Lightweight aggregate concrete for heat preservation of structures

A technology of lightweight aggregate concrete and structural insulation, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effects of improving performance, reducing structural weight, and reducing density difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

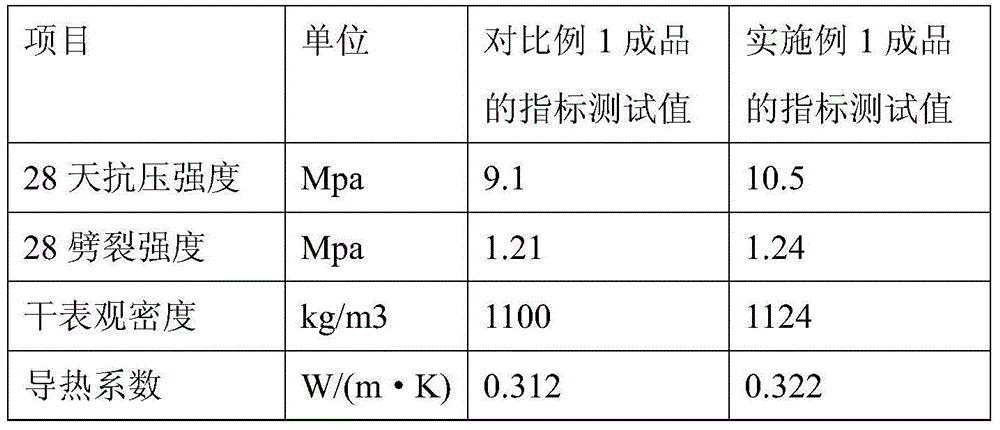

[0048] According to the number of parts by mass: 337 parts of 42.5 grade ordinary Portland cement, 37 parts of fly ash, 110 parts of modified vitrified microspheres, 415 parts of clay ceramsite, 15.8 parts of concrete modifier, 3.74 parts of water reducer Parts, 273 parts of water. The concrete modifying agent comprises: 95.01% of dispersible latex powder; 0.24% of 3-5mm long chemical polypropylene fiber; and 4.75% of thickening agent in terms of mass percentage. The water reducer is a polycarboxylate high-efficiency water reducer, and its water reducing rate is 25%. It is prepared according to the above-mentioned preparation, molding and maintenance methods to obtain a finished product. Detect its performance, and the specific detection values are shown in Table 1.

[0049] Table 1: Test items and test values of the finished product of Implementation Example 1

[0050] project

Embodiment 2

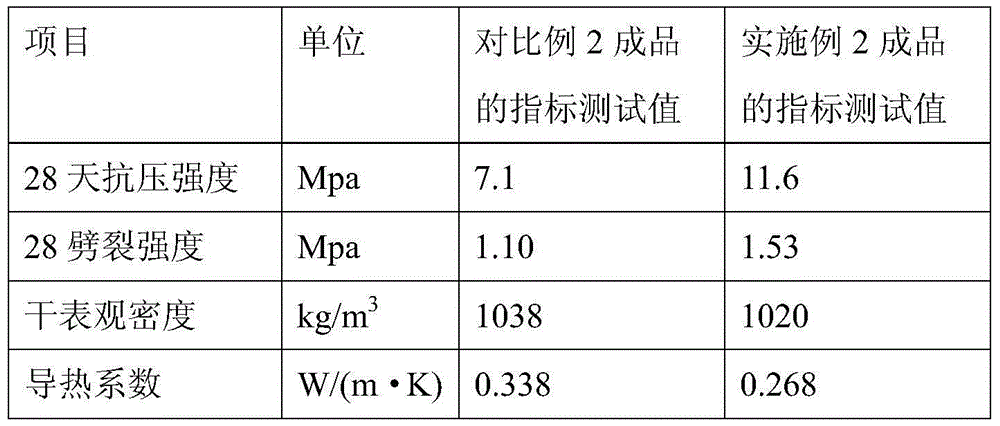

[0052] Prepared by mass parts: 375 parts of 42.5 grade ordinary Portland cement, 42 parts of fly ash, 113 parts of modified vitrified microspheres, 447 parts of clay ceramsite, 17.9 parts of concrete modifier, 4.12 parts of water reducer part, 260 parts of water. The concrete modifier comprises: 94.16% of dispersible latex powder; 0.19% of 3-8mm long chemical polypropylene fiber; and 5.65% of thickening agent in terms of mass percentage. The water reducer is a polycarboxylate high-efficiency water reducer, and its water reducing rate is 25%. After the finished product is produced, its performance is tested, and the specific detection values are shown in Table 2.

[0053] Table 2: Test items and test values of the finished product of Implementation Example 2

[0054] project

Embodiment 3

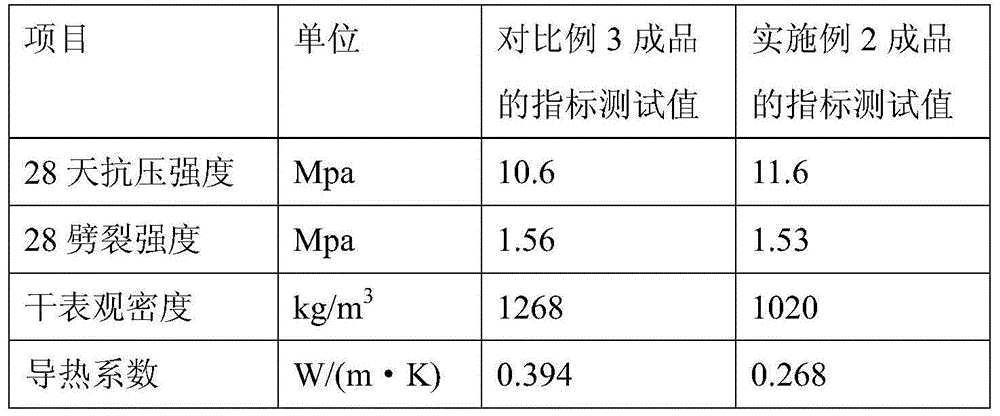

[0056] Prepared in parts by mass: 409 parts of 42.5 grade ordinary Portland cement, 45 parts of fly ash, 120 parts of modified vitrified microspheres, 430 parts of ceramsite in saturated surface dry state, 19.3 parts of concrete modifier, 4.54 parts of water reducer, 261 parts of water. The concrete modifier comprises: 93.46% of dispersible latex powder; 0.31% of 3-8mm long chemical polypropylene fiber; and 6.23% of thickening agent in terms of mass percentage. The water reducer is a polycarboxylate high-efficiency water reducer, and its water reducing rate is 25%. After the finished product is produced, its performance is tested, and the specific detection values are shown in Table 3.

[0057] Table 3: Test items and test values of the finished product of Implementation Example 3

[0058] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com