Composite sound absorption sunk fence and manufacturing method thereof

A manufacturing method and technology of low walls, applied in noise absorbing devices, buildings, etc., can solve problems such as discomfort of passengers in vehicles, damage to natural scenery along railway lines, cumbersome maintenance and repairs, etc., and achieve smooth surface, high cylinder compressive strength, and mechanical good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

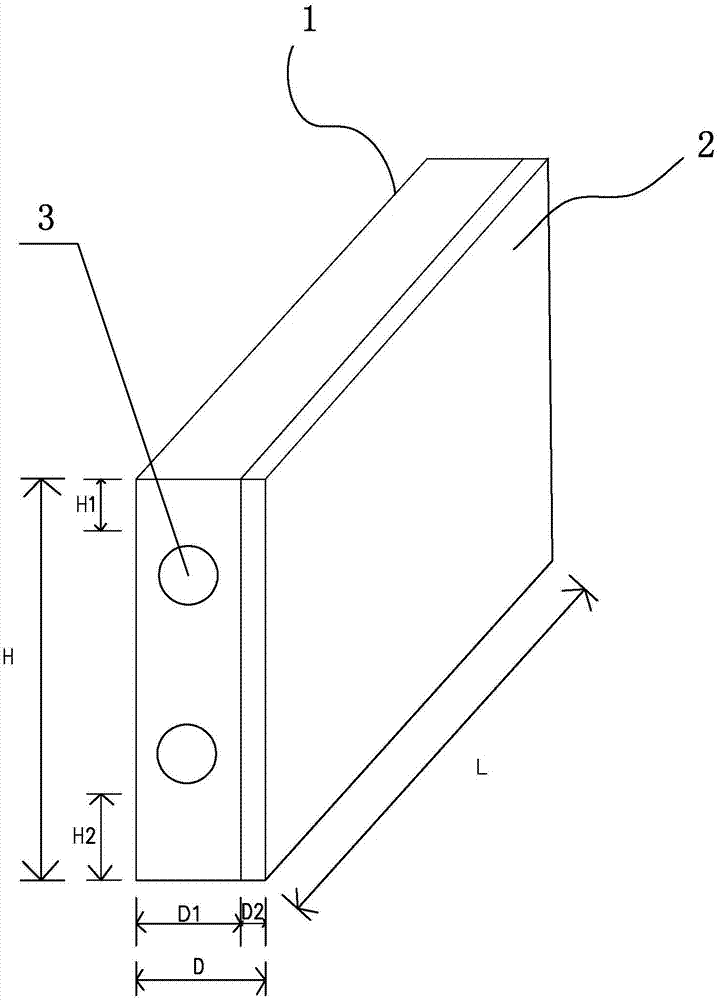

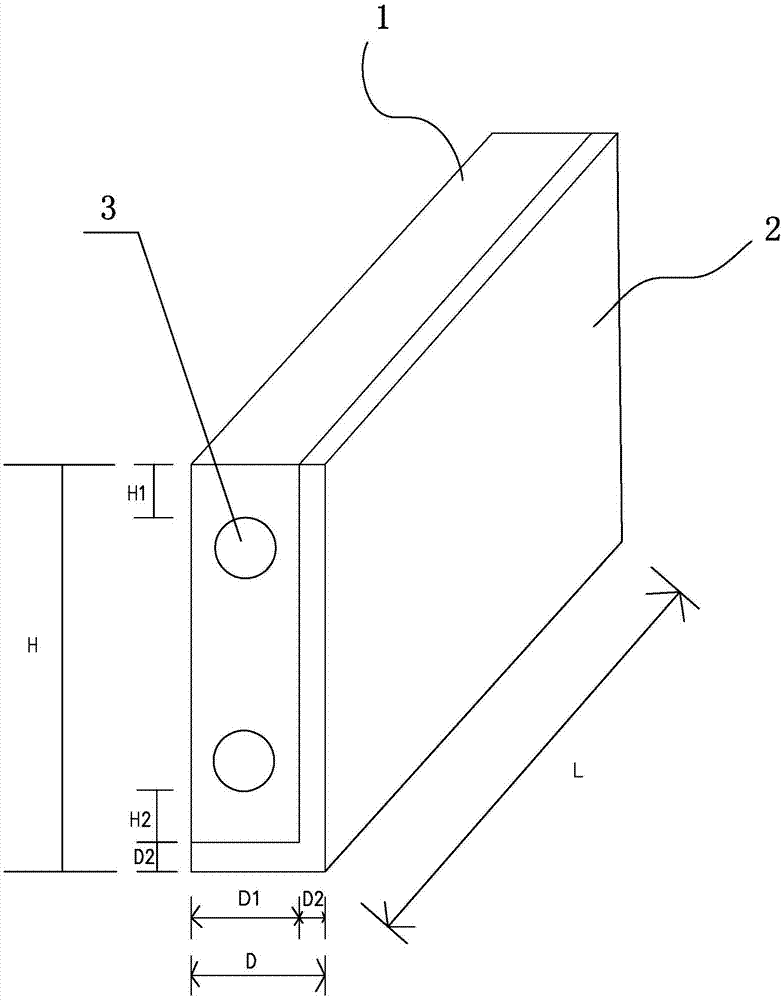

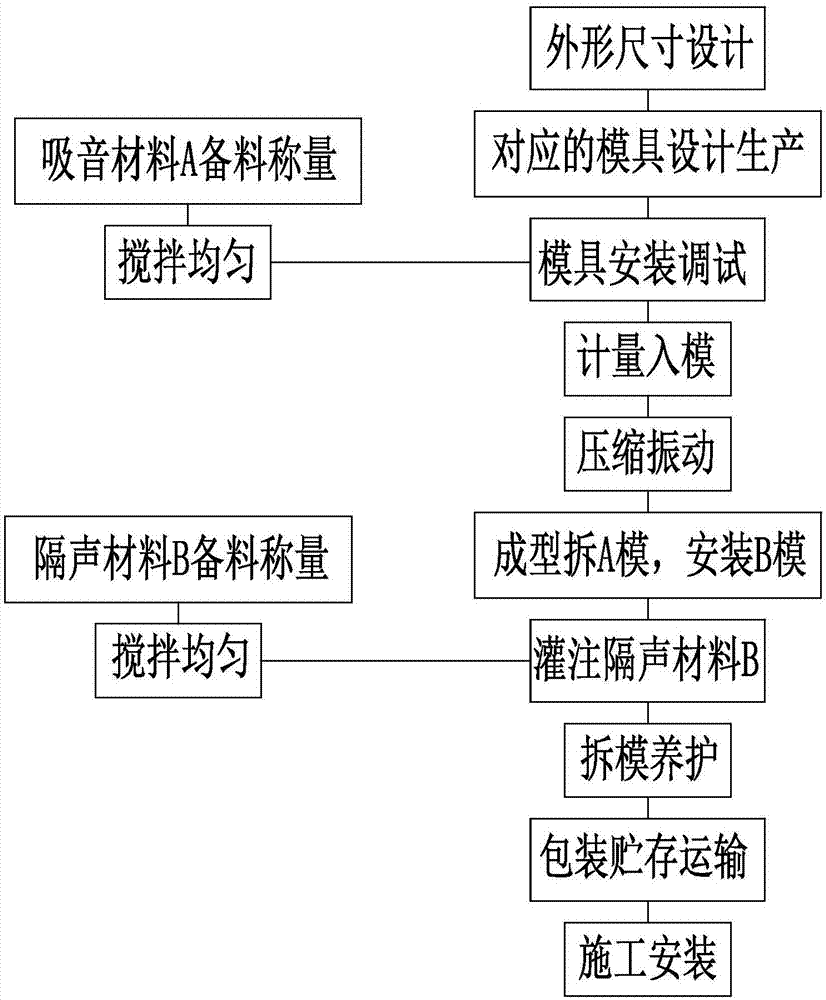

[0036] First design the external dimensions of the composite sound-absorbing low wall length L×thickness D×height H=1000mm×200mm×1000mm, manufacture and produce the A mold with the sound-absorbing layer wall and the composite sound-absorbing low wall according to the size of the composite sound-absorbing low wall For mold B, adjust the mixing ratio of the mixing equipment, and then put the raw materials of the sound-absorbing layer into the mixing equipment according to the following parts by weight and mix them evenly: 100 parts of ordinary silicate 42.5# cement, construction waste with a particle size distribution within the range of 1~10mm 1200 parts of non-fired ceramsite and fly ash, 0.2 part of polycarboxylate superplasticizer, 0.2 part of polyester fiber, 0.1 part of redispersible latex powder, 0.1 part of antifungal agent and 50 parts of water; stir well Pour the final sound-absorbing layer raw material mixture into mold A, vibrate and press, control the compression rat...

Embodiment 2

