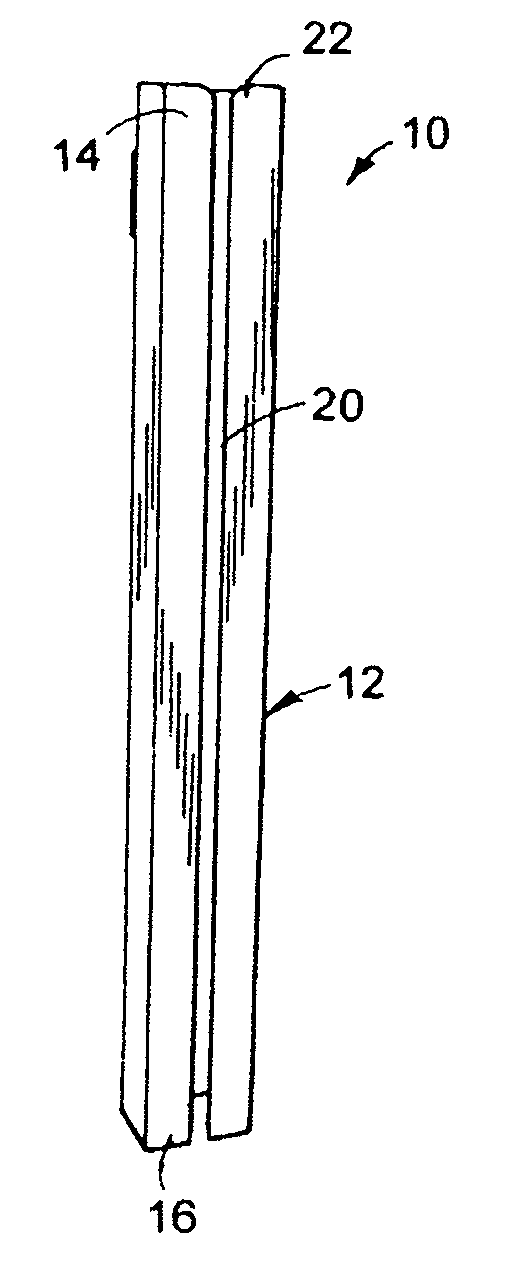

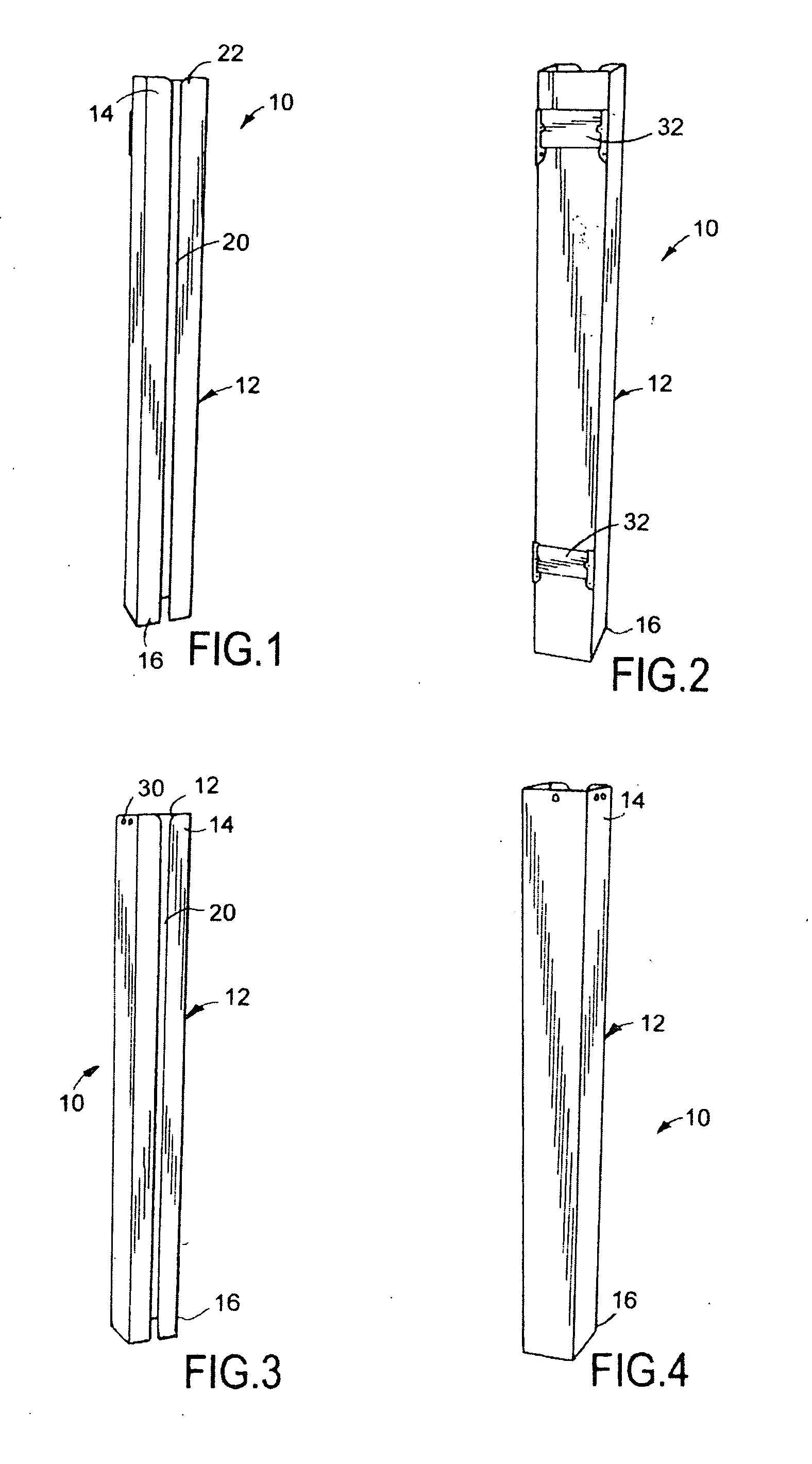

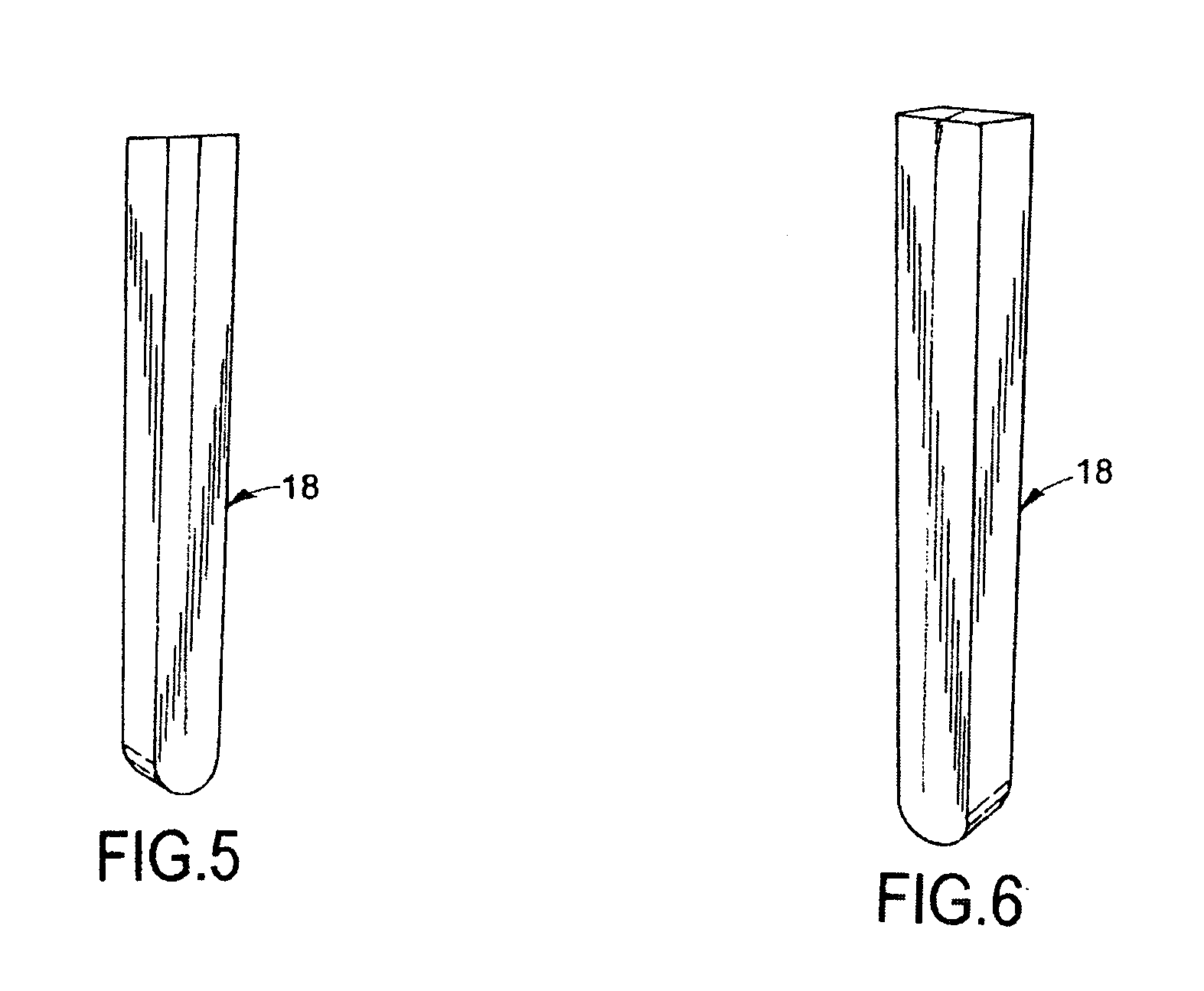

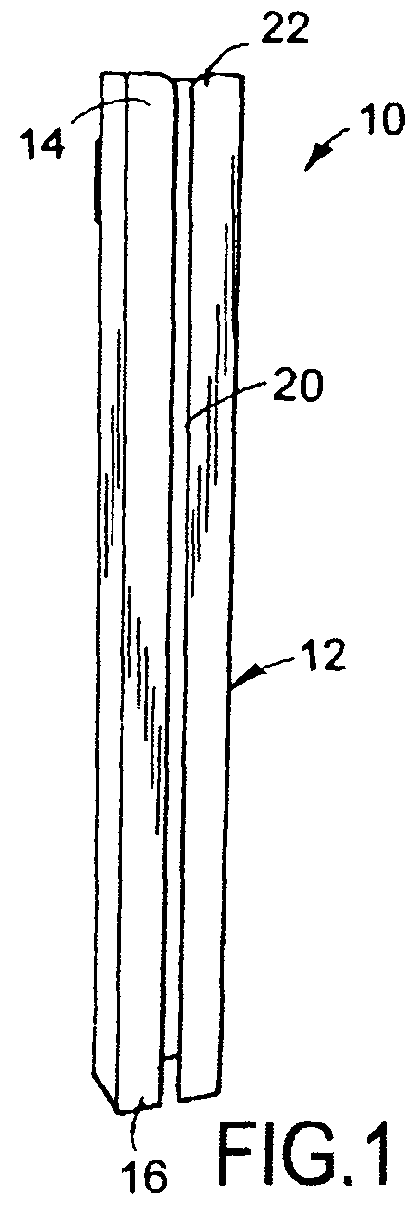

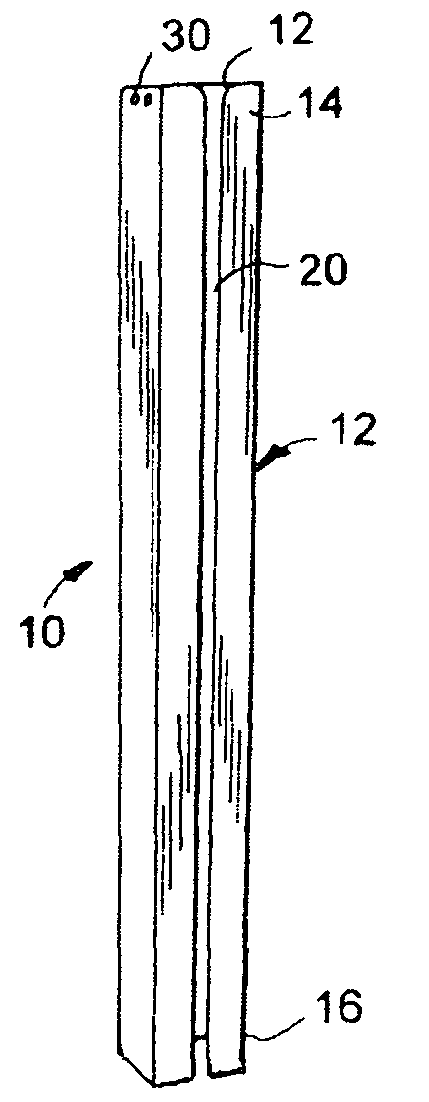

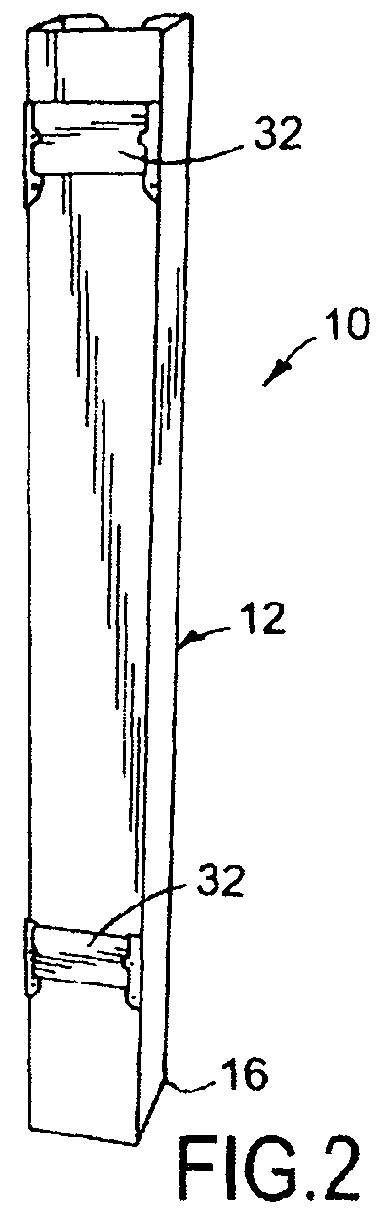

Vertical hydroponic plant production apparatus

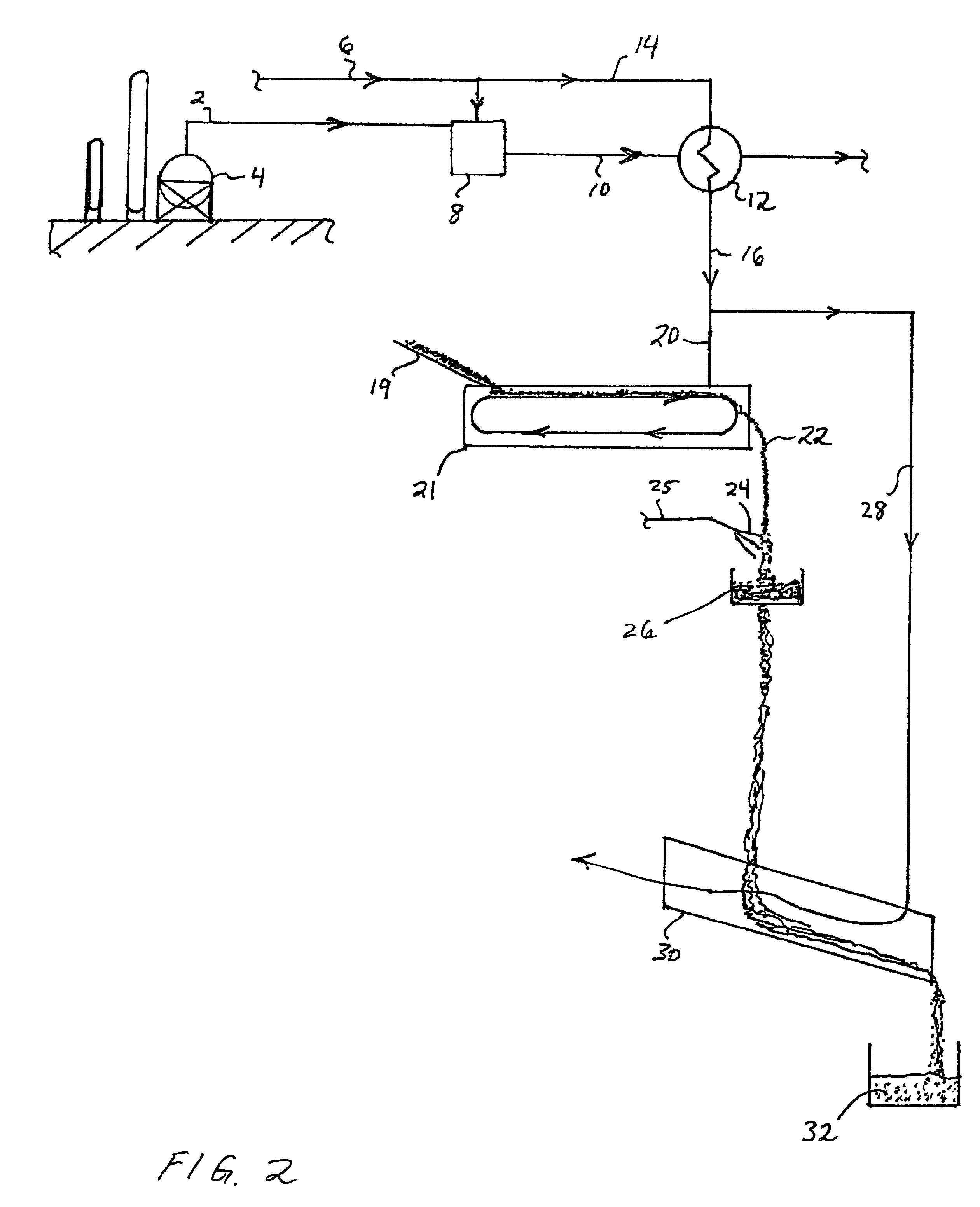

A vertical hydroponic plant production apparatus for allowing vertical hydroponic greenhouse crop production is provided. The apparatus comprises a hollow grow tube having a front face, a back face, a first end, and a second end. A slot is formed in the front face of the grow tube. A media material is insertable into the grow tube wherein the grow tube is positionable in either a horizontal position, vertical position, or any position between the horizontal position and the vertical position allowing inclined, multi-angled crop production and multi-storied conveyor style crop production.

