Patents

Literature

42results about How to "Heavy quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

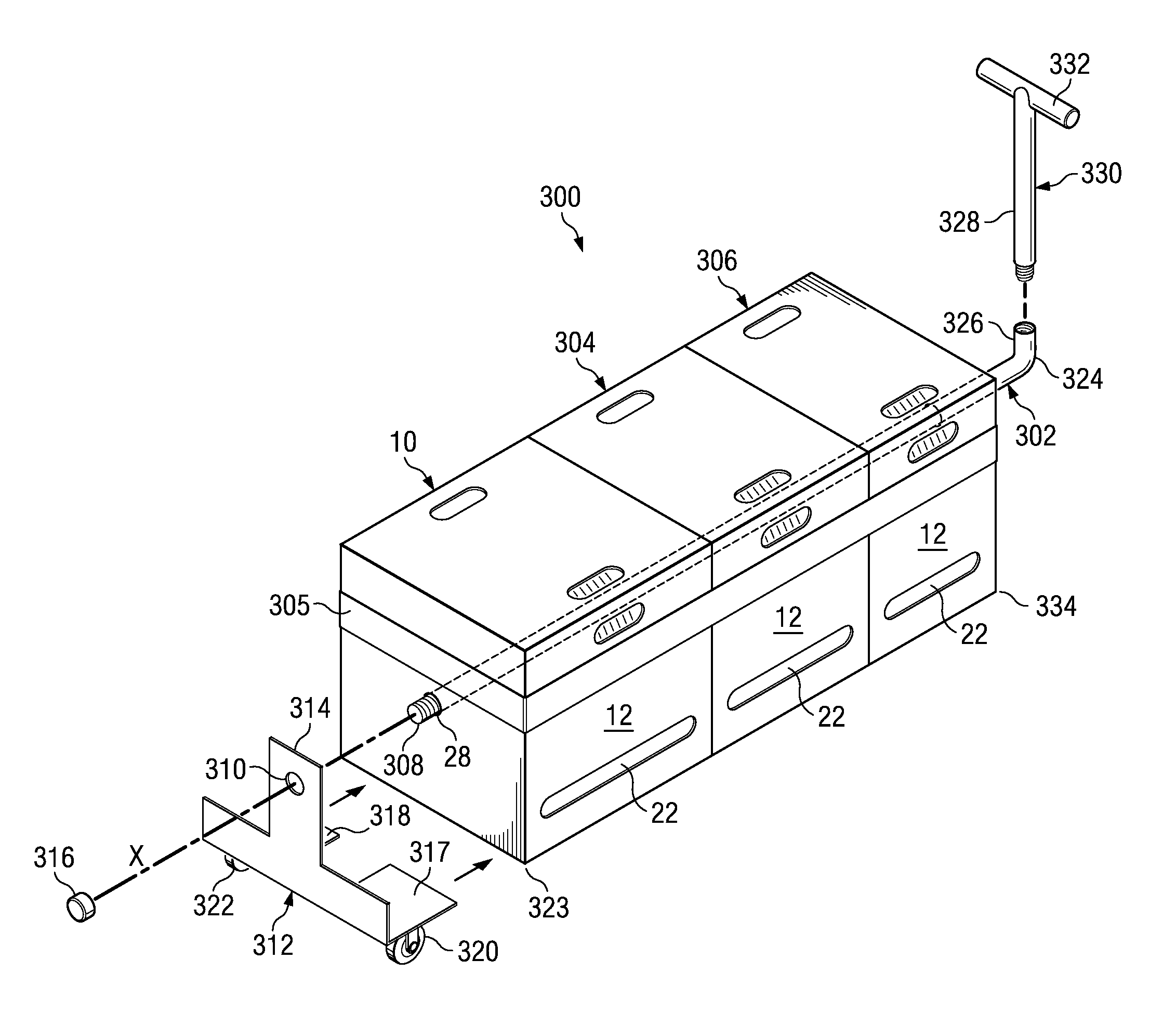

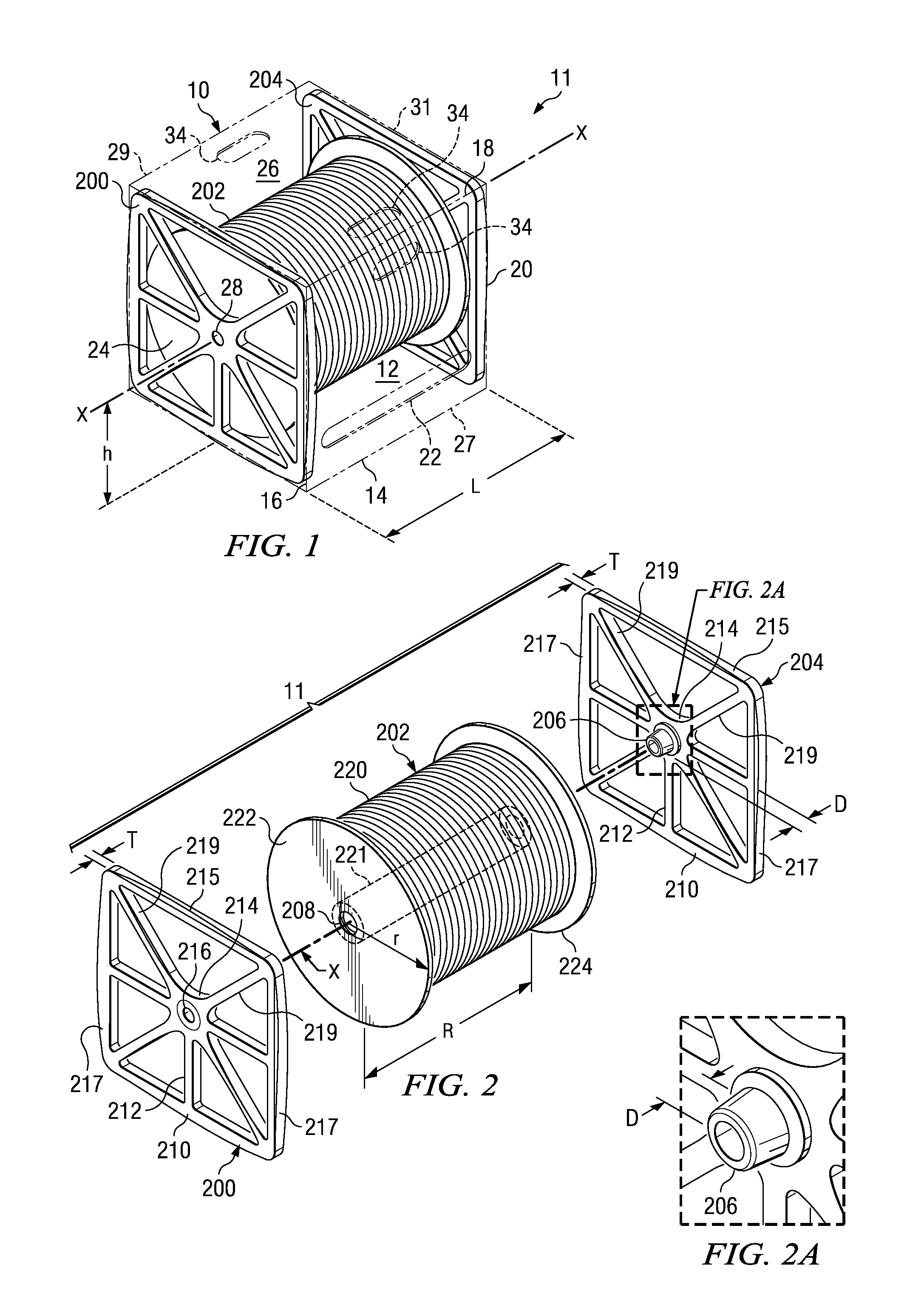

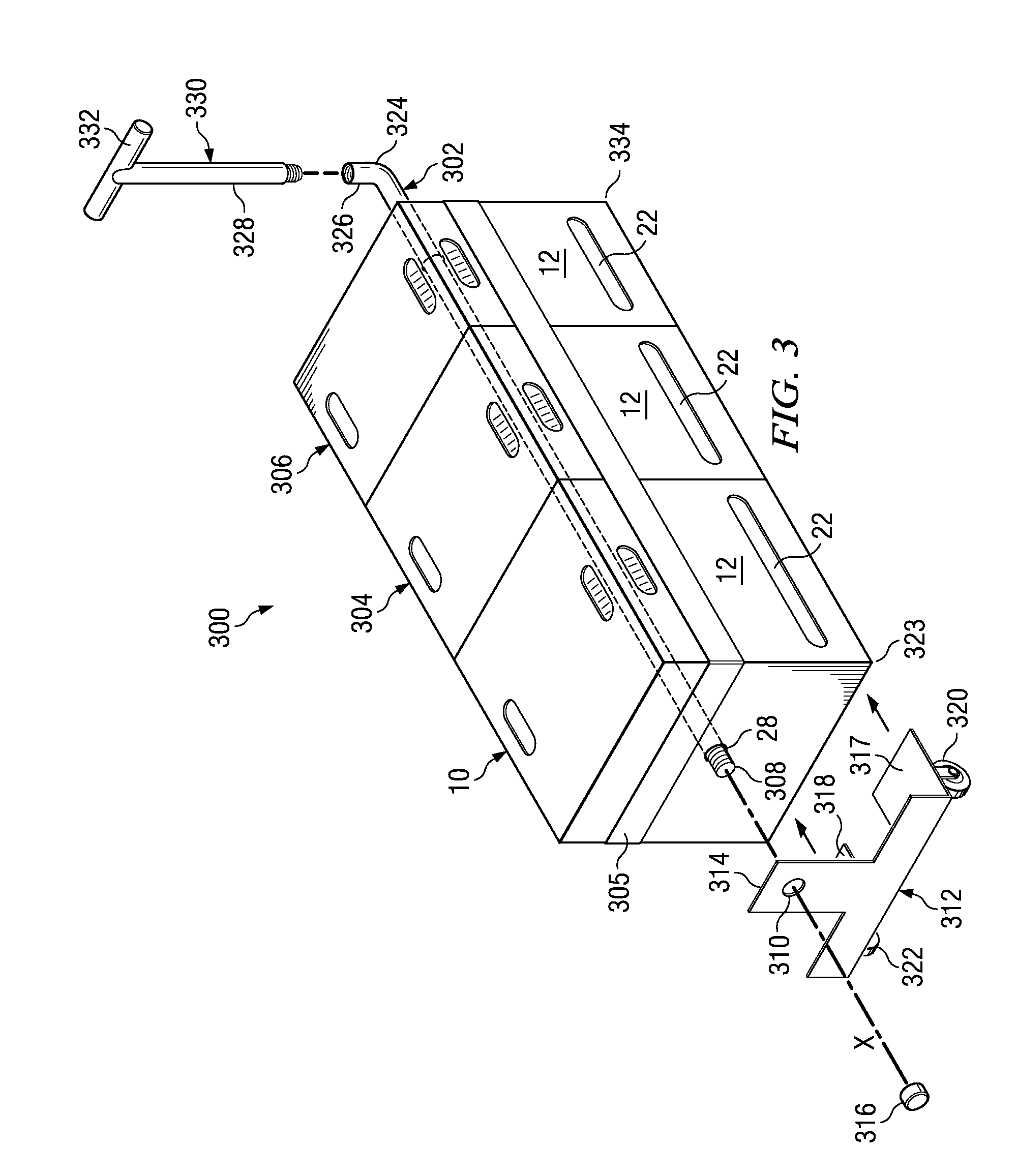

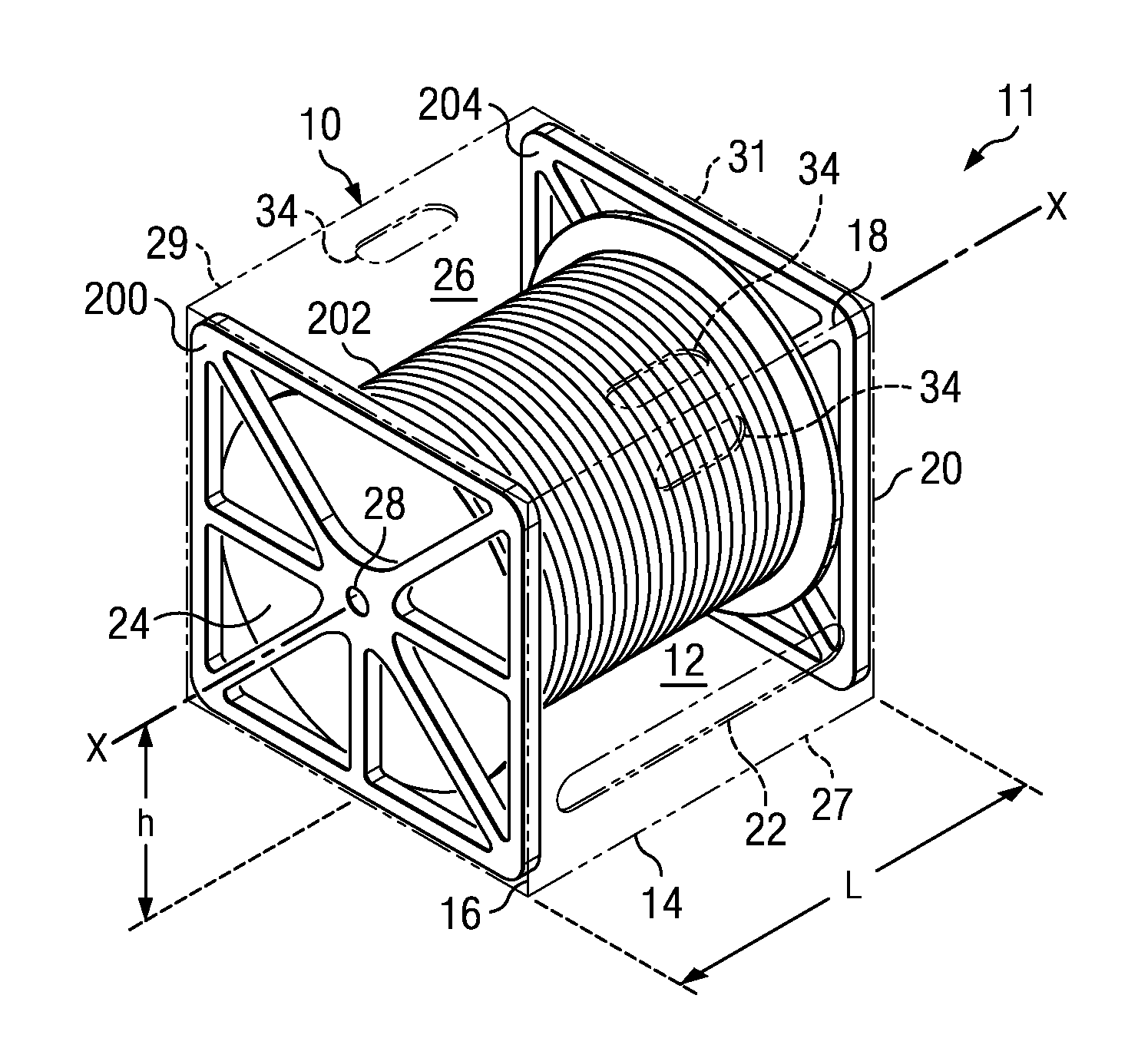

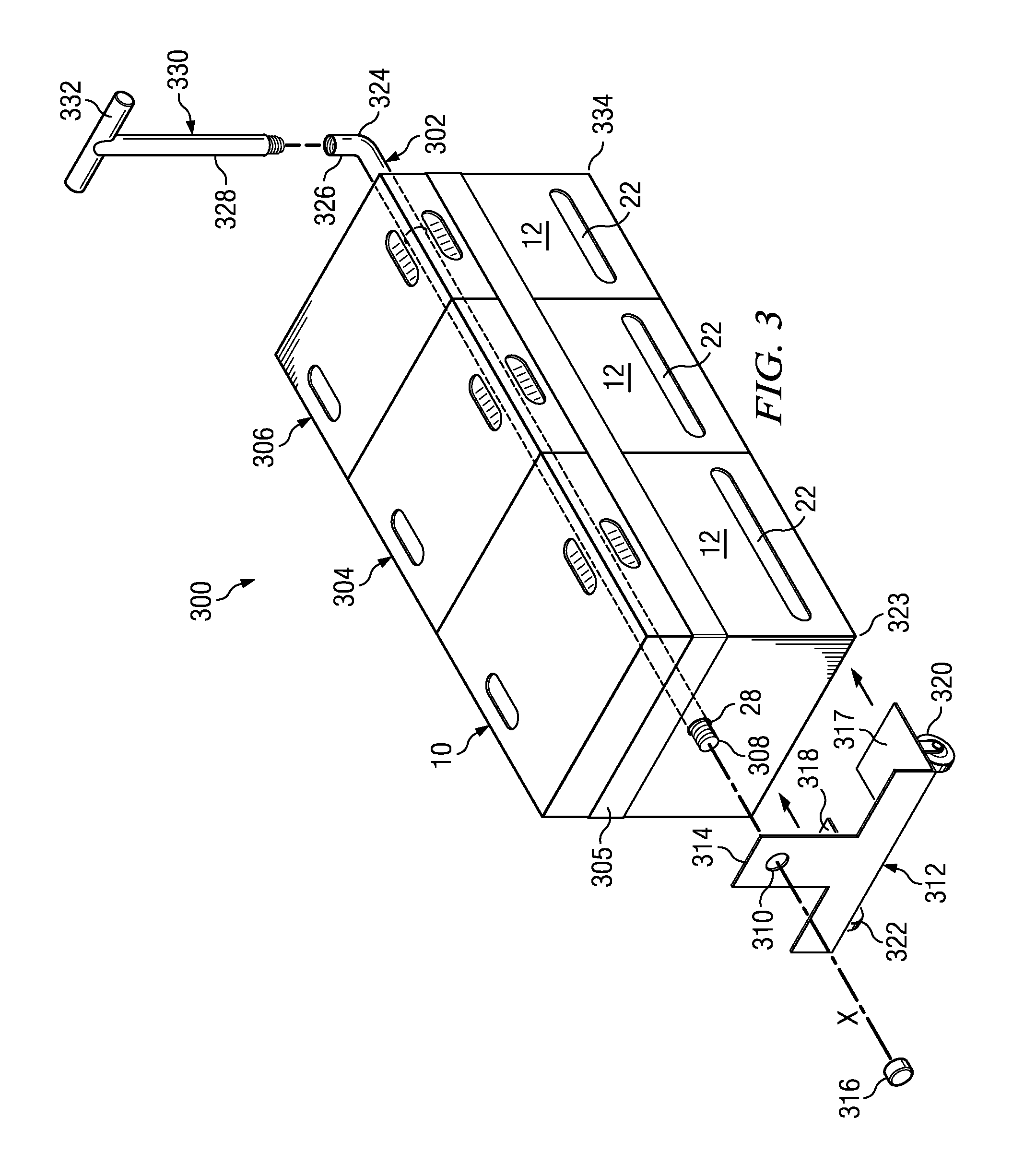

Wire and cable dispensing container and systems

ActiveUS20080191436A1Easy withdrawalHeavy qualityContainers for annular articlesCarriage/perambulator with multiple axesFree rotationCarton

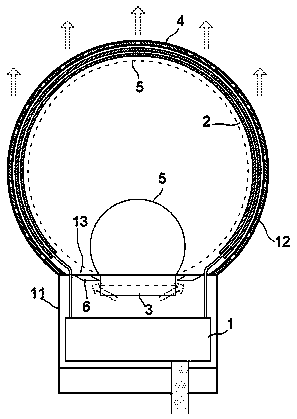

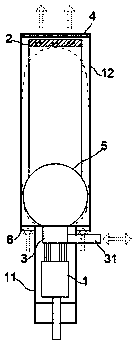

A container for the dispensing of wire or cable has an external carton which receives a reel of cable as supported by two caddies. Each caddy has an inwardly extending substantially cylindrical bushing which is received in a central hole of a respective cable reel flange. The cylindrical bushings are disposed on an axis which is a first distance from the upper surface of the bottom panel of the carton. The largest radius of each reel flange is preselected to be smaller than this such that the reel may freely rotate inside of the carton on the bushings. Cable is pulled through a slot in the carton's front panel. Preferably, left and right panels of the carton each have an arbor hole formed therein which receives an axial rod, the rod also extending through the reel and caddies. The axial rod may be used to join two or more containers together and may further serve as a support for attachment of a wheel truck on one end of the joined-together containers and a handle at its other end. An alternative, four-wheeled cart has multiple axial rods. An alternative hand truck likewise receives multiple axial rods through respective container passageways. In one embodiment, cable may be pulled through one or more pass-through slots formed in the tops and bottoms of stacked containers, such that cable from multiple containers is drawn through one slot on the top of the stack.

