Planting sand prepared by utilizing sludge and a preparing method thereof

A sludge and domestic sludge technology, applied in the field of planting sand, can solve the problems of dust pollution, vermiculite matrix is easily broken, difficult to fix, etc., and achieves the effect of ensuring the safety of use, increasing the specific surface area, and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

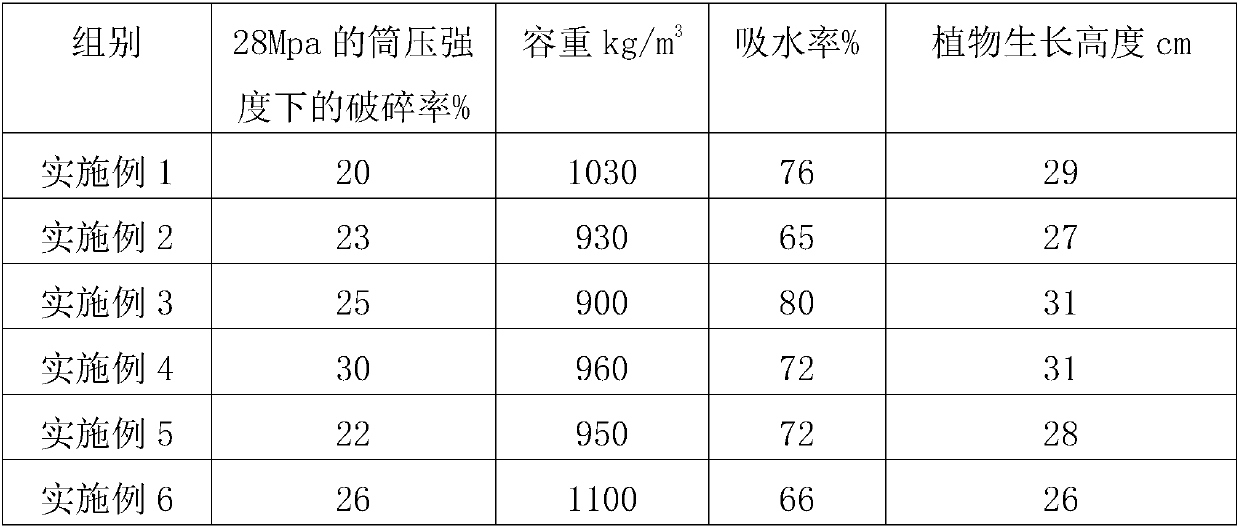

Examples

Embodiment 1

[0033] In this embodiment, the planting sand prepared from sludge is prepared from the following raw materials in parts by weight: 100 parts of fly ash, 15 parts of domestic sludge, 5 parts of kaolin and 1 part of quartz powder.

[0034] The preparation method of planting sand in the present embodiment may further comprise the steps:

[0035] (1) Mixing: Mix 100 parts of fly ash, 15 parts of domestic sludge, 5 parts of kaolin and 1 part of quartz powder to obtain a mixture;

[0036] (2) Granulation: the mixture is poured into a granulator for granulation treatment, the rotating speed of the granulator is 1500r / min, and the granulation time is 2min to obtain particles with a particle size of 10-100 mesh;

[0037] (3) Drying: Dry the granular mixture in a drying oven at 70°C for 90 minutes;

[0038] (4) Sintering: the dried mixture is heated up to 400°C at 10°C / min, and kept for 10 minutes; then heated to 700°C at 5°C / min, kept for 5 minutes; finally heated to 900°C at 20°C / min...

Embodiment 2

[0041] The planting sand prepared from sludge in this example is prepared from the following raw materials in parts by weight: 100 parts of fly ash, 20 parts of papermaking sludge, 10 parts of kaolin and 1 part of silica fume.

[0042] The preparation method of planting sand in the present embodiment may further comprise the steps:

[0043] (1) Mixing: Mix 100 parts of fly ash, 20 parts of papermaking sludge, 10 parts of kaolin and 1 part of silica fume to obtain a mixture;

[0044] (2) Granulation: the mixture is poured into a granulator for granulation treatment, the rotating speed of the granulator is 2000r / min, and the granulation time is 1.5min to obtain particles with a particle size of 10-100 mesh;

[0045] (3) Drying: Dry the granular mixture in an oven at 80°C for 80 minutes;

[0046] (4) Sintering: the dried mixture is heated up to 400°C at 15°C / min, and kept for 10 minutes; then heated to 700°C at 7°C / min, kept for 5 minutes; finally heated to 1000°C at 25°C / min, k...

Embodiment 3

[0049] In this embodiment, the planting sand prepared from sludge is prepared from the following raw materials in parts by weight: 100 parts of coal gangue fine powder, 20 parts of domestic sludge, 2.5 parts of kaolin, 2.5 parts of bentonite, 0.5 part of quartz powder and silica fume 0.5 servings.

[0050] The preparation method of planting sand in the present embodiment may further comprise the steps:

[0051] (1) Mixing: Mix 100 parts of coal gangue fine powder, 20 parts of domestic sludge, 2.5 parts of kaolin, 2.5 parts of bentonite, 0.5 part of quartz powder and 0.5 part of silica fume to obtain a mixture;

[0052] (2) Granulation: the mixture is poured into a granulator for granulation treatment, the rotating speed of the granulator is 2000r / min, and the granulation time is 1min to obtain particles with a particle size of 10-100 mesh;

[0053] (3) Drying: Dry the granular mixture in a drying oven at 90°C for 80 minutes;

[0054](4) Sintering: The dried mixture is heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com