Method for secondary pouring of staircase columns through formwork supporting

A secondary pouring and stairwell technology, which is applied in the processing of building materials, the preparation of building components on site, construction, etc., can solve the problems of poor durability, increased labor intensity of workers, and lack of energy saving and environmental protection, and achieve drying shrinkage. And immersion linear deformation rate is small, save material and cleaning work, significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

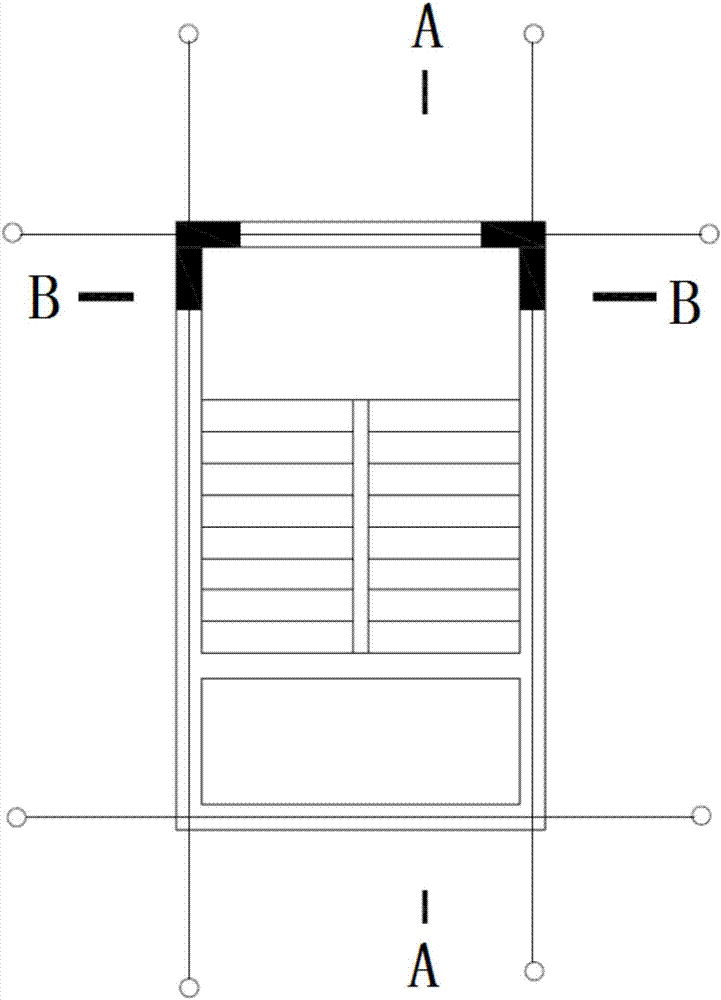

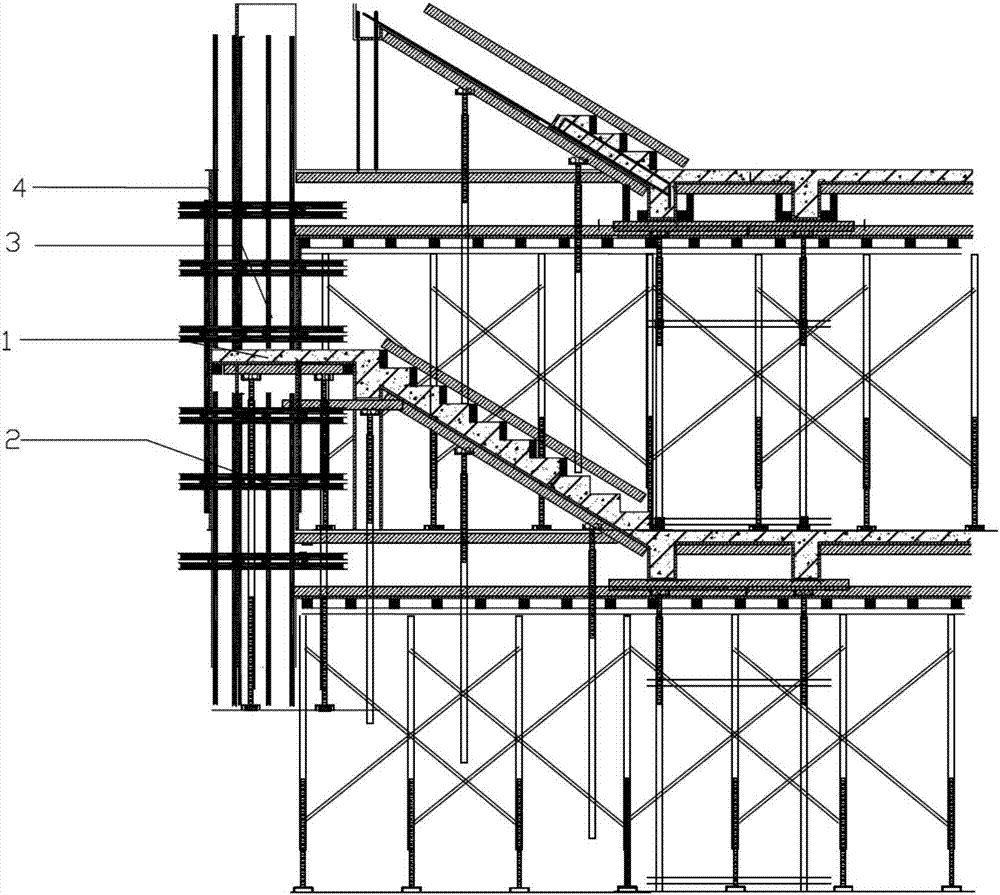

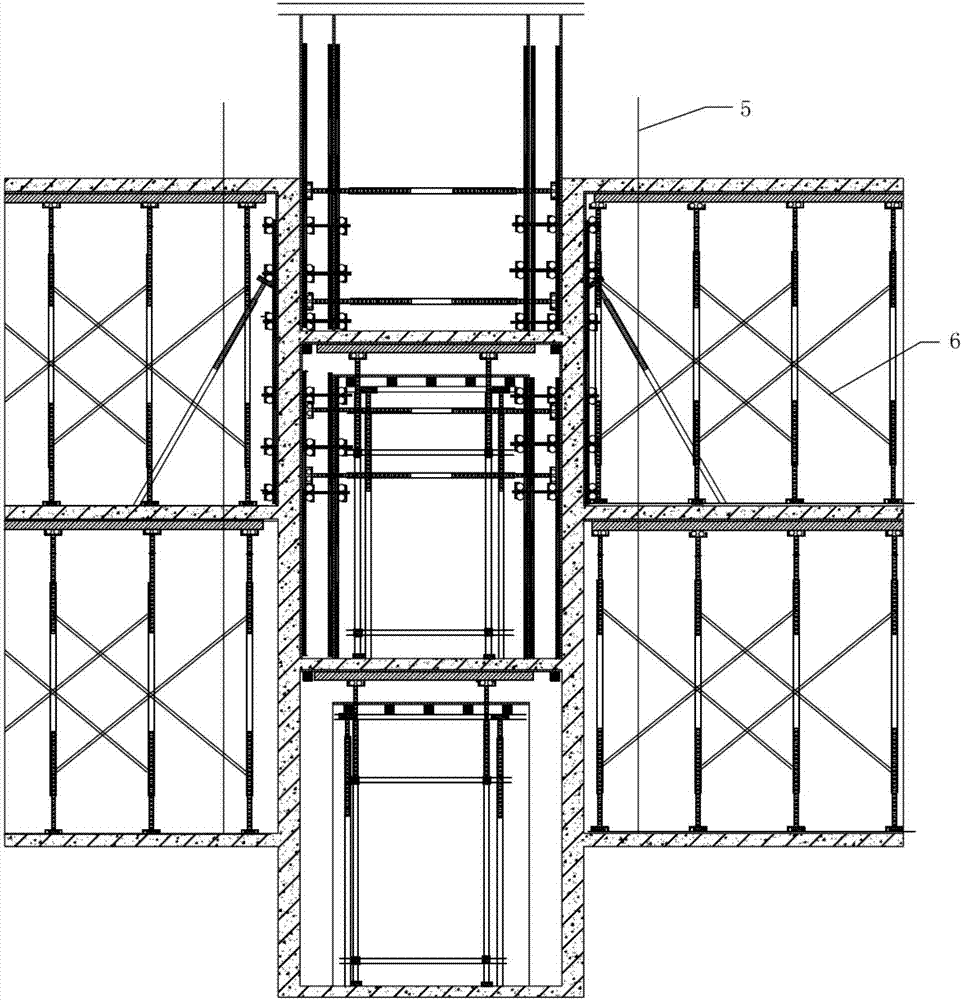

[0044] Such as Figure 1-Figure 3 As shown in Fig. 1, a method for secondary pouring of stairwell columns with formwork, the column formwork is made according to the dimensions of the stairwell columns and shear walls. The height of the column formwork exceeds the construction height of the structural layer and extends to the upper layer of the structural construction layer to rest The bottom of the beams and slabs of the platform is matched with formwork, and then the column formwork of the next construction section is configured according to the height of the floor. The formwork is set continuously from bottom to top on the side of the stairwell.

[0045] In this embodiment, the second-story formwork is prepared by the column formwork in the stairwell during construction, and other formworks are supported by traditional methods.

Embodiment 2

[0047] A method for formwork secondary pouring stairwell columns, comprising the steps of:

[0048] S1. Stairwell formwork configuration

[0049] Specifically: Familiar with the construction drawings —→ acceptance of the approach formwork —→ release a large sample of the stairwell formwork —→ configuration of the stairwell formwork;

[0050] In this step, the following points are adopted: the surface of the formwork should be flat, the material properties should meet the strength requirements of the design, the blanking should be accurate, the cuts should be even, the male and female corners should be square, the edges and corners should be straight, and there should be no distortion or warping;

[0051] S2. Formwork construction

[0052] Specifically: check the positioning of the components—→reinforcement binding—→reinforcement concealed acceptance—→garbage cleaning in the formwork—→assemble the column formwork—→install the column hoop under the rest platform—→fix the root c...

Embodiment 3

[0068] A method for formwork secondary pouring stairwell columns, comprising the steps of:

[0069] S1. Stairwell formwork configuration

[0070] Specifically: Familiar with the construction drawings —→ check and accept the approach formwork —→ place a large sample of the stairwell formwork —→ configure the stairwell formwork;

[0071] In this step of this embodiment, follow the following operating points:

[0072] Familiarize yourself with the drawings carefully before making the formwork, check the architectural and structural construction drawings, release the large sample drawing of the support form according to the size of the construction drawing, and list the specifications and quantities of the formwork according to the large sample drawing to ensure that the formwork size is accurate.

[0073] The thickness of the formwork, the section and spacing of the crosspieces and corrugated wood, and the configuration of the support system can all be selected according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com