Owner:WINDY CITY WIRE CABLE & TECH PRODS

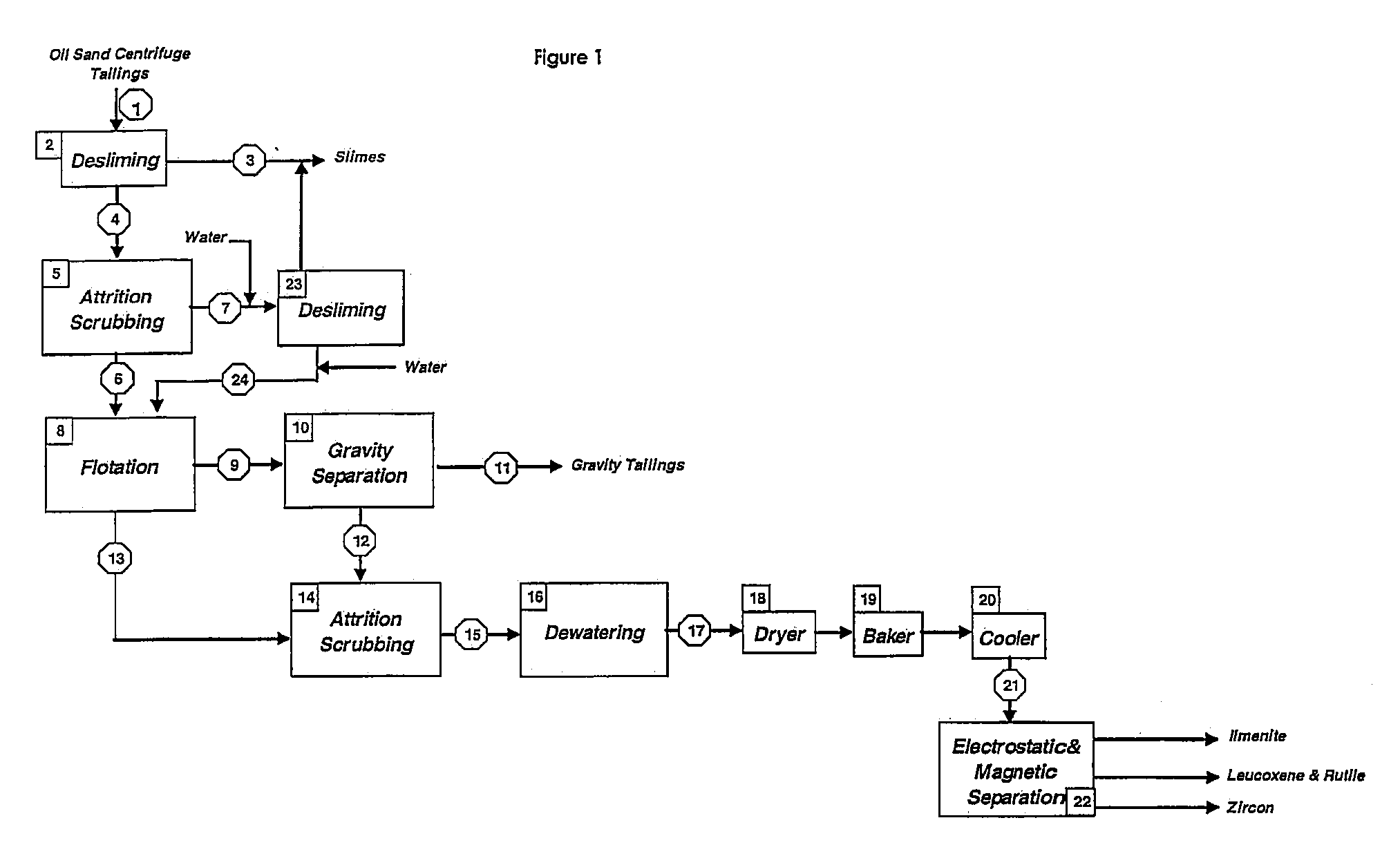

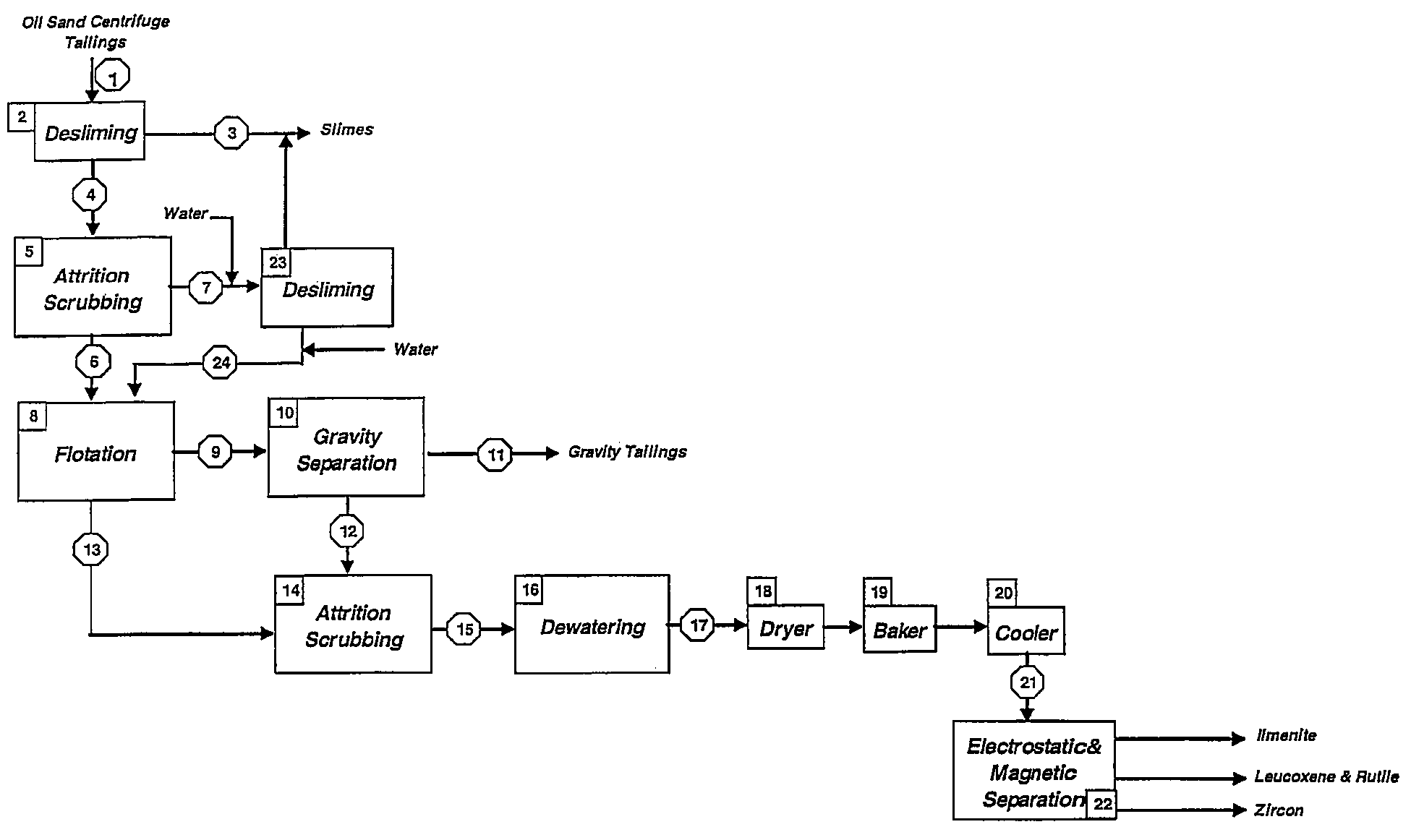

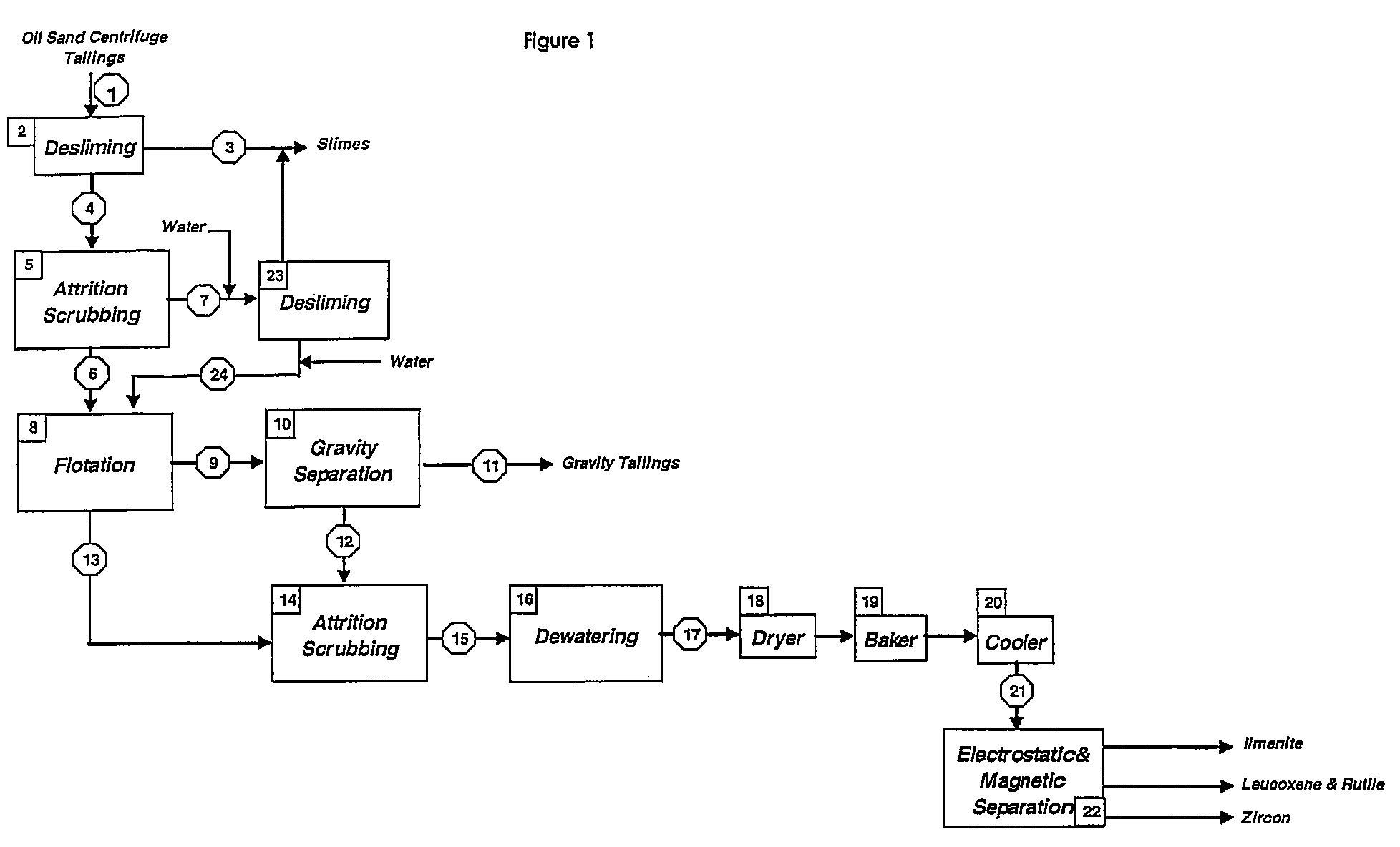

Process for recovering heavy minerals from oil sand tailings

ActiveUS20070272596A1Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

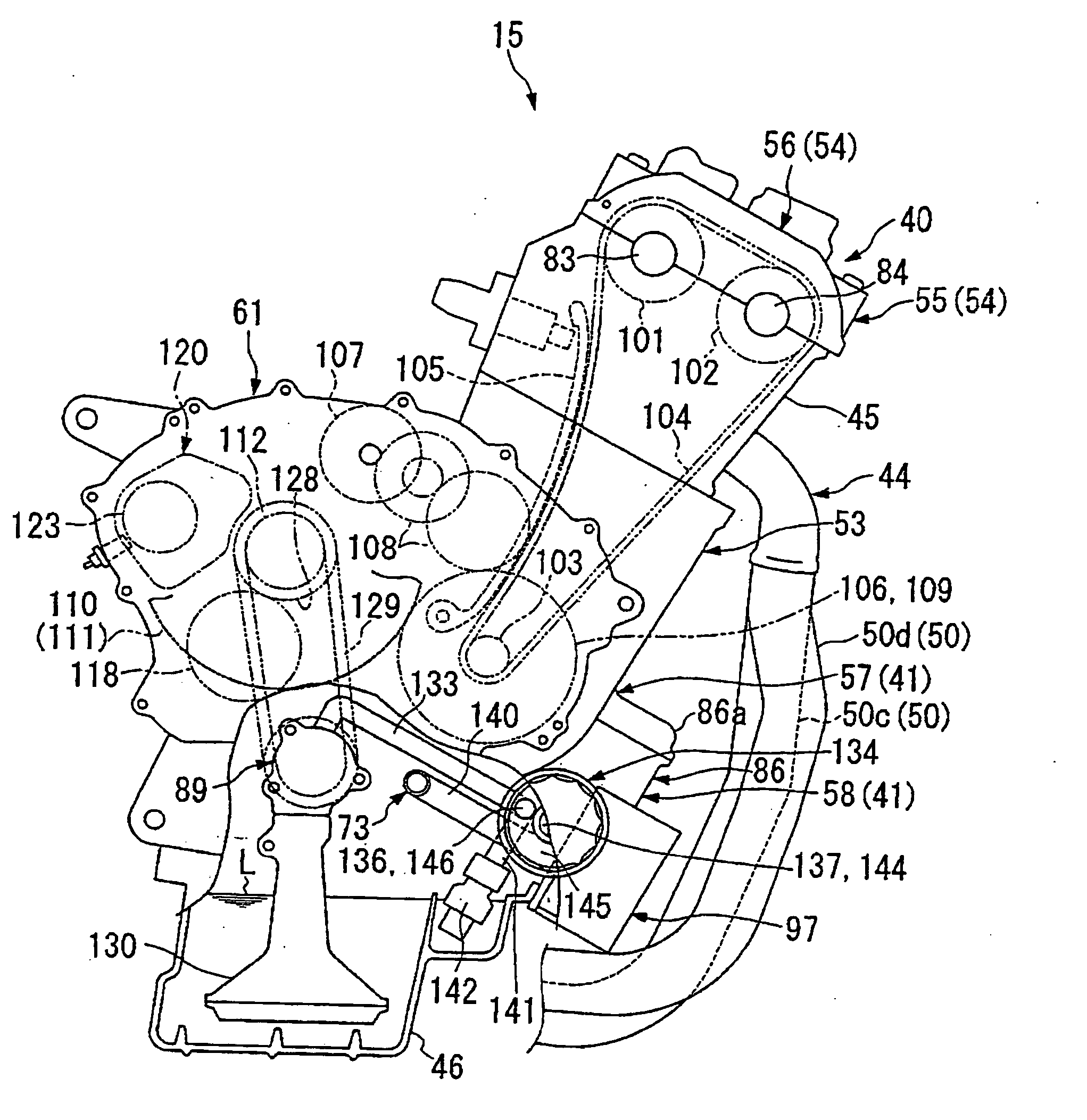

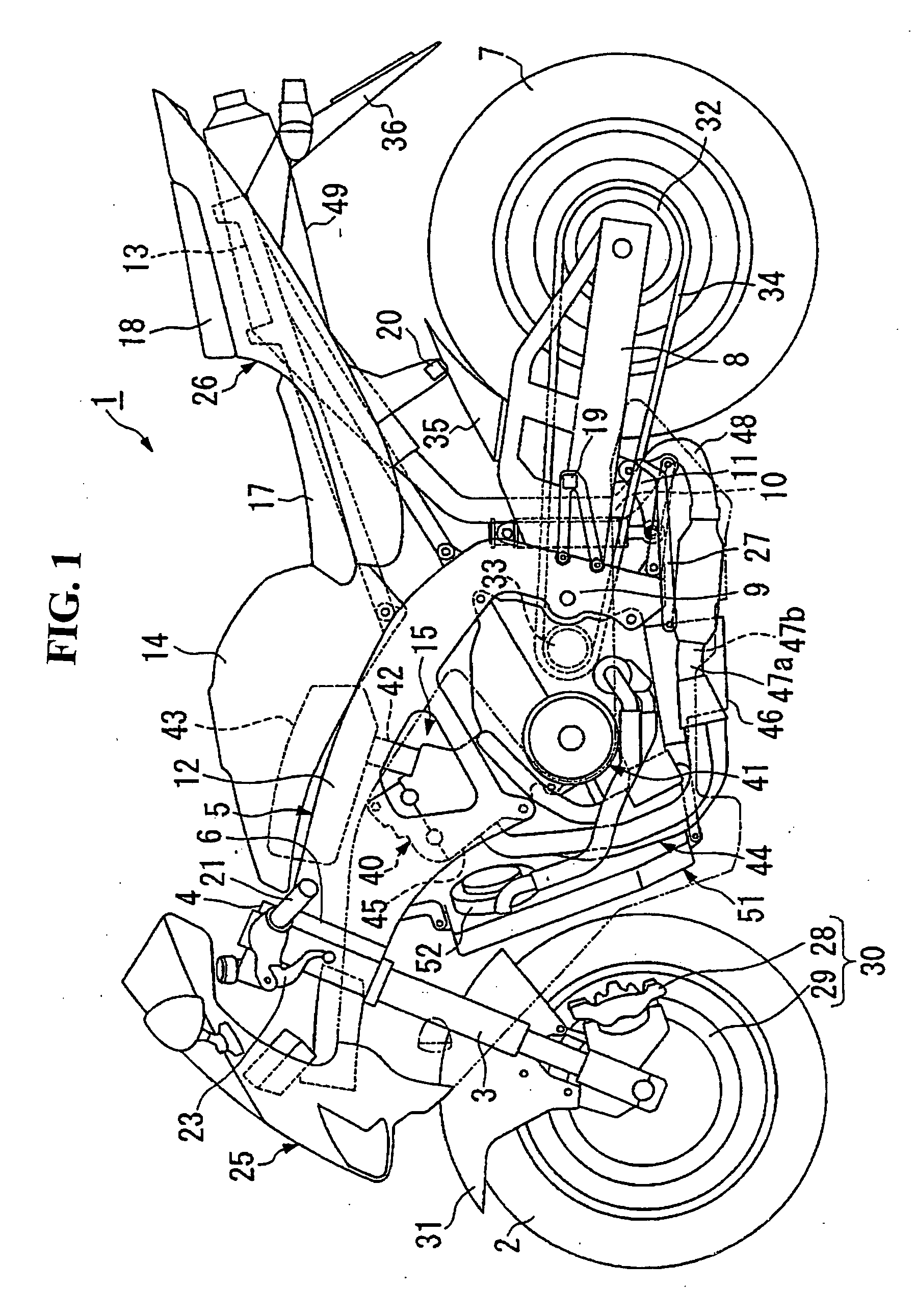

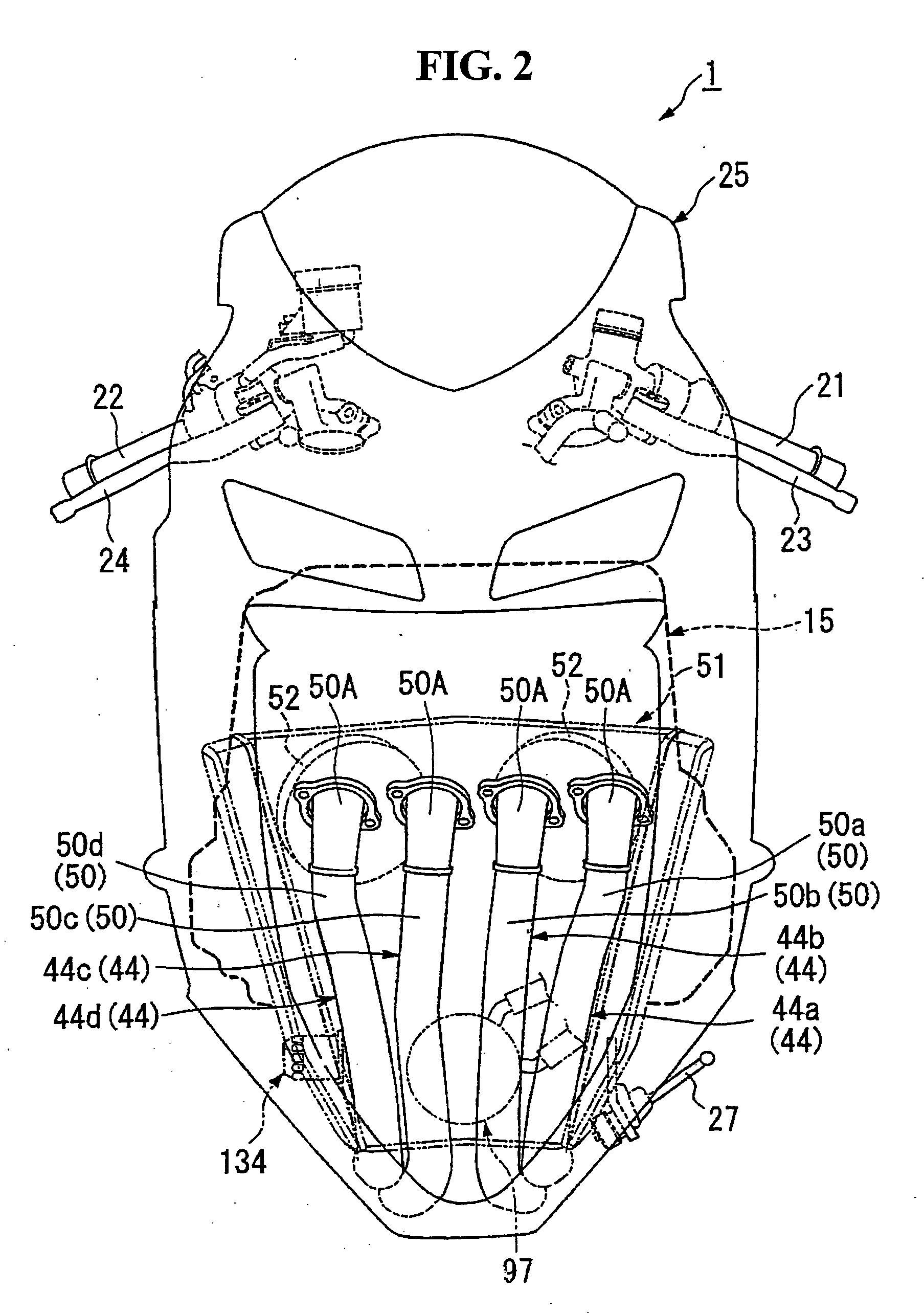

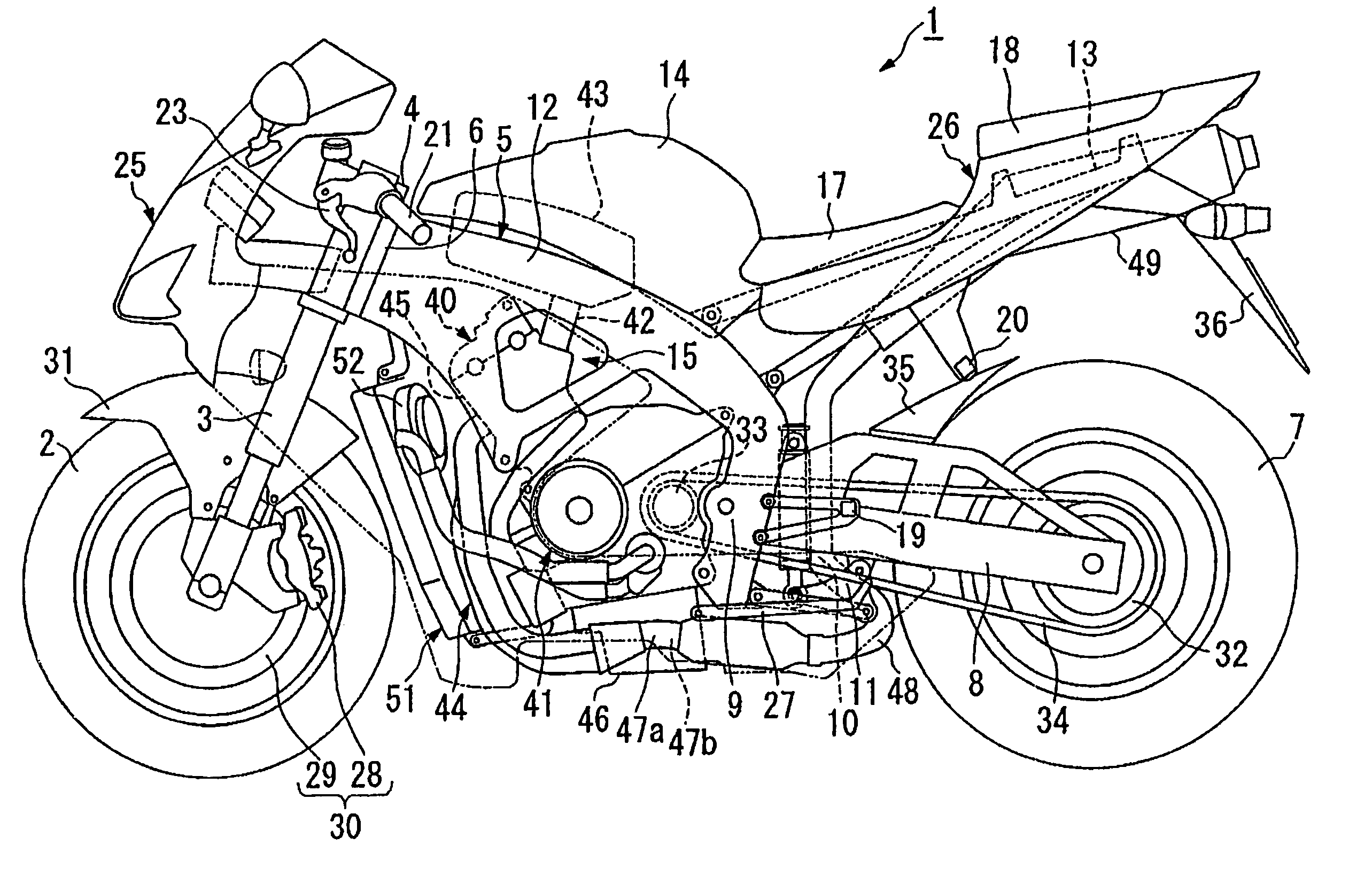

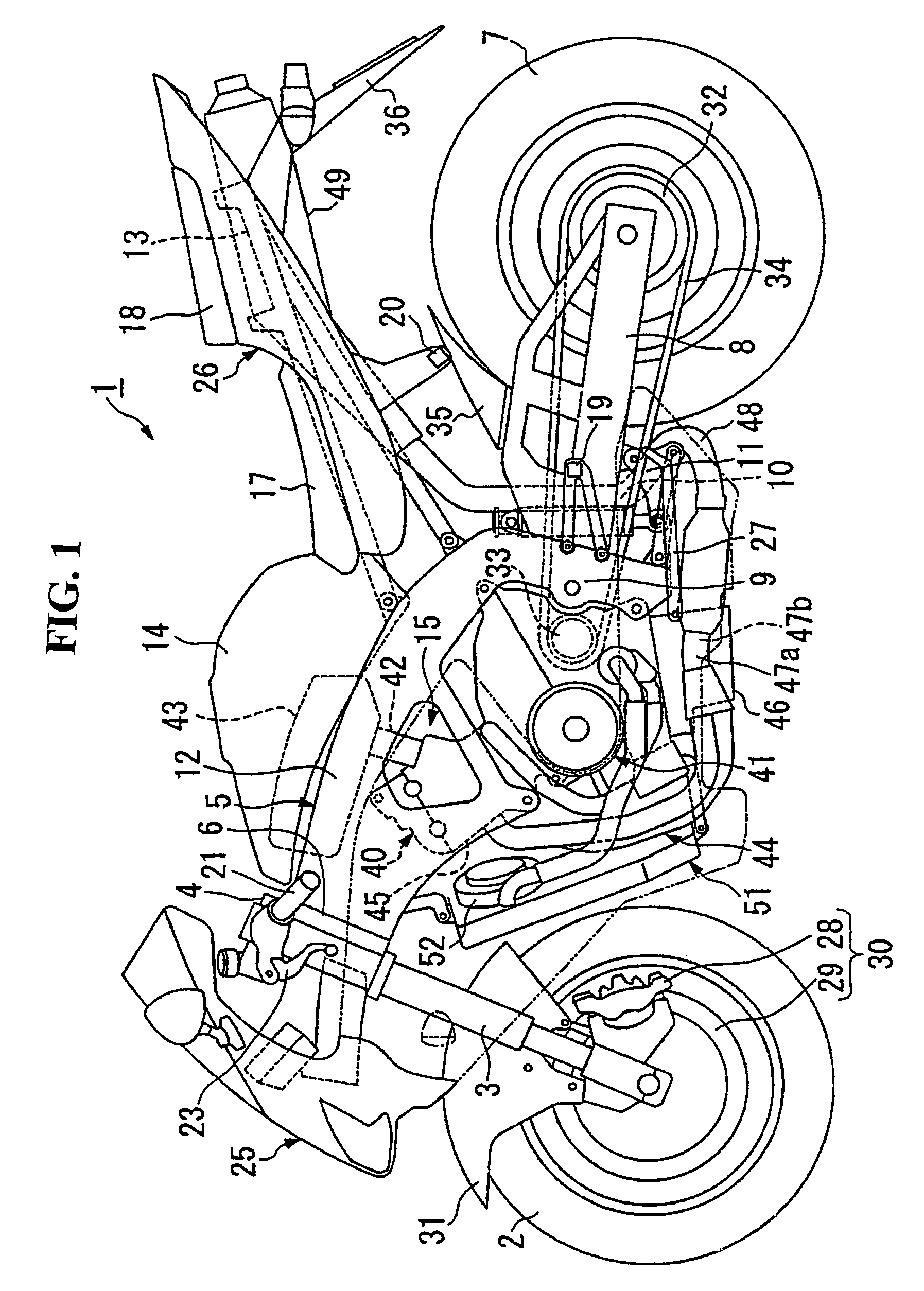

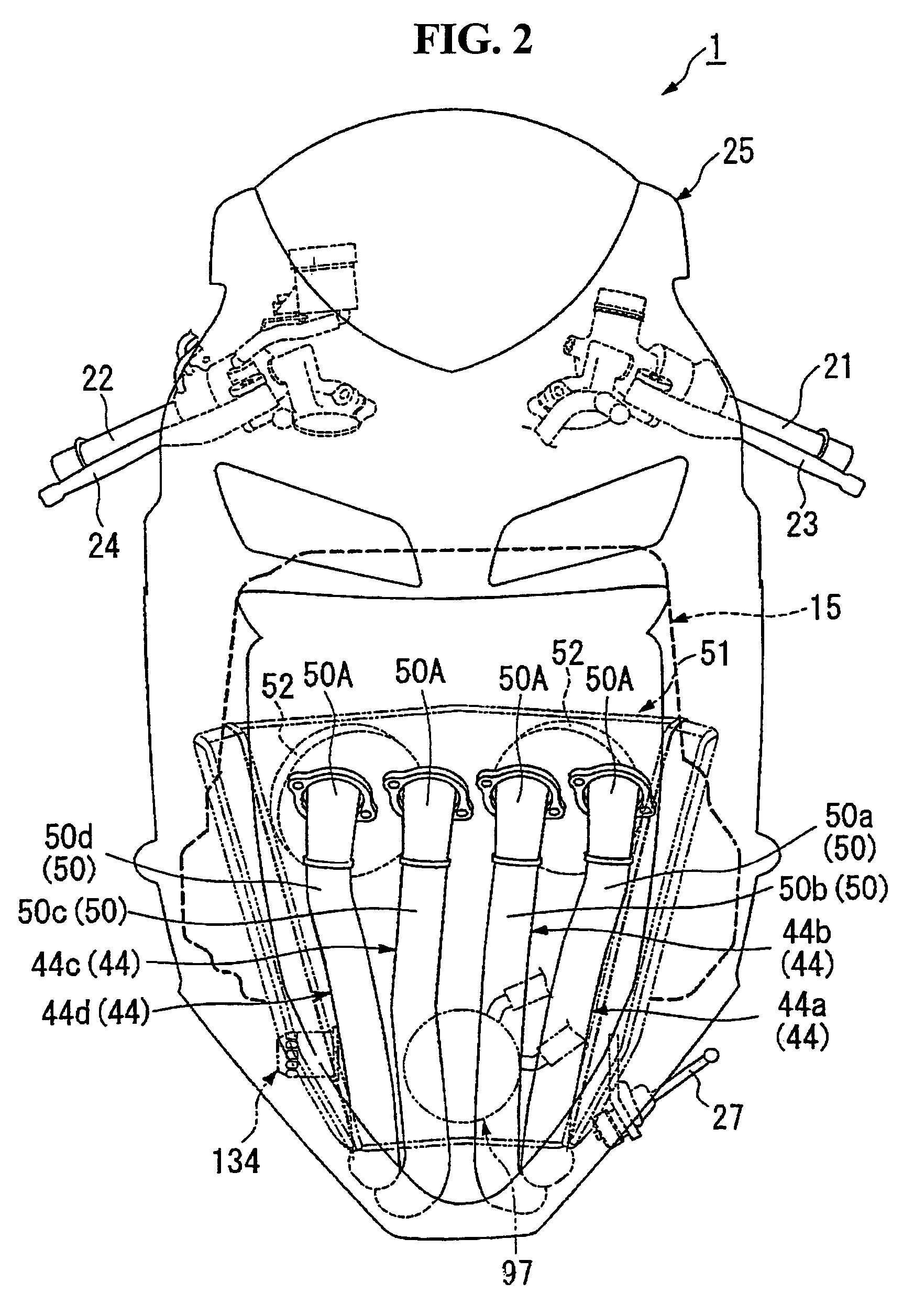

Engine crankcase structure

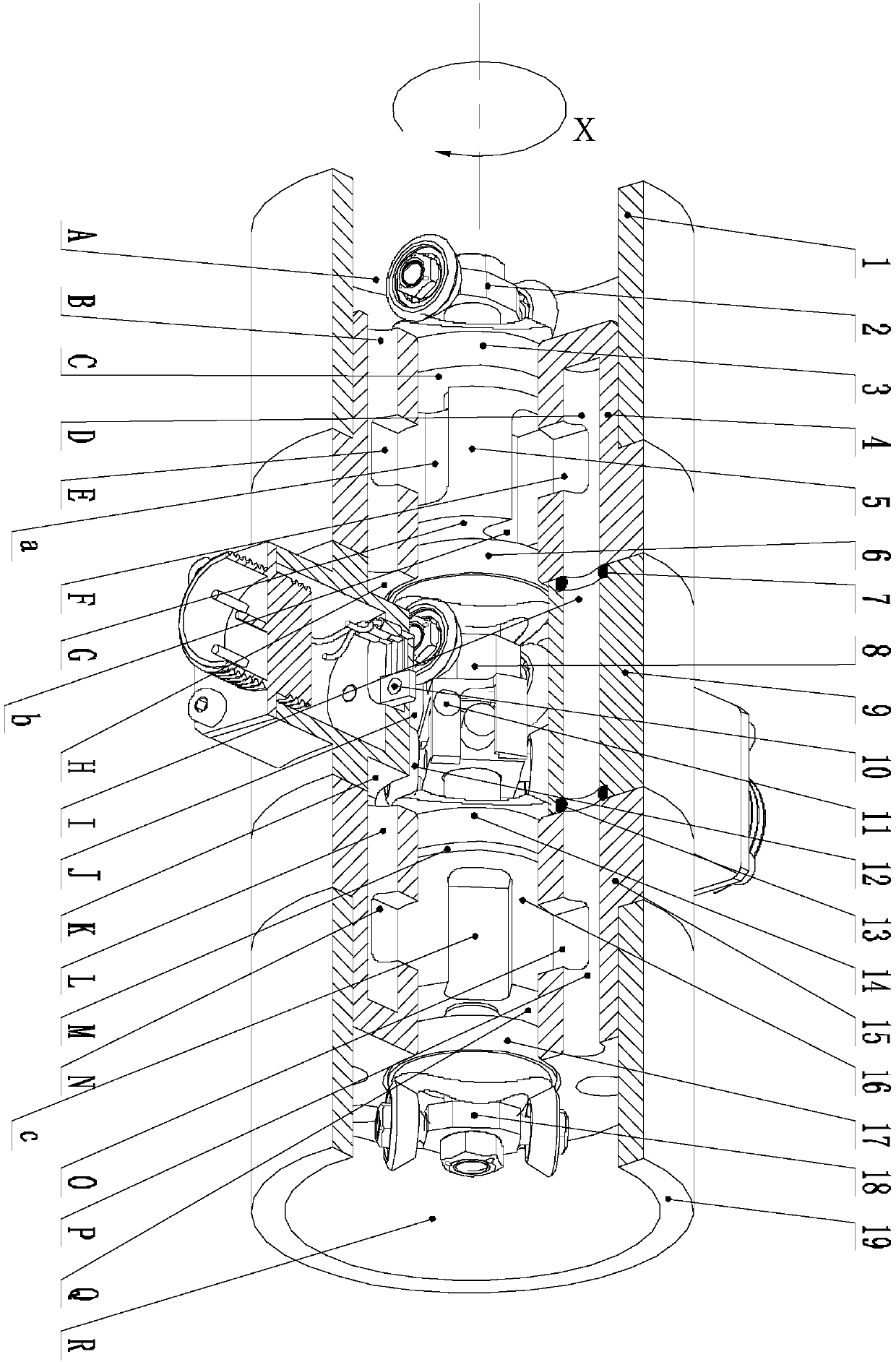

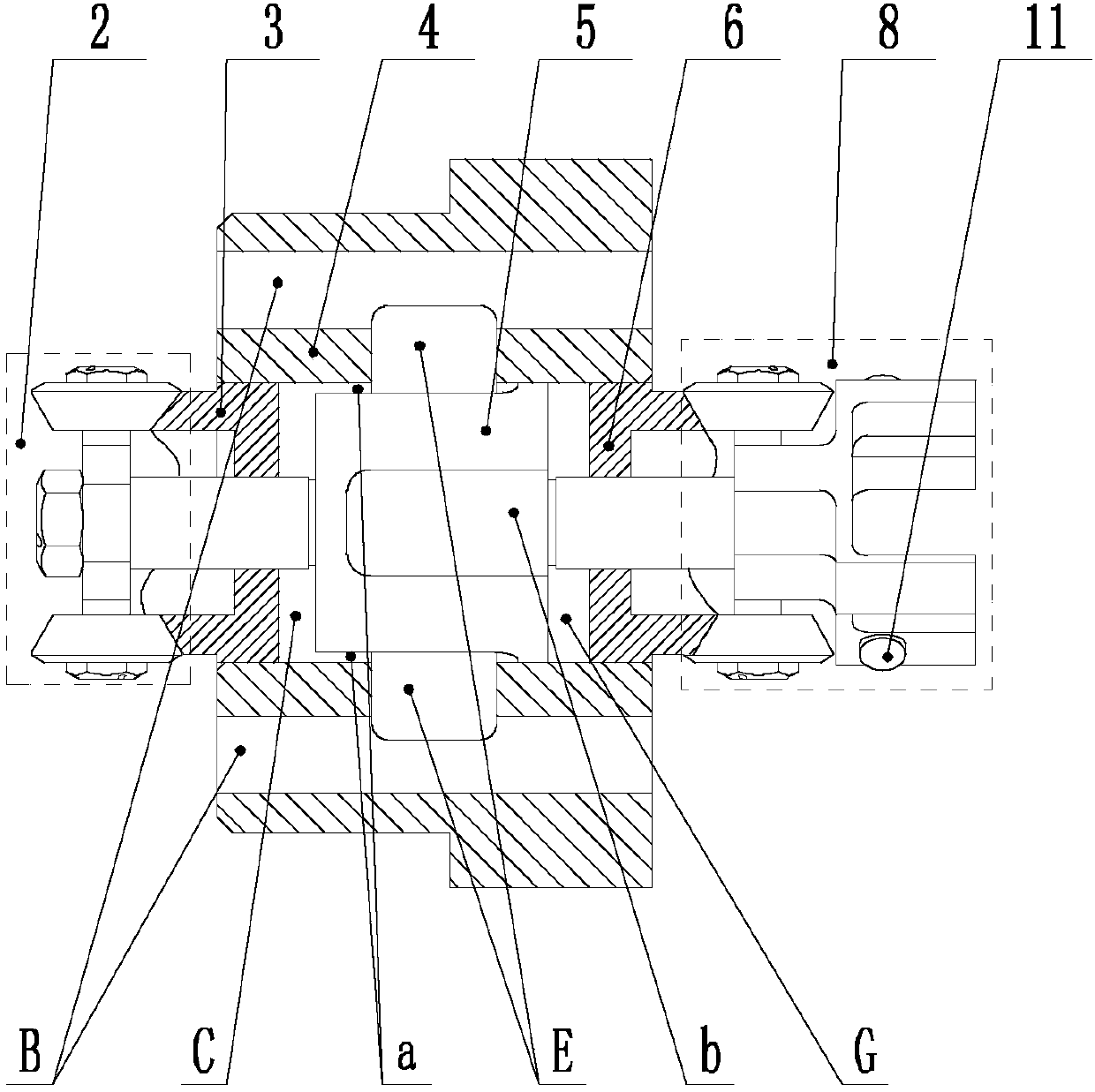

ActiveUS20050016488A1Friction loss be reduceReduce friction lossCasingsLubricant conduit arrangementsFriction lossRotational axis

To miniaturize an engine, to concentrate heavy masses and to reduce friction loss of a balancer. An engine crankcase structure in which a crankcase is vertically partitioned into an upper case and a lower case, each journal supporter is formed in the upper case and in the lower case so that the rotational axis of a crankshaft is located on a partition face of the crankcase in parallel with a direction of the width of the body. The crankshaft is supported so that the crankshaft can be rotated. An oil filter is directly attached to the lower case. An oil cooler and a secondary balancer are arranged in the front of the lower case.

Owner:HONDA MOTOR CO LTD

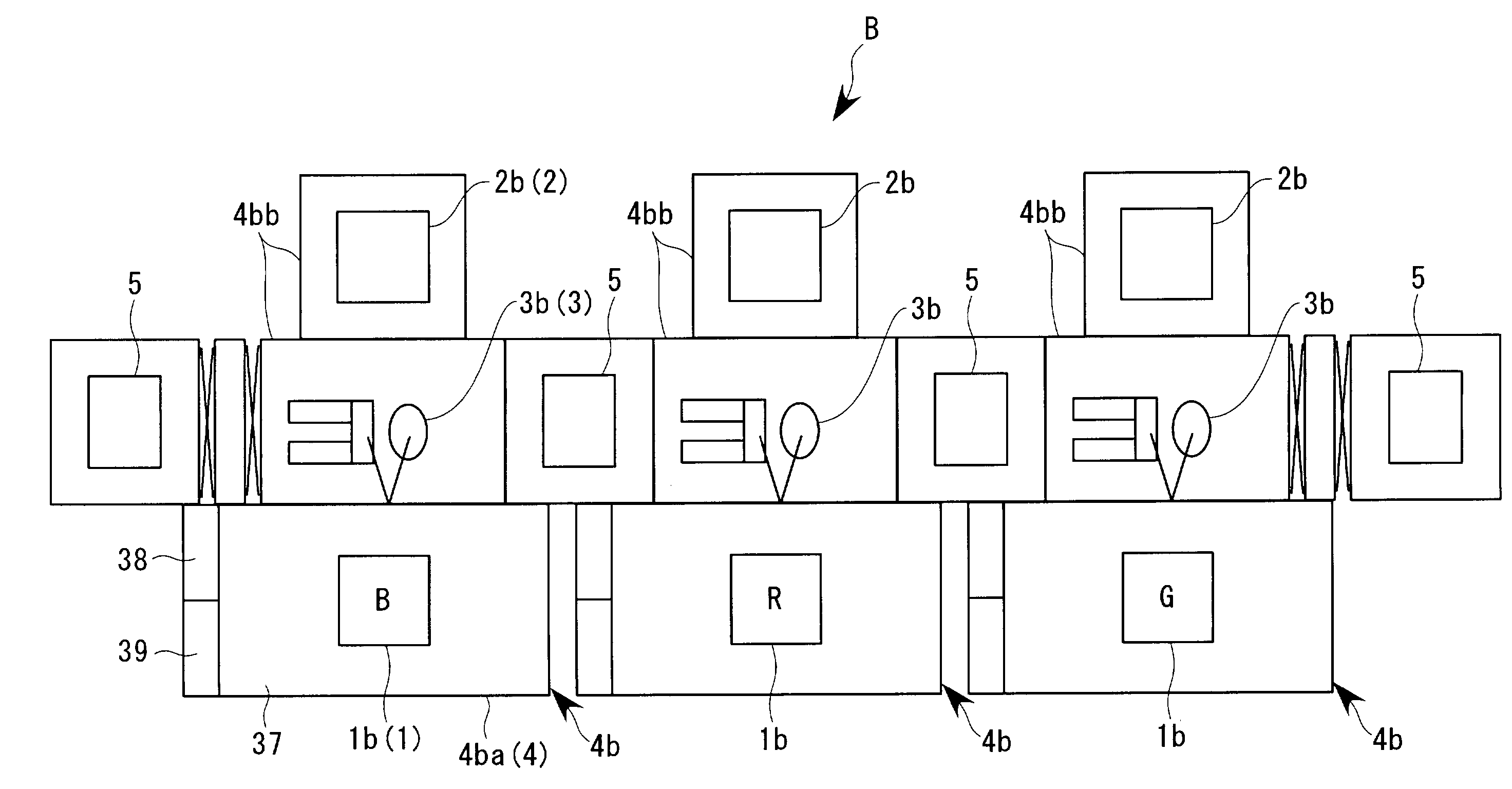

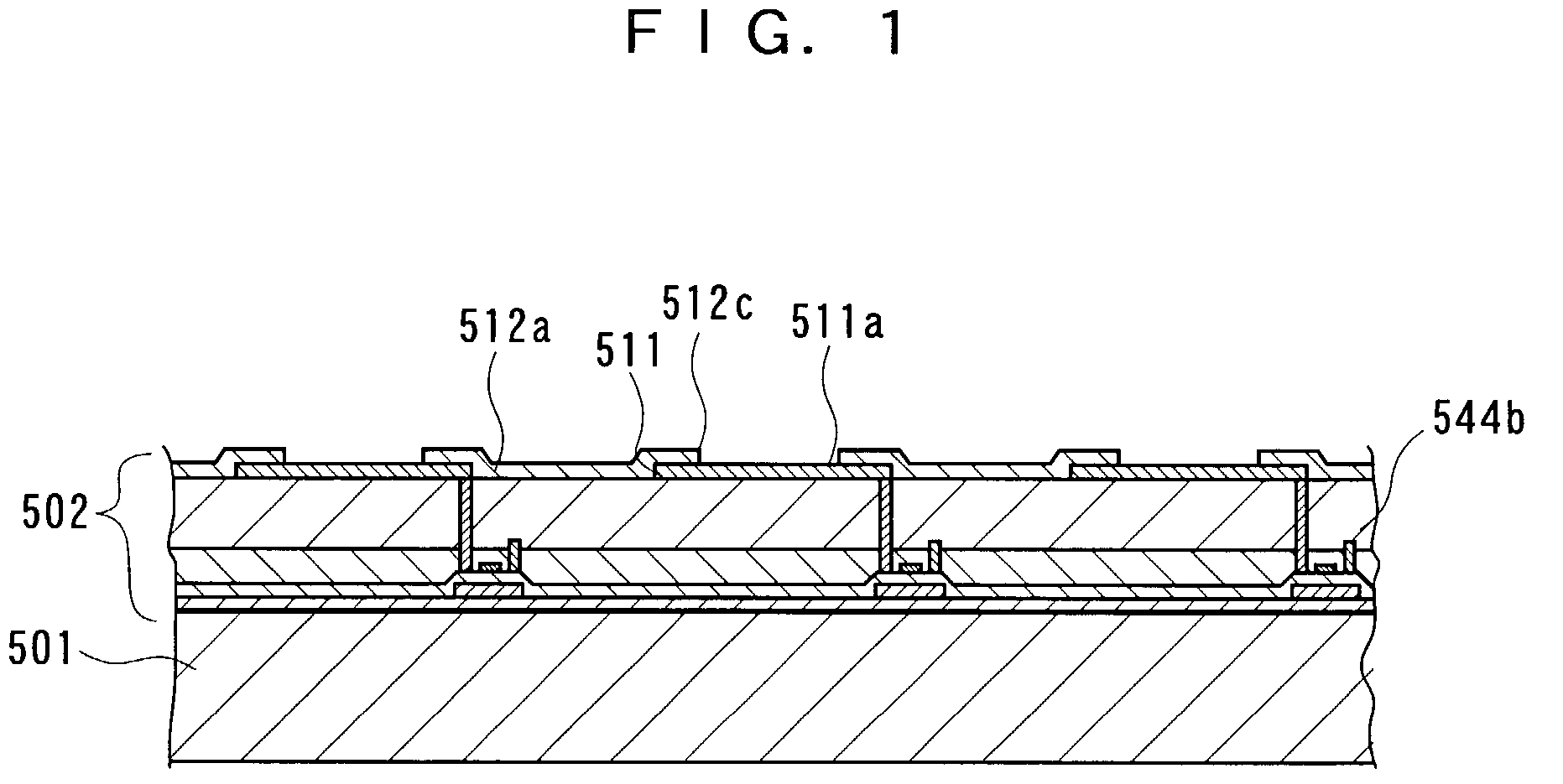

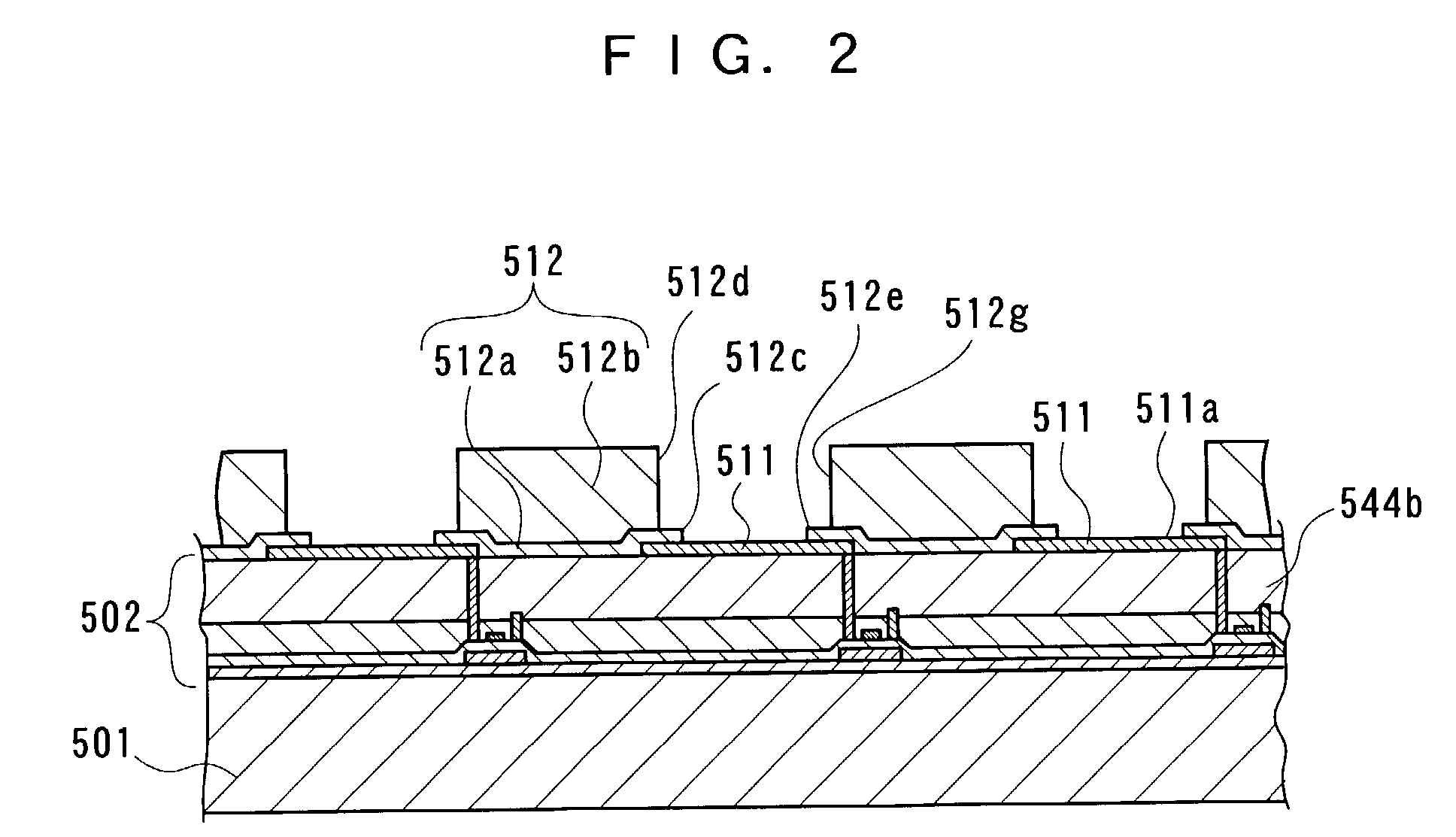

Method of, and apparatus for, manufacturing organic EL device; organic EL device; electronic device; and liquid droplet ejection apparatus

InactiveUS7517549B2Eliminate contactDamage in qualityInking apparatusVacuum evaporation coatingEngineeringElectron

An organic EL function layer is formed in the following manner. Namely, relative scanning is carried out between a substrate and a function liquid droplet ejection head having introduced therein a light function material is selectively ejected toward the emitting function material. The light emitting substrate such that an organic EL function layer is formed on a multiplicity of pixel regions on the substrate. The work of ejecting the light emitting function material is carried out in an atmosphere of an inert gas.

