Patents

Literature

82results about How to "Freeze-thaw resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive for compounding marble veneer with base material and preparation method thereof

ActiveCN101948667AEasy to useFast curing at room temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a bi-component modified epoxy adhesive for compounding a marble veneer with base materials such as a marble slab, a granite slab, a porcelain slab and a preparation method thereof. The adhesive comprises a component A and a component B, wherein the component A is prepared from epoxy resin, polyether, torispherical silicon micro-powder, heavy calcium carbonate and an auxiliary agent; and the component B is prepared from homemade modified amine, polyether amine, the torispherical silicon micro-powder, the heavy calcium carbonate and the auxiliary agent. The product has the characteristics of room temperature curing, high bond strength, water, heat and freeze-thaw resistance, low cost, convenient construction and the like.

Owner:HUNAN MAGPOW ADHESIVE INDS

Water wall paint for external wall

The present invention features that by selecting different sort and amount of emulsion and assistants, four kinds of wall finish paint, including styrene-acrylate wall finish paint, acrylate wall finish paint, organosilicon modified acrylate wall finish paint and high elasticicty wall finish paint, of different performance / cost ratio are proposed. They features the introduction of hydroxyethyl cellulose and non-transparent hollow polymer. Therefore, the outer wall finish paint has excellent alkali resistance, color maintaining property, antifouling property, ultraviolet ray resistance, freeze thawing resistance, waterproof property, etc.

Owner:GUANGDONG BADESE CHEM

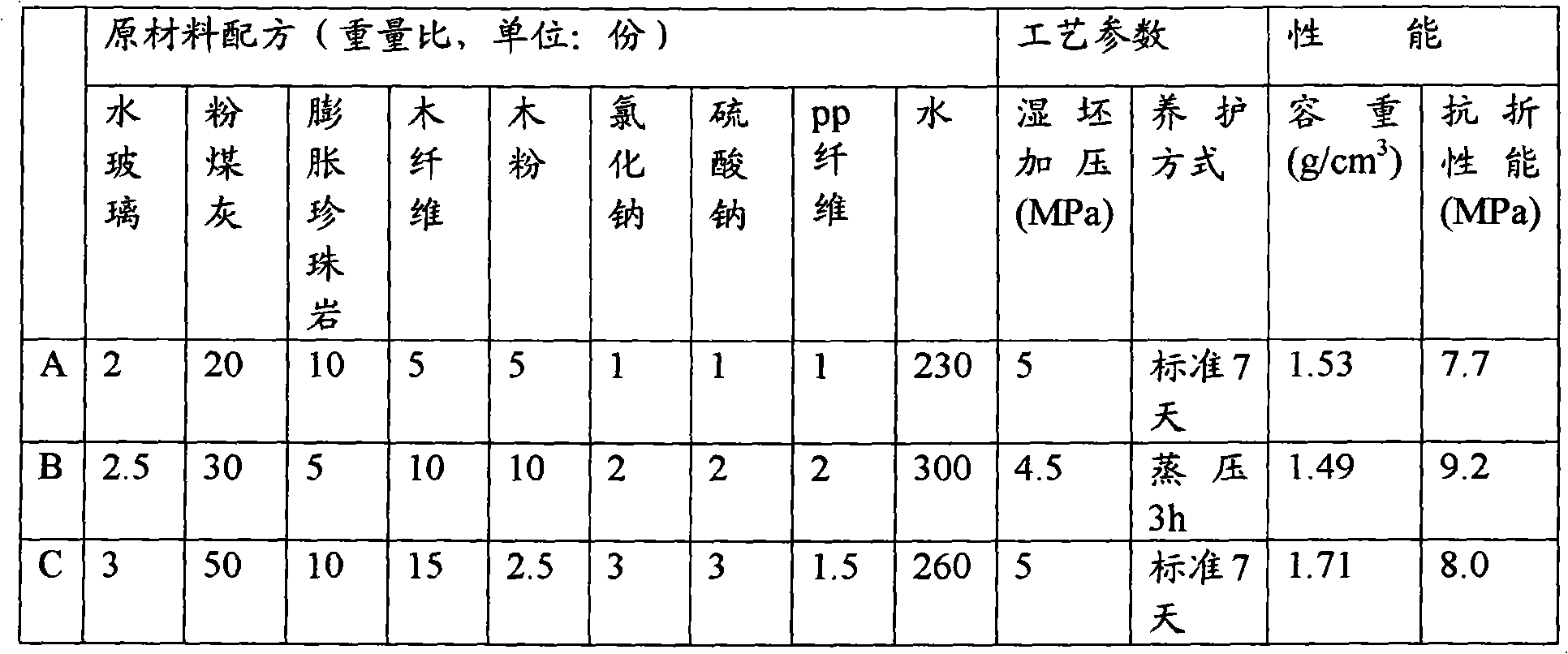

Light-weight fiber reinforced cement board and manufacturing method thereof

ActiveCN101781106AHigh tensile strengthHigh impact strengthSolid waste managementCement boardMethyl cellulose

The invention provides a light-weight fiber reinforced cement board. The light-weight fiber reinforced cement board comprises 100 parts of cement, 20 parts of silicon powder, 15 parts of calcium powder, 5 to 10 parts of expanded perlite, 4 parts of paper pulp, 5 to 15 parts of wood fibers, 5 to 10 parts of wood powder, 1 to 2 parts of polypropylene fibers, 0.8 part of methyl cellulose, 1 to 3 parts of sodium chloride, 1 to 3 parts of sodium sulphate, 2 to 3 parts of sodium silicate, and 230 to 300 parts of water. The invention also discloses a method for manufacturing the light-weight fiber reinforced cement board, which comprises the following steps of: 1, weighing each component according to formula; 2, placing the weighed dry materials into a mixer for uniformly mixing; 3, preparing wet materials, placing the mixed materials obtained by the step 2 into a kneader, adding water and the wet materials into the mixed materials, and kneading the mixture; and 4, placing the kneaded slurryinto a mold, performing compression moulding by using a plate fluidizing machine, and then demolding. The manufacturing method greatly improves the tensile strength, the impact strength, the water-retaining property, and the extrusion property of the materials.

Owner:BEIJING NEW BUILDING MATERIALS PLC

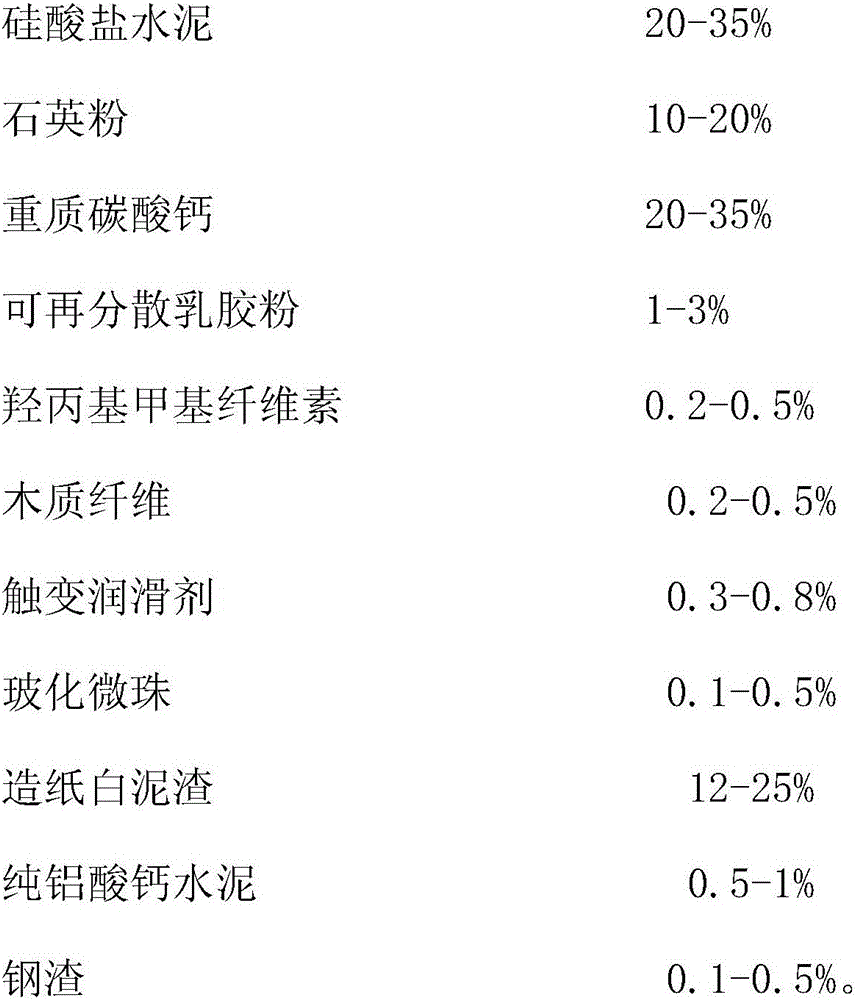

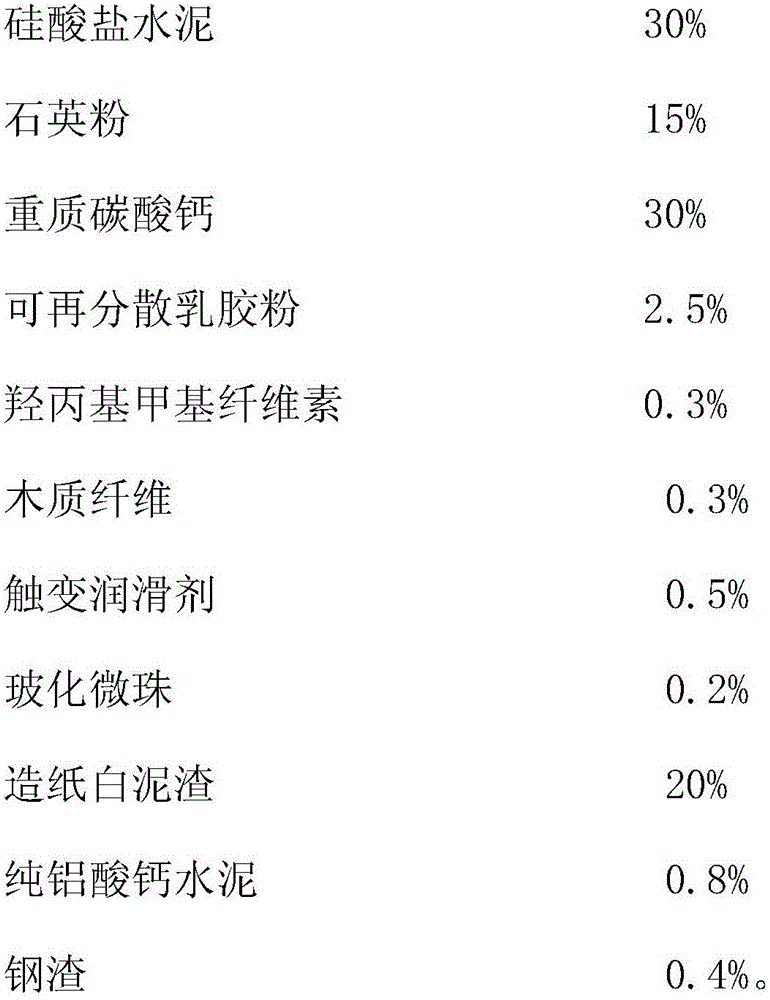

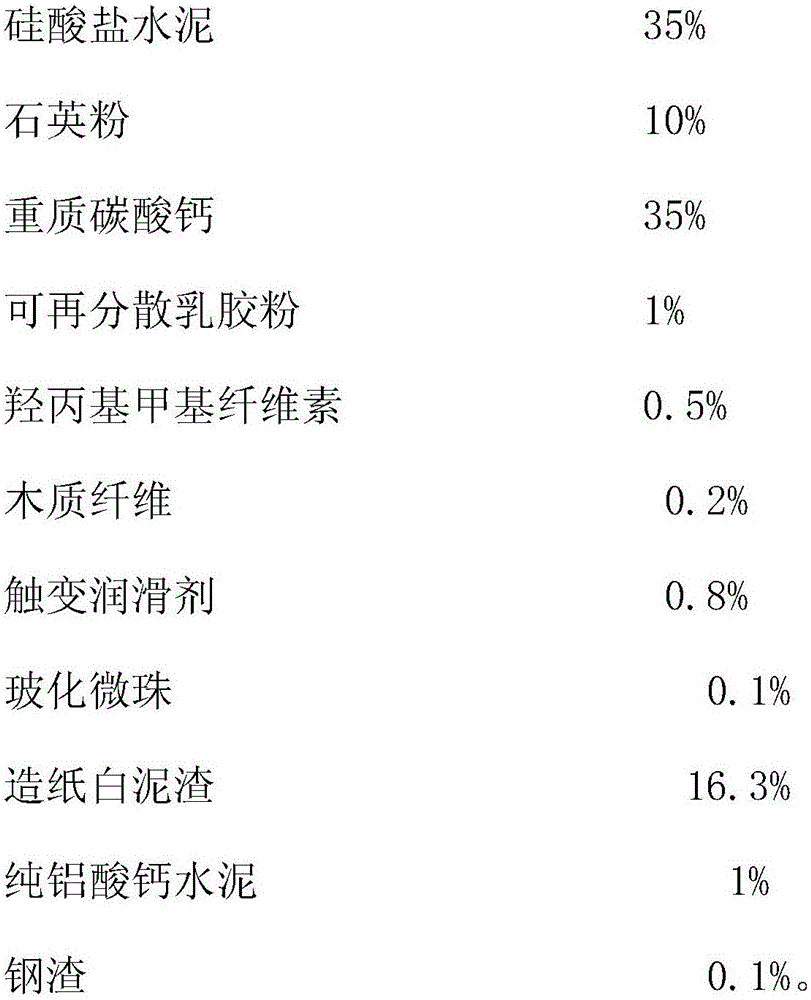

Environment-friendly external wall thermal-insulation putty and preparation method thereof

The invention relates to an environment-friendly external wall thermal-insulation putty. The putty is prepared by adding paper making white clay slag, steel slag and pure calcium aluminate cement on the basis of the conventional formula, and thus, belongs to a pure inorganic material. The putty has the characteristics of environment friendliness, no toxicity or odor, light weight, higher strength, lower heat conductivity coefficient and the like, and thus, has the advantages of thermal-insulation property, light dead weight, flame retardancy, sound insulation, weather resistance, aging resistance, freeze-thaw resistance, moisture resistance, seepage resistance, stable performance, excellent operating performance, convenient construction, low manufacturing cost and the like, thereby satisfying the determination of the design or construction technical scheme. The putty is suitable for internal / external wall thermal-insulation engineering in the regions with hot summer and cold winter, regions with hot summer and warm winter and part of cold regions, is also suitable for thermal insulation for party walls, floors, channels, basements, floor heating and other positions of the buildings, and can achieve the energy-saving effect. The putty can also be used for energy-saving reconstruction of the existing buildings.

Owner:长兴贝斯德邦建材科技有限公司

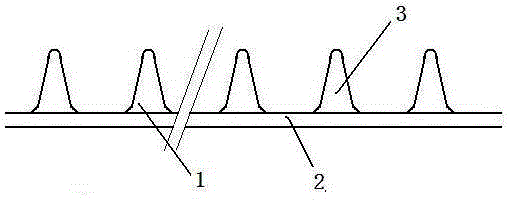

Nest type thermal insulation board and preparation method

The invention discloses a nest type thermal insulation board and belongs to the technical field of building external wall materials. A board body of the board is constituted by an assembling layer, a resistor bridge layer, a thermal insulation layer, a crack resisting layer and a decoration layer in sequence from the bottom surface layer to the external surface layer, and a preparation method comprises the steps of fabricating materials such as expanded perlite, cement, glass fibers and other accessory materials into different slurry materials, making a structure provided with multiple cone-tower-shaped nests out of the bottom surface, then continuing with the steps of formation, curing, trimming, steam curing, drying and the like, and obtaining the nest type thermal insulation board. The nest type thermal insulation board has the advantages that the dry surface of the thermal insulation board is low in density, the thermal conductivity coefficient is low, the compressive strength is high, the combustion-resisting perform level is high, the board has the fireproof function, and the board has the advantages of being low in weight, heat preservative, high in dimension stability, aging resistant, frost resistant, convenient to install, simple to construct, beautiful in appearance and the like. In the construction process, the flowing dust pollution caused by application of powder materials is reduced, approximately 60% of construction time is saved in the construction cycle, the construction cost is greatly reduced, and the energy consumption is saved in the building construction in the real sense.

