Patents

Literature

116results about How to "High cylinder compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for burning haydite by solid castoff

InactiveCN101215150AHigh cylinder compressive strengthLow water absorptionCeramic materials productionClaywaresSludgeExpanded clay aggregate

A process for preparing baking ceramsite from solid waste belongs to the field of architectural materials. The invention bakes ceramsite products with high property by employing coal gangue, sludge and waste glass powder as raw materials. Components percentage by weight in the formula comprise the coal gangue of 15-45%, urban domestic dry sludge of 25%-50% and waste glass powder of 20%-50%. Ceramsite green-ware prepared according to the formula are heat-insulated at a temperature of 300DEG C-600DEG C for 20-50 minutes after being dried and carbon discharging is carried out, and then baked at a temperature of 950DEG C-1100DEG C for 8-20 minutes to obtain the ceramsite products, the property of which meets the Lightweight Aggregates and its Test Methods GB / T 17431.1-1998 Standards.

Owner:BEIJING UNIV OF TECH

Composite solid-waste lightweight high-strength haydite and preparation method therefor

InactiveCN106242514ALightweightCorrosion resistantCeramic materials productionCeramicwareFoaming agentSludge

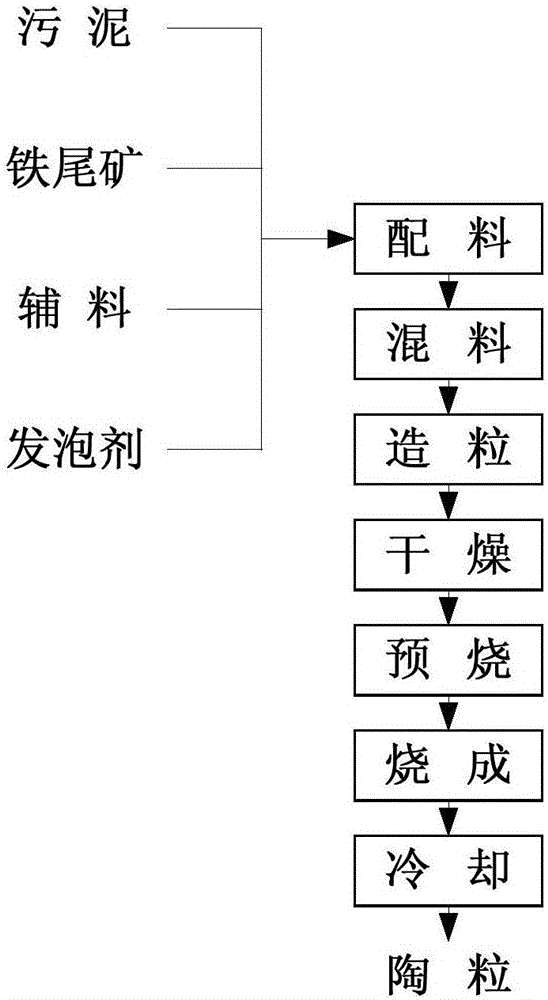

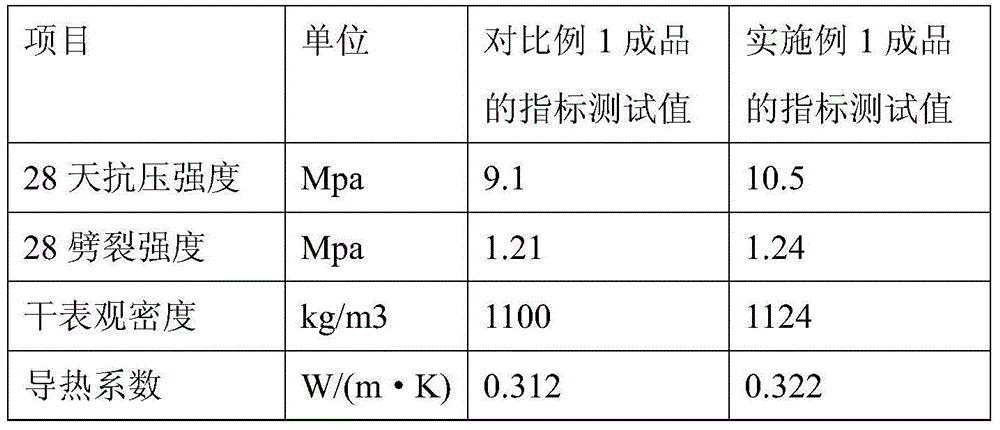

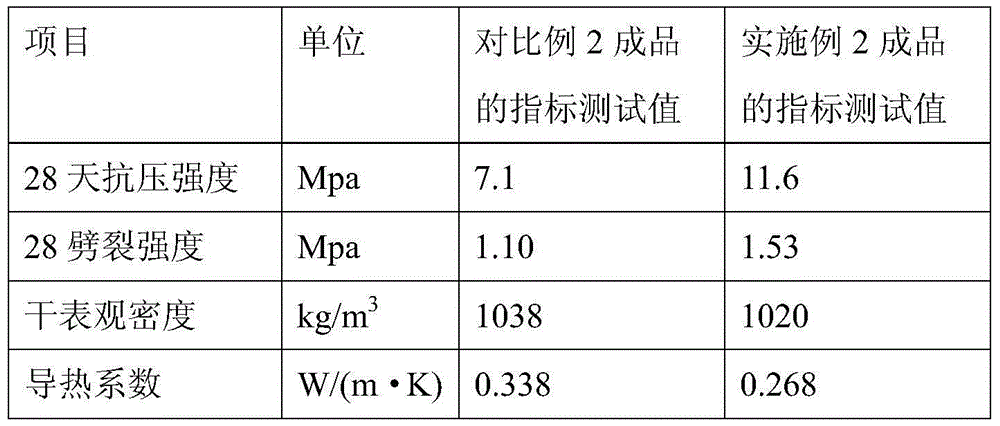

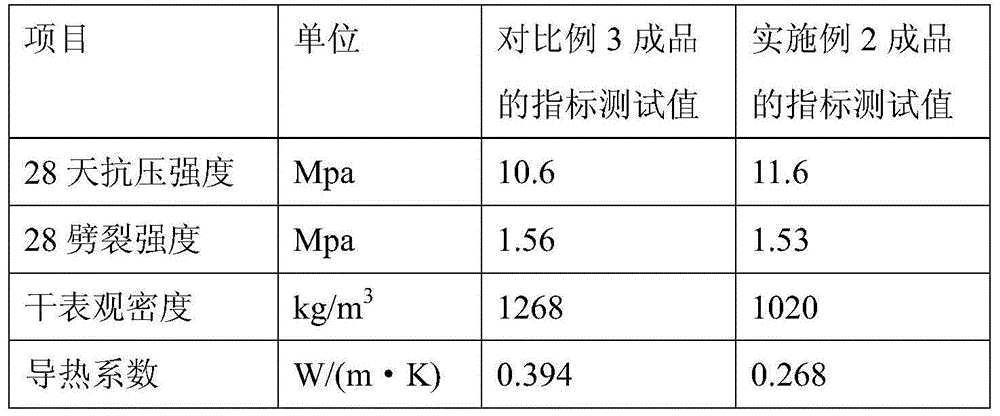

The invention provides composite solid-waste lightweight high-strength haydite and a preparation method therefor. The composite solid-waste lightweight high-strength haydite is mainly prepared from the following raw materials in parts by weight: 40.0-60.0 parts of iron tailings, 10.0-15.0 parts of auxiliary raw materials and 0.1-3.0 parts of foamer. The composite solid-waste lightweight high-strength haydite further contains sludge, wherein the dry sludge content of the sludge is 30.0-50.0 parts. The preparation method comprises the steps: accurately weighing the sludge, the iron tailings, the auxiliary raw materials and the foamer according to a designed ingredient proportioning ratio, and carrying out uniform mixing so as to form a uniform basic mixture; and carrying out granulating and shaping so as to obtain unburned haydite, burning the unburned haydite, and carrying out annealing and cooling, thereby obtaining municipal sludge and iron tailing cooperated haydite. The haydite is prepared from the sludge and the iron tailings, which are cooperated with each other and serve as main raw materials, so that the sludge is subjected to harmless treatment and resource-converting utilization, the sludge, which is a municipal mineral product, is used for replacing a primary mineral raw material, and thus the economic and environmental benefits are remarkable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

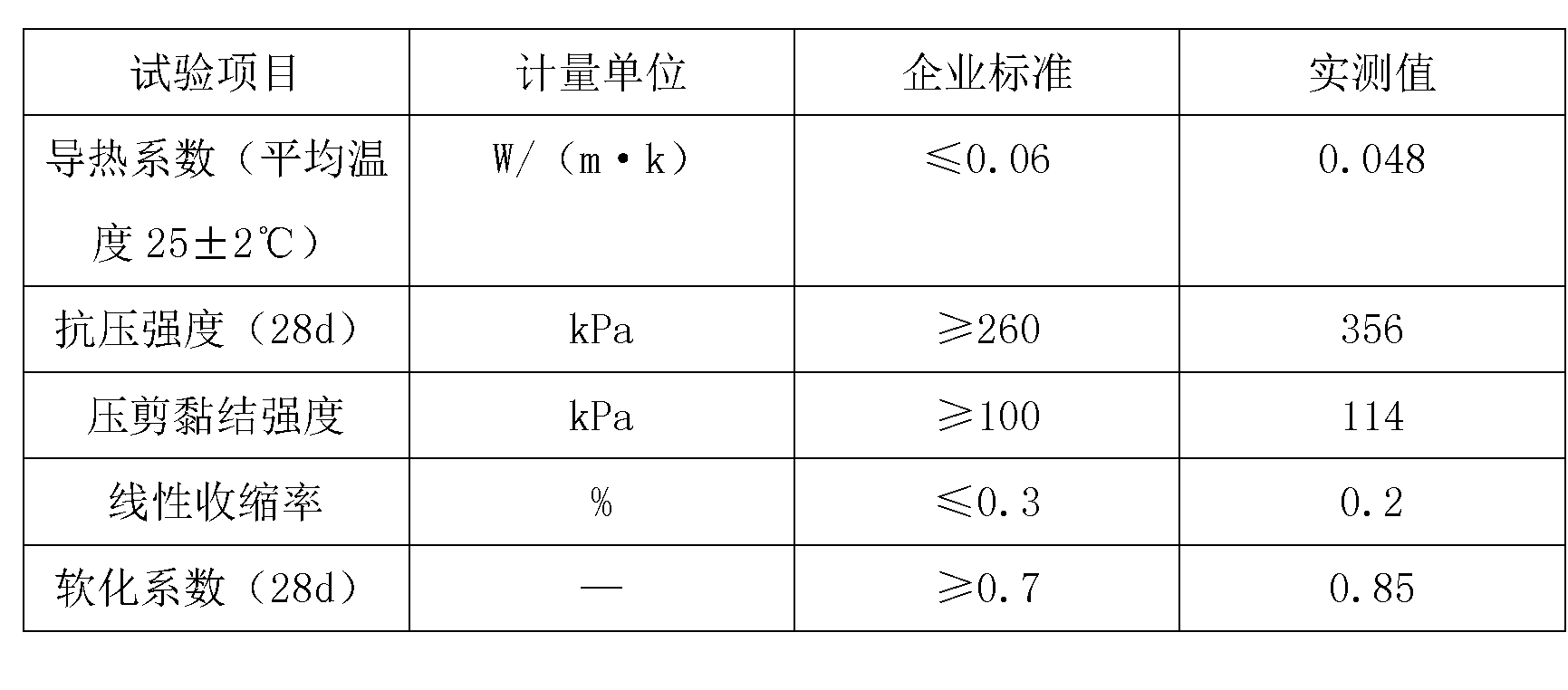

Modified nano-kieselguhr inorganic thermal-insulation mortar coated with plant ash and preparation method thereof

InactiveCN103011721AHigh cylinder compressive strengthLow water absorptionEnvironmental resistanceMicrosphere

The invention discloses a modified nano-kieselguhr inorganic thermal-insulation mortar coated with plant ash. The thermal-insulation mortar comprises the following raw materials in parts by weight: 50-60 parts of 42.5-level ordinary Portland cement, 20-30 parts of coal slack powder, 10-20 parts of plant straw powder, 10-20 parts of nano-kieselguhr, 40-50 parts of plant ash, 10-15 parts of starch emulsion, 2-3 parts of tetraisopropyl di(dioctylphosphate) titanate, 10-15 parts of modified vitrified microspheres, 2-4 parts of redispersible latex powder, 0.5-1.5 parts of methyl cellulose ether, 0.5-1 part of wood fiber, and 1-2 parts of polypropylene fiber. According to the invention, the produced thermal-insulation mortar is excellent in thermal insulation property and construction performance, high in intensity, good in weatherability, green and environment-friendly, and has extremely great market space and development prospect in the field of the building energy-saving application in China.

