Gangue ceramsite, and preparation method thereof

A technology of coal gangue ceramsite and coal gangue, which is applied in the field of building materials, can solve problems such as high cost, unfavorable commercial production, and large problems, and achieve the effects of simple formula, efficient resource utilization, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

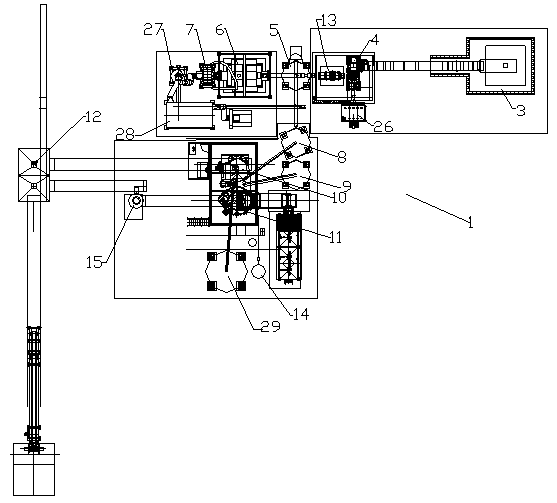

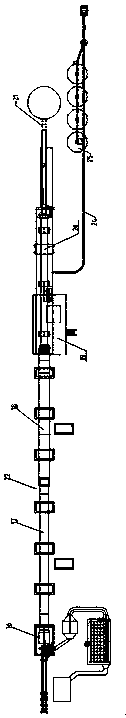

Method used

Image

Examples

Embodiment 1

[0044] 1. Raw material drying and storage

[0045] Dry the coal gangue naturally until the moisture content is <5% and then store it in other batching bins for later use; (Because only coal gangue powder and calcium carbonate powder are used in this example, so the preparation is only written as follows two)

[0046] 2. Broken

[0047] Put the coal gangue into the two-stage crusher for crushing, the crushing particle size is 2-5 mm, and use the bucket elevator to enter the buffer bin after crushing;

[0048] 3. Raw material grinding

[0049] The crushed coal gangue is put into the resonance mill for grinding, and then enters the winnowing and classifying machine for winnowing. The particle size of the winnowing material is 12.5-74 μm, and after winnowing, it enters the gangue powder bin for storage for use;

[0050] 4. Stirring and granulation

[0051] According to the particle size requirements of the product, 92% coal gangue powder and 8% calcium carbonate powder stored ...

Embodiment 2

[0055] 1. Raw material drying and storage

[0056] Naturally dry the coal gangue until the moisture content is <5% for use, and store the calcium carbonate powder and quartz tailings in other batching bins and admixture bins according to the ratio for use;

[0057] 2. Broken

[0058] Put the coal gangue into the two-stage crusher for crushing, the crushing particle size is 2-5 mm, and use the bucket elevator to enter the buffer bin after crushing;

[0059] 3. Raw material grinding

[0060] The crushed coal gangue is put into the resonance mill for grinding, and then enters the winnowing and classifying machine for winnowing. The particle size of the winnowing material is 12.5-74 μm, and after winnowing, it enters the gangue powder bin for storage for use;

[0061] 4. Stirring and granulation

[0062] According to the particle size requirements of the product, 90% coal gangue powder, 6% calcium carbonate powder and 4% quartz tailings stored in the coal gangue powder silo, ot...

Embodiment 3

[0066] 1. Raw material drying and storage

[0067] Naturally dry the coal gangue until the moisture content is <5% for use, and store the calcium carbonate powder and quartz tailings in other batching bins and admixture bins according to the ratio for use;

[0068] 2. Broken

[0069] Put the coal gangue into the two-stage crusher for crushing, the crushing particle size is 2-5 mm, and use the bucket elevator to enter the buffer bin after crushing;

[0070] 3. Raw material grinding

[0071] The crushed coal gangue is put into the resonance mill for grinding, and then enters the winnowing and classifying machine for winnowing. The particle size of the winnowing material is 12.5-74 μm, and after winnowing, it enters the gangue powder bin for storage for use;

[0072] 4. Stirring and granulation

[0073] According to the particle size requirements of the product, 92% coal gangue powder, 6% calcium carbonate powder and 2% quartz tailings stored in the coal gangue powder silo, ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com