Owner:TOKYO ELECTRON LTD

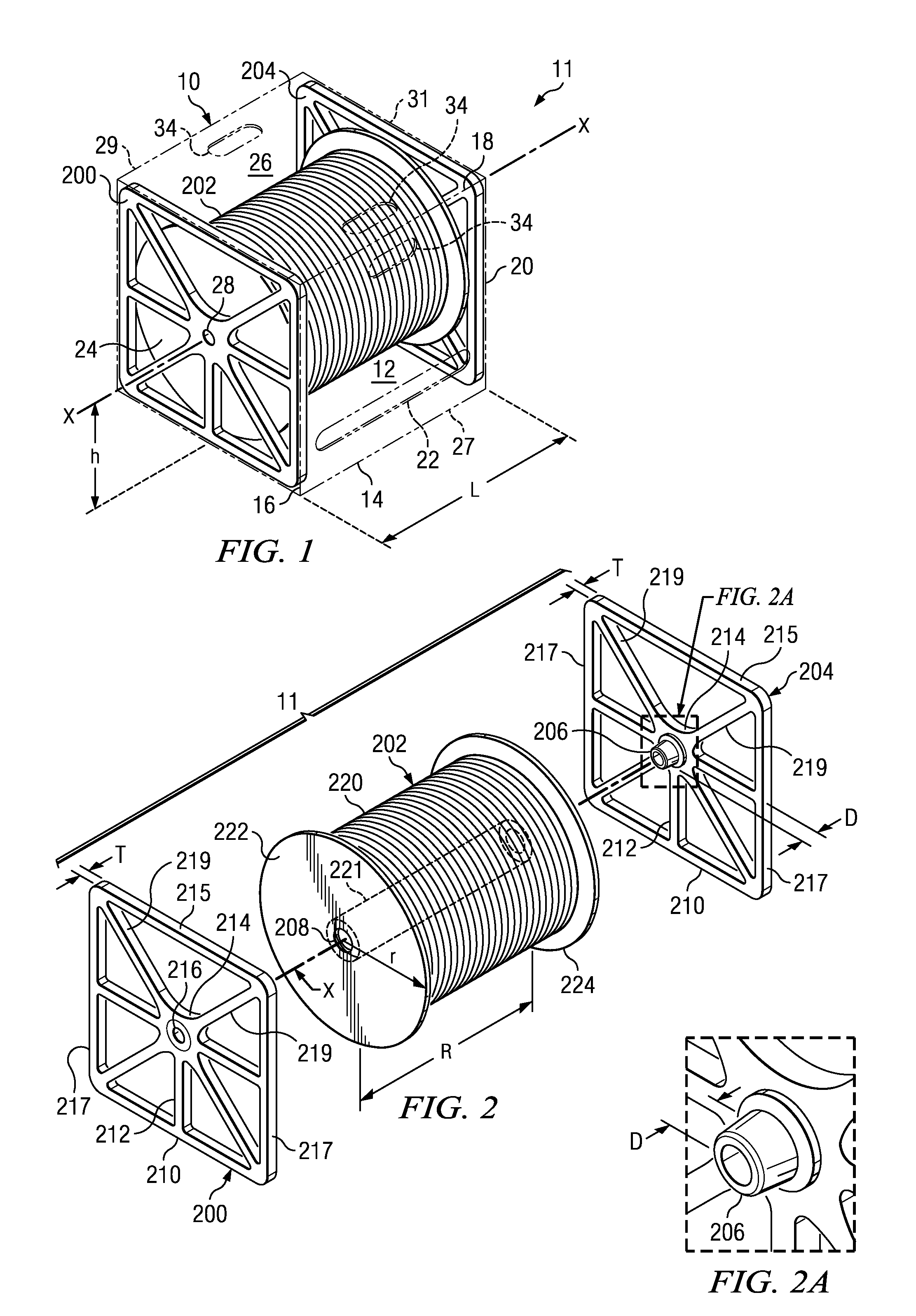

Wire and cable dispensing container and systems

ActiveUS20100006692A1Easy withdrawalHeavy qualityContainers for annular articlesProjector film strip handlingFree rotationCarton

A container for the dispensing of wire or cable has an external carton which receives a reel of cable supported by two caddies. Each caddy has an inwardly extending substantially cylindrical bushing which is received in a central hole of a respective cable reel flange. The cylindrical bushings are disposed on an axis which is a first distance from an upper surface of a bottom panel of the carton. The largest radius of the reel flanges is preselected to be smaller than this first distance such that the reel may freely rotate inside of the carton on the bushings. Cable is pulled through a slot in the carton's front panel. Left and right panels of the carton each have an arbor hole formed therein which may receive an axial rod, the rod also extending through the reel and caddies. The axial rod may be used to join two or more cartons together and may further serve as a support for attachment to a dolly, hand truck, or four-wheeled cart. In one embodiment, cable may be pulled through one or more pass-through slots formed in the tops and bottoms of stacked containers, such that cable from multiple containers is drawn through one slot on the top of the stack.

Owner:WINDY CITY WIRE CABLE & TECH PRODS

Engine crankcase structure

ActiveUS7104239B2Reduce friction lossLower center of gravityCasingsLubricant conduit arrangementsRotational axisFriction loss

To miniaturize an engine, to concentrate heavy masses and to reduce friction loss of a balancer. An engine crankcase structure in which a crankcase is vertically partitioned into an upper case and a lower case, each journal supporter is formed in the upper case and in the lower case so that the rotational axis of a crankshaft is located on a partition face of the crankcase in parallel with a direction of the width of the body. The crankshaft is supported so that the crankshaft can be rotated. An oil filter is directly attached to the lower case. An oil cooler and a secondary balancer are arranged in the front of the lower case.

