Patents

Literature

56results about How to "Simplify on-site construction procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

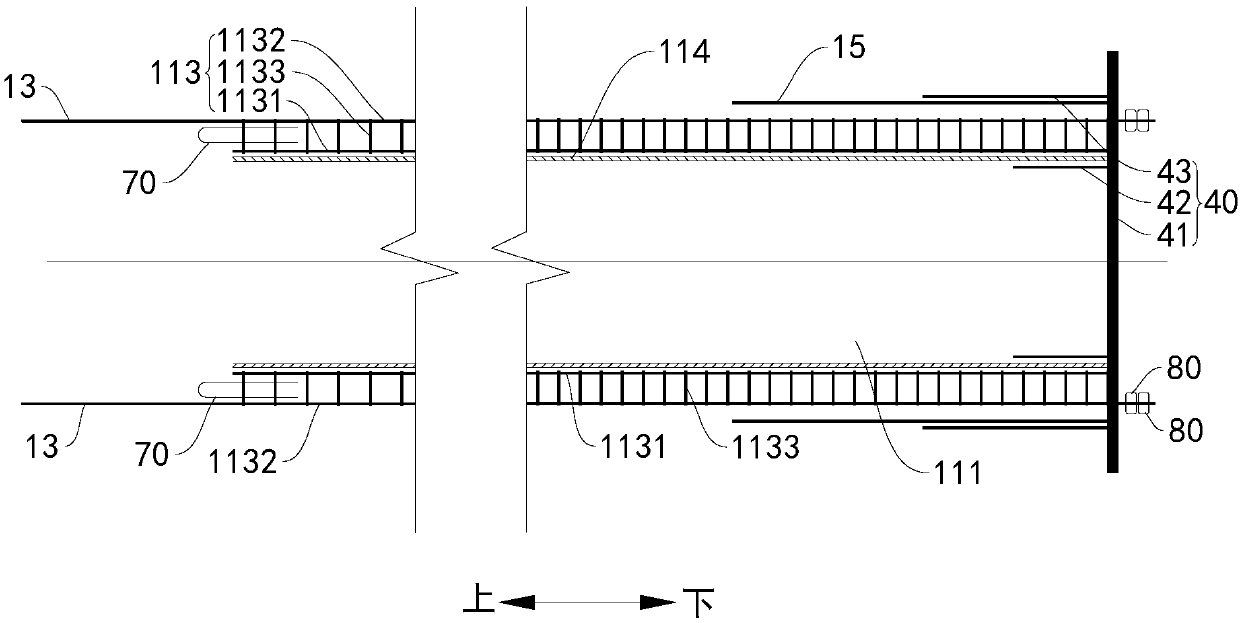

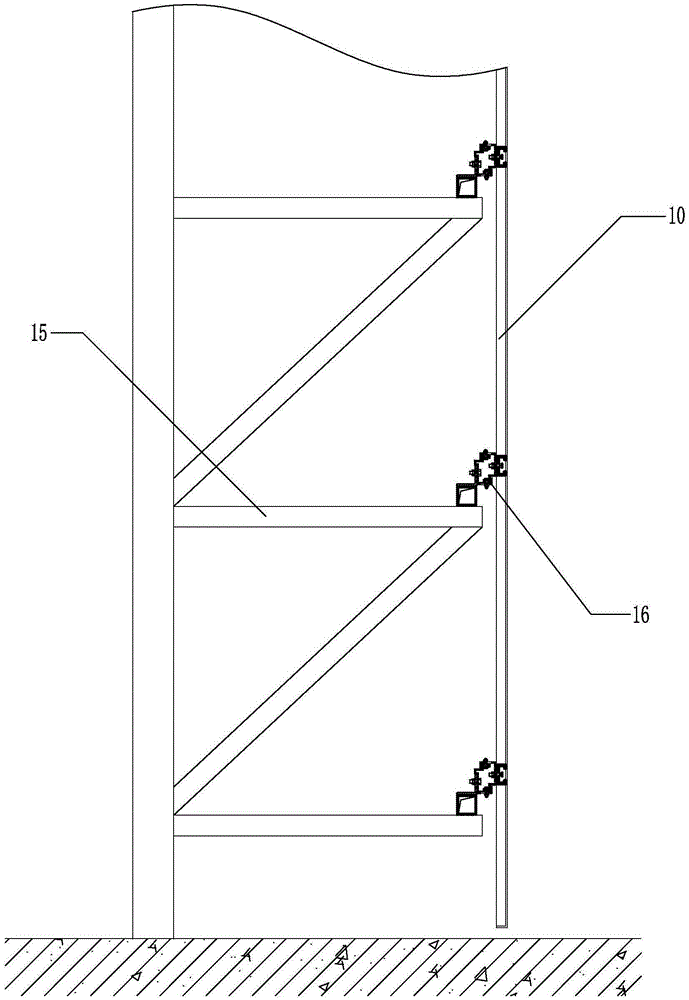

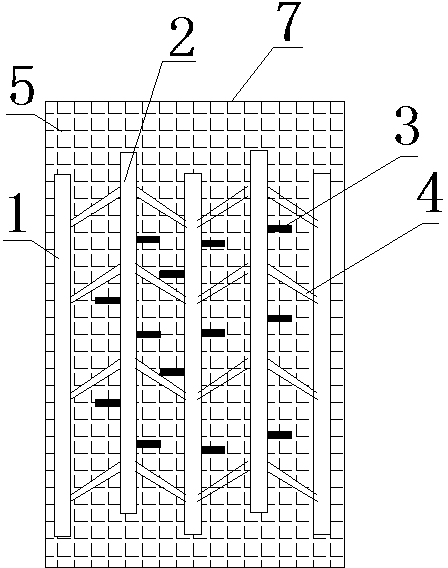

Composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and construction method thereof

InactiveCN102704598AAct as a constraintImprove binding abilityWallsBuilding material handlingSteel frameSteel bar

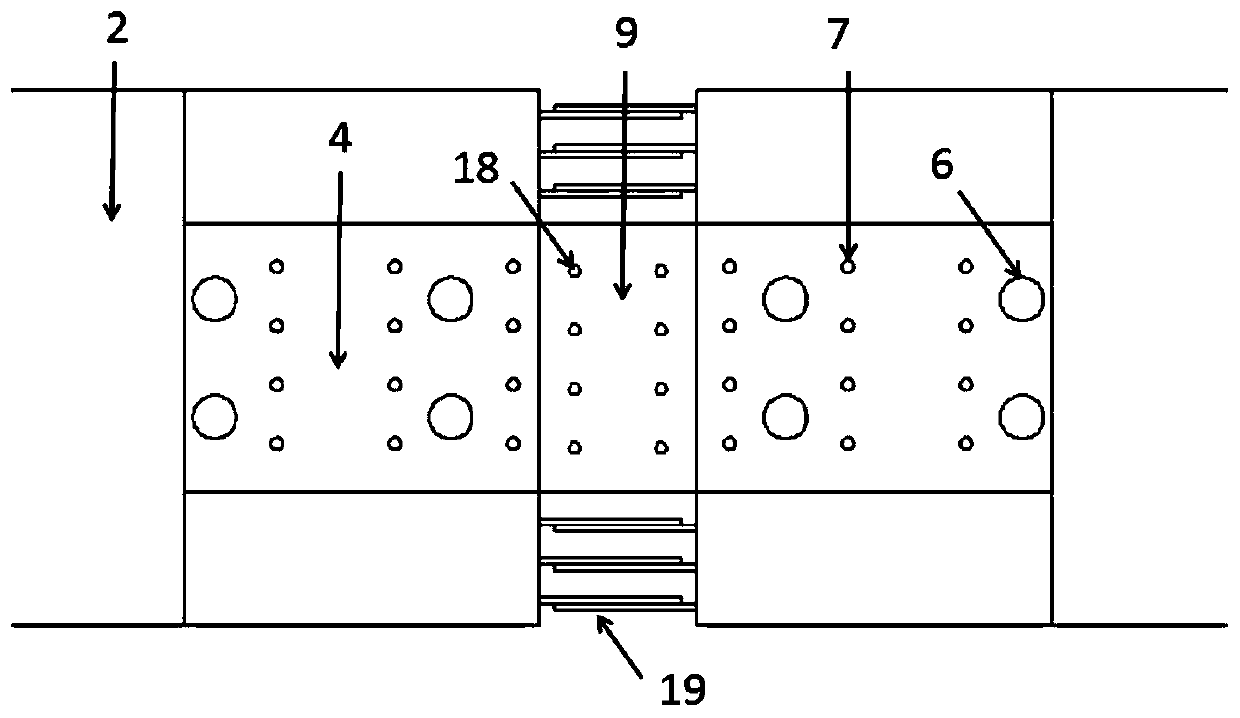

A composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and a construction method thereof relate to the field of construction. According to the invention, the composite shear wall is formed by combining reinforced concrete frames, a double steel plate shear wall and steel plates with concealed bracings. The reinforced concrete frames are formed by pouring concrete into steel tubes; then, the double steel plates are placed, the double steel plates are welded to the reinforced concrete frames, and the steel plates are perforated and are connected through studs; oblique crossing concealed bracings are placed between the double steel plates, and the oblique angle of the concealed bracings is between 45 degrees and 60 degrees; tie bars are threaded through the interspace between the concealed bracings; a reinforcing mesh composed of transverse steel bars in horizontal arrangement and longitudinal steel bars in vertical arrangement is arranged between the concealed bracings and the steel plates; and concrete is poured between the double steel plates. The composite shear wall has the advantages that the bearing capability is enhanced, the bearing capacity and the rigidity attenuate slowly, the ductility and the energy dissipation of the shear wall are enhanced due to multi-defenses, and the earthquake resistant capability is more excellent. The composite shear wall also has the advantage of convenience in steel structure construction, and can be used in high-rise or large complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