Owner:合肥神舟建筑集团有限公司

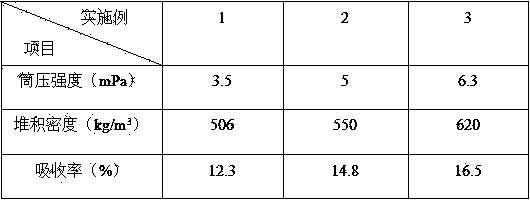

Sludge coal ash high-strength ceramsite and preparation method thereof

ActiveCN104261802AIn line with the principles of sustainable developmentRaise the ratioCeramic materials productionClaywaresSludgeExpanded clay aggregate

The invention discloses sludge coal ash high-strength ceramsite and a preparation method thereof. By using sludge and coal ash as main raw materials, the ceramsite is prepared by mixing, prilling and calcining by synergic match with an additive. The ceramsite is prepared from the following raw materials in parts by weight: 40-70 parts of sludge, 30-55 parts of coal ash, 0.5-1.5 parts of calcium sulphoaluminate, 0.5-1 part of phthalate, 1-3 parts of water glass and 0.5-1 part of a deodorant, wherein the water content of sludge is controlled within 35-50wt%. The sludge coal ash high-strength ceramsite is prepared by the following steps: mixing the materials; prilling; drying; calcining; and cooling. The ceramsite disclosed by the invention is economical, environment-friendly, efficient and energy-saving and scientific and reasonable in match of components of raw materials, and the prepared sludge coal ash high-strength ceramsite has the advantages of high cylinder compressive strength and high absorption.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

Haydite and production thereof

InactiveCN101439963ALight weightHigh cylinder compressive strengthCeramic materials productionClaywaresExpanded clay aggregateMixed materials

The invention discloses a porcelain granule and a method for producing the same. The porcelain granule is prepared from 30 to 60 weight portions of sludge, 35 to 65 weight portions of silt and 1 to 5 weight portions of auxiliary admixture. The method comprises the following steps: mixing and stirring the living sludge and the silt for piling up and aging; and then matching an appropriate amount of the auxiliary admixture, mixing and stirring the mixture to obtain a mixed material; and performing granulating, pre-heating, baking and high temperature burning expansion on the mixed material to obtain the porcelain granule. With the use of the raw materials, the porcelain granule has light volume weight and higher cylinder pressure intensity; besides, the materials used in the method are mainly the living sludge and the silt, thus not only the material cost is lower, but also an effective utilizing way is provided for minimized, harmless and resource treatments of municipal sewage sludge.

Owner:福建省三角洲陶粒科技有限公司

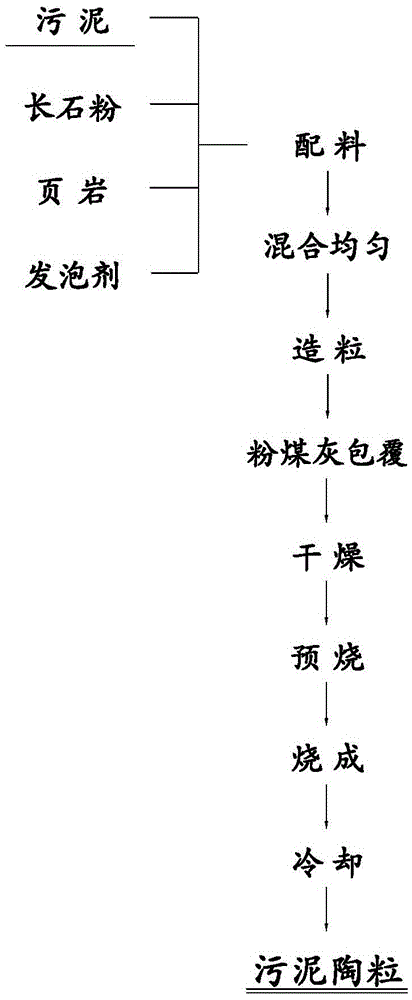

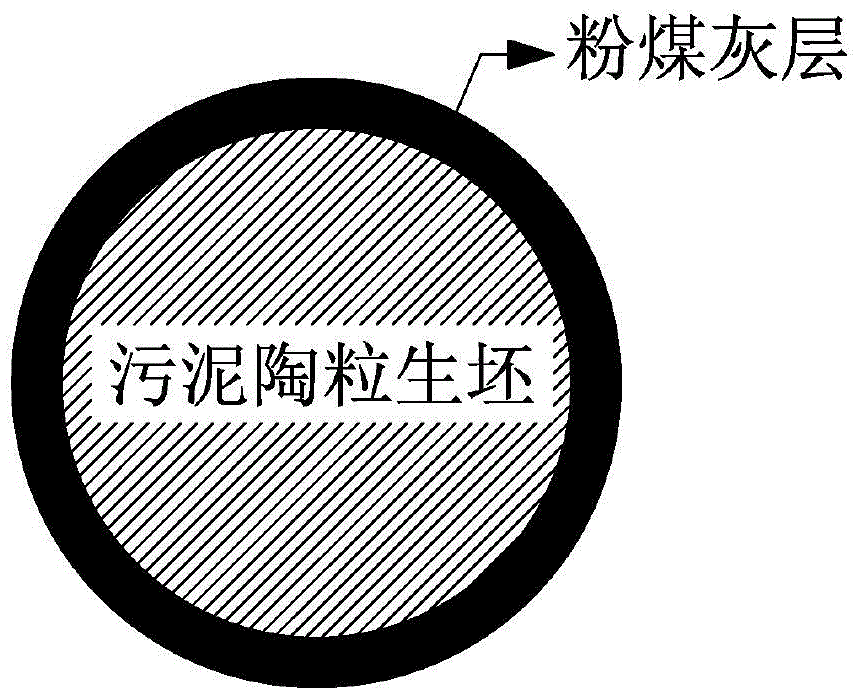

Fly ash coated sludge ceramsite and preparation method therefor

ActiveCN105541380AAvoid stickingIncreased viscosity of viscous substancesCeramicwareClaywaresSocial benefitsFoaming agent

The invention relates to fly ash coated sludge ceramsite and a preparation method therefor. According to the fly ash coated sludge ceramsite, sludge serves as a main raw material, shale, feldspar powder and a foamer serve as auxiliary raw materials, and the mixed amount of dry sludge in the raw materials of the ceramsite is 35.0-58.0wt.%. The preparation method comprises the steps of firstly accurately weighing the dry sludge or wet sludge with certain moisture, the shale, the feldspar powder and the foamer according to a designed ingredient proportioning ratio, then, carrying out uniform mixing, granulating the mixture, coating the surface of each unburnt sludge ceramsite with a layer of fly ash, meanwhile, adding a certain volume of fly ash into a rotary kiln, then, carrying out foaming burning on the fly ash coated unburnt sludge ceramsites, and carrying out annealing cooling, thereby obtaining the sludge ceramsite. According to the fly ash coated sludge ceramsite and the preparation method therefor, the ceramsite is prepared by taking the sludge as the main raw material; due to fly ash coated sludge ceramsites, the mutual adhesion among the ceramsites in a dynamic burning process can be effectively prevented, so that the rate of final ceramsite products is increased; and meanwhile, the utilization of the sludge of sewage plants is developed towards a harmless, volume-reducing and resource-converting direction, so that the fly ash coated sludge ceramsite and the preparation method therefor have remarkable economic, environmental and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Light sand without burning and preparation method thereof

The invention discloses light sand without burning and a preparation method thereof. The light sand without burning is prepared by the following steps: crushing aerated concrete leftover material or waste aerated concrete into particles, stirring cement, finely ground silicon-contained material and water storage material uniformly so as to prepare powder body material with canned surface; and spraying a surface modifier solution on the surfaces of aerated concrete particles, then canning the aerated concrete particles and the powder body into a ball, standing for one hour so as to conduct secondary canning to a ball, standing the formed spherical particle for 2-10h, and then pressurizing and evaporating the particle under the conditions of 80-190 DEG C and 1atm-15atm, thereby obtaining light particles with particle size being not more than 5mm, stacking density being not more than 1200kg / m3, cylinder pressure being more than 3.5MPa and water absorbing rate being not more than 5%. On the basis of saving production raw materials, the strength of the light aggregate can be improved effectively, and the water absorbing rate is reduced.

Owner:HOHAI UNIV +1

High-performance polyurethane external thermal insulation anti-crack leveling mortar and construction method thereof

The invention discloses a high-performance two-component polyurethane external thermal insulation anti-crack leveling mortar which is prepared by mixing a component A and a component B, wherein the component A comprises the following compositions in percentage by weight: 60 to 80 percent of gelled materials, 20 to 30 percent of aggregates and 0 to 10 percent of functional admixtures; and the component B is water repellents. The construction method of the mortar comprises the following steps: mixing the component A and the component B; adding an appropriate amount of water in the obtained mixture; and uniformly stirring the obtained object until the obtained object reaches the consistence suitable for mechanical spraying or manual construction, namely, the obtained object can be subject to mechanical spraying or manual construction. The external thermal insulation anti-crack leveling mortar of the invention has the advantages of low water absorption rate, low modular ratio, high caking property and stable performance; and the interface processing carried out on a polyurethane insulation coating can be omitted, and the quality problems that a polyurethane external thermal insulation system is easy to produce crazes and hollowing, and the like can be solved.

Owner:JIANGSU NIGAO SCI & TECH +1

Method for preparing lightweight high-strength ceramsite by aid of coal gangue

PendingCN106966707AMeet the requirements of ceramsite proppant materials for developmentHigh strengthFluid removalDrilling compositionMolding machinePotassium feldspar

The invention discloses a method for preparing lightweight high-strength ceramsite by the aid of coal gangue. The method includes steps of crushing and grinding the coal gangue with the carbon content of 5-15% to obtain coal gangue powder which can completely pass 325-mesh sieves; uniformly mixing, by weight, 40%-80% of coal gangue powder, 0%-45% of bauxite powder, 1%-9% of calcium oxide and 5%-15% of potassium feldspar with one another to obtain raw materials; carrying out ball-milling on the raw materials, then granulating the raw materials in a granulator, mixing the raw materials which are subjected to ball-milling with one another and molding, drying and screening the raw materials on a ceramsite molding machine to obtain ceramsite green bodies; heating and calcining the ceramsite green bodies thrice and cooling the ceramsite green bodies with furnaces to obtain the lightweight high-strength ceramsite. The method has the advantages that the coal gangue content can reach 40%-80%, the bulk density of the lightweight high-strength ceramsite prepared by the aid of the method ranges from 0.6 g / cm<3> to 1.55 g / cm<3>, and the strength of the lightweight high-strength ceramsite is improved by 10%-15% as compared with the prior art under the condition of identical density; requirements on ceramsite propping agent materials for building light aggregate and oil and gas exploitation can be met.