Owner:CHONGQING YUDING ENERGY SAVING BUILDING MATERIAL

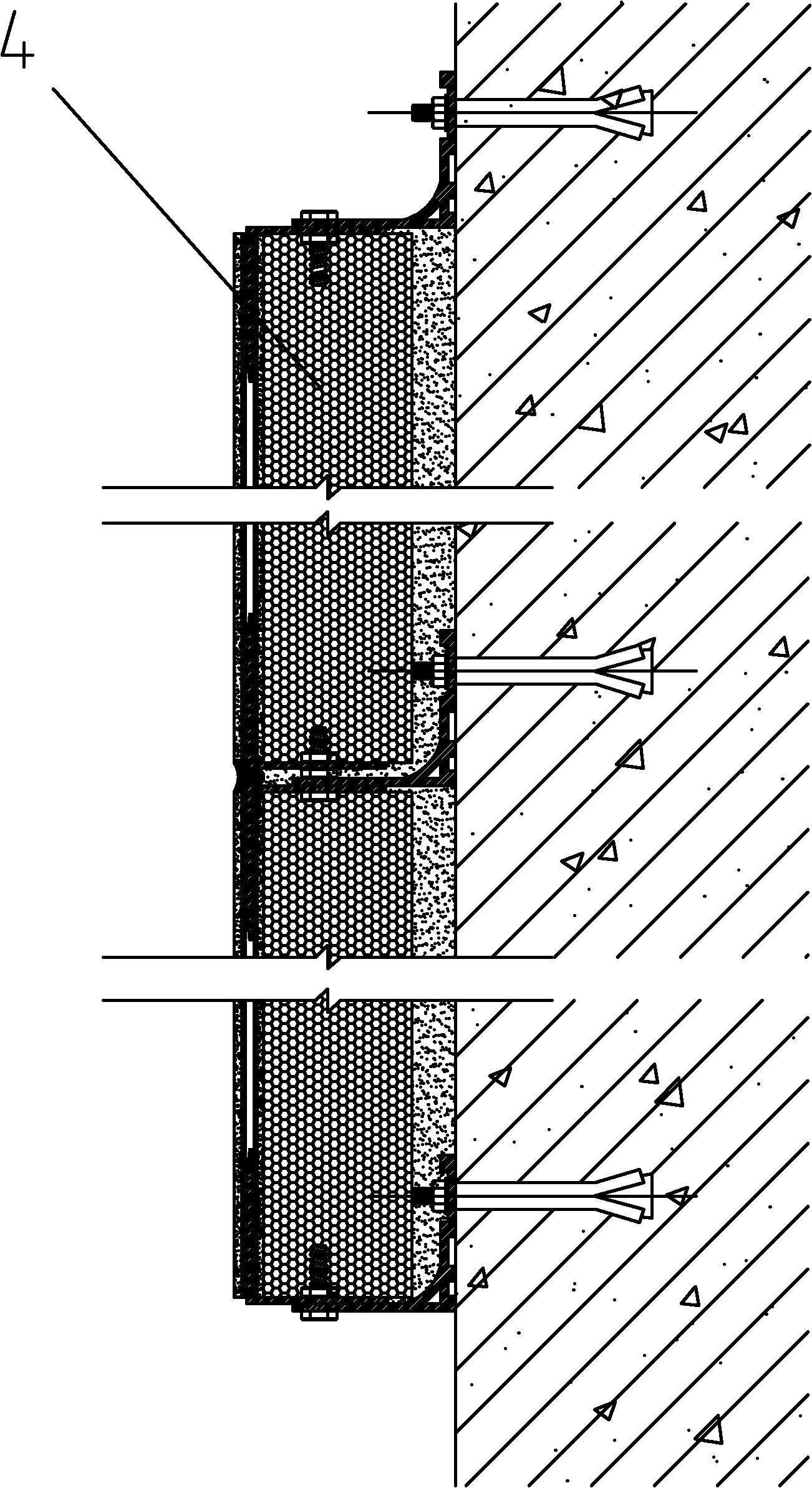

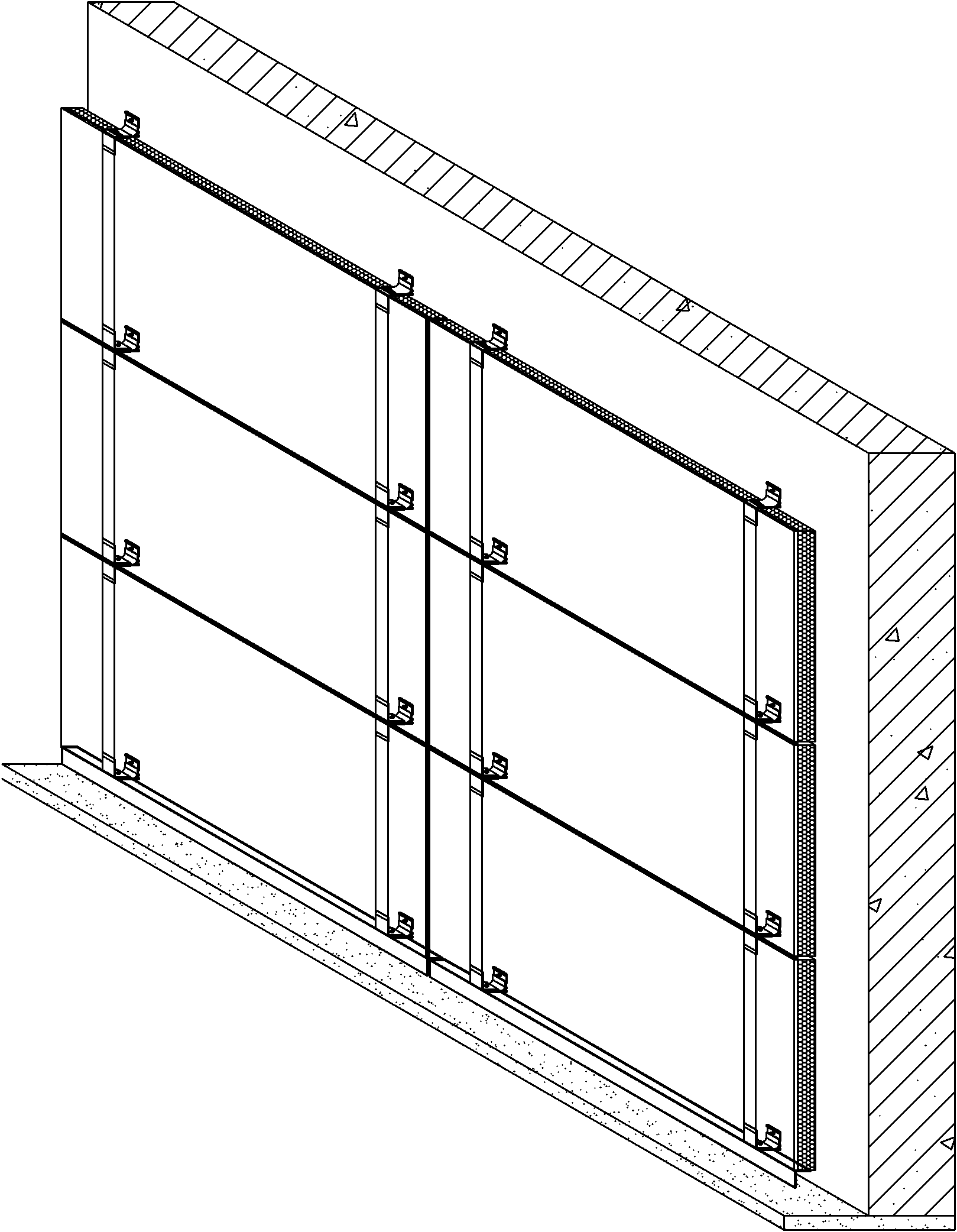

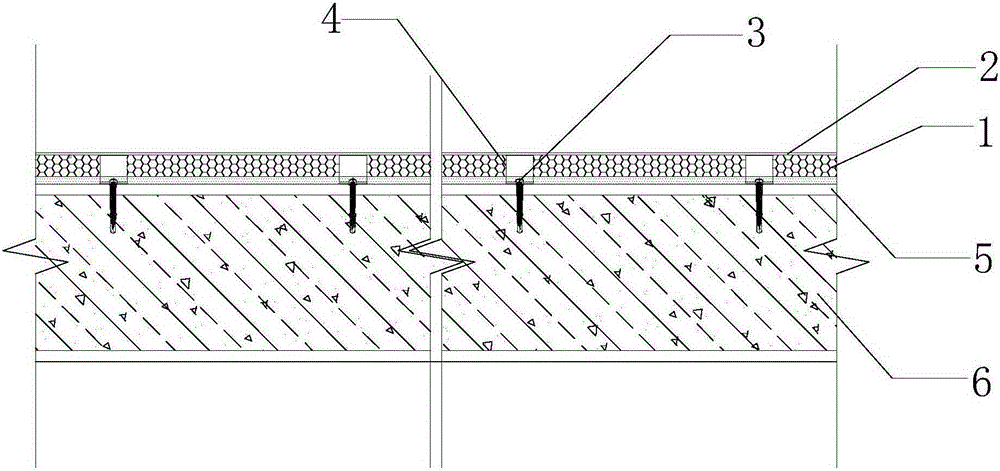

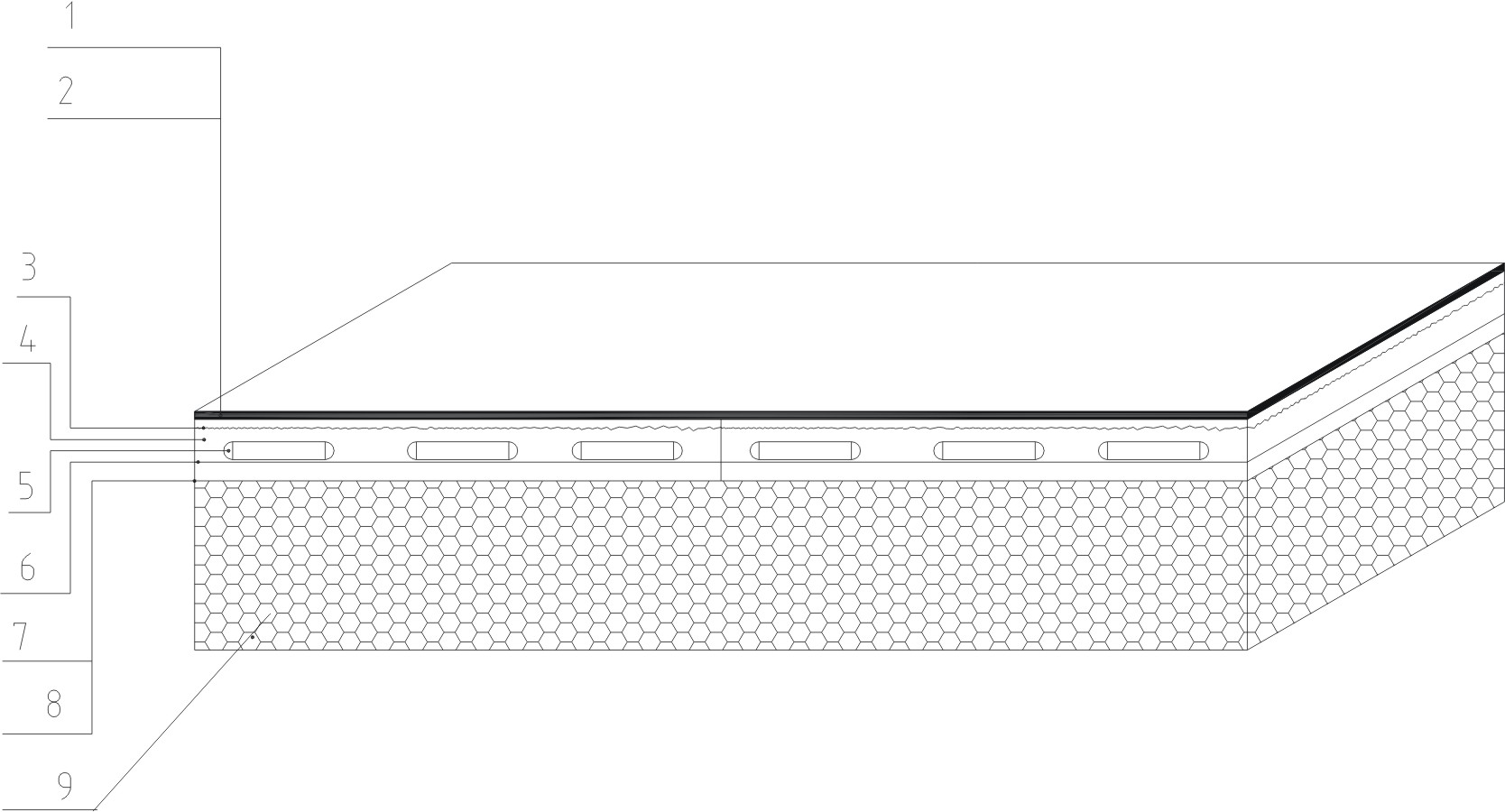

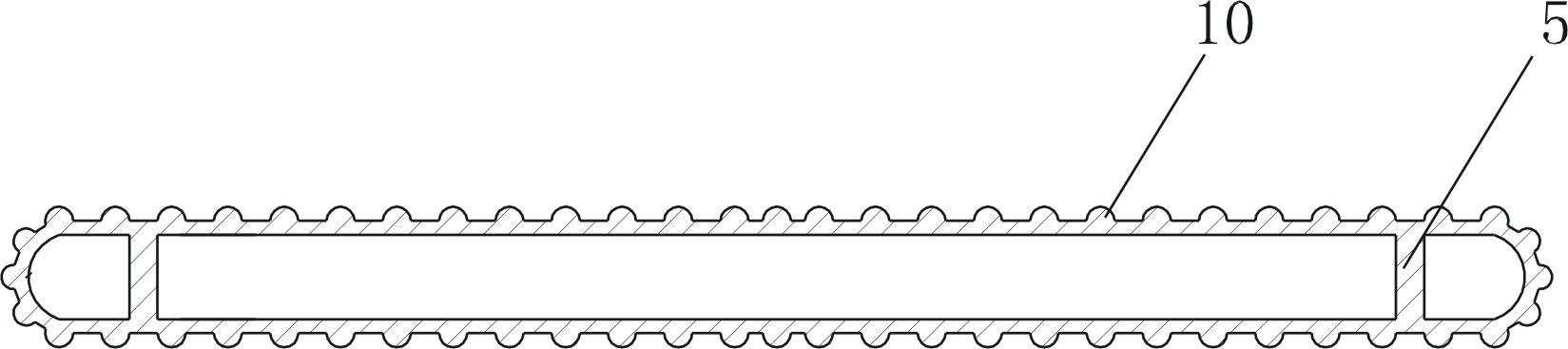

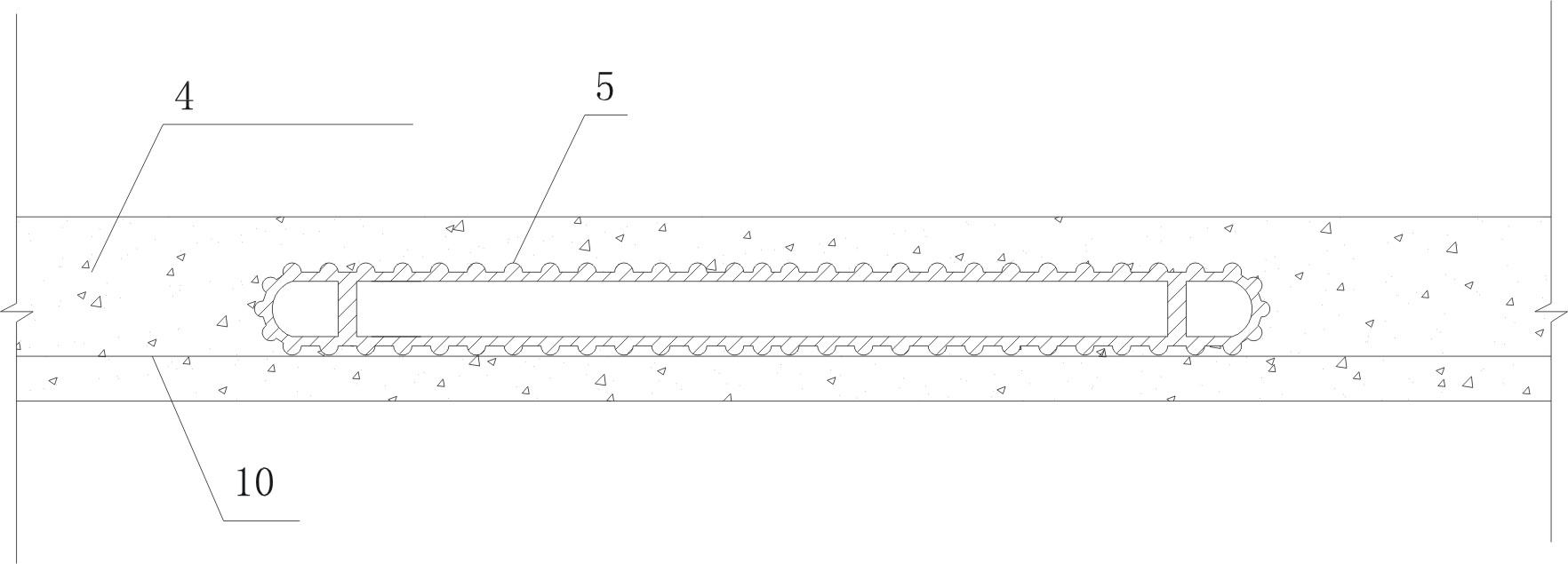

Process for mounting splicing type low-carbon heat insulating energy-saving plate

The invention relates to a process for mounting a splicing type low-carbon heat insulating energy-saving plate. The process is characterized by comprising the following specific steps of: processing a base layer; hanging a wire; anchoring a customized connecting hanging piece A; mounting a low-carbon heat insulating energy-saving plate of a bottom layer starting position; mounting a low-carbon heat insulating energy-saving plate; and cleaning the surface of the low-carbon heat insulating energy-saving plate, wherein a layer construction method from top to bottom is adopted during the installation. The invention has the advantages that the process for mounting the low-carbon heat insulating energy-saving plate is simple and quick; a special adjustable dry hanging connecting piece is matched; and a hollow splicing pipe is pre-embedded in a surface material decoration layer to ensure that the mounting process is firm and reliable and saves labor and time, thereby the construction period is shortened, and the mounting cost is greatly reduced.

Owner:易科美德(天津)环保建材有限公司

Antique brick and applications thereof

The invention discloses an antique brick and applications thereof. The antique brick comprises the following active ingredients in parts by weight: 100-200 parts of mineral powder, 20-50 parts of pulverized coal ash, 5-20 parts of excitant, 1-10 parts of iron oxide black, 250 parts of sand, 500 parts of stones and 25-39 parts of water. The antique brick has the properties of early strength, durability, permeability resistance, corrosion resistance, freezing and thawing resistance, low heat of hydration, good crack resistance, environment-friendliness and the like, and can replace cement products to be applied to restoration engineering of historic buildings.

Owner:TSINGHUA UNIV +1

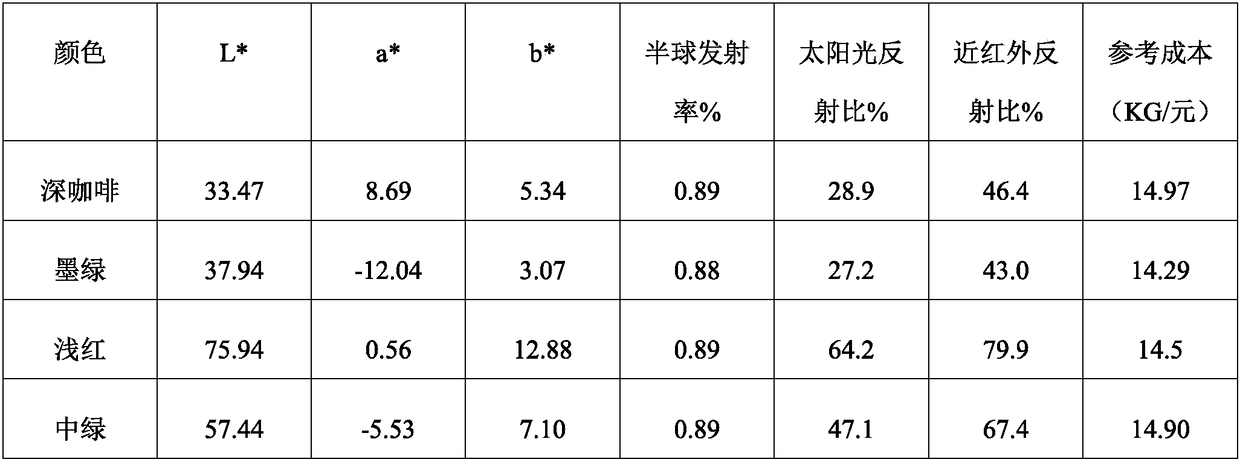

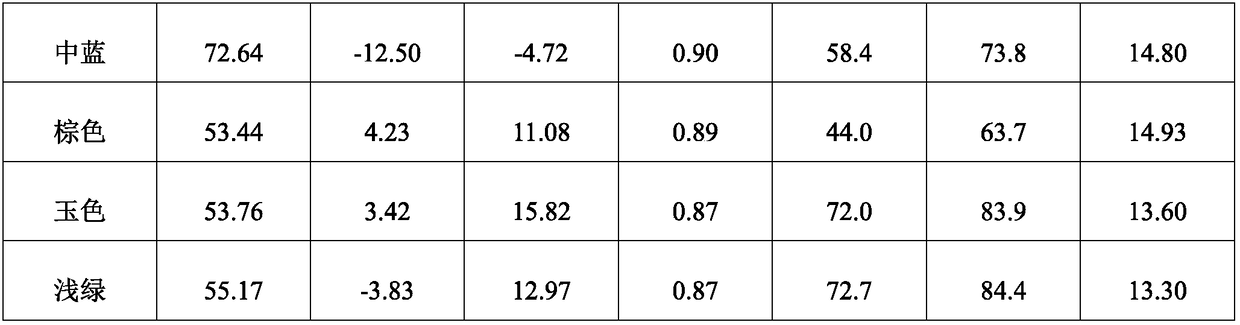

Soft ceramic wall surface composite material and preparation method thereof

The invention belongs to the technical field of building walls and discloses a soft ceramic wall surface composite material. The soft ceramic wall surface composite material is prepared from, by mass,10-35 parts of polymer emulsion, 25-65 parts of inorganic filler, 0.1-0.2 part of a wetting agent, 0.2-0.4 part of an antifoaming agent, 0.1-0.3 part of cellulose, 10-15 parts of deionized water and0.1-0.3 part of polyvinyl alcohol fibers. The soft ceramic wall surface composite material has advantages of high water-repellency breathability, light weight, flexibility, acid-base resistance, freeze thawing resistance, aging resistance, quake resistance, crack resistance and high exterior wall external insulation system compatibility. The soft ceramic wall surface composite material overcomes potential safety hazards including proneness to falling to hurt people and the like of traditional ceramic tiles, mosaics and the like and is especially suitable for serving as an exterior wall facingmaterial for high-rise buildings and exterior wall external insulation systems. Especially, the soft ceramic material can be adhered directly to an old wall without knocking off old ceramic tiles andmosaics in old wall renovation or space renovation.

Owner:广东福莱特建筑材料有限公司

Polymer vitrified microsphere building heat-insulating mortar

InactiveCN101811846AImprove crack resistanceLow costSolid waste managementPolymer scienceMicrosphere