Owner:UNIVERSITY OF WYOMING

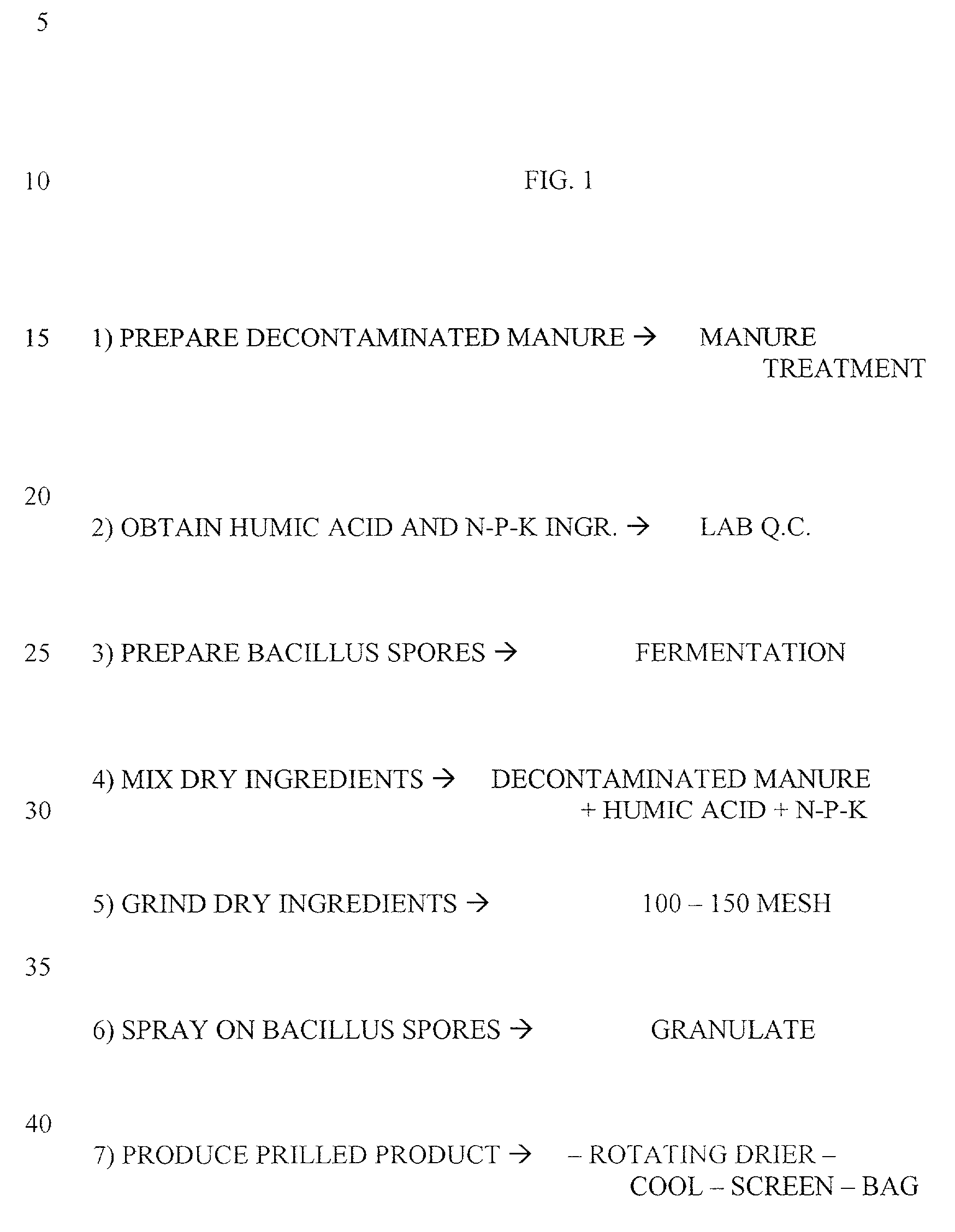

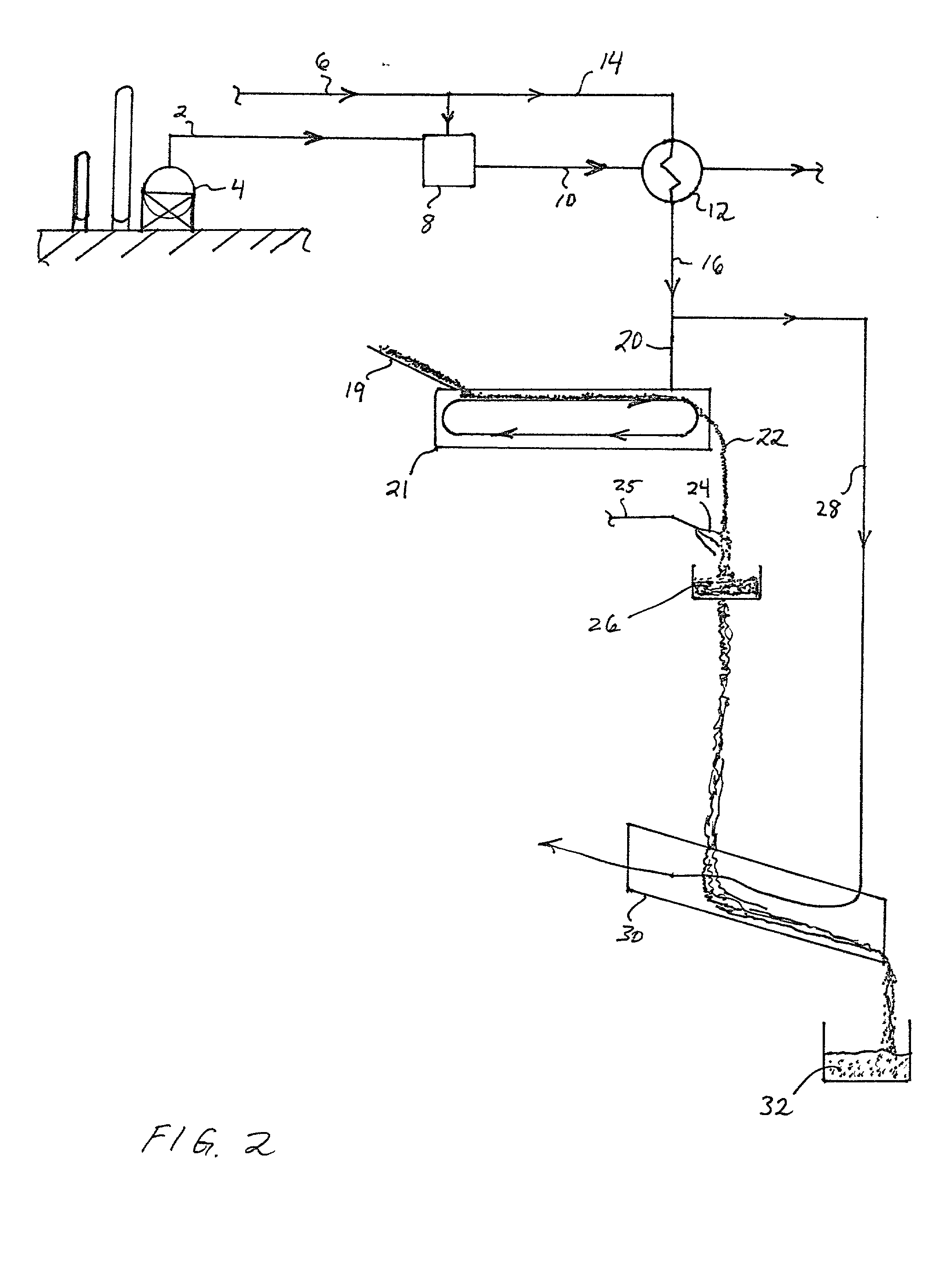

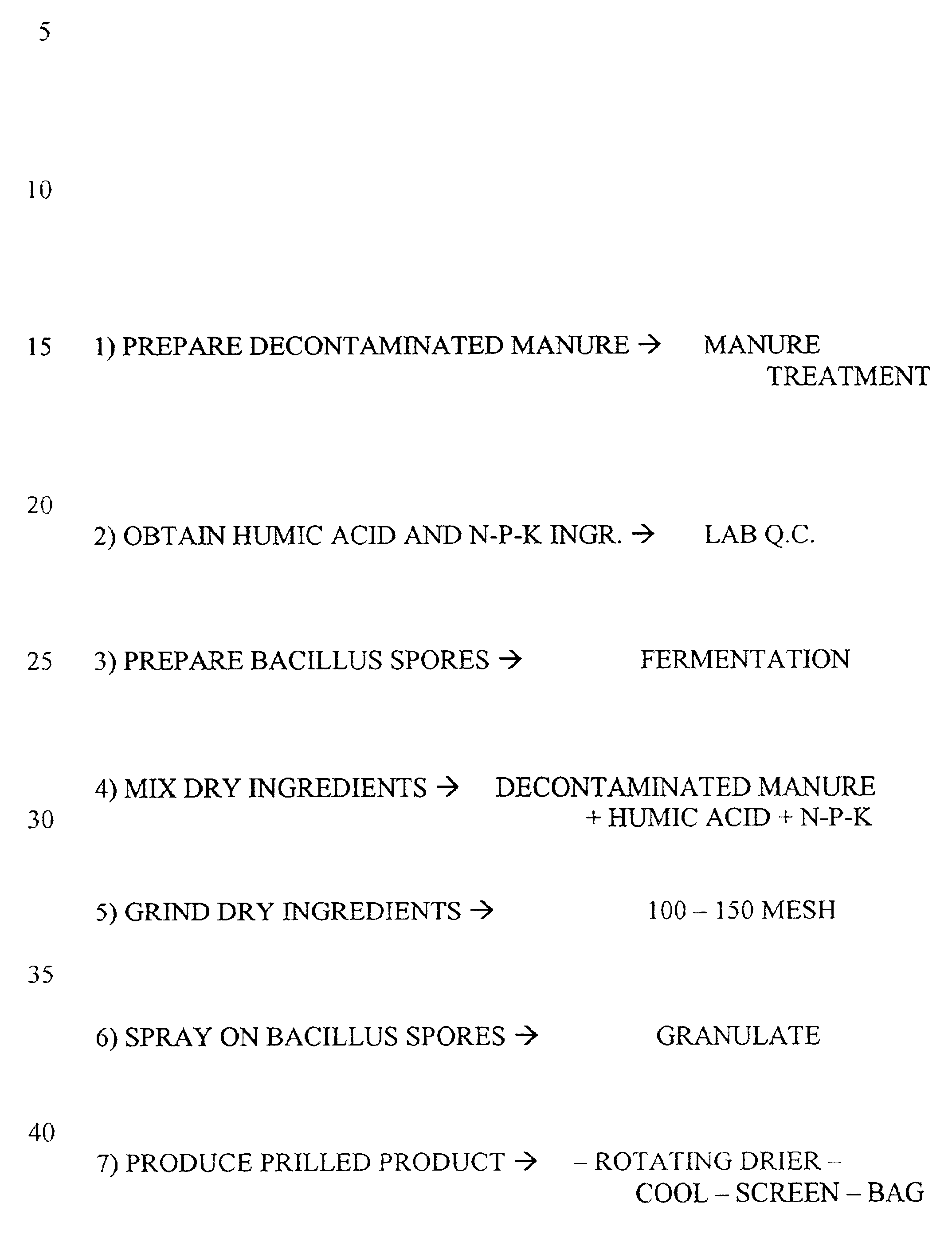

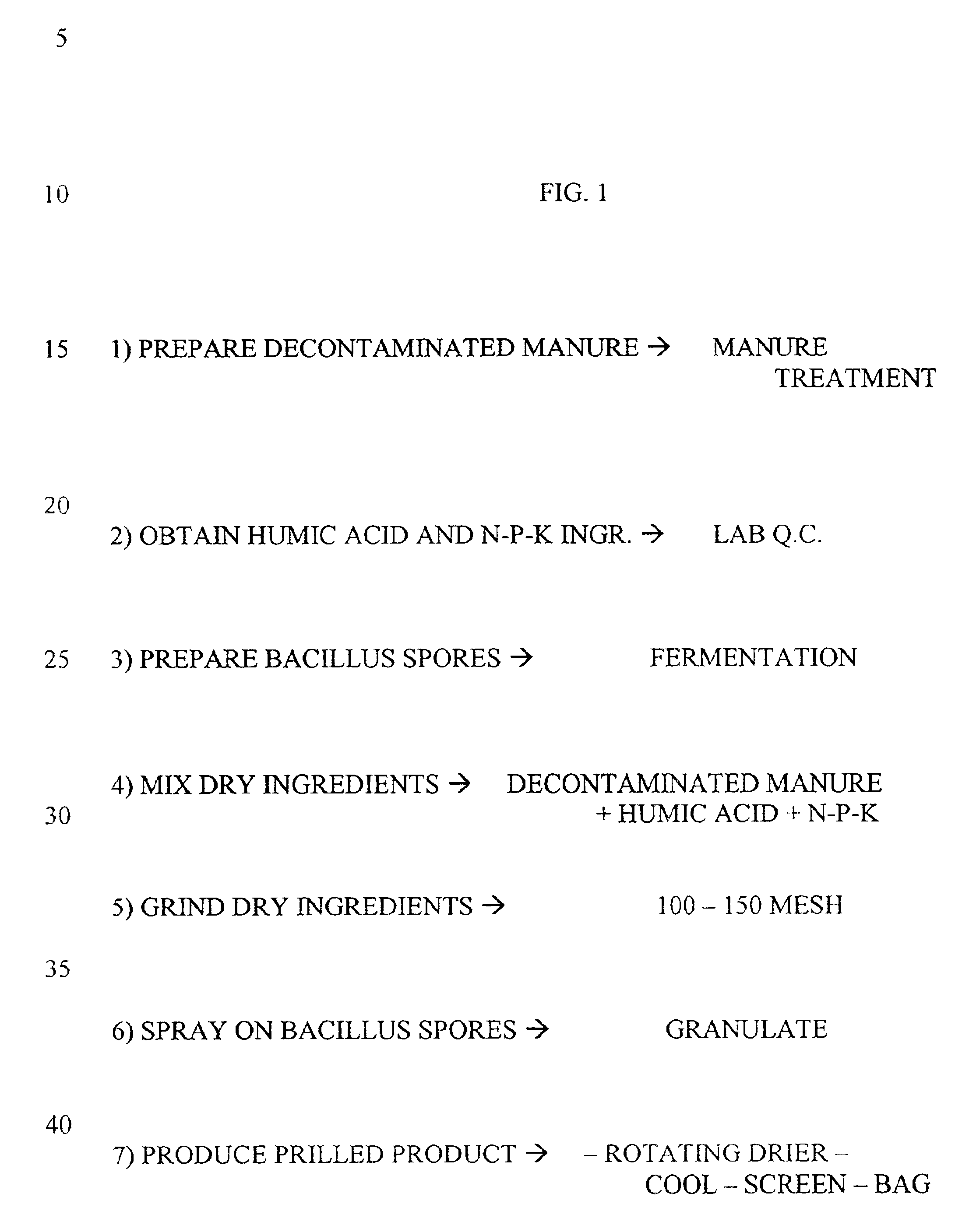

Fertilizer compositions and methods of making and using same

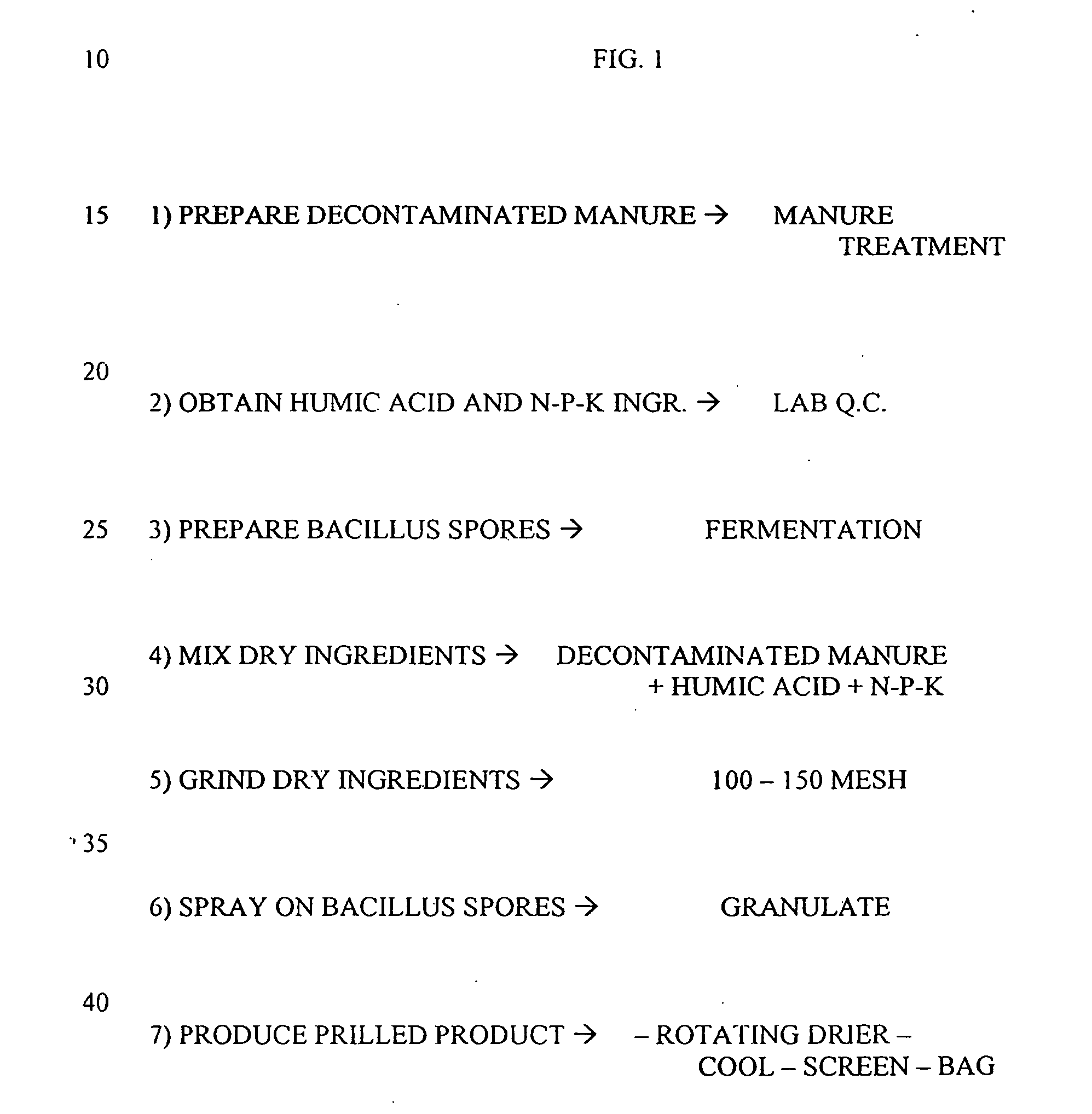

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

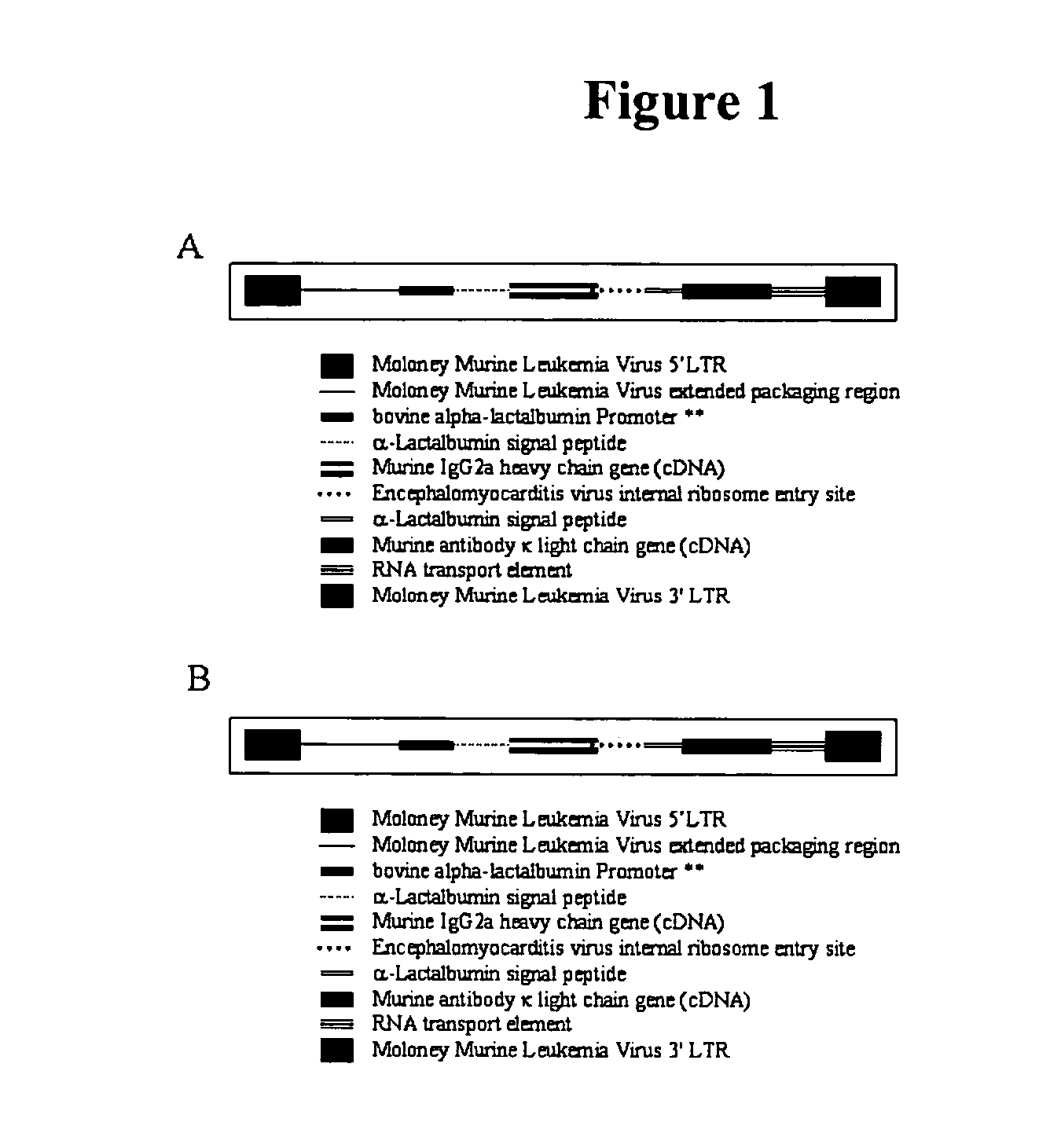

Targeted biocides

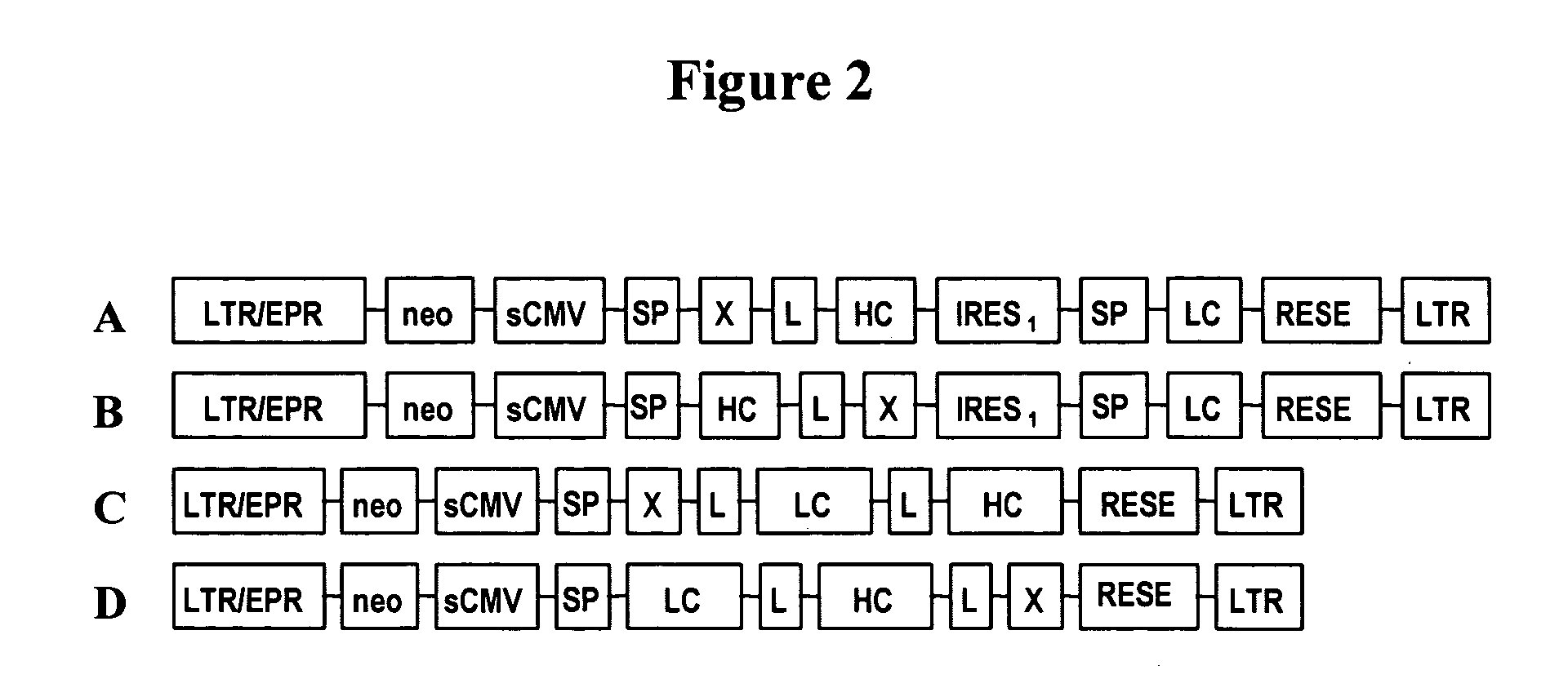

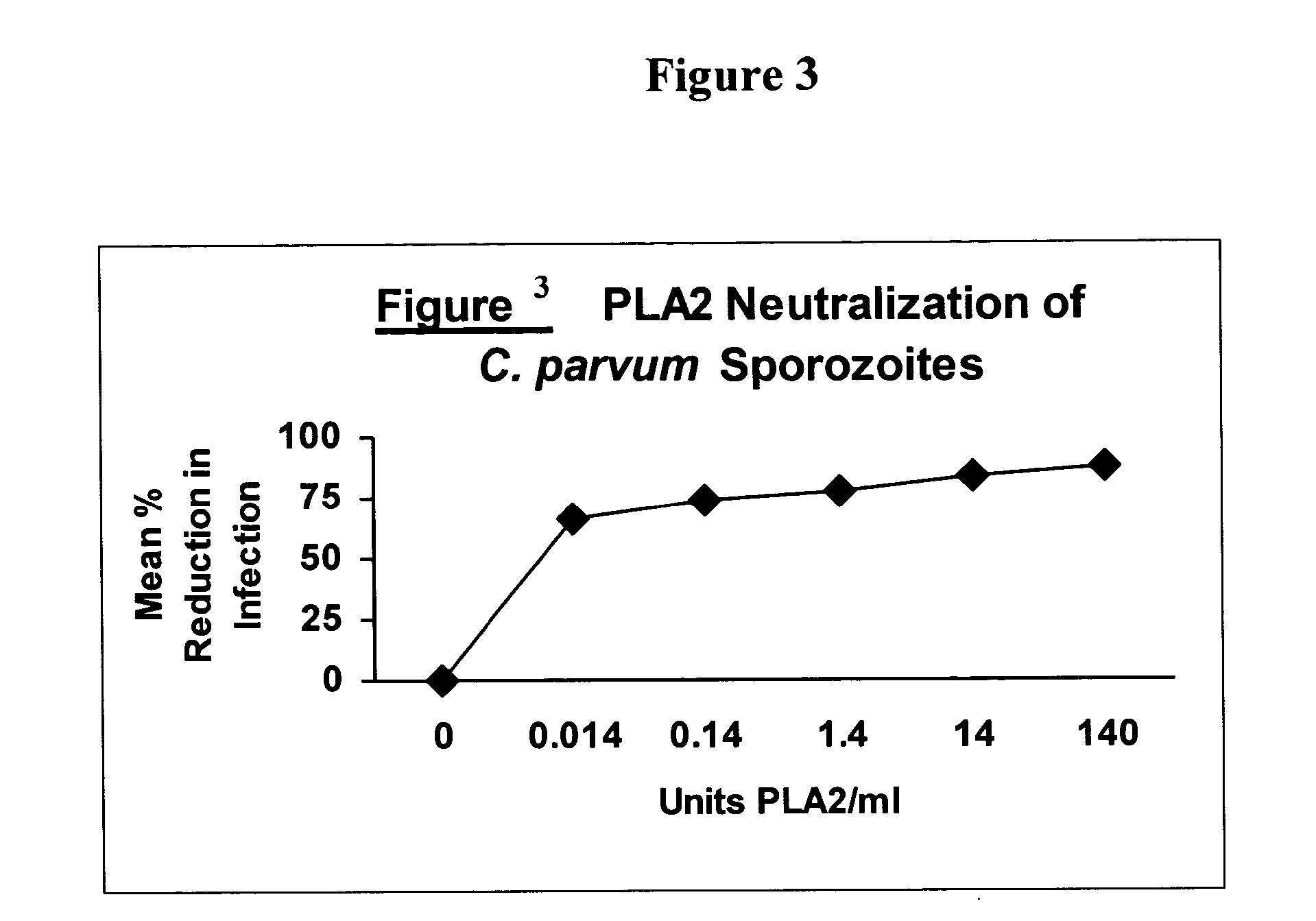

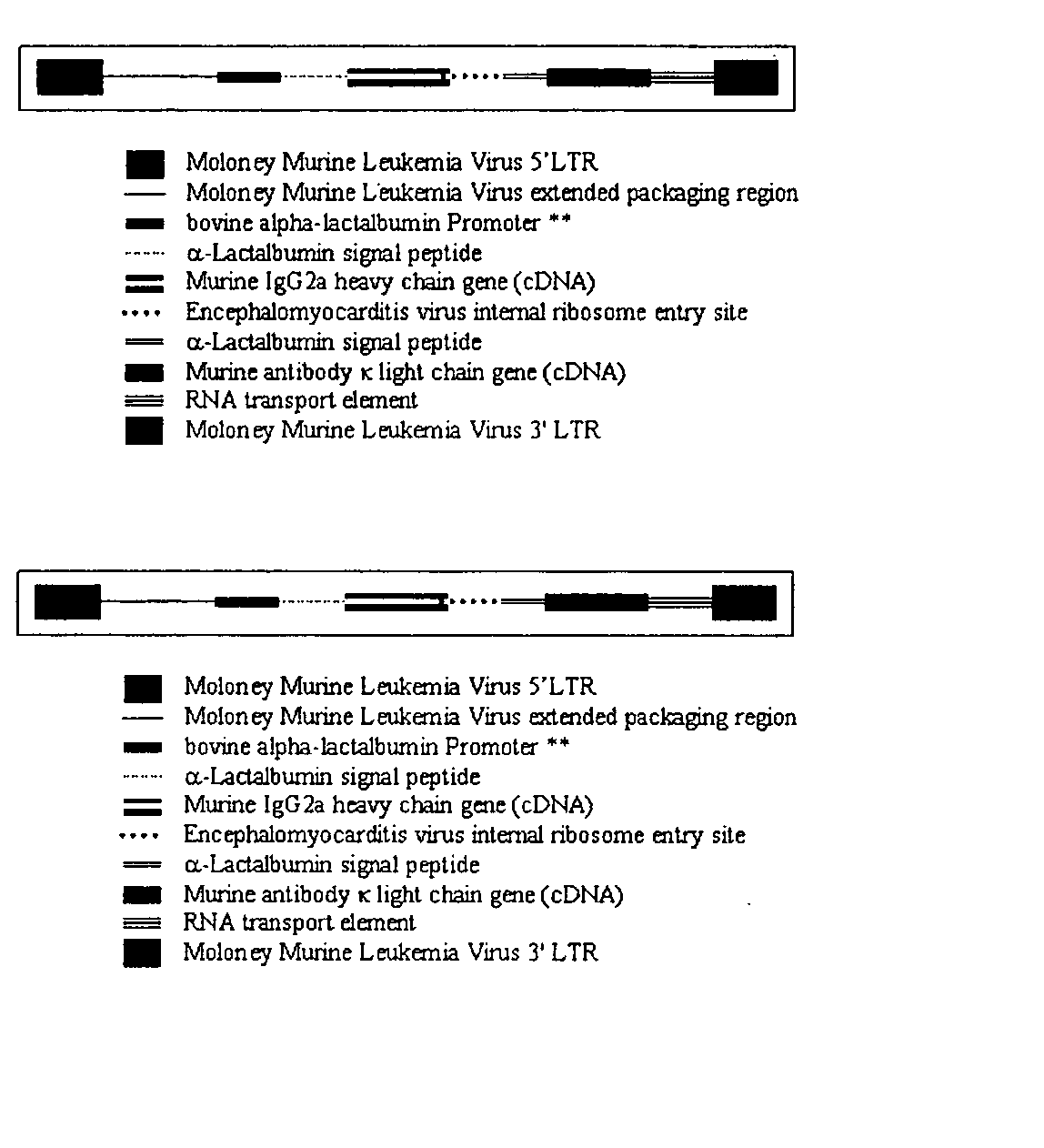

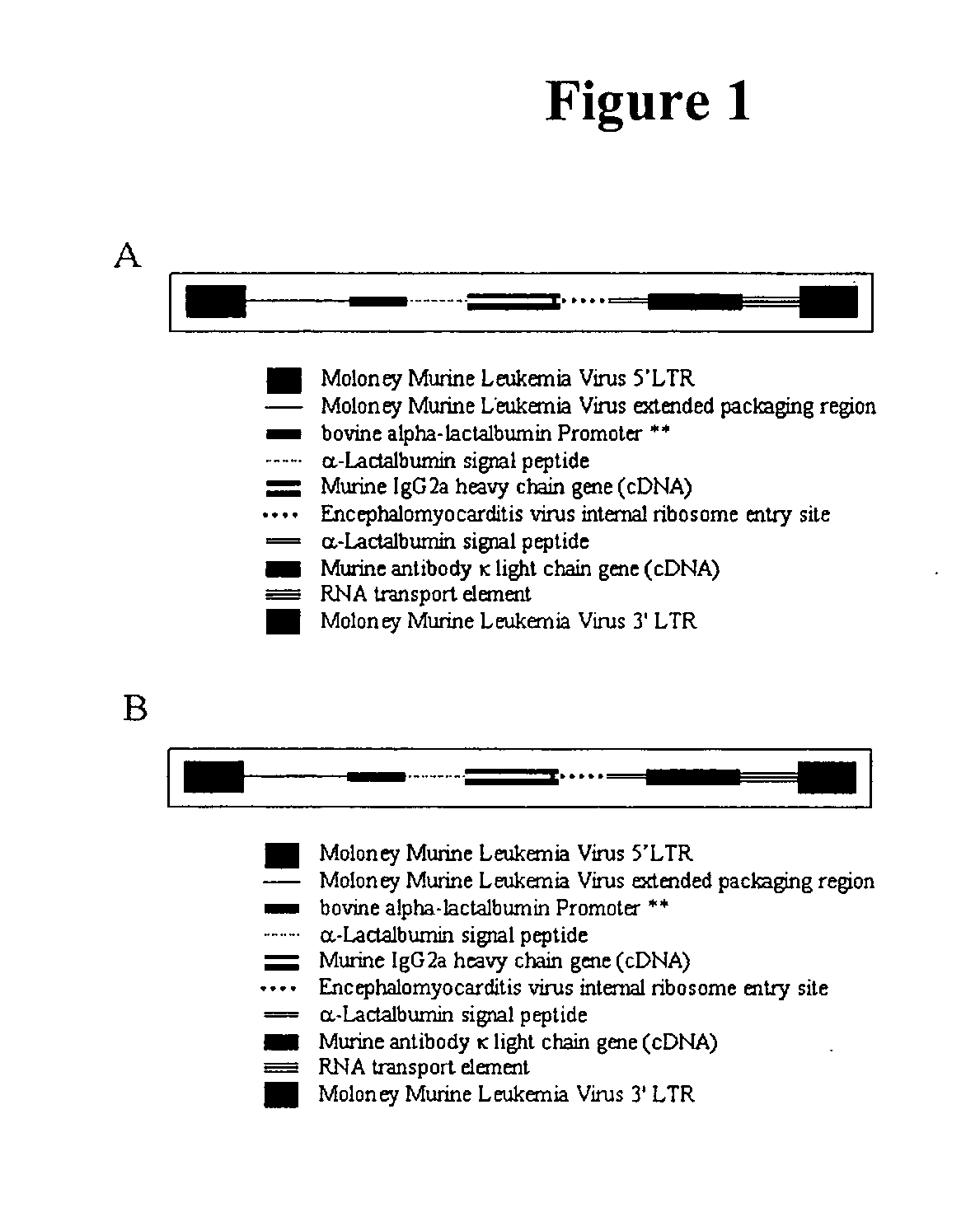

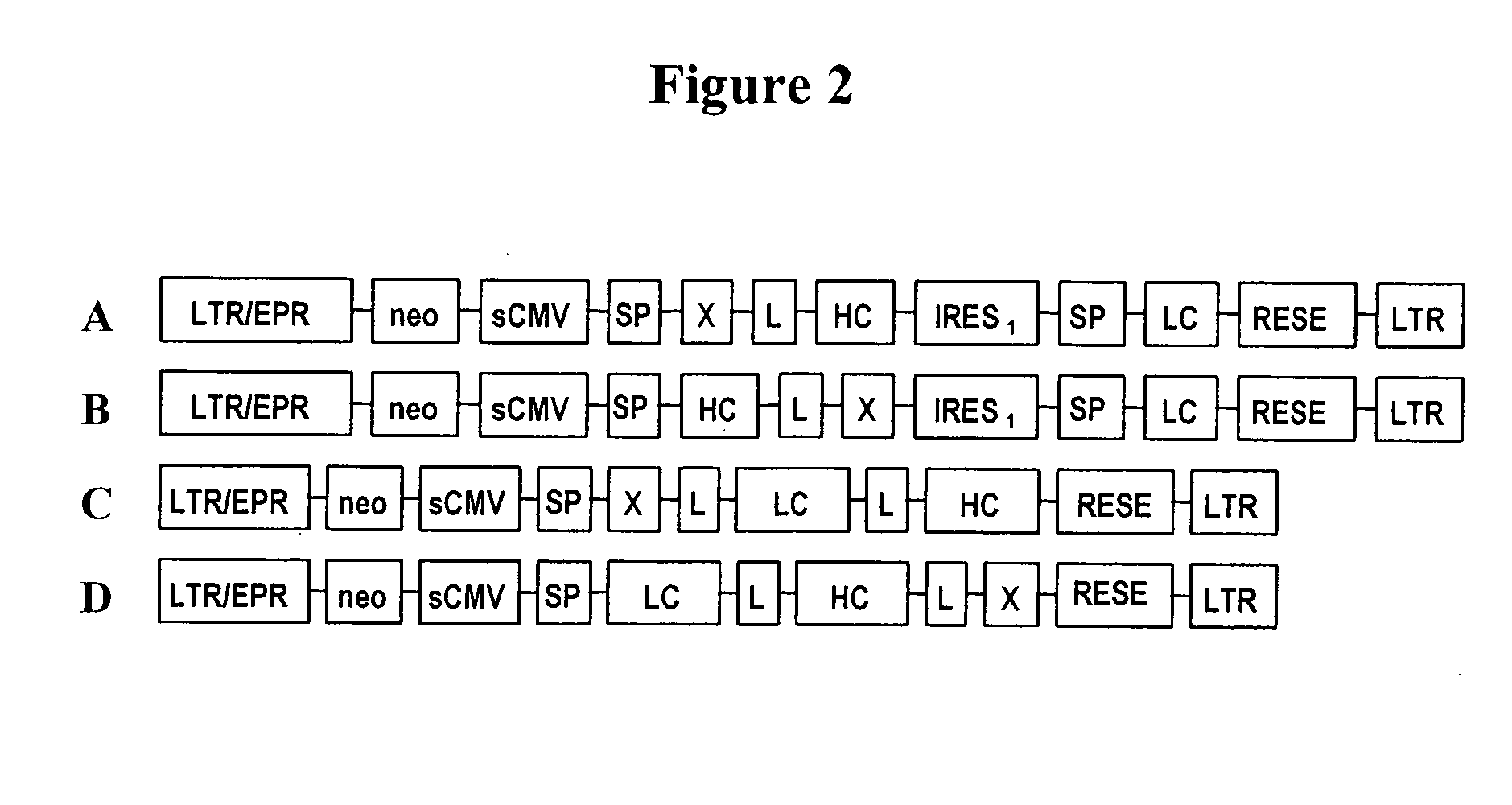

InactiveUS20050014932A1Sure easyPrevent relapseBiocideAntibody mimetics/scaffoldsInnate immune systemReceptor molecule