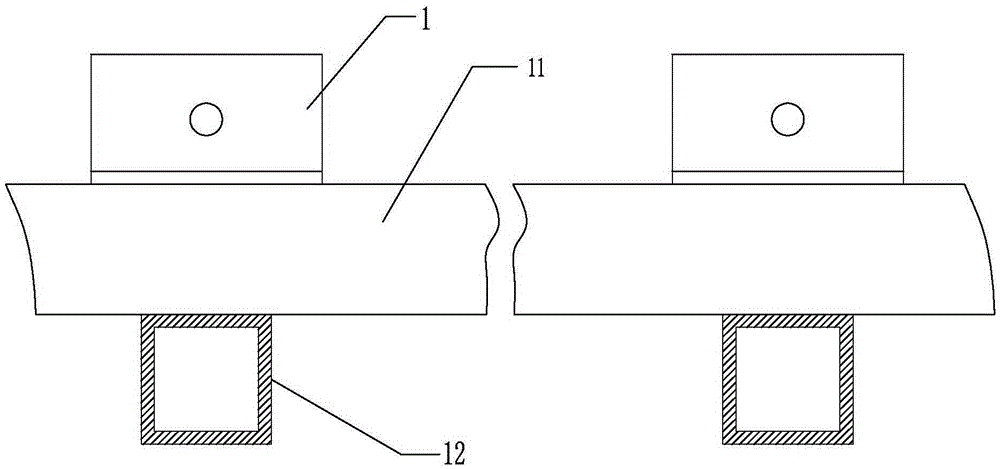

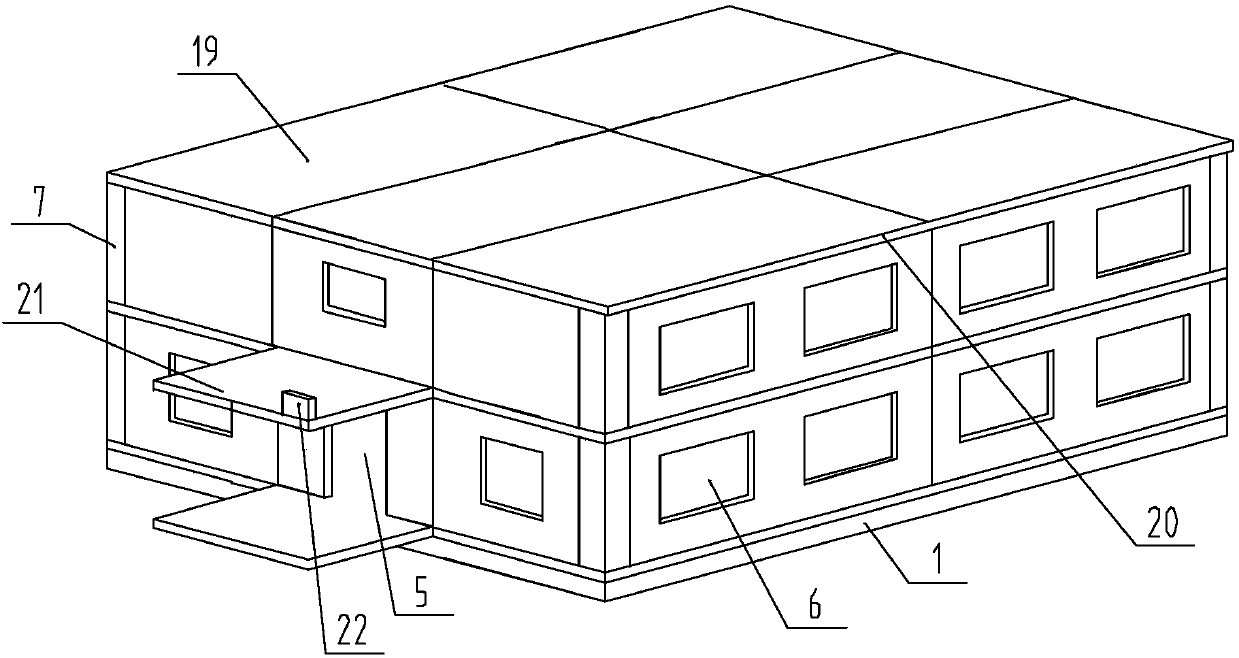

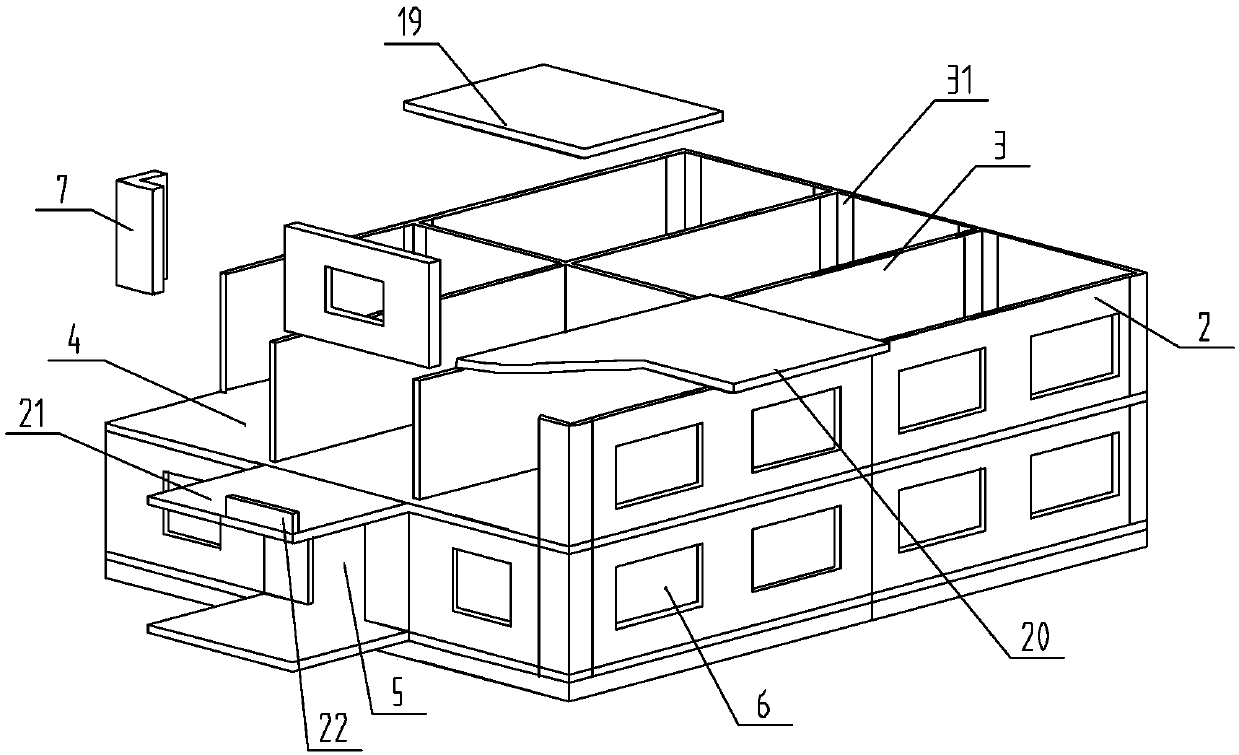

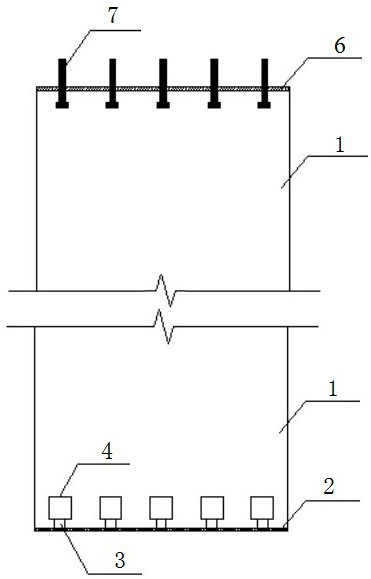

Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

ActiveCN105696817AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingDwelling buildingFloor slabEngineering

Owner:SOUTHEAST UNIV

Water stopping device for tunneling machine going in and out of tunnel and water stopping method

The invention relates to the field of building construction, in particular to a water stopping device for a tunneling machine going in and out of a tunnel and a water stopping method. The water stopping device for the tunneling machine going in and out of the tunnel comprises at least one water stopping casing box with openings at the front part and the back part. The water stopping casing box isarranged at the periphery of a doorway part which is in an enclosure protection structure, is fixedly connected with the enclosure protection structure in a sealing way, and comprises a sleeve with openings at the front part and the back part and a freezing pipe. The freezing pipe is arranged on the inner wall of the sleeve, and is used for injecting refrigerant. A grouting pipe which is communicated with the inner cavity of the sleeve is arranged on the sleeve. The invention also discloses the water stopping method adopting the water stopping device. The freezing pipe can change mixed paste between the water stopping casing box and the tunneling machine or a pipeline into a freezing body. The freezing body can block off a leakage path, ensure that groundwater which possibly leaks can be frozen in time when the tunneling machine or the pipeline structure moves relative to the water stopping casing box, thereby achieving the purpose of water stopping.