Owner:TIANJIN CHENGJIAN UNIV

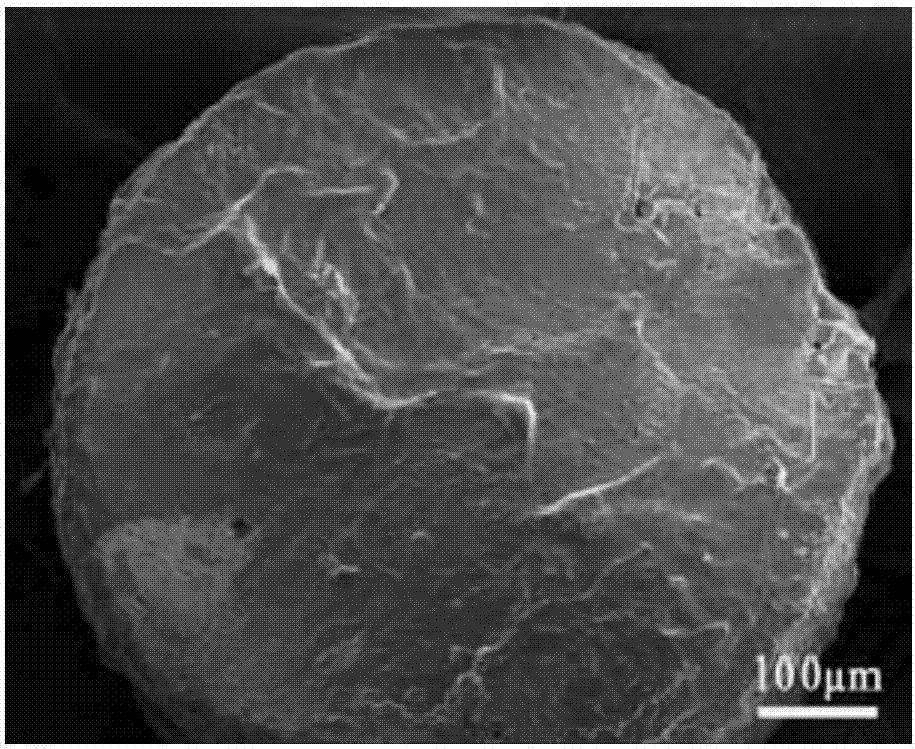

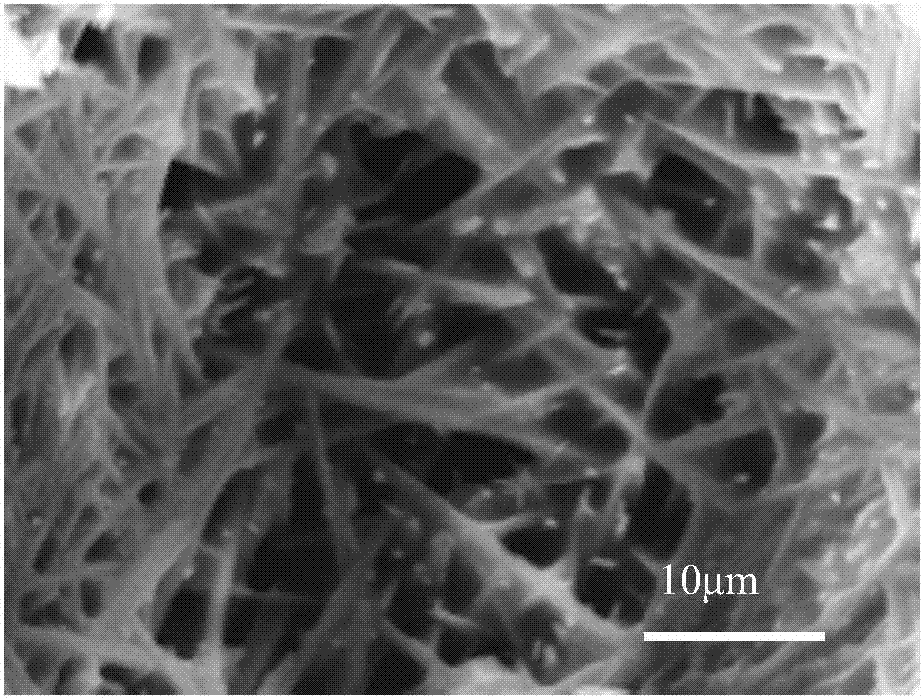

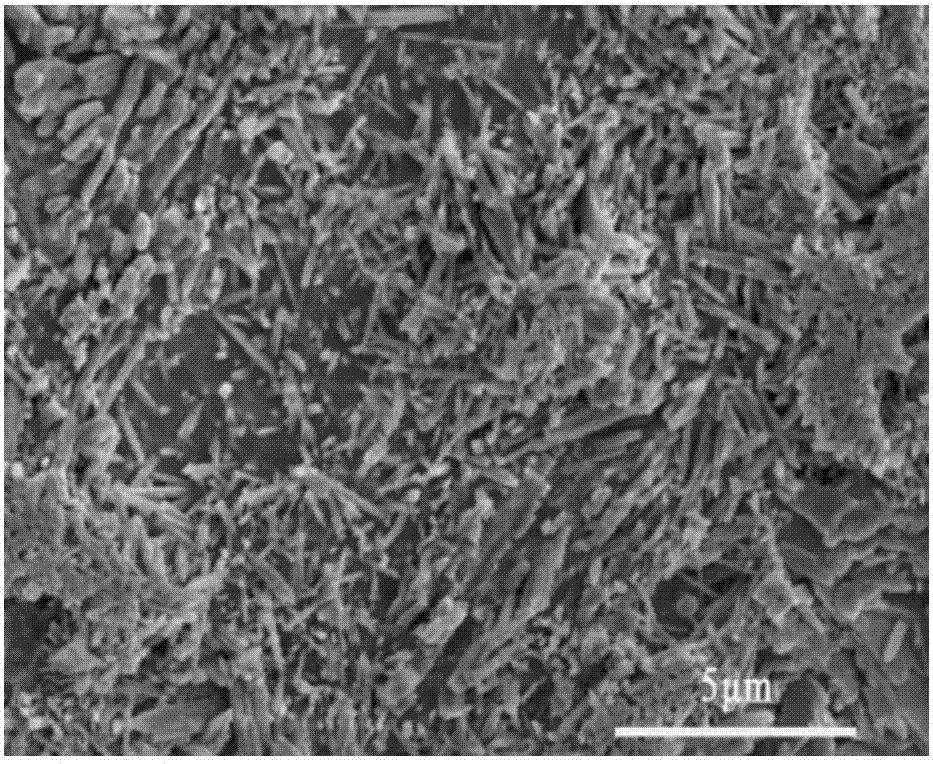

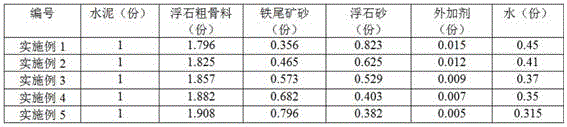

Environment-friendly lightweight aggregate concrete and preparation method thereof

InactiveCN106116355AEfficient use ofReduce overexploitationSolid waste managementSocial benefitsMass ratio

The invention relates to the technical field of building materials, in particular to the technical field of high-strength lightweight aggregate concrete materials, and particularly discloses environment-friendly lightweight aggregate concrete and a preparation method thereof. The concrete is prepared from, by weight, 1 part of cement, 1.796-1.908 parts of pumice coarse aggregate, 0.356-0.796 part of pumice sand, 0.382-0.823 part of ferrous mill tailings, 0.005-0.015 part of additive and 0.315-0.45 part of water. The pumice coarse aggregate is subjected to hole sealing treatment, and a hole sealing material is formed by evenly mixing ordinary sand with granularity not larger than 1.18 mm and cement according to the mass ratio of 1:1. The environment-friendly lightweight aggregate concrete has the advantages of being low in manufacturing cost, high in strength and environmentally friendly; the preparation process is simple, the optimization and utilization of pumice resources and ferrous mill tailing waste are effectively achieved, and the concrete has remarkable economic and social benefits.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Porous phosphorus removal ceramisites and preparation method thereof

InactiveCN104876639ARealize resource utilizationLarge specific surface areaCeramicwareClaywaresPhysical chemistryStrong acids

The invention provides porous phosphorus removal ceramisites and a preparation method thereof. The ceramisites are prepared from the following raw materials in parts by weight: 55-85 parts of attapulgite, 10-30 parts of crop straws and 10-20 parts of lanthanum carbonate. The raw materials are subjected to the steps of blending, preparing a blank, sintering and cooling to prepare the porous phosphorus removal ceramisites. The ceramisites provided by the invention are simple in preparation process and high in adsorption rate, the cylinder pressure strength meets cylinder requirements on high-strength lightweight aggregates in national standards, the phosphorus adsorption capacity of the ceramisites in a wide pH value range of 1-12 is high, and the maximum phosphorus removal rate can reach 98.6%. Because the ceramisites have strong acid and alkali resistance, after adsorbing phosphorus and being eluted by a sodium hydroxide solution, the porous phosphorus removal ceramisites not only can realize recovery of adsorbed phosphorus but also can be obtained again, and are convenient to recycle, so that resources can be effectively saved. The ceramisites can be widely applied to the field of practical engineering to achieve an aim of treatment of wastes with processes of wastes against one another.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Fly ash non-burned high-strength ceramsite and preparation method thereof

ActiveCN106082731AHigh cylinder compressive strengthEasy to operateCeramicwareAdhesiveExpanded clay aggregate