Owner:HONDA MOTOR CO LTD

Process for recovering heavy minerals from oil sand tailings

ActiveUS7695612B2Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

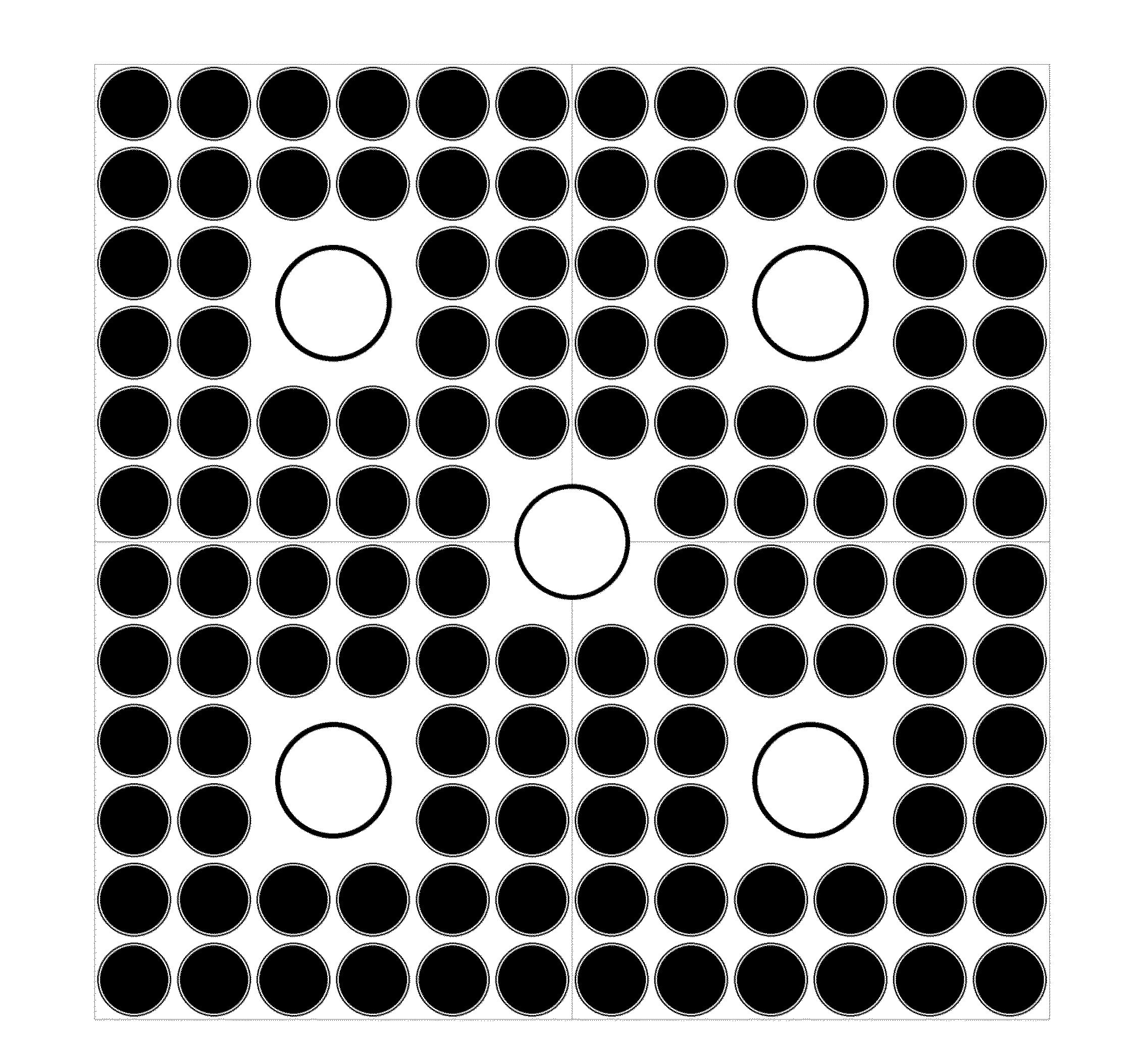

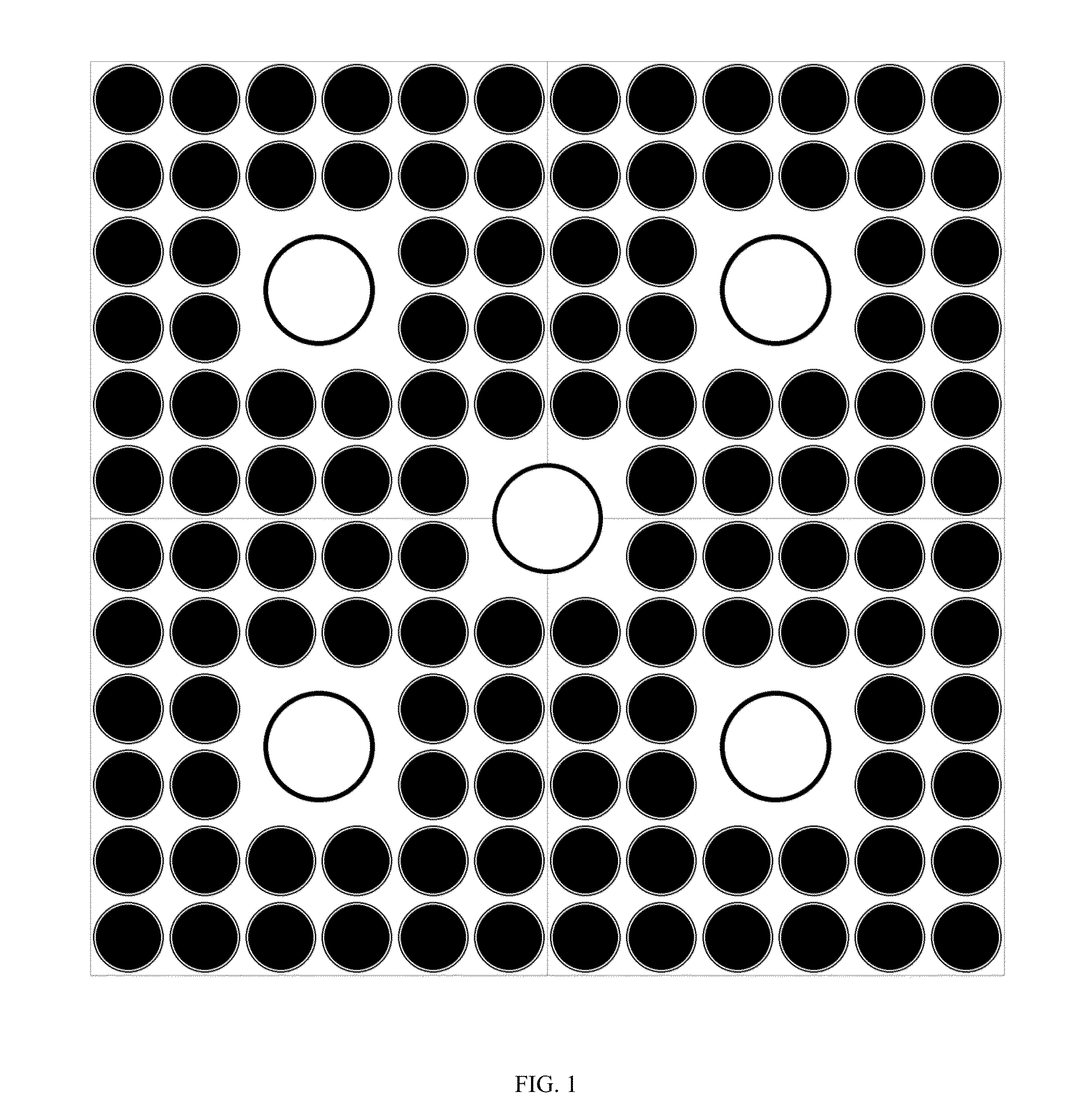

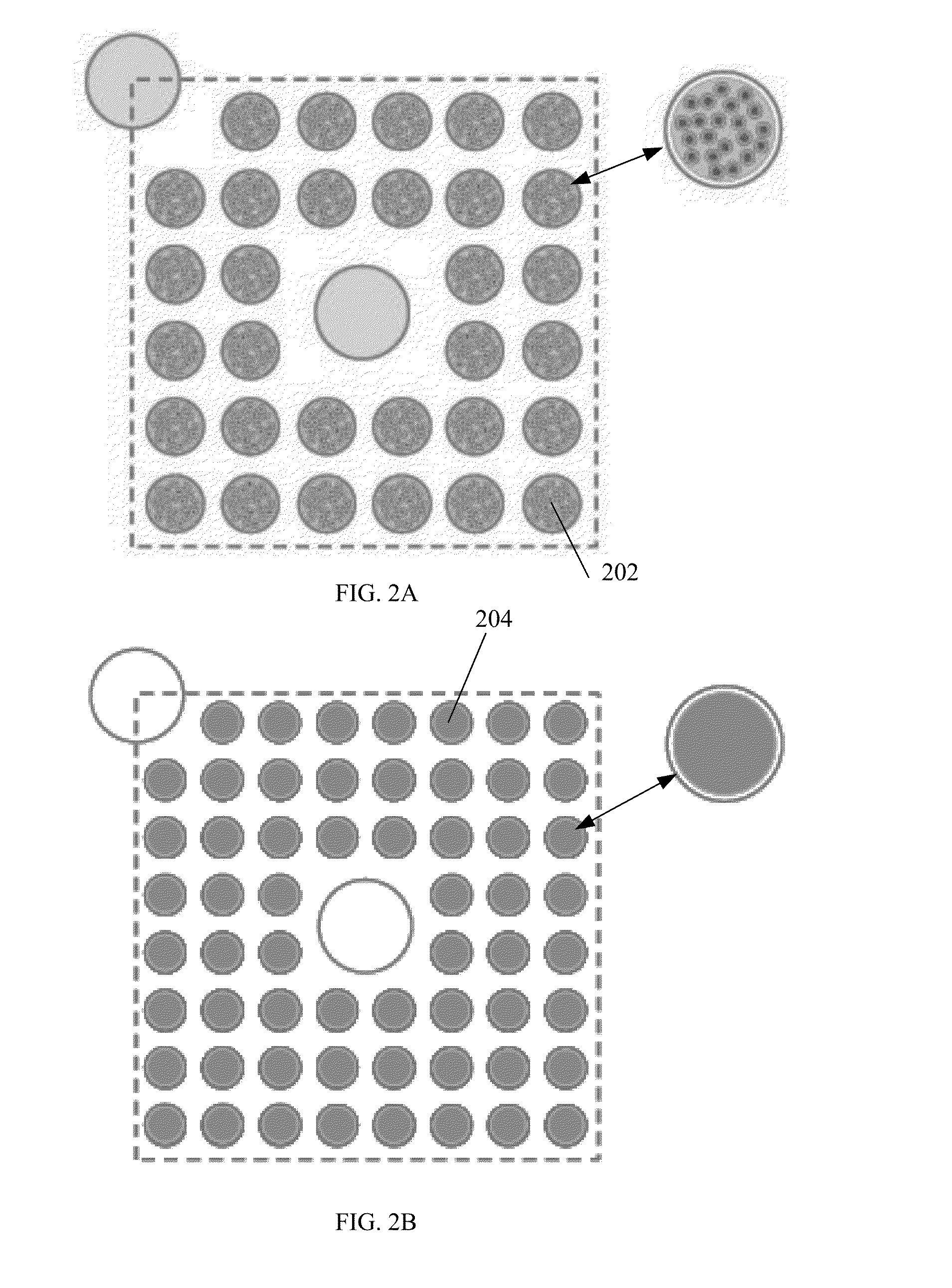

Fully ceramic microencapsulated replacement fuel assemblies for light water reactors

InactiveUS20130114781A1Quality improvementImprove securityOptical rangefindersNuclear energy generationAlternative fuelsBurnup

A fully ceramic micro-encapsulated fuel assembly for a light water nuclear reactor includes a set of FCM fuel rods bundled in a square matrix arrangement. Fully ceramic micro-encapsulated fuel assemblies replace standard reference solid fuel assemblies with smaller number of FCM fuel rods that have a larger diameter than the diameter of the solid standard reference fuel rods, while keeping similar amounts of fissile material in the fuel assembly and maintaining comparable rates of burnup and number of EFPDs, and compatible power production, heat transfer and thermo-hydraulic features. A fully ceramic micro-encapsulated fuel rod includes multiple fully ceramic micro-encapsulated fuel pellets, which are comprised of tristructural-isotropic particles. In order to obtain compatible burnup rates with the standard reference fuel, the tristructural-isotropic particles have preferentially large diameter and packing fraction. Furthermore, Erbium oxide is included in the sintered mix of the SiC compact to serve as a burnable poison.

Owner:KOREA ATOMIC ENERGY RES INST

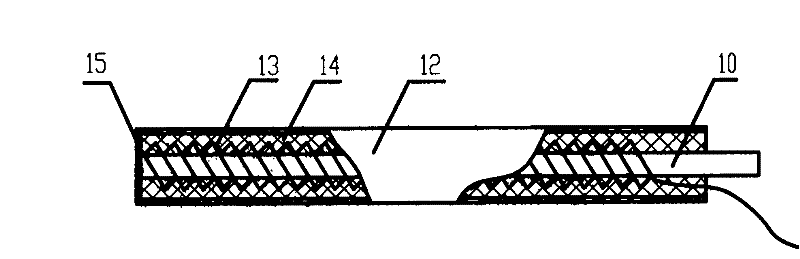

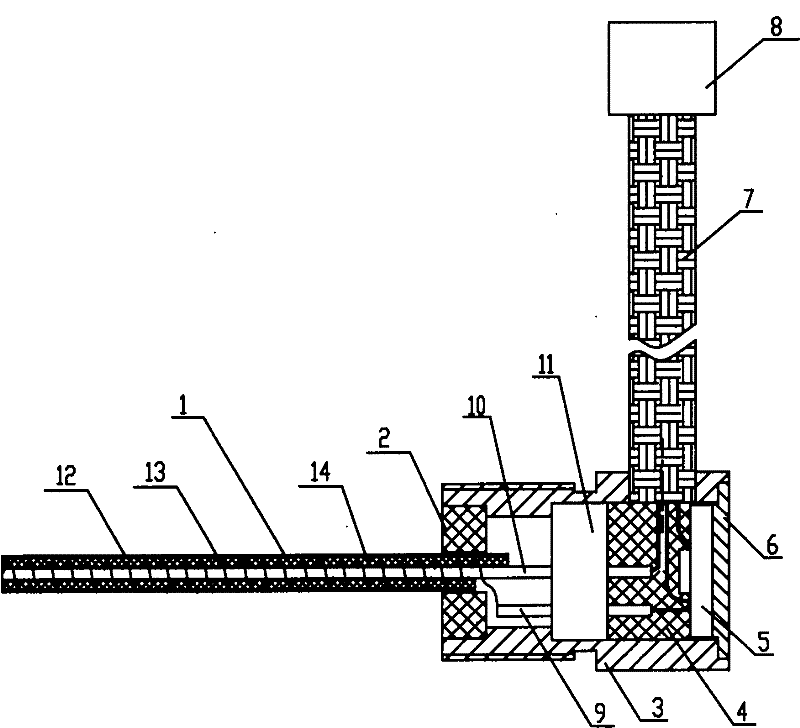

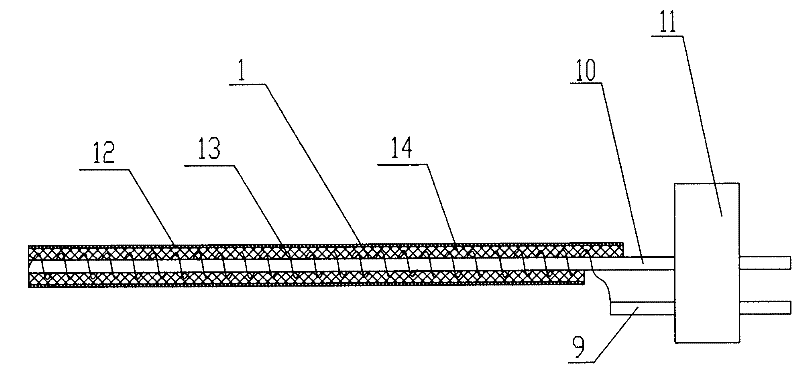

Sensor capable of continuously measuring ablation

ActiveCN102183196AHigh measurement accuracyOverall damage is smallElectrical/magnetic thickness measurementsContinuous measurementFilling materials

The invention relates to a sensor capable of continuously measuring ablation, which comprises a sensitive component, a clogged block, a shell, a printed board assembly, a rear cover, a cable and a connector, wherein the sensitive component comprises a lead, a core wire, an insulating base, a capillary, a winding and filler material. In the invention, wire winding technology is adopted to wind wires on the core wire evenly and densely, and then the filling material is filled between the wound wire and the core wire to form the sensitive component, one end of the sensitive component is insert into the shell and fixed with the clogged block; then the lead wire of the sensitive component is connected to the printed board assembly, signals are led out through the cable and the connector; after the rest space in the shell is filled with glue solution, the shell and the rear cover are welded. The sensor capable of continuously measuring ablation has the characteristic of continuous measurement, and can output signals which are in direct proportion to the ablation thickness of a heat shielding layer. According to the invention, an ablative material used in manufacture does not need to be in the same batch with the heat shielding layer, thereby reducing cost and shortening production period; the measurement accuracy is improved greatly, and the integral damage to the heat shielding layer is very small.

Owner:BEIJING RES INST OF TELEMETRY +1

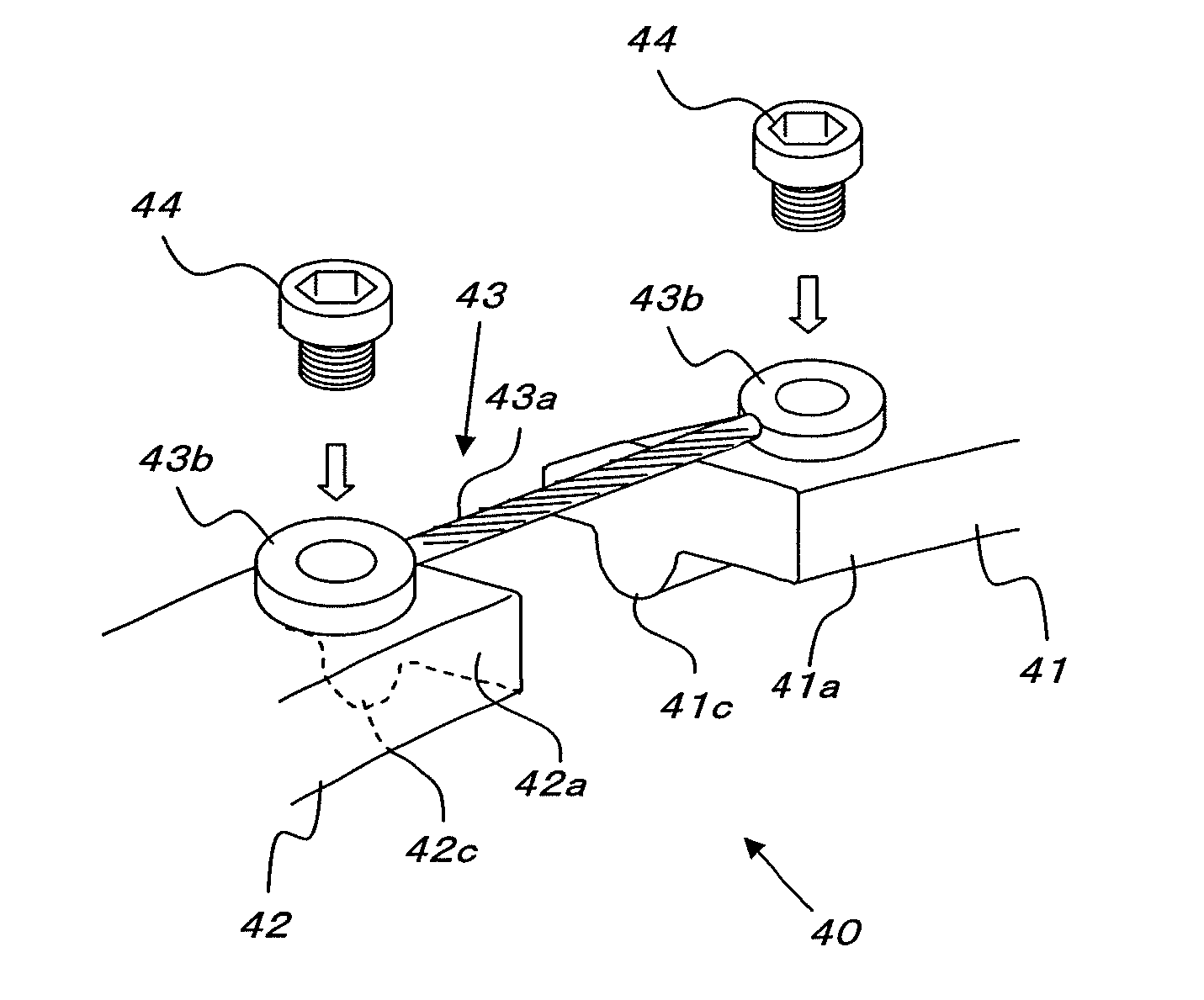

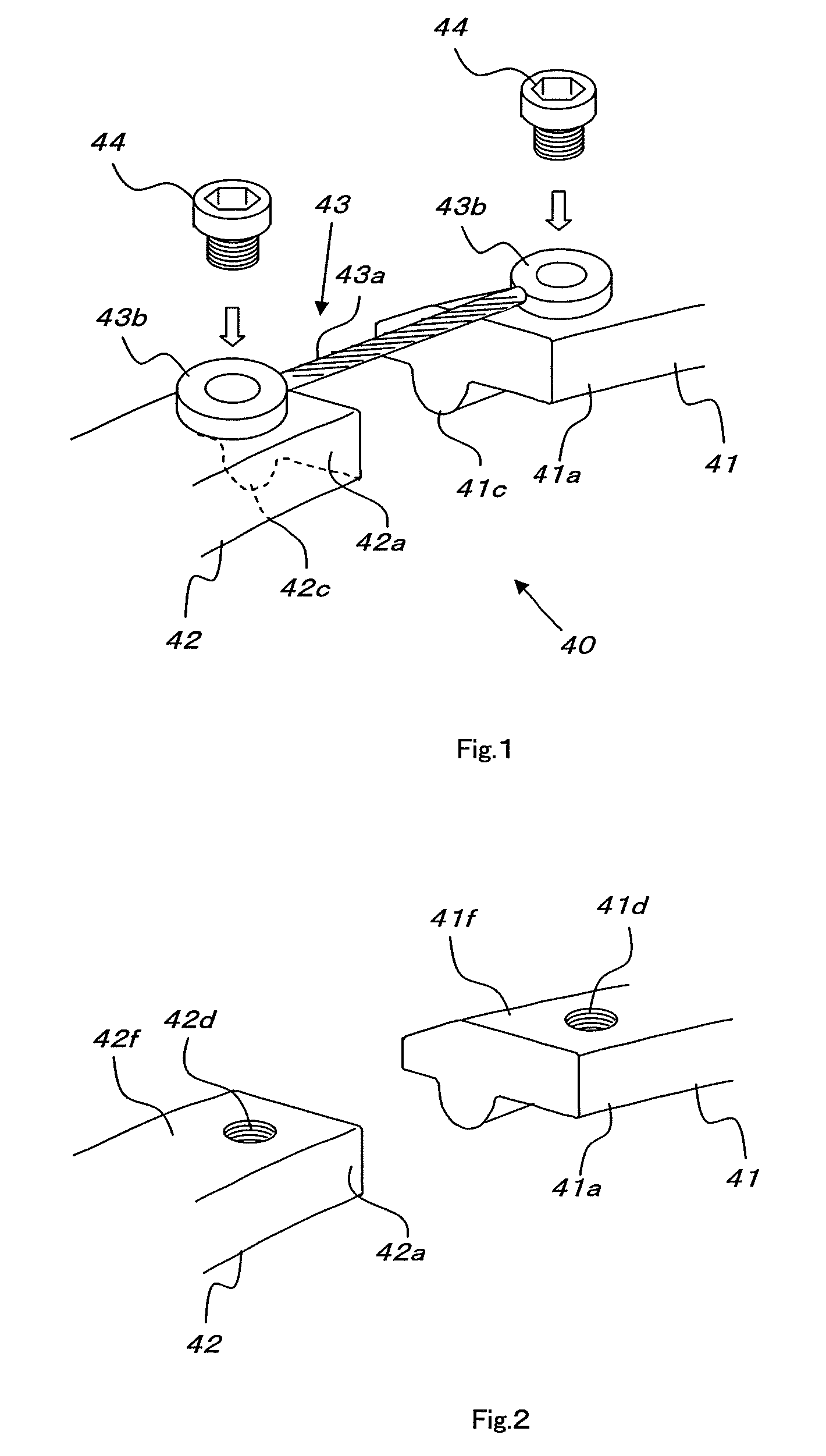

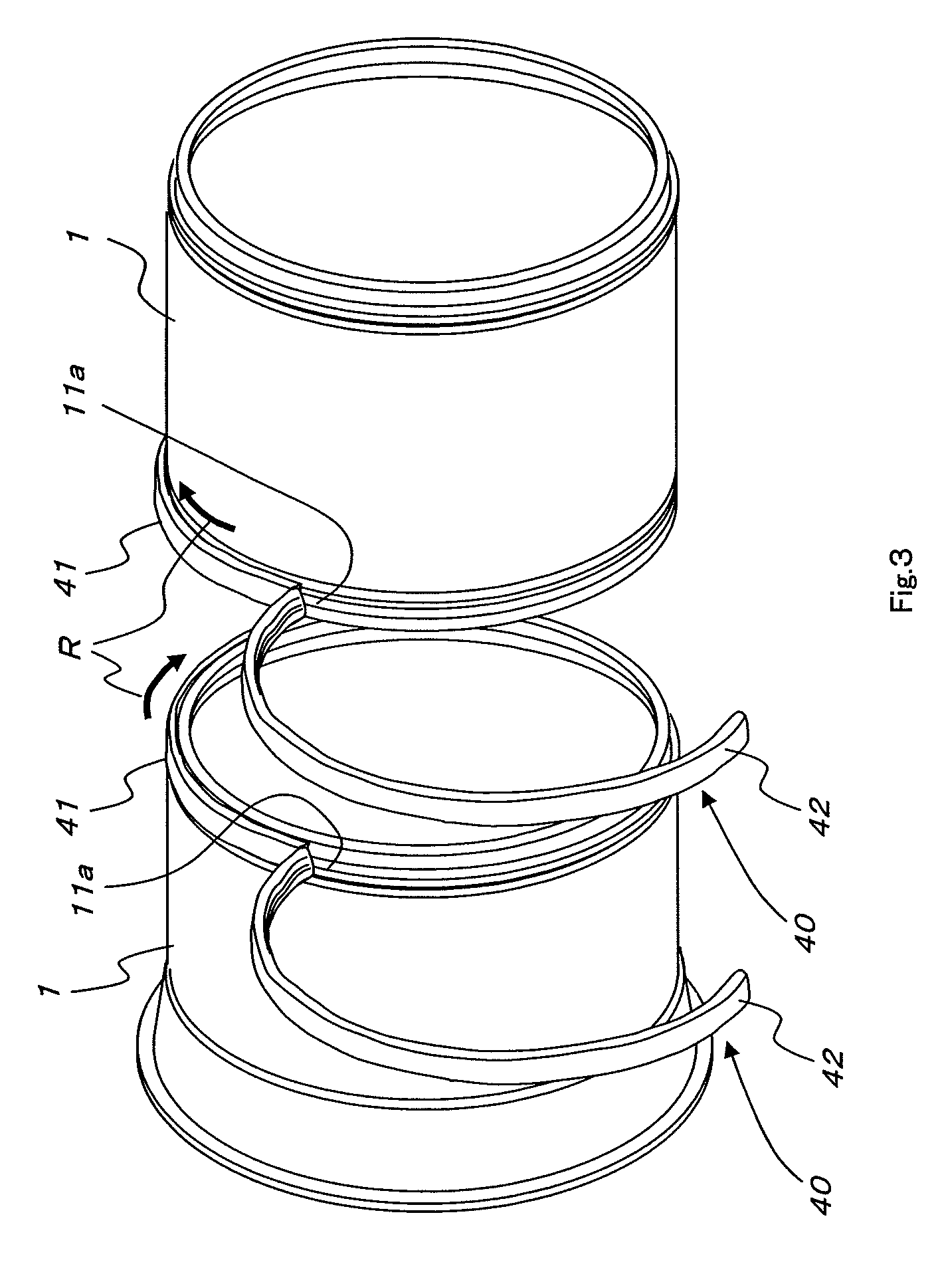

Multi-piece rim and its attaching/removing method

InactiveUS8347929B2Fit tightlyHeavy qualityWithout separate inflatable insertsRimsCouplingEngineering

It is an object of the present invention to provide a multi-piece rim which does not need much labor for supporting, and does not increase the number of components to be managed and the number of needed tasks.The present invention constructs a lock ring (40) to be fitted in the groove (11a) of a gutter band (11), which ring is divided in a plurality of portions (41, 42) being coupled at each end (41a, 42a) thereof by a flexible coupling member (43). Alternatively, a lock ring (140) is formed into a substantially C-shape being manufactured by cutting a part of a circular ring, and comprises a first portion (141) wherein a length of a chord at the cut portion is substantially equal to the diametral of a hub, and a second portion (142) having a shape corresponding to the cut portion of a circular ring in the first portion.

Owner:TOPY INDUSTRIES

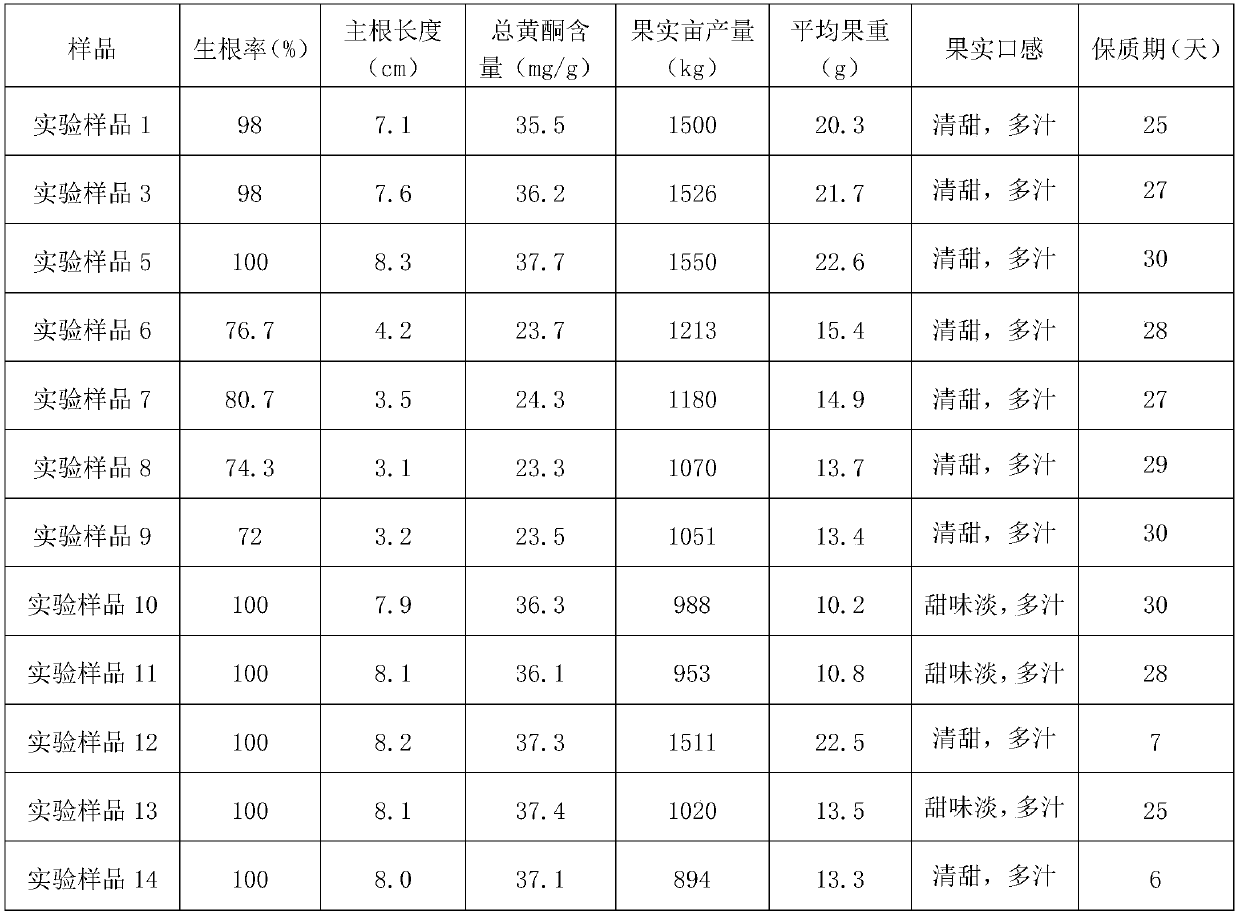

Melastoma dodecandrum lour planting method

InactiveCN109819834AHeavy qualitySweetness enoughPlant growth regulatorsBiocideSweetnessPlant cultivation

The invention provides a melastoma dodecandrum lour planting method, and particularly relates to the technical field of plant cultivation. The method adopts a mode for planting melastoma dodecandrum by using a seedling solution for rooting culture of cutting strips. Firstly, the cutting strips are placed and soaked in rooting water, cultivating and rooting are conducted with the seedling solution,field planting is conducted in a planting field, when water and fertilizer management is carried out, a vine enhancing agent and a fruit promoting agent are sprayed at the right time, the rooting rate of the cutting strips is over 98%, the total flavonoid content of active ingredients of a plant is above 35mg / g, which makes fruits have a heavy weight, enough sweetness and high yield, the shelf life of fresh fruits is prolonged to more than 20 days, so that the fresh fruits keep the original taste and freshness and do not easily rot, and the planting method is green, environmentally friendly,easy to operate, convenient to manage and suitable for scale and industrialization popularization.