The invention discloses a polymer vitrified microsphere building heat-insulating mortar. The preparation of the heat insulating mortar is implemented by the following steps: firstly, preparing a special additive; secondly, preparing mixed cementitous powder; and finally, uniformly mixing the mixed cementitous powder and vitrified microspheres in a weight ratio of 1:0.6 to obtain the polymer vitrified microsphere building heat-insulating mortar. The heat-insulating mortar of the invention, on the premise of meeting national standards in performance, is improved in bonding strength and lowered in manufacturing cost and suitable for use in projects of interior and exterior plastering of mid- and high-rise building walls made of various materials, particularly, projects of old building heat-insulating modification.

Owner:河南省绿韵建材有限公司

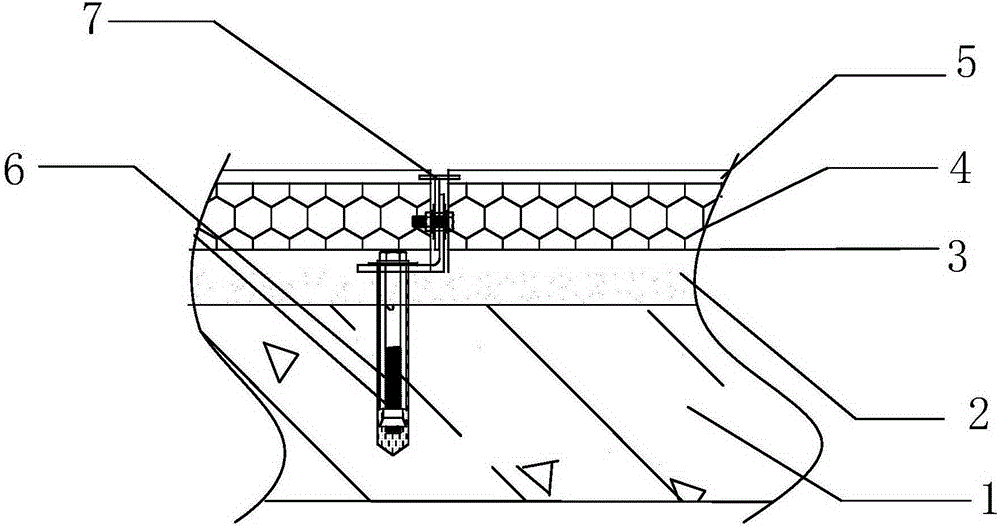

Foamed ceramic insulated composite aluminum veneer

InactiveCN105332489AReduce construction costsReduce shipping costsCovering/liningsFlooringThermal insulationFreeze thaw resistance

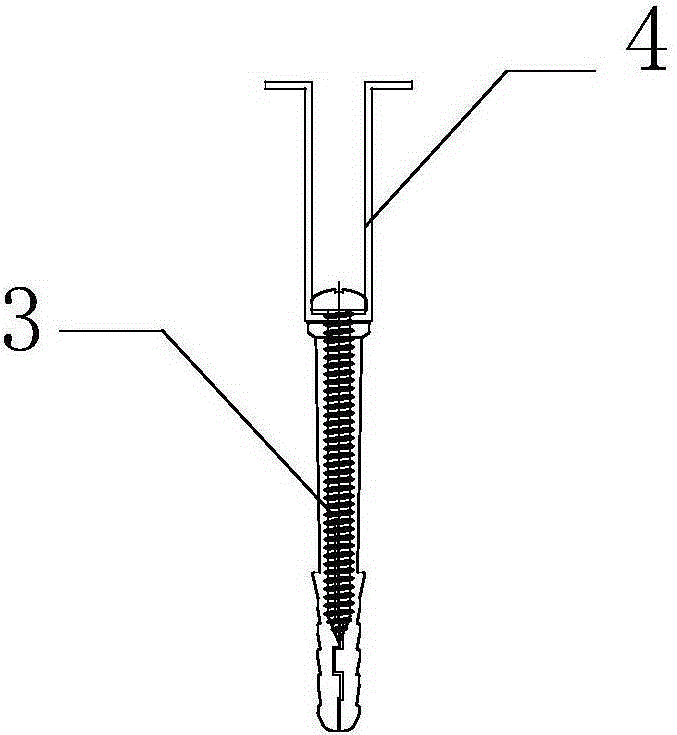

The invention relates to a foamed ceramic insulated composite aluminum veneer which comprises a foamed ceramic insulated board, an aluminum veneer, an anchor bolt and a stainless steel anchoring part, wherein the foamed ceramic insulated board is bonded with the aluminum veneer through a high molecular strong bonding agent, a slot is formed in the aluminum veneer, the stainless steel anchoring part is embedded in the slot through the anchor bolt, and the slot is filled with a silicone weather-resistant sealant. The foamed ceramic is formed by sintering waste ceramic, porcelain clay and assistants at 1100 DEG C through the phase change principle, has good characteristics of thermal insulation, ageing resistance, freeze-thawing resistance, light weight, no combustion and the like, is easy to process and has service life the same with that of a building; and the foamed ceramic and the aluminum veneer are formed by gluing to be pasted on the internal wall or external wall of the building to achieve the effect the same as that of the traditional metal curtain wall. A steel framework and thermal insulation are not needed for the external wall of any building, thereby greatly lowering the construction costs for raw materials, labor and building space as well as greatly reducing the transportation cost.

Owner:徐留旺 +1

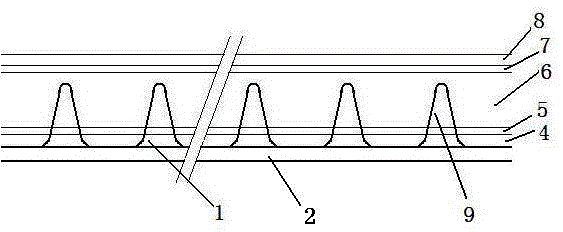

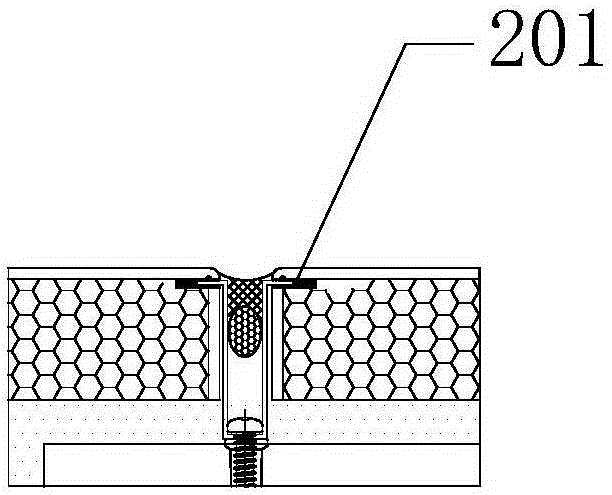

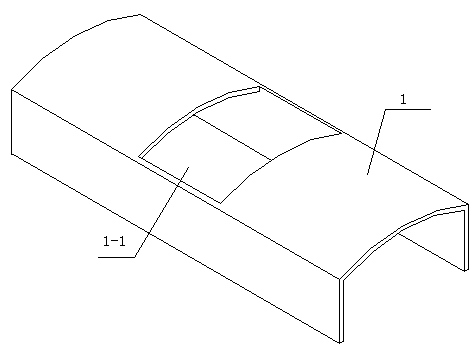

Plug-in type low-carbon heat preservation energy-saving board

The invention relates to a plug-in type low-carbon heat preservation energy-saving board, which is characterized in that the board is an integral board formed by sequentially connecting a decorative finishing layer, a finishing layer, a middle layer glass fiber mesh, a low-carbon board, a stainless steel welded mesh, a bottom layer glass fiber mesh, a soundness glue layer and an SPS extrusion molding heat preservation board. The invention has the advantages that the board not only is an excellent substitute for coatings, ceramic tiles, stones, timbers and metal boards, but also has a heat preservation function which simultaneously simplifies the complicated construction steps specified in three-step energy-saving requirements of national regulation, and ensures that the heat preservation and energy saving as well as decorative effects are achieved synchronously; and the installation process is simple and fast, special matched adjustable dry hanging connecting pieces are provided, and a hollow plug-in pipe is embedded in a plane material decorative layer in advance, which enables the installation process to be firm and reliable.