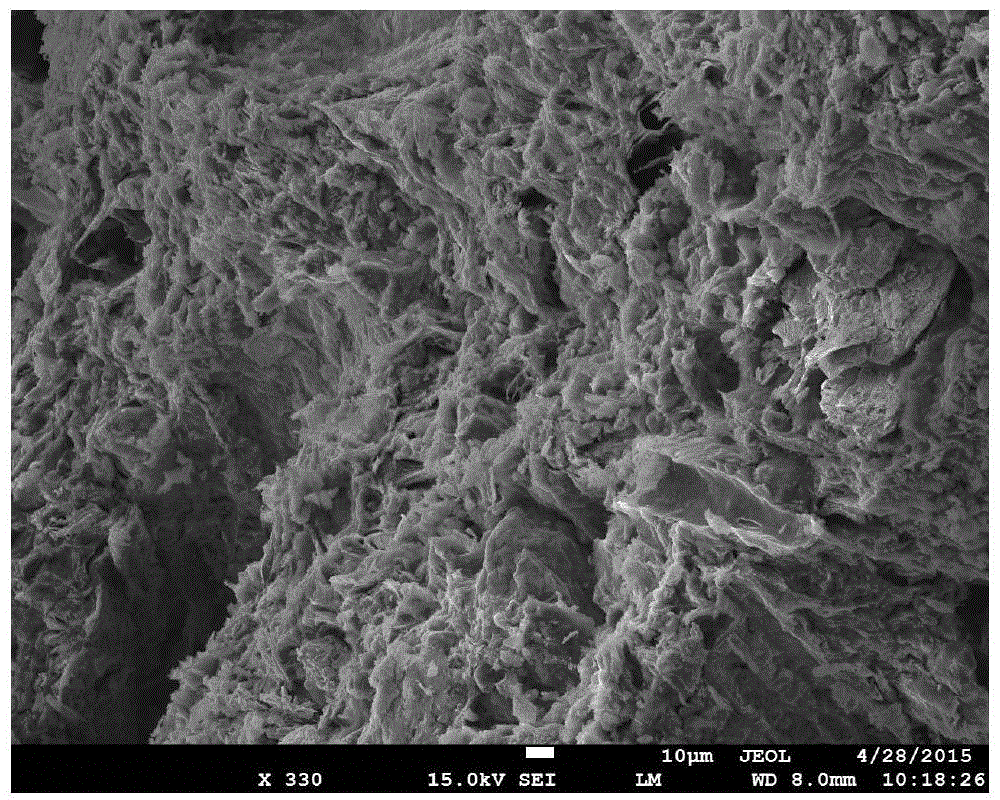

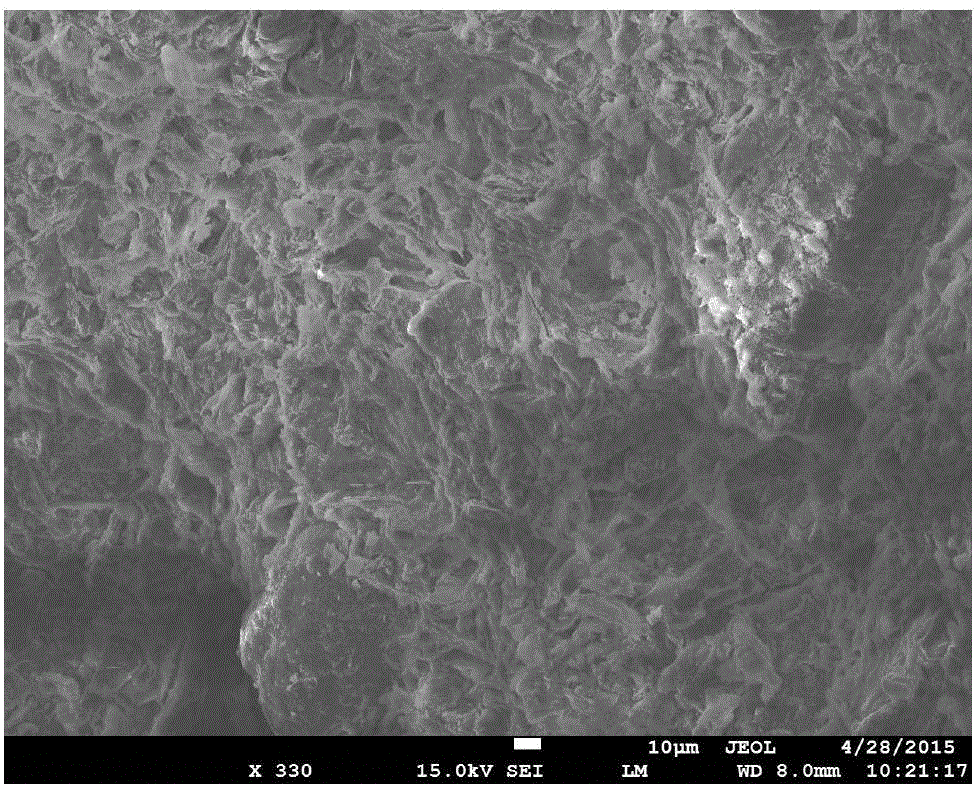

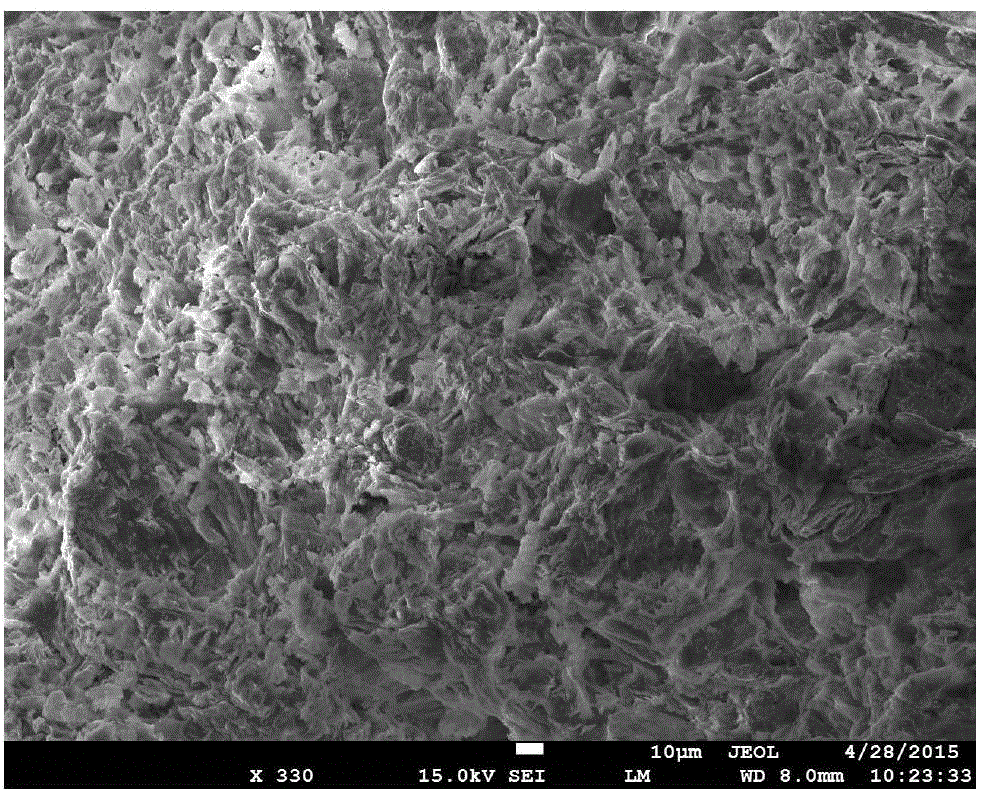

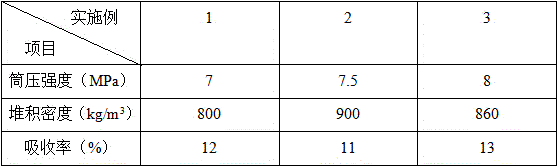

The invention discloses a fly ash non-burned high-strength ceramsite and a preparation method thereof, wherein the ceramsite comprises the following components in parts by weight: 93.5-94.5 parts of fly ash, 2.95-3.05 parts of an adhesive, and 2.95-3.05 parts of an enhancer. The method comprises the steps: preparing an adhesive liquid and an enhancement liquid respectively from the adhesive and the enhancer with water; pouring the weighed fly ash into a ball formation disc, starting up the ball formation disc, spraying the adhesive liquid into the fly ash, rotating the ball formation disc, and rolling to form balls; at the same time, spraying the enhancement liquid to the surface of formed ball bodies to prepare ceramsite; and putting the ceramsite into a steam curing kiln, curing for 8-9 h, and thus obtaining the product. A sintering process is not required, and the high-strength ceramsite can be obtained; tests verify that the prepared fly ash ceramsite has the packing density of 800-900 kg / m<3>, the cylinder compressive strength of 7-8 MPa and the water-absorbing rate of less than or equal to 15% and has good quality.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

Burning-free light aggregate, lightweight concrete, and preparation methods of burning-free light aggregate and lightweight concrete

InactiveCN106986568AMeet the requirements of energy saving and environmental protectionLow costAcid waterFly ash

The invention discloses a burning-free light aggregate preparation method, and a high strength and low thermal conductivity lightweight concrete based on secondary molding and a preparation method thereof. The preparation method specifically comprises: preparing a light aggregate, uniformly mixing 2.2-3.65 parts of the light aggregate, 1 part of cement and 0.00-0.30 part of fly ash, and adding 0.32-0.75 part of water and 0.003-0.012 part of a polycarboxylic acid water reducing agent to obtain the light aggregate concrete. The invention further provides the lightweight concrete prepared through the preparation method, wherein the raw materials and the preparation method of the light aggregate are defined in the claims of the specification. According to the present invention, the light aggregate concrete does not require the pre-wetting process, has advantages of good stability, excellent mechanical property, excellent durability and low thermal conductivity, and is the energy-saving and high-performance structure lightweight aggregate concrete.

Owner:CENT SOUTH UNIV

Ceramsite prepared from residues generated in oil containing sludge pyrolysis and preparation method thereof

InactiveCN109851323AExpand application channelsHigh porosityCeramic materials productionCeramicwarePorositySludge

The invention provides a ceramsite prepared from residues generated in oil containing sludge pyrolysis and a preparation method thereof. The ceramsite is prepared from following raw materials in percentage by weight through burning: 45 to 50% of residues generated in oil containing sludge pyrolysis, 35 to 40% of fly ash, and 10 to 20% of waste glass powder. Residues generated in oil containing sludge pyrolysis are taken as the main raw material and is mixed with fly ash and waste glass powder to prepare the ceramsite having the advantages of lightness, high porosity, high cylinder compressivestrength, low bulk density, and low water absorption; the application range of residues generated in oil containing sludge pyrolysis is enlarged; a new approach is provided for converting residual solid phases in oil containing sludge processing into valuable resources; the residue utilization rate can reach 50%; the problem that the residues generated in oil containing sludge pyrolysis cannot beeffectively processed and radically utilized is solved, sustainable development of oil fields is realized, and good social benefits and economic benefits are generated.

