Environment-friendly lightweight aggregate concrete and preparation method thereof

A lightweight aggregate concrete and environmental protection technology, applied in the field of building materials and high-strength lightweight aggregate concrete materials, can solve the problems of endangering the life and property safety of surrounding residents, wasting land resources, and increasing the burden on enterprises, and achieve significant economic and social benefits , increase the pressure bearing capacity and reduce the effect of over-exploitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of environment-friendly lightweight aggregate concrete, its raw material comprises the following components by weight ratio:

[0044] 1 part of cement;

[0045] 1.796 parts of pumice coarse aggregate;

[0046] 0.356 parts of iron tailings;

[0047] 0.823 parts of pumice sand;

[0048] Admixture 0.015 parts;

[0049] 0.45 parts of water;

[0050] The pumice coarse aggregate is crushed stone aggregate with a continuous gradation of particle size from 2.5mm to 20mm. The particle size of pumice sand is 2.36mm-4.75mm.

[0051] The selected model of raw cement is P·O, and the strength grade is 42.5; the admixture is polycarboxylate water reducer.

[0052] The iron tailings belong to the third zone of gradation, the fineness modulus is 2.16, the mud content is less than 2%, and the bulk density is 1460kg / m 3 .

[0053]The preparation method of this environment-friendly lightweight aggregate concrete, according to the following steps:

[0054] Step 1, sealing of...

Embodiment 2-5

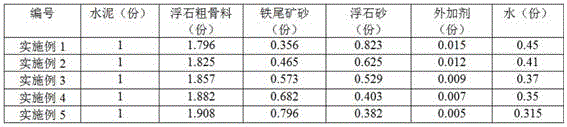

[0058] Implementation 2-5 The raw materials of environment-friendly lightweight aggregate concrete in four embodiments are as shown in the following table by weight ratio, and the rest are the same as in embodiment 1.

[0059] Table 1 The distribution ratio of each component of environmentally friendly lightweight aggregate concrete

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com