Owner:易科美德(天津)环保建材有限公司

Curb and discharge spout manufacture method

InactiveCN1422824ASuitable for mechanizationLarge-scale production and manufacturingPaving gutters/kerbsClimate change adaptationFiberChloride

The invention is a method making curb stone and drainage tank. The technical project as follows: use magnesia as gelatinizing agent, magnesium-chloride water solvent as solidifying one, and sand, mine waste residue, stone scraps and fiber material as aggregate, fill reinforced denaturing agent, coloring agent and waterproof agent, stir in a certain proportion to make denatured magnesium-oxygen concrete, shape by mould press or extrusion and maintain to make the finished product which can be used to separate road, drainage and slope protection placed on two sides of road, railroad and street and used as decorative stone material.

Owner:张名君 +2

Weather-resistant high-strength environment-friendly antique-imitation brick and preparation method thereof

The invention discloses a weather-resistant high-strength environment-friendly antique-imitation brick. The weather-resistant high-strength environment-friendly antique-imitation brick is prepared from the following raw materials in parts by weight: 10-20 parts of blue stone powder, 3-7 parts of antique-imitation auxiliaries, 7-9 parts of blast-furnace slag, 5-7 parts of steel slag, 4-8 parts of coal gangue, 10-14 parts of purified landfill, 8-12 parts of waterproof latex, 6-8 parts of tackifying additives, 13-15 parts of ore powder, 10-14 parts of fine sand and 7-11 parts of silicate cement. The environment-friendly antique-imitation brick disclosed by the invention has excellent performance in imperviousness, corrosion resistance and freeze-thaw resistance, the compression strength is relatively high, the appearance is pure in color and full in antique tone, and the environment-friendly antique-imitation brick has a realistic effect when the environment-friendly antique-imitation brick is applied to the repair or imitation of antique buildings; meanwhile, by adopting a large amount of industrial and agricultural wastes, the resources are saved, the cost is reduced, the raw materials are readily available, the process is simple, and the environmental hazards are effectively reduced, so that the preparation method disclosed by the invention has a relatively high practical value and a good application prospect.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

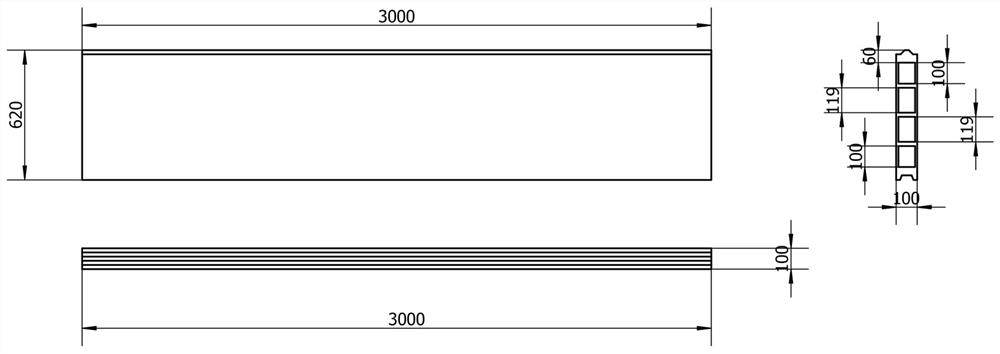

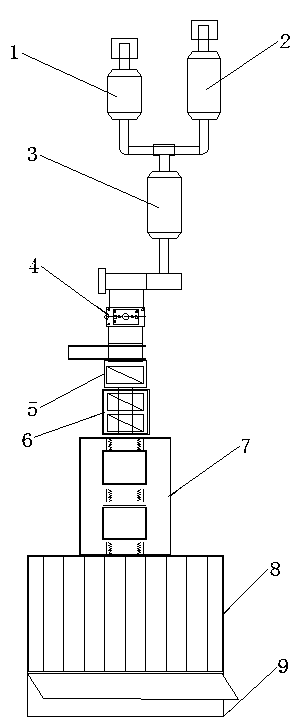

Method for preparing stoneware batten for fabricated building by utilizing industrial solid waste

PendingCN113387681ALightweight and high strengthWith sound insulation and noise reductionCeramic materials productionClaywaresHeat conservationProcess engineering

The invention relates to a method for preparing a stoneware batten for a fabricated building by utilizing industrial solid waste. The stoneware batten is formed by mixing solid powder and water according to the weight ratio of 1: (0.1-0.25), and comprises the following components in percentage by weight: 75%-95% of solid waste raw materials; 3%-15% of raw mineral materials; and 2%-10% of chemical raw materials. The method comprises the following steps: preparing formula raw materials; mixing and stirring; homogenizing and aging; performing vacuum pugging; performing extrusion molding; drying the green body; sintering at high temperature; and processing. The technical problems that a traditional wall material is large in volume weight, poor in waterproof effect and poor in energy-saving and heat-preserving effect are well solved.

Owner:SHENYANG POLYTECHNIC UNIV

Vitrified-microbead decorative thermal-insulation board

The invention relates to a vitrified-microbead decorative thermal-insulation board, belonging to the technical field of architectural boards. The vitrified-microbead decorative thermal-insulation board is prepared from expanded vitrified microbeads, white lime, quicklime, cement, silica fume, gypsum, high-quality PP (polypropylene) fiber, waterproofing agent, rubber powder, fly ash and foaming agent in a certain ratio by a certain technique. The average dry apparent density of the product is 265kg / m<3>, the average heat conductivity coefficient is 0.058w / m.k, the average compressive strength is 0.67mpa, and the combustion performance is non-inflammable Grade A. The vitrified-microbead decorative thermal-insulation board has the function of fireproofing, and has the characteristics of light weight, thermal insulation, high dimensional stability, aging resistance, freeze thawing resistance, simple construction, beautiful appearance and the like. Besides, the invention reduces the pollution of flying dust due to use of powder in the construction process, saves the construction time by 50% in the aspect of construction cycle, greatly lowers the construction cost, and implements energy consumption saving in building construction in deed.

Owner:重庆冠科低碳环保科技有限公司

SCS sub-nanometer silicon spar and preparation method thereof

InactiveCN110981428AFreeze-thaw resistantFire resistantCeramic materials productionClaywaresDistribution controlSlurry

To overcome the problems that an existing industrial solid waste treatment technology is low in treatment capacity and that industrial solid waste cannot be well utilized, the invention provides SCS sub-nanometer silicon spar and a preparation method thereof. The SCS sub-nanometer silicon spar is prepared mixing raw materials including solid powder and water in a weight ratio of 1: (0.3-0.6). Thesolid powder comprises the following components in percentage by weight: 75 to 95% of industrial solid waste, 3 to 15% of a mineral raw material and 2 to 10% of a chemical raw material. The preparation method of the silicon spar comprises the following six steps: preparation of the raw materials, preparation of slurry, spray drying, distribution control, powder firing, and processing and forming.The novel SCS sub-nanometer silicon spar material prepared by the invention has excellent performances which are incomparable by conventional building materials, such as light weight, high strength, heat preservation performance, water resistance, moisture resistance, sound insulation performance, noise reduction performance, fire resistance, durability, freeze thawing resistance and easiness in cutting and processing, and is a novel building wall material with high quality.

Owner:谢贵全

Coal ash thermal insulating material and preparation method thereof

The invention discloses a coal ash thermal insulating material and a preparation method of the coal ash thermal insulating material, belongs to the field of building material, and relates to a thermal insulating material and a preparation method of the thermal insulating material. The coal ash thermal insulating material is prepared by expanding and sintering coal ash and soda ash serving as raw material. The preparation method comprises the following steps of: mixing and stirring the coal ash and the soda ash in proportion; preheating the mixture to 600-1000 DEG C in a rotary kiln, and introducing the preheated mixture into a temperature resistant distributor; uniformly distributing a layer of material from the upper part of a tunnel kiln to a kiln car located inside the high-temperature area of the tunnel kiln by using the distributor, sintering and expanding the material at 1200-1250 DEG C so that the material is bonded together; when the material inside the tunnel kiln is sintered and formed to the prescribed thickness, sending the material and the kiln car out of the tunnel kiln, distributing, sintering, expanding and forming the material inside next kiln car, and repeatedly carrying out the operations; and introducing the material sent out of the kiln car into an insulating kiln, carrying out thermal insulation for 24 hours, then reducing the temperature to be below 300 DEG C, and cooling, cutting and forming. The preparation method disclosed by the invention has the advantages of controllable kiln temperature, low production cost, and good thermal insulation effect; moreover, place and equipment are saved.

Owner:哈尔滨琪裕新材料科技有限公司

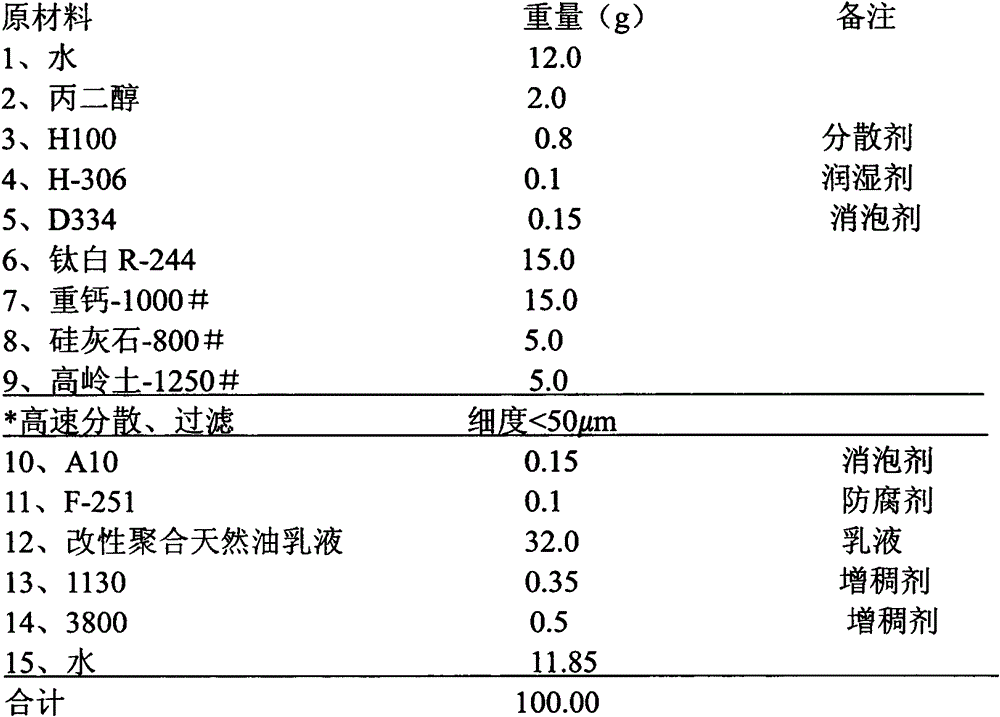

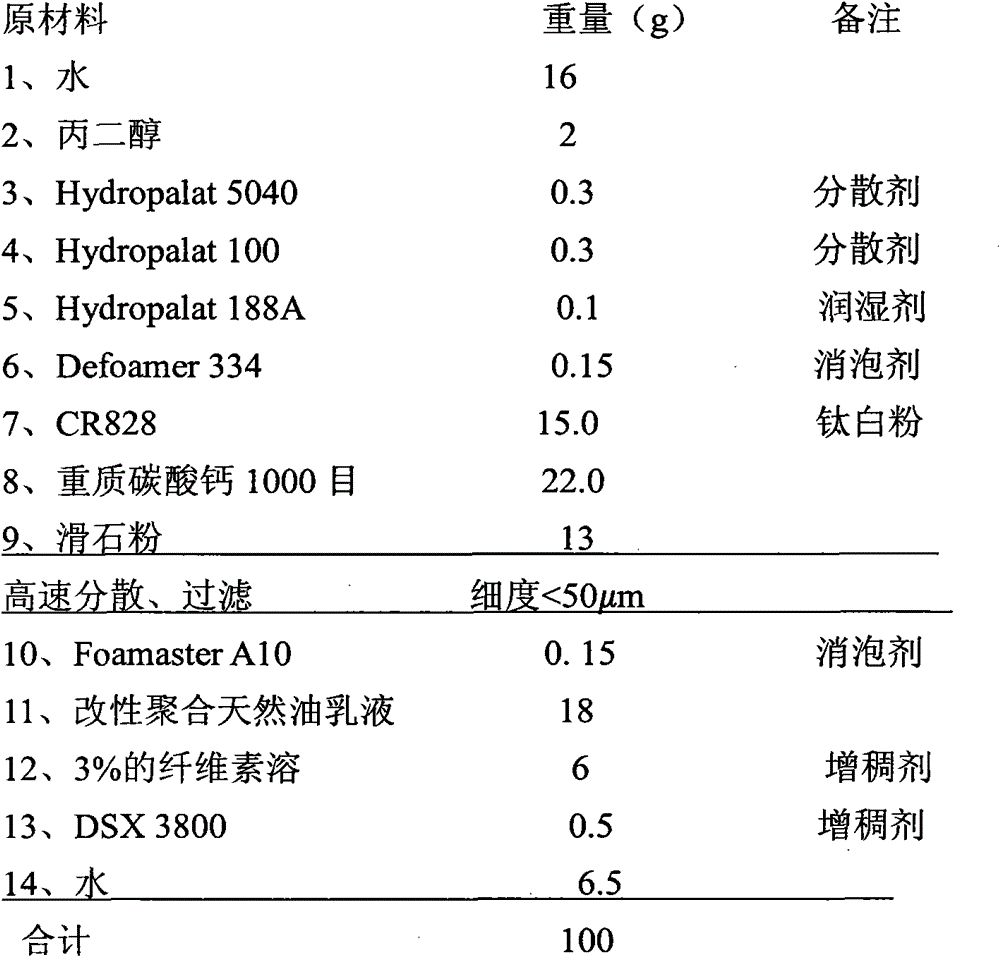

Emulsion foundation paint for outer wall and preparation method of paint

InactiveCN102796443AMeet application requirementsFreeze-thaw resistantAnti-corrosive paintsEmulsion paintsEmulsionLacquer

The invention provides emulsion foundation paint for an outer wall. The emulsion foundation paint for the outer wall comprises the following components in parts by weight: 8-20 parts of water, 2-4 parts of cosolvent, 0.5-1.2 parts of dispersing agent, 0.1-0.25 part of wetting agent, 0-40 parts of pigment, 0-65 parts of filler, 8-70 parts of emulsion, 0.2-1 part of thickening agent, and 0.1-0.4 part of defoaming agent. Meanwhile, the invention also provides a preparation method of emulsion foundation paint for the outer wall, and in particular stipulates the adding order and mixing condition of materials. The emulsion foundation paint for the outer wall, which is prepared by the invention, has the advantages of water resistance and alkaline resistance, meanwhile the emulsion foundation paint for the outer wall also can keep good performances under the ultraviolet effect, and also has the functional characteristics of freezing and thawing resistance, and moreover, the emulsion foundation paint is nontoxic and is low in VOC (volatile organic compounds), can meet the application requirements of the current outer wall, and has positive environment friendly significance.