Owner:WUHAN UNIV OF TECH

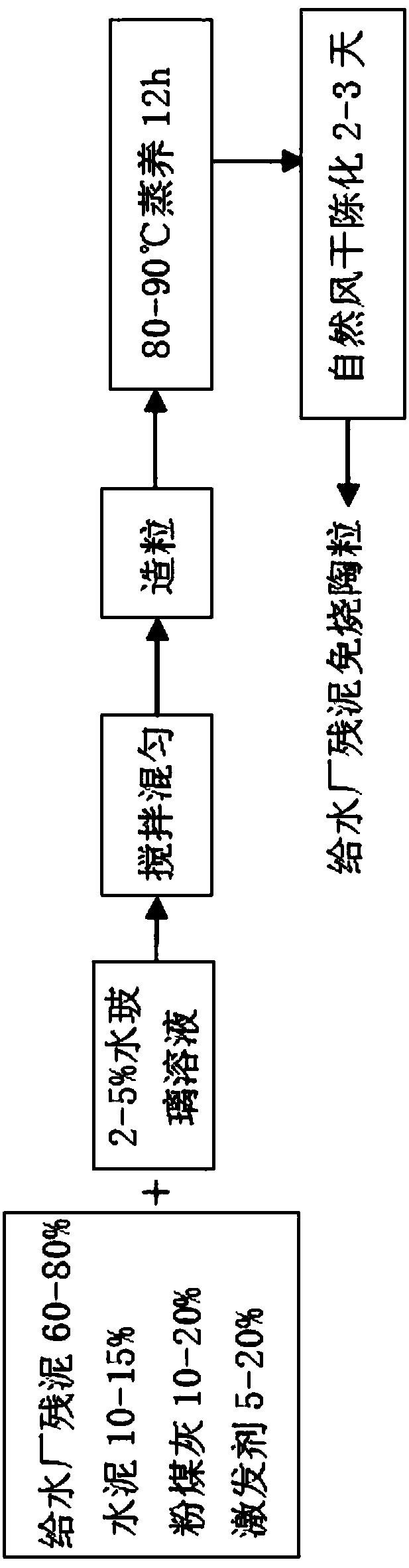

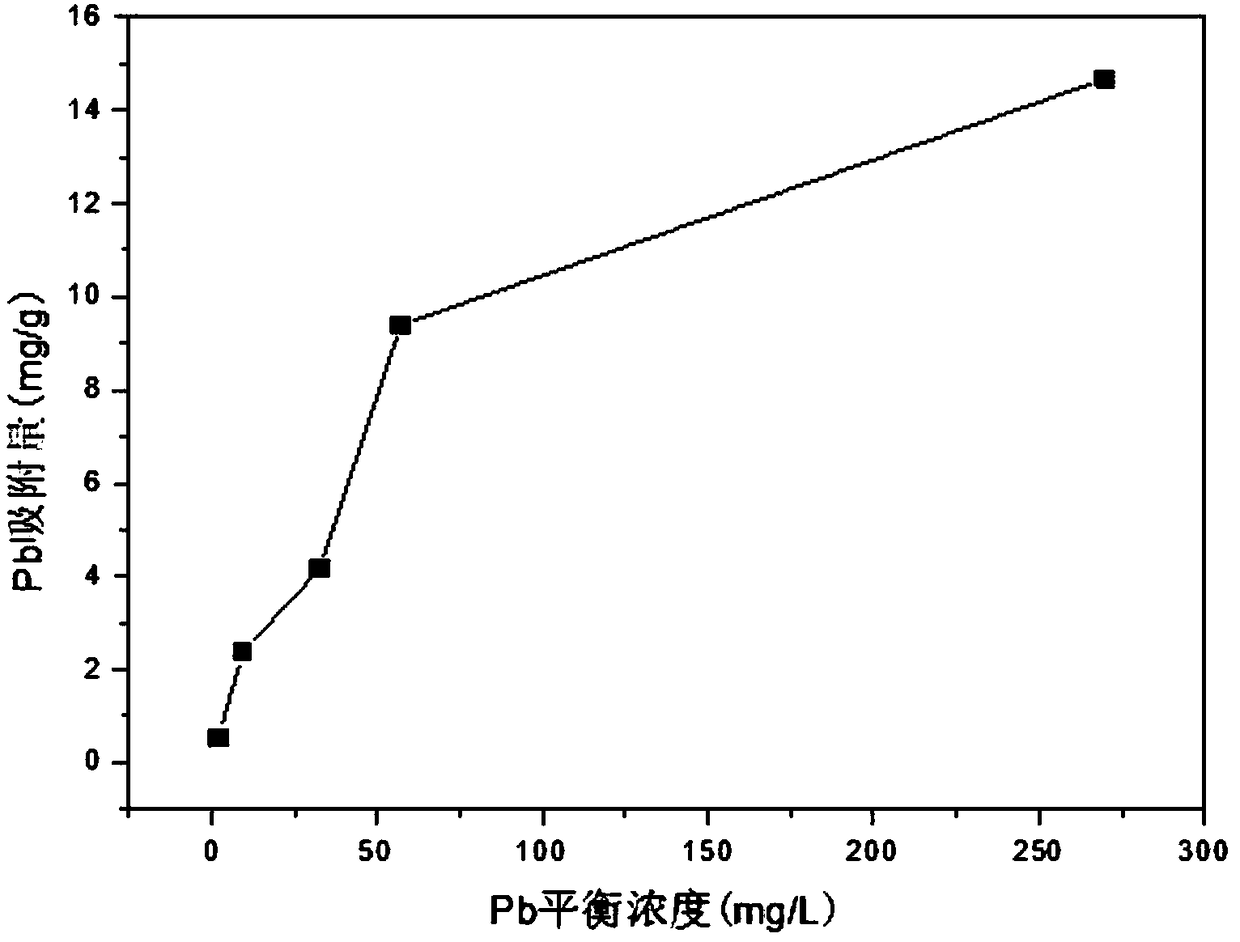

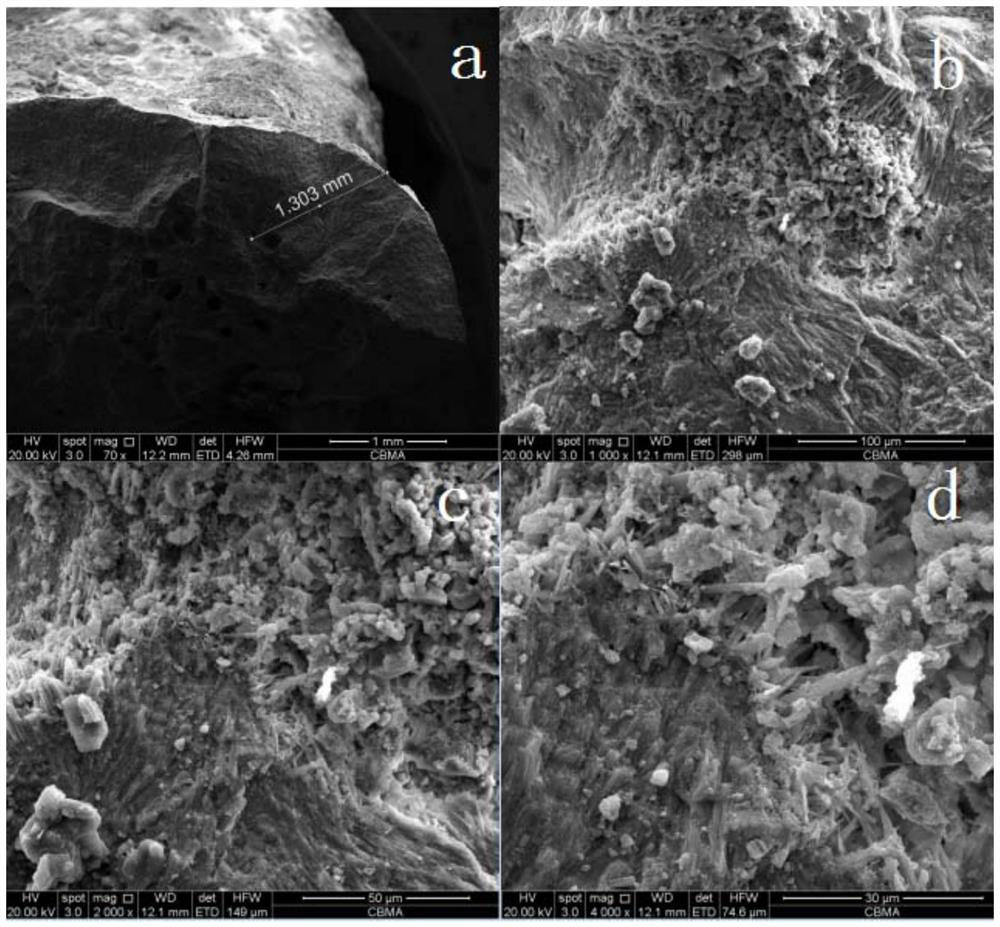

Preparation method and application of high adsorption performance water supply plant residual mud non-sintered ceramsite

ActiveCN108178605ARaw materials are cheap and easy to getHigh cylinder compressive strengthWater contaminantsWater/sewage treatment by sorptionExpanded clay aggregateAdsorption effect

Relating to the technical field of water treatment, the invention discloses a preparation method and application of a high adsorption performance water supply plant residual mud non-sintered ceramsite. The preparation steps include: mixing air dried and grinded water supply plant residual mud with cement, an activator, fly ash and the like evenly, adding a water glass binder and then performing granulation, placing a ceramsite raw material in a 70-90DEG C sterilization pot and performing steam curing for 12h, then conducting air drying and aging for 2-3d, thus obtaining the water supply plantresidual mud non-sintered ceramsite. The preparation method provided by the invention has the advantages of simplicity, cheap and easily available raw materials, low equipment investment and operationcost, and the prepared non-sintered ceramsite has excellent adsorption effect, can be applied as an adsorption material in a wastewater treatment process, and has strong adsorption capacity on heavymetals, phosphorus, anionic organic pollutants and the like. The invention builds a new bridge for application of water supply plant residual mud laboratory study to water treatment technology, can provide a new solution for wastewater pollutant emission reduction and WTR disposal, and is beneficial to achieve the win-win goal of "waste control by waste".

Owner:湖南省环境保护科学研究院

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of haydite from municipal sludge

ActiveCN107216126AReduce generationLess breaking workSolid waste managementCeramic materials productionSlagSludge

The invention provides a preparation method of haydite from municipal sludge. The method particularly comprises the following steps: performing drying; preparing the following raw materials: sludge, fly ash, kaolin, steelmaking furnace slag, zeolite, hematite, calcareous shale, refuse incineration fly ash, Fe2O3, waste glass, calcium carbonate, lauryl sodium sulfate and sodium benzoate; uniformly stirring the raw materials, adding the mixture into a granulator, and performing granulation; performing drying and preheating on the granules, quickly transferring the granules into a sintering apparatus, performing low-temperature sintering, performing high-temperature sintering, and crushing the massive sintered product; and screening the crushed material. The method for preparing haydite reduces the generation of the massive sintered product, thereby correspondingly reducing the subsequent crushing work, and saving the energy consumption. The prepared haydite has the advantages of high cylindrical compressive strength and low bulk density, and the quality and properties of the haydite are obviously improved. The method implements conversion and cyclic utilization on the wastes, and thus, is beneficial to environment protection.

Owner:QINGDAO YI ECO ENVIRONMENTAL PROTECTION TECH CO LTD

Coal gangue concrete and preparation thereof

The invention relates to a concrete product using coal gangue aggregate as a major raw material and a method for preparing the same, in particular to a method for preparing the concrete through calcining coal gangue artificially, which belongs to the technical field of concrete materials. The coal gangue used in the method is an artificially calcined gangue with the calcination temperature of between 1,100 and 1,200 DEG C; the artificial coal gangue comprises the following components by weight percentage: 40 to 50 percent of the artificially calcined gangue, 15 to 23 percent of cement, 25 to 28 percent of medium sand and 5 to 12 percent of water which are mixed and stirred evenly. The concrete product makes use of the characteristics of high pressure, light weight, low thermal conductivity, energy conservation, no radioactivity and the like of a coal gangue cylinder to change waste into valuable, and the produced concrete can be cast-in-place concrete or precast concrete, and can be used for the preparation of high-strength structural gangue concrete. The concrete product has simple process without new equipment, and can make use of the prior equipment to calcine natural gangue; besides, the concrete product has significant economic and social benefits in the aspects of land conservation, energy conservation, waste recycling, environmental protection and the like, and accords with the national industrial policy and is easy for popularization and implementation.