Owner:SHANGHAI CONSTRUCTION GROUP

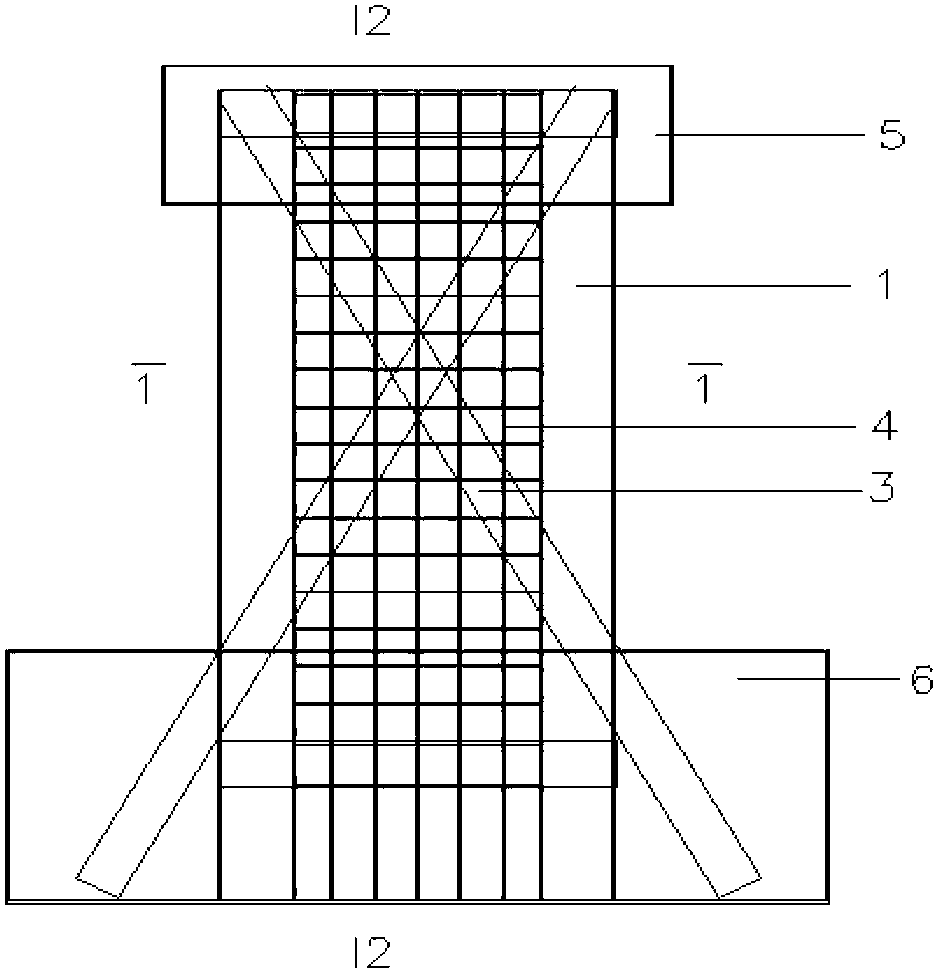

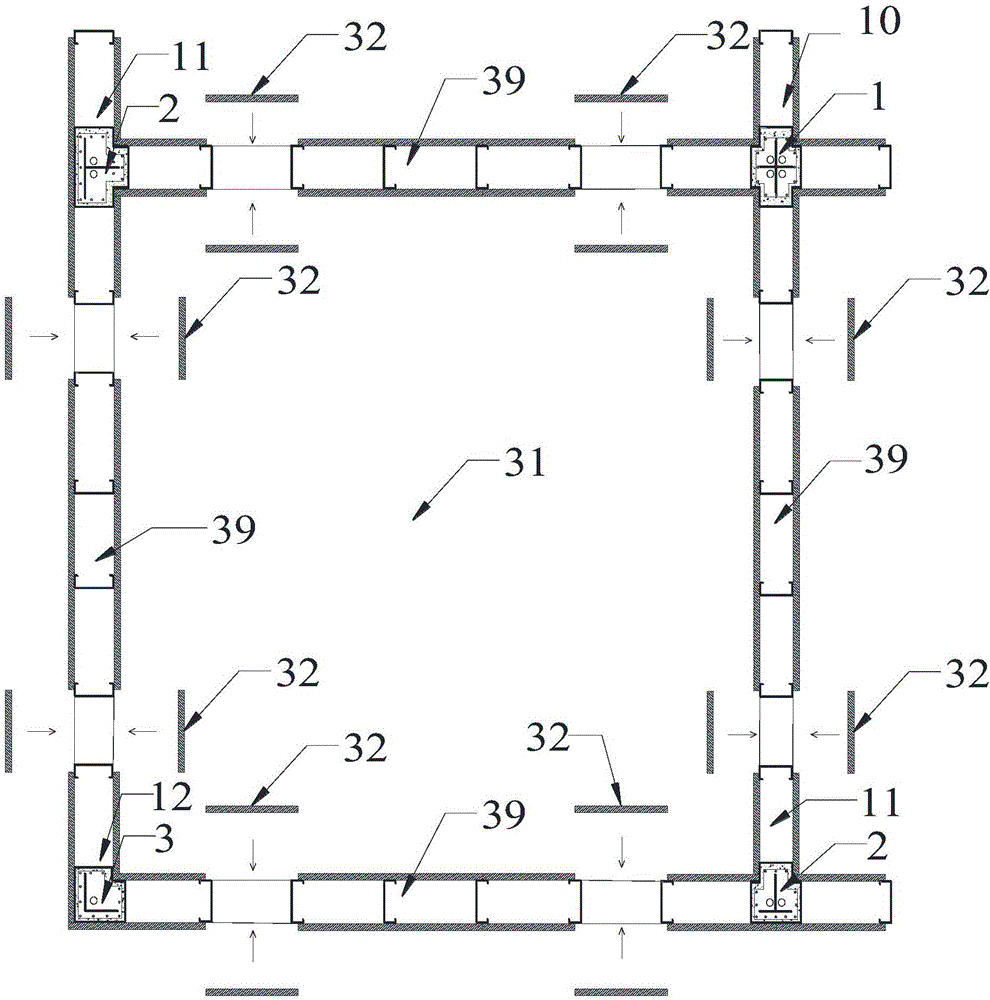

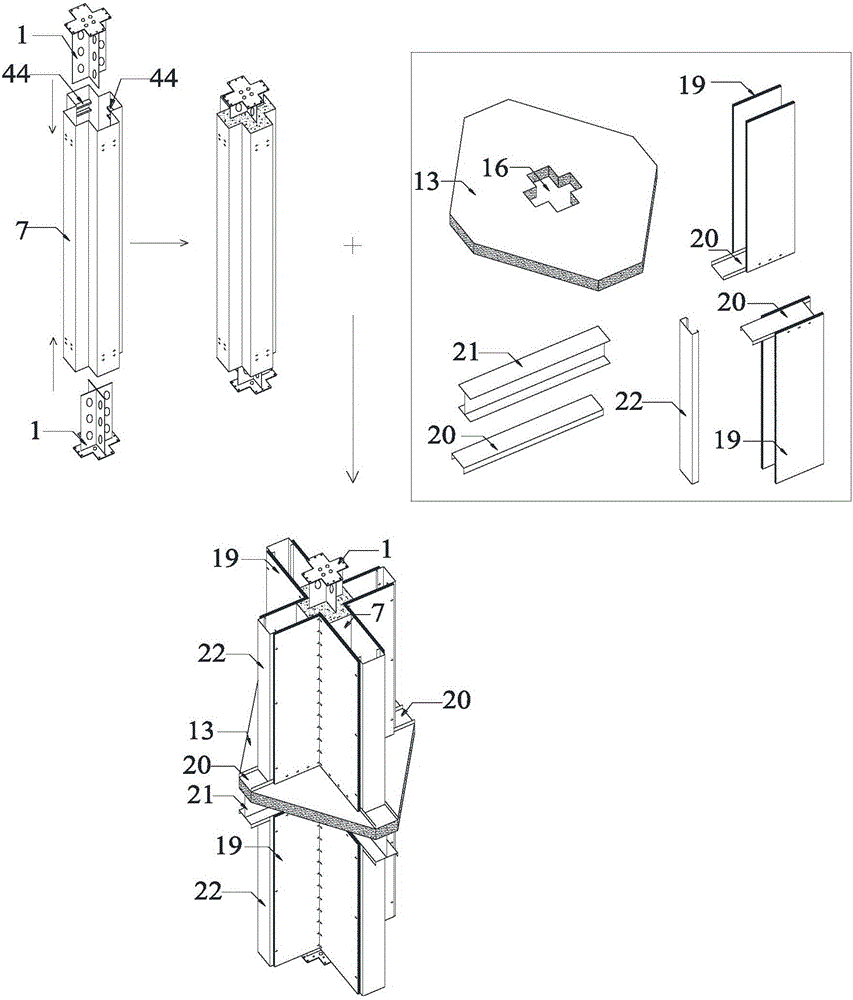

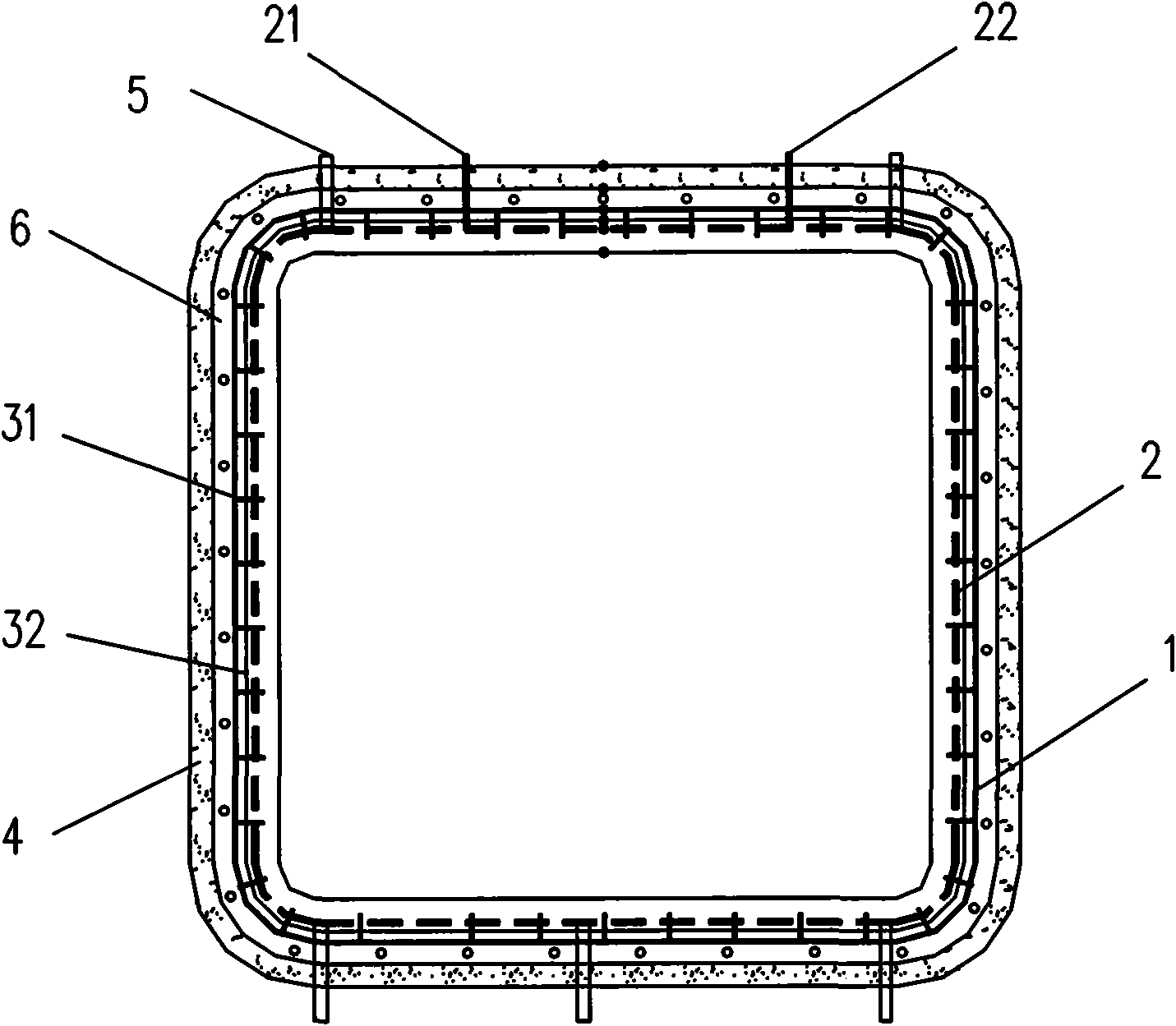

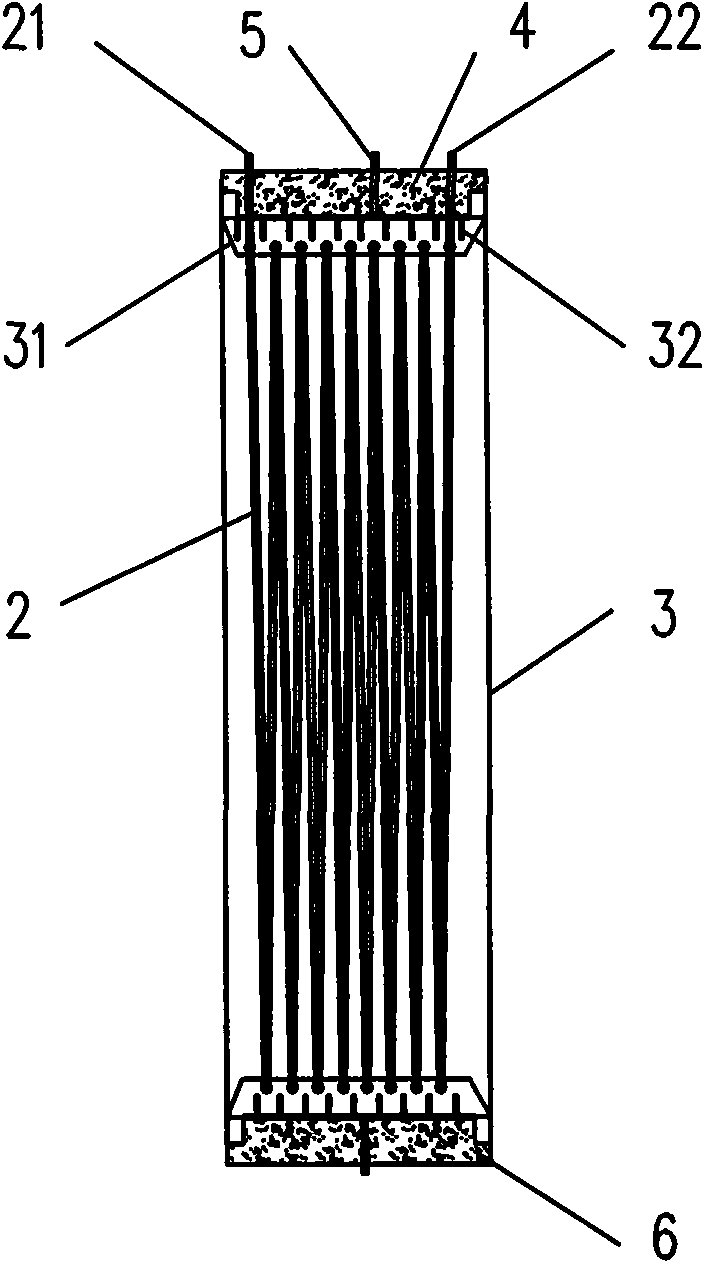

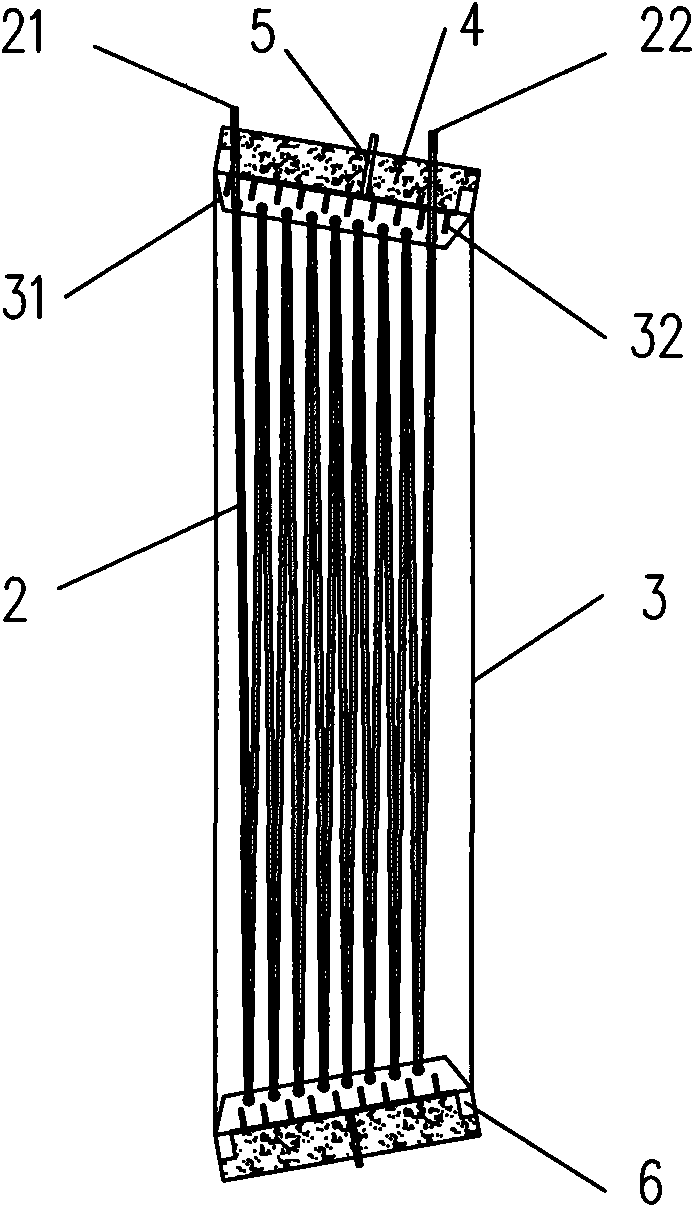

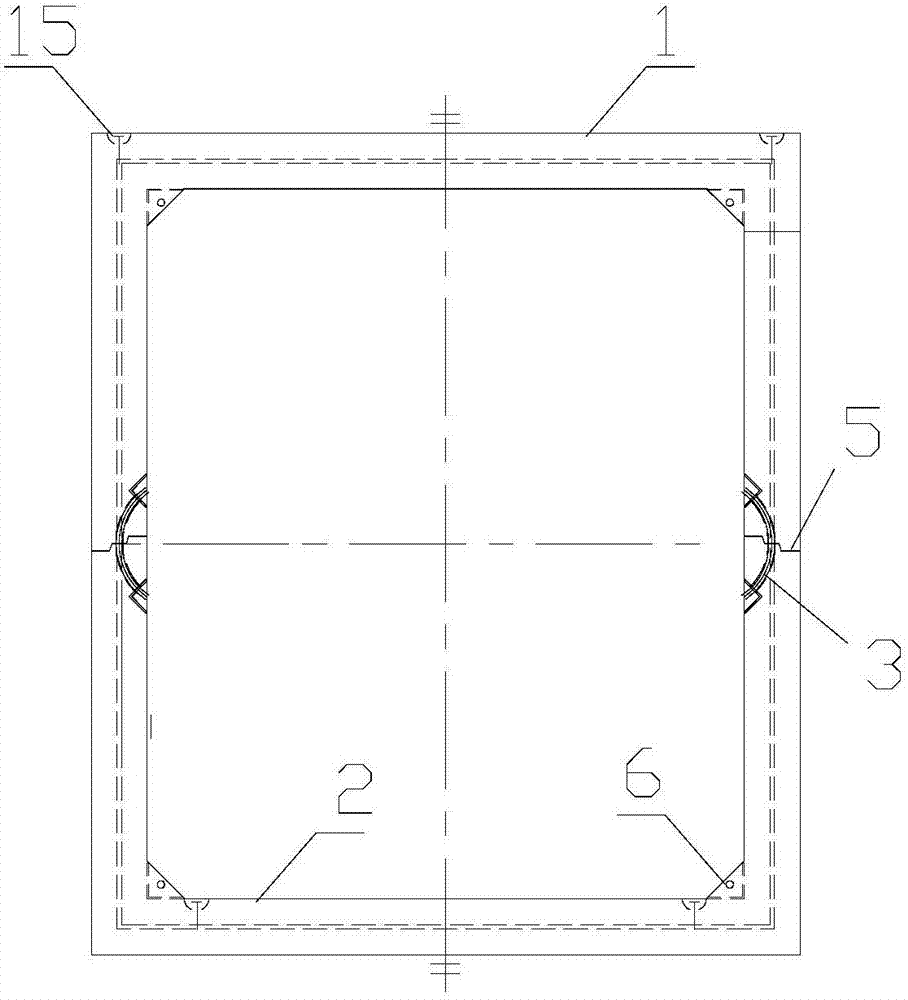

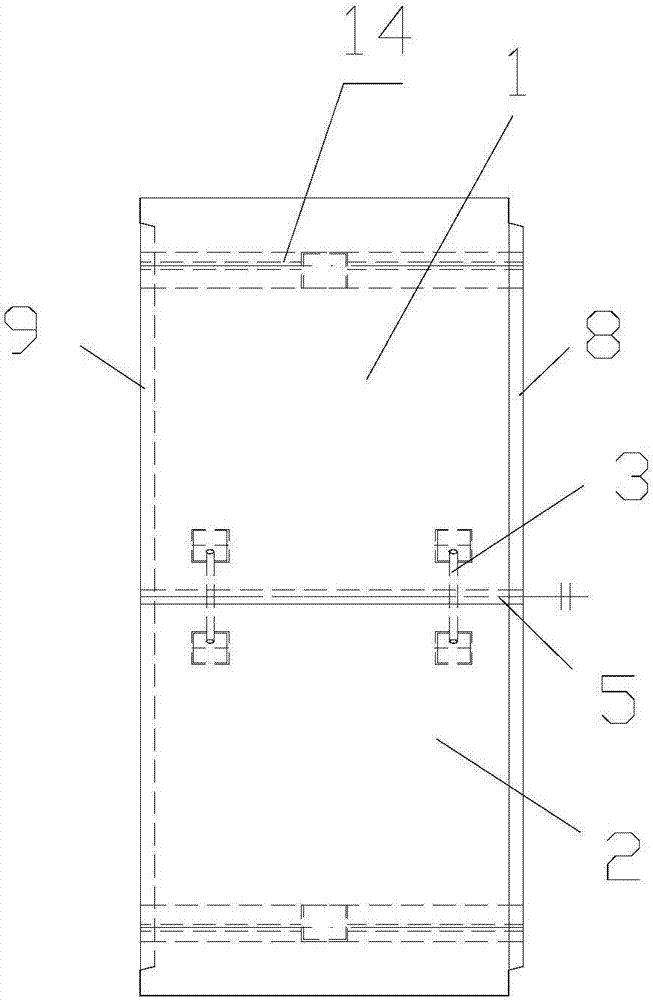