The present invention relates to retroviral constructs that encode novel monoclonal antibodies, novel fusion proteins, and chimeric monoclonal antibodies and to methods of using and producing the same. In particular, the present invention relates to methods of producing a fusion protein comprising a microorganism targeting molecule (e.g., immunoglobulin or innate immune system receptor molecule) and a biocide (e.g., bactericidal enzymes) in transgenic animals (e.g., bovines) and in cell cultures. The present invention also relates to therapeutic and prophylactic methods of using a fusion protein comprising a microorganism targeting molecule and a biocide in health care (e.g., human and veterinary), agriculture (e.g., animal and plant production), and food processing (e.g., beef carcass processing). The present invention also relates to methods of using a fusion protein comprising a microorganism targeting molecule and a biocide in various diagnostic applications in number of diverse fields such as agriculture, medicine, and national defense.

Owner:IOGENETICS

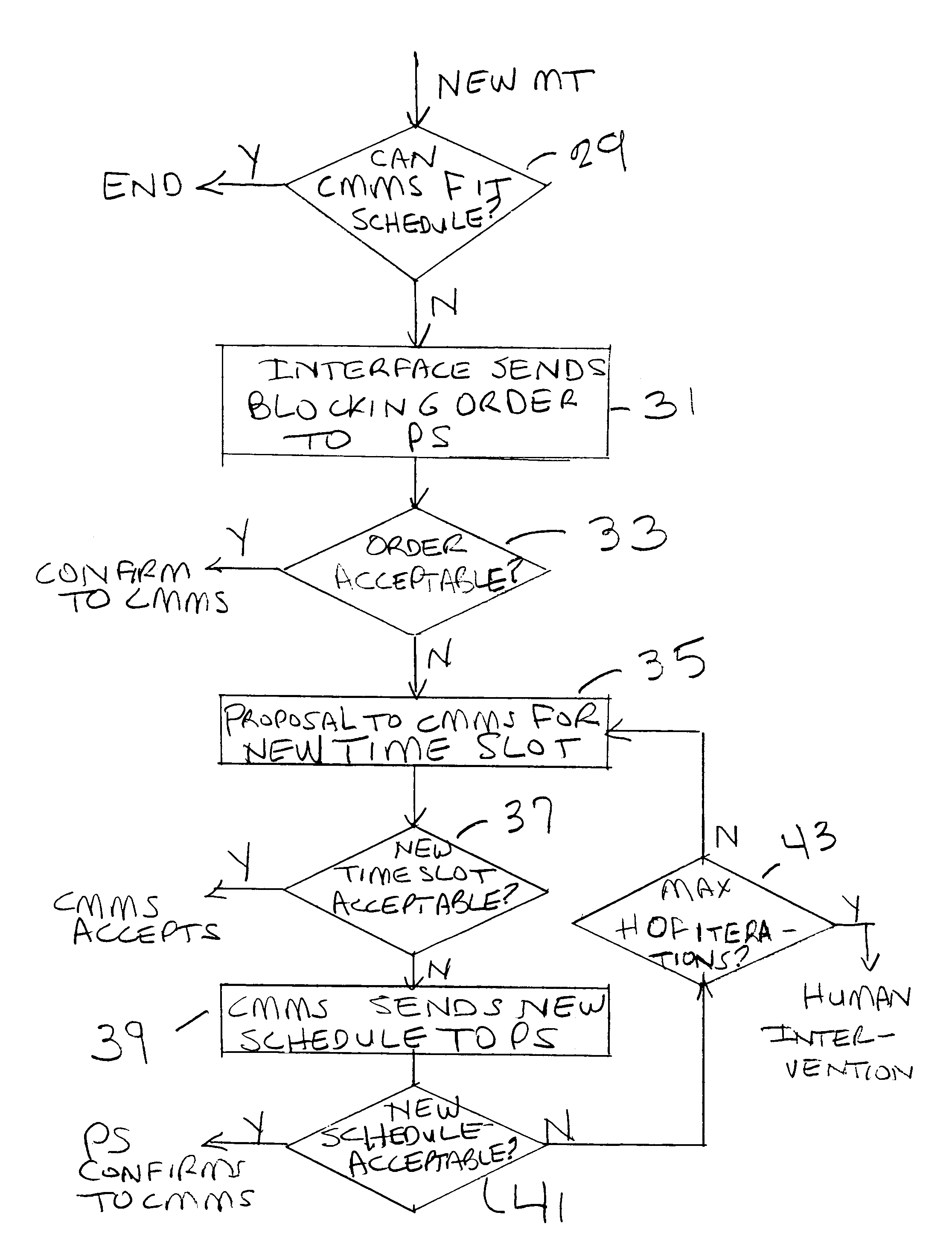

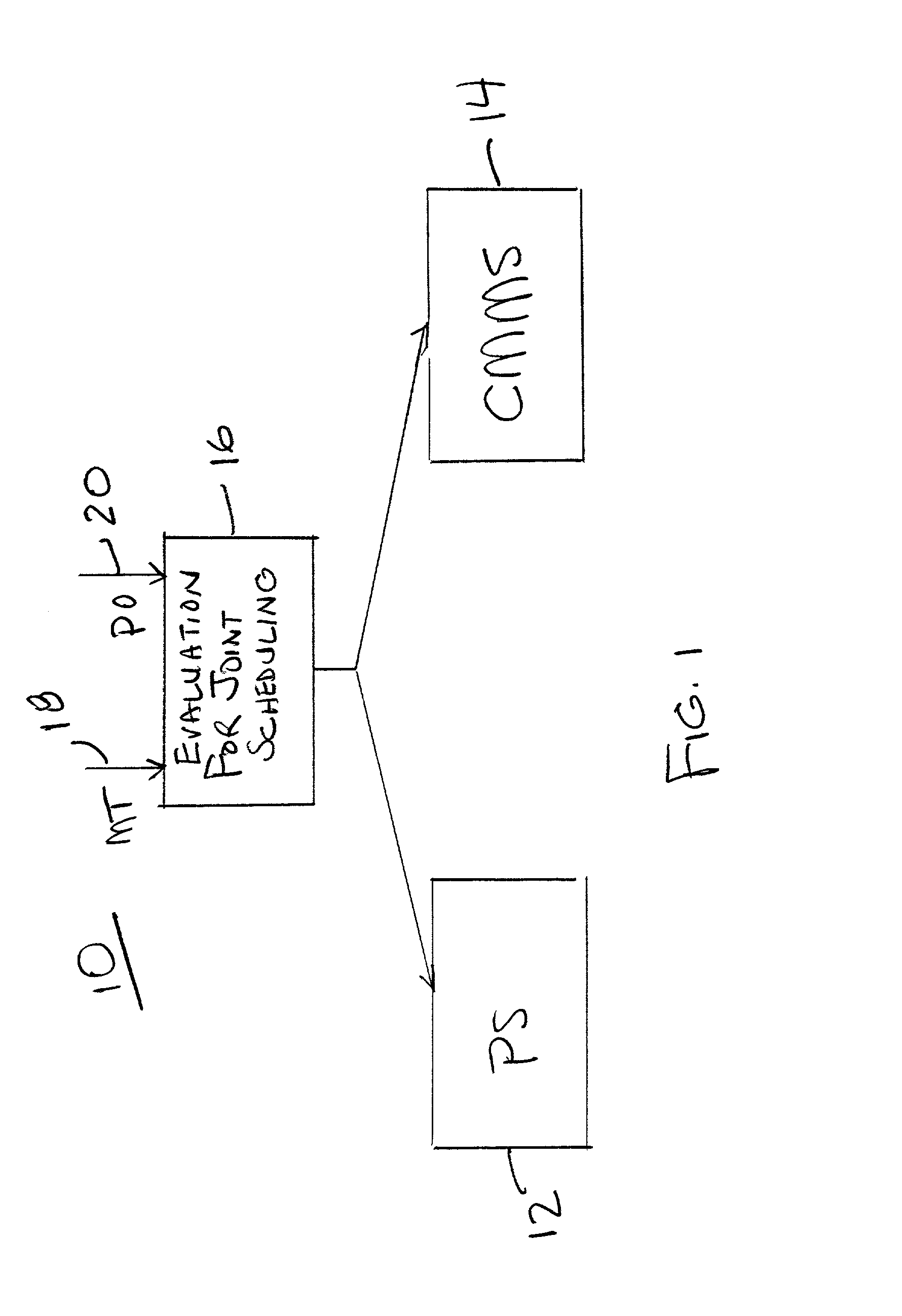

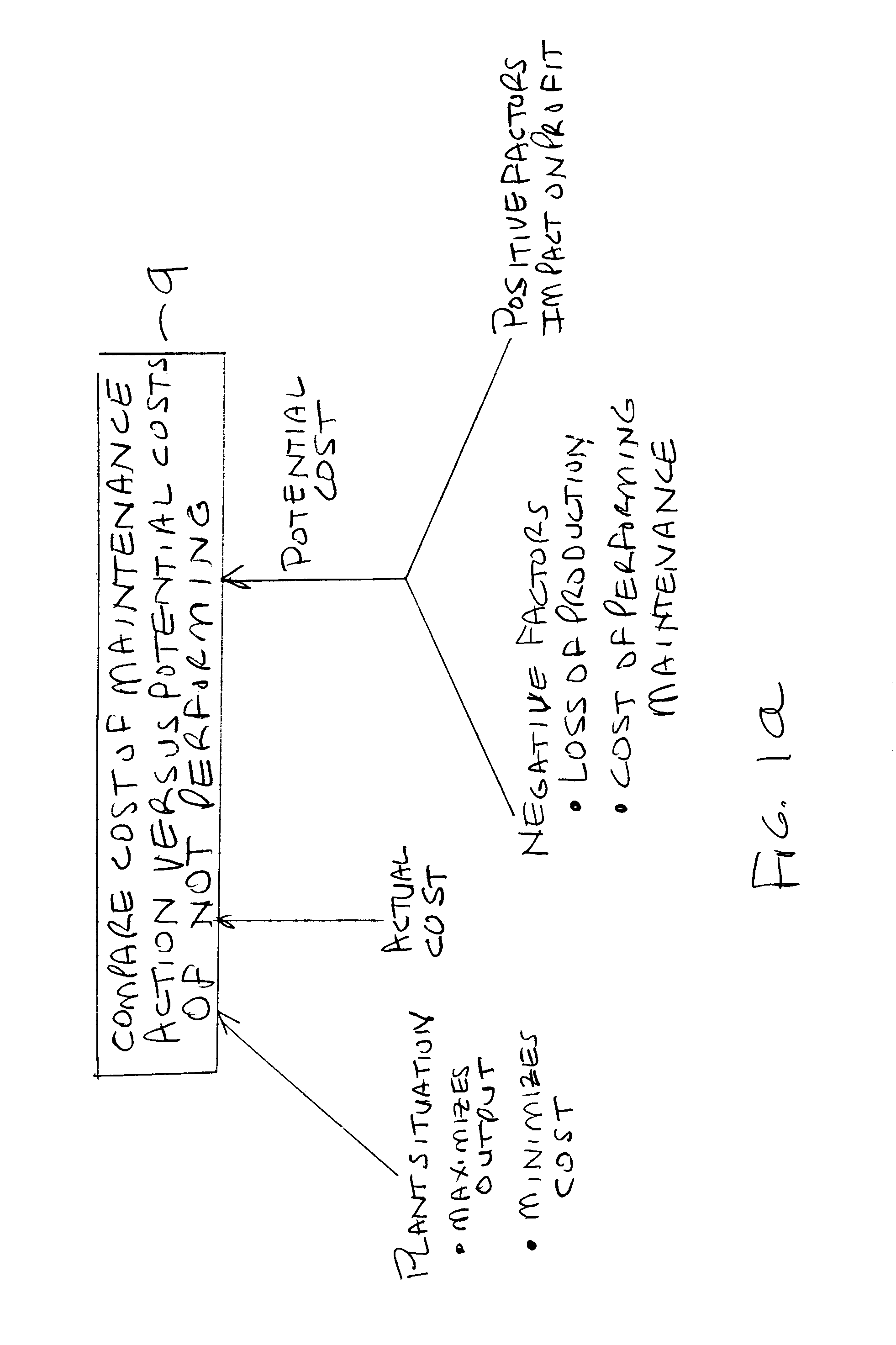

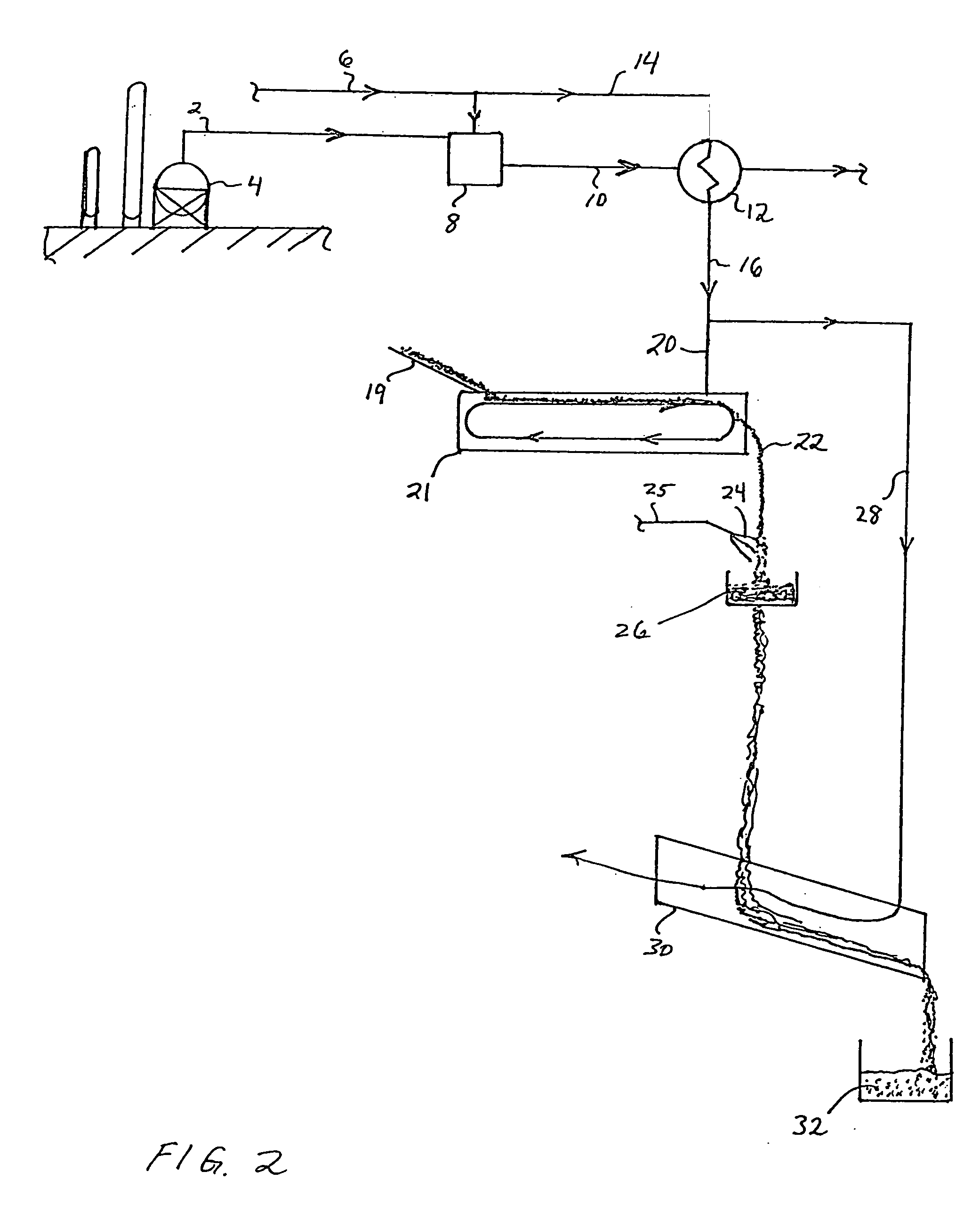

Real time asset optimization

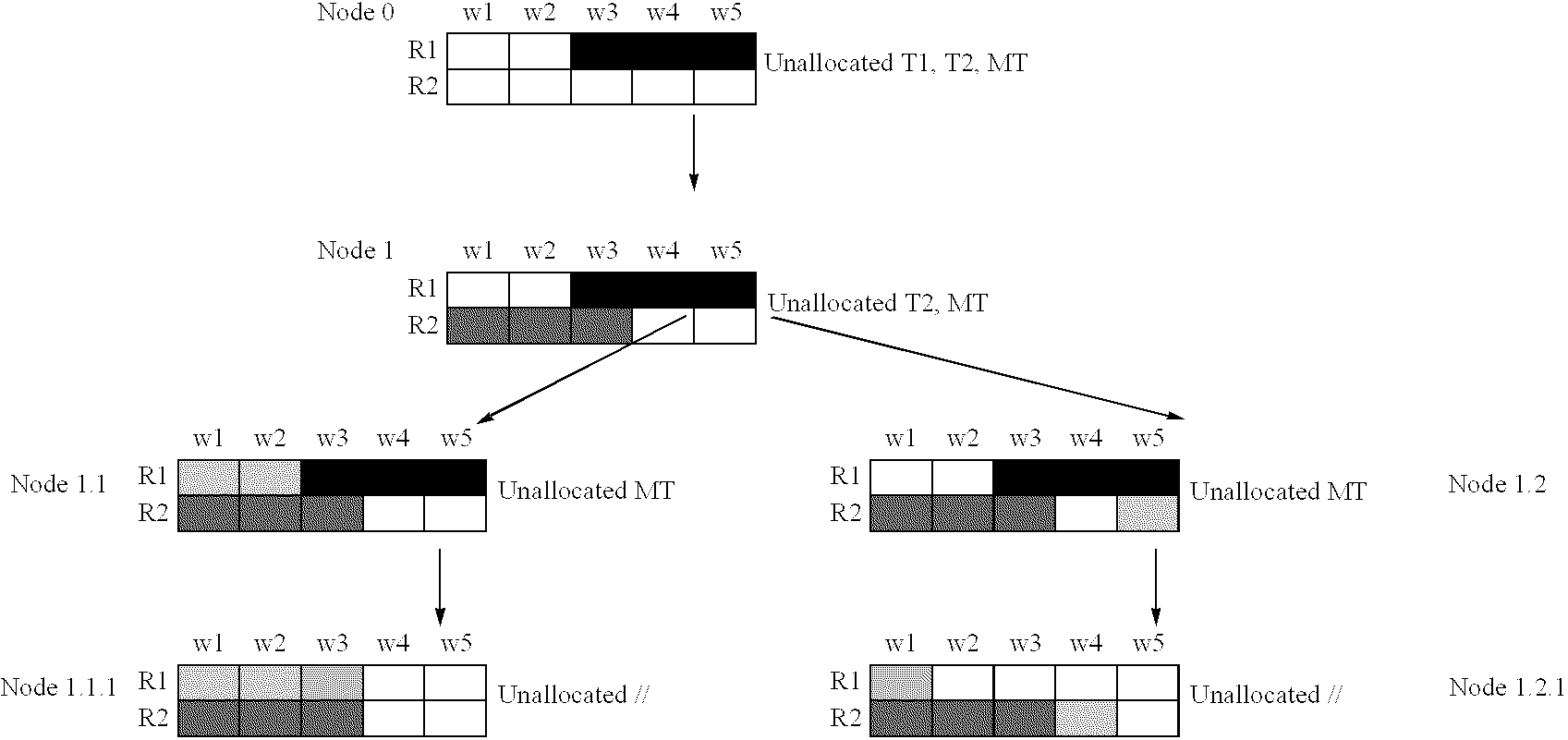

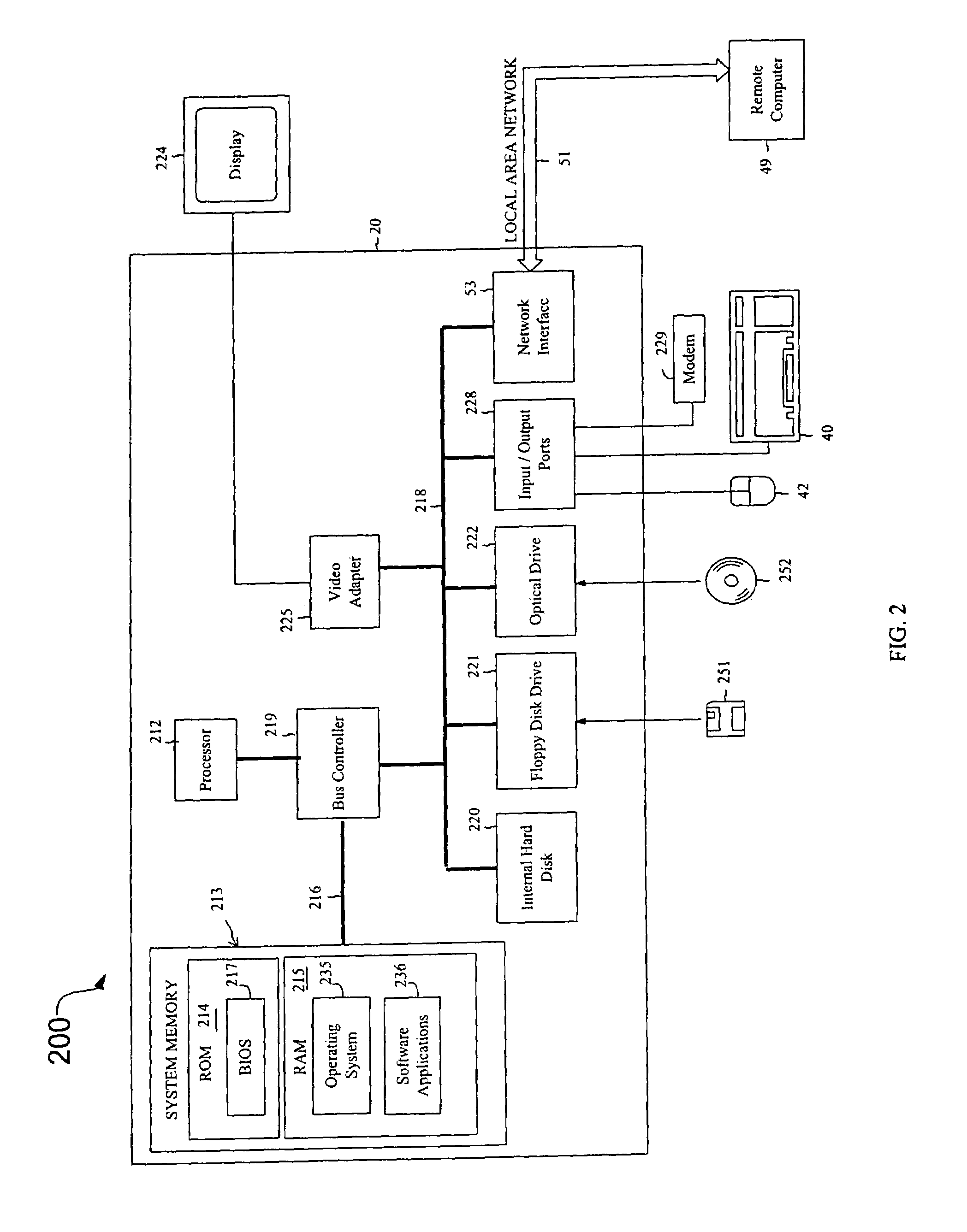

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

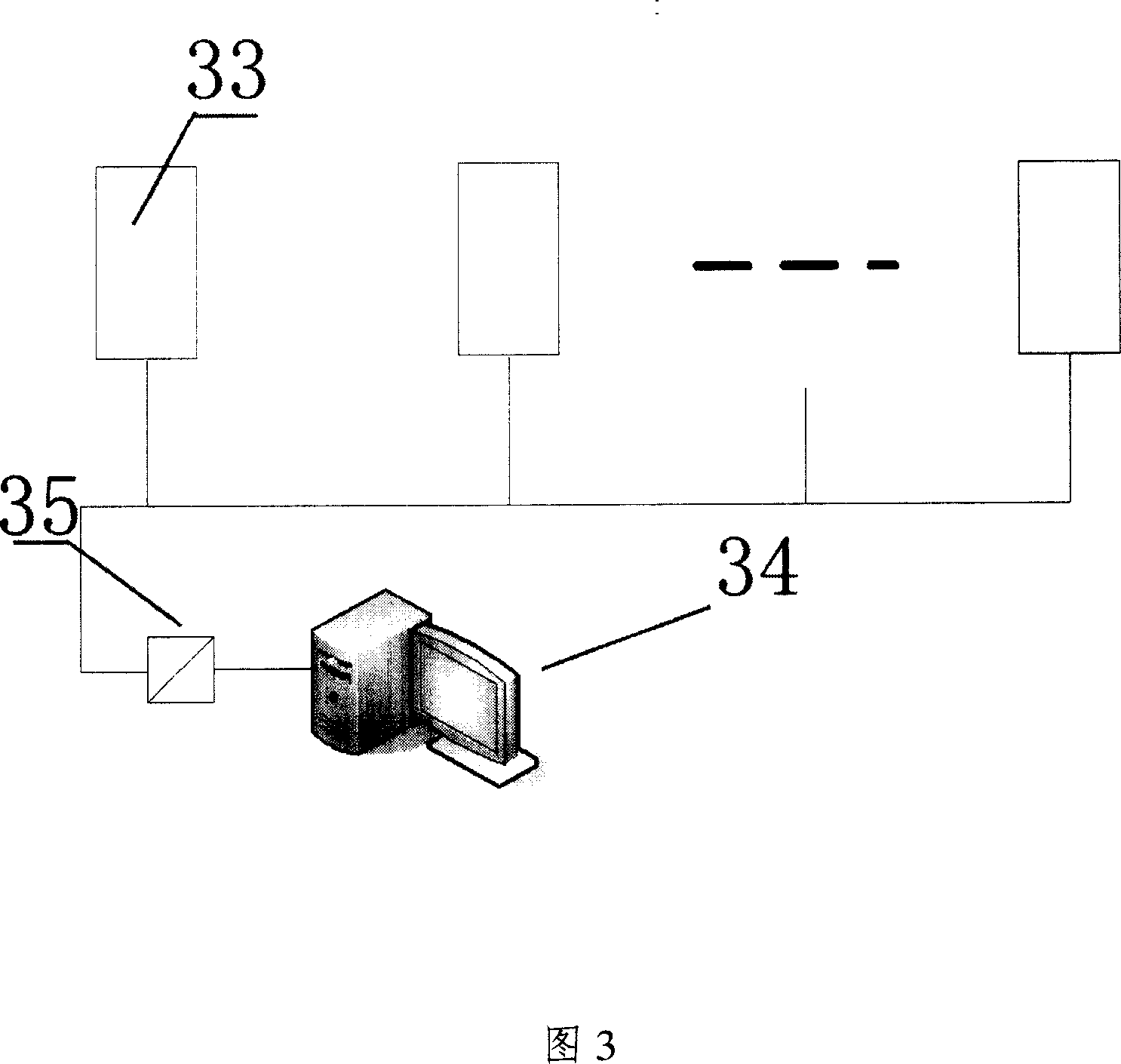

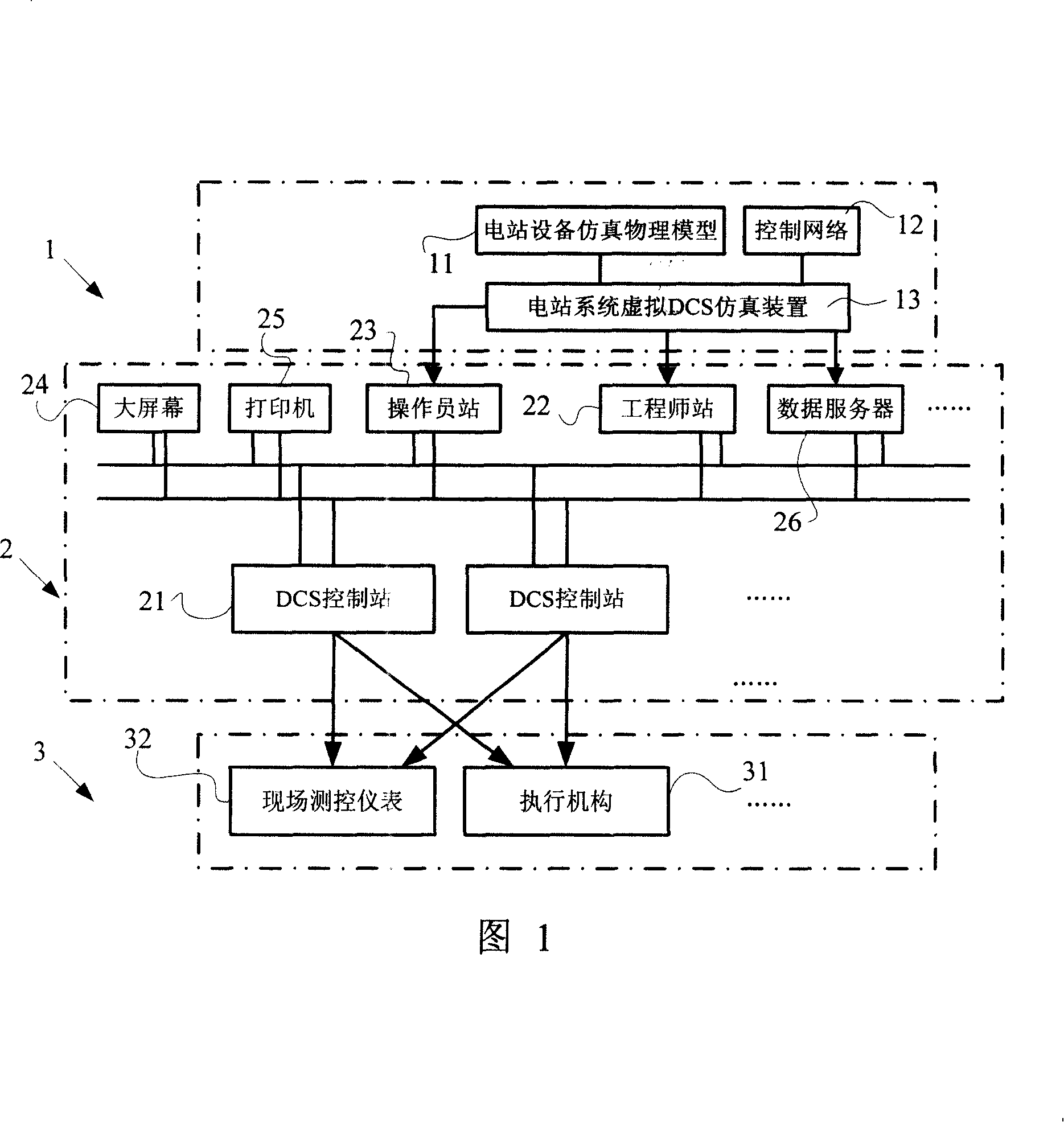

Simulation platform of macrotype power station integrated automation system

InactiveCN101154213AImprove operating economyImprove operational safetyComputer controlPower network operation systems integrationFiberSystems design

The invention relates to an comprehensive automatic system imitation platform for a large power plant, comprising that an 'imitation machine' part is a power station imitation platform for simulating the power plant production process by real-time and providing an actual and effective testing and analysis platform to improve the power station automatic level; a distributed control system comprises a plurality of control points in the actual site, a work station, a display, a printer, a data server and a double-redundancy fiber optical ring-shaped communication network; the 'actual power' part is the 'actual power' part of the power station simulation platform, and comprises a site input signal collecting system, a site testing and control instrument and an execution mechanism of the output signal of the simulation platform. The invention is constructed into a comprehensive automatic system research platform of the completely interacted power plant so as to conduct the analysis and research of the operation of the entire equipment of the power plant system without being limited by each condition on site, thereby, the time and the cost of the system design, testing and optimization can be largely saved, the economy and the safety of the power plant operation can be improved.

Owner:SHANGHAI ELECTRICGROUP CORP

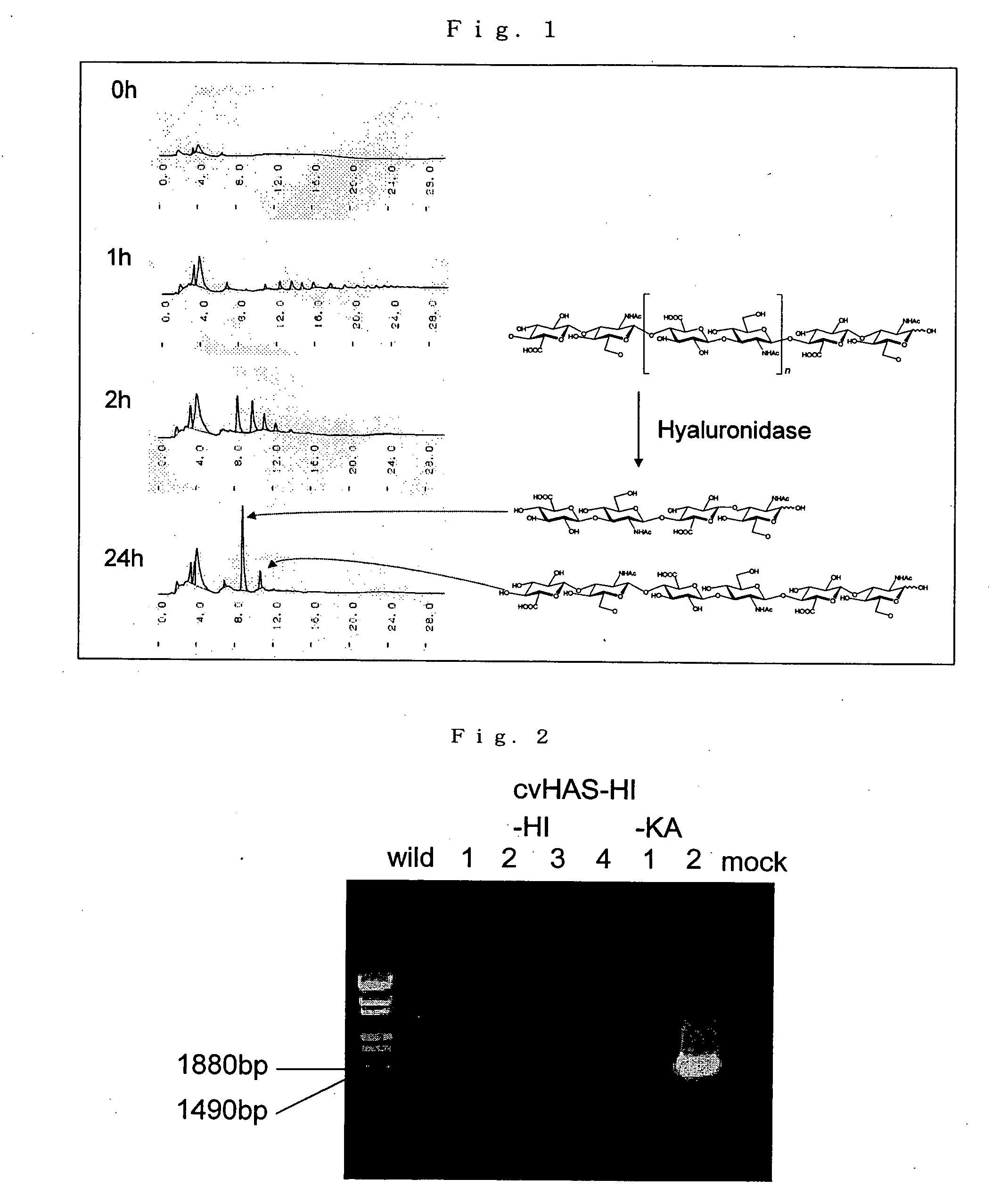

Plant producing hyaluronic acid