Owner:三江县丰农农业科技有限公司

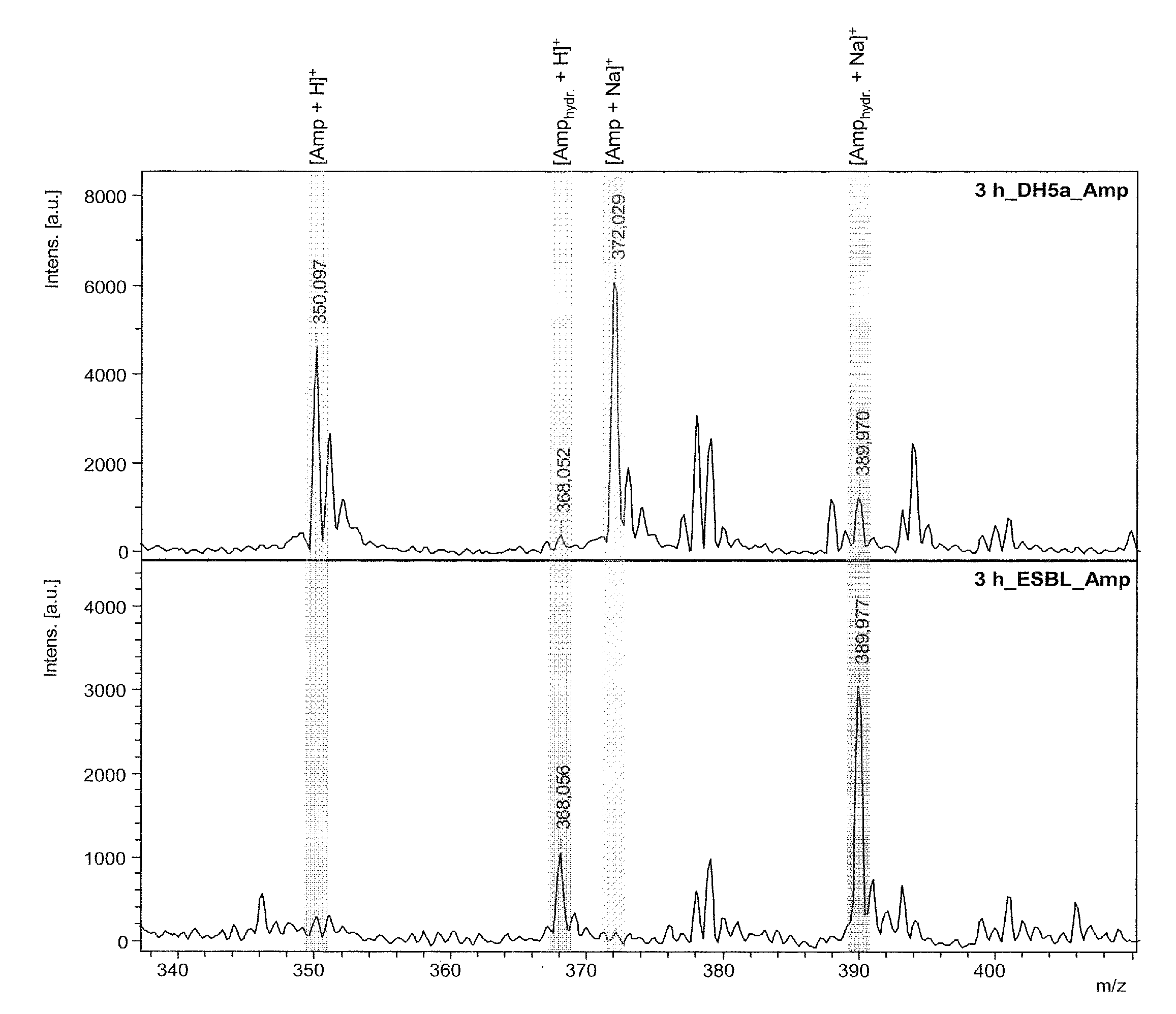

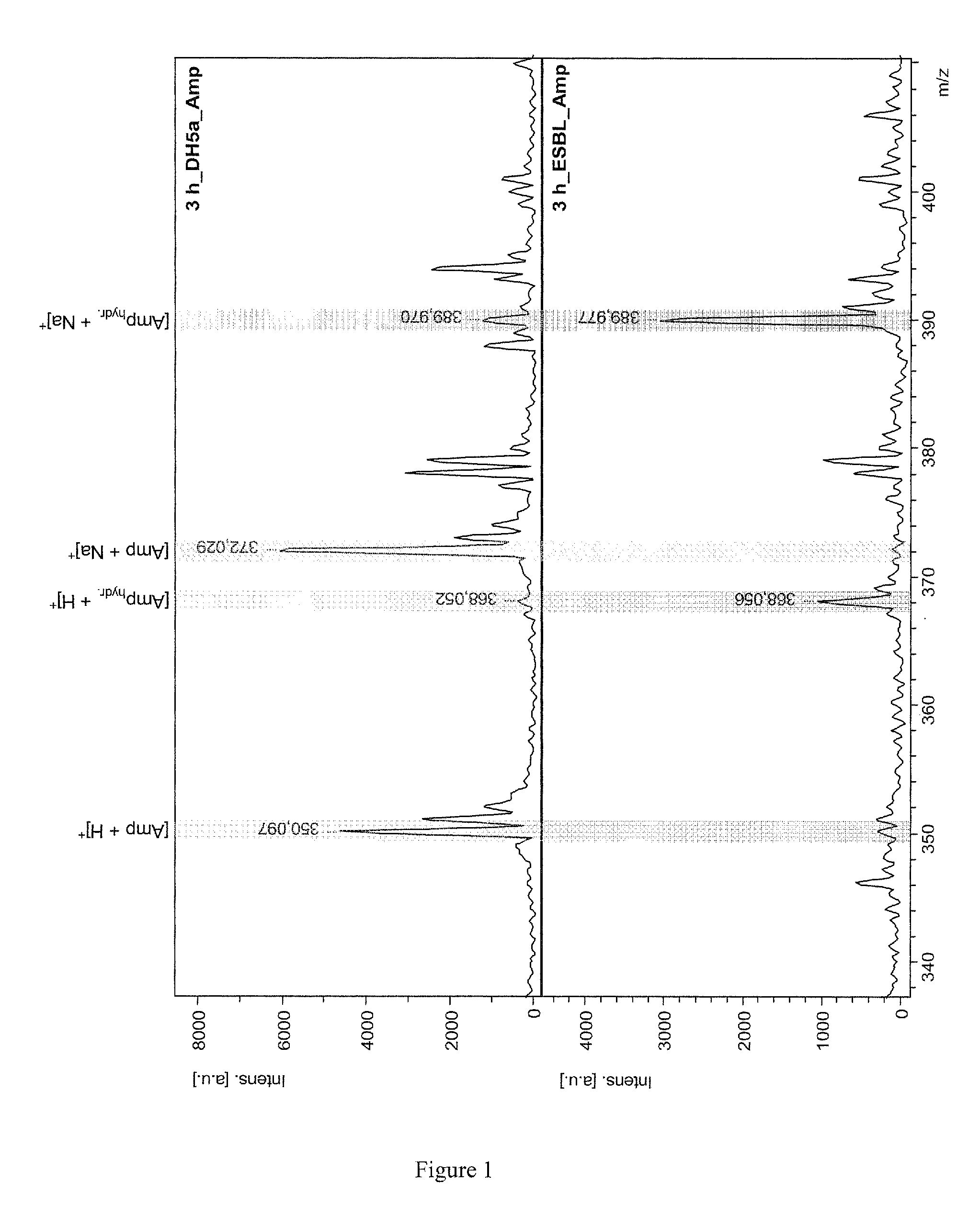

Mass spectrometric measurement of b-lactamase resistances

PendingUS20130095511A1Quickly and easily measureDecrease in amountMicrobiological testing/measurementDisease diagnosisChemistryMass spectrometry

The invention relates to the determination of resistances of microorganisms which produce β-lactamases, in particular “extended spectrum β-lactamases” (ESBL). The invention provides a method whereby the microbial resistance can be measured very simply and quickly by means of the catalytic effect of the microbially produced β-lactamases on β-lactam antibiotics, which consists in a hydrolytic cleavage of the β-lactam ring. The method determines the resistance of the bacteria a few hours after a suitable substrate, either a β-lactam antibiotic or a customized β-lactam derivative, has been added to a suspension of the microbes, by direct mass spectrometric measurement of the substrate breakdown caused by the β-lactamases.

Owner:BRUKER DALTONIK GMBH & CO KG

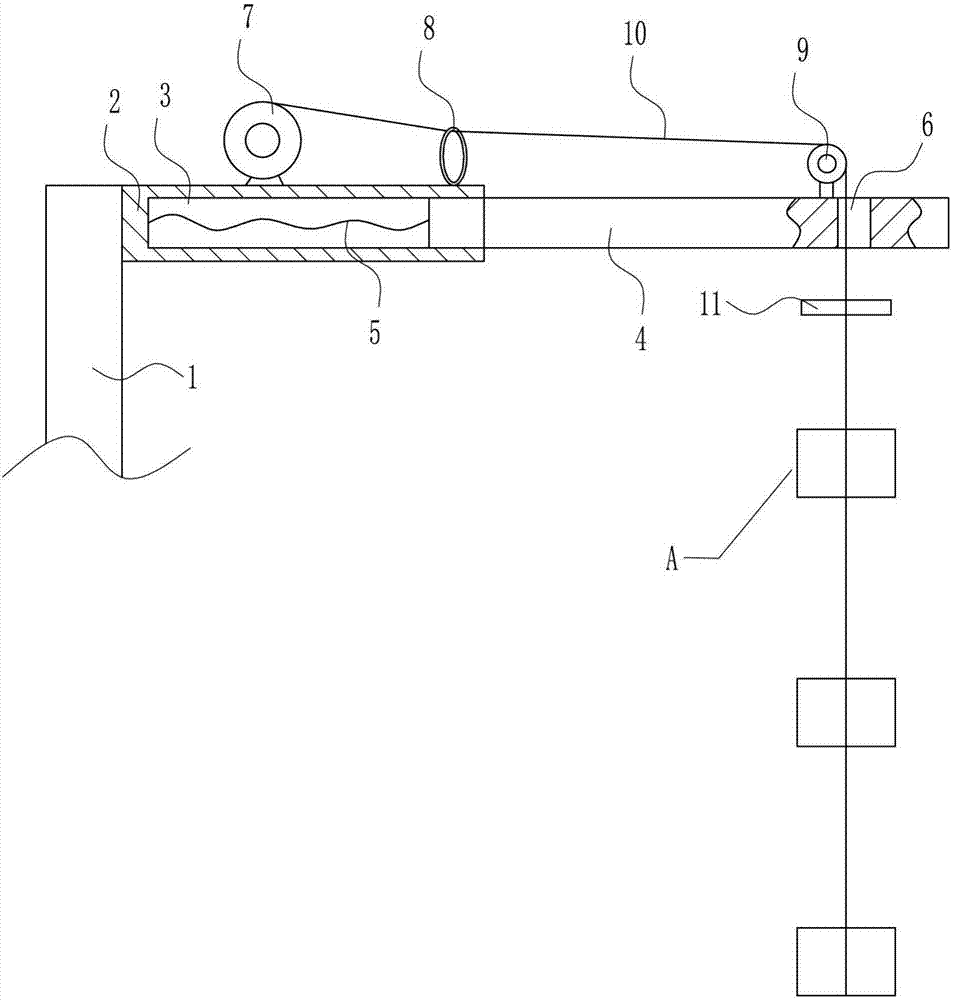

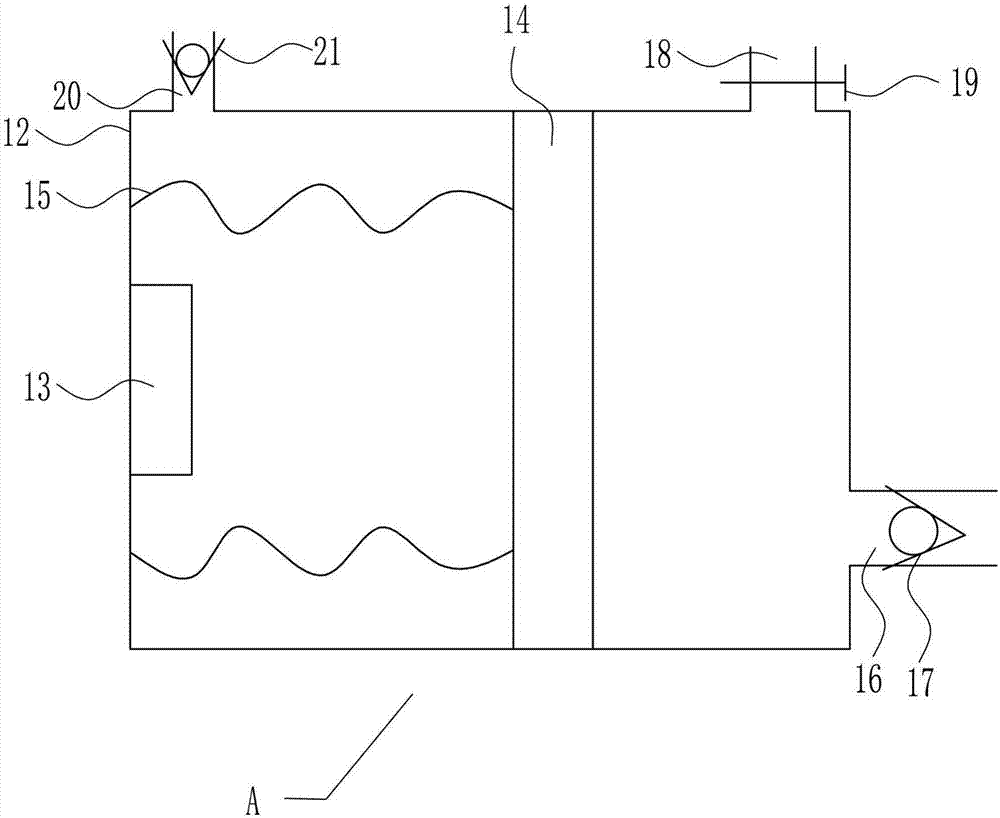

Extracting device for water bodies with different depths and production and use methods of extracting device

InactiveCN108007727AWill not flowFor quick outflowWithdrawing sample devicesWater qualityEngineering

The invention relates to an extracting device for water bodies with different depths. The device comprises a support, a top plate, a telescopic rod, a first spring, an electric winding wheel, a guidering, a fixed pulley, a stay cord, a floating plate, a water collector, an electromagnet, an iron piston and the like, wherein the top plate is horizontally connected to the right side of the top of the support; a sliding chute is formed in the top plate. The extracting device disclosed by the invention achieves simple structure and convenience in operation, and can simultaneously sample differentdeep water segments at the same position, so that the result of water quality detection is more accurate and high precision is realized.

Owner:NANJING CUIZHI WATER CONSERVANCY TECH CO LTD

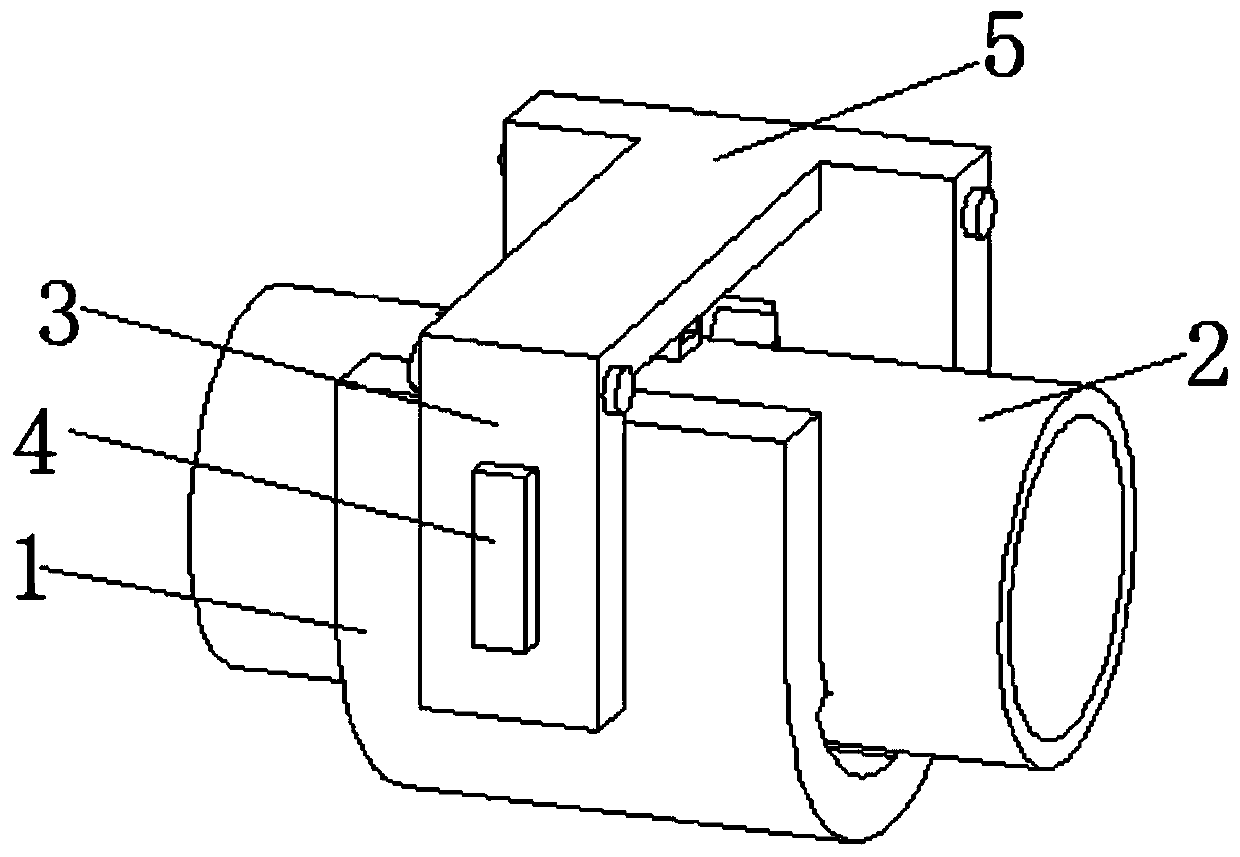

Light power transmission line suspension clamp pin mounting device and using method thereof

InactiveCN110932214AHeavy qualityReduce wearSuspension arrangements for electric cablesApparatus for overhead lines/cablesRelative motionTower

The invention provides a light power transmission line suspension clamp pin mounting device and a using method thereof. The suspension clamp comprises a U-shaped frame, a clamp hull is arranged in theU-shaped frame, a sliding block is installed at the bottom of the clamp hull, a sliding rail is arranged at the bottom of an inner cavity of the U-shaped frame, the sliding rail is in sliding connection with the sliding block through the sliding block in the sliding rail, and a first spring is installed on one side of the sliding block. Second spring, a riveting aluminum pressing plate and a plastic wire pressing plate match one another. A cable penetrates through the hollow inner part of the ship clamping body. The second springs on the two sides are used for telescopic extrusion; the riveting aluminum pressing plates on the two sides and the plastic wire pressing plates on the two sides extrude each other, so that cables and the clamp ship body are clamped, the loosening phenomenon isnot prone to occurring, relative movement between the cables and the clamp ship body can be reduced, abrasion of the cables can be effectively reduced, the overall weight of the clamp is not heavy, and the load of a tower can also be reduced.

Owner:朱永林

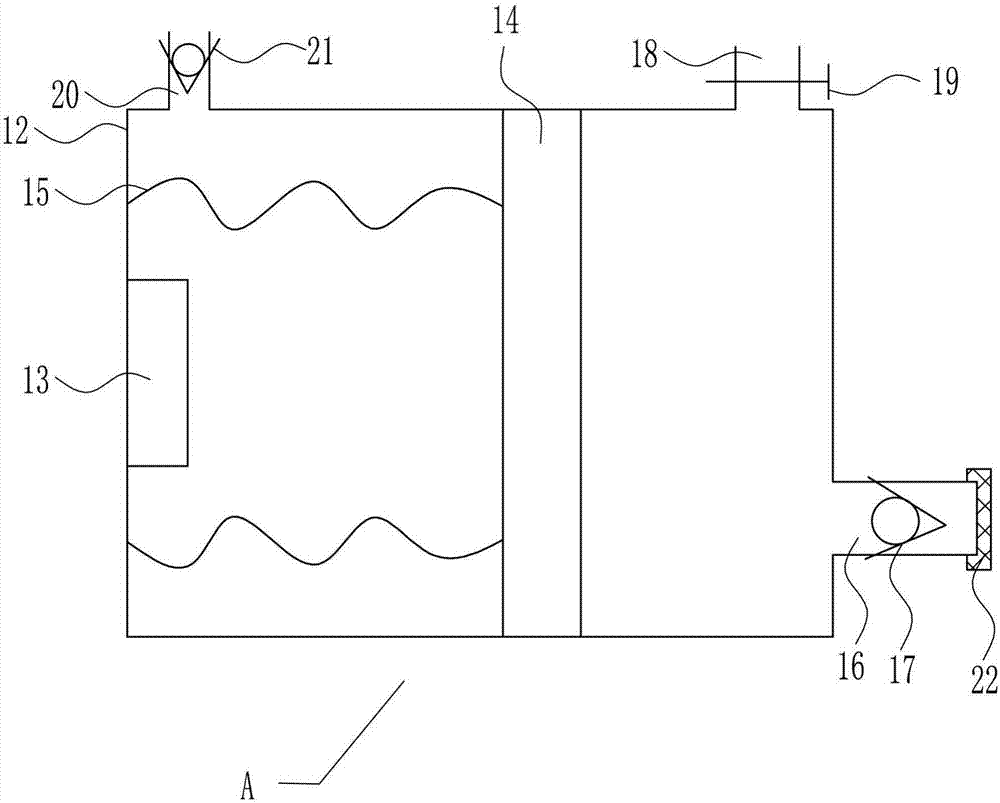

Respiration type air conditioner external unit

ActiveCN110274312ASlow down coolingIncrease power consumptionLighting and heating apparatusAir conditioning systemsRespiratorEngineering

The invention relates to a respiration type air conditioner external unit which comprises a housing, a compressor, a heat exchange plate and an air guide device. The housing comprises a control cavity and a cake-shaped heat exchange cavity; the heat exchange plate extends along the circular ring panel of the heat exchange cavity; one-way exhaust holes are formed in the circular ring panel, directly facing the heat exchange plate, of the heat exchange cavity; the air guide device is arranged on a division plate, and comprises a respirator made of an elastic material; the air guide device pulls air out from the respirator and injects air into the respirator periodically and prompts the respirator to be deformed; when the respirator expands to the amplitude peak, the side wall of the respirator is close to the surface of the heat exchange plate; and when a respiration hole of the air guide device extends out of the housing, the one-way air inlets are formed in the heat exchange cavity, and extend out of the housing. The respiration type air conditioner external unit is novel in structure and unique in principle, the heat dissipation efficiency of the external unit can be effectively improved, meanwhile noise generated in working is reduced, and an influence on the normal life of a user is effectively reduced.

Owner:广东雅顿空调设备制造有限公司

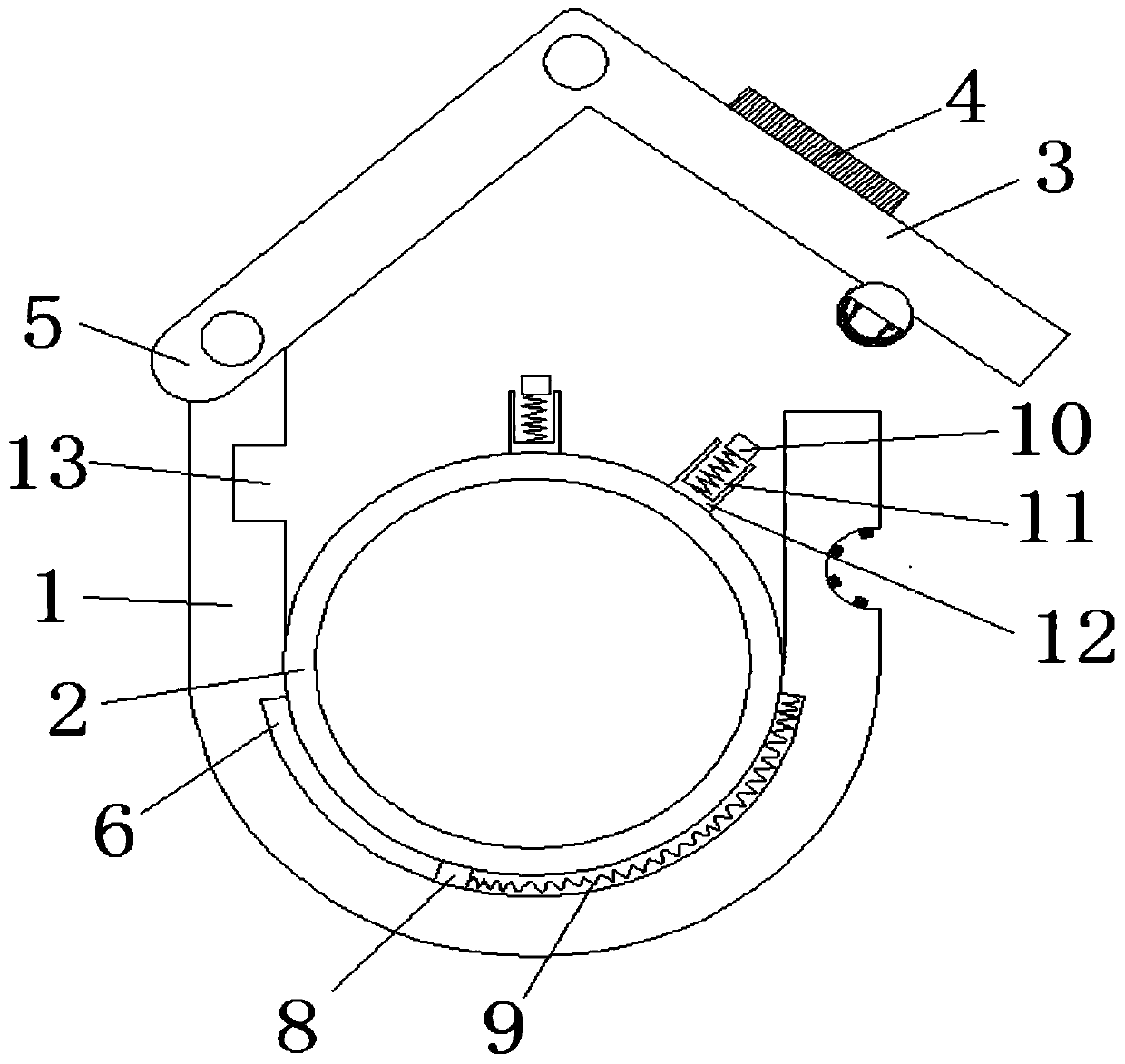

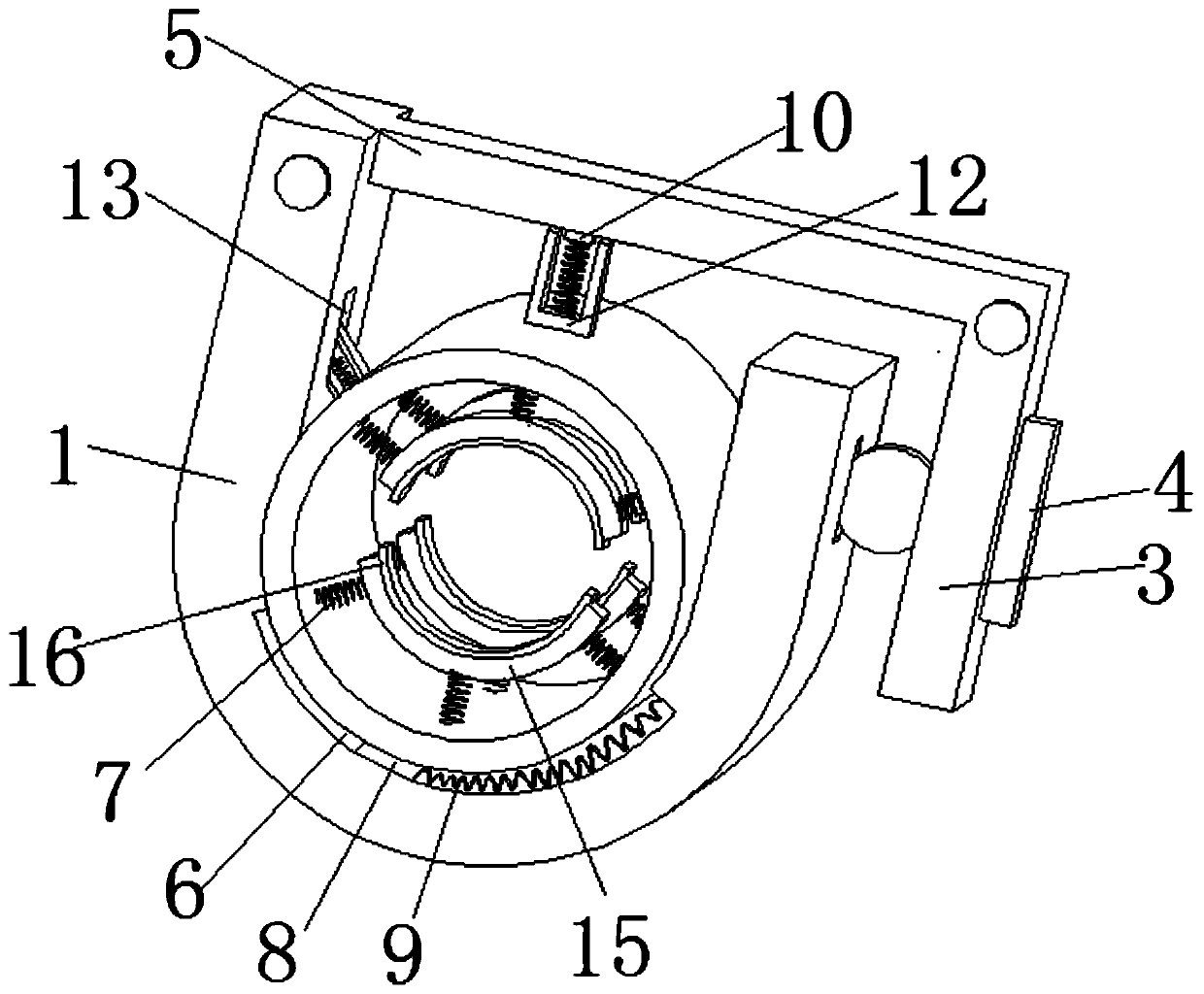

Double-link two-dimensional piston type flowmeter

PendingCN110346007ASimple structureContinuous liquid feeding and discharging functionContracting/expanding measuring chambersVolume variation compensation/correction apparatusHall elementEngineering

The invention relates to a double-link two-dimensional piston type flowmeter comprising a left cylinder block and a right cylinder block. The left cylinder block and the right cylinder block are sealed and communicated by a connecting cylinder. A left metering unit is arranged in the left cylinder block; and a right metering unit is arranged in the right cylinder block. The left cylinder block andthe right cylinder block carries out liquid feeding and draining in turn by using the left metering unit and the right metering unit respectively. A Hall element is arranged on the outer wall of theconnecting cylinder; and a magnetic steel sensitive to the Hall element is arranged at the outer side of a shifting fork. A central processor receives a pulse electrical signal from the Hall element and calculates a flow rate based on the pulse electrical signal. According to the invention, liquid feeding and drainage are performed in turn based on the double-link mode of linkage of the left metering unit and the right metering unit; the symmetrical characteristic is realized; the liquid has no flow pulsation and the pressure pulsation after metering. Moreover, the double-link two-dimensionalpiston type flowmeter has advantages of simple structure, reliable work, high measurement accuracy, high dynamic frequency response, small flow and low pressure pulsation and the like.