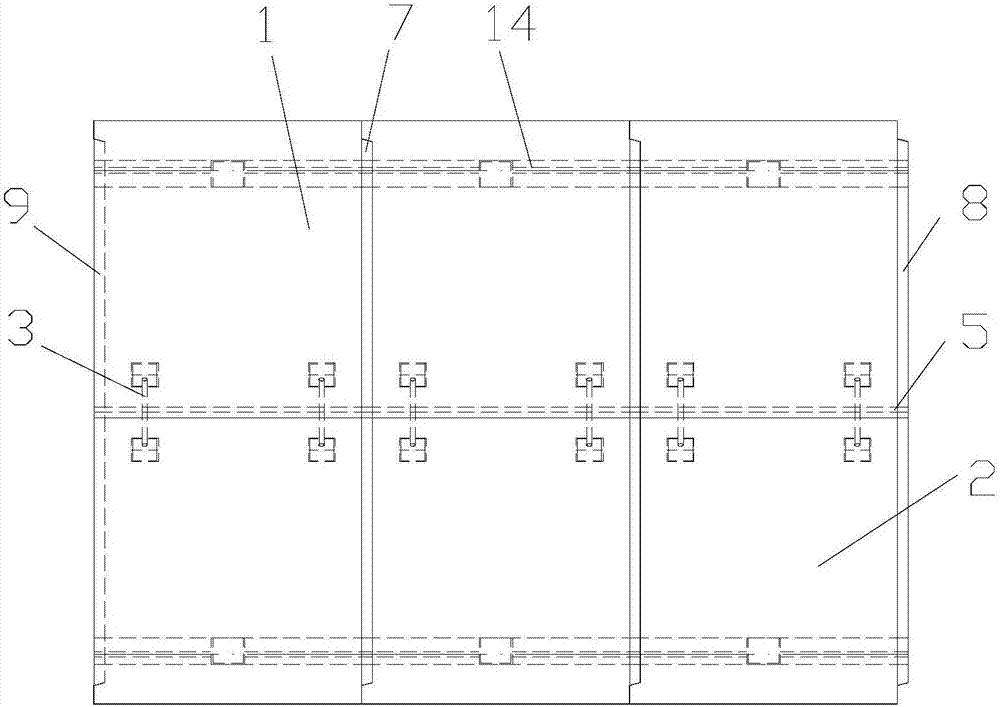

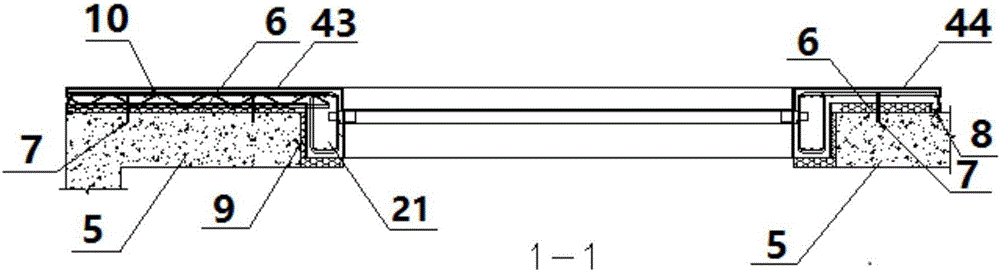

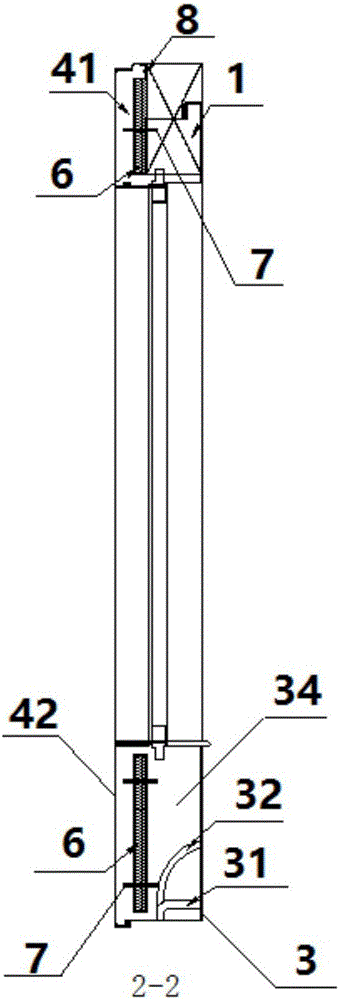

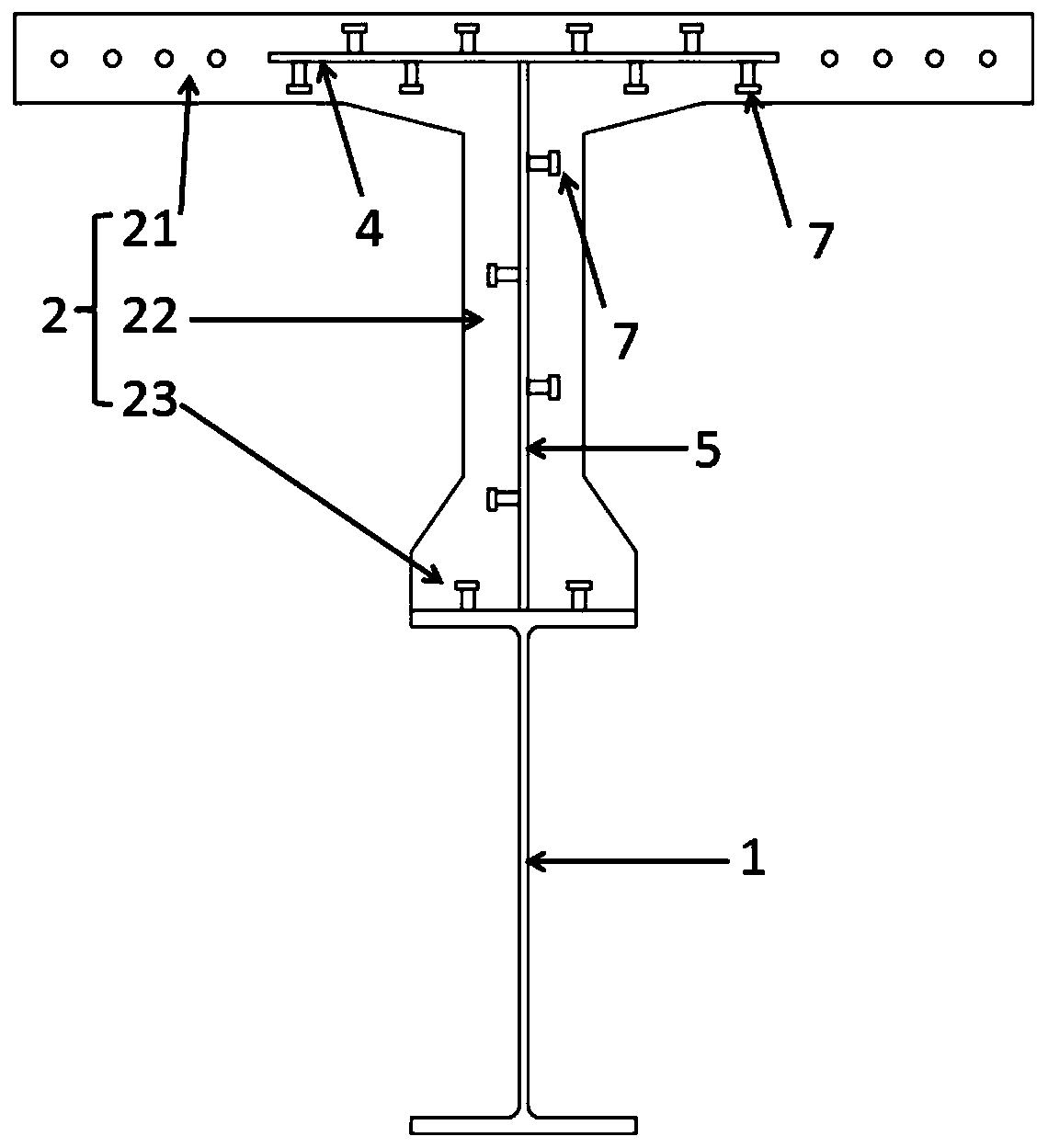

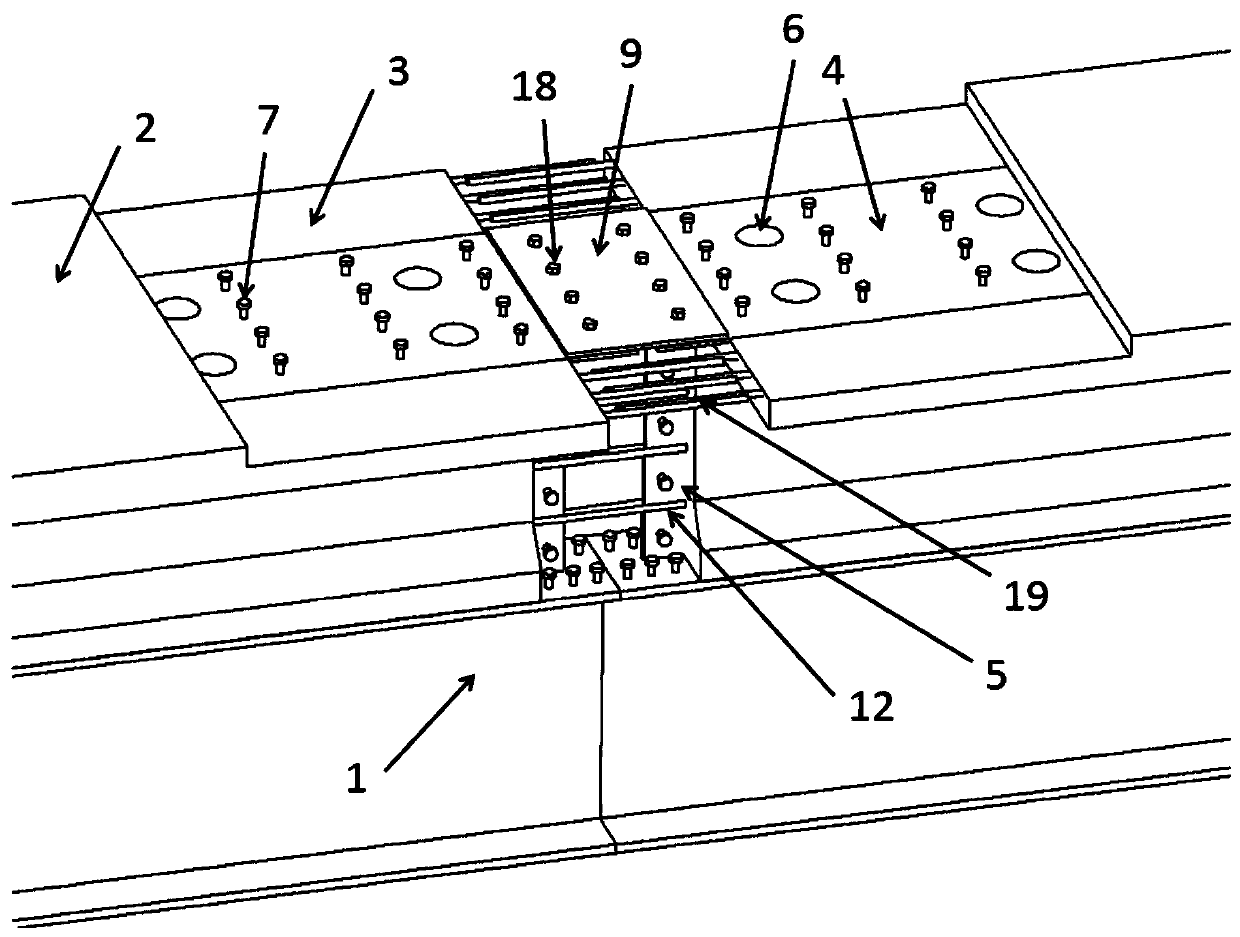

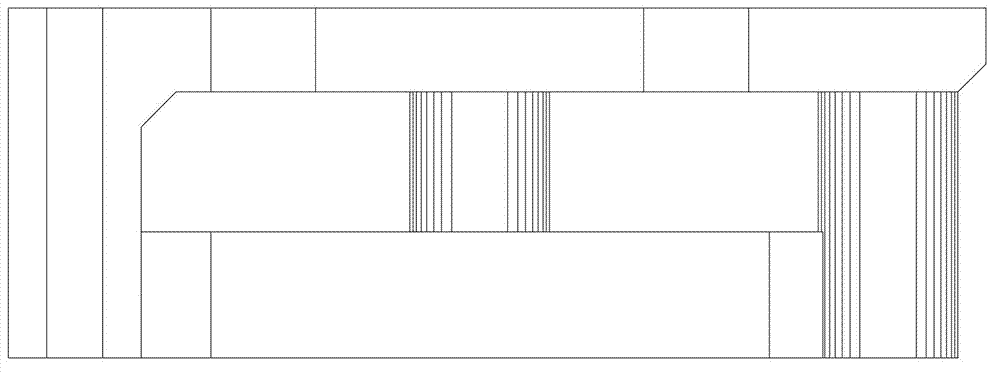

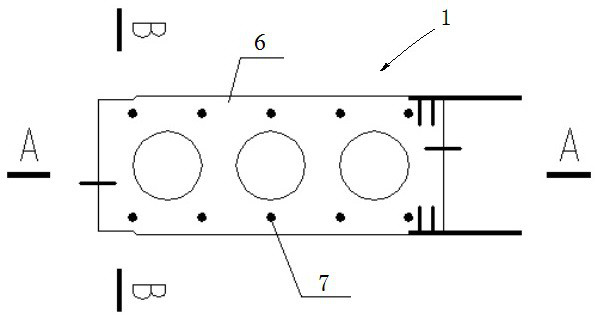

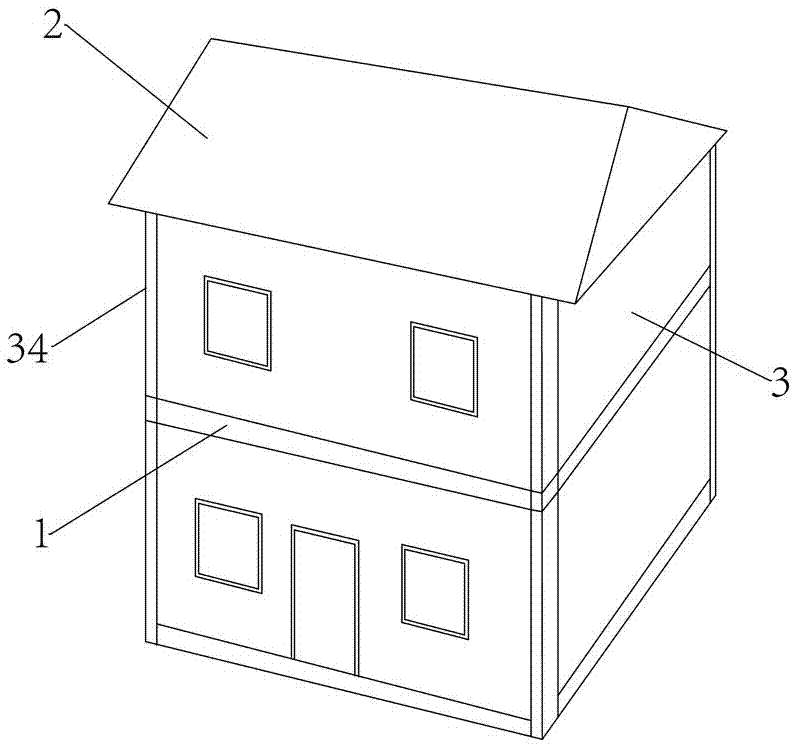