Owner:HEYUAN OCEAN POWER TECH +2

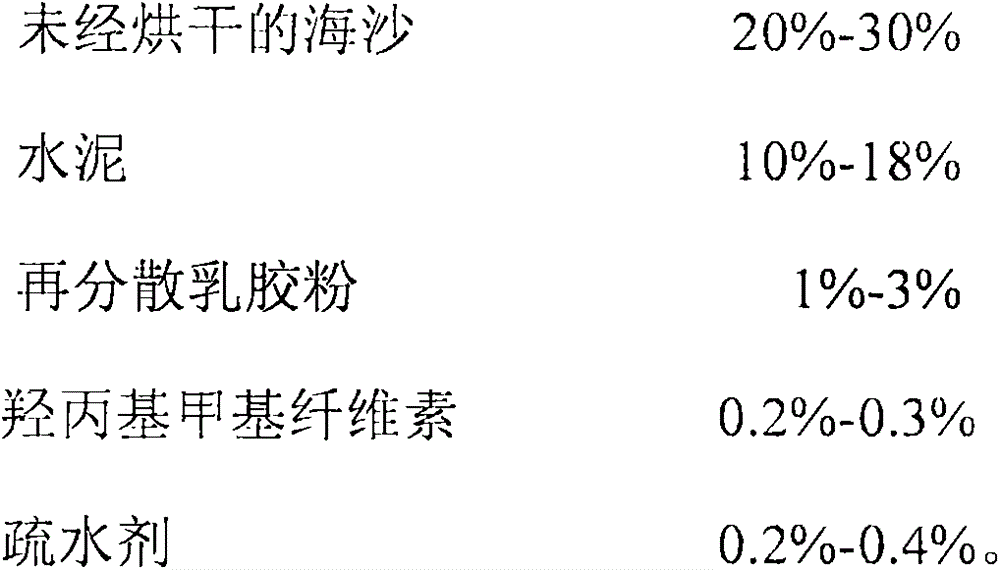

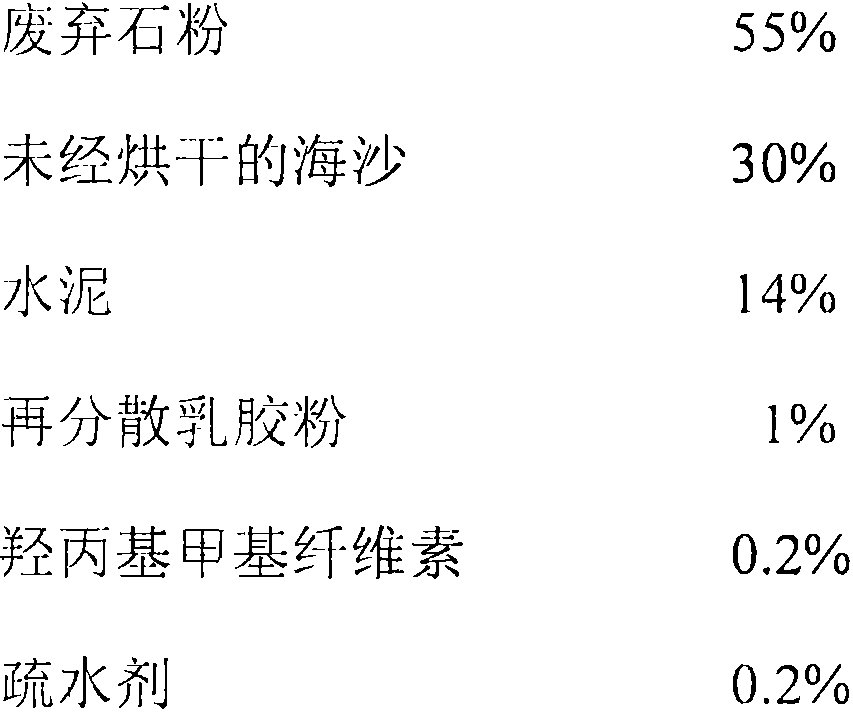

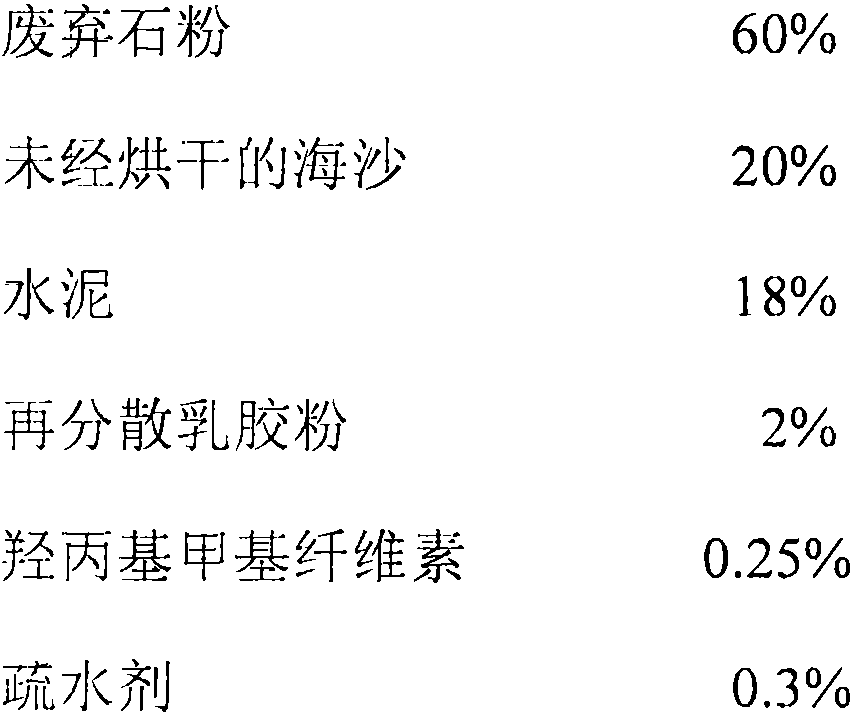

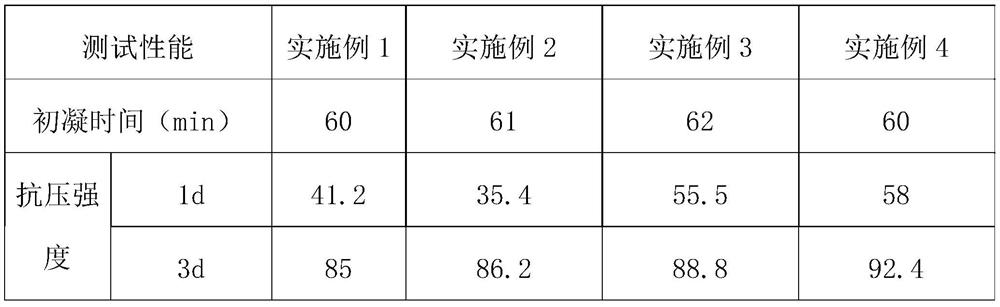

Stone powder waste material regeneration easy plaster and preparation method thereof

InactiveCN105753387AHeat resistantFreeze-thaw resistantSolid waste managementFreeze thawingAging resistance

The invention discloses stone powder waste material regeneration easy plaster and a preparation method thereof. The stone powder waste material regeneration easy plaster is prepared from the following ingredients: 55 percent to 65 percent of waste stone powder, 20 percent to 30 percent of not-dried sea sand, 10 percent to 18 percent of cement, 1 percent to 3 percent of redispersible latex powder, 0.2 percent to 0.3 percent of hydroxypropyl methyl cellulose and 0.2 percent to 0.4 percent of hydrophobing agents. The stone powder waste material regeneration easy plaster is prepared by extracting stone powder waste materials and performing drying and recycling; the effects of environment protection and no pollution are achieved; the advantages of high bonding strength, high anti-permeability force, good water resistant performance, heat resistance, freeze thawing resistance and ageing resistance are realized.

Owner:陈谓清

High-fluidity ultrahigh-strength cement-based grouting material and preparation method thereof

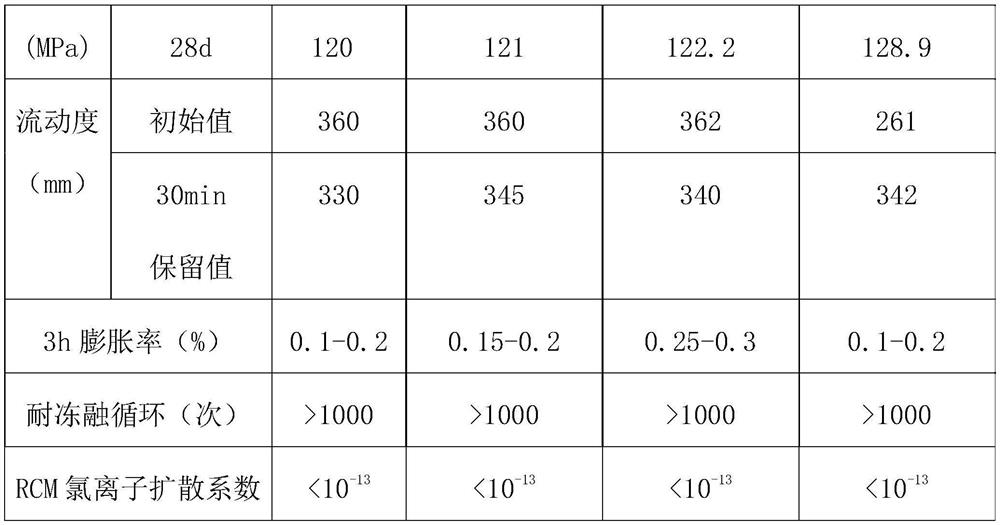

The invention discloses a high-fluidity ultrahigh-strength cement-based grouting material comprising the following ingredients in parts by weight: 10 to 30 parts of water, 50 to 150 parts of cementing materials, 60 to 100 parts of quartz sand, 1 to 5 parts of a water reducing agent, 0.1 to 3 parts of a coagulation accelerator and 0.01 to 0.1 part of an expanding agent. The cement-based grouting material has the characteristics of low viscosity, high fluidity, early strength, ultrahigh strength, high toughness, ultrahigh durability, micro-expansion, high compactness, shrinkage resistance and the like, is low in cost, and can meet the requirement of environmental protection. The chloride ion migration and diffusion coefficient of the high-flowability ultrahigh-strength cement-based grouting material is less than 10<-13>, and the high-flowability ultrahigh-strength cement-based grouting material has few pores and can well resist permeation of water and various zwitterions, so that the high-flowability ultrahigh-strength cement-based grouting material is suitable for offshore structure grouting construction. The invention also discloses a preparation method of the high-fluidity ultrahigh-strength cement-based grouting material, wherein the preparation method is simple, simple and convenient to operate, easy in control of preparation conditions and low in requirements on production equipment, and is a method for easily realizing industrial production.

Owner:华新超可隆新型建材科技(黄石)有限公司 +1

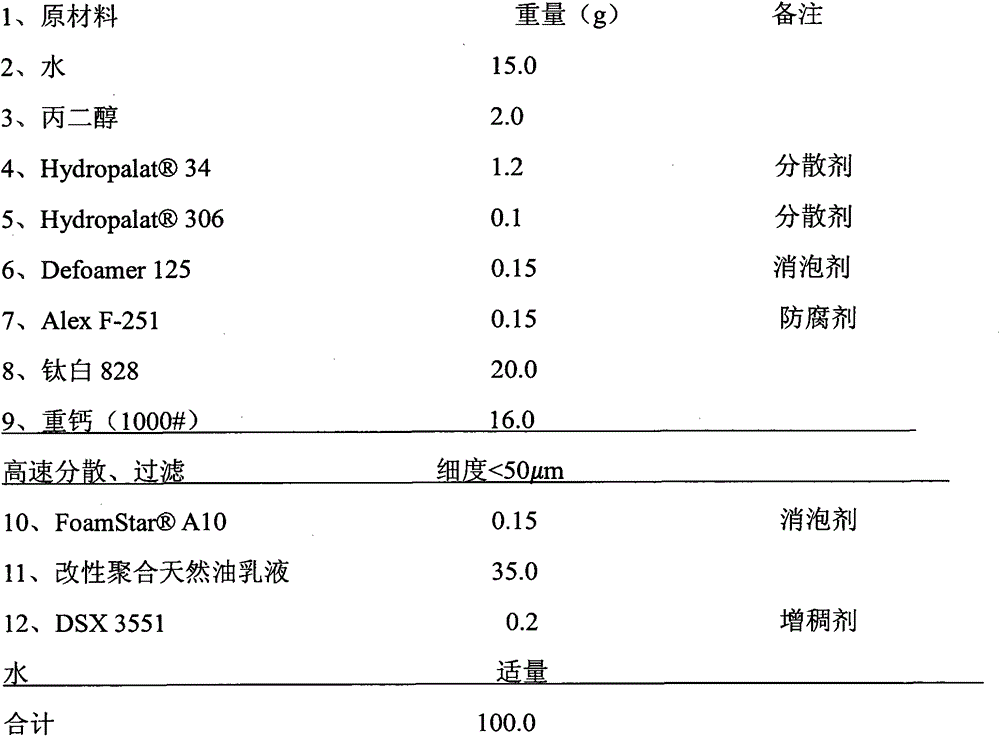

Base latex coating for interior wall and preparation method for base latex coating

InactiveCN102796409AMeet application requirementsFreeze-thaw resistantEmulsion paintsPolyester coatingsEmulsionUltraviolet

The invention provides a base latex coating for an interior wall. The base latex coating comprises the following components in part by weight: 8 to 20 parts of water, 2 to 4 parts of cosolvent, 0.5 to 1.2 parts of dispersant, 0.1 to 0.25 part of wetting agent, 0 to 40 parts of pigment, 0 to 65 parts of filler, 8 to 70 parts of emulsion, 0.2 to 1 part of thickener and 0.1 to 0.4 part of defoaming agent. The invention also provides a preparation method for the base latex coating for the interior wall. According to the method, the material adding sequence and mixing conditions are specified. The base latex coating for the interior wall has the advantages of water resistance and alkali resistance, can keep good performance under the action of ultraviolet, has functional characteristics of freezing and thawing resistance and the like, is nontoxic, has low content of volatile organic compounds (VOC), can meet the application requirement of the interior wall at present, and has an active environment-friendly significance.

Owner:HEYUAN OCEAN POWER TECH +2

Internal wall thermal insulating mortar

The invention discloses internal wall thermal insulating mortar which is prepared from the following raw materials in parts by weight: 45-55 parts of slag cement, 3-6 parts of citric acid residue, 15-25 parts of quick lime, 10-15 parts of volcanic rock, 2-4 parts of asbestos fiber, 20-30 parts of hollow microsphere, 10-15 parts of calcined zeolite, 3-5 parts of soybean protein powder, 2-3 parts of sodium hexametaphosphate, 4-6 parts of guar gum powder, 2-3 parts of polyoxyethylene, 1-2 parts of sodium acetate, 2-3 parts of sugar calcium and 3-6 parts of composite packing. Compared with conventional thermal insulating mortar, the thermal insulating mortar disclosed by the invention has the characteristics of low volume-weight, high strength, stable thermal insulation property, freeze-thawing resistance, aging resistance, anti-cracking property, good anti-mold effect and the like, is green and environment-friendly, safe and reliable, simple and convenient to construct, low in cost, and can be widely applied to internal wall heat preservation systems.