Owner:ZHEJIANG UNIV OF TECH

Hollow inflation-free plastic foaming wheel

InactiveCN105061871AStrong sense of weightImprove slip resistanceCarrying capacityButadiene-styrene rubber

The invention discloses a hollow inflation-free plastic foaming wheel which is formed by carrying out low-temperature pelletizing on a composition, carrying out low-temperature injection-molding on the composition by use of an injection molding machine to form wheel blank, and putting the wheel blank into a mould to carry out high-temperature foaming, wherein the composition comprises the following components in parts by weight: 55-60 parts of ethylene-vinyl acetate (EVA), 20-30 parts of styrene-butadiene (SBS), 15-25 parts of rubber softening oil, 10-20 parts of calcium carbonate, 15-25 parts of polyethylene (PE), 2-4 parts of an AC foaming agent, and 1-2 parts of dicumyl peroxide (DCP). The hollow inflation-free plastic foaming wheel has the advantages that the weight is relatively great, the sense of weight is strong, and the visual sense has sense of rubber; and more importantly, on usability, the wear resistance can be improved by 2.5 times, the carrying capacity can be improved by 3-4 times, the skid resistance is greatly improved, and the service life can be prolonged by more than three times.

Owner:JIANGXI GUOSU IND CO LTD

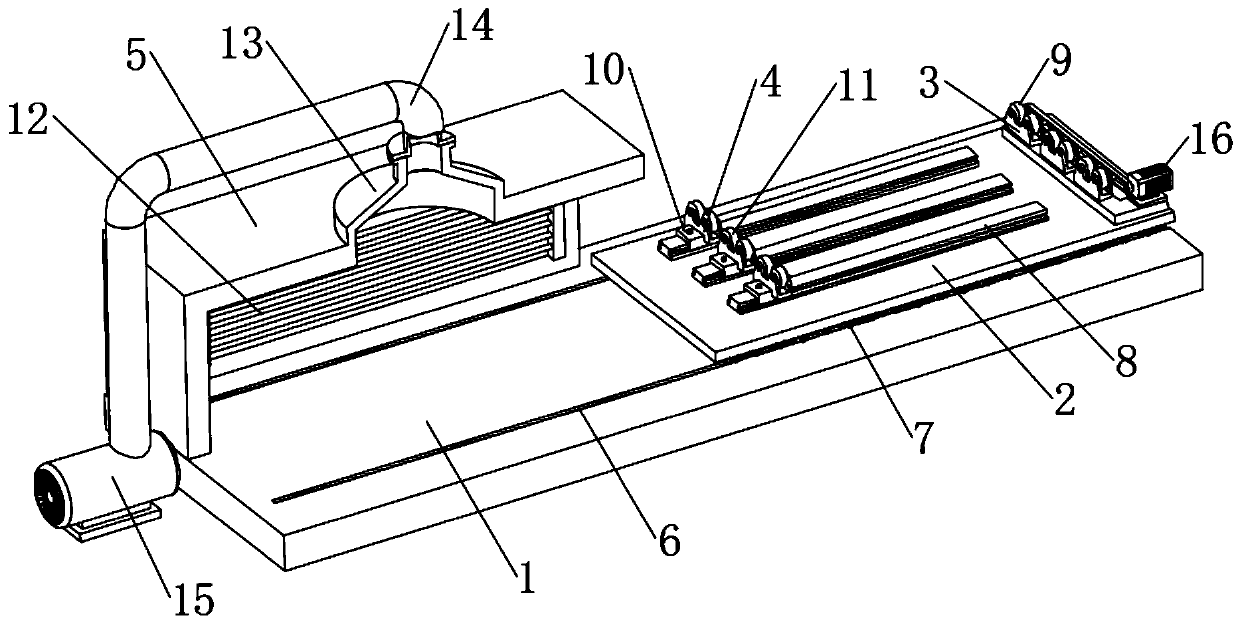

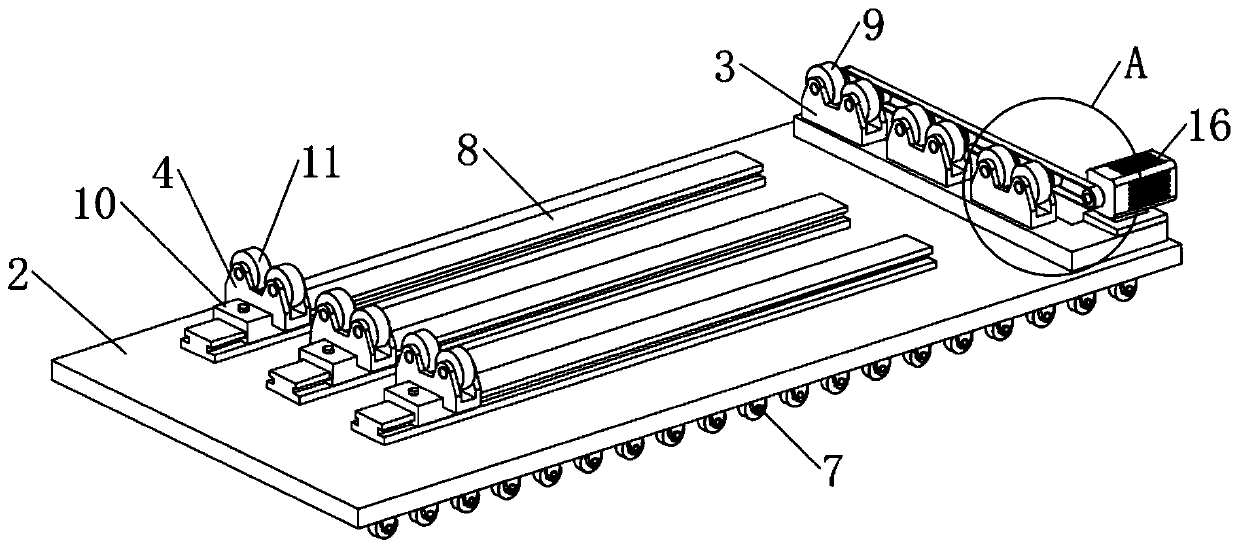

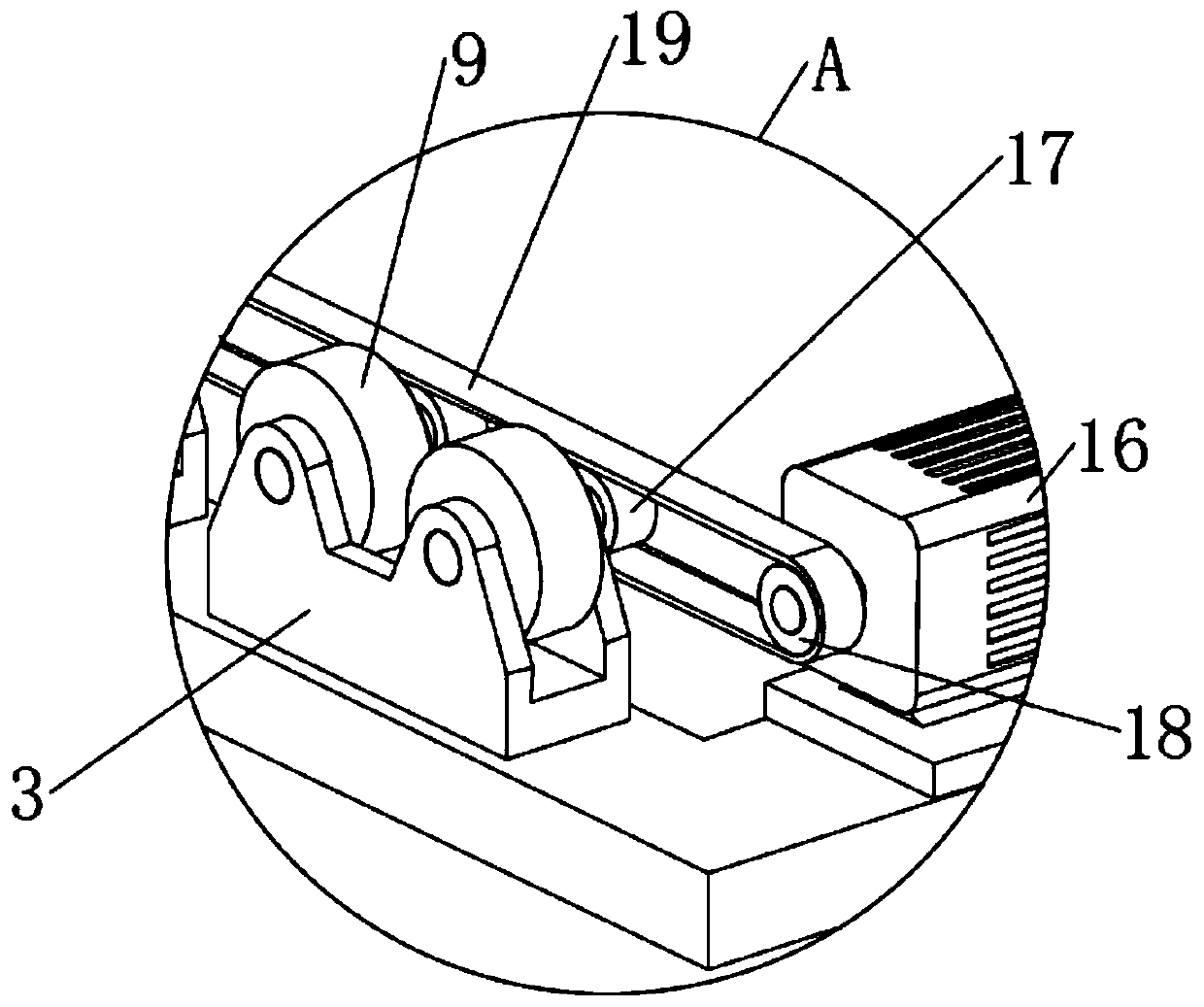

High-efficiency hardware pipe fitting paint drying facility

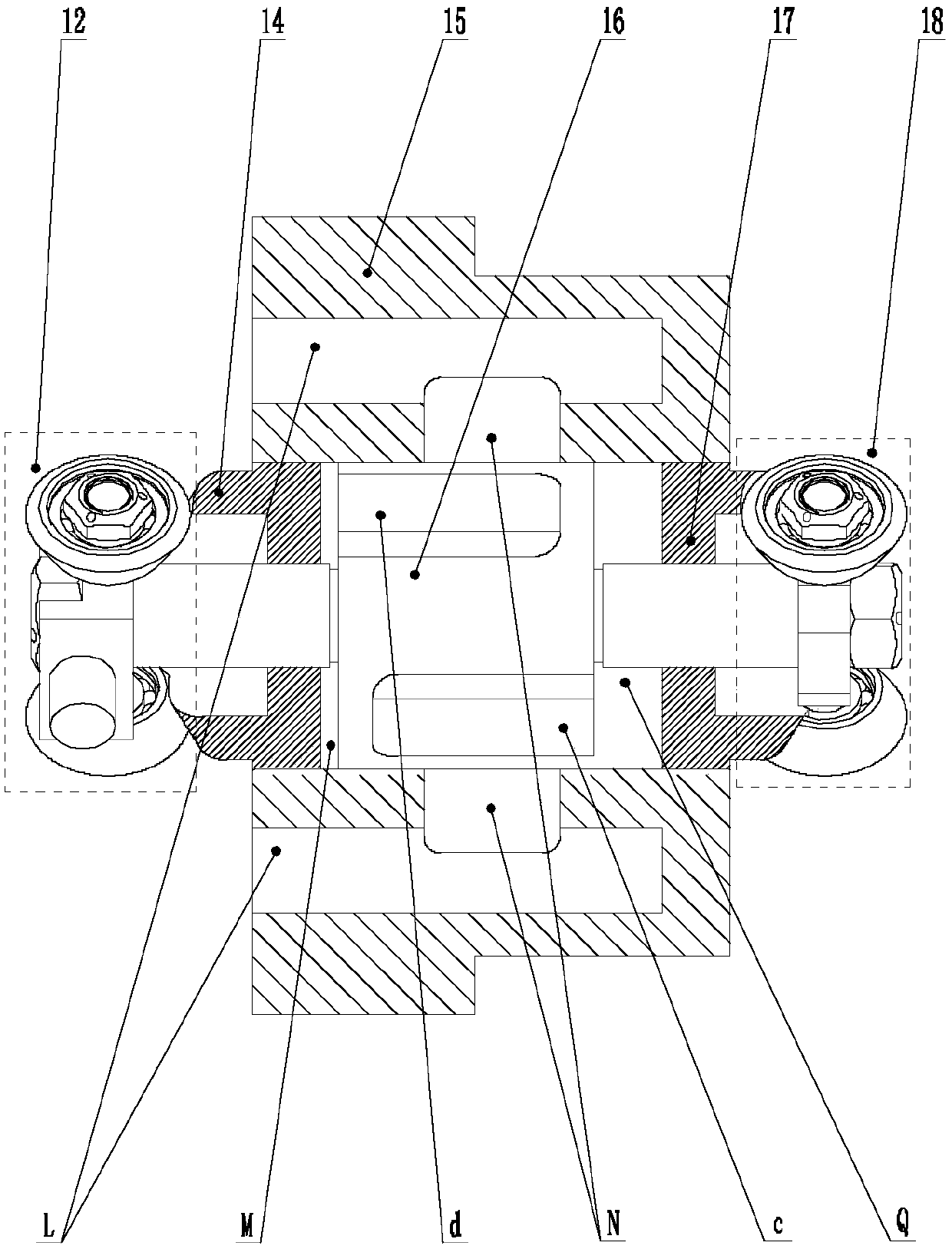

The invention discloses a high-efficiency hardware pipe fitting paint drying facility, and relates to the field of hardware processing equipment. The high-efficiency hardware pipe fitting paint dryingfacility comprises a base, a sliding disc, fixing wheel bases, adjusting wheel bases and a heating box. The sliding disc makes rolling contact with the interiors of two sliding wheel grooves of the base through two rows of rolling wheels. Adjusting guide rails which are arranged on the sliding disc are connected with the adjusting wheel bases in a sliding mode, and each fixing wheel base is arranged at one end of the corresponding adjusting guide rail. By the adoption of the high-efficiency hardware pipe fitting paint drying facility, sliding bases are subjected to sliding movement on the adjusting guide rails according to the lengths of steel pipes, and can be adjusted to the positions where the steel pipes can be well placed. When an electric motor works, multiple driven wheels are driven by a transmission belt, fixing wheels can be rotated, and therefore the steel pipes can be rotated and overturned, and the uniform heating of the steel pipes is facilitated. The air is sucked froman exhaust opening formed in the top wall of the heating box through an air guide pipe, and the poisonous gas which is generated when the paint is heated is sucked and exhausted.

Owner:陈烁

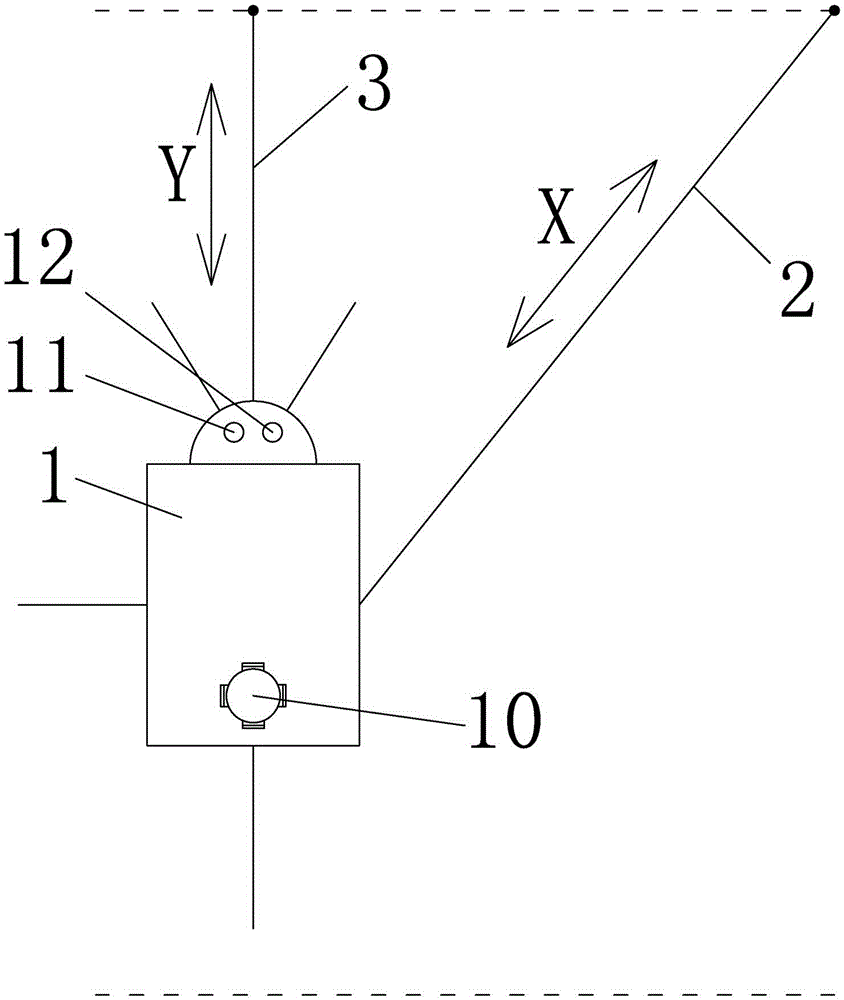

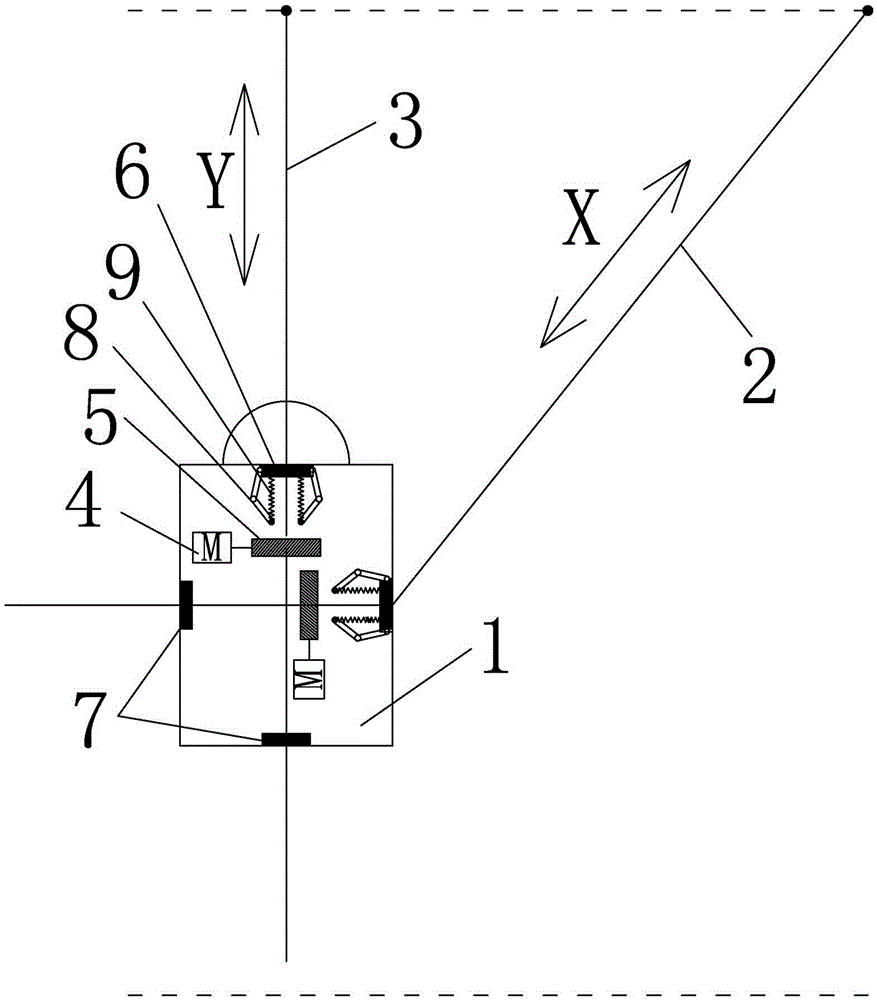

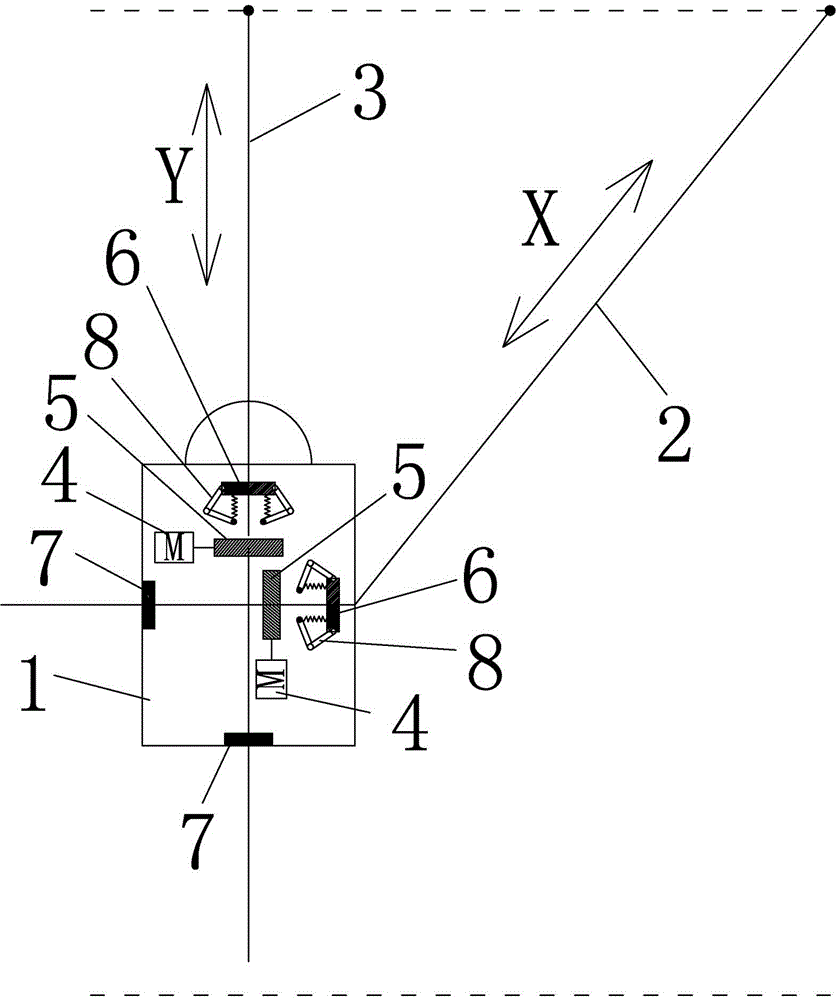

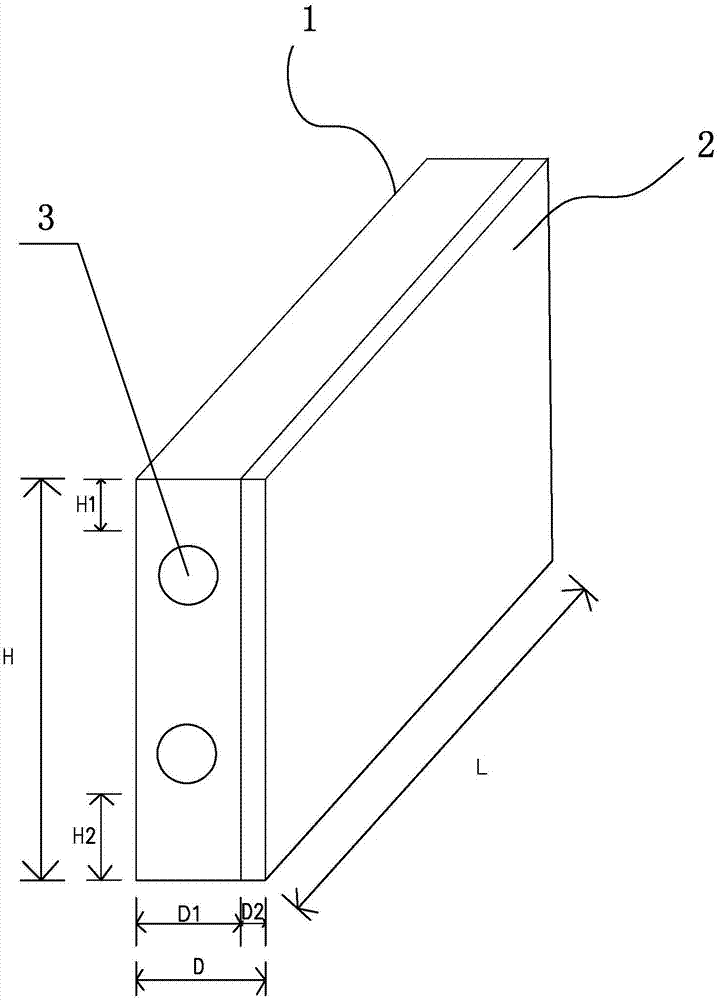

X-Y both-way unmanned remote control climbing robot

An X-Y both-way unmanned remote control climbing robot is characterized by comprising a main machine, a climbing device and a rescuing device, wherein the climbing device and the rescuing device are arranged in the main machine, the climbing device comprises an X-axis steel wire rope and a Y-axis steel wire rope fixed to the top, and the X-axis steel wire rope and the Y-axis steel wire rope are connected with corresponding winding devices and corresponding electromagnet clamping devices in the main machine respectively; and the winding devices are rollers driven by motors, the steel wire ropes are wound on the rollers, and the main machine can be driven to move in the corresponding direction during rotation of the rollers. The X-Y both-way unmanned remote control climbing robot has the beneficial effects that a winding type rope collecting climbing type structure is adopted, climbing force can be improved while climbing stability is guaranteed, and more functions can be easily achieved in the robot; stepping type advancing of the robot can be achieved through cooperation of electromagnets and the winding devices, steel wires wound on the winding devices can be released in time, and it is avoided that due to too many wound steel wires, the size of the robot is large, and the mass is large.

