Method for preparing lightweight high-strength ceramsite by aid of coal gangue

A technology of high-strength ceramsite and coal gangue, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of high cost of alumina chopped fibers, complicated preparation technology, etc., and can achieve cylinder compressive strength Improved, broad application prospects, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

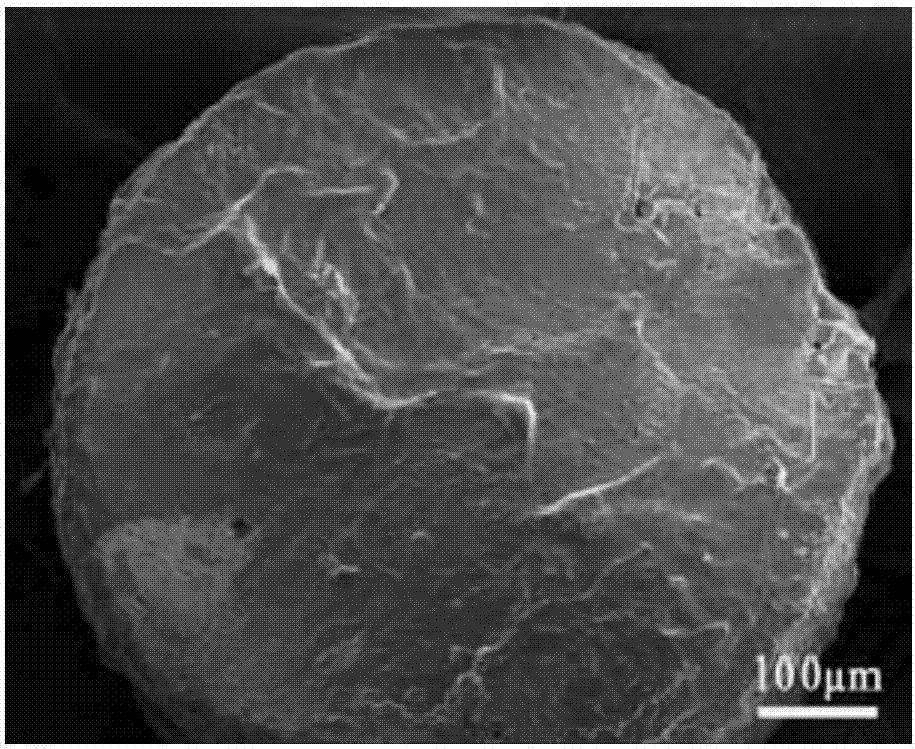

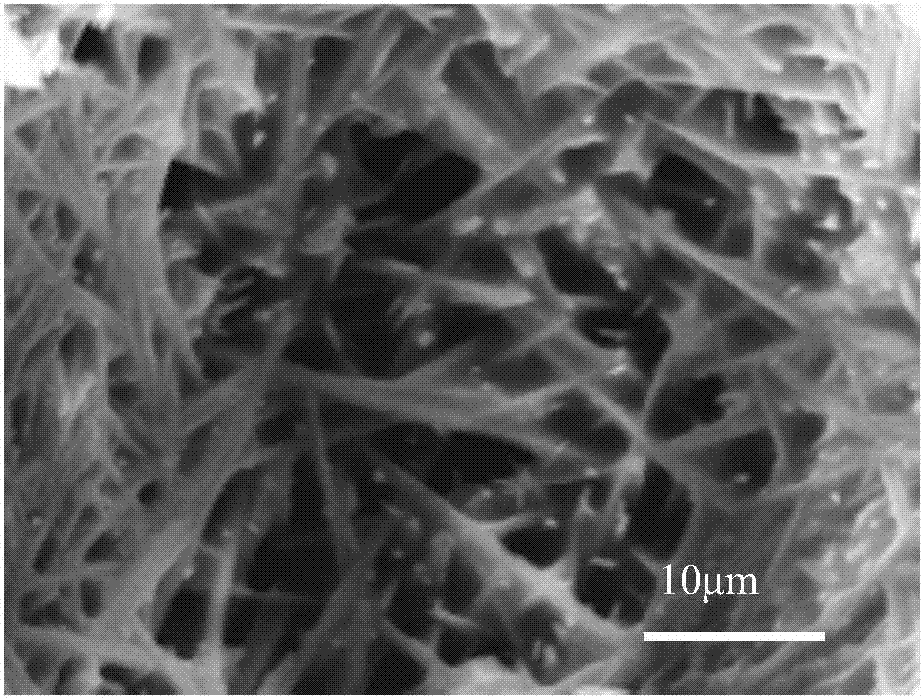

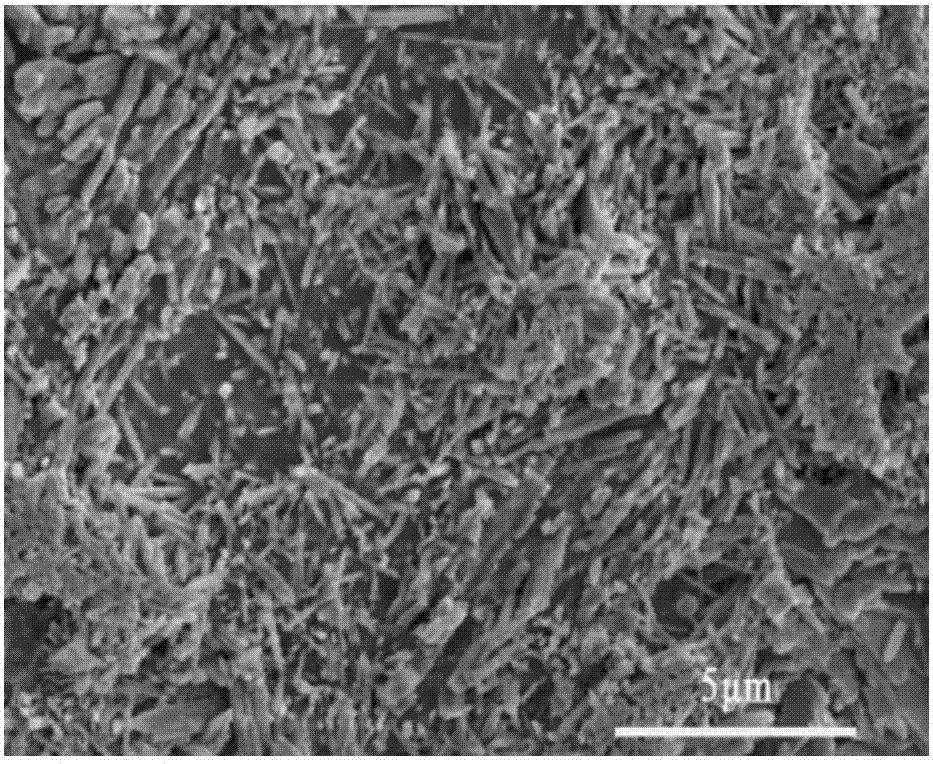

Image

Examples

Embodiment 1

[0031] A method for preparing lightweight high-strength ceramsite from coal gangue, comprising the steps of:

[0032] 1) Calcining coal gangue with a carbon content of 20% at 800°C to obtain coal gangue with a carbon content of about 7% and an aluminum oxide content of 40%, and the coal gangue block is obtained by crushing and grinding Powder with a particle size of 400 mesh;

[0033] 2) By mass percentage, 69% coal gangue powder, 14% bauxite (65% aluminum oxide content), 5% calcium carbonate (2% calcium oxide is formed after calcining), and 12% potassium Mix evenly to obtain raw materials;

[0034] 3) Put the raw materials in a ball mill, add high alumina balls according to the ball-to-material ratio of 1:1, and after ball milling for 1 hour, take out the mixed powder through a 600-mesh standard sieve;

[0035] 4) Put the mixed powder in a high-speed stirring mixing granulator, spray water accounting for 15% of the total mass of the powder at one time during the high-speed ...

Embodiment 2

[0041] A method for preparing lightweight high-strength ceramsite from coal gangue, comprising the steps of:

[0042] 1) The coal gangue with a carbon content of 15% and an aluminum oxide content of 30% is crushed and ground to obtain powder with a particle size of 400 mesh;