Owner:ANHUI FUYANG SIKEDA SCI & TECH BUILDINGMATERIAL

Building heat insulation material

InactiveCN105418150AReduce pollutionReduce manufacturing costCeramic materials productionCeramicwareWeather resistancePortland cement

The invention discloses a building heat insulation material, and belongs to the technical field of building materials. The building heat insulation material is prepared from, by mass, 36-45% of ordinary Portland cement, 15-25% of ceramic waste, 15-25% of coal ash, 5-10% of magnesium oxide, 5-8% of hydrogen peroxide and 2-6% of a modification additive. Compared with the prior art, the building heat insulation material has the technical advantages that the ceramic waste, the coal ash and other industrial waste are selected and used in the formula, so that production cost is reduced, and meanwhile the environmental pollution problem brought by stockpiling treatment of the ceramic waste and the coal ash is relieved; the selected ceramic waste and coal ash can improve the heat insulation performance of the heat insulation material, and the heat insulation material has weather resistance, corrosion resistance, freezing and thawing resistance and the like; the selected modification additive has the foam stabilizing effect and further has the effect of prompting rapid coagulating and hardening of cement and the ceramic waste and rapid coagulating and hardening of cement and the coal ash.

Owner:SUZHOU YUXI NEW MATERIAL TECH

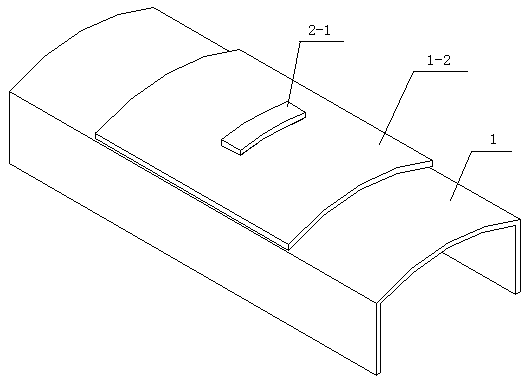

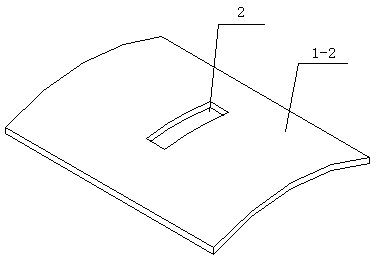

Ceramic foaming and insulation integrated stone

The invention relates to a ceramic foaming and insulation integrated stone. The ceramic foaming and insulation integrated stone comprises a granite surface layer or marble surface layer, a ceramic foaming and insulation board, a cement mortar plaster layer, expansion bolts and a stainless steel anchor part, wherein the granite surface layer or marble surface layer is cohered to the ceramic foaming and insulation board through a macromolecular strong adhesive to form a finished lump material; the ceramic foaming and insulation board is cohered to the cement mortar plaster layer through the macromolecular strong adhesive; a groove is formed in the side surface of the granite surface layer or marble surface layer; the stainless steel anchor part is inserted into the groove and is fixed with AB glue; and the expansion bolts are embedded into a wall body, so that the ceramic foaming and insulation integrated stone and the wall body form a whole.

Owner:徐留旺 +1

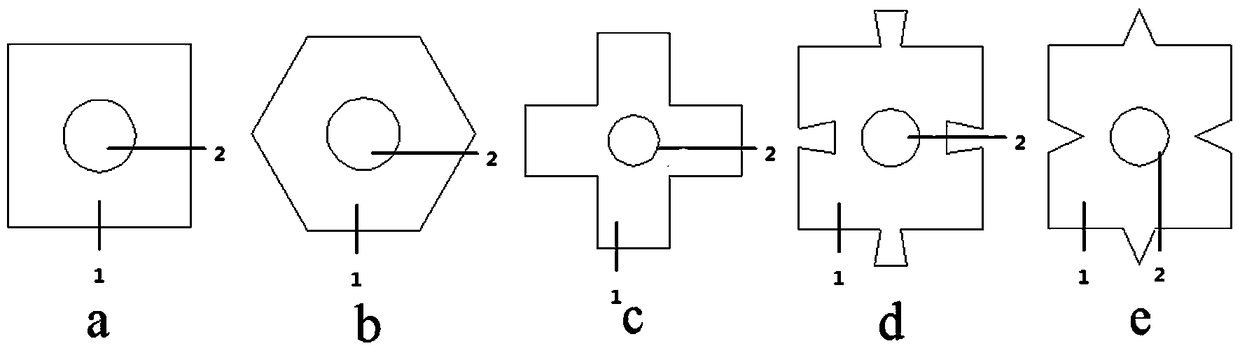

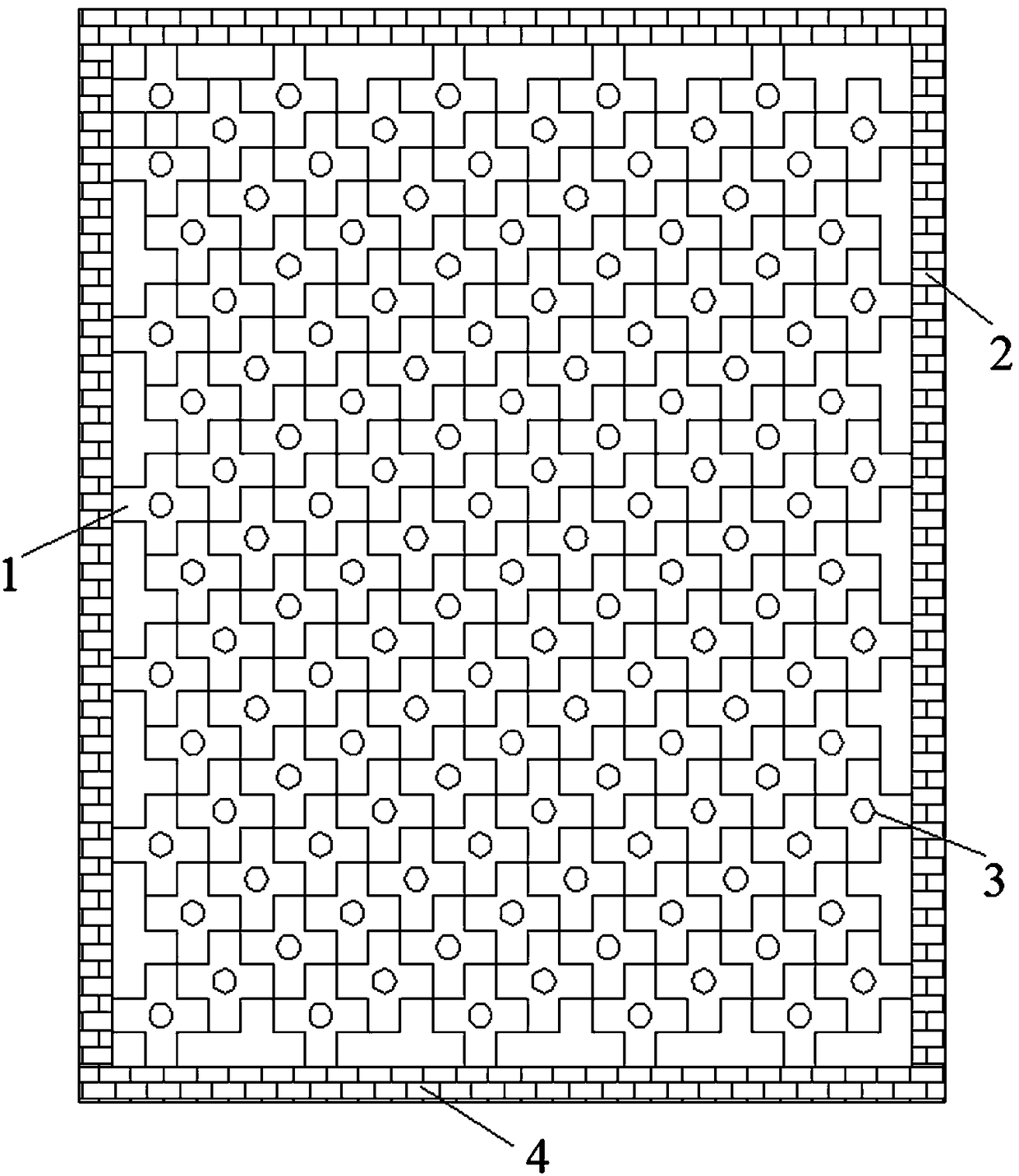

Method for protecting arsenic sand rock side slope by adopting arsenic sand rock modified building blocks

ActiveCN108218308ARealize on-site resource utilizationSolve problems that require constant re-protection every yearCoastlines protectionWoody plantGeomorphology

The invention discloses a method for protecting an arsenic sand rock side slope by adopting arsenic sand rock modified building blocks. The method comprises the following steps: 1, dividing slope surfaces into steep slopes and gentle slopes according to slope gradient of a side slope; 2, roughly flattening the slope surfaces with different slope gradients and building the arsenic sand rock modified building blocks on the flattened slope surfaces in a grouping manner; 3, planting herbal plants or woody plants in plant-growing holes of the arsenic sand rock modified building blocks which are built in a grouping manner in the step 2, planting grass in building block plant-growing holes of the steep slope section, and planting the grass or trees on the steep slope. According to the method disclosed by the invention, the arsenic sand rock side slope is protected by using the arsenic sand rock modified building blocks, so that in-place resource utilization of the arsenic sand rock is realized, and the problem that an existing side slope protection way needs to be continuously and renewedly protected every year is also solved; moreover, by adopting the method, the characteristic of the arsenic sand rock is comprehensively utilized, materials are taken in place, and protection of the side slope by using green planting and preparation of the modified building blocks are combined effectively, so that a protection effect is enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

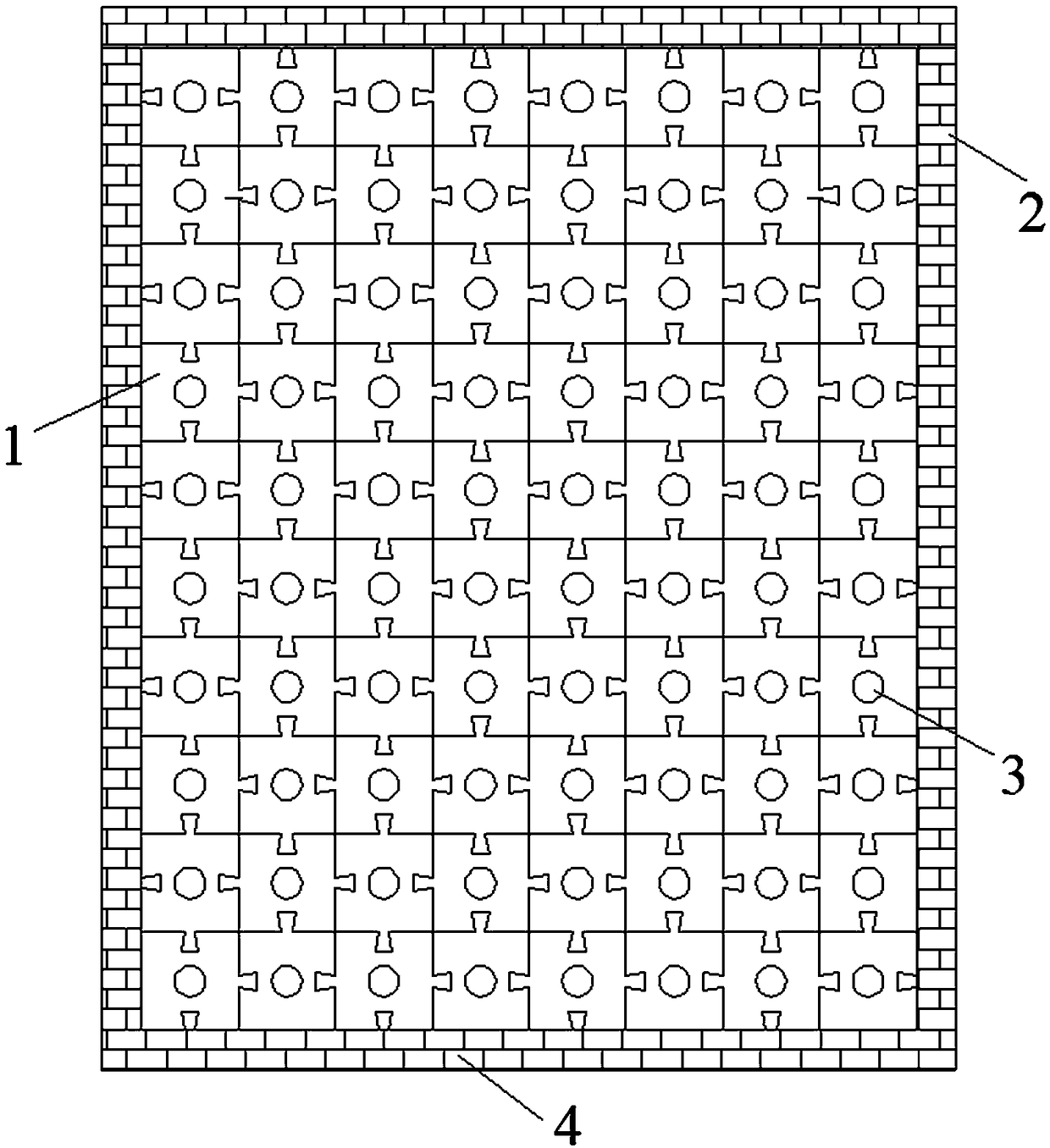

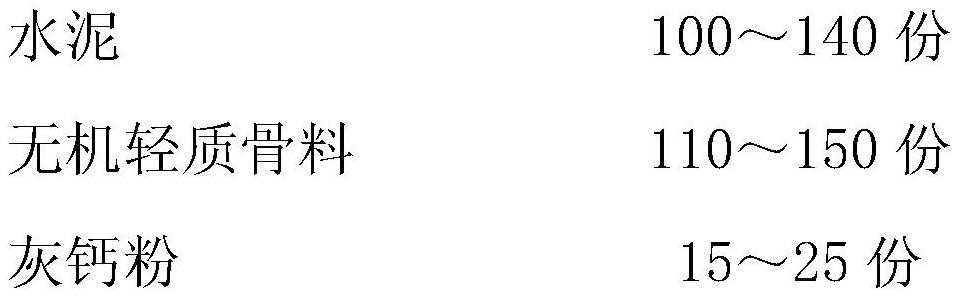

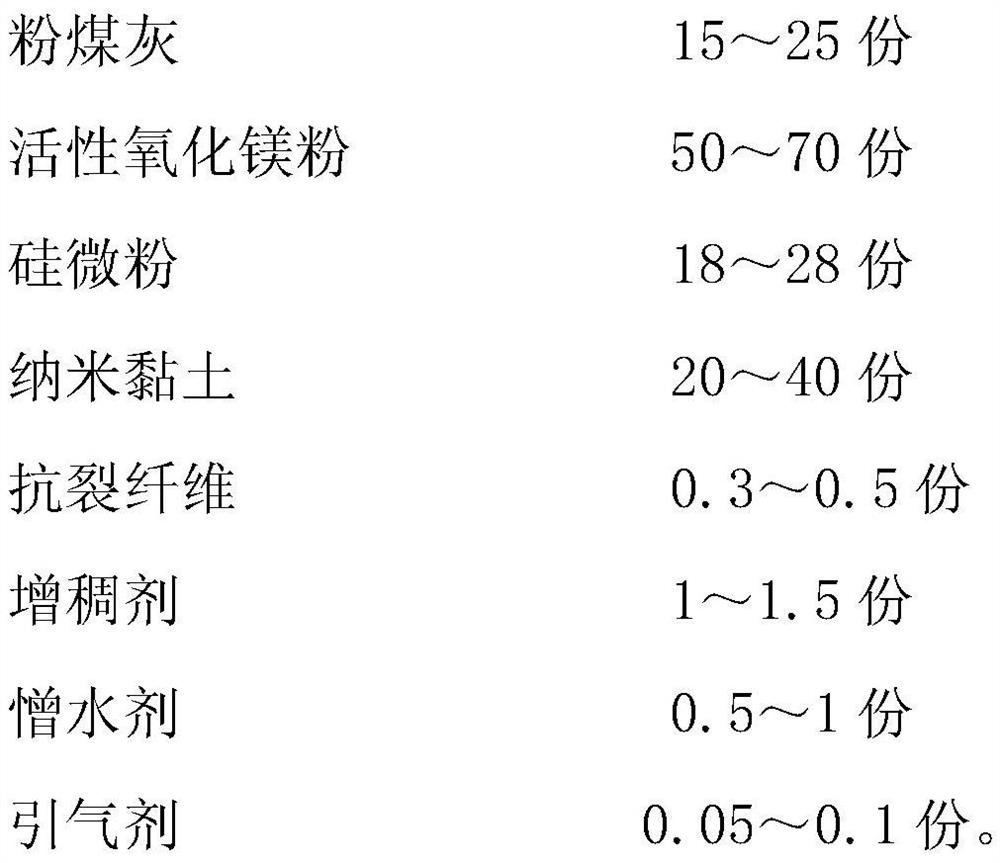

Inorganic active thermal-insulation mortar

The invention provides inorganic active thermal-insulation mortar. The inorganic active thermal-insulation mortar is prepared from the following raw materials in parts by weight: 100 to 140 parts of cement, 110 to 150 parts of inorganic lightweight aggregate, 15 to 25 parts of ash calcium powder, 15 to 25 parts of fly ash, 50 to 70 parts of active magnesium oxide powder, 18 to 28 parts of silica powder, 20 to 40 parts of nano clay, 0.3 to 0.5 part of anti-crack fibers, 1 to 1.5 parts of a thickening agent, 0.5 to 1 part of a water repellent and 0.05 to 0.1 part of an air entraining agent. The inorganic active thermal-insulation mortar provided by the invention has the characteristics of environmental protection, no toxicity, aging resistance, pressure resistance, impermeability and high strength, is safe and reliable, realizes A-level fire prevention, presents good heat insulation performance and has a heat conductivity coefficient as low as 0.059; the waterproof and anti-cracking performance of the motor is excellent, a waterproof film is formed on the surface of the produced motor after the motor is naturally dried, and the waterproof and anti-cracking performance is achieved; and the anti-freezing and anti-thawing performance of the motor is excellent, and construction can be performed at a temperature of -15 DEG C.