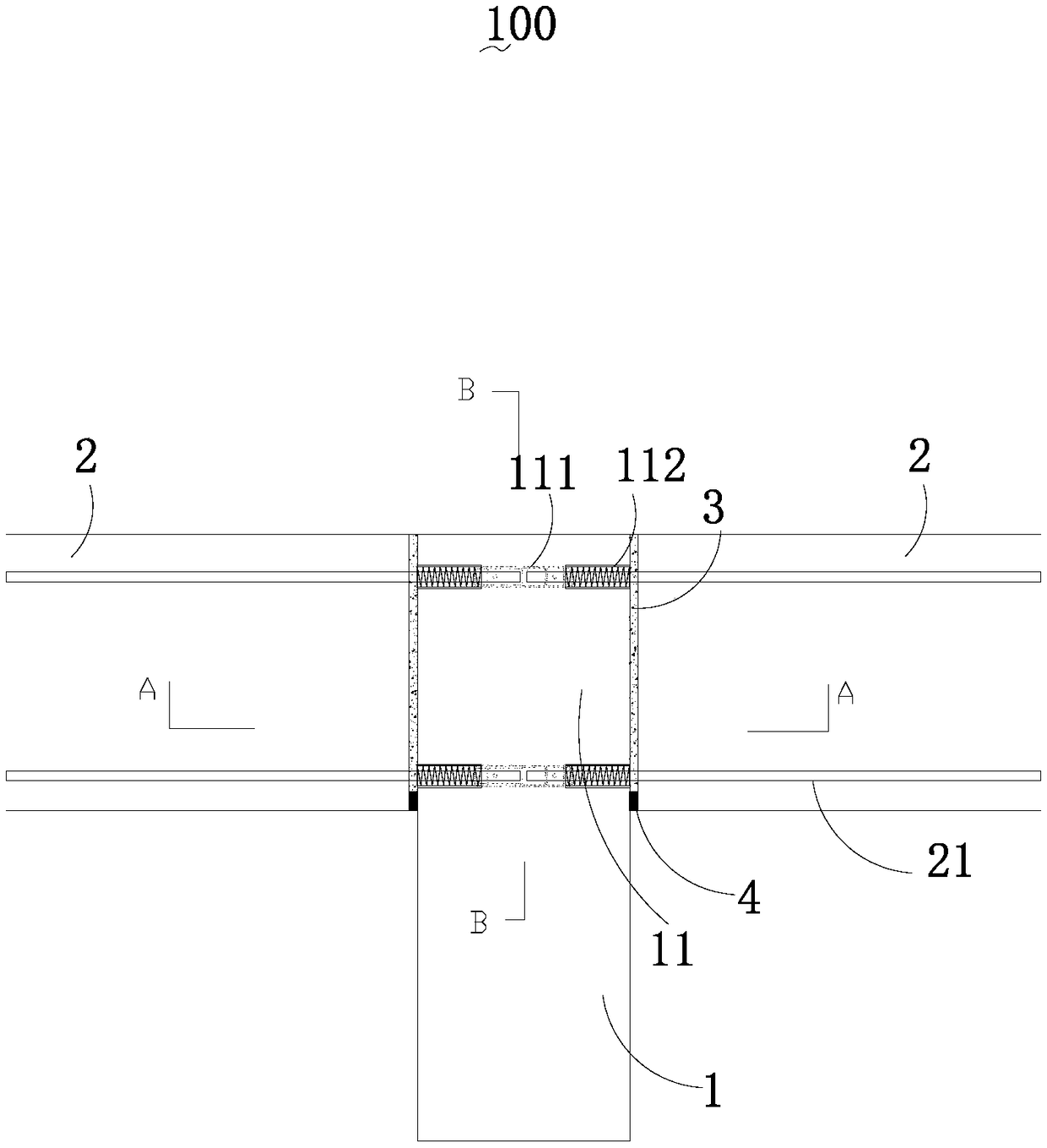

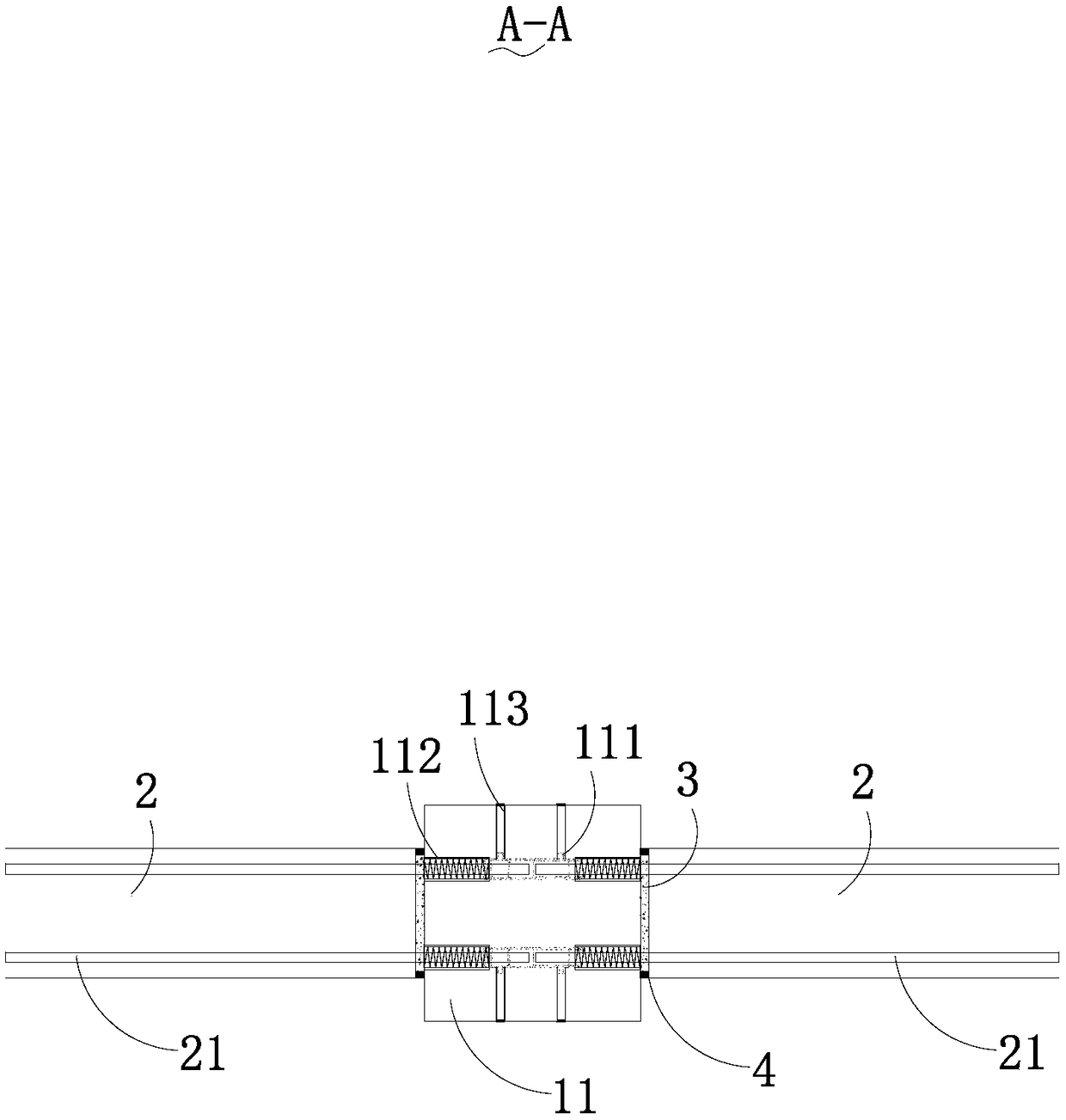

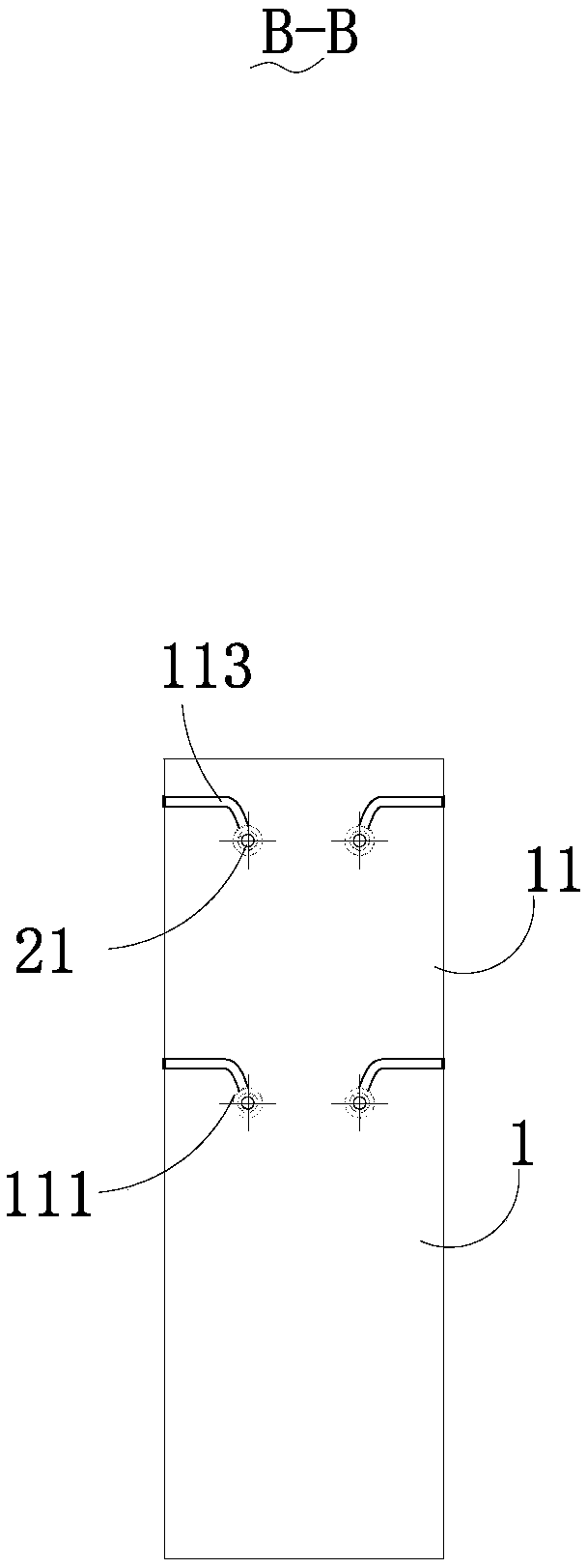

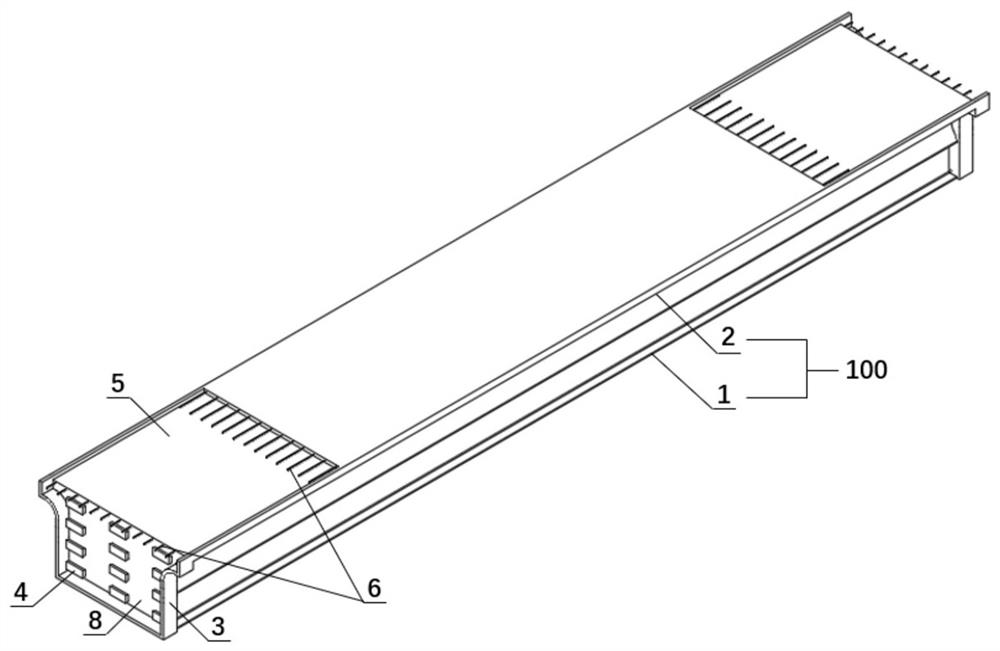

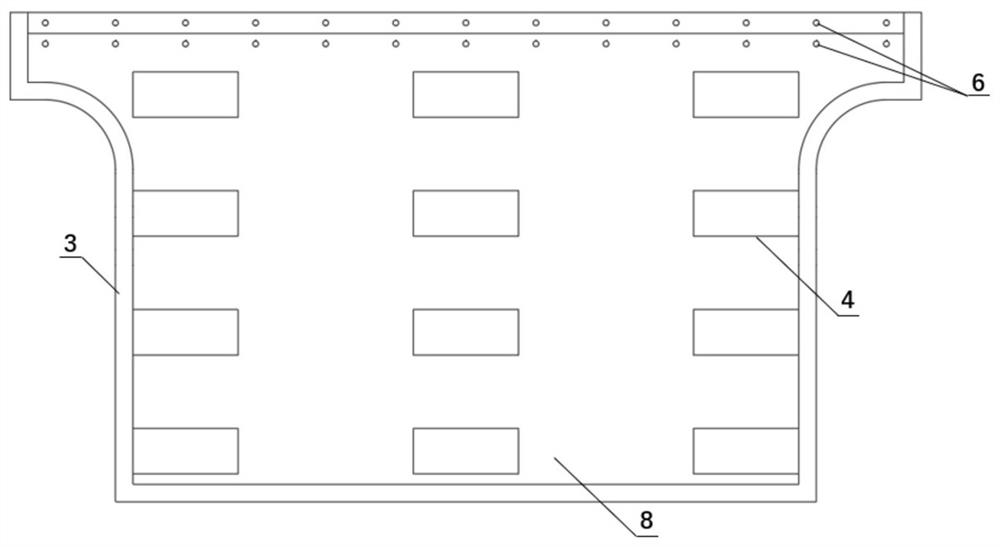

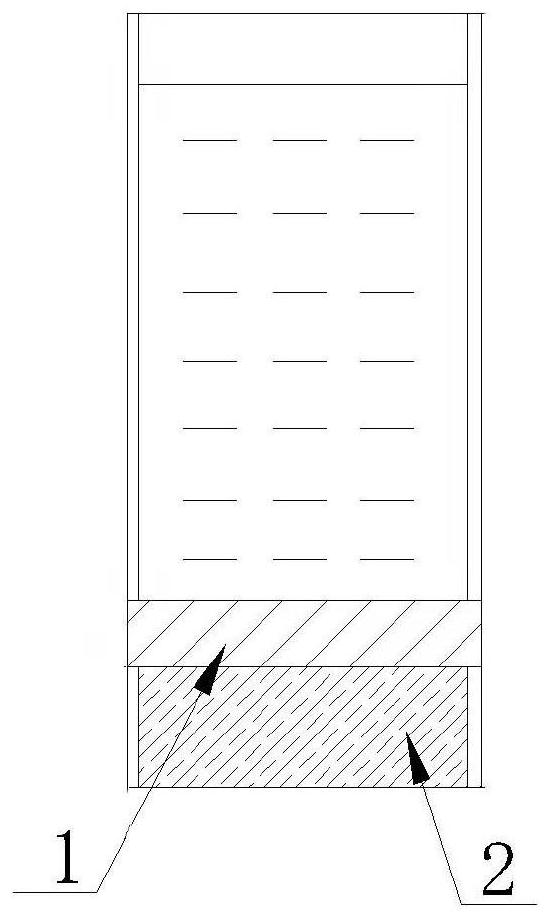

Split component prefabricated type comprehensive pipe gallery and construction method thereof

