Closed type fully using artificial light environment controlled plant factory

An artificial light, airtight technology, applied in the fields of botanical equipment and methods, greenhouse cultivation, agricultural machinery and equipment, etc., can solve the problems of high energy consumption, limited technological development, high cost, etc., to improve the utilization efficiency and increase the unit area. Yield, the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings, but are not used to limit the protection scope of the present invention.

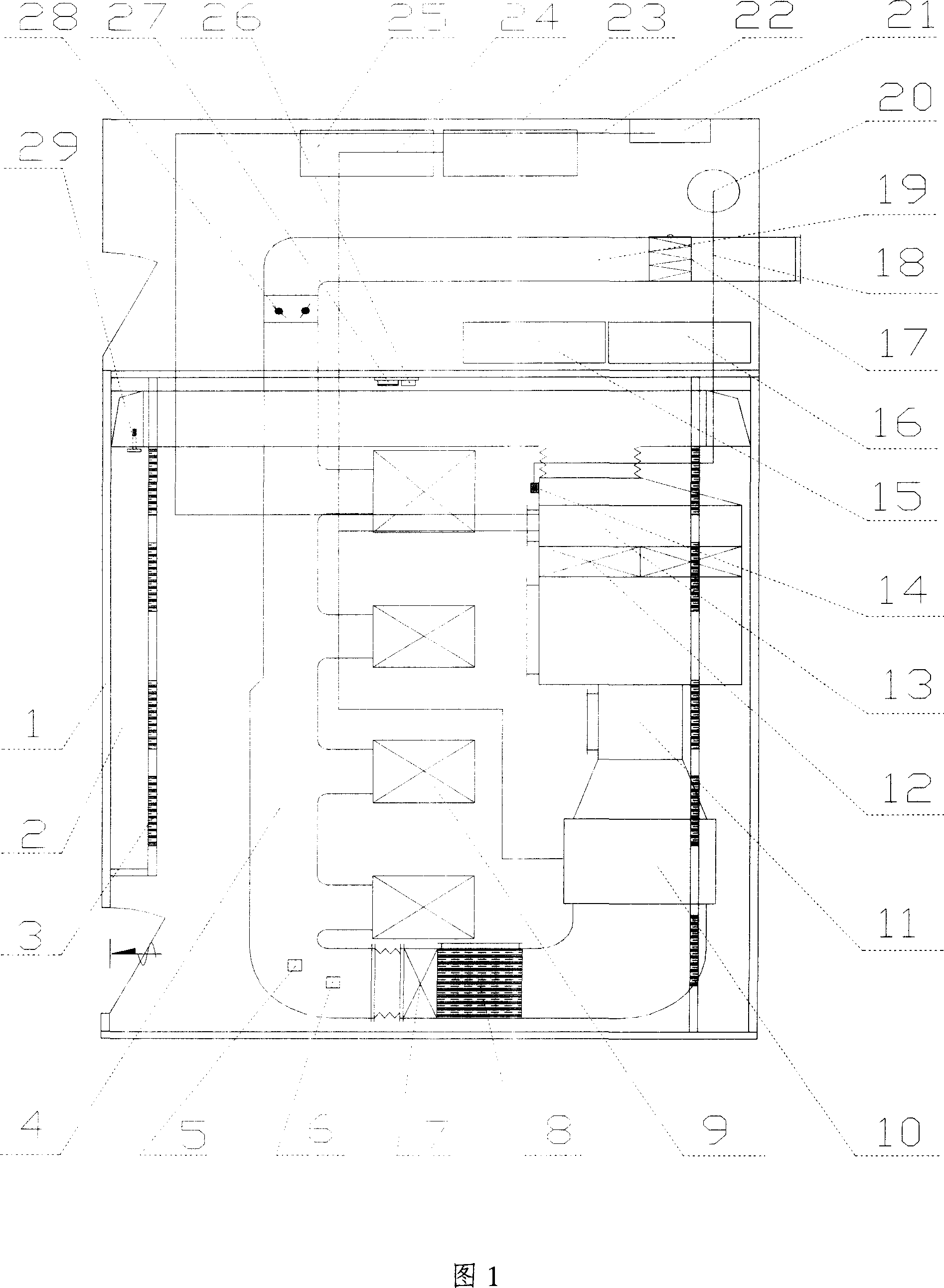

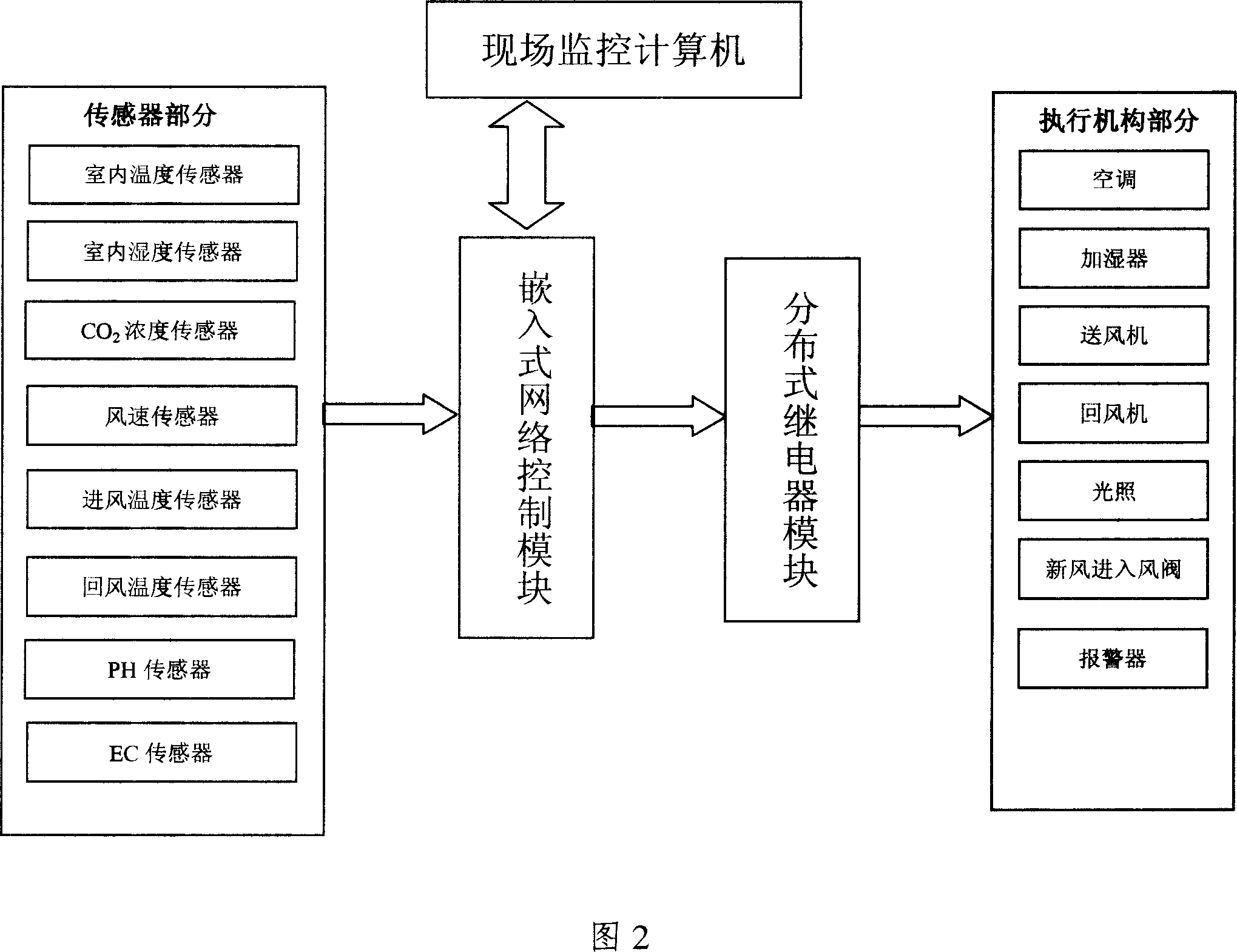

[0035] As shown in Figure 1, in this embodiment, the maintenance structure 1 is made of heat-insulating color steel plates, which provides a sealed, heat-insulated, and light-proof physical building structure for the system. The air circulation system used is a positive pressure self-circulation system, and the ventilation pipe 4 is used to connect the equipment to form a closed circulation channel. The indoor air passes through the primary filter at the return air inlet 9 and is extracted by the return air fan 8. After the temperature adjustment process of the air conditioner 10, it is sent to the high efficiency filter 12 by the blower 11 for filtering, and then passes through the humidifier 13 and CO 2 Air supply pipe 18 regulates relative humidity and CO 2 After the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com