The invention relates to a method of producing hyaluronic acid comprising (1) a step of transforming a plant cell using an expression recombinant vector comprising (i) a DNA encoding hyaluronic acid synthase or (ii) a DNA encoding a polypeptide having an amino acid sequence having one or more amino acid deletions, substitutions, additions or insertions in an amino acid sequence of the hyaluronic acid synthase and having an activity of synthesizing the hyaluronic acid, (2) a step of growing a transformant obtained by transformation, and (3) a step of separating the hyaluronic acid produced by the transformant.

Owner:TOYO TOYOBO CO LTD

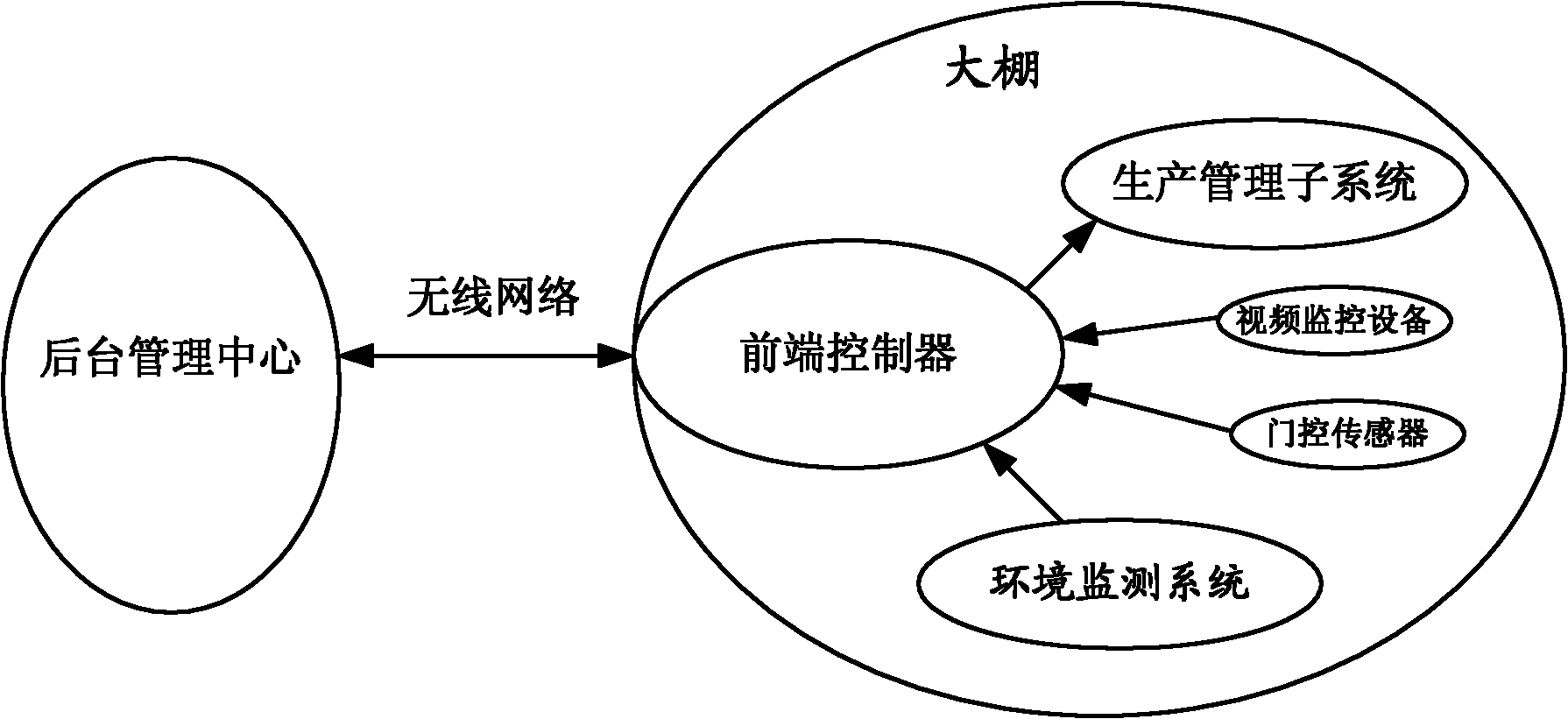

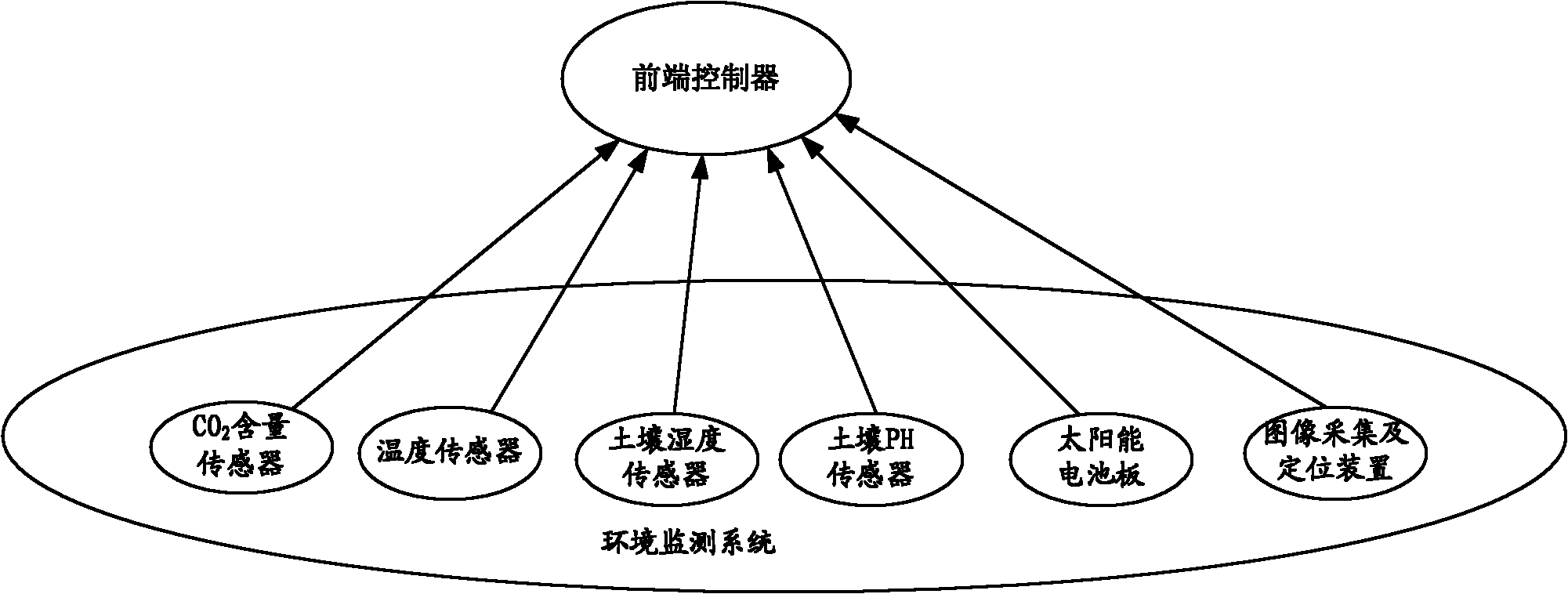

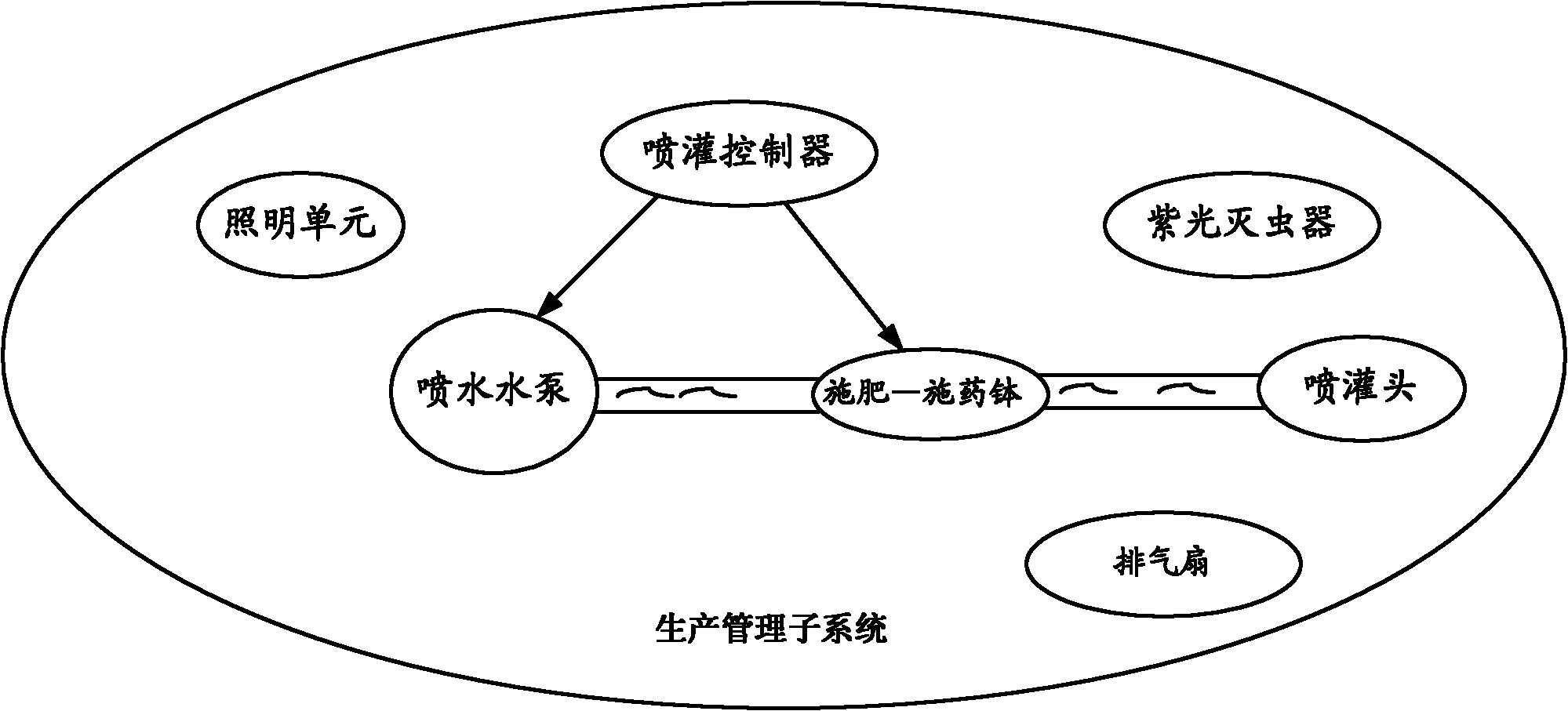

Comprehensive plant production management system and method

InactiveCN102156923ARealize fully automatic collection and monitoringThe growth environment is clearly understoodData processing applicationsWatering devicesMonitoring systemEngineering

The invention discloses a comprehensive plant production management system and an implementation method thereof. The comprehensive plant production management system comprises an environment monitoring system, a front controller and a background management center, wherein the environment monitoring system acquires growth environment parameters and growth status parameters of plants in a production field; the front controller uploads the growth environment parameters and the growth status parameters to the background management center, and controls a production management subsystem to execute corresponding production management operations according to control instructions sent by the background management center; and the background management center receives the growth environment parameters and the growth status parameters uploaded by the front controller, and sends the control instructions to the front controller. In the system, as the growth environment parameters and the growth status parameters of the plants in the field are acquired, and are uploaded to the background management center through a network, the background management center can automatically analyze the growth environment parameters and the growth status parameters, or sends the control instructions to the front controller through a human-machine interaction means to control the production management subsystem to perform corresponding production management operations on the plants according to the control instructions, therefore the probability of needing a person to visit the production field is reduced, and the production efficiency is improved.

Owner:华建武 +1

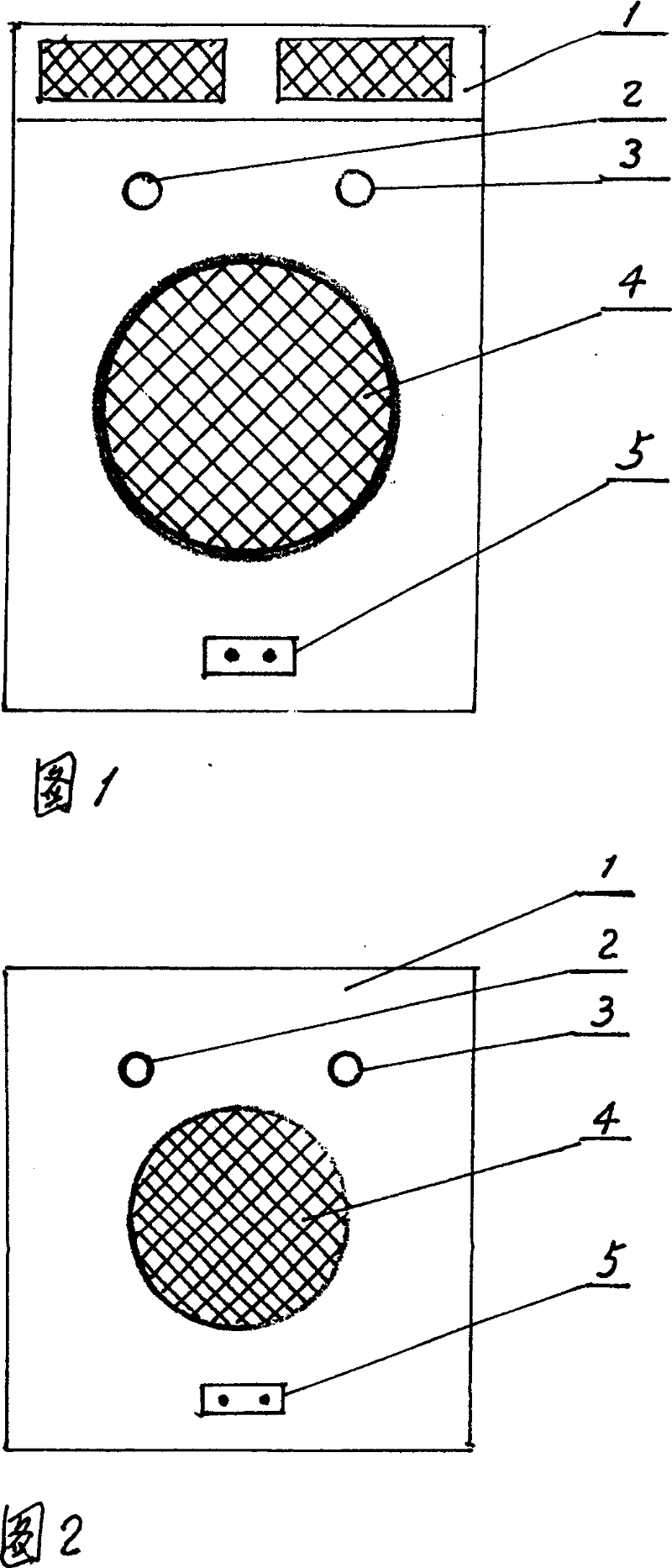

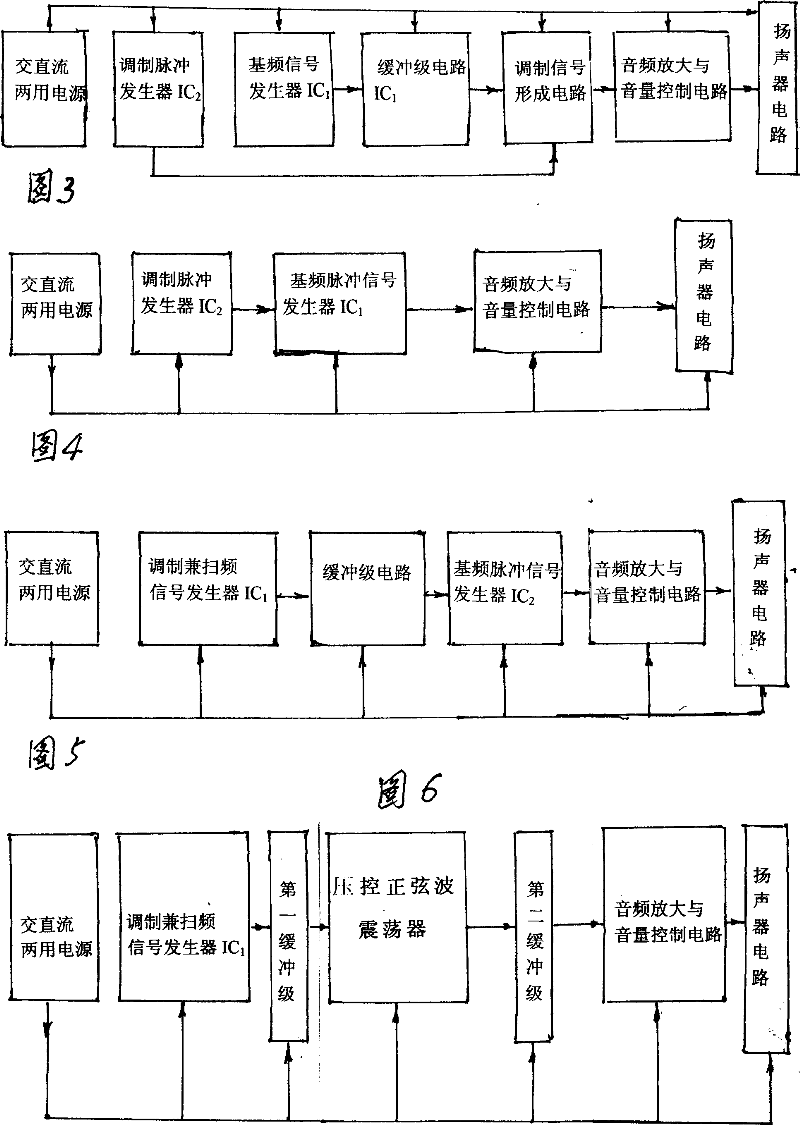

Multifunctional sonic wave processing technology and sonic wave generator for increasing quality plant production with protection

InactiveCN100356836CMeet the needs of useIncreased dose of sonicationElectrophonic musical instrumentsHorticulture methodsFrequency spectrumEngineering

A multifunctional sonic treating techinque for increasing the yield of plant and improving its quality and its sound wave generator are disclosed. The pulse modulated sound waves and sweep-frequency sound waves, which have strong force energy and information actions, are emitted toward the plant to promote the sequential activity of mass, energy and information, resulting in high yield and quality.