Owner:河南省宜居建材科技有限公司

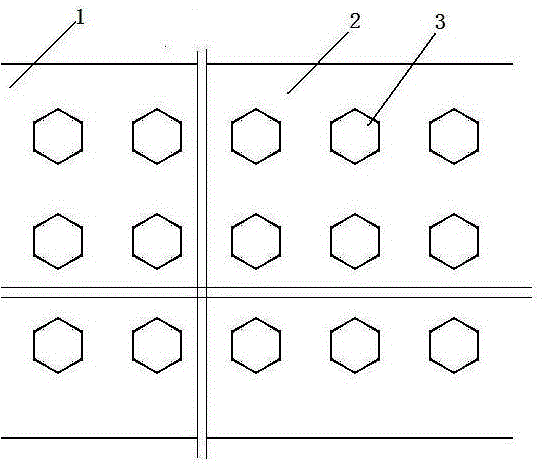

Curtain wall decorative finish vacuum heat insulation board and preparation method

The invention discloses a curtain wall decorative finish vacuum heat insulation board and belongs to the technical field of building external wall materials. A board body of the curtain wall decorative finish vacuum heat insulation board is composed of a connecting layer, a resistor bridge layer, a vacuum heat insulation layer, an anti-cracking layer and a curtain wall decorative finish layer from inner surface to the outer surface, nanometer perlite, vacuum glass micro beads and other auxiliary materials are prepared into different slurries, and the curtain wall decorative finish vacuum heat insulation board is manufactured through forming, curing, edge trimming, steaming, drying steps and the like. The curtain wall decorative finish vacuum heat insulation board has the advantages of being low in dry surface appearance density, low in heat conductivity coefficient, high in compressive strength and high in burning resistant performance class, has a fire-proof function and further has the advantages of being light in weight, heat-insulation, high in size stability, anti-aging, anti-freezing, convenient to install, simple in construction, attractive in appearance and the like. Raising dust pollution caused by powder usage is reduced in the construction process, construction time is saved by 60% in construction period, construction cost is greatly reduced, and energy saving in building construction is really achieved.

Owner:CHONGQING YUDING ENERGY SAVING BUILDING MATERIAL

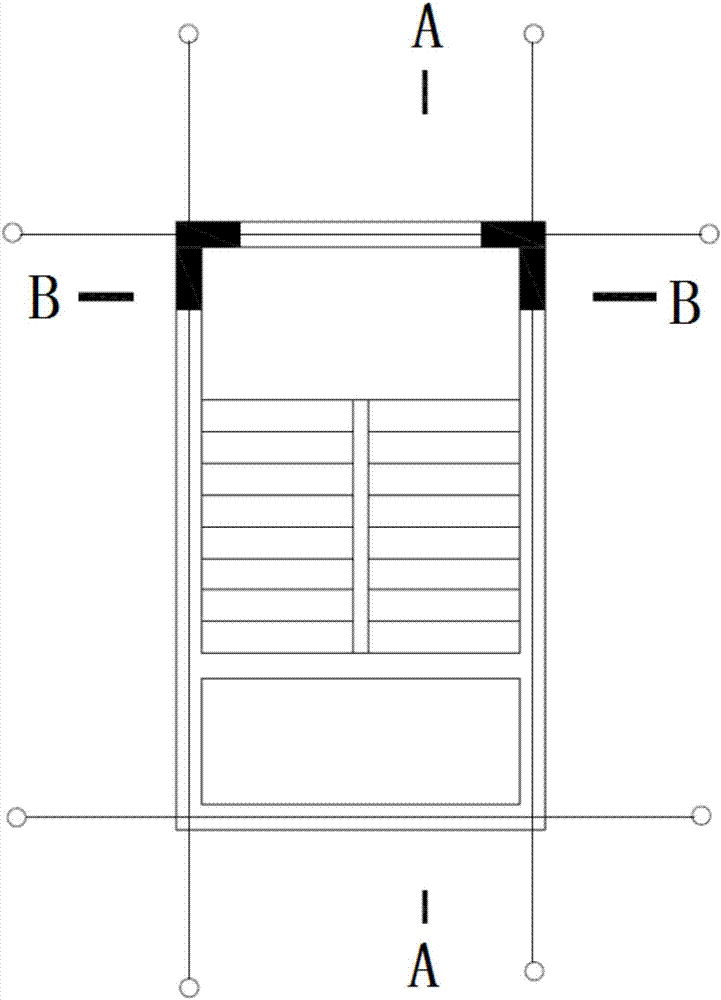

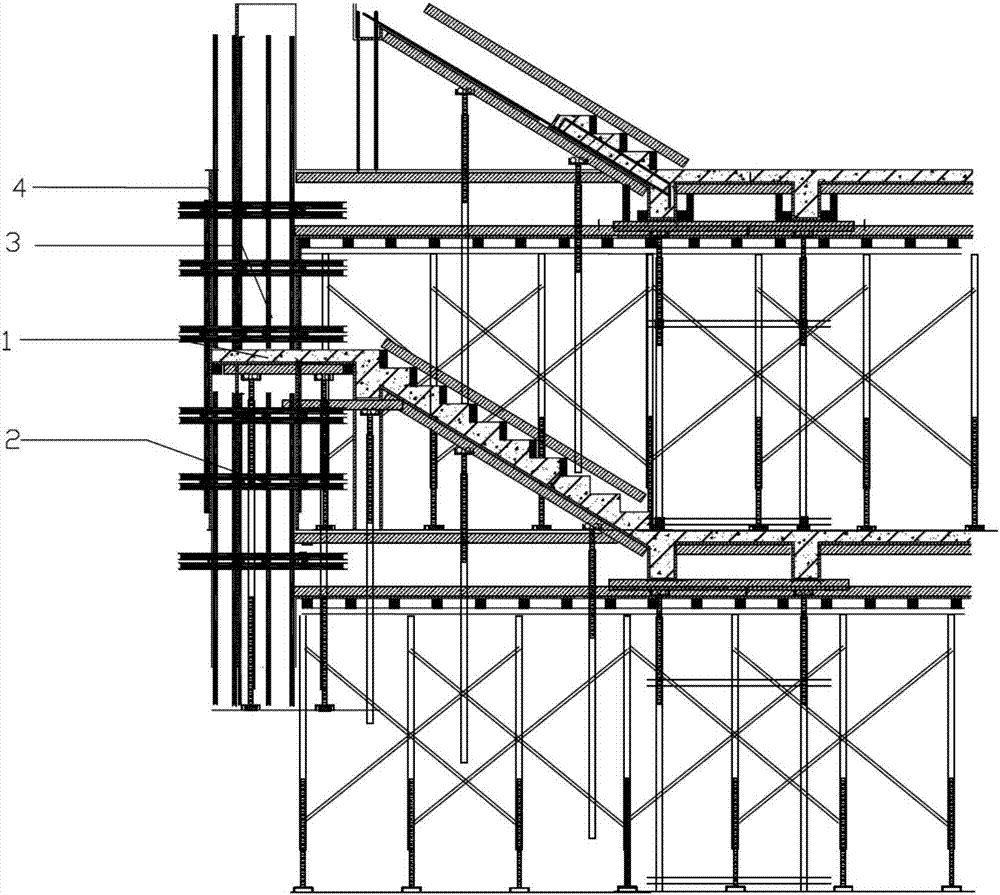

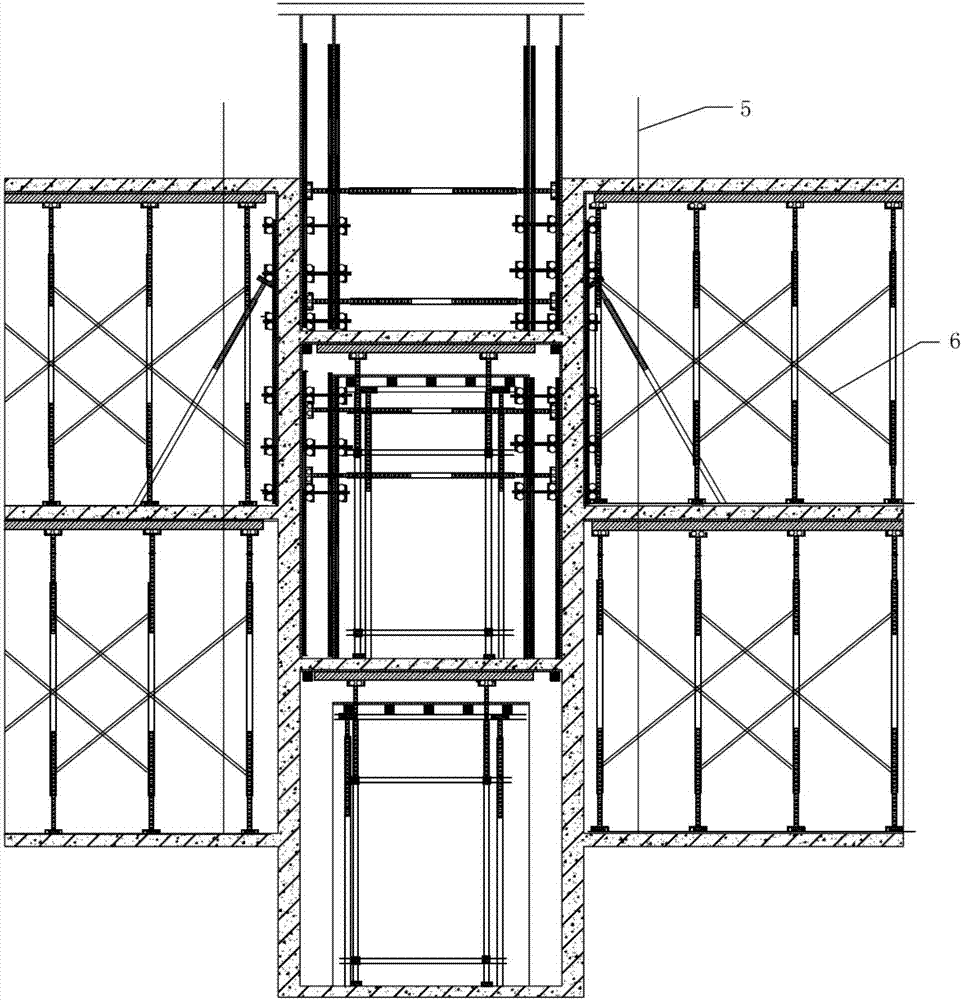

Method for secondary pouring of staircase columns through formwork supporting

InactiveCN107060338ASolve common quality problemsQuality improvementForms/shuttering/falseworksBuilding material handlingEngineeringUltimate tensile strength

The invention relates to a method for secondary pouring of staircase columns through formwork supporting. The method for pouring of the staircase columns comprises the steps that according to the constructed sizes of the staircase columns and a shear wall, column formworks are manufactured, the supporting heights of the column formworks exceed the construction height of a structural layer, and the column formworks extend to the bottoms of beams and plates of an upper-layer resting platform of the structural construction layer to be subjected to formwork distribution; and then, according to the storey height, the arrangement of column formworks of the next construction section is conducted, supporting upper openings of the column formworks of the previous construction section serve as the basis of next formwork supporting, formwork supporting is advanced sequentially, and the sides, close to staircases, of the column formworks are arranged continuously from bottom to top. The overall appearance quality of concrete of the staircases is improved, the checking link is reduced, meanwhile, the labor intensity of workers is reduced, the construction speed is increased, and the technical problems that the staircase columns are difficult to reinforce, and displacement is liable to occur are solved effectively.