Owner:朝阳华龙科建股份有限公司

High-aluminum insulating refractory raw material with titanium-iron slag as main material and preparation method thereof

InactiveCN106904982ASimple processSave labor resourcesCeramic materials productionCeramicwareSlagFiltration

The invention relates to a high-aluminum insulating refractory raw material with titanium-iron slag as a main material and a preparation method thereof. The preparation method comprises the following steps: immersing crushed titanium-iron slag in water of 90-95 DEG C for 1-2 h, filtering, drying, and screening; adding a hydrochloric acid solution into the screened titanium-iron slag particles, stirring, washing and carrying out suction filtration, and wet-grinding to obtain wet-ground titanium-iron slag powder; adding the wet-ground titanium-iron slag powder and aluminum powder into a mixer, and mixing to obtain a mixture; Adding a phosphoric acid solution into the mixture, uniformly mixing, vibrating for moulding, and maintaining; finally placing the product into a muffle furnace, heating to 1355-1420 DEG C at the heating rate of 3-5 DEG C / min, carrying out thermal insulation, cooling with the furnace to room temperature, and crushing to obtain the high-aluminum insulating refractory raw material with titanium-iron slag as the main material. The method of the invention has characteristics of simple process, low production cost and no special requirements on equipment. The prepared high-aluminum insulating refractory raw material with titanium-iron slag as the main material has small heat conductivity coefficient, high cylinder compressive strength and good resistance to corrosion of slag.

Owner:WUHAN UNIV OF SCI & TECH

Planting sand prepared by utilizing sludge and a preparing method thereof

ActiveCN107746284ASolve the problem of difficult collaborative processingEvenly distributedGrowth substratesCulture mediaSlagSludge

The invention relates to planting sand prepared by utilizing sludge and a preparing method thereof. The planting sand is prepared from, by weight, 100 parts of solid waste, 15-30 parts of a pore forming agent, 5-15 parts of a plasticizer and 1-2.5 parts of a reinforcing agent, wherein the solid waste is one or more of fly ash, coal gangue, slag, tailings and waste residues, and the pore forming agent is one or more of household sludge, papermaking sludge and river sludge. The planting sand is prepared through mixing, granulation, drying, sintering and cooling steps. The prepared planting sandhas a uniform particle size, a high degree of sphericity, high cylinder compressive strength, and long service lifetime. The water absorption rate of the planting sand is 60-80%. The planting sand hasgood water retaining and fertilizer retaining properties, and water and fertilizers can be uniformly distributed.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

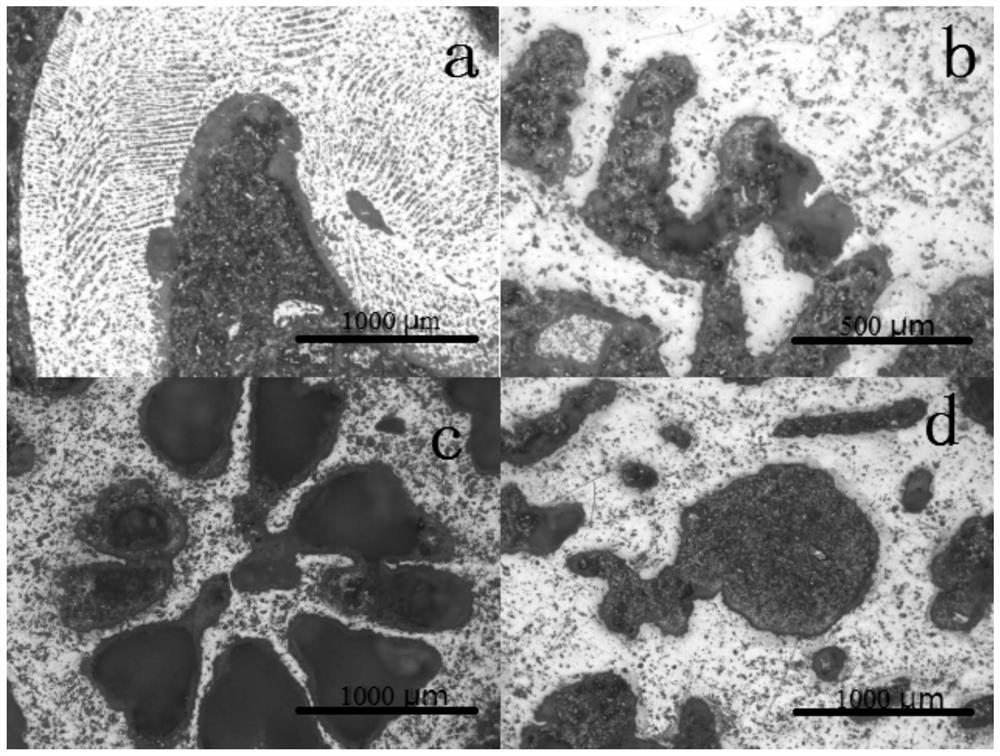

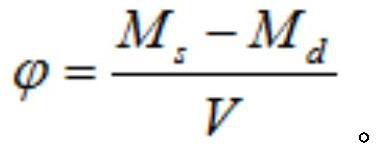

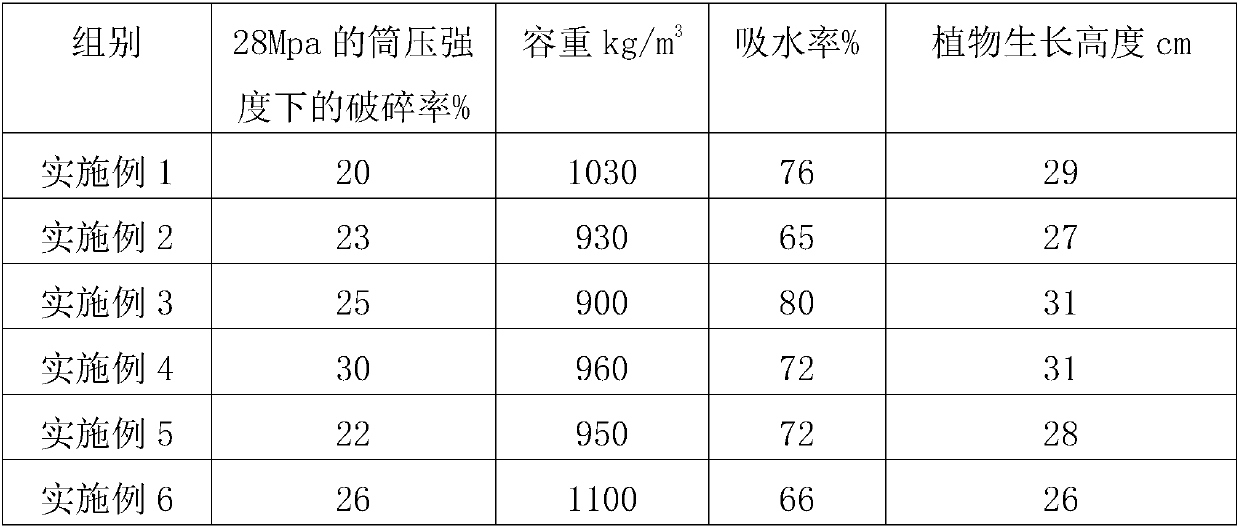

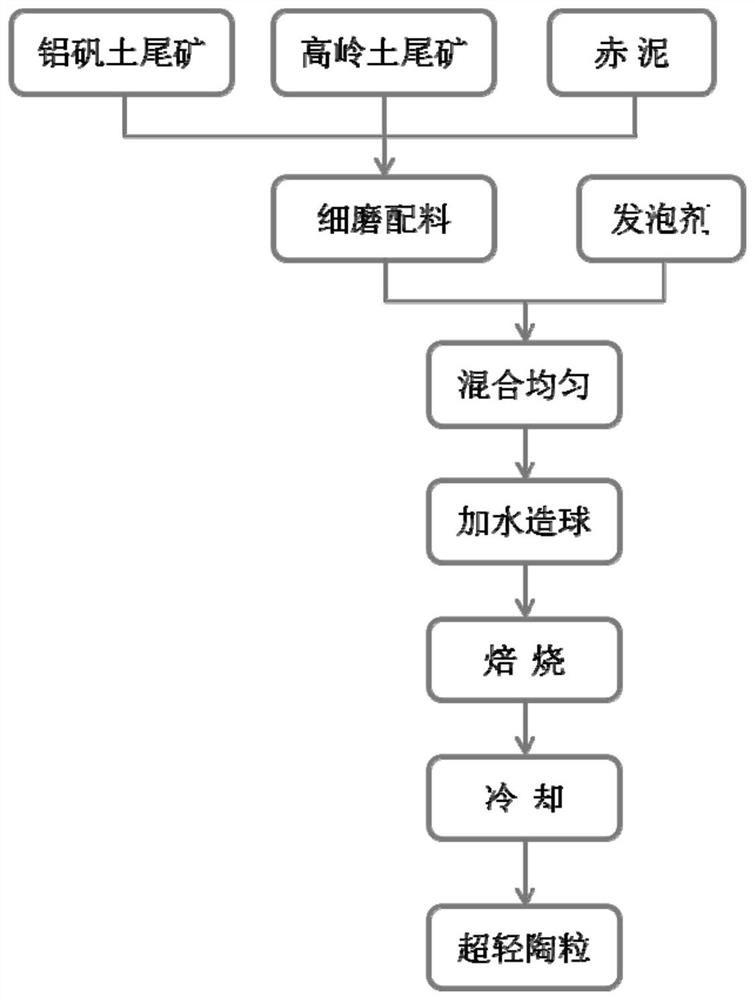

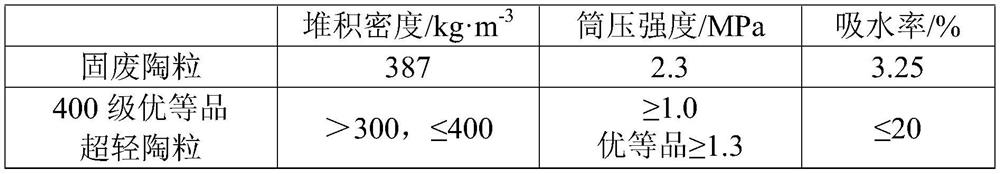

Ultra-light ceramsite prepared from solid waste and preparation method of ultra-light ceramsite

ActiveCN112062598AReduce energy consumptionHigh cylinder compressive strengthCeramic materials productionCeramicwareTalcClay soil

The invention provides ultra-light ceramsite prepared from solid waste and a preparation method of the ultra-light ceramsite. The ultra-light ceramsite is prepared from the following solid waste raw materials: bauxite tailings, red mud and kaolin tailings, and the chemical components of the three solid waste raw materials after proportioning are as follows: 12-18.5 wt% of Al2O3, 48-54 wt% of SiO2and 14-19 wt% of alkali metal and alkaline earth metal. According to the method, the requirements of grade-400 high-quality ultra-light ceramsite are met, the bauxite tailings, the kaolin tailings andthe red mud are synergistically utilized, traditional shale, clay and talc do not need to be added, the main raw materials of the light building ceramsite are all solid waste, and comprehensive utilization of solid waste raw materials is achieved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