[0040] First design the external dimensions of the composite sound-absorbing low wall. Length L×thickness D×height H=500mm×100mm×600mm. According to the size of the composite sound-absorbing low wall, A mold with sound-absorbing layer and C with sound-insulating layer are produced. Then put the raw materials of the sound-absorbing layer into the mixing equipment according to the following parts by weight and mix them evenly: 100 parts of ordinary silicate 42.5# cement, construction waste and fly ash unburned ceramsite with a particle size distribution within the range of 1-10mm 1800 parts, 0.5 parts of polycarboxylate superplasticizer, 1 part of polyester fiber, 0.4 parts of redispersible latex powder, 0.5 parts of antifungal agent and 35 parts of water; pour the sound-absorbing layer raw material mixture into A In the mould, vibrate and press, control the compression ratio to 20%, and form the sound-absorbing layer on the second day of maintenance, remove the mold A and clean ...

Embodiment 3~ Embodiment 5

[0044] Embodiment 3-Embodiment 5 is a transformation of Embodiment 1 and Embodiment 2 of the present invention, and the amount of each component that makes up the raw material of the sound-absorbing layer and the raw material of the sound-insulating layer is compared with that of Embodiment 1 and Embodiment 2. It can be increased or decreased. Generally, the value range of each component (parts by weight) of the sound-absorbing layer is:

[0045] 100 parts of cement, 1200~1800 parts of unburned ceramsite, 0.2~0.5 parts of polycarboxylate superplasticizer, 0.2~1 part of polyester fiber, 0.1~0.5 part of redispersible latex powder, 0.1~0.5 part of antifungal agent and 20-50 parts of water; the cylinder compressive strength of the unfired ceramsite is ≥6MPa, the roundness of the shape is ≥95%, and the particles are complete.

[0046] The value range of each component (parts by weight) of the general sound insulation layer is:

[0047] 100 parts of cement, 10~20 parts of sulphoalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com