Owner:仇剑锋

Hemp-material viscose fiber and preparing method thereof

InactiveCN101130885AQuality improvementHigh whitenessWet spinning methodsVegetable materialAfter treatmentHemp plant

The present invention discloses a method for preparing hemp viscose fiber by using hemp plant and hemp visose fiber prepared by adopting said method. Said method includes the following steps: preparing raw material, digesting, washing material, pulping, removing sand, bleaching, water-washing, fiber-making, impregnating, pressing, pulverizing, aging, xanthating, dissolving, mixing, filtering, defoaming, spinning, drawing, cutting and making after-treatment.

Owner:CHTC HELON

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

Tobacco cultivar 'aob 171'

ActiveUS20090119788A1Nervous disorderOther foreign material introduction processesNicotiana tabacumCultivar

The present invention relates to a novel tobacco cultivar designated AOB 171, which has low to intermediate nicotine content. The invention provides seeds of the cultivar AOB 171, plants and parts thereof of the cultivar AOB 171, a tissue culture derived from the cultivar AOB 171, hybrids produced from cultivar AOB 171 and lines derived from cultivar AOB 171, as well as genetically modified forms of the foregoing plants and tissue culture. Also provided are methods of producing cultivar AOB 171 plants, cultivar AOB 171 hybrid plants, and tobacco lines derived from cultivar AOB 171. In addition, products produced from the plants of the present invention are provided.

Owner:PYXUS HLDG INC

Treatment of genetically modified crops with a mixture of phenylpyrazoles and nicotinoyl chloride

The present invention relates to a method for increasing the productive potential of plants and / or for controlling pests in plants having at least one transgenic modification associated with increased yield compared to corresponding wild-type plants, comprising treating plants having The area where at least one transgenic modified plant is planted or is expected to be planted and / or the transgenic plant with at least one transgenic modification or the propagation material of the plant with at least one transgenic modification, said pesticidal composition comprising: Component A, selected from imidacloprid, thiacloprid, clothianidin, acetamiprid, dinotefuran, nitenpyram and thiamethoxam; and component B selected from fipronil and ethiprole.

Owner:BAYER CROPSCIENCE AG

Fertilizer compositions and methods of making and using same

InactiveUS20050138978A1Good effectHigh yieldExcrement fertilisersFertiliser formsAdditive ingredientHumic acid

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

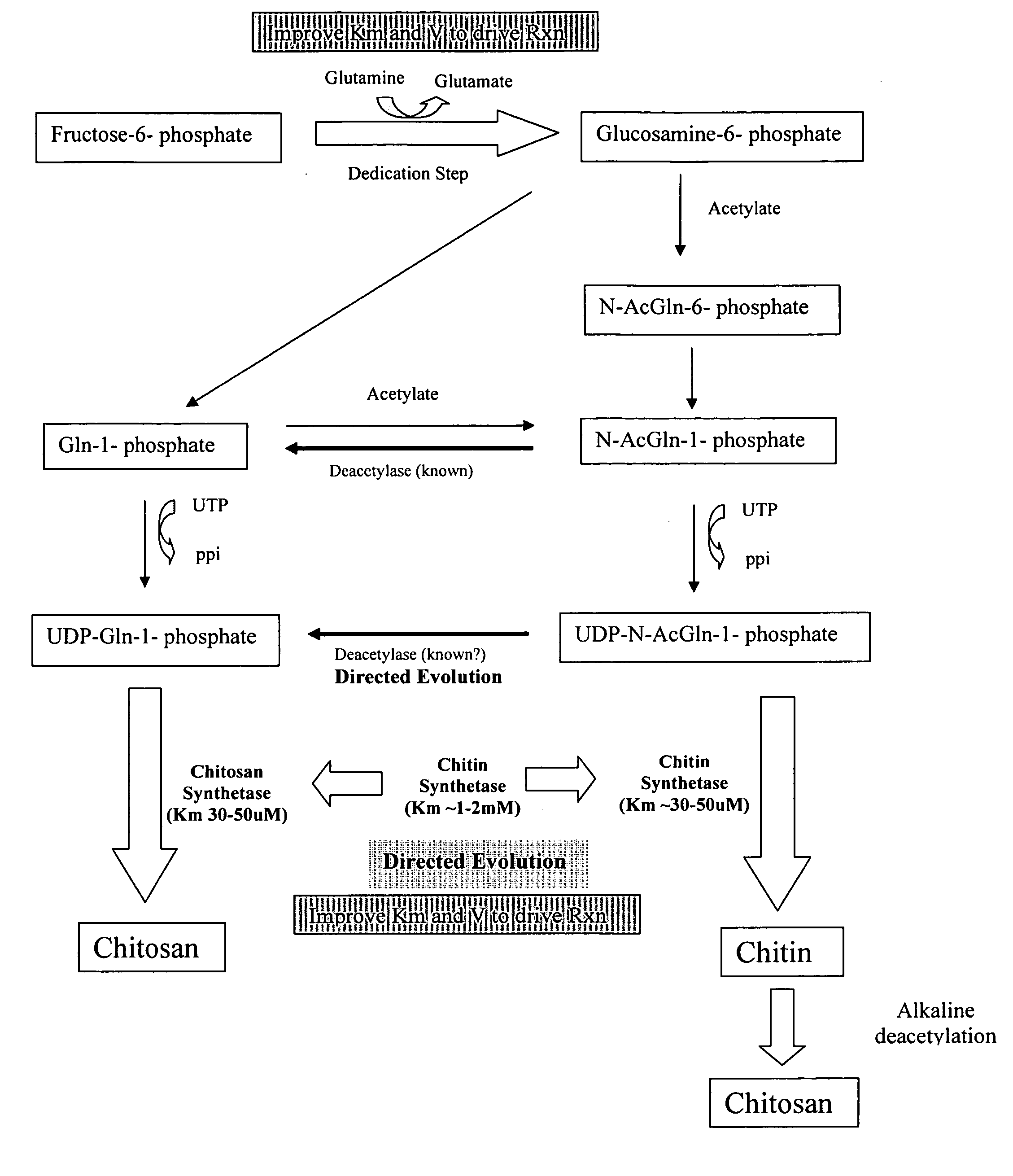

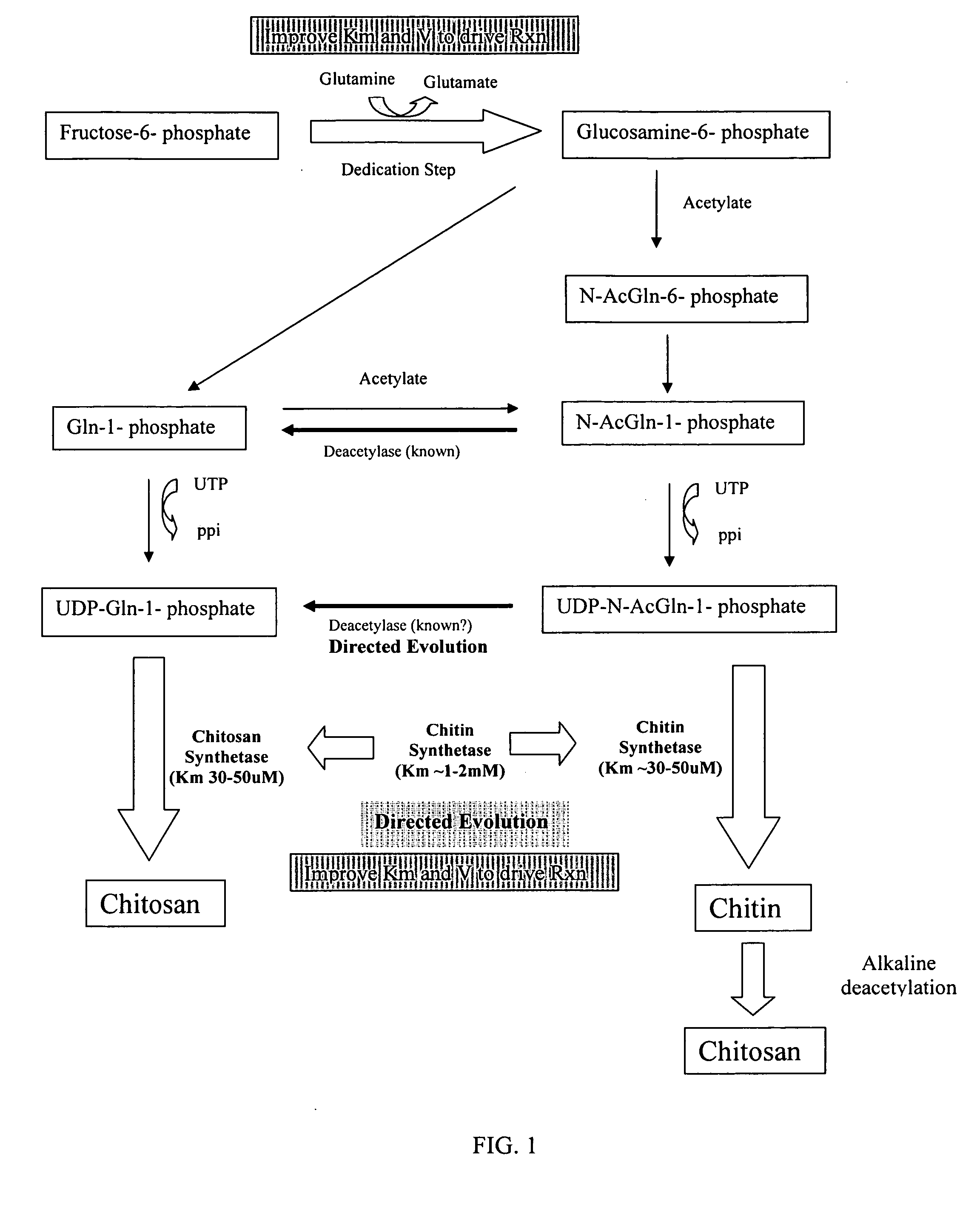

Methods for production of chitin and chitosan

Compositions and methods for producing chitin and chitosan are provided. The compositions comprise genetically modified organisms, including fungi, yeast, bacterial and plant organisms that have been engineered to express heterologous genes involved in chitin and chitosan synthesis. Microorganisms and plants that have been modified for production of chitin and / or chitosan within the vacuole of a cell are encompassed. Methods for production of chitin also comprise culturing the genetically engineered organisms in conditions that allow for chitin production. Further methods include converting the chitin to chitosan by a chemical process. Production of chitosan also comprises culturing organisms that are genetically modified to produce chitosan without the need for chemical modification. Methods for in vitro chitosan production are also encompassed.

Owner:ATHENIX

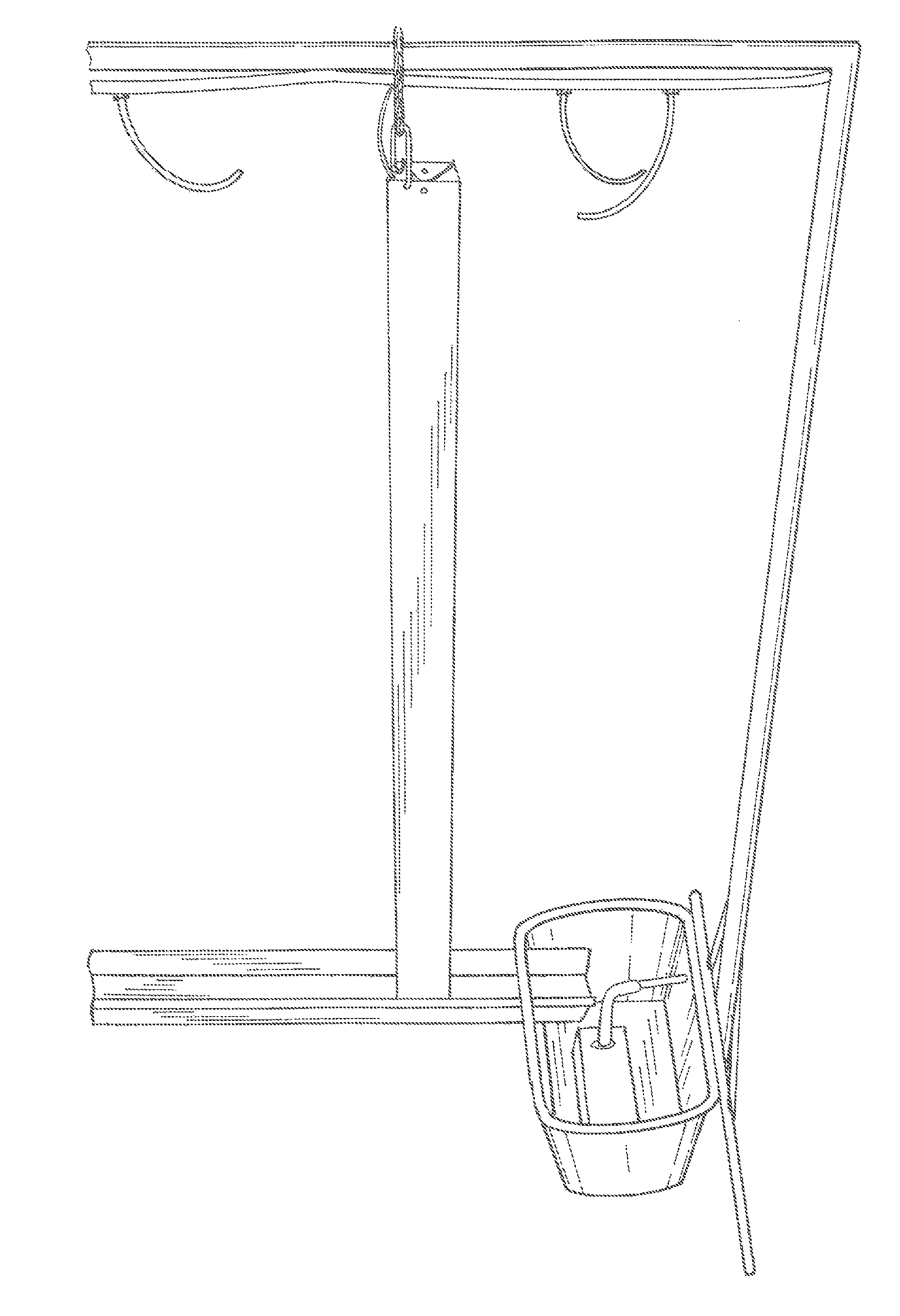

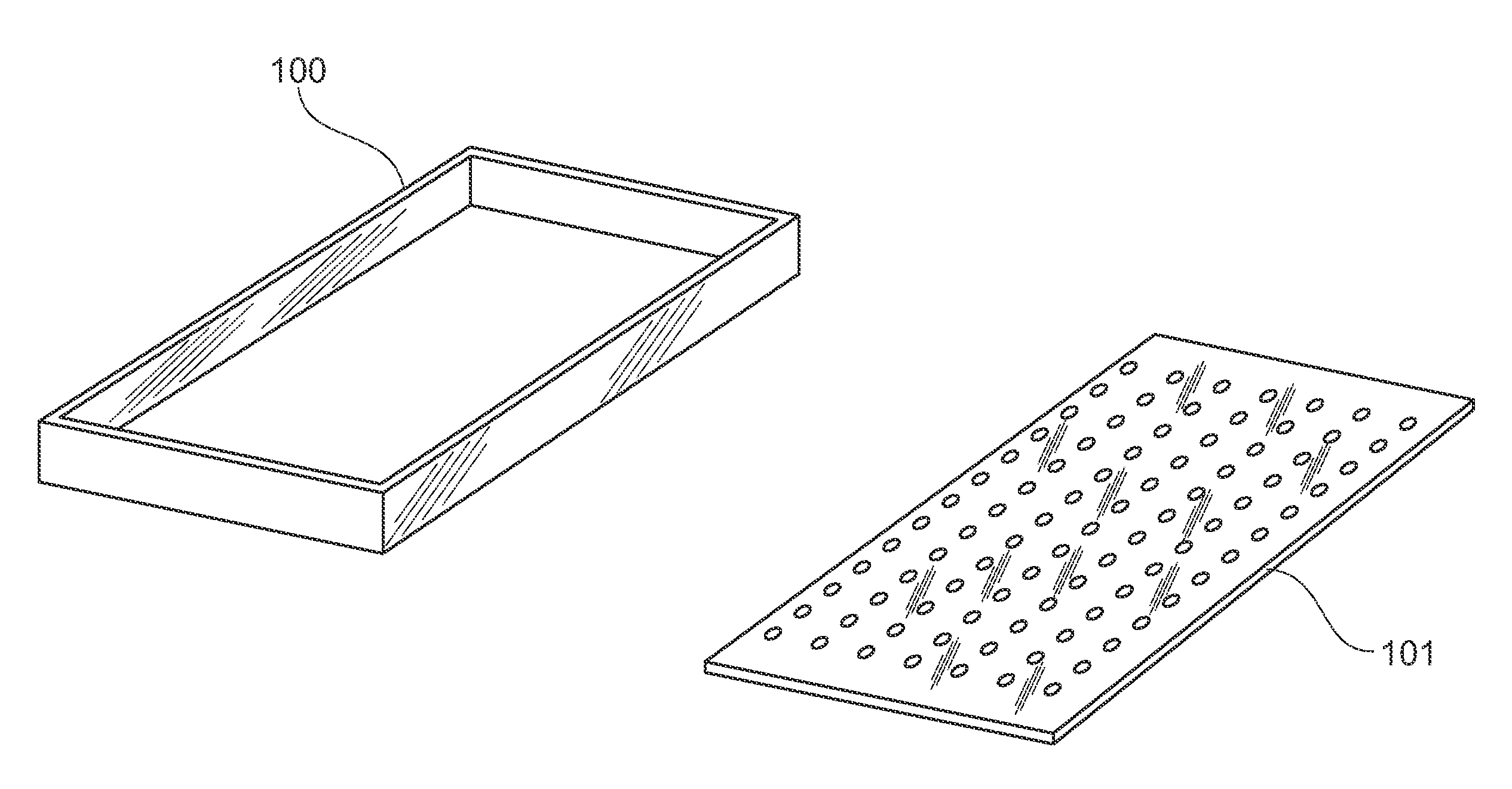

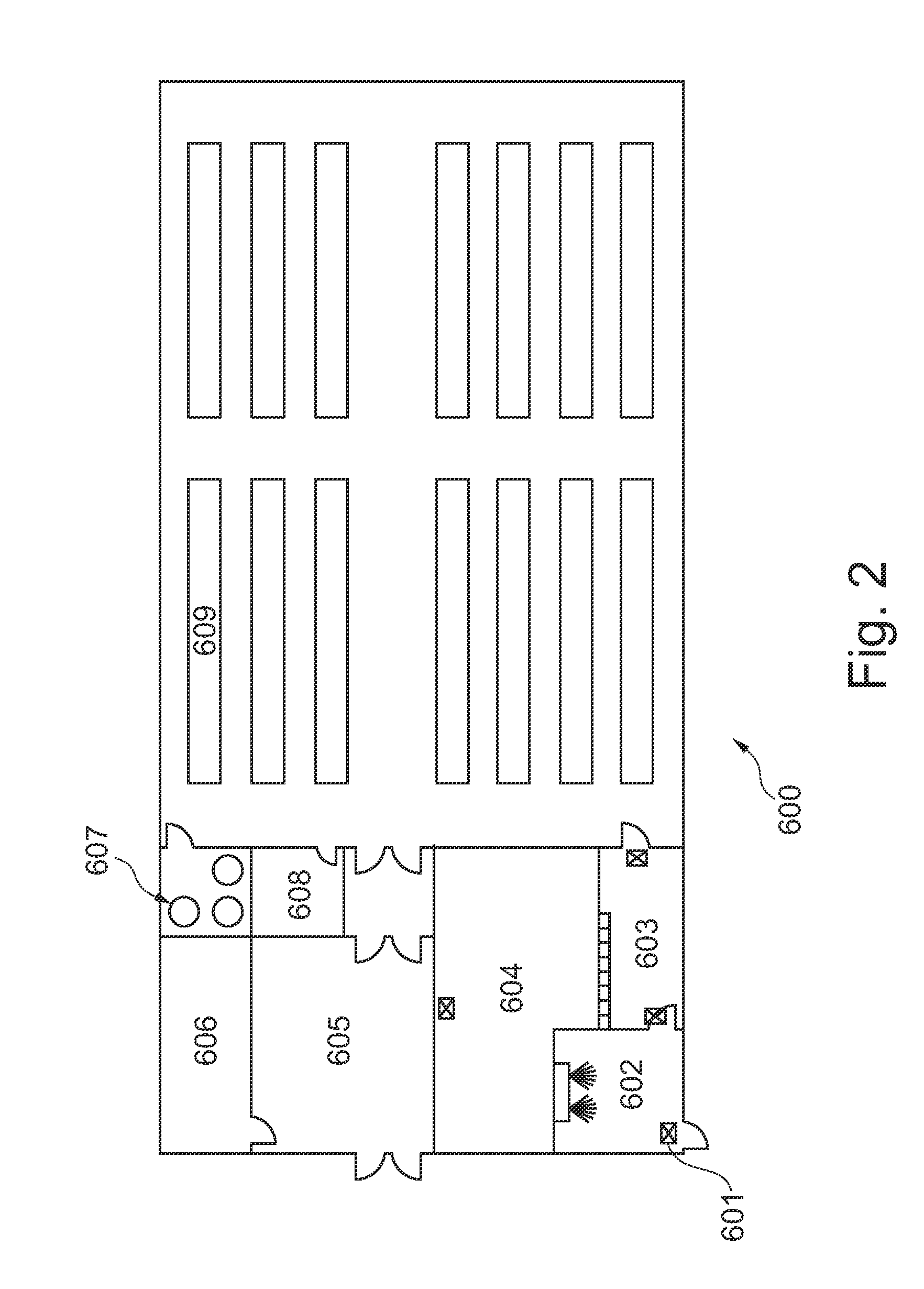

PURE-Grown totally concealed clean room vegetable factory

InactiveUS20120144740A1Promote resultsImprove the environmentAgriculture gas emission reductionCultivating equipmentsPlant rootsEnvironment of Albania

Plant roots are moved by various means and sometimes exposed to air within a clean room system of plant production. A tub and lid system of plant containment and plant care may be integrated into a rack system which may be contained within a clean room environment devoid of bugs, environmental deviations, pollution and other contaminates found in a typical organic system of the prior art.