ActiveCN107059917ALow costEasy to transport and hoistArtificial islandsUnderwater structuresEngineeringPrefabrication

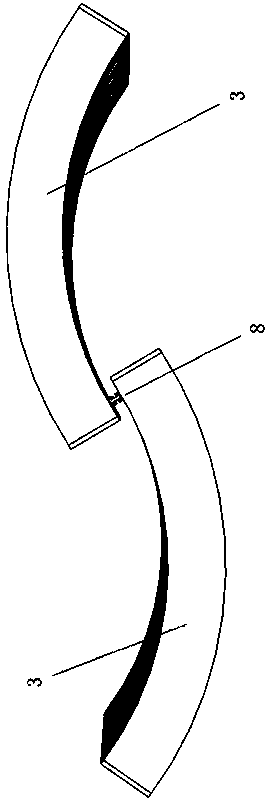

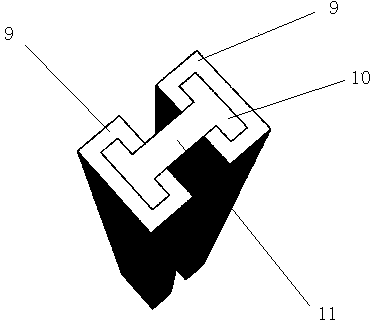

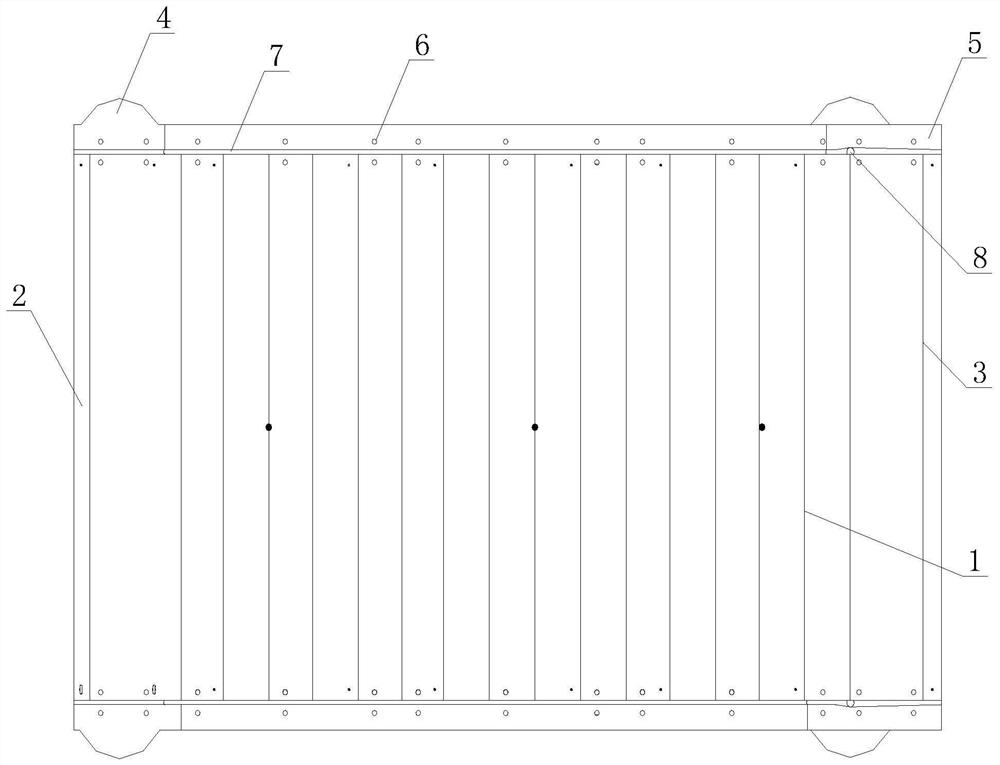

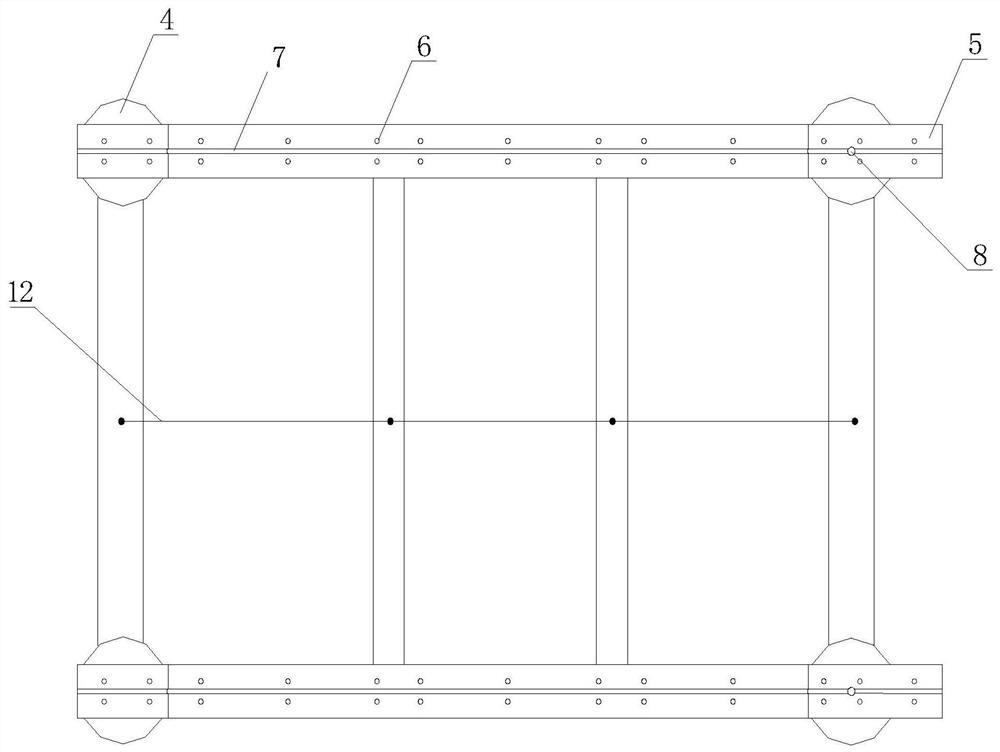

The invention discloses a split component prefabricated type comprehensive pipe gallery and a construction method thereof. The split component prefabricated type comprehensive pipe gallery is formed by connecting a plurality of prefabricated pipe gallery sections; each prefabricated pipe gallery section is split into an upper prefabricated pipe gallery section part (1) and a lower prefabricated pipe gallery section part (2), wherein the upper prefabricated pipe gallery section part (1) is connected with the lower prefabricated pipe gallery section part (2) through a first bell and spigot (5) in a meshed manner, and the upper prefabricated pipe gallery section part (1) and the lower prefabricated pipe gallery section part (2) are jointed with the first bell and spigot (5) through prestress wires (3); and sealing rods are arranged between the first bells and spigots (5) to form waterproof layers. The split component prefabricated type comprehensive pipe gallery integrates advantages of a full prefabricated pipe gallery and a stacked pipe gallery; through reasonable splitting, dead loads of prefabricated components are reduced, the problem that the process of the stacked pipe gallery is complex is solved through prefabrication, and the problems about prefabrication of a multi-cabin pipe gallery and pipe gallery non-standard sections can be solved.

Owner:中建五局第三建设有限公司 +1

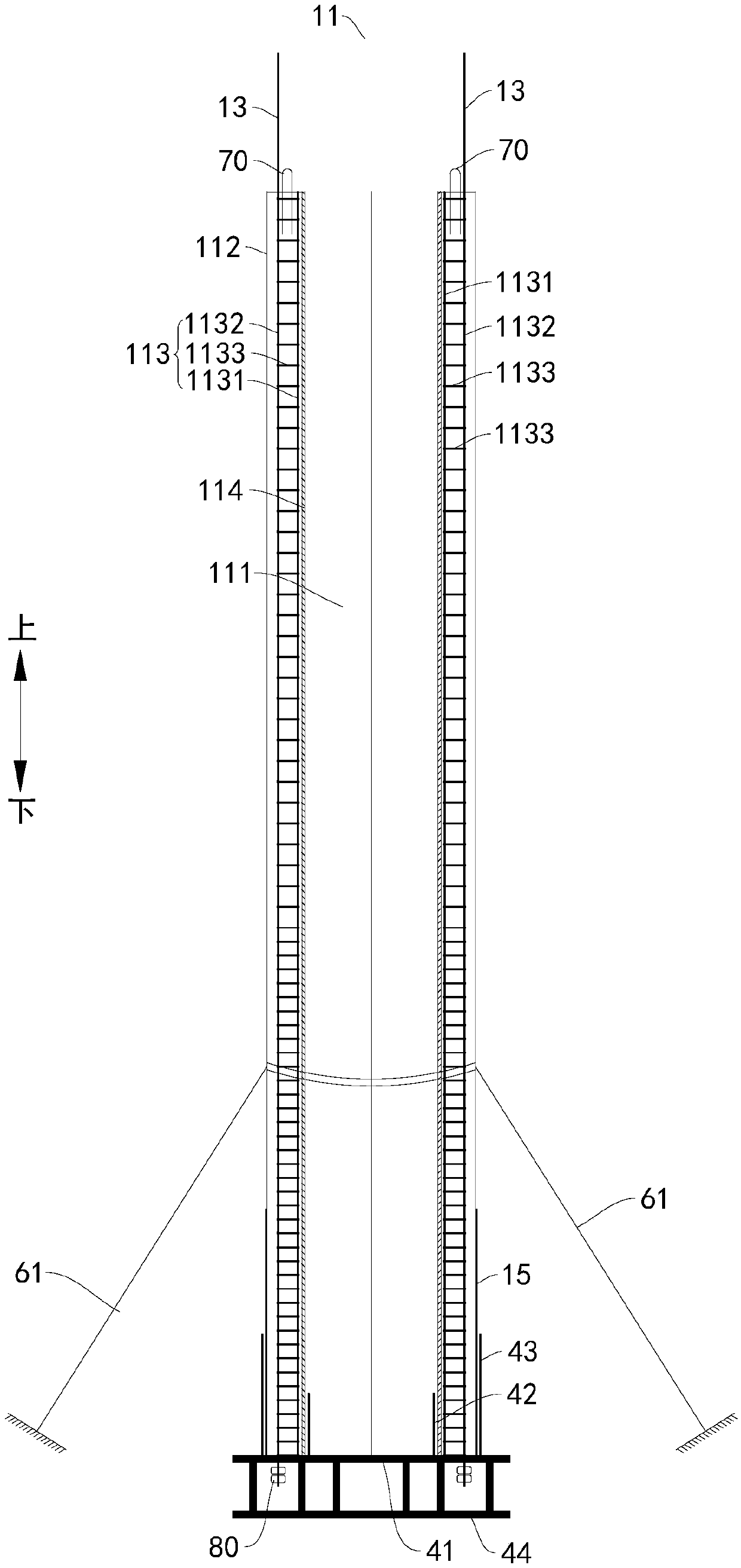

Manufacturing method of bridge pier

ActiveCN110656574AReduce adverse effectsThe connection structure is stable and reliableCeramic shaping apparatusBridge structural detailsArchitectural engineeringPier

The invention discloses a manufacturing method of a bridge pier. The manufacturing method of the bridge pier comprises the following steps of obtaining a pier stud prefabricated part and a capping beam prefabricated part, wherein a pier stud prefabrication chamber extending in the axial direction is formed in the pier stud prefabricated part; a capping beam prefabrication chamber is formed in thepier stud prefabricated part; a connecting rib extending upwards is arranged on the pier stud prefabricated part; the pier stud prefabricated part is placed on a mounting surface; concrete is injectedinto the pier stud prefabrication chamber from an opening in the upper end of the pier stud prefabrication chamber to be cured to form a pier stud concrete layer; the capping beam prefabricated partis mounted at the upper part of the pier stud prefabricated part, and the connecting rib is enabled to extend into the capping beam prefabrication chamber; and concrete is injected into the capping beam prefabrication chamber to be cured to form a capping beam concrete layer connected with the pier stud concrete layer and the connecting rib. According to the manufacturing method of the bridge pierdisclosed by the embodiment of the invention, the site construction procedure is simple, the construction speed is increased, the construction safety is enhanced, adverse effect of a traditional fullcast-in-situ process on traffic environment is avoided, and moreover, the connection between a pier stud and a capping beam is firmer.