Owner:ZHUHAI ANZHUO ROBOT AUTOMATION CO LTD

Building fence material prepared by compounding steel core and PVC material

InactiveCN111234419AGuaranteed performancePerformance impact, enhanced wind pressure resistance guaranteeFencingFoaming agentPolyvinyl chloride

The invention discloses a building fence material prepared from a steel core composite PVC material. Weight part, the composition comprises the following components, the material comprises the following components in parts by weight: 70-85 parts of PVC resin particles, 5-15 parts of polyvinyl chloride, 5-15 parts of phenolic resin particles, 0.1-0.5 part of p-phenylenediamine, 0.1-0.5 part of barium-zinc composite salt, 1-5 parts of a foaming agent, 0.5-3 parts of a filling agent, 0.1-0.5 part of titanium dioxide and 0.1-0.5 part of an antistatic agent. The flame retardance, wind pressure resistance, heat resistance, freezing resistance and the like of the fence material are enhanced, and weathering and oxidation are avoided.

Owner:湖南翰坤实业有限公司

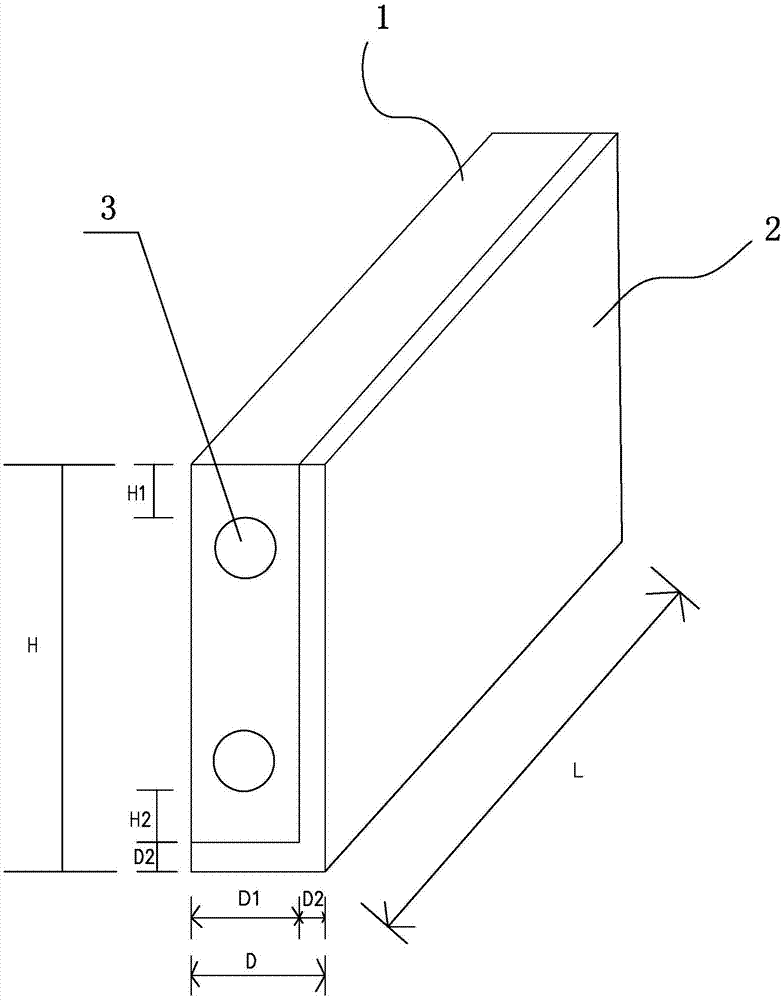

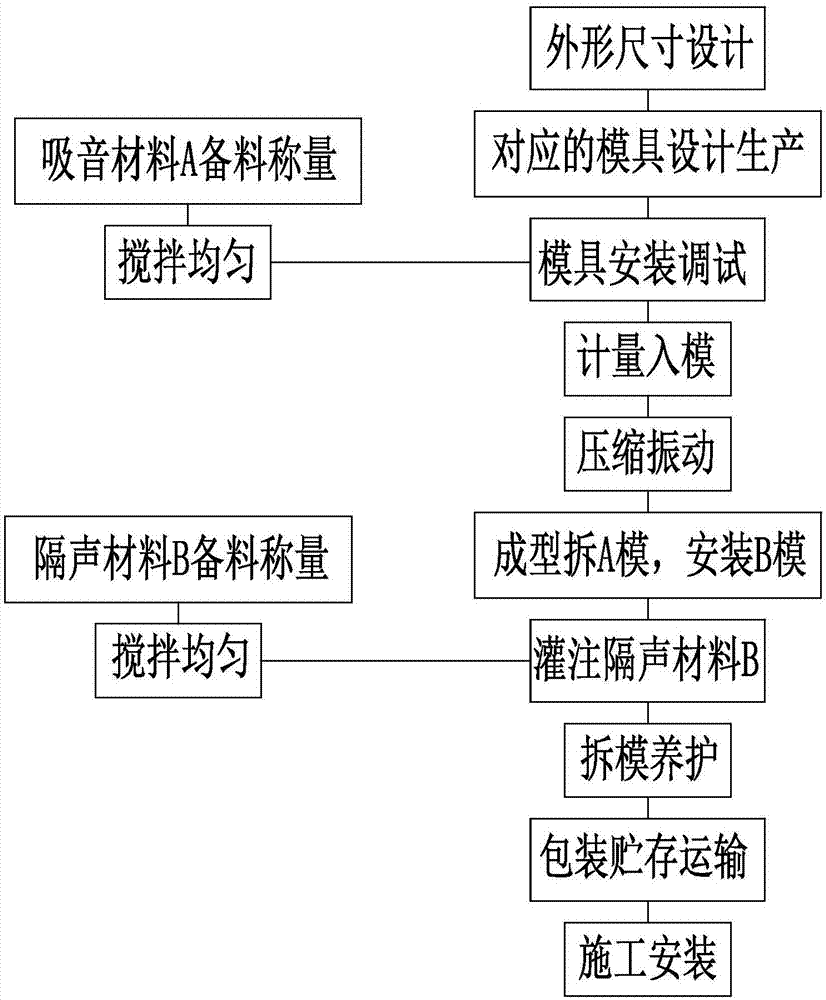

Composite sound absorption sunk fence and manufacturing method thereof

ActiveCN108002781AImprove the noise reduction effectGood sound absorption and noise reduction effectNoise reduction constructionPolyesterFiber

The invention discloses a composite sound absorption sunk fence. The composite sound absorption sunk fence is composed of a sound absorbing layer and a sound insulating layer, wherein the sound absorbing layer is formed by pressing ceramsite concrete half-dried materials, the sound insulating layer is formed by blending sound insulating materials, and the thickness of the sound absorbing layer isgreater than that of the sound insulating layer; the sound absorption layer is mainly formed by blending and pressing cement, unfired ceramsite, polycarboxylate superplasticizer, polyester fibers, redispersible latex powder, mildew preventive and water; the sound insulating layer is mainly formed by blending and pressing cement, sulphate aluminium cement, coal ash, quartz sand, an HEA expanding agent, a water reducing agent, 5111L latex powder, fibers, a defoaming agent, aluminite powder, sodium gluconate and water. The composite sound absorption sunk fence has the advantages of being excellent in noise reduction capability and mechanical performance, capable of beautifying the spatial environment and the like. The manufacturing method of the composite sound absorption sunk fence is simplein process and scientific in production and forming process, and a die of the product can be designed according to the required shape for compression molding.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

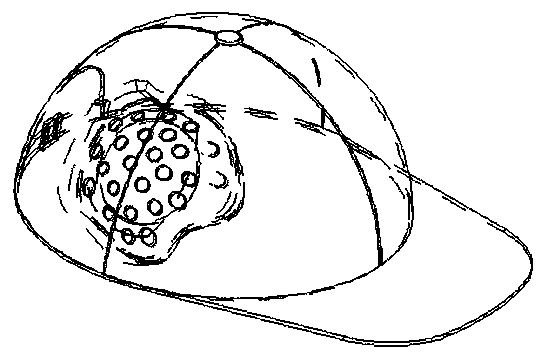

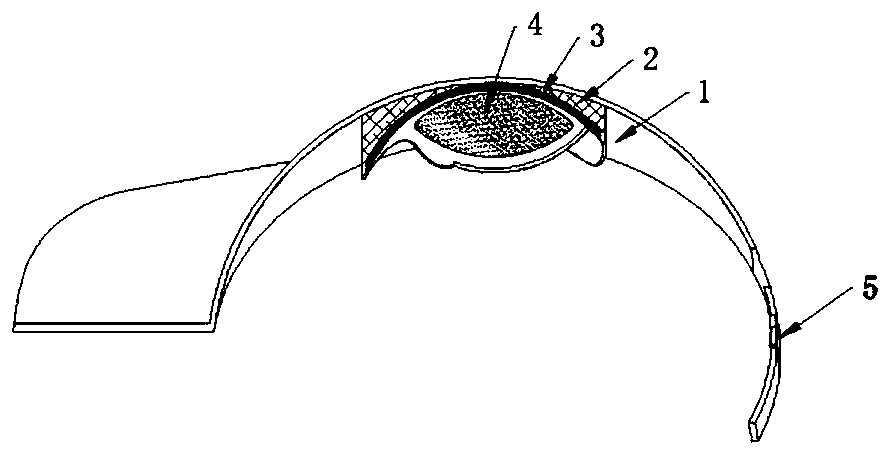

Personalized skull defect protection device and preparation method

PendingCN111544178ANot easy to dropImprove comfortAdditive manufacturing apparatusNon-surgical orthopedic devicesSkull boneImage extraction

The invention provides a personalized skull defect protection device and a preparation method. The protection device comprises a cap body and a 3D printing protection support matched with a damaged part of a patient, the 3D printing protection support is provided with a smooth contour edge and can cover a skull defect part of the patient, the outer side of the 3D printing protection support is wrapped with a connecting cover, and the side, away from the damaged part of the patient, of the connecting cover is connected with the inner side of the cap body. Due to the arrangement of the personalized 3D printing protection support, the defect part can be substantially protected. The preparation method comprises the following steps: reconstructing a three-dimensional computer image of the headof a patient according to three-dimensional data of the head of the patient to obtain a three-dimensional computer image of a defect part of the patient, extracting a curved surface of the three-dimensional computer image of the defect part, reconstructing a protection support computer three-dimensional model according to the curved surface, and printing a solid body of the protection support in a3D mode so that the protection support matched with the defect portion of the patient is obtained, recovery of head defects of the patient is facilitated, and comfort of the patient is improved.

Owner:HUNAN BOKE BIOTECH CO LTD

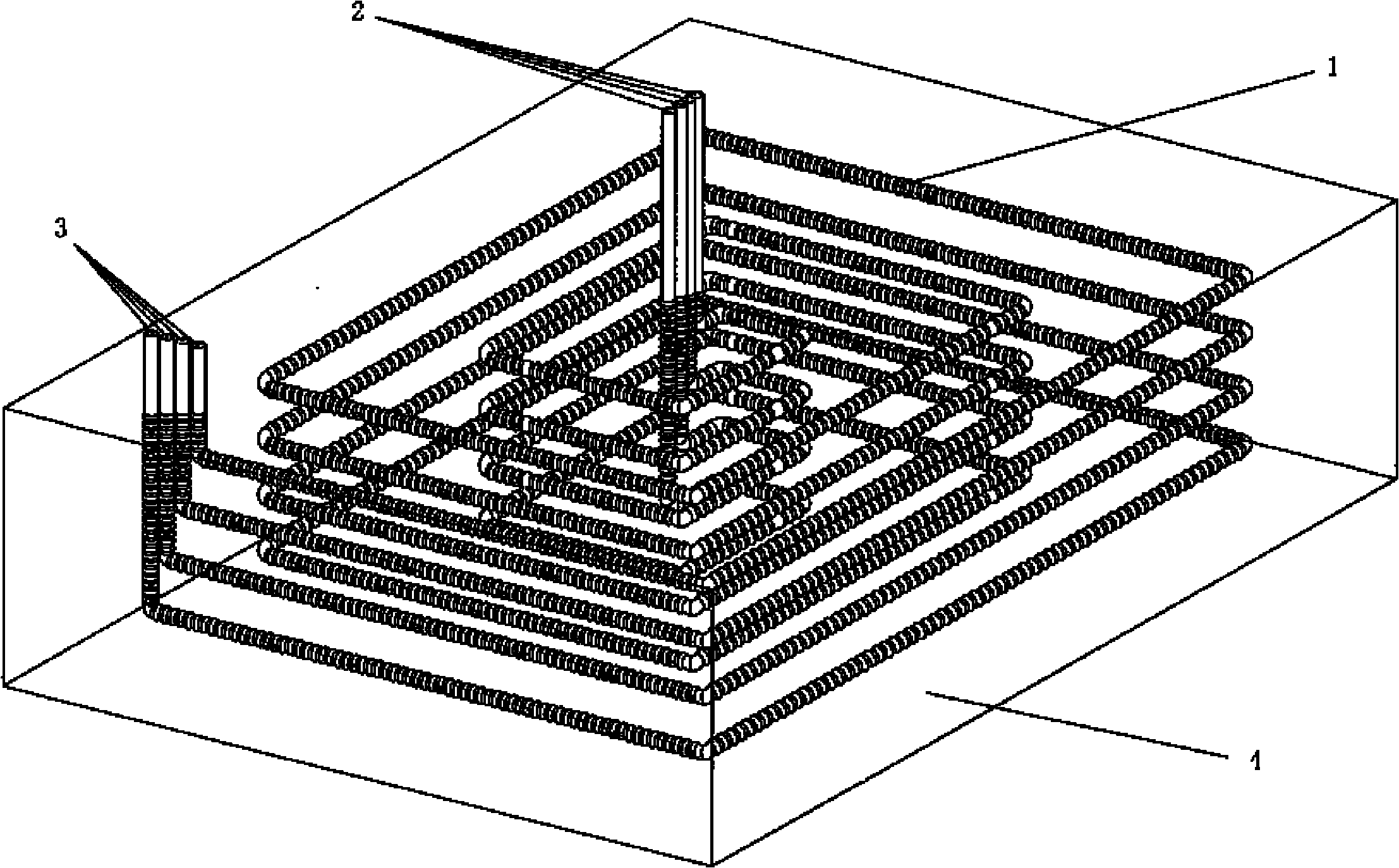

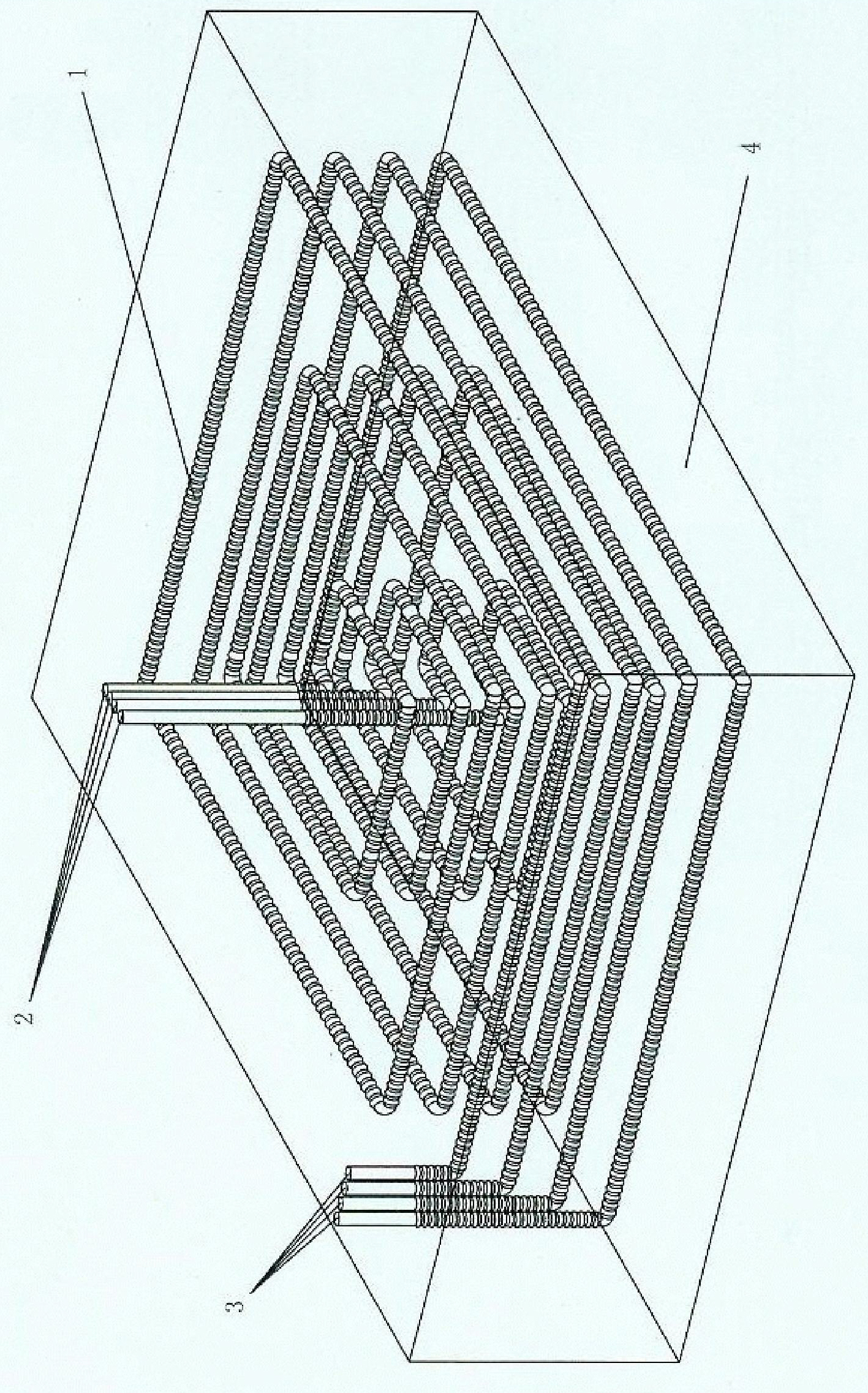

Construction method of temperature decrease and crack prevention of mass concrete by utilizing thin-walled corrugated pipe circulating water system

InactiveCN101672106BImprove thermal conductivityImprove heat transfer performanceBuilding material handlingArchitectural engineeringRebar

The invention relates to a construction method of mass concrete temperature decrease and crack prevention by utilizing a thin-walled corrugated pipe circulating water system, which comprises the following steps: (1) selecting circulating water pipes: selecting thin-walled iron-sheet corrugated pipes as the pipeline materials for arranging circulating water pipes; (2) arranging a circulating waterpipe system: in the process of binding a reinforcing cage, installing and fixing the corrugated pipes to the reinforcing cage in a spiral or laminated way according to the structure form of a mass concrete, wherein, the distance between layers is from 500 mm to 2000 mm, the distance between rows in the layers is also from 500 mm to 2000 mm, and providing a water inlet pipe and a water outlet piperespectively connected with the corrugated pipes on the upper part of the mass concrete; (3) arranging temperature measuring points; (4) pouring the concrete; and (5) keeping maintenance. The construction method has the advantages of obvious effect on the temperature decrease and crack prevention of the mass concrete, low cost, simple operation, convenient and quick construction and convenience in the connection of the corrugated pipes.

