A radio frequency identification system for tracking and managing materials in a manufacturing process

A technology for tracking systems and manufacturing processes, applied in the direction of general control systems, control/regulation systems, record carriers used by machines, etc., can solve the problem of not controlling the flow of processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

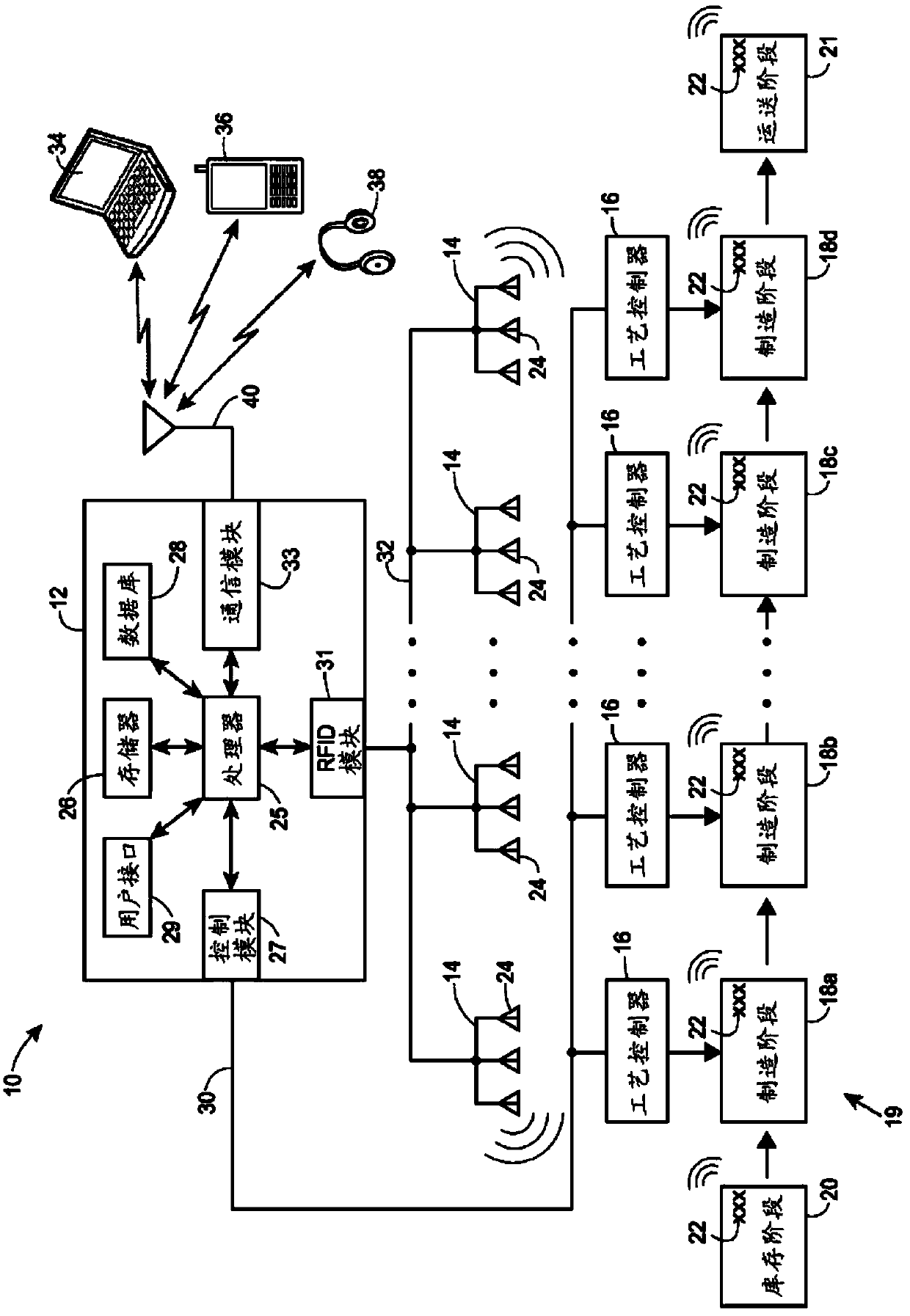

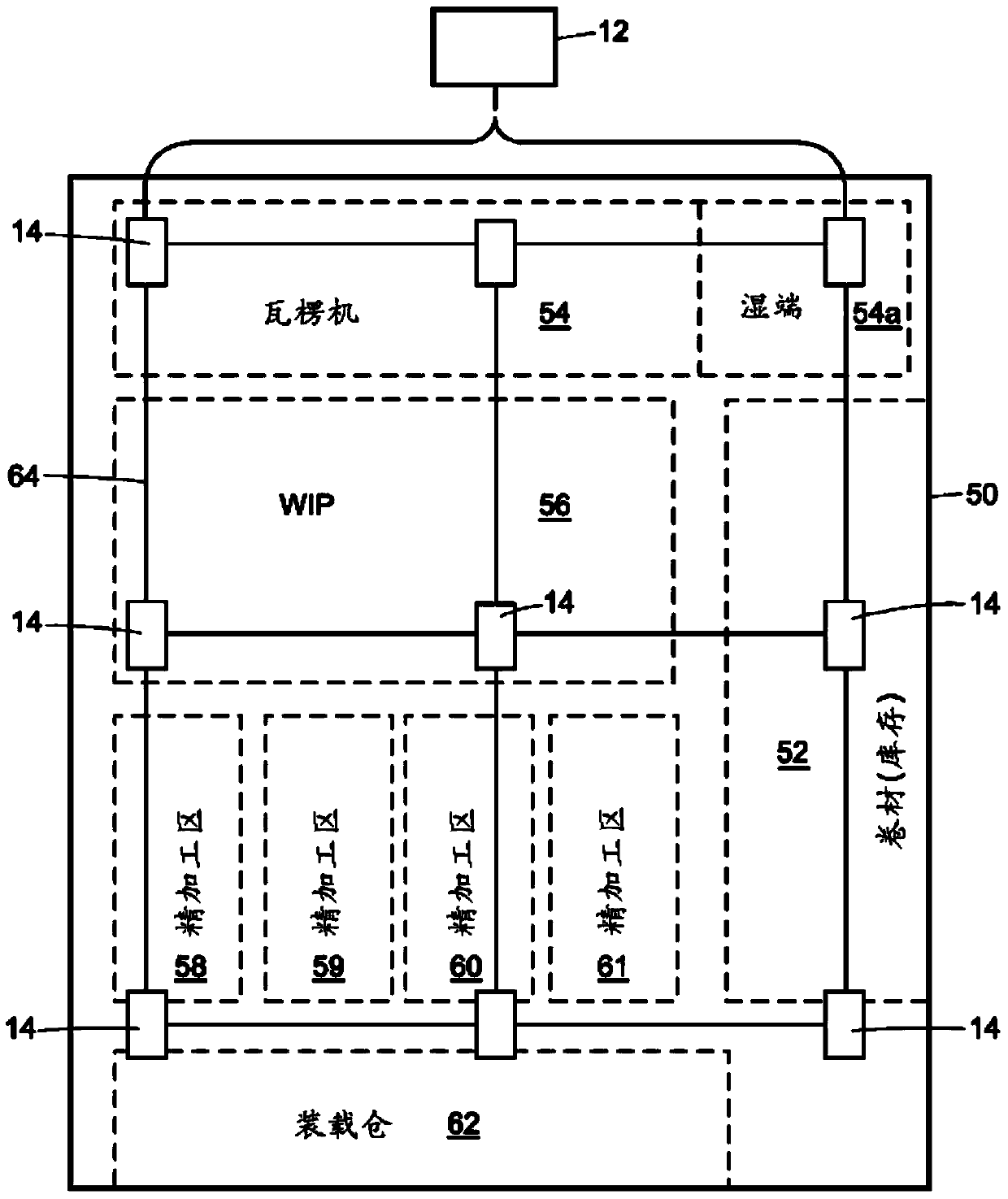

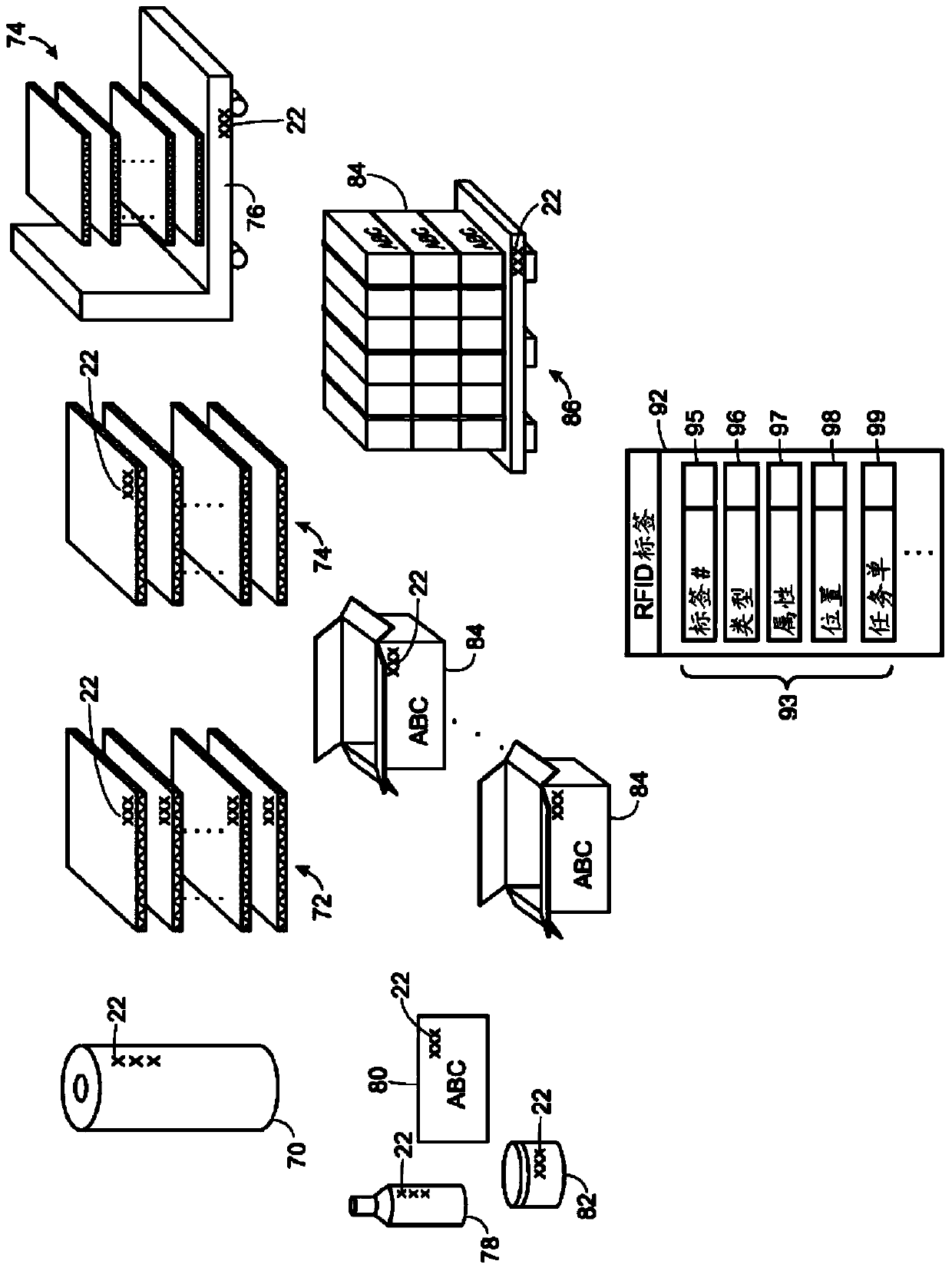

[0046] Inventory and process management or tracking systems use RFID technology to track and control the flow of inputs and outputs in a manufacturing process by using a single steerable antenna or a network of steerable antennas such as a beam steerable phased array antenna or other beam steerable antenna) to provide real-time, three-dimensional position detection and tracking of RFID-tagged materials and items used in inventory or manufacturing processes. The system uses the detected location and movement of RFID-tagged materials and items to perform various steps in managing the flow or use of materials within a process to increase the productivity of a process including inventory management, improve the production accuracy of a process, or Production quality and minimizing labor costs and other costs associated with manual operating errors within a plant or process.

[0047] More specifically, the process management system performs inventory management by using a 3D RFID d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com