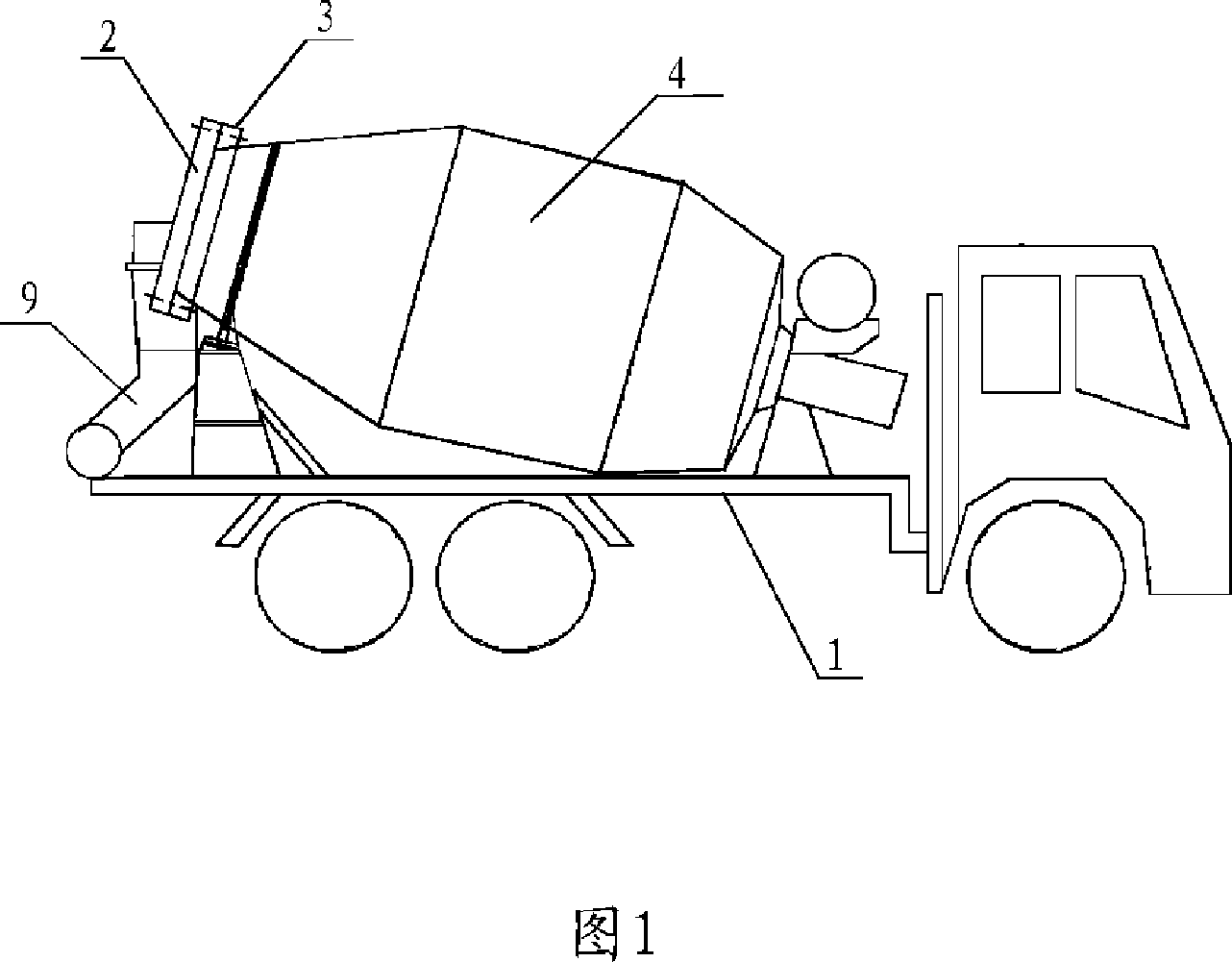

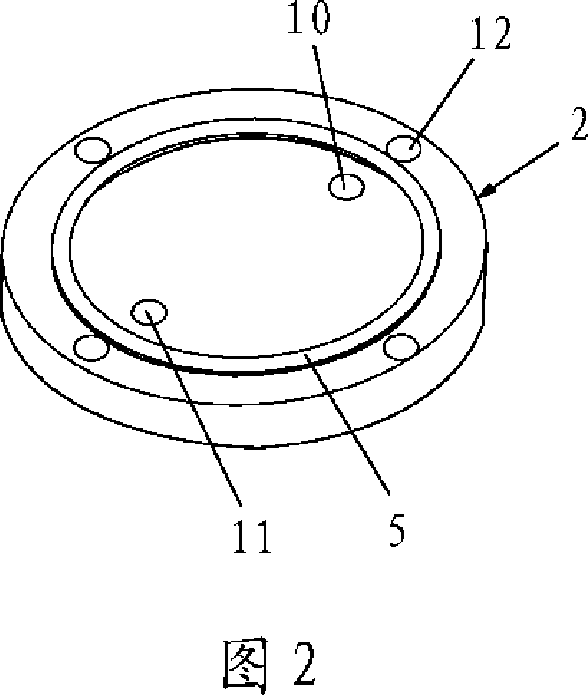

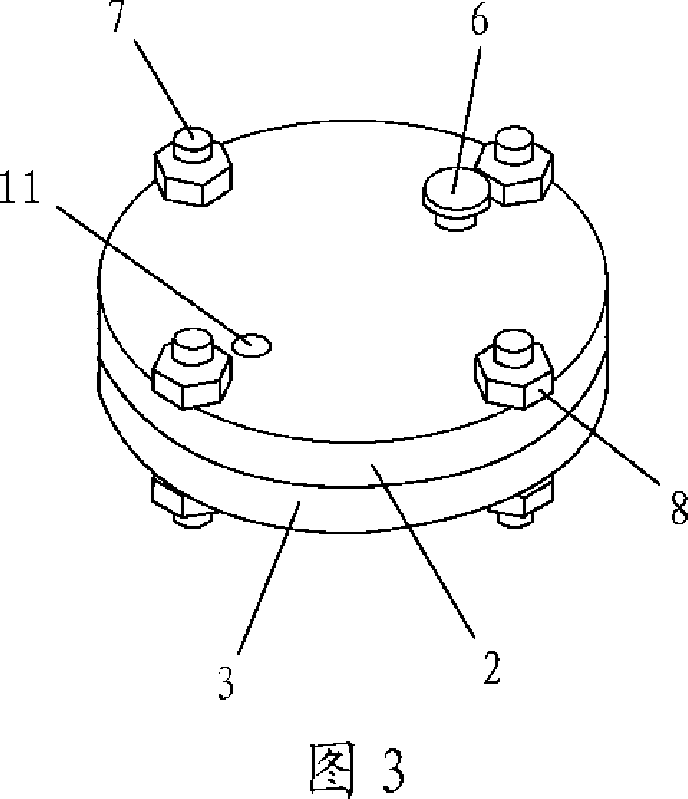

Lightweight aggregate pretreatment method and its device

InactiveCN101077596AAccelerate the pre-wetting speedImprove preprocessing efficiencyCement mixing apparatusPre treatmentPretreatment method

The present invention is light aggregate pre-treating process and apparatus. The light aggregate is first pressurized and humidified in a sealed pressure container as the light aggregate pre-treating apparatus in the pressure of 5-8 MPa for 30-120 min to reach water absorbing rate of 60-80 %; and then shell forming treated through mixing with cement for 90-180 min, with the cement adding amount being 50-100 kg for 1 cu m of aggregate without free water, to form watertight shell in the surface of the aggregate. The present invention has high aggregate pre-treating speed, high efficiency, and capacity keeping free water amount and maintaining high pumpability of the concrete.

Owner:北京东方建宇混凝土科学技术研究院有限公司 +2

Microorganism-based crack depth-width three-dimensional self-repairing concrete and preparation method thereof

The invention discloses microorganism-based crack depth-width three-dimensional self-repairing concrete and a preparation method thereof. The concrete is prepared from 30-120 parts of a microbial self-repairing agent, 0-50 parts of probiotics-loaded expanded perlite, 0-50 parts of an oxygen slow-release agent, 0-50 parts of nutrient-loaded expanded perlite, 23 parts of expanded perlite with the particle size of 120 mesh, 350-500 parts of cement, 1000-1300 parts of pebbles, 400-600 parts of sand, 30-50 parts of silica fume, 2-4 parts of polypropylene fiber, 4-6 parts of a water reducer and 250-350 parts of water. A four-component repair system composed of the microbial self-repairing agent, the oxygen slow-release agent, the probiotics-loaded expanded perlite and the nutrient-loaded expanded perlite is combined with the polypropylene fiber to form the crack depth-width three-dimensional self-repairing concrete. The concrete can remedy the deficiency that the crack depth-direction repaireffect of a current concrete crack self-repairing technology is poor, the durability of the concrete is improved, and meanwhile the concrete is environmentally friendly and light and has a heat insulation function.