[0043] 2) 80% coal gangue powder, 10% calcite (5% calcium oxide is formed after calcining), and 10% potassium are mixed evenly by mass percentage to obtain raw materials;

[0044] 3) Put the raw materials in a ball mill, add high alumina balls according to the ball-to-material ratio of 1:1, and after ball milling for 1 hour, take out the mixed powder through a 500-mesh standard sieve;

[0045] 4) Put the mixed powder in a high-speed stirring mixing granulator, spray water accounting for 10% of the total mass of the powder during the high-speed stirring and rotating process of the powder, and stir at a high speed for 15 minutes to form fine and dense particles;

[0046] 5) adding 15% mixed powder to the pa...

Embodiment 3

[0051] A method for preparing lightweight high-strength ceramsite from coal gangue, comprising the steps of:

[0052] 1) The coal gangue with a carbon content of 5% and an aluminum oxide content of 50% is crushed and ground to obtain powder with a particle size of 600 mesh;

[0053] 2) Mix 50% coal gangue powder, 40% bauxite (70% aluminum oxide content), 4% calcium oxide, and 6% potassium by mass percentage to obtain raw materials;

[0054] 3) Put the raw materials in a ball mill, add high alumina balls according to the ball-to-material ratio of 1:1, and after ball milling for 2 hours, take out the mixed powder through a 500-mesh standard sieve;

[0055] 4) Place the mixed powder in a high-speed stirring mixing granulator, spray water accounting for 18% of the total mass of the powder during the high-speed stirring and rotating process of the powder, and stir at a high speed for 10 minutes to form fine and dense particles;

[0056] 5) Add 10% mixed powder to the disc molding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com