Owner:BYD CO LTD

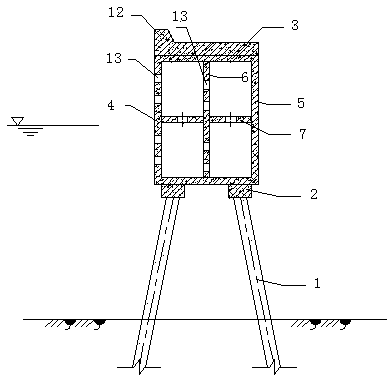

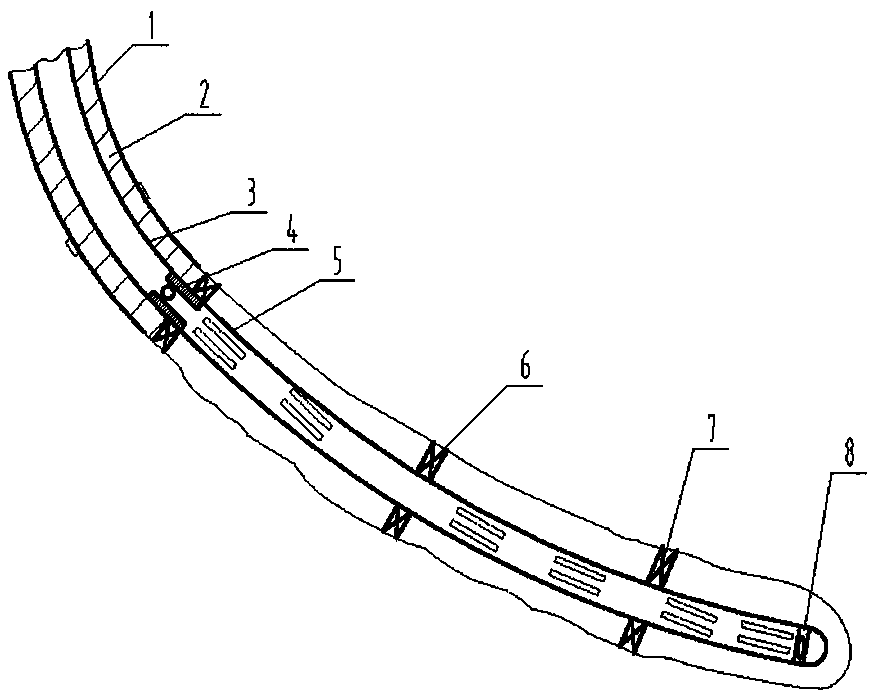

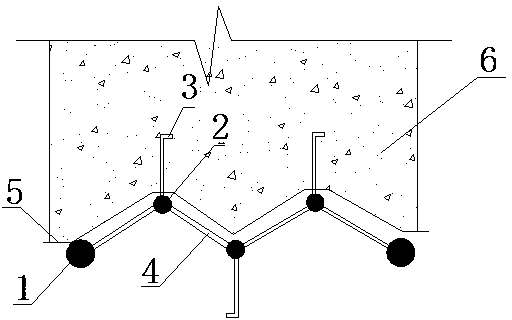

Arc-shaped transparent breakwater

ActiveCN103774611ASimple structureIngenious designMarine site engineeringEngineeringBuilding construction

The invention discloses an arc-shaped transparent breakwater. The arc-shaped transparent breakwater comprises pile bases (1) and pile caps (2); the arc-shaped transparent breakwater is characterized in that caissons (3) are arranged above the pile caps (2), the caissons (3) comprise outer walls (4) which are positioned at a sea-facing side and inner walls (5) which are positioned at a port-facing side, central baffle plates (6) which are arranged on axial lines of the caissons (3) are arranged between the outer walls (4) and the inner walls (5), the caissons (3) are also internally provided with horizontal plates (7), the central axis of each caisson (3) is an arc line, and two axial ends of multiple caissons (3) are connected into an integrated structure through connecting pieces (8). The arc-shaped transparent breakwater disclosed by the invention is simple in structure, ingenious in design, low in cost and convenient and fast in construction, and has a good wave absorbing effect.

Owner:DALIAN UNIV OF TECH

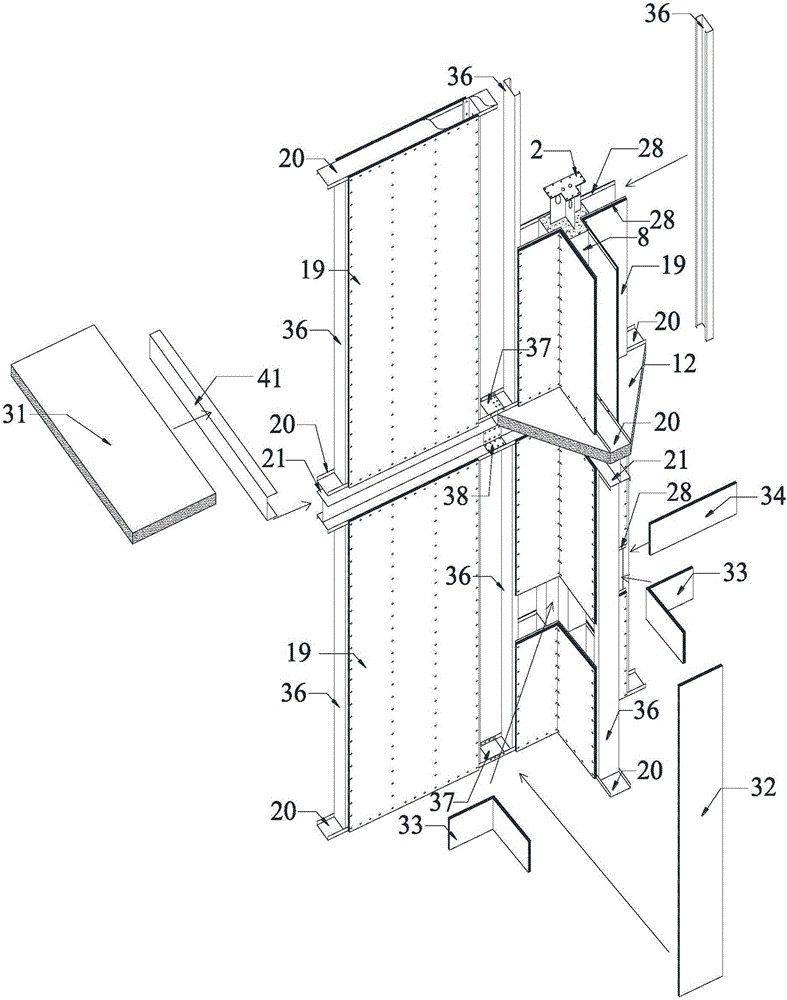

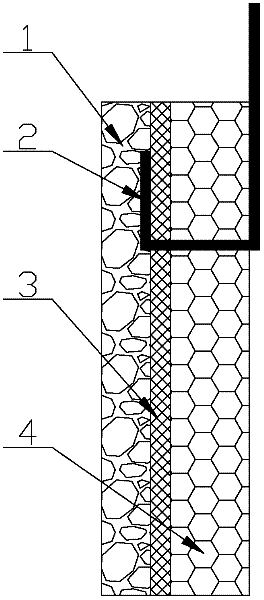

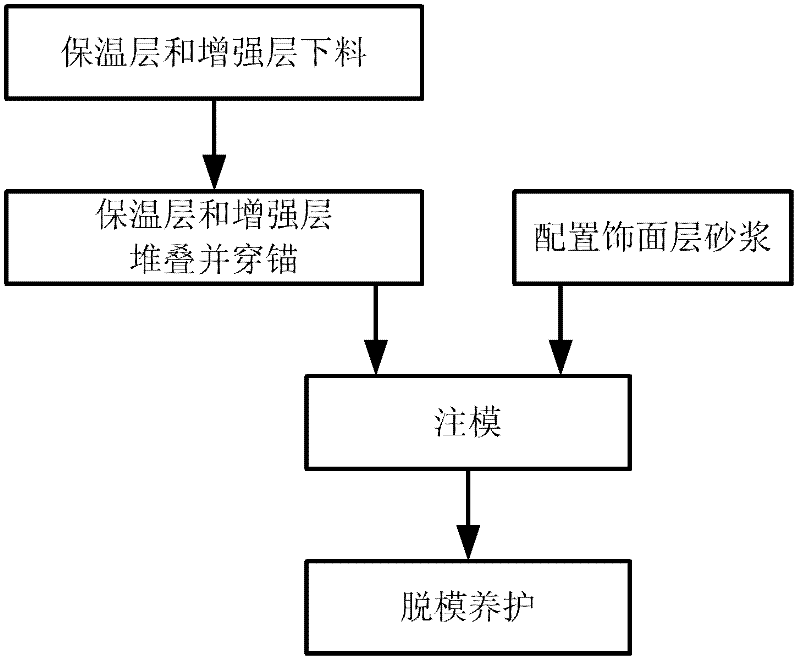

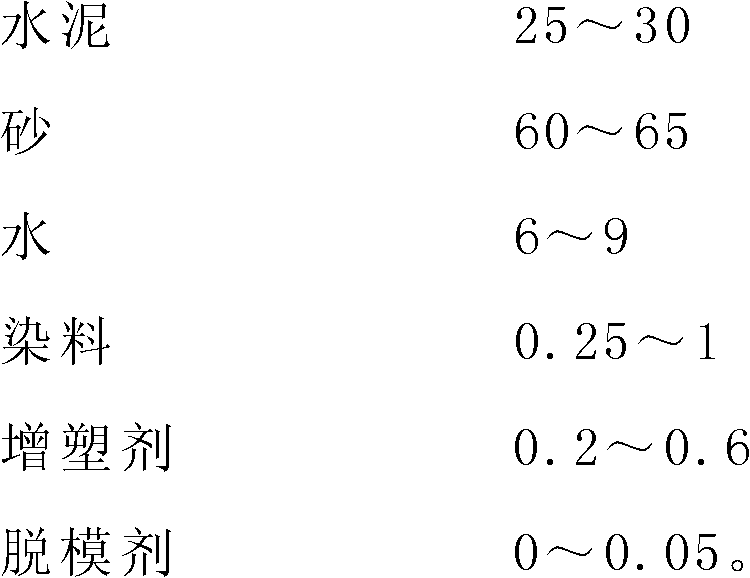

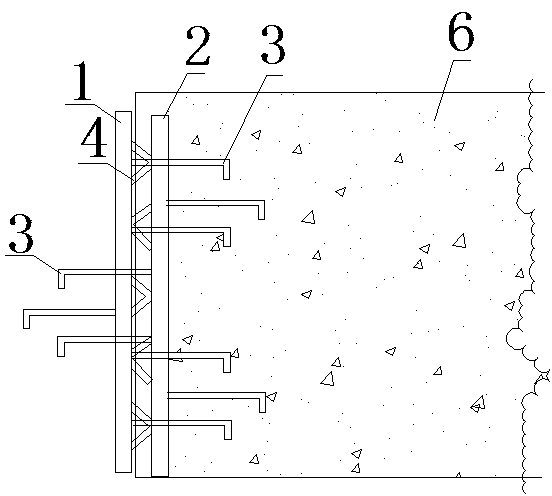

Thermal insulation decorative composite board and manufacturing method thereof

InactiveCN102409822ASimplify on-site construction proceduresReduce construction costsCovering/liningsLaminationSurface layerThermal insulation

The invention discloses a thermal insulation decorative composite board, which comprises a decorative surface layer, an enhanced layer and a thermal insulation layer. The thermal insulation decorative composite board is also internally embedded with an anchor bolt. One end of the anchor bolt is embedded in the decorative surface layer while the other end of the anchor bolt permeates out from the enhanced layer and the thermal insulation layer to be anchored onto a basic unit wall body of a building. The thermal insulation decorative composite board disclosed by the invention integrates the thermal insulation layer with the decorative surface layer so that on-site construction procedure is simplified greatly, construction cost is reduced and construction period is shortened.