Owner:山西晟科微生物建材科技有限公司

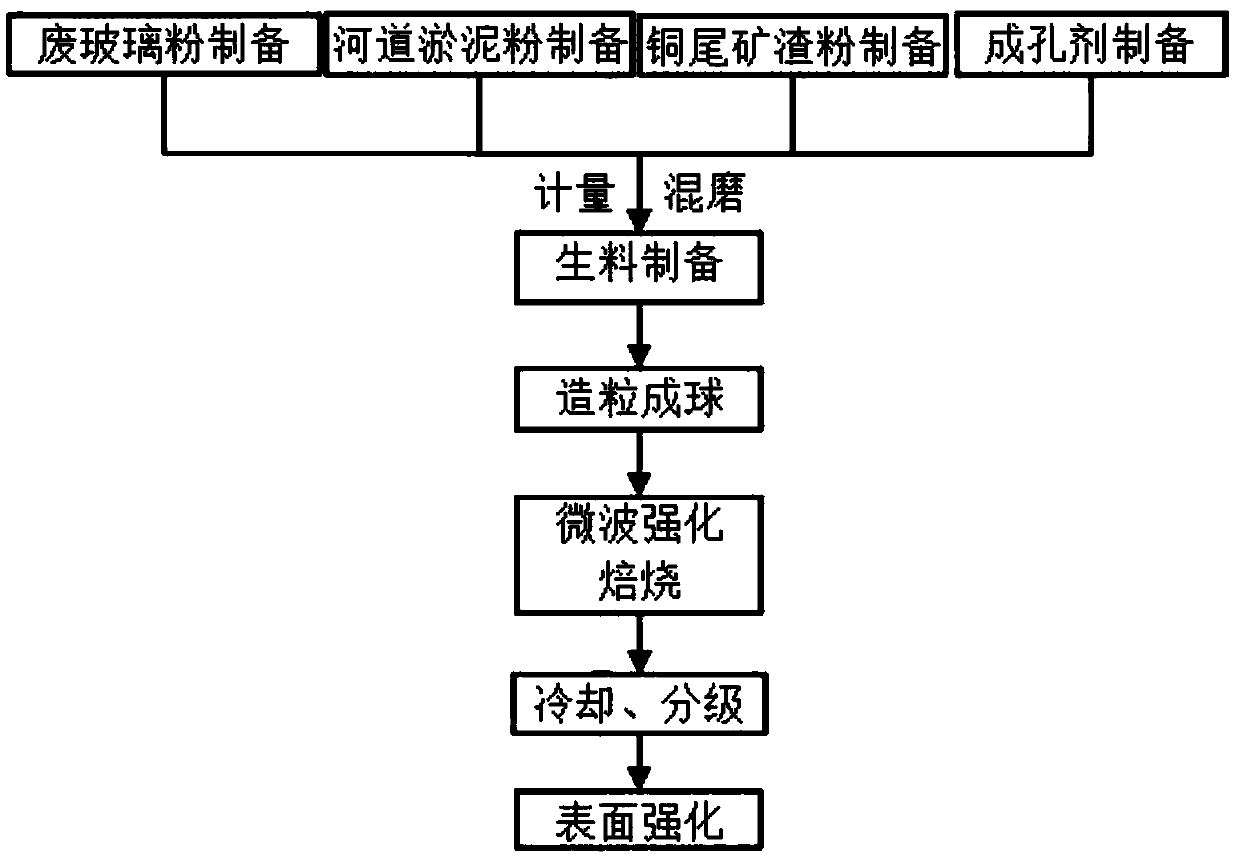

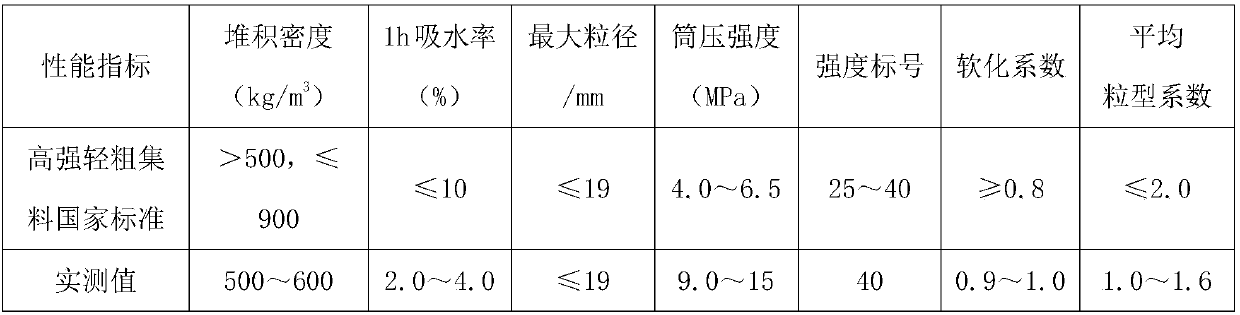

Light-weight high-intensity waste glass ceramsite and preparation method thereof

The invention provides light-weight high-intensity waste glass ceramsite and a preparation method thereof. The light-weight high-intensity waste glass ceramsite is characterized by being prepared fromthe following raw material ingredients in parts by weight: 70 to 80 parts of waste glass powder, 15 to 25 parts of riverway silt powder, 4 to 6 parts of copper tailing powder and 1 to 2 parts of pore-forming agents. The preparation method comprises the following steps of (1) raw material preparation; (2) granulation balling; (3) microwave reinforced roasting; (4) surface reinforcing. Waste such as waste glass is used as main raw materials; the raw materials are subjected to mixing, pelleting, roasting and surface reinforcement; finally, the ceramsite with light weight and high intensity is prepared; the porosity is high; the weight is light; the tube pressure intensity is high; the softening coefficient is great; high water resistance, low water absorption rate and good particle shape arerealized; the prepared light aggregate concrete has good durability. The problem that the waste glass and the like are difficult to dispose can be effectively solved; waste materials are changed intovaluable materials; the ecological environment can be protected; in addition, the raw material resources are rich; the cost is low; the process is simple.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Gangue ceramsite, and preparation method thereof

InactiveCN110282894AIncrease dosageHigh strengthCeramic materials productionCeramicwareLand resourcesSludge

The invention discloses gangue ceramsite, and a preparation method thereof. The gangue ceramsite comprises, by weight, 70 to 97% of gangue, 3 to 30% of calcium carbonate powder, 0 to 15% of quartz tail mud, and 0 to 10% of papermaking white sludge. According to the preparation method, calcining pre-heating temperature is controlled to be 200 to 1100 DEG C, pre-heating time is controlled to be 30 to 40min, roasting temperature is controlled to be 1100 to 1380 DEG C, and roasting time is controlled to be 2 to 8min. According to the above formula and the technology, gangue doping amount can be higher than 90%, problems such as pollution of ground and atmosphere by gangue, and large land resource occupying are solved effectively; at the same time, the formula is simple, using of environment burden high and exploitation limited raw materials is avoided, adopted materials are easily available, an advanced high efficiency flow production line is constructed, the strength of prepared ceramsite is higher than that of conventional product, the bulk density is 921.3Kg / m3, and the highest cylinder compressive strength is 16.8MPa.

Owner:HUAINAN DONGCHEN GROUP

Granite waste rock powder ceramsite and preparation method thereof

InactiveCN107445646AHigh in silicaHigh hardnessCeramic materials productionCeramicwareExpanded clay aggregateCoal

The invention discloses granite waste rock powder ceramsite, which is prepared from the following ingredients in percentage by mass: 50.0 to 80.0 percent of granite waste rock powder, 4.0 to 15.0 percent of clay tailings, 10.0 to 20.0 percent of waste porcelain powder, 5.0 to 10.0 percent of clay and 1.0 to 5.0 percent of pulverized coal. The invention also discloses a preparation method of the granite waste rock powder ceramsite. The process is simple; the cost is low; a large amount of granite waste rock powder is consumed; the waste utilization rate is high; the performance of the prepared granite waste rock powder ceramsite is excellent; the application prospects are wide. By the process, the raw materials are directly mixed and pelletized, and are then put into a high-temperature furnace to be calcined to be prepared into the granite waste rock powder ceramsite; the formation process is simplified; the work efficiency is improved; meanwhile, the preparation method is suitable for mass production.

Owner:UNIV OF JINAN

High-strength coal gangue ceramsite and preparation method thereof

InactiveCN111825430ASimple recipeHigh cylinder compressive strengthCeramic materials productionClaywaresChemical industrySlag

The invention discloses a high-strength coal gangue ceramsite and a preparation method thereof, and relates to a building material and a preparation method thereof. The high-strength coal gangue ceramsite comprises the following raw materials by weight: 90%-97% of coal gangue, 2%-8% of carbide slag, and 0%-10% of papermaking white mud, wherein the coal gangue is uncalcined coal gangue or calcinedcoal gangue or a mixture of the uncalcined coal gangue and the calcined coal gangue, the carbide slag is solid waste discarded after chemical industry products are prepared from acetylene, and the papermaking white mud is solid waste abandoned in a papermaking process. According to the invention, coal gangue, carbide slag and papermaking white mud in ceramsite manufacturing raw materials are all solid waste, and the mixing amount of the coal gangue in the raw materials is higher than 90%, so that the problems that the coal gangue pollutes the earth surface and the atmosphere and wastes land are effectively solved, and resource utilization of the waste can be effectively achieved; and the ceramsite prepared by the method is simple in formula, low in stacking density, high in cylinder compressive strength, simple in formula and low in raw material cost, and the technological process is adopted.

Owner:HUAINAN DONGCHEN GROUP

Resource utilization method of hexavalent chromium contaminated soil

ActiveCN111675549ASolve pollutionImprove performanceSievingScreeningChromium contaminationSoil treatment

The invention relates to the technical field of soil treatment, in particular to a resource utilization method of hexavalent chromium contaminated soil. The method comprises the following steps: (1) physically crushing and screening hexavalent chromium contaminated soil, (2) physically crushing and screening blast furnace slag, (3) uniformly stirring and mixing water, the screened hexavalent chromium contaminated soil and blast furnace slag, (4) granulating the mixture to form a ceramsite raw material, (5) drying and roasting the ceramsite raw material, and (6) cooling the roasted ceramsite toobtain a ceramsite product taking hexavalent chromium contaminated soil and blast furnace slag as raw materials. According to the method, the remediation problem of the remediated soil is solved in aresource utilization mode, resources such as raw coal do not need to be purchased additionally, the purpose of treating waste with waste is achieved, and the disposal cost is reduced.

Owner:山东洛尔环保科技有限公司

Particle pretreatment wrapping technology capable of reducing water-absorbing rate of ceramsite

InactiveCN108483963ALow water absorptionHigh cylinder compressive strengthPre treatmentMaterials science

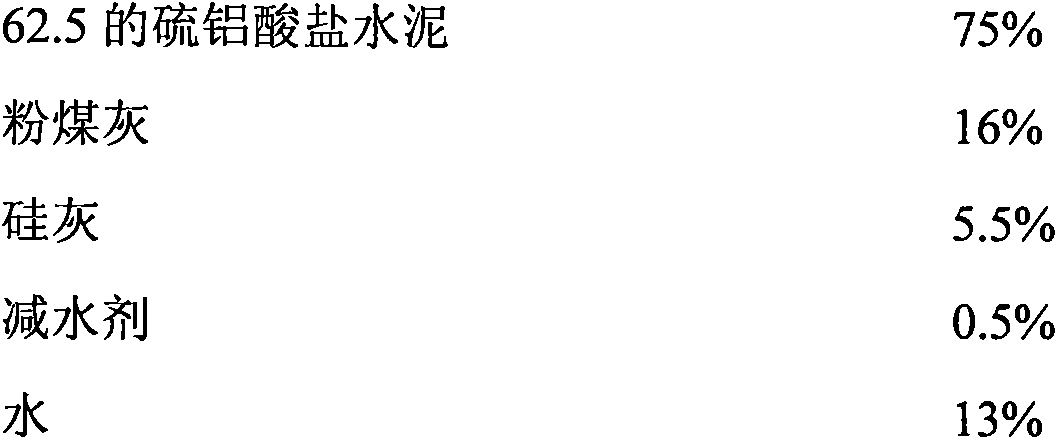

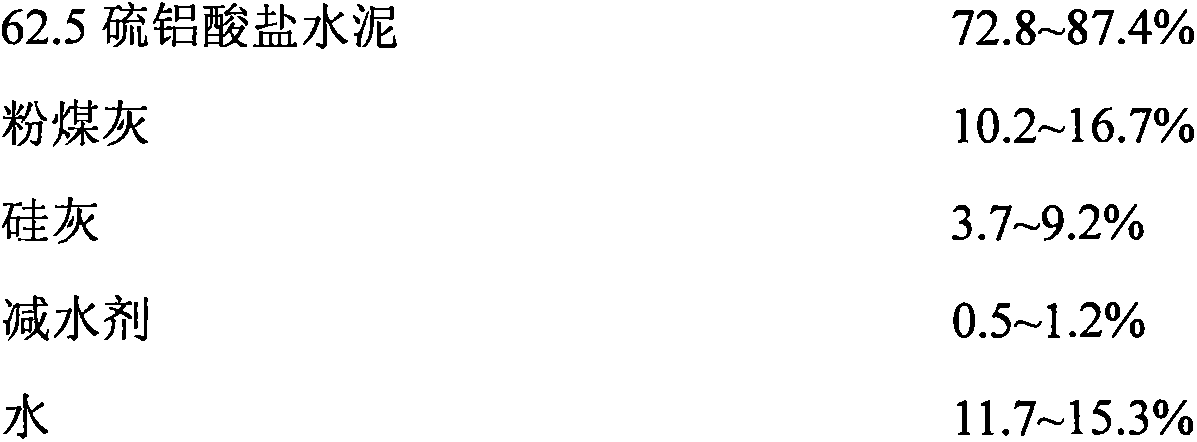

The invention relates to a particle pretreatment wrapping technology capable of reducing the water-absorbing rate of ceramsite. The particle pretreatment wrapping technology capable of reducing the water-absorbing rate of the ceramsite comprises the following steps: 1, mixing 2 parts of a surfactant and 100 parts of water uniformly into a mixture of the surfactant and the water; 2, spraying the mixture of the surfactant and the water on the surfaces of the ceramsite particles to preliminarily wet the ceramsite particles; 3, stirring sulfoaluminate cement according to the proportion to form flowing cement paste; 4, spraying the cement paste on the ceramsite particles until the ceramsite particles are wrapped completely, and discharging; and 5, maintaining for 6 hours under the condition ofroom temperature and forming a uniform wrapping layer with the thickness of 1 to 2 mm at the outer part of the ceramsite after the sulfoaluminate cement is completely set and hardened. The surface ofthe ceramsite with high water-absorbing rate is wrapped with one high-strength sulfoaluminate cement shell layer; the wrapped ceramsite has high strength; and the water-absorbing property of the particles can be obviously reduced and the water-absorbing rate per hour is only 0.5 percent.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com