Owner:IGARASHI LARRY Y

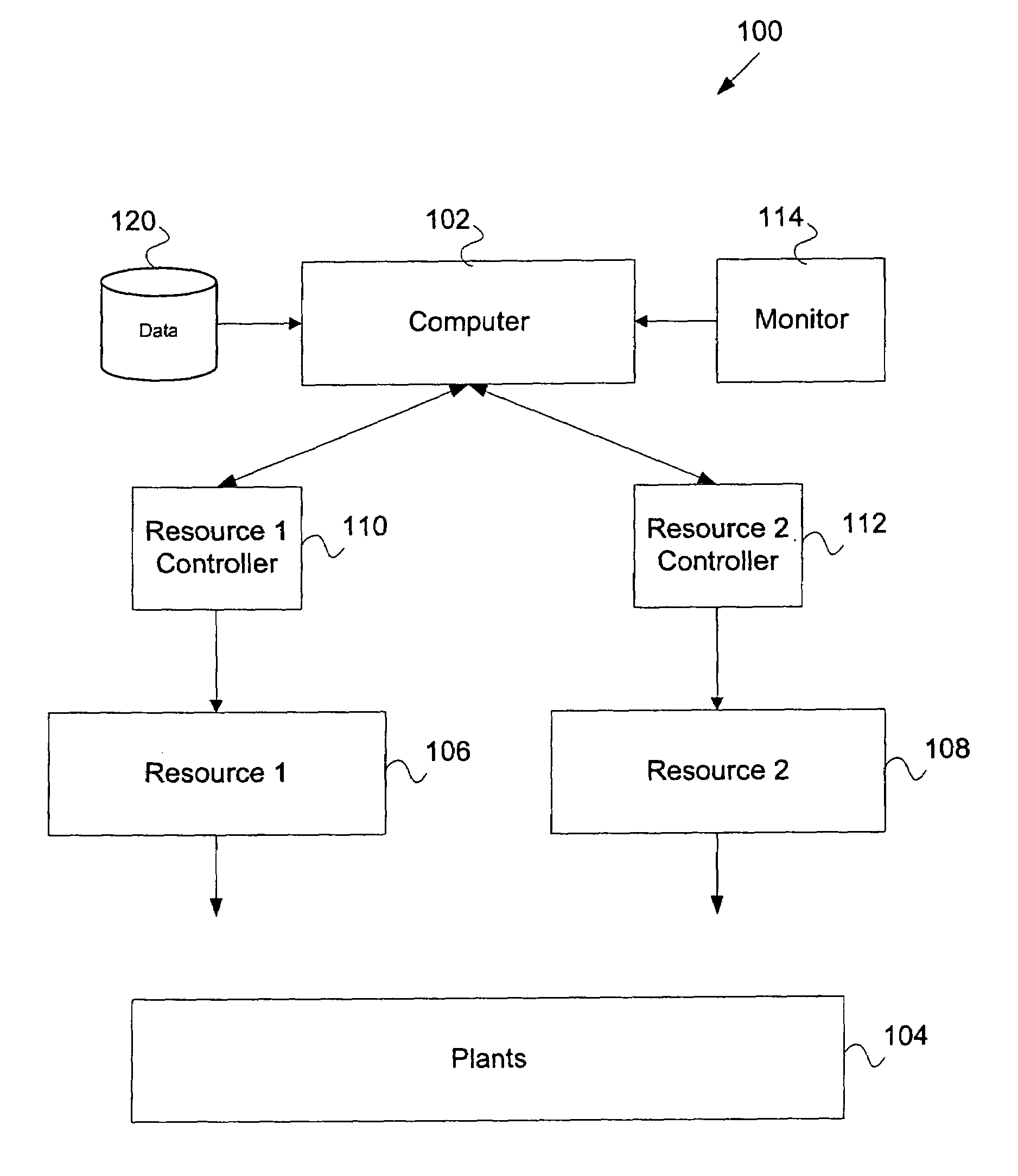

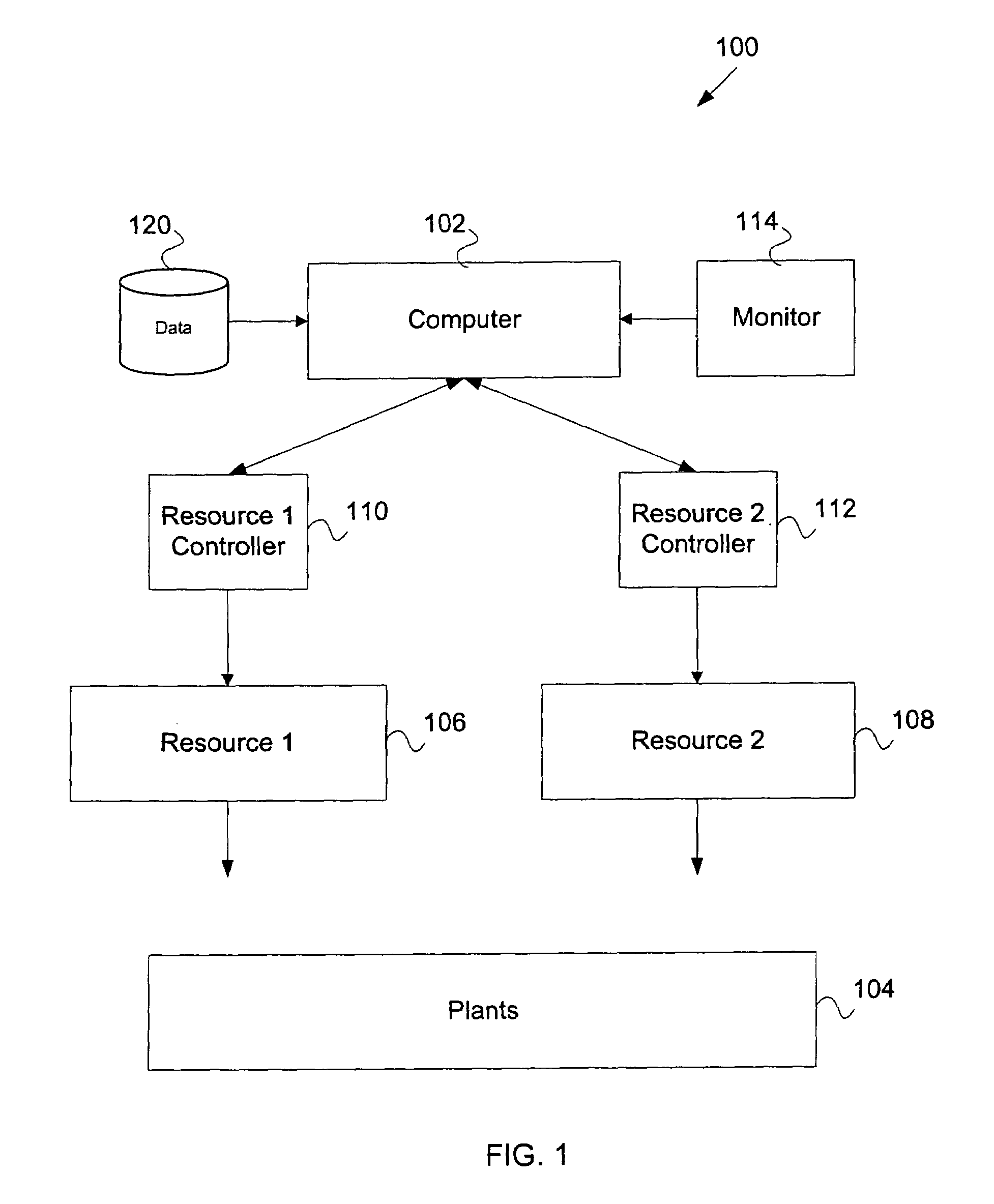

Systems and methods for providing optimal light-CO2 combinations for plant production

Method and system for optimizing plant production in a cost effective manner. System (100) includes a processor (102) in communication with resource controllers (110, 112) for controlling resources (106, 108) such as, for example, lighting and carbon dioxide. Each resource has a cost that varies temporally or with other factors. The processor implements an algorithm that receives a desired plant production rate and other input, such as operating conditions of the system and environment, and determines amounts of each resource to expend consistent with plant production goals and resource costs.

Owner:CORNELL RES FOUNDATION INC

Vertical Hydroponic Plant Production Apparatus

ActiveUS20130067813A1Agriculture gas emission reductionCultivating equipmentsGreenhouse cropsMechanical engineering

A vertical hydroponic plant production apparatus for allowing vertical hydroponic greenhouse crop production is provided. The apparatus comprises a hollow grow tube having a front face, a back face, an open first end, and an open second end. A slot is formed in the front face of the grow tube with the slot having a width equal to only a portion of a width of the front face. A media material is insertable into the grow tube. The slot allows the front face to expand outward during insertion of the media material and biased inward against the media material once the media material is inserted. The grow tube is positionable in either a horizontal position, vertical position, or any position between the horizontal position and the vertical position allowing inclined, multi-angled crop production and multi-storied conveyor style crop production.

Owner:UNIVERSITY OF WYOMING

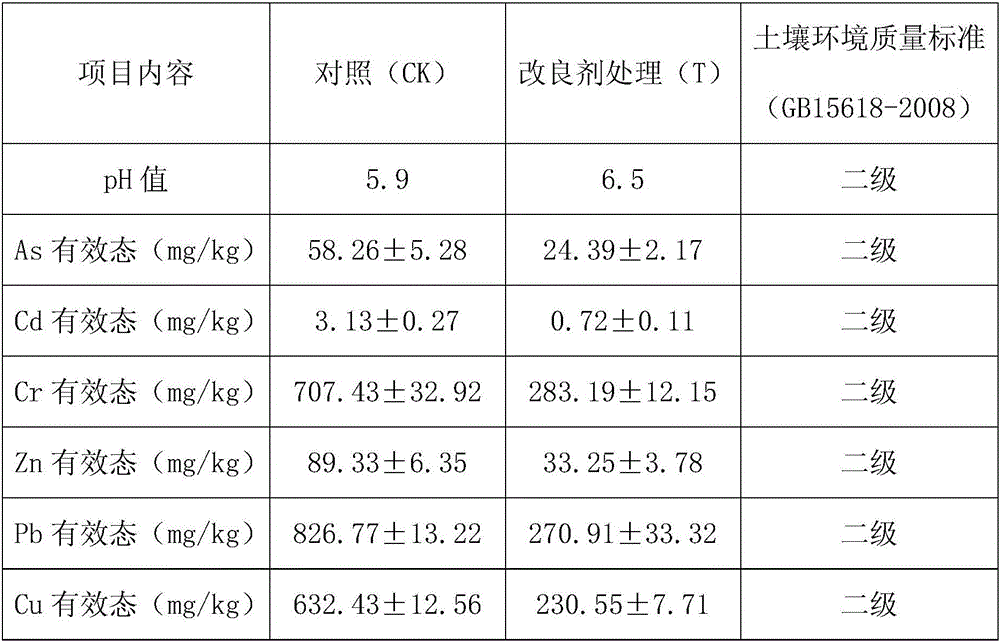

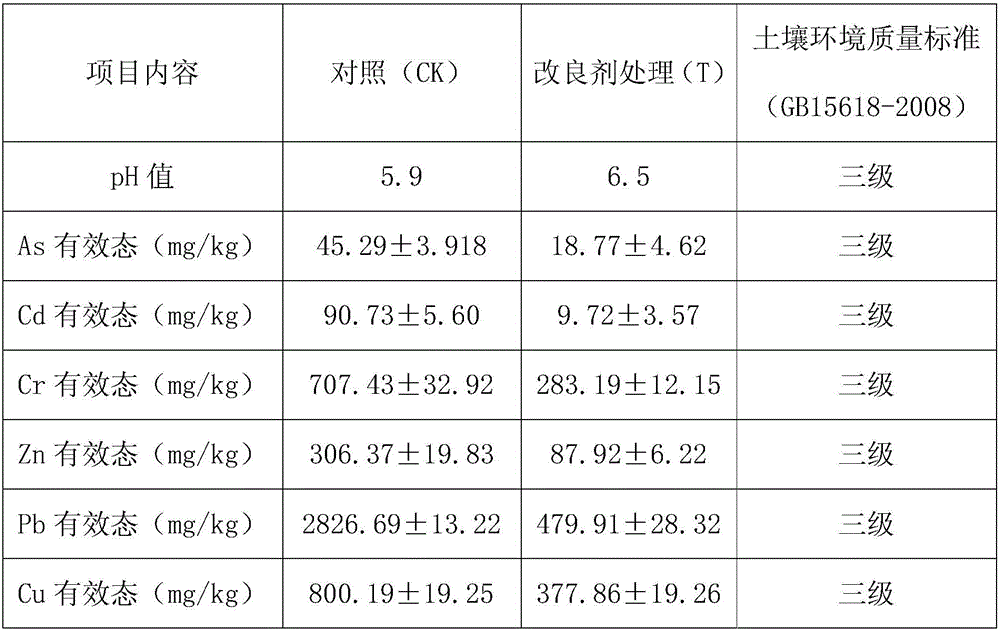

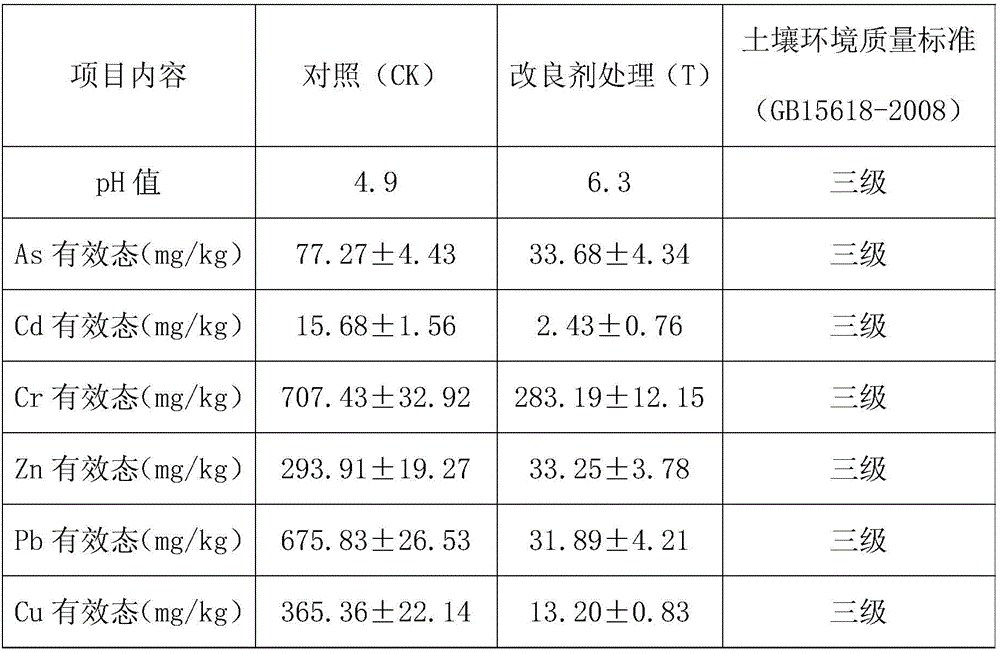

Biochemical compound soil heavy metal pollution fixed remediation agent and application

ActiveCN106147775AReduce contentEasy to operateContaminated soil reclamationOrganic fertilisersSodium BentoniteSoil heavy metals

The invention provides a biochemical compound soil heavy metal pollution fixed remediation agent and application, and belongs to the technical field of soil heavy metal pollution control and remediation. The preparing raw materials include sulfydryl bentonite, sulfydryl chitosan, zeolite, iron powder, photosynthetic bacteria, actinomycetes, saccharomycetes and lactic acid bacteria by the weight ratio of 35-65%: 33-52%: 1-8%: 0.2-1%: 0.2-1%: 0.2-1%:0.2-1%:0.2-1%. The fixed remediation agent is effective for unitary or combined heavy metal pollution soil, reduces the effective state and mobility of heavy metal in the soil and therefore ensures safety of soil and plant production, wherein pollution metal includes cadmium, chromium, copper, zinc, mercury, arsenic and lead. The used materials are wide in source, low in cost, remarkable in repair effect and free of secondary pollution, and the fixed remediation agent is environment-friendly soil heavy metal passivation and remediation agent.

Owner:GUANGDONG GEOLONG BIOTECH

Vertical hydroponic plant production apparatus

ActiveUS9380751B2Agriculture gas emission reductionCultivating equipmentsGreenhouse cropsEngineering

A vertical hydroponic plant production apparatus for allowing vertical hydroponic greenhouse crop production is provided. The apparatus comprises a hollow grow tube having a front face, a back face, an open first end, and an open second end. A slot is formed in the front face of the grow tube with the slot having a width equal to only a portion of a width of the front face. A media material is insertable into the grow tube. The slot allows the front face to expand outward during insertion of the media material and biased inward against the media material once the media material is inserted. The grow tube is positionable in either a horizontal position, vertical position, or any position between the horizontal position and the vertical position allowing inclined, multi-angled crop production and multi-storied conveyor style crop production.

Owner:UNIVERSITY OF WYOMING

Fertilizer compositions and methods of making and using same

InactiveUS6878179B2Good effectHigh yieldExcrement fertilisersBioloigcal waste fertilisersSporeBacillus sp. ET

Owner:MICROBES

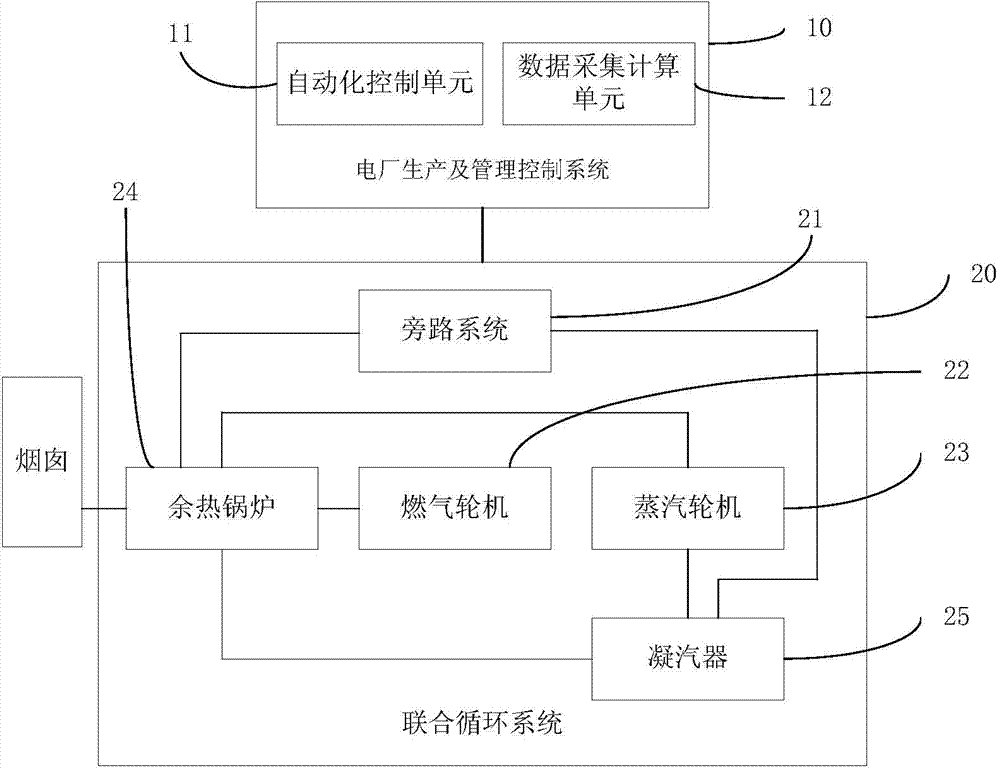

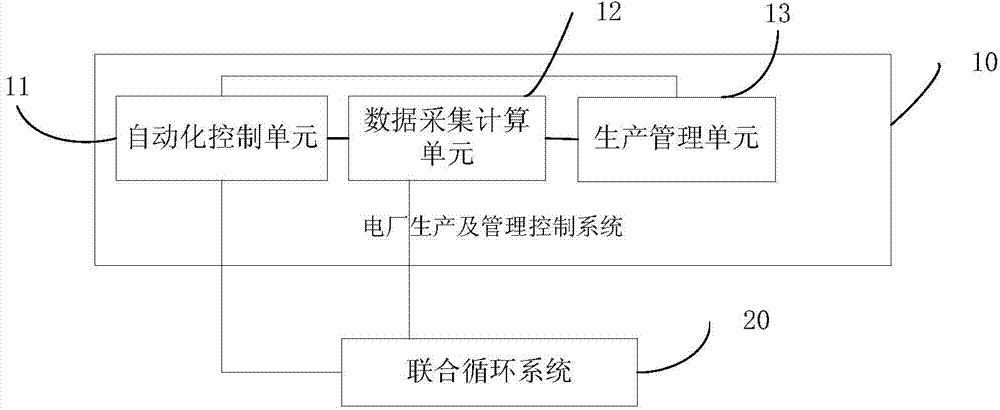

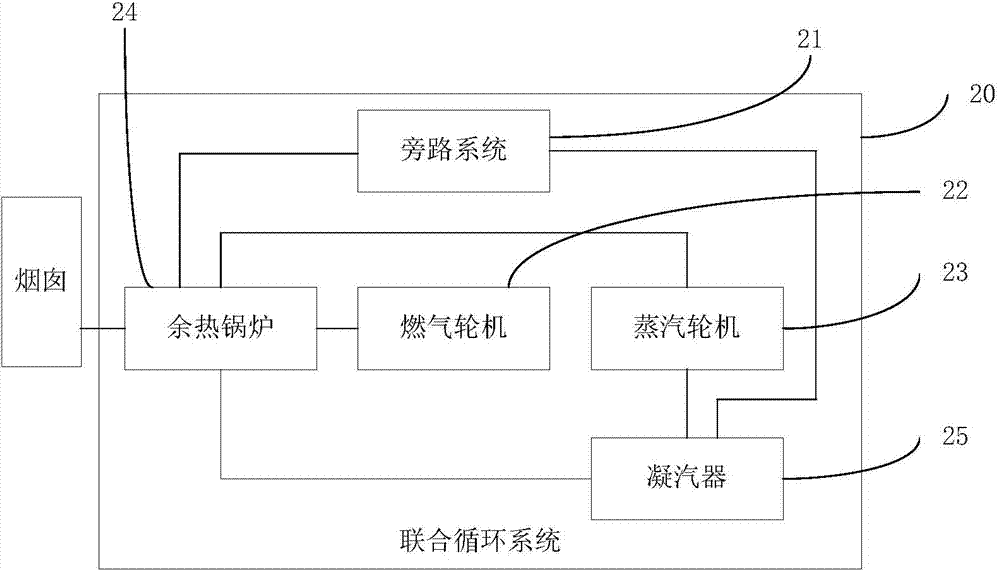

Power plant production and management control system

ActiveCN103885433AAvoid problems with hard-to-automate management controlsTotal factory controlProgramme total factory controlAutomatic controlControl system

The embodiment of the invention discloses a power plant production and management control system, and relates to the technical field of thermal power generation. The power plant production and management control system comprises an automatic control unit and a data collecting and calculating unit. The automatic control unit is used for being connected with unit devices in a combined circulating system, and the unit devices are controlled to operate through control instructions without manual intervention so that breakpoint-free automatic operating can be achieved. The data collecting and calculating unit is used for monitoring the current operating parameter of a unit when the combined circulating system operates and calculating and generating an operating strategy according to the current operating parameter of the unit so as to automatically control the combined circulating system through the operating strategy. Breakpoint-free unit-level starting and stopping without manual intervention of the unit can be achieved, and therefore the problem that automatic production and management control is hard to achieve through a power plant production and management control system in the prior art is solved.

Owner:北京京桥热电有限责任公司

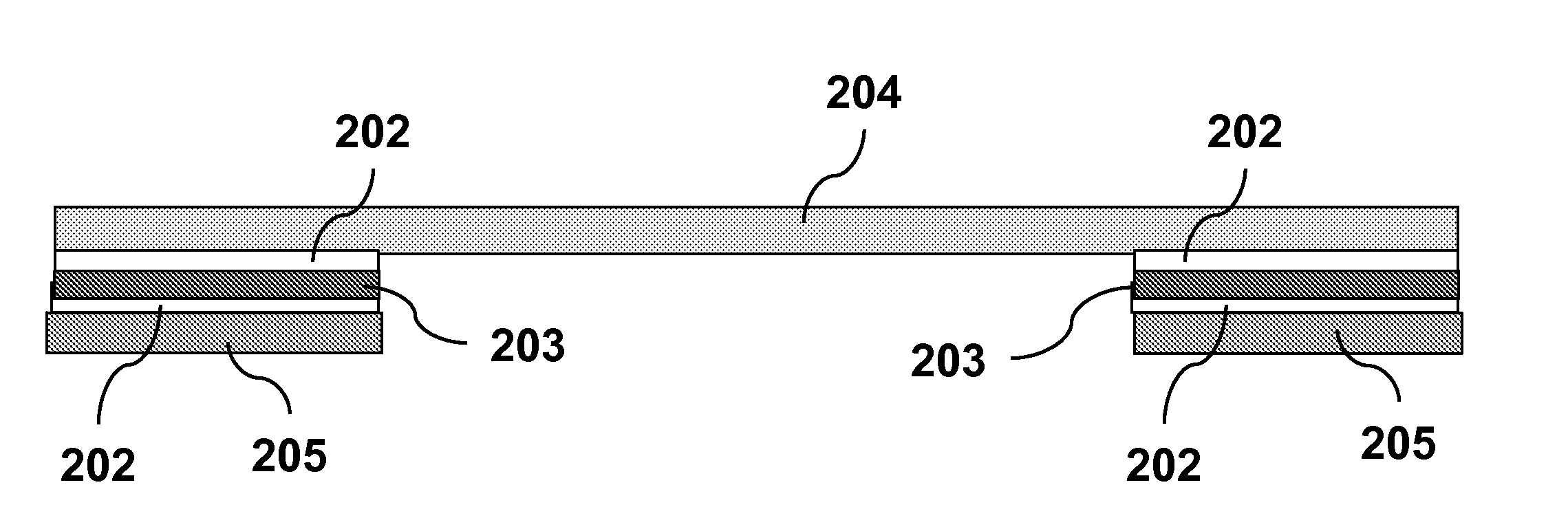

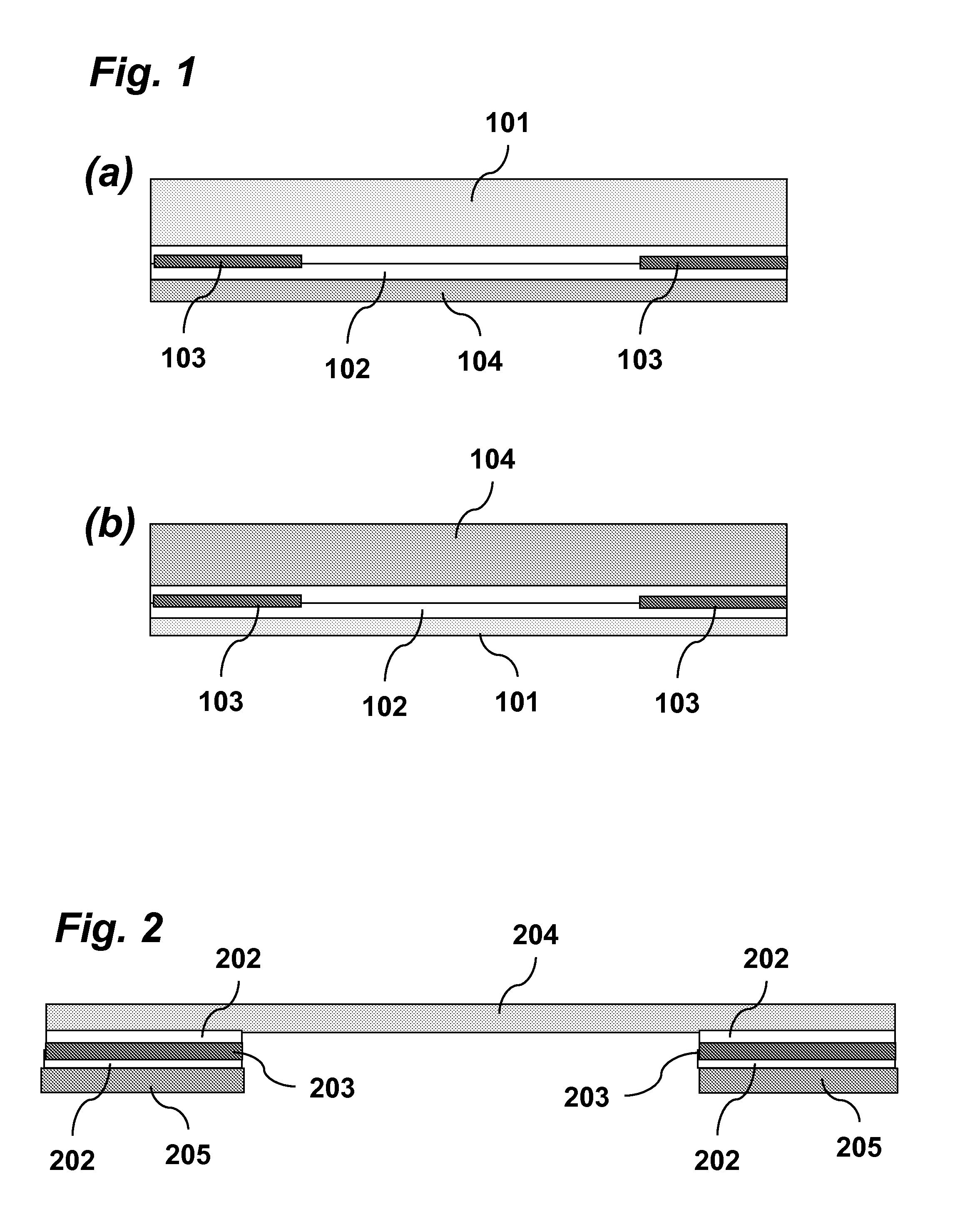

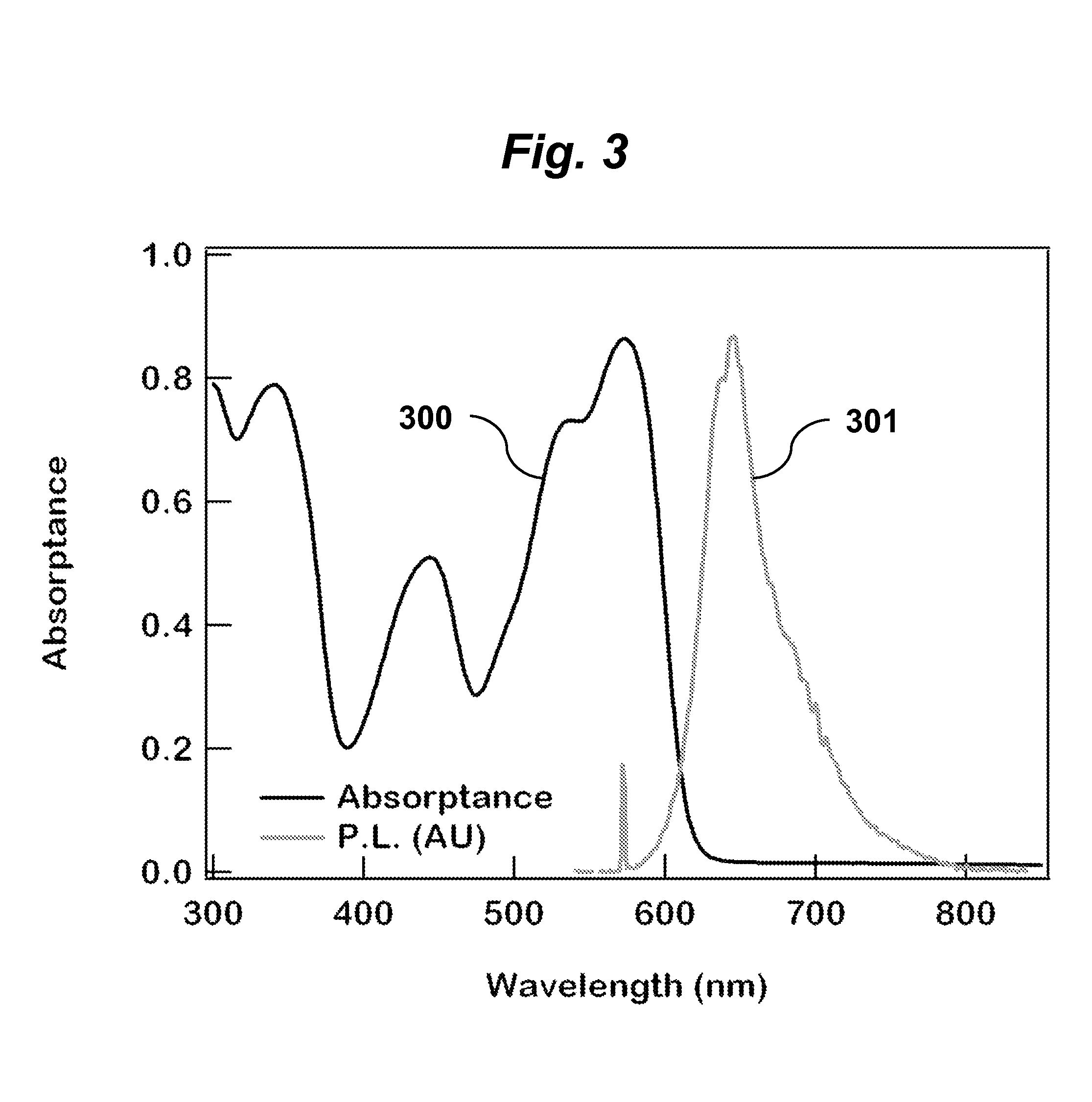

Luminescent Electricity-Generating Window for Plant Growth

InactiveUS20140352762A1Improve efficiencyEnhance plant growthPV power plantsClimate change adaptationLight energyEngineering

A window for a greenhouse is provided that is comprised of a sheet of luminescent material [104] and light-energy converter [103]. The sheet comprises one or more luminescent materials [104] that absorb the peak wavelengths of the sun, emitting the absorbed photons to wavelengths primarily between 600 and 690 nm where they are converted to electrical power and / or enhance plant production. The luminescent material [104] is also transparent to a fraction of the wavelengths in the blue and red-portion of the solar spectrum which are required for plant growth and flowering. An additional polymer layer may be added as a luminescent layer, diffuser and / or IR reflector to further enhance plant growth and electricity generation.