Owner:中国建筑第五工程局有限公司东莞分公司

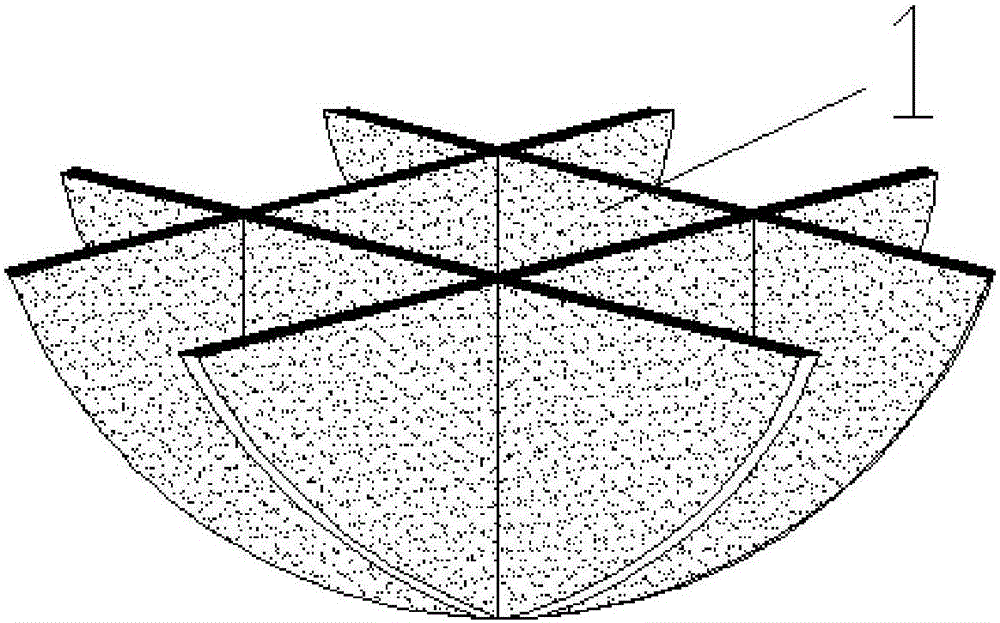

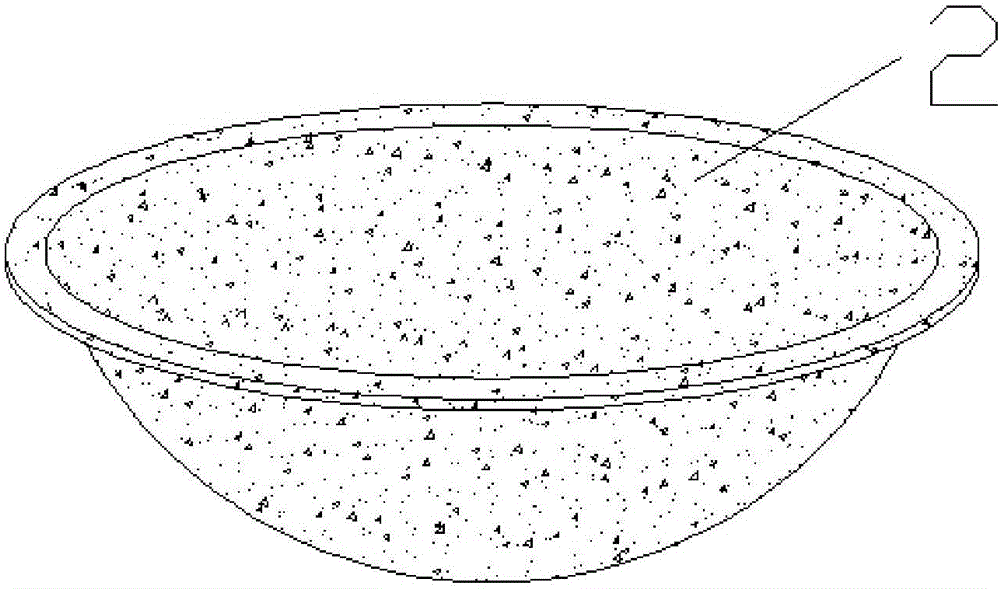

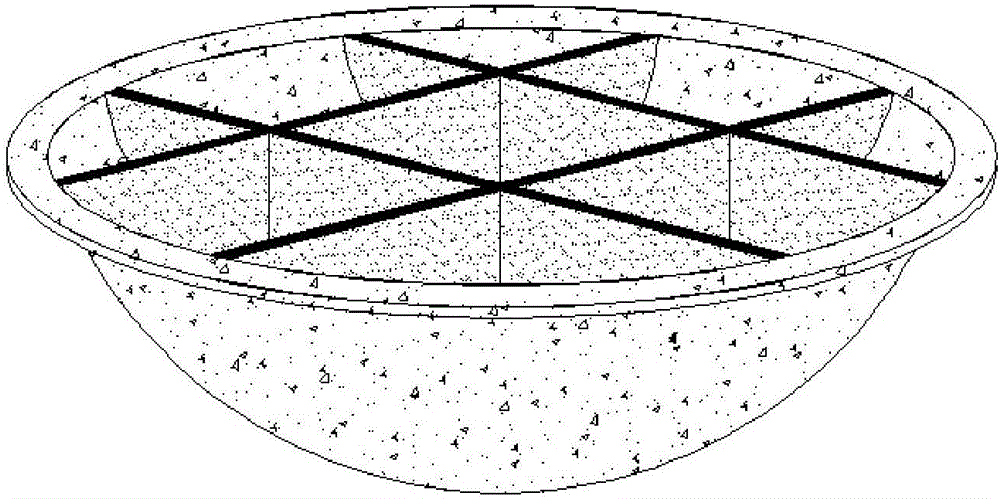

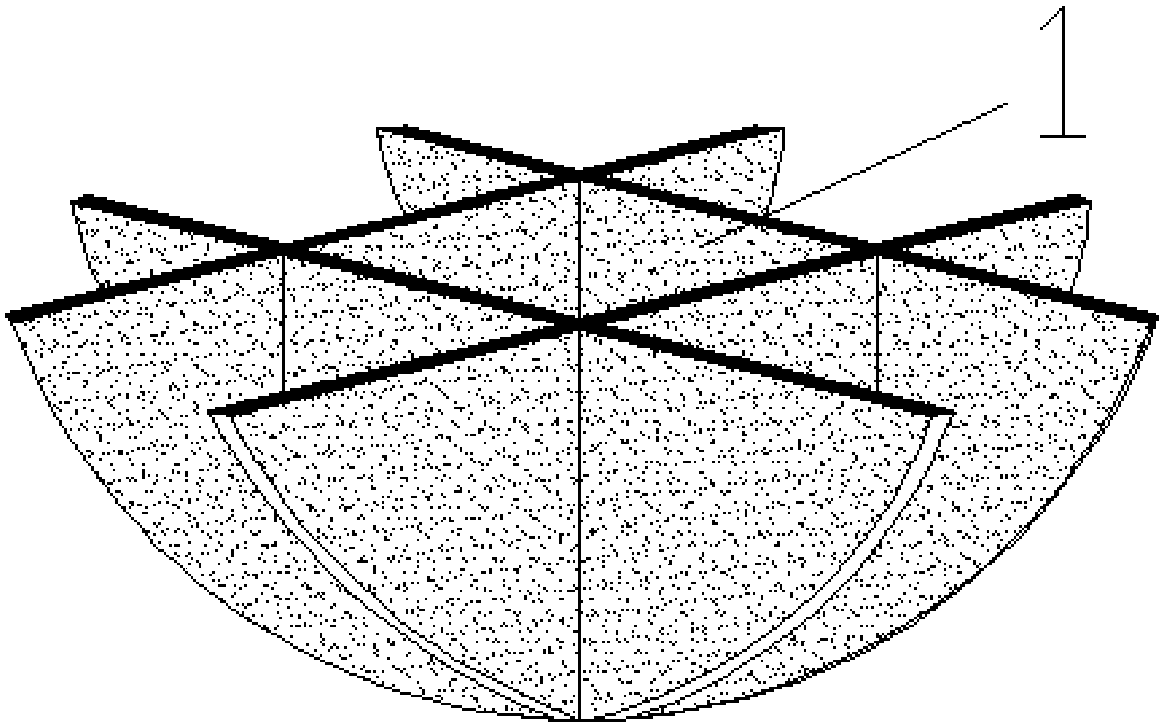

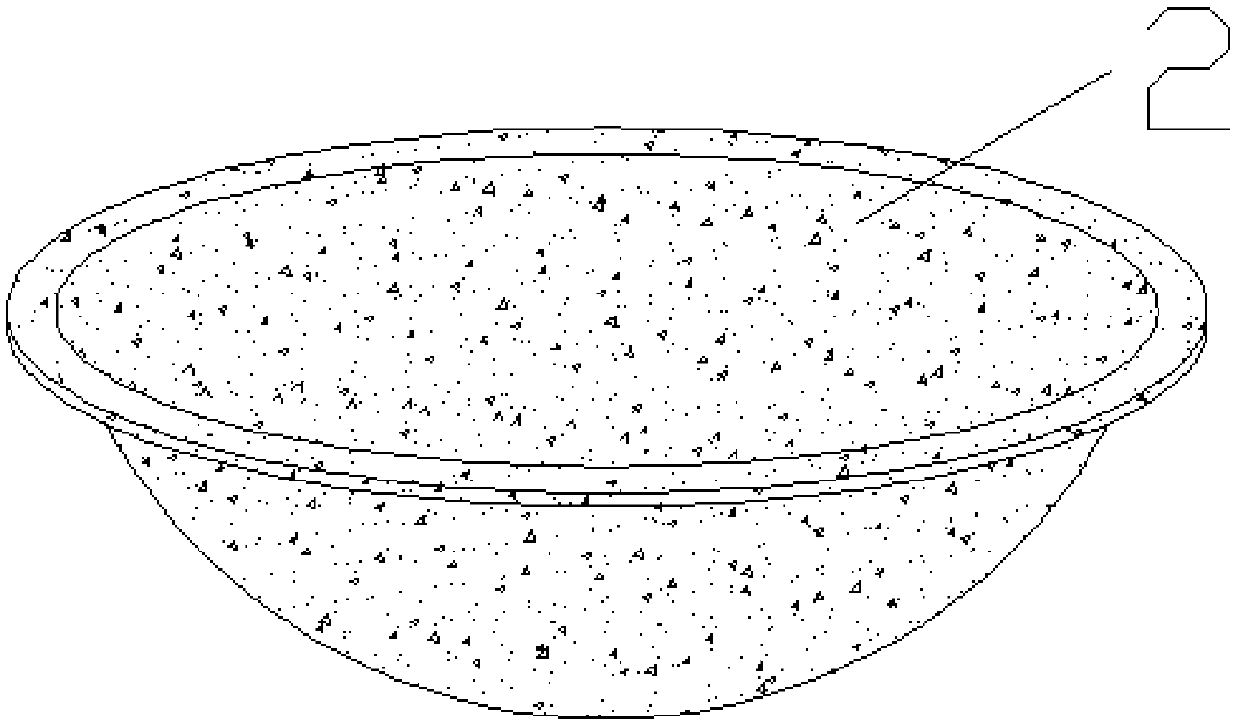

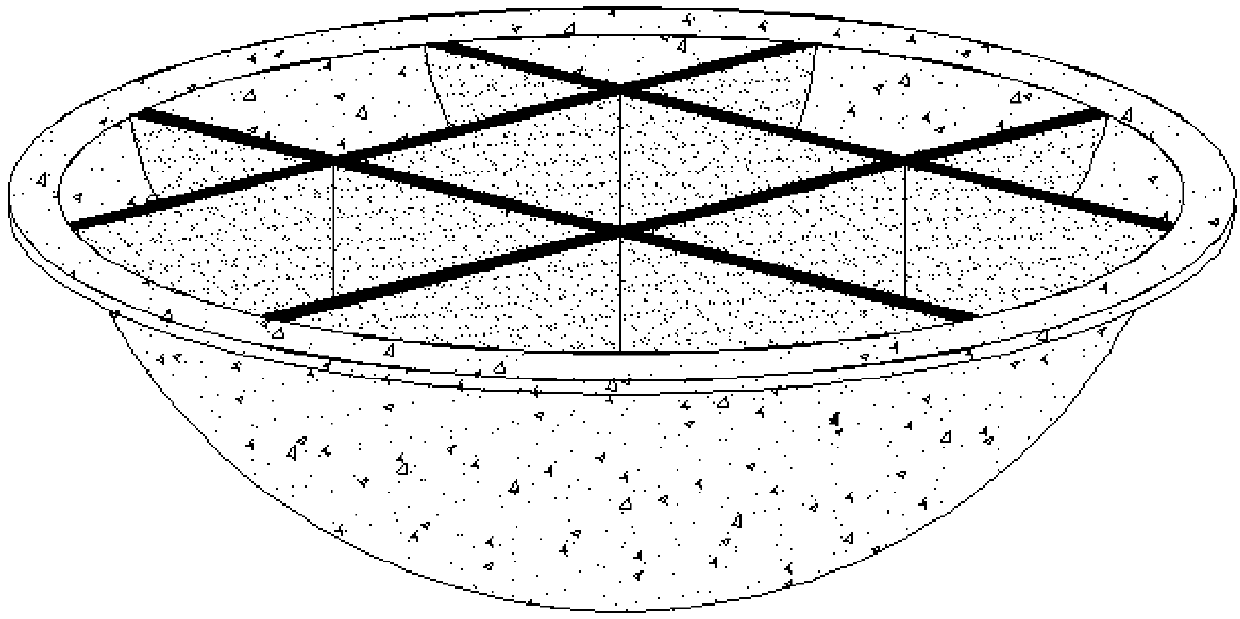

Method for casting multi-box hot pot

The invention provides a method for casting a multi-box hot pot, and belongs to the technical field of iron pot casting. According to the hot pot, partition plates are cast at first, and then the partition plates and a pot body are in melting combination to achieve seamless connection. The method includes the main steps that (1) the partition plates are formed; (2) the partition plates are placed into a mold to be polished; (3) the pot body and the partition plates are combined; and (4) cooling molding is performed. By the adoption of the method, the hot pot is made of cast iron which is natural, environmentally friendly, safe and stable in performance, the hot pot is divided into a plurality of small boxes through the partition plates, and the partition plates and the pot body are subjected to casting molding directly without welding; hence, hazardous substances at the welding position can be prevented from entering human bodies along with the hot pot, corrosion of the connecting portion between the partition plates and the pot body due to cooking the hot pot for a long time is prevented, the phenomenon of being tainted by other odors between all the small boxes is effectively avoided, and hot pot quality is improved. Moreover, the pot body is separated by the partition plates, each person can use his / her different small boxes, different hot pot materials can be boiled, and therefore the hot pot not only is sanitary but also can be used for boiling different kinds of food at the same time.

Owner:陆川县浦宝铁锅厂

Silk floss quilt

The invention discloses a silk floss quilt of which the edges are difficult to turn up. The silk floss quilt comprises a coverlid and silk floss arranged in the coverlid, wherein the edges of the coverlid are provided with balancing weights. The silk floss quilt has the following advantages: the mass is relatively heavy, the edges of the quilt are difficult to turn up and generate wrinkles in use, and the quilt has an attractive appearance and is convenient to use.

Owner:朱叶蕾

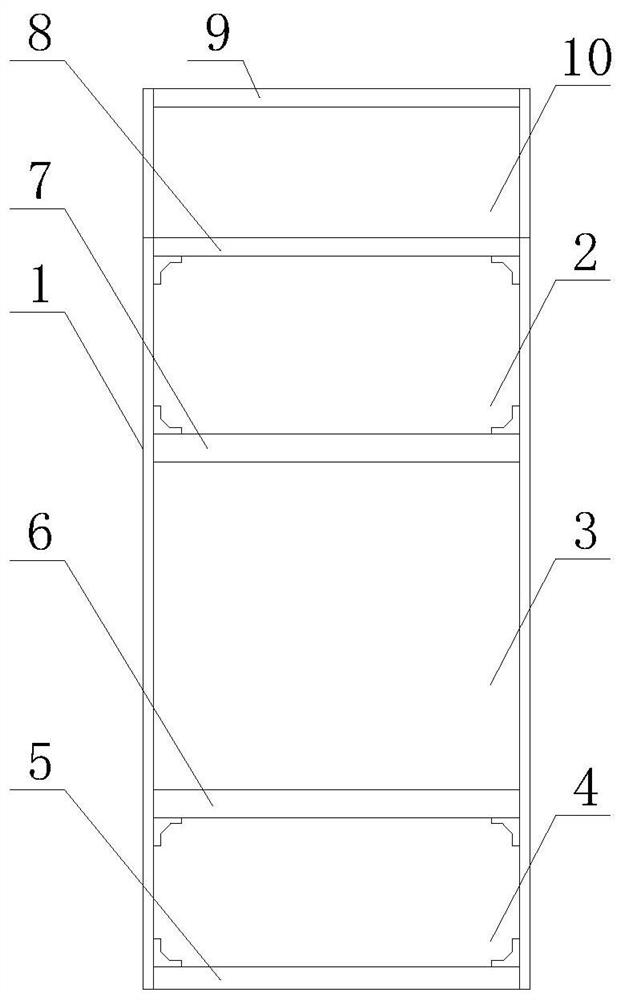

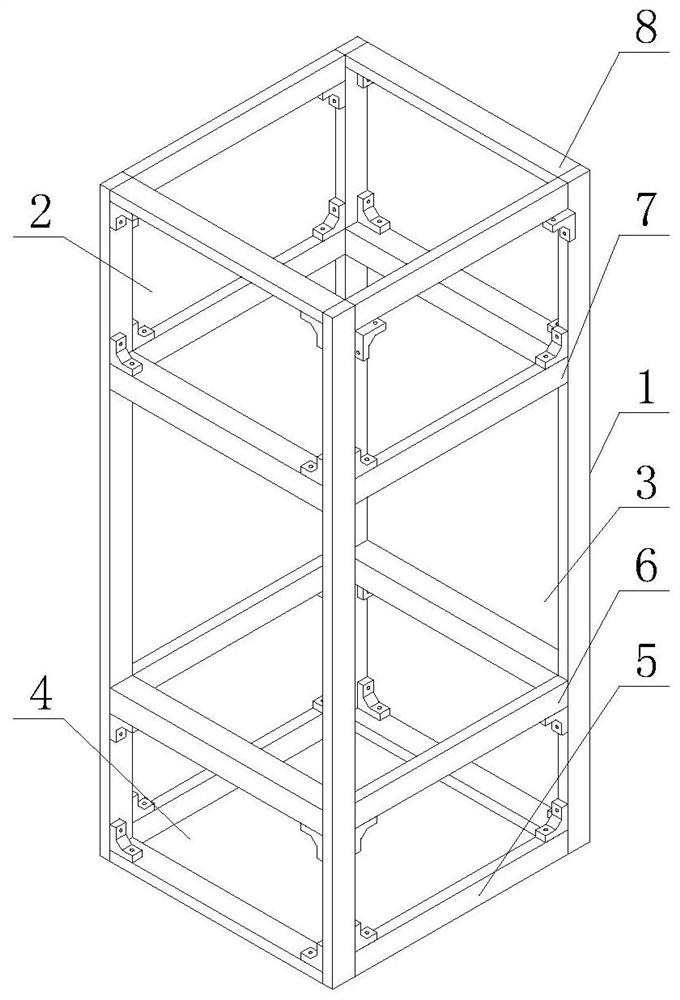

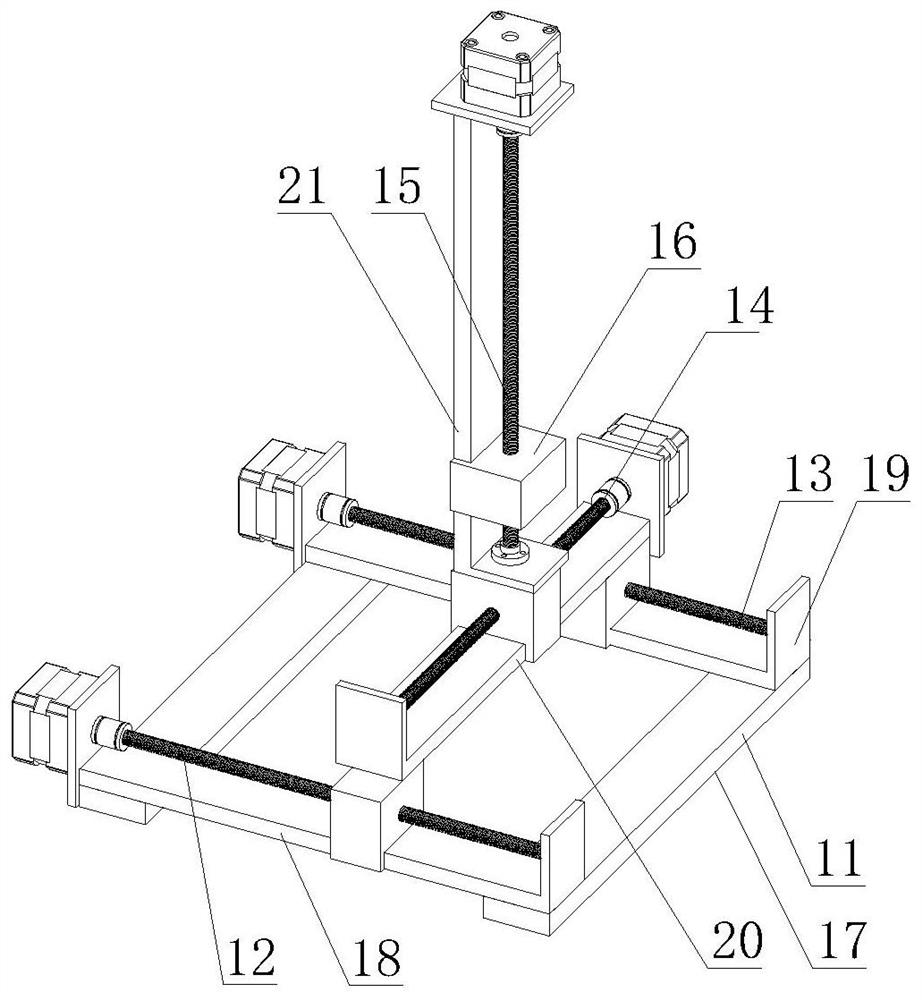

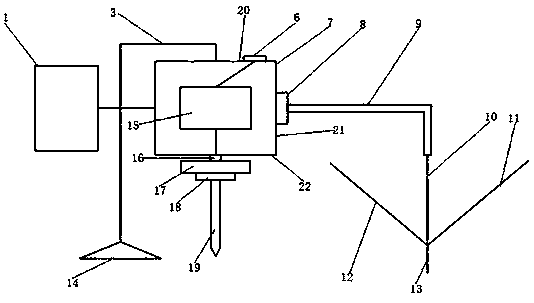

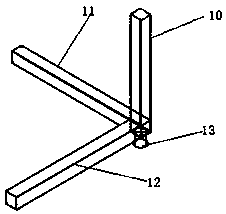

Automatic numerical control welding device

PendingCN112643168AAvoid stickingPrevent sticking and unable to start arcWelding accessoriesNumerical controlControl theory

The invention discloses an automatic numerical control welding device. The automatic numerical control welding device comprises a box body and a frame body, wherein the frame body is supported by stand columns; the interior of the box body is divided into a to-be-welded area, a sliding table area and a fan filtering area which communicate with one another; a sliding table part is mounted in the sliding table area; the sliding table part comprises a sliding table base, a Y-axis sliding table, a C-axis sliding table, an X-axis sliding table, a Z-axis sliding table and an electrode holder clamping table, the Y-axis sliding table and the C-axis sliding table are fixedly mounted on the sliding table base, the X-axis sliding table is slidably mounted on the Y-axis sliding table and the C-axis sliding table, one end of the Z-axis sliding table is slidably mounted on the X-axis sliding table, the Z-axis sliding table and the X-axis sliding table are installed in a relative perpendicular mode, the electrode holder clamping table is installed on the Z-axis sliding table in a sliding mode, and a welding gun is installed on the electrode holder clamping table. The inclined plane machining tool with the angle capable of being adjusted at will is compact in structure; and auxiliary wedge blocks are additionally arranged, and the application range in the industrial production field is wide.

Owner:LANZHOU INST OF TECH

Casting method of multi-format hot pot pot

The invention provides a method for casting a multi-box hot pot, and belongs to the technical field of iron pot casting. According to the hot pot, partition plates are cast at first, and then the partition plates and a pot body are in melting combination to achieve seamless connection. The method includes the main steps that (1) the partition plates are formed; (2) the partition plates are placed into a mold to be polished; (3) the pot body and the partition plates are combined; and (4) cooling molding is performed. By the adoption of the method, the hot pot is made of cast iron which is natural, environmentally friendly, safe and stable in performance, the hot pot is divided into a plurality of small boxes through the partition plates, and the partition plates and the pot body are subjected to casting molding directly without welding; hence, hazardous substances at the welding position can be prevented from entering human bodies along with the hot pot, corrosion of the connecting portion between the partition plates and the pot body due to cooking the hot pot for a long time is prevented, the phenomenon of being tainted by other odors between all the small boxes is effectively avoided, and hot pot quality is improved. Moreover, the pot body is separated by the partition plates, each person can use his / her different small boxes, different hot pot materials can be boiled, and therefore the hot pot not only is sanitary but also can be used for boiling different kinds of food at the same time.

Owner:陆川县浦宝铁锅厂

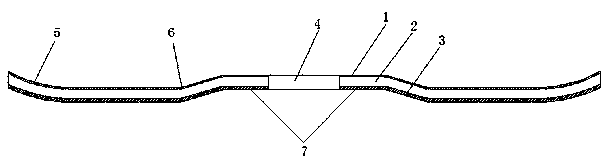

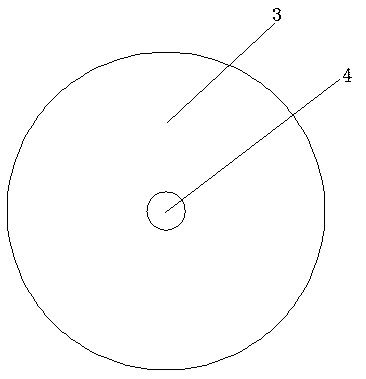

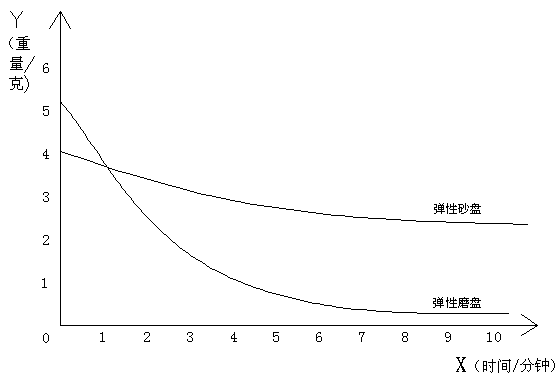

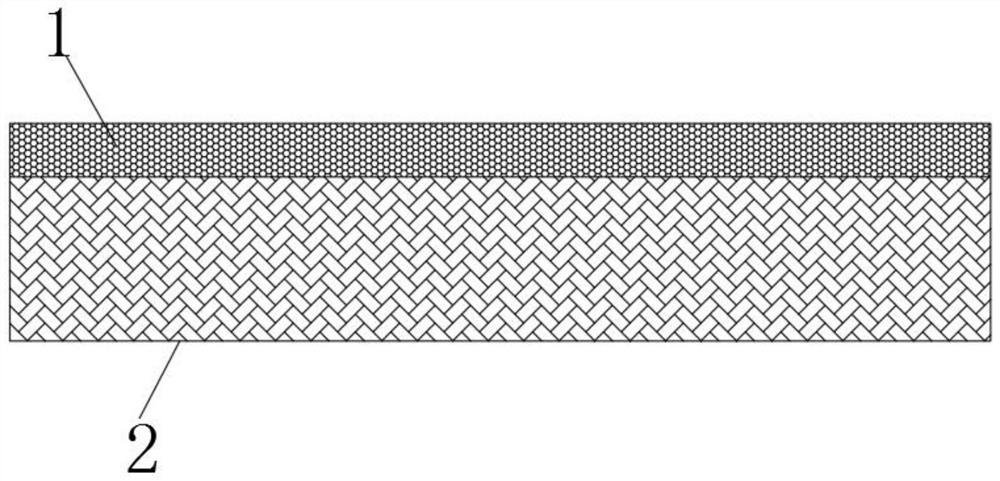

Elastic abrasive disc and manufacturing process thereof

PendingCN108818334ASimple production processIncrease productivityBonded abrasive wheelsGrinding devicesEngineeringTransportation cost

Provided are an elastic abrasive disc and a manufacturing process thereof. The elastic abrasive disc comprises a label layer, a supporting layer and a polishing layer, wherein the supporting layer islocated between the label layer and the polishing layer, the label layer, the supporting layer and the polishing layer are in the same shapes and are in circular ring shapes, mounting holes are formedin the centers of the label layer, the supporting layer and the polishing layer, and the label layer, the supporting layer and the polishing layer are solidified to be of an integrated structure by being heated in a die. The elastic abrasive disc and the manufacturing process have the beneficial effects that the manufacturing process is simple, the weight is low, the elastic abrasive disc cannotswing when being mounted on a tool, the safety performance is high, the elastic abrasive disc is degradable, high in grinding efficiency and high in self-sharpening performance, the use rate of abrasive cloth is high, the elastic abrasive disc is suitable for polishing of corners and gaps, the size is small, the package and transportation cost is low, the shape is smooth, wind resistance is small,and there is almost no noise at work.

Owner:河南圣叠磨具有限公司

Metal workpiece punching machine with positioning device

The invention discloses a metal workpiece punching machine with a positioning device. The metal workpiece punching machine with the positioning device mainly comprises a coordinate value input unit, asupport frame, a motor box, a coordinate receiver, a coordinate cross rod, a Z-axis rod, an X-axis rod, a Y-axis rod, a support base, a motor, a wire rod, a rotary shaft chassis, a drilling tool installation frame and a drilling tool. The coordinate value input unit is electrically connected with the motor box; the motor box comprises a top surface, side surfaces, a bottom surface and a motor; acharging interface is formed in the top surface; one end of the support frame is arranged in the center of the top surface; the other end of the support frame is connected with the support base; and the coordinate value input unit is arranged in the center of the side surfaces. According to the device, during the use process, the stability of the punching machine is favorably improved, and a coordinate axis positioning device for positioning workpieces is arranged, so that the accuracy in processing the workpieces can be effectively improved, and the whole applicability of the device is increased.

Owner:如皋市昌旭机械制造有限公司

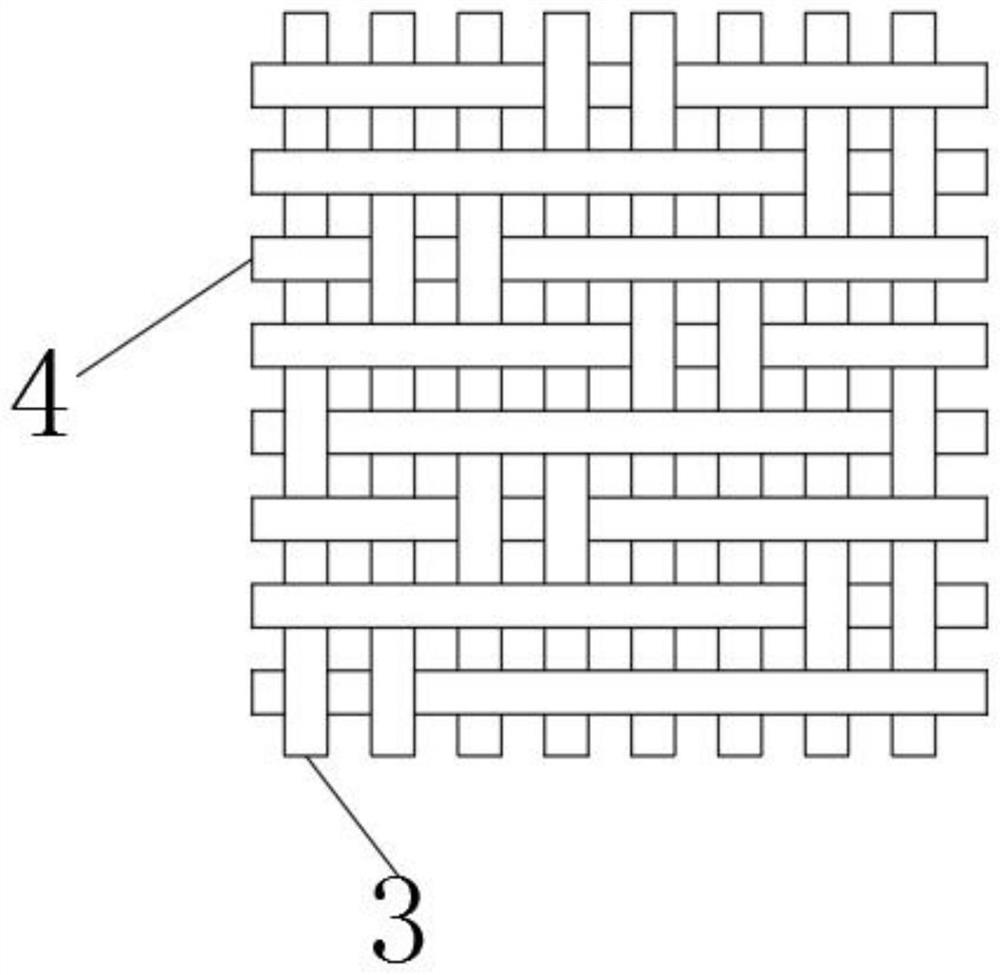

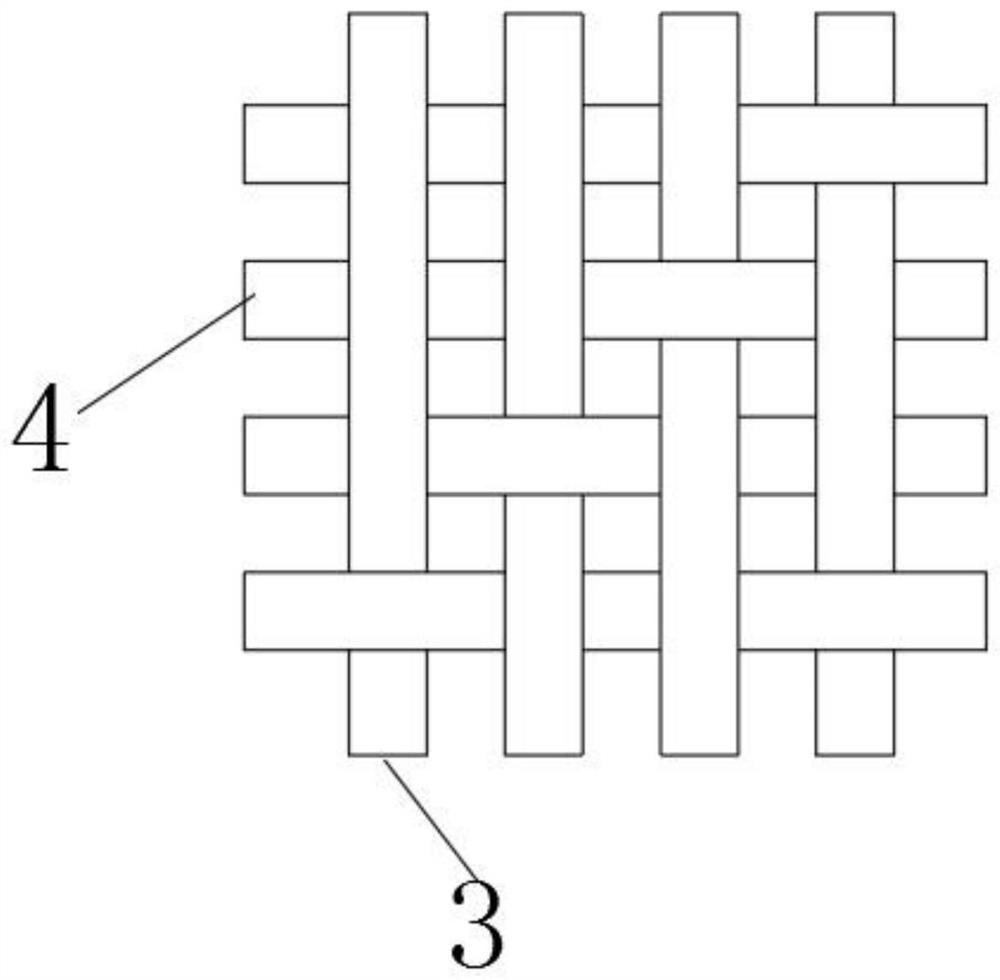

Glass fiber coated filter cloth and manufacturing method thereof

InactiveCN113209719ADifferent physical propertiesHeavy qualitySynthetic resin layered productsLaminationGlass fiberPolytetrafluoroethylene

The invention discloses a glass fiber coated filter cloth and a manufacturing method thereof. The glass fiber coated filter cloth comprises a polytetrafluoroethylene film layer, a glass fiber layer, glass fiber warps and glass fiber wefts, the glass fiber layer is connected below the polytetrafluoroethylene film layer, and the glass fiber layer is formed by weaving the glass fiber warps and the glass fiber wefts. The thickness of the glass fiber layer is greater than that of the polytetrafluoroethylene film layer. The method comprises the following steps: preparing glass fibers, preparing expanded polytetrafluoroethylene, and laminating and packaging expanded filter cloth. A plurality of weaving processes, namely a double twill process, a 1 / 3 twill process and a weft double process are set. According to the glass fiber coated filter cloth, the glass fiber warps and the glass fiber wefts in the glass fiber base cloth are combined in various modes, so that the final glass fiber coated filter cloth has different physical properties, has good working performance in different fields, can exert the maximum advantages in different fields, and improves the use effect of the glass fiber coated filter cloth.

Owner:江苏碧博士纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com