Owner:徐仁贵

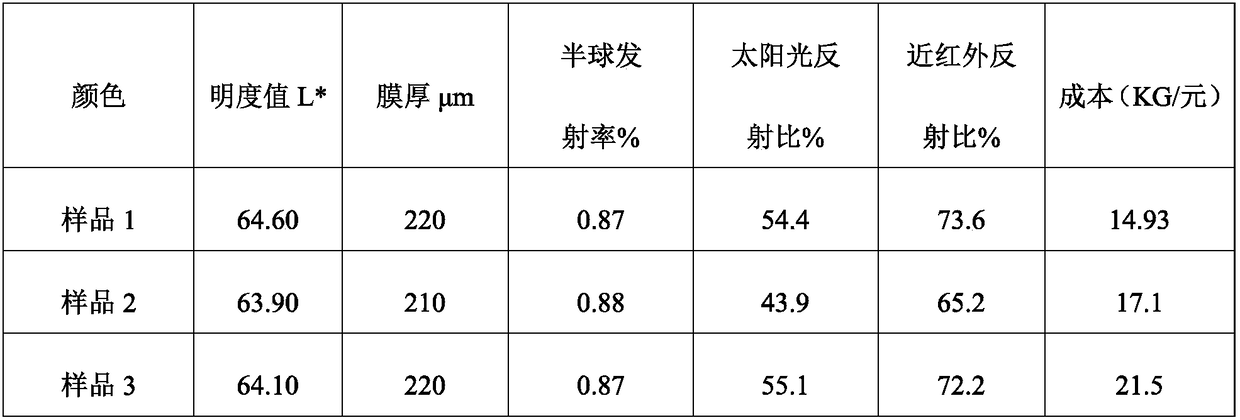

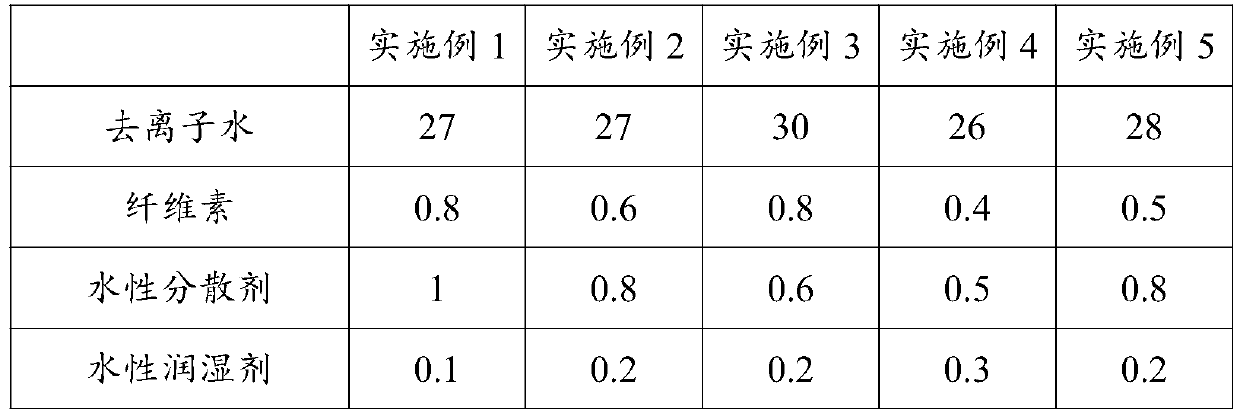

Soft porcelain material with visible light reflecting properties and method for preparing soft porcelain material

The invention discloses a soft porcelain material with visible light reflecting properties, and belongs to the technical field of building wall materials. The soft porcelain material comprises, by weight, 25-50 parts of polymer emulsion, 20-45 parts of inorganic fillers, 0.5-1 part of wetting agents, 0.5-1 parts of defoaming agents, 1-5 parts of coupling agents, 0.1-0.3 part of celluloses, 1-5 parts of leveling agents, 10-30 parts of light reflecting pigment, 5-10 parts of dispersing agents and 20-40 parts of deionized water. The soft porcelain material has the advantages that the soft porcelain material is high in water repellency and gas permeability and is light; the soft porcelain material is flexible, acid-resistant, alkali-resistant, freeze-thawing-resistant, aging-resistant, shock-resistant and crack-resistant, and is good in compatibility to external thermal-insulation systems of external walls; the shortcoming of potential safety hazards due to the fact that the traditional ceramic tiles, mosaic and the like are easy to fall off to injure people can be overcome by the aid of the soft porcelain material, and the soft porcelain material is particularly suitable to be used asan external wall facing materials for high-rise buildings and the external thermal-insulation systems of the external walls.

Owner:广东福莱特建筑材料有限公司

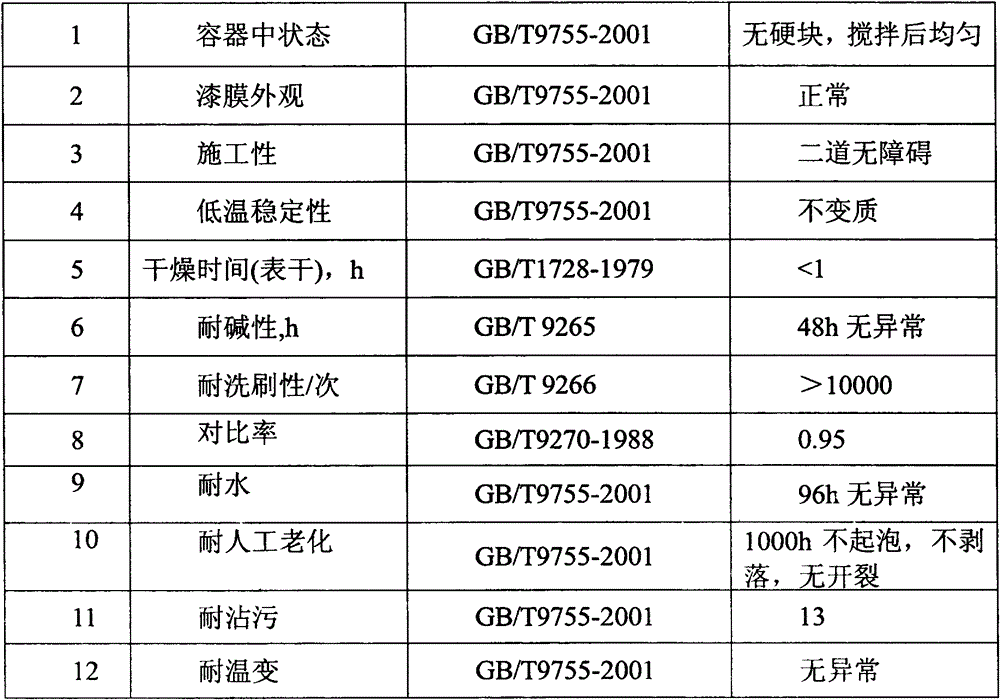

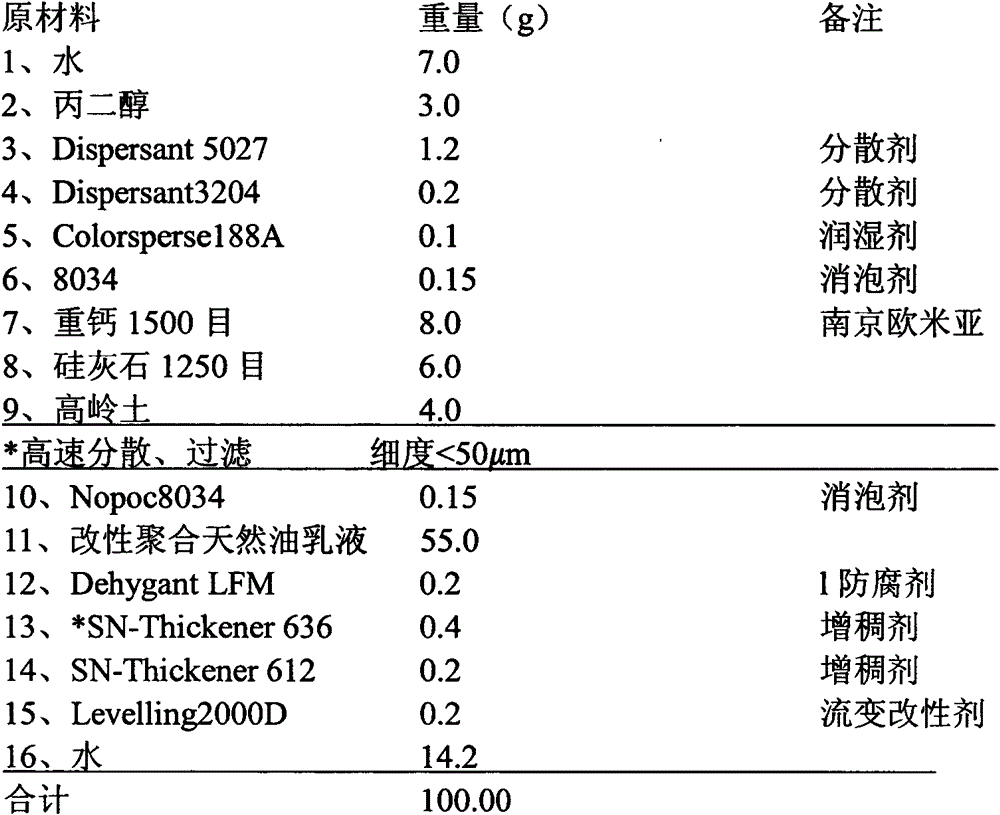

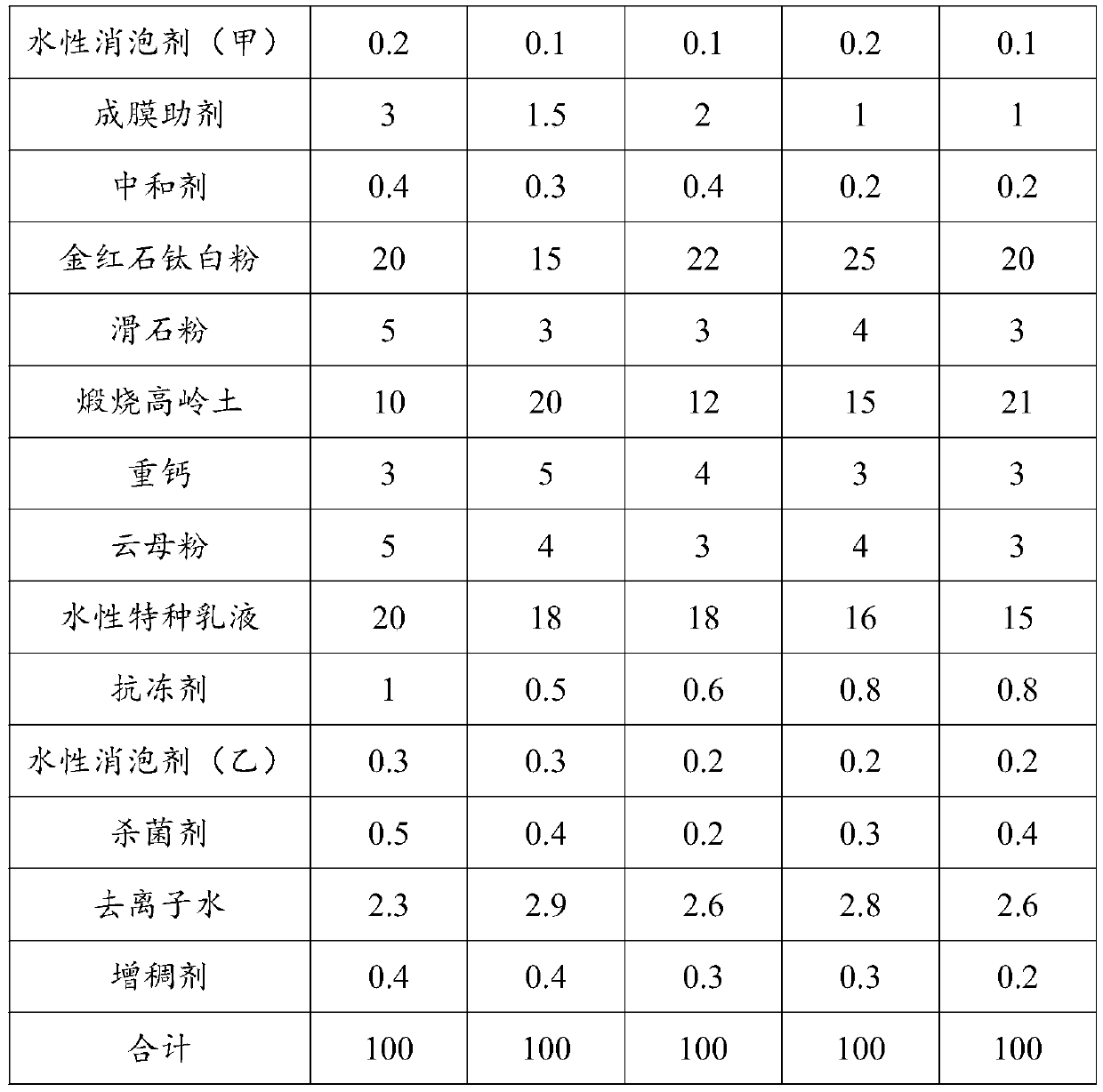

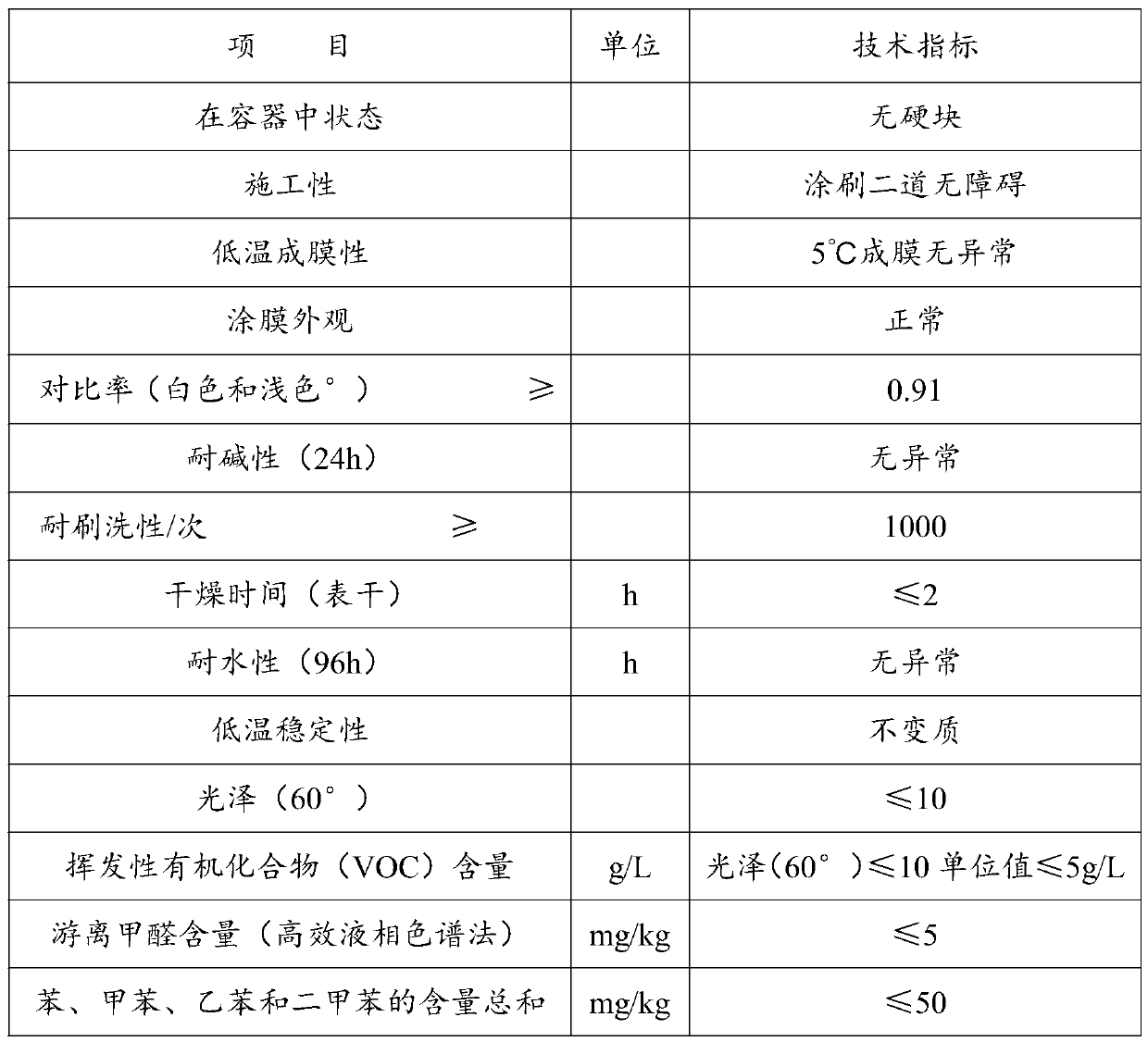

Interior wall water paint and preparation method thereof

InactiveCN111154364AScrub resistanceFreeze-thaw resistantAntifouling/underwater paintsPaints with biocidesIsothiazolinoneEmulsion

The invention relates to the technical field of interior wall water paint. The invention provides an interior wall water paint and a preparation method thereof. A water-based special emulsion is used,and the inner wall water paint is prepared by matching a coalescing agent, an additive, a pigment filler, water and the like; the obtained interior wall water paint has excellent performances such asscrub resistance, freeze-thaw resistance, high contrast ratio, good water resistance and the like; the comprehensive performance is superior to that of a superior product of GB / T9756-2018 'syntheticresin emulsion coatings for interior wall'; meanwhile, the interior wall water paint provided by the invention has the advantages of ultralow VOC, zero formaldehyde and ultralow heavy metal element content, the content of dichloro-zinc-based isothiazolinone (DCOIT) is less than 50 mg / kg, and the total content of isothiazolinone is less than 400 mg / kg.

Owner:CHENGDU HONRE PAINT MAKING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com