Owner:RGT UNIV OF CALIFORNIA

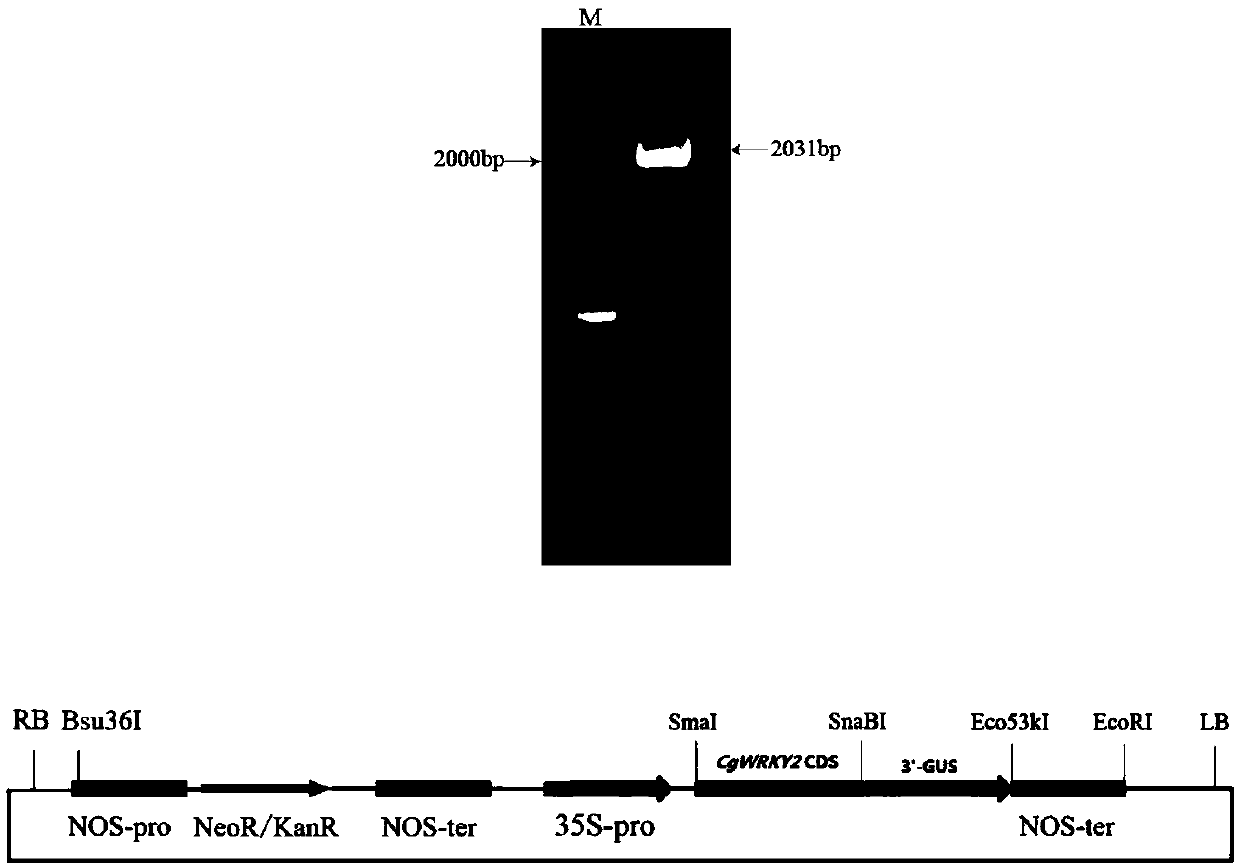

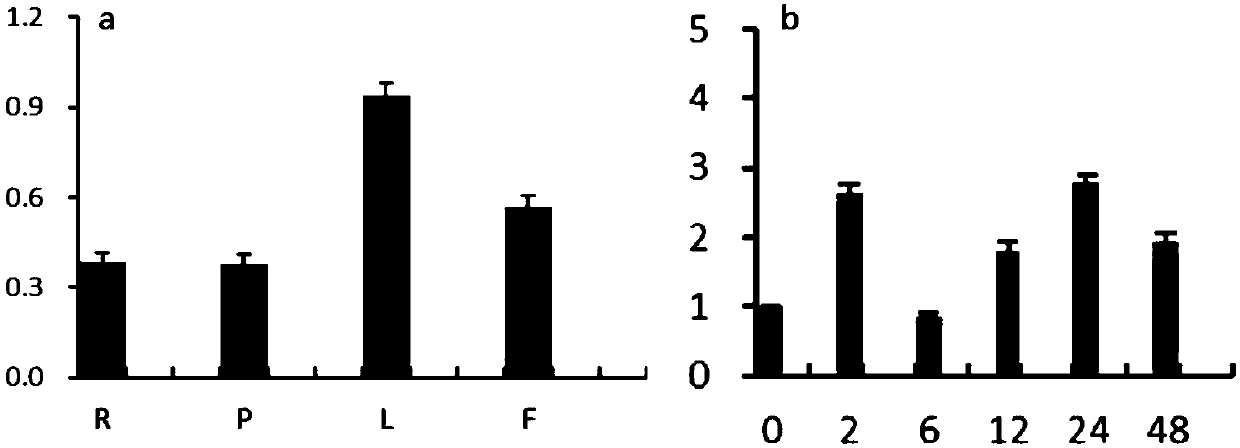

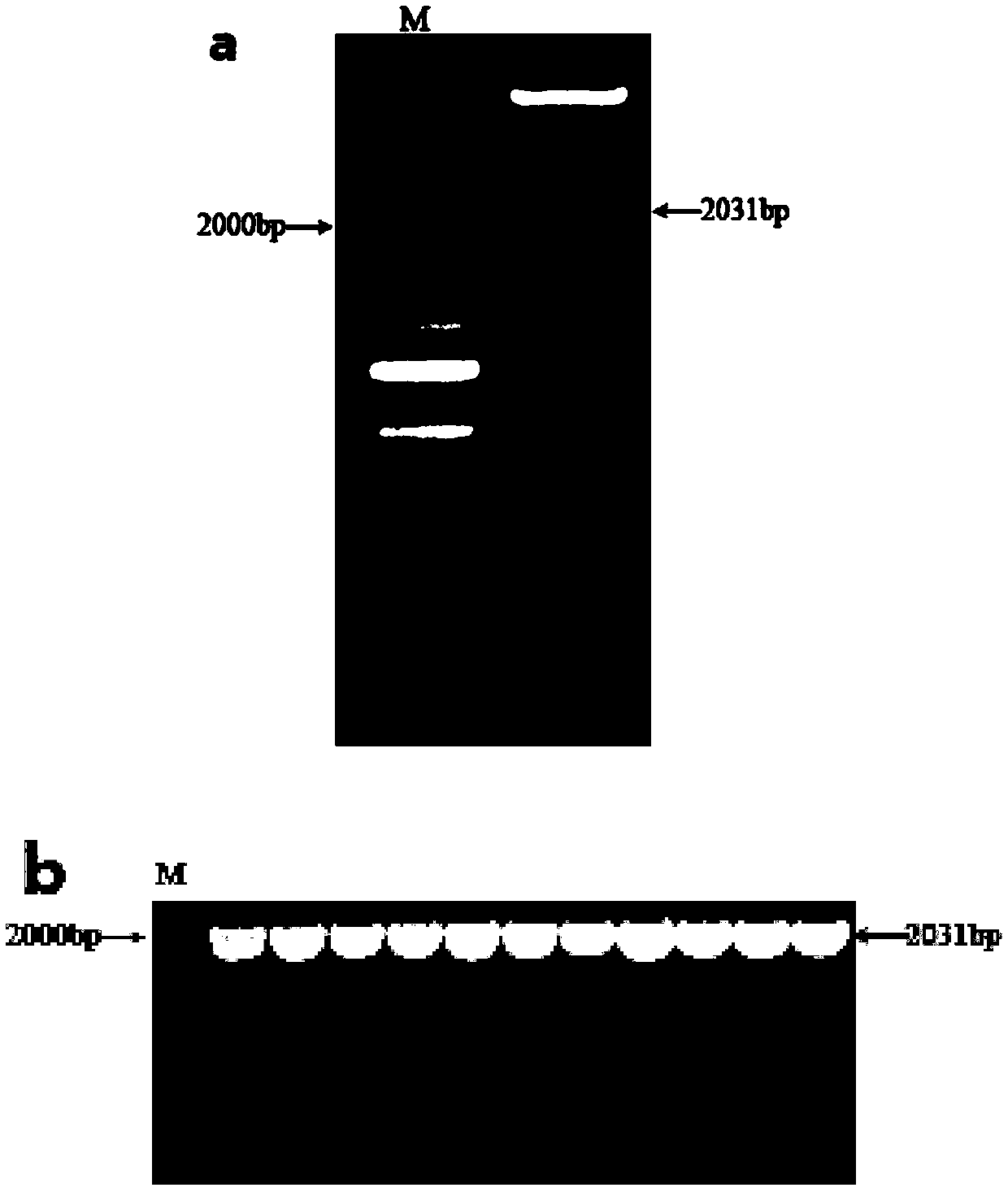

Spring orchid CgWRKY2 gene and application thereof

The invention discloses a spring orchid CgWRKY2 encoding gene and application thereof. The nucleotide sequence of the CgWRKY2 gene is shown as SEQ ID NO.1, and the amino acid sequence of an expressedprotein is shown as SEQ ID NO.2. According to cloning and identification of the CgWRKY2 gene of a spring orchid variety 'Song Mei', gene expression analysis and function verification, it's found thatan arabidopsis thaliana plant over expressing the CgWRKY2 gene grows slowly and is dwarfed with the phenotype of premature aging like early blight of leaves, thereof, the gene has a wide range of usesin production and breeding of the orchid and other plants.

Owner:NANJING FORESTRY UNIV

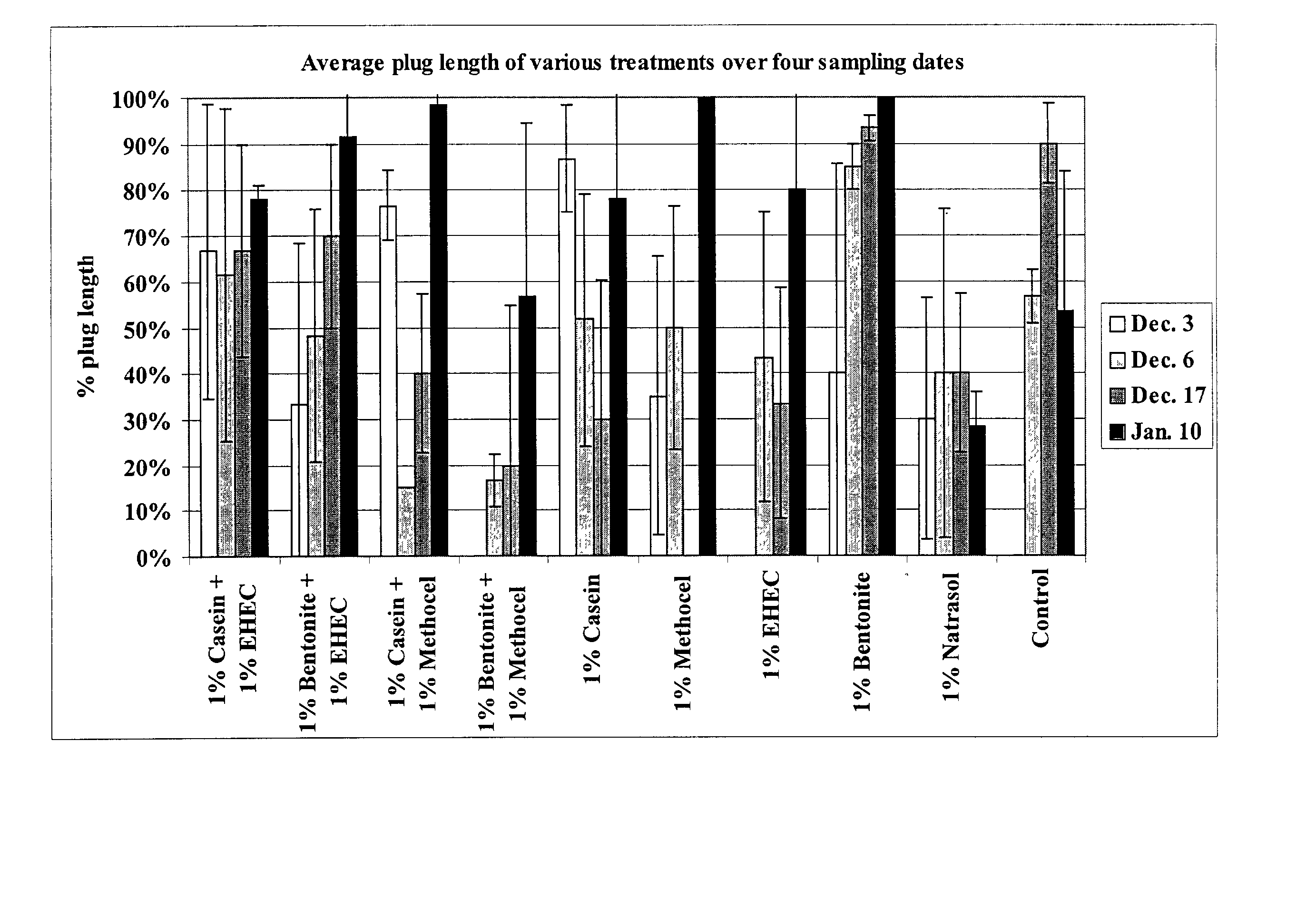

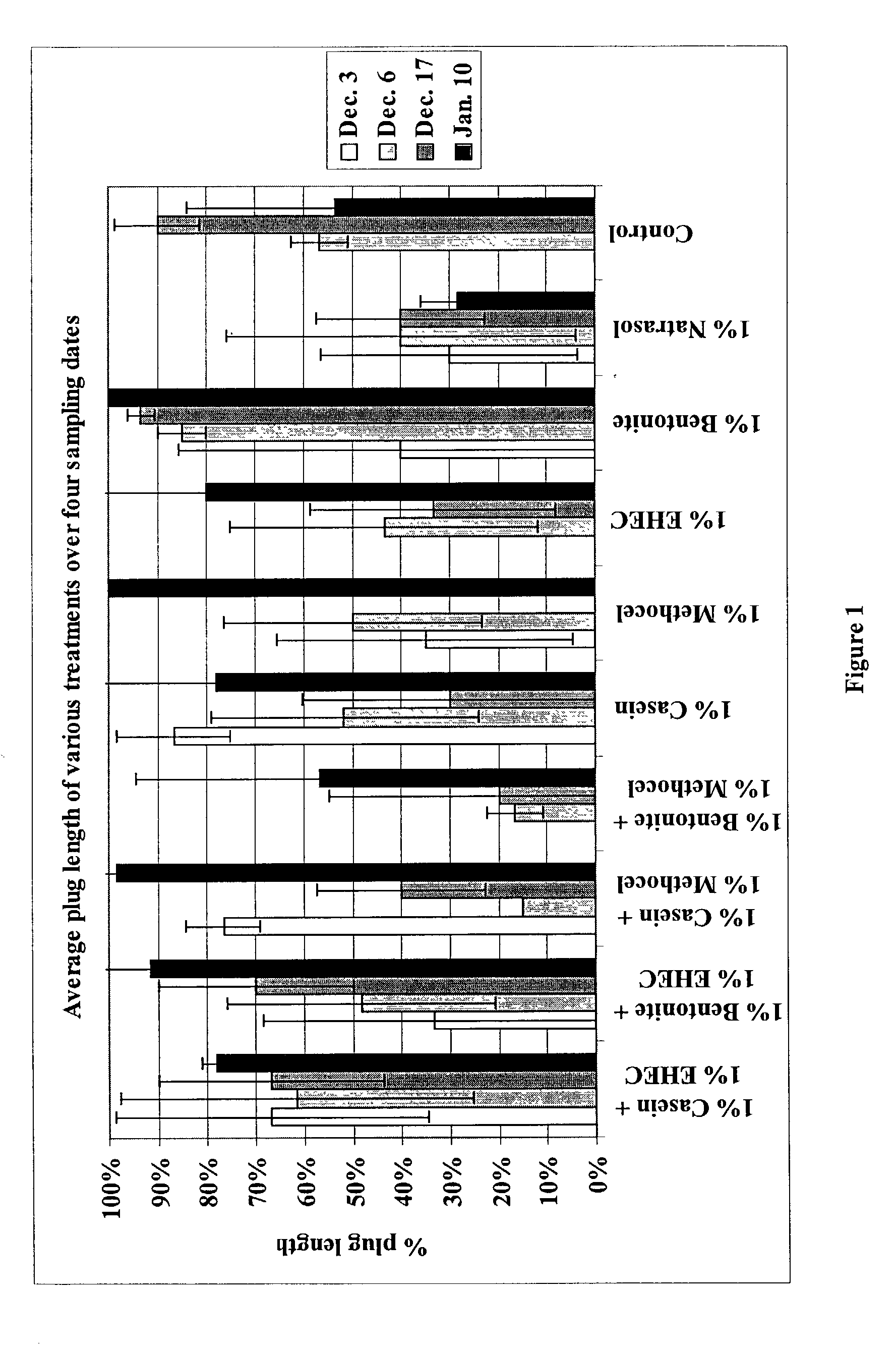

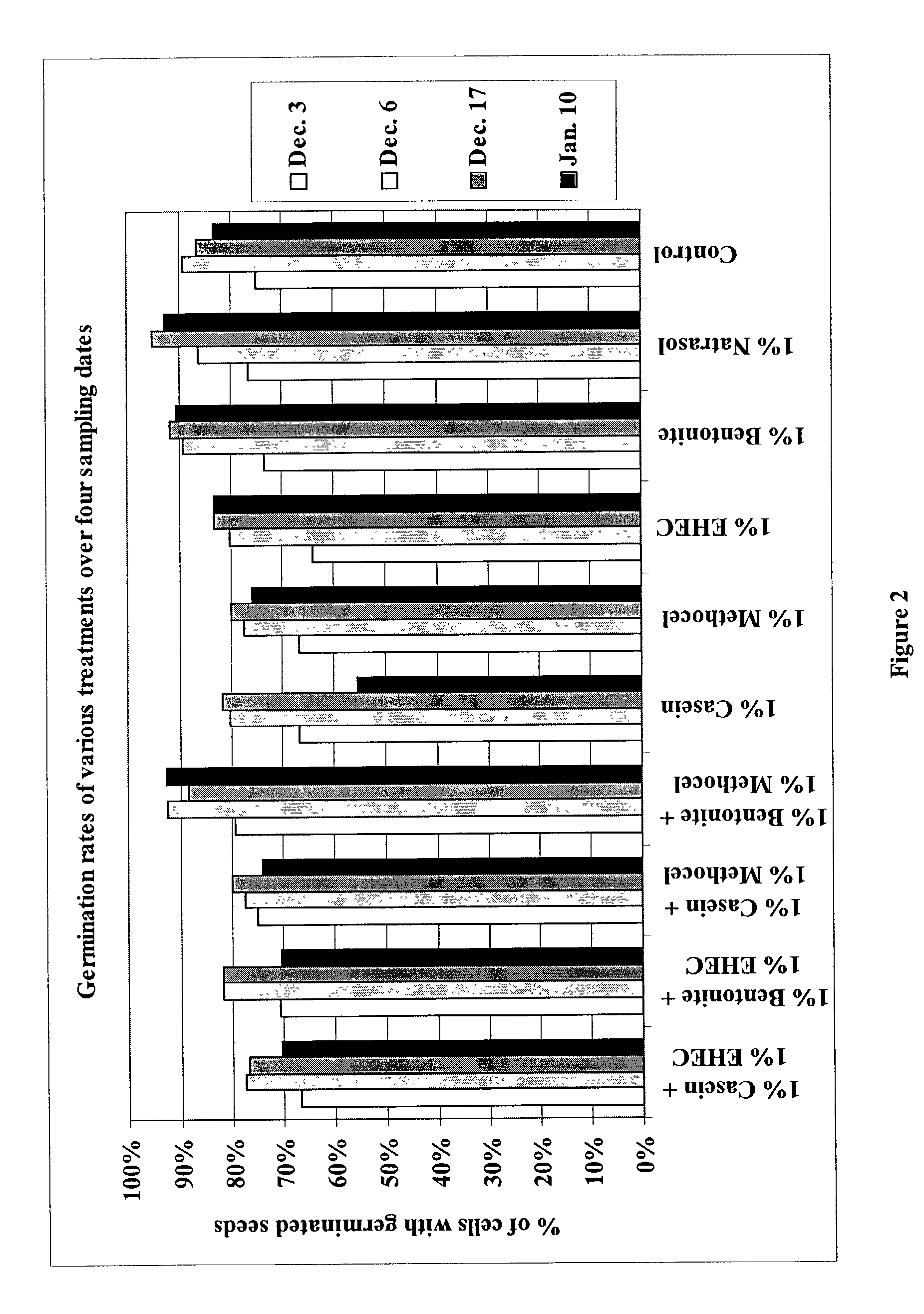

Cohesive soil plugs for use in plant production

This invention relates to novel formulations for cohesive soil plugs used in plant nurseries. More particularly, this invention pertains to novel compositions for forming soil plugs for use in plant propagation that resist disintegration when the soil plugs containing germinating seedlings are relocated from small growth containers to larger growth containers. An adhesive soil mixture comprising: (a) growing medium; and (b) a binder containing one or more of bentonite and cellulose alkyl ether.

