Ultra-light ceramsite prepared from solid waste and preparation method of ultra-light ceramsite

An ultra-light pottery, content technology, applied in ceramic products, clay products, other household appliances, etc., can solve the problems of insufficient strength, failure to comprehensively utilize solid waste, low added value, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

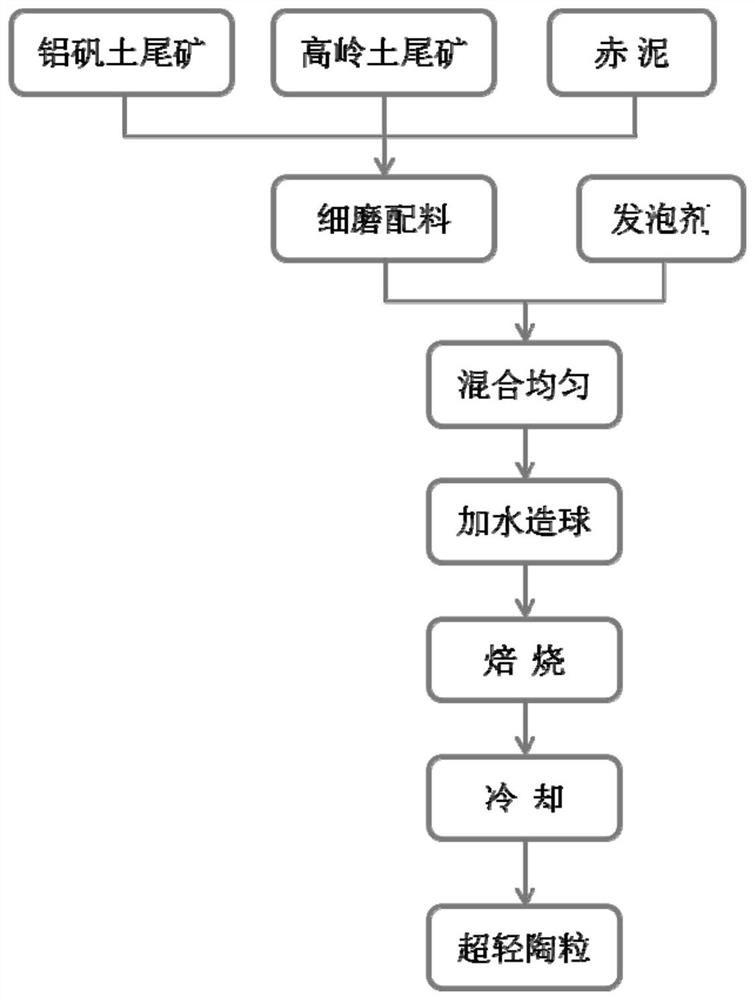

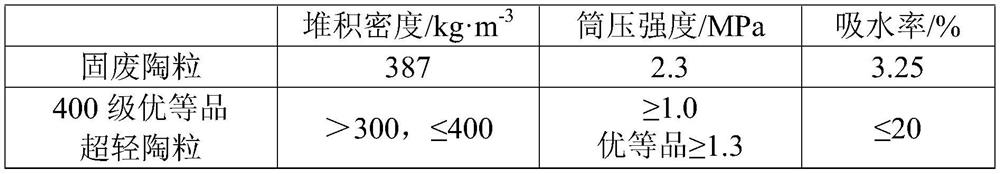

[0024] A preparation method for preparing ultra-light ceramsite from solid waste, comprising the following steps:

[0025] (1) Grinding bauxite tailings, red mud and kaolin tailings to below -0.074mm;

[0026] (2) According to the chemical composition of bauxite tailings, kaolin tailings and red mud, formula is designed so that the chemical composition of the three solid waste raw materials is: Al 2 o 3 The content is 12~18.5wt%, SiO 2 The content is ≥ 45wt%, and the total content of alkali metal and alkaline earth metal is: 14-19wt%;

[0027] (3) According to the formula in step (2), take the three kinds of solid waste raw materials after grinding, add foaming agent and mix evenly, add water, homogenize for 2 hours, pelletize and dry to obtain green pellets;

[0028] (4) Put the raw balls into the muffle furnace and roast to obtain ultra-light building ceramsite products.

[0029] The roasting temperature is as follows: from room temperature to 100°C, the heating rate is ...

Embodiment 1

[0033] The bauxite tailings in this test are the bauxite beneficiation tailings of Zhongzhou Aluminum Industry in Jiaozuo, Henan Province, and the analysis results of its main chemical components are shown in Table 1. Al in tailings 2 o 3 The content is as high as 38.90%, as the main raw material of aluminum source.

[0034] Table 1 Main chemical composition of bauxite tailings (%)

[0035] Element al 2 o 3

SiO 2

MgO Na 2 o

K 2 o

CaO Fe 2 o 3

content / % 38.90 28.12 0.49 0.26 3.80 0.63 12.32

[0036] The kaolin tailings in this test are sandy kaolin beneficiation tailings, and the analysis results of its main chemical components are shown in Table 2. SiO 2 The content is as high as 84.55%, as the main raw material of silicon source.

[0037] Table 2 Composition of main chemical elements of kaolin tailings

[0038] Element Al 2 o 3

SiO 2

MgO Na 2 o

K 2 o

CaO Fe 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com