Particle pretreatment wrapping technology capable of reducing water-absorbing rate of ceramsite

A technology of pretreatment and water absorption, which is applied in the field of building materials, can solve the problems of reduced mechanical properties of mortar, high water absorption, and increased water consumption, and achieves the effects of simple technology, high cylinder compressive strength, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A particle pretreatment wrapping technology to reduce water absorption of ceramsite, the implementation process is as follows:

[0030] (1) 2 parts of surfactant and 100 parts of water are uniformly mixed into a mixture of surfactant and water;

[0031] (2) Spray the mixture of surfactant and water on the surface of the ceramsite particles to fully moisten the ceramsite particles;

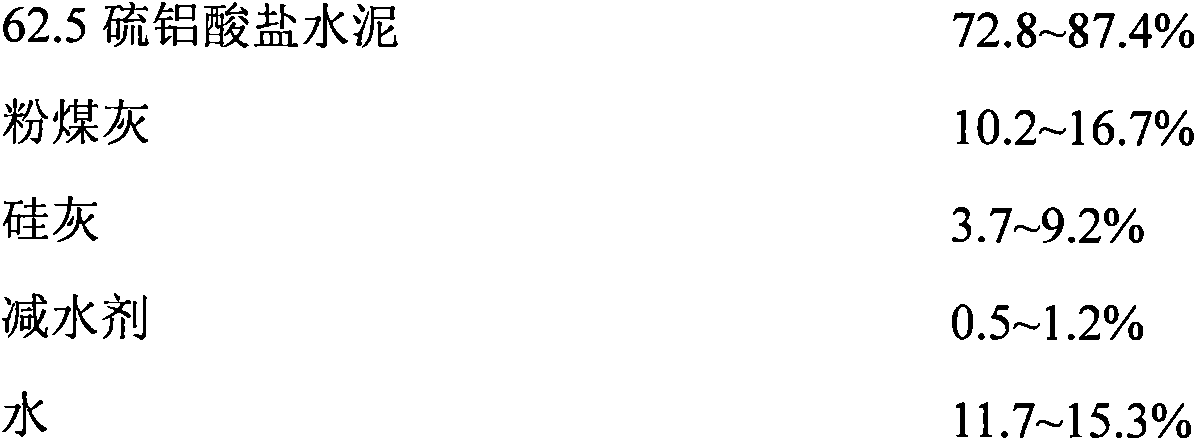

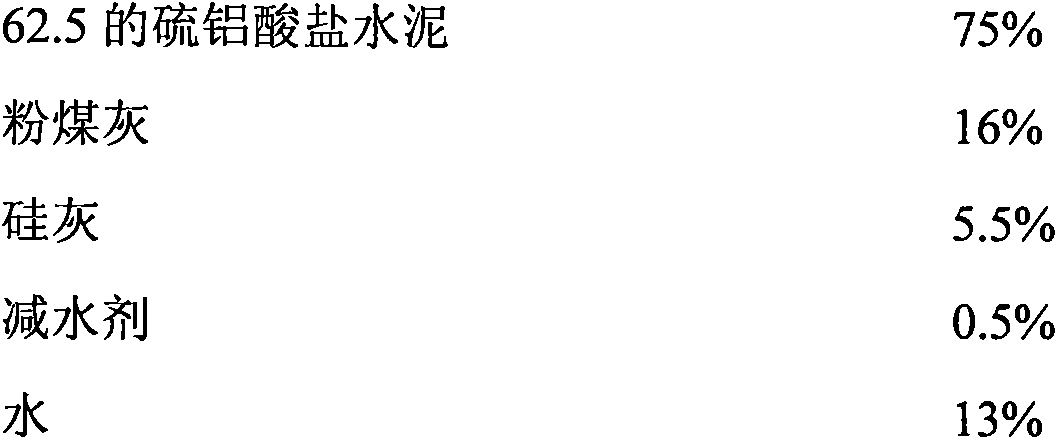

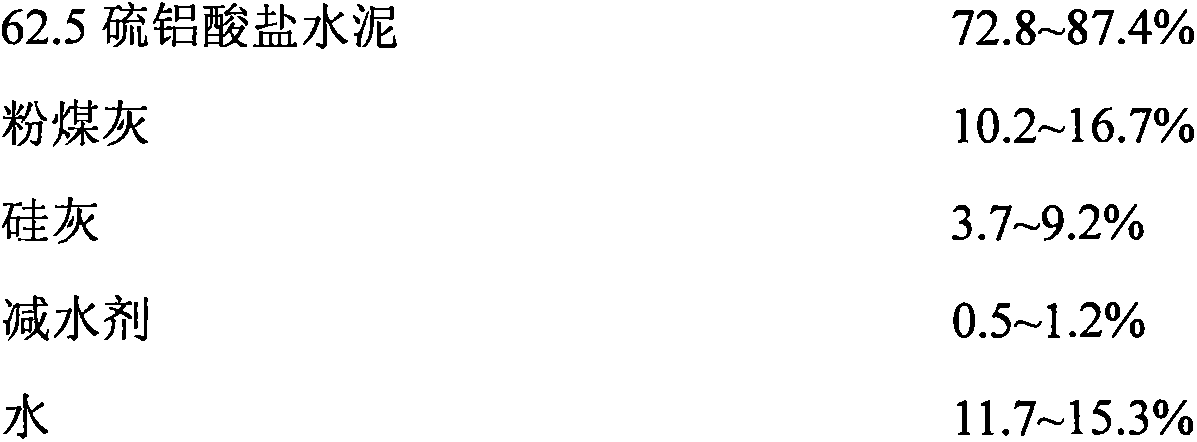

[0032] (3) The material should be weighed according to the following quality:

[0033]

[0034] Stir the sulphoaluminate cement into a fluid cement slurry according to the mixing ratio.

[0035] (4) Pour the wet ceramsite into the mixer for stirring, spray sulphoaluminate cement slurry during the stirring process, control the thickness of the coating layer by spraying the amount of sulphoaluminate cement slurry, stir and spray After the ceramsite is completely wrapped by sulphoaluminate cement, it is discharged;

[0036] (5) Curing at room temperature for 6 hours. After the sulphoalumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com