Owner:WEST CREEK FARMS +1

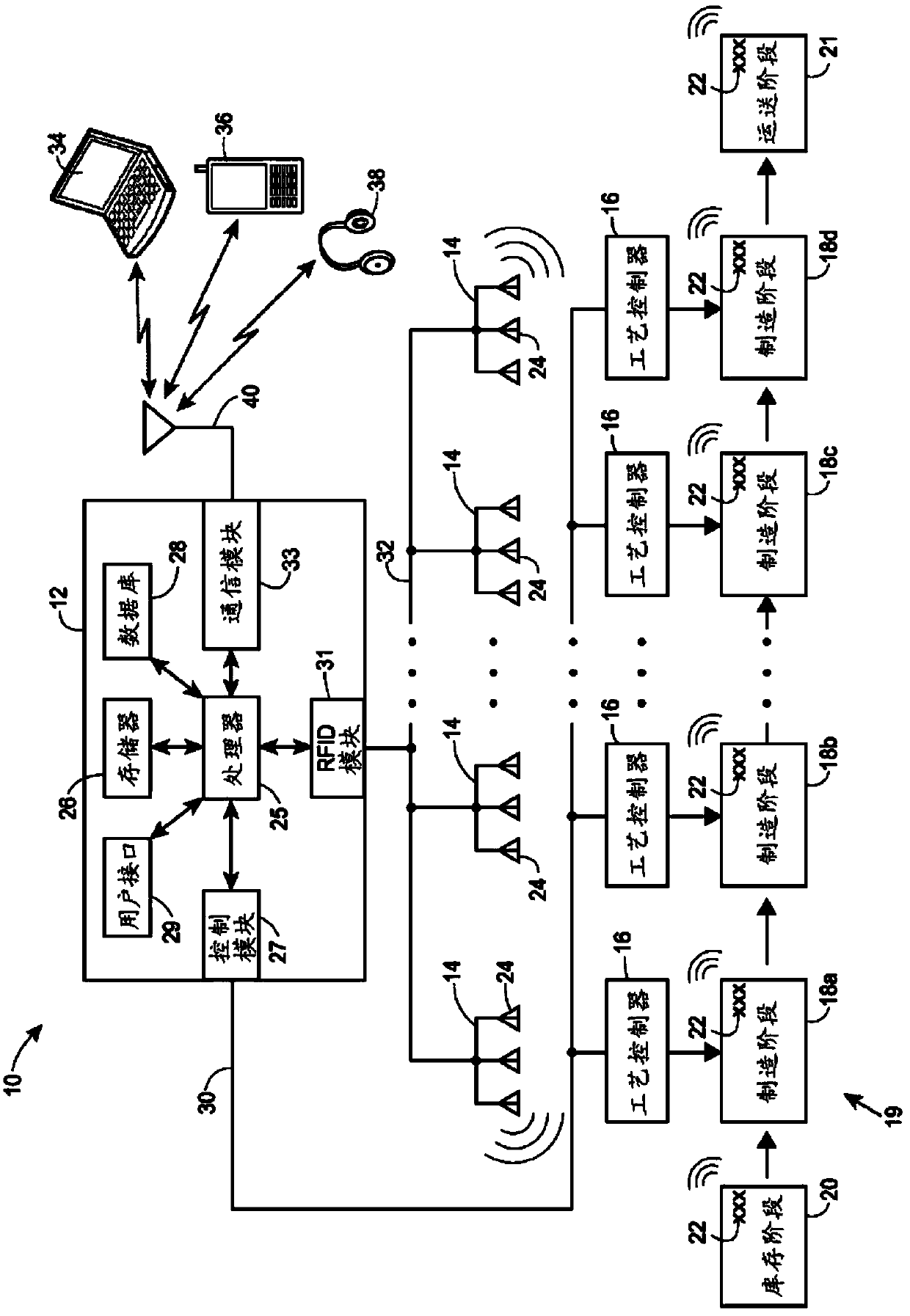

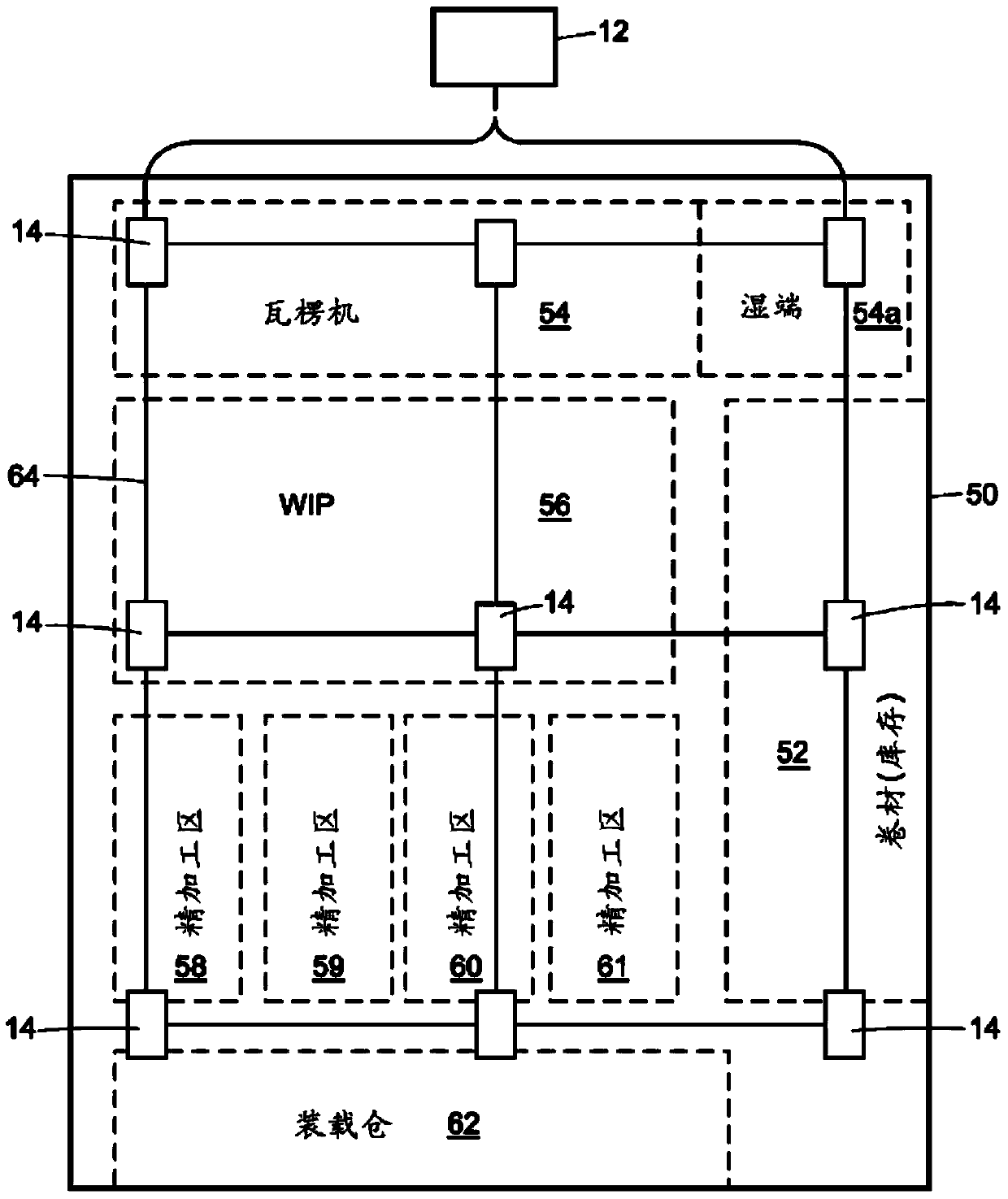

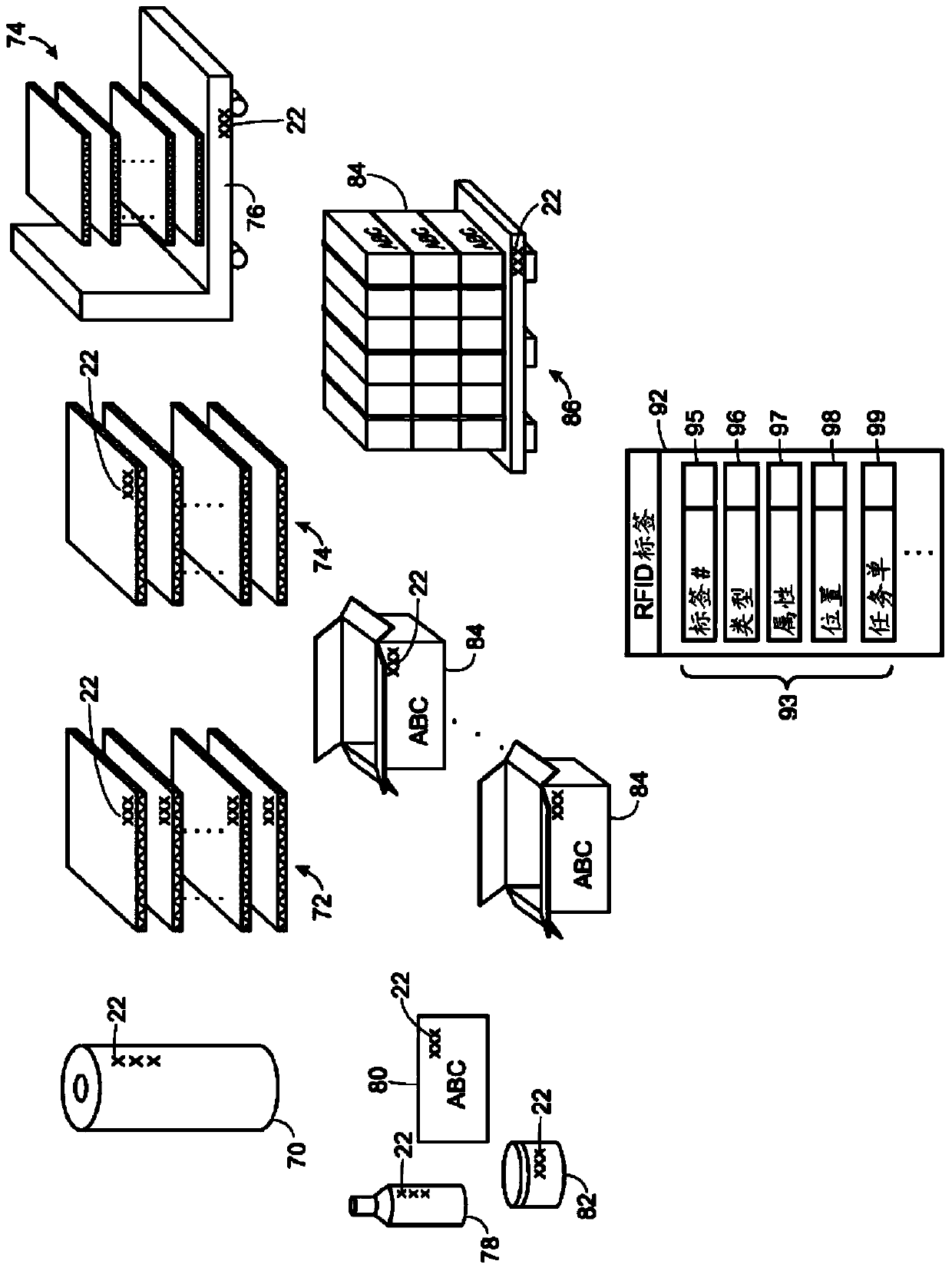

A radio frequency identification system for tracking and managing materials in a manufacturing process

InactiveCN104221035AProgramme controlCo-operative working arrangementsSystem usagePhase array antenna

A process management system uses a radio frequency identification (RFID) detection system in the form of, for example, a phased array antenna based RFID detection system to track and manage material storage and flow in a manufacturing process or plant. The process management system operates in conjunction with the various machines that implement manufacturing stages or steps of the manufacturing process to assure that the correct materials and processing procedures are used at or on the various production machines of the process to produce a particular product as defined by a job number or job order. The process management system is thereby able to increase the efficiencies of the plant and to increase the quality of the plant production by reducing or eliminating waste, manufacturing errors and shipping errors in the production facility.

Owner:A 1 PACKAGING SOLUTIONS

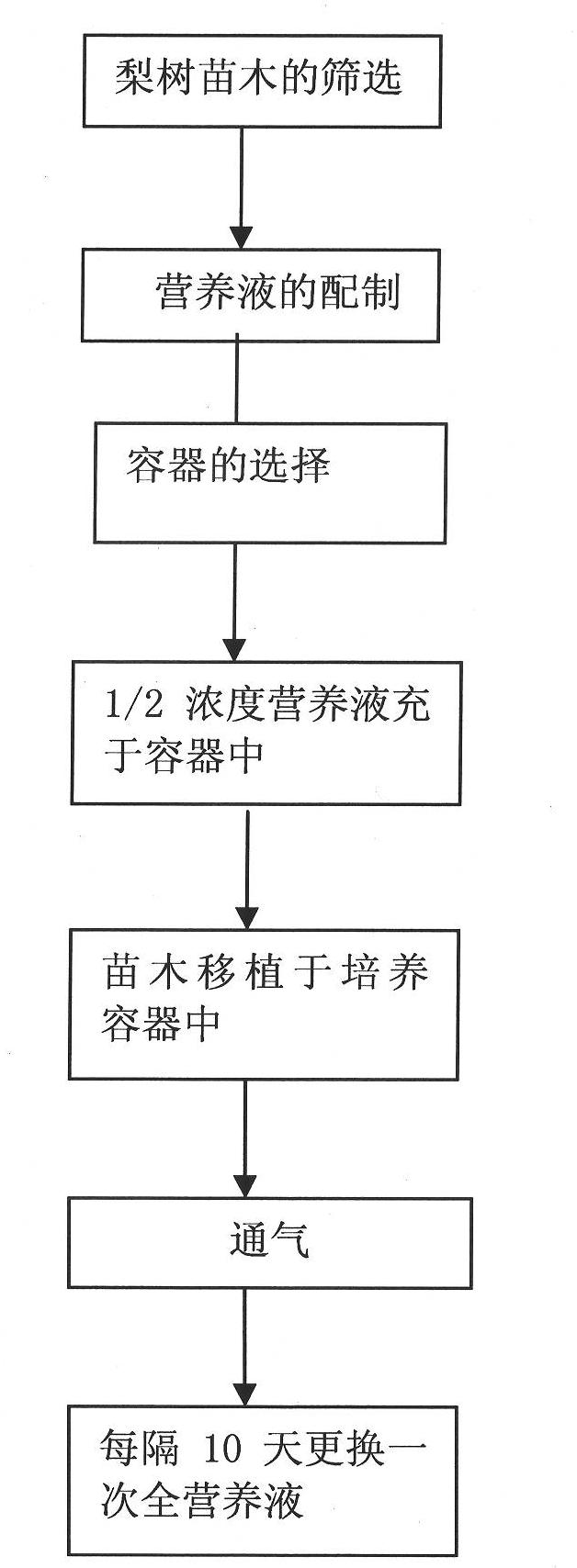

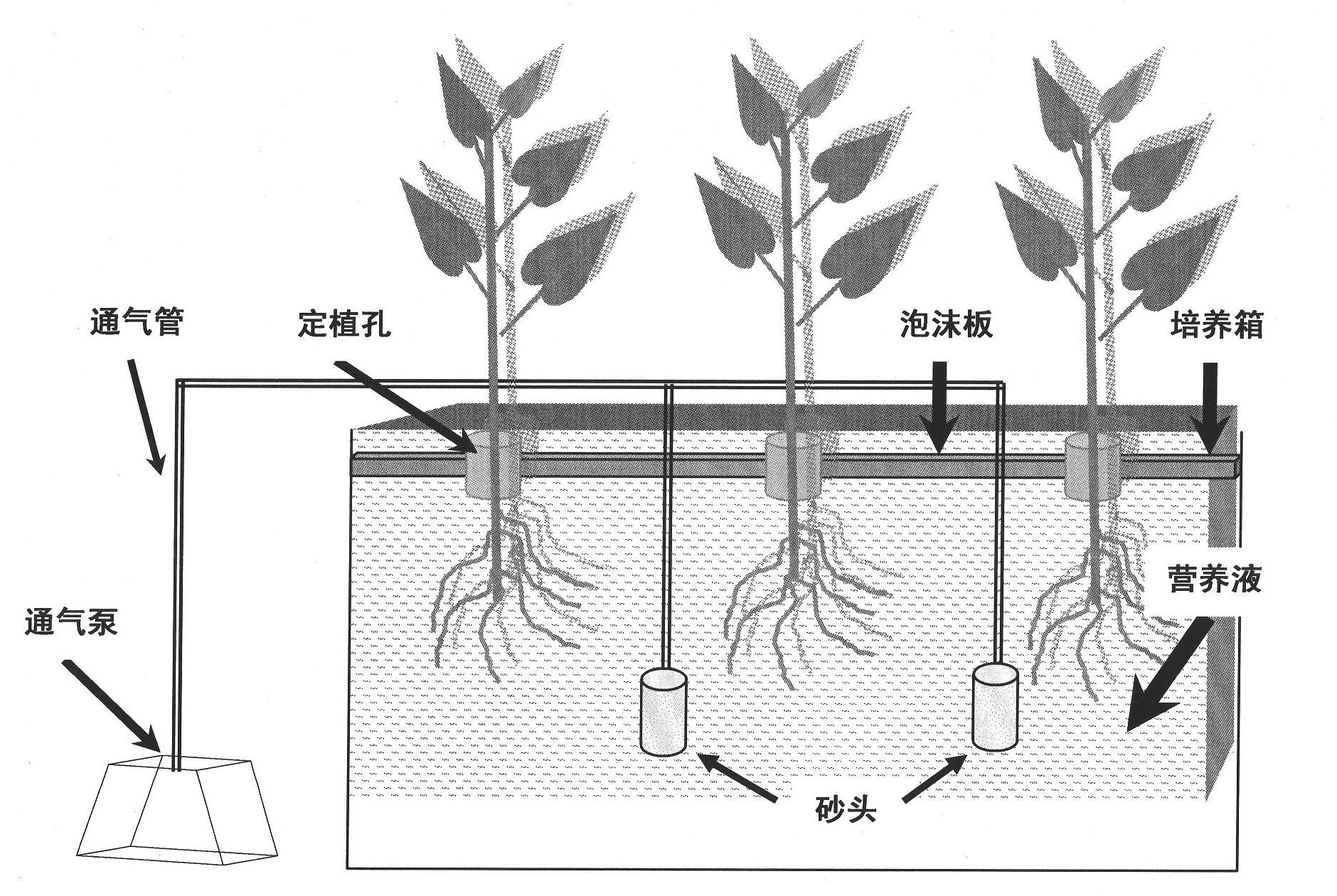

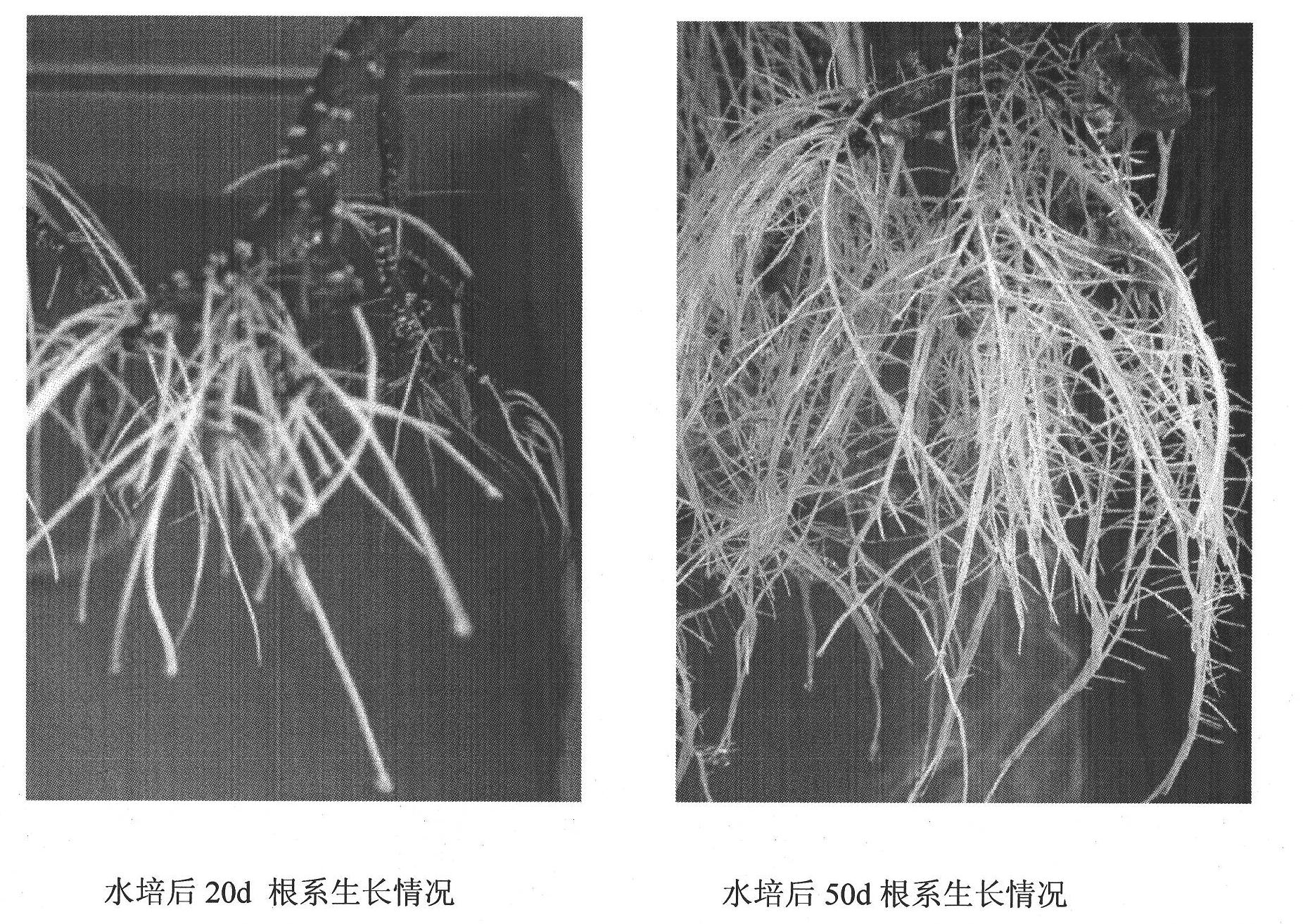

Pear tree water culturing method

InactiveCN101953290AAchieve soilless cultivationNormal growth and developmentAgriculture gas emission reductionCultivating equipmentsPear treeNutrient solution

The invention discloses a pear tree water culturing method, belonging to the technical field of plant production. The method comprises the following four steps of: (1) selecting plantlets: selecting one-year or two-year pear graftings in production which are uniform in size and growth; (2) determining the formula of a water culturing nutrient solution consisting of 6mM of KNO3, 4mM of Ca(NO3)2, 2mM of NH4H2PO4, 1mM of MgSO4, 50muM of KCl, 10muM of H3BO3, 2muM of MnSO4, 2muM of ZnSO4, 0.5muM of CuSO4, 0.065muM (NH4)6Mo7O24 and 50muM of Fe-EDTA; (3) selecting a water culturing container; and (4) ventilating and changing the nutrient solution during the culture. The pear tree subjected to soilless culture of the method has the advantages of fast root system growing speed, good growth, high survival rate, healthy tree growth, and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

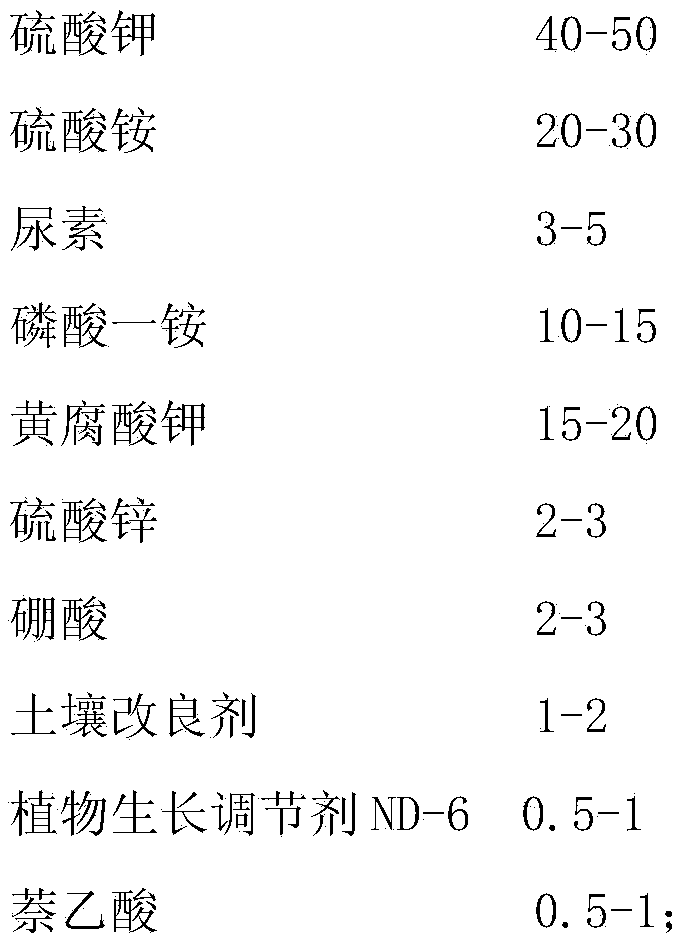

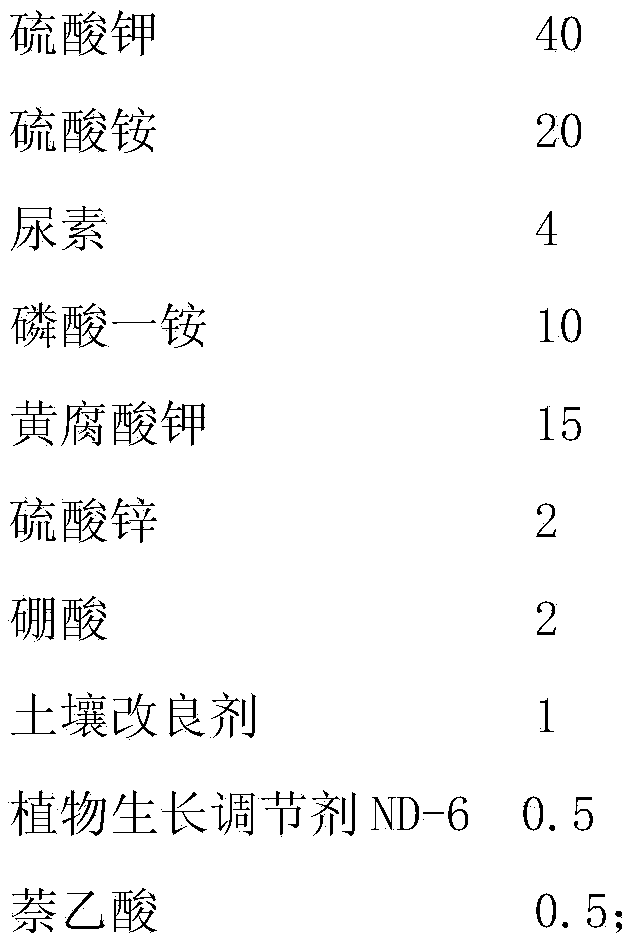

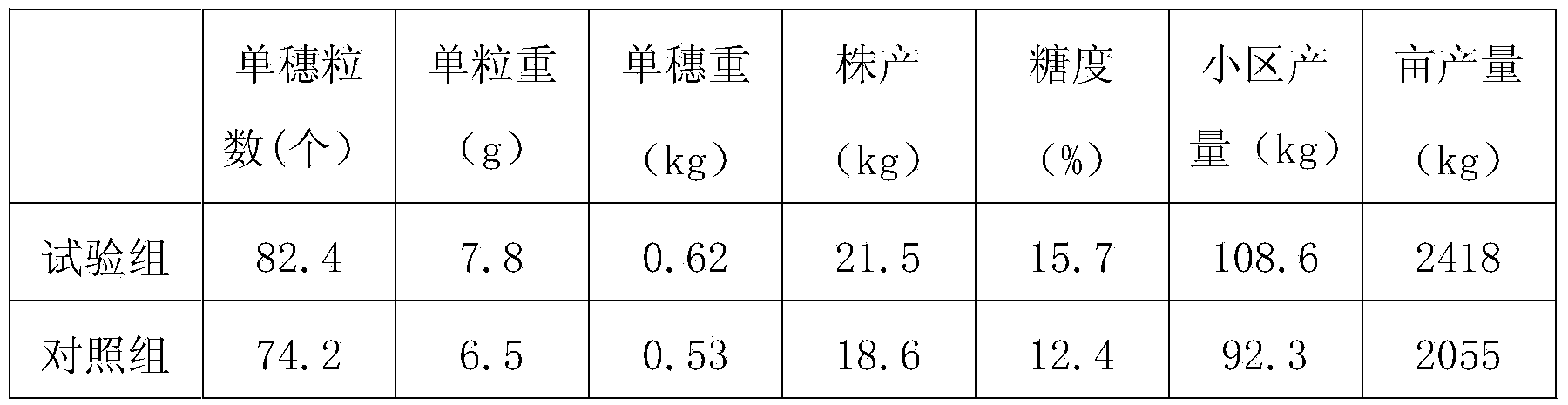

Fulvic acid macro-element water-soluble fertilizer and preparation method thereof

The invention discloses a fulvic acid macro-element water-soluble fertilizer and a preparation method thereof. The fertilizer is composed of the raw materials of, by weight: 40-50 parts of potassium sulfate, 20-30 parts of ammonium sulfate, 3-5 parts of urea, 10-15 parts of monoammonium phosphate, 15-20 parts of potassium fulvate, 2-3 parts of zinc sulfate, 2-3 parts of boric acid, 1-2 parts of a soil improving agent, 0.5-1 part of a plant growth regulator ND-6, and 0.5-1 parts of naphthylacetic acid. The fertilizer has the characteristics of full nutrition, full water solubility, no pollution, and sterilizing property. The fertilizer contains NPK macro-elements sulfur, calcium, magnesium, zinc, boron, and the like needed by plants, potassium fulvate with a chealation effect, and the plant growth regulator. The fertilizer has the advantages of fast absorption, high efficiency, high quality, water saving, and significant yield increase. With the fertilizer, growth and reproduction of harmful microbes such as soil nematode can be inhibited, soil-source pest and disease can be reduced, and crop disease resistance can be improved.

Owner:安徽沃福农业生物科技股份有限公司

Biocides

The present invention relates to the use of biocide (e.g., bactericidal enzyme) to target pathogens. In particular, the present invention provides biocides for use in health care (e.g., human and veterinary), agriculture (e.g., animal and plant production), and food processing (e.g., water purification).

Owner:IOGENETICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com