Owner:张鹏

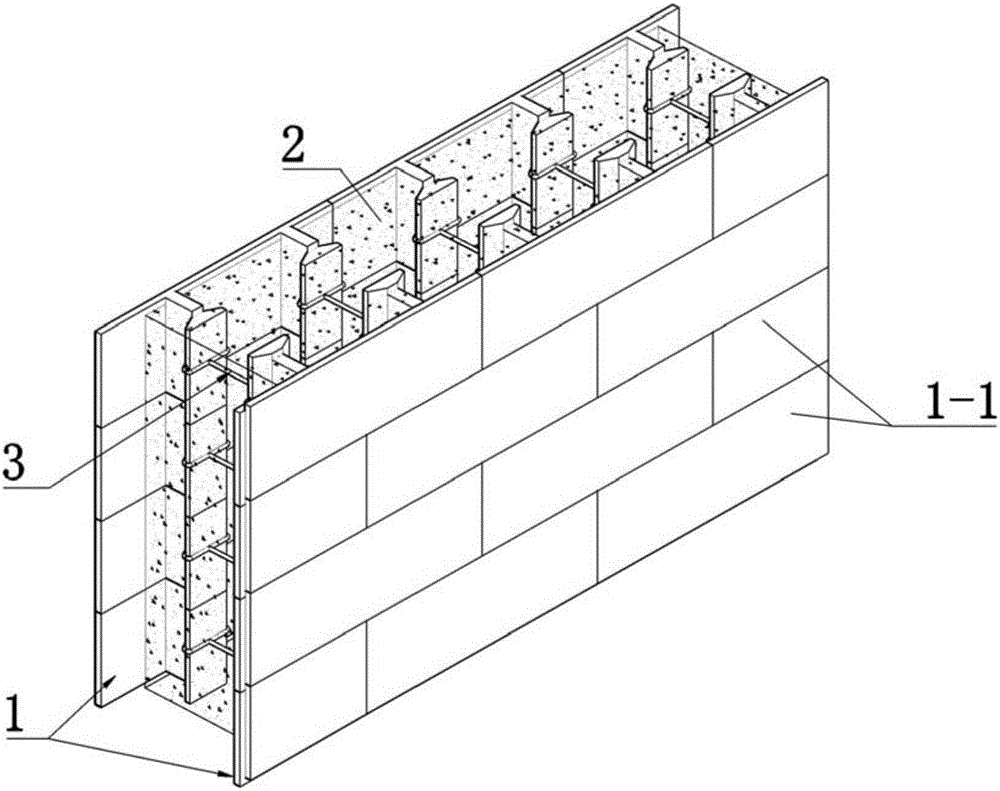

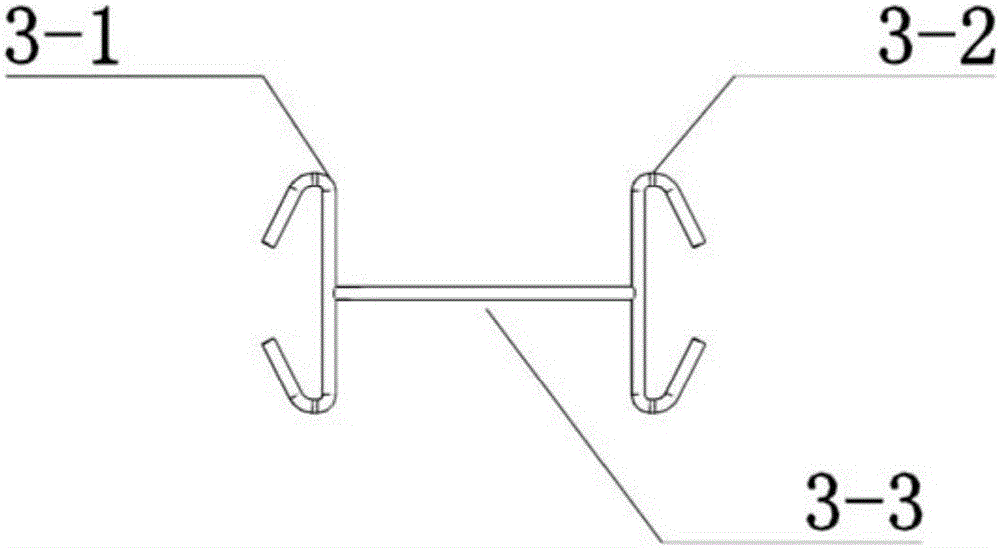

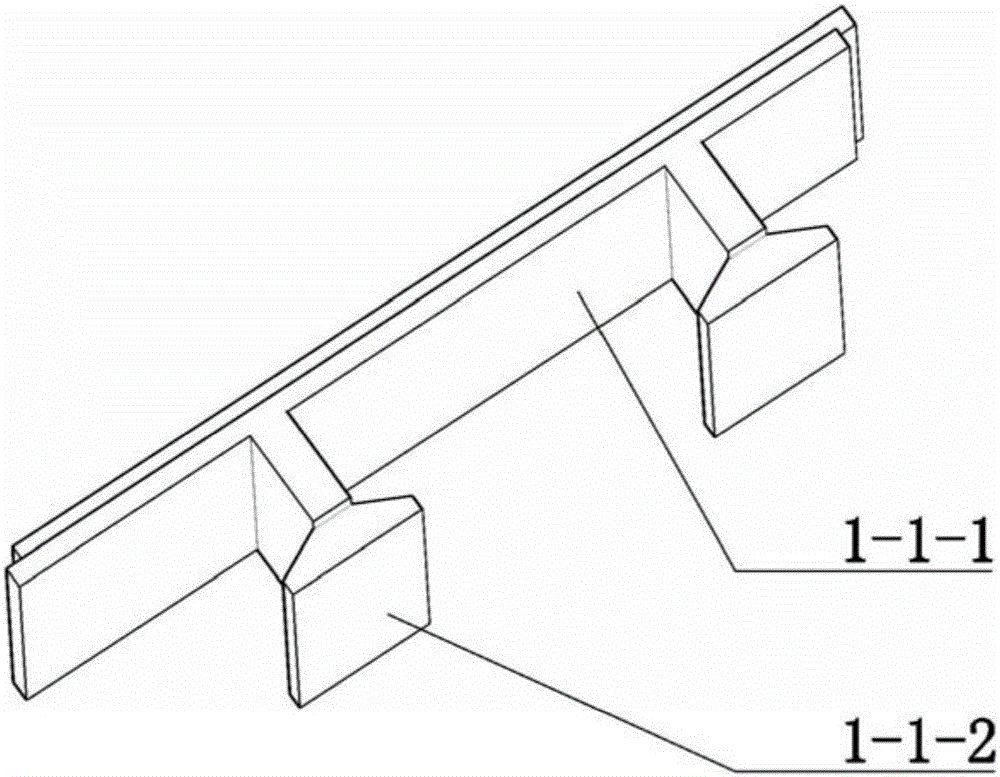

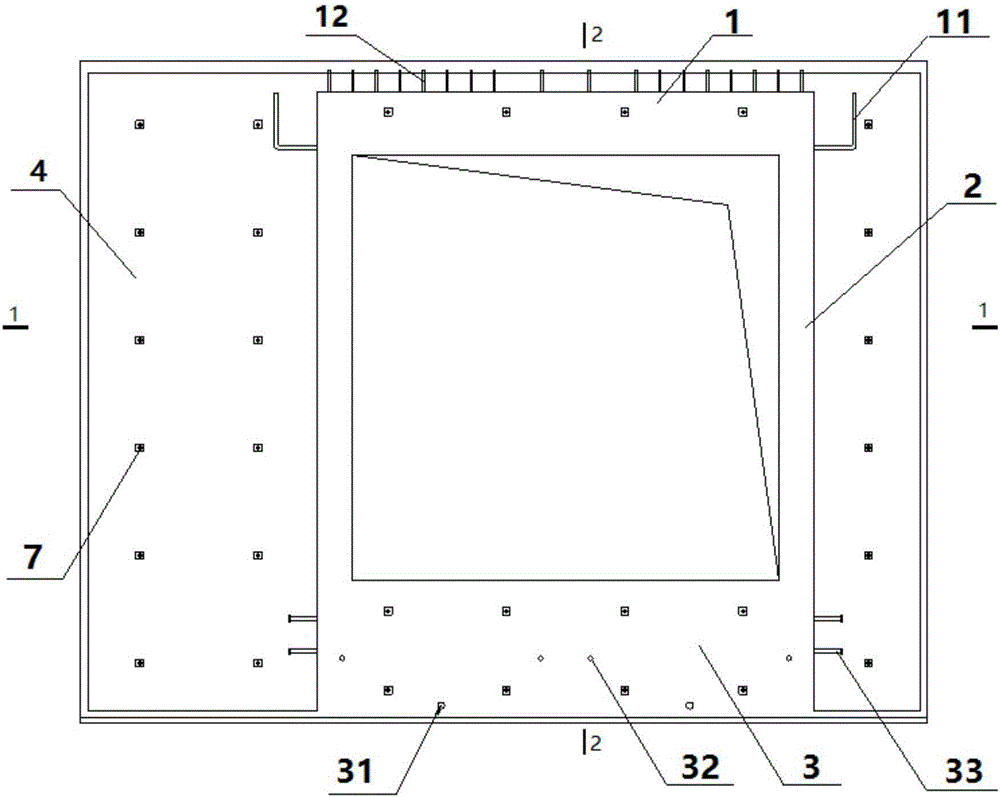

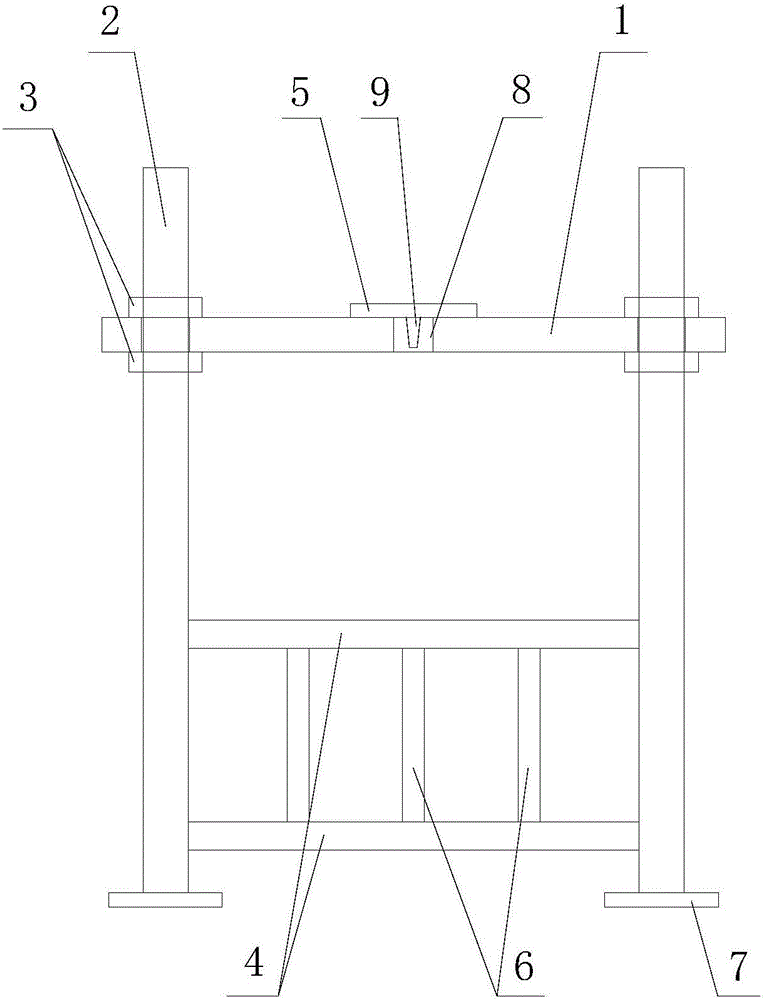

Composite rammed-earth wall, template device adopted in construction thereof and construction method thereof

InactiveCN105804294AHigh strengthPlay a protective effectWallsBuilding material handlingArray data structureWeather resistance

The invention relates to a composite rammed-earth wall, a template device adopted in the construction thereof and a construction method thereof. The wall comprises two wallboards which are arranged in a mirror symmetry manner and a rammed-earth main body filling between the two wallboards, wherein each wallboard is formed by splicing a plurality of unit wallboards according to a way of multiple layers in a vertical direction and multiple wallboards at each layer, each unit wallboard is of a reinforced concrete structure, and a reinforced bar connection part is arranged between every two opposite unit wallboards; a template structure comprises wall templates arranged on two surfaces, side baffle plates arranged at two sides and a plurality of groups of template fixing assemblies, wherein the wall templates on two surfaces form the two wallboards, during the construction process of the wall, the side baffle plates at two sides temporarily limit two sides of filled rammed earth, and the plurality of groups of template fixing assemblies are detachably clamped on the upper end parts of the two wall templates. The construction method comprises: performing construction by adopting the template device, first ramming a first layer of the wall, and then gradually ramming the wall upwards layer by layer until a set height of the wall is achieved. The rammed composite wall is relatively high in strength and relatively good in weather resistance and durability.

Owner:TIANJIN CHENGJIAN UNIV

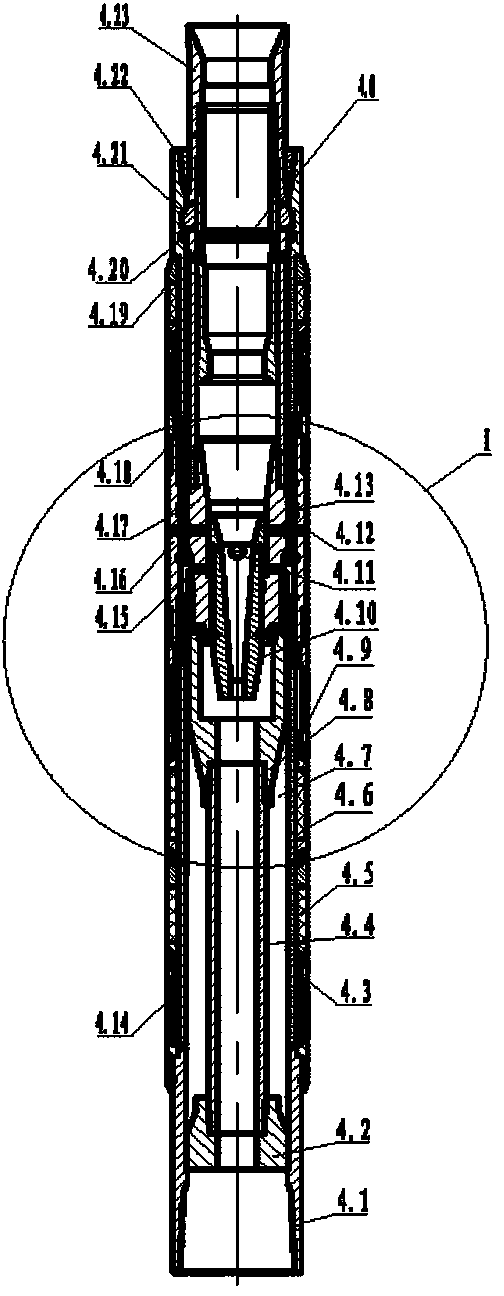

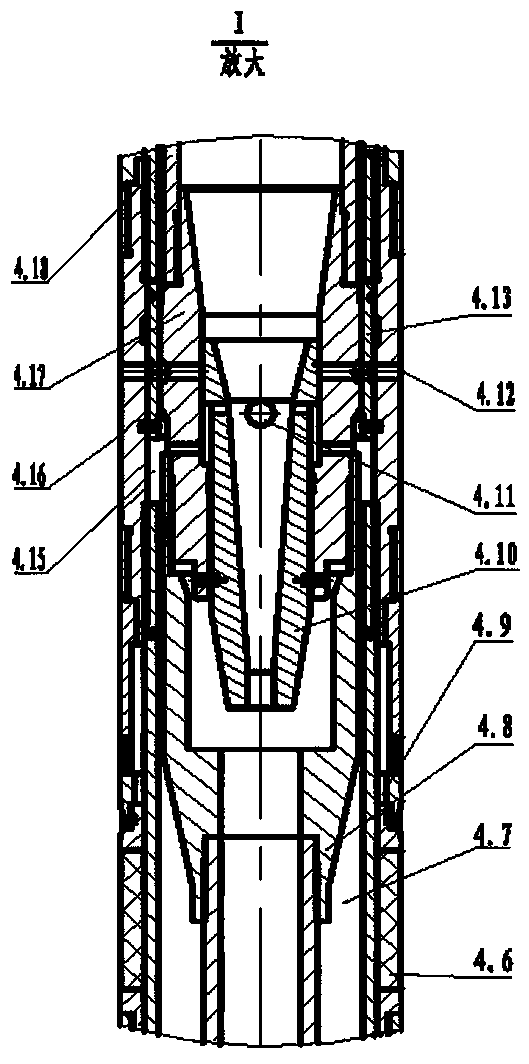

Top well cementation method and device for self-communicated double-process screen pipe

InactiveCN104343413AReduce collapseReduce riskWell/borehole valve arrangementsSealing/packingEngineeringCasing string

The invention discloses a top well cementation method and device for a self-communicated double-process screen pipe, and the top well cementation method and device are suitable for a top well cementation and completion process of a screen pipe of an oil-gas well. The method comprises the following steps: connecting an intermediate casing (1), a screen pipe (3), a casing (2), a self-communicated screen pipe top well cementation device (4), a screen pipe (5), an upper external packer (6), a lower external packer (7) and a pickling circulation valve (8) as designed; lowering to a well along with a casing string; circulating mud at an interval in the process of lowering the casing; throwing balls for keeping the pressure after putting in place to expand and seal a lower rubber barrel (4.5) and an upper rubber barrel (4.6) of a packer of the self-communicated screen pipe top well cementation device (4); keeping the pressure for opening the well cementation hole (4.12) of the self-communicated screen pipe top well cementation device (4); circularly performing well cementation; generating colliding pressure; continuing to keep the temperature; releasing the pressure; lowering a fishing spear to fish out a self-communicated inner pipe (4.0) of the self-communicated screen pipe top well cementation device (4); communicating the screen pipe (3) with the inside of the casing (1), so that the top well cementation and completion process of the screen pipe (3) is finished. According to the method, the mud can be circulated after the casing is lowered to the well, so that the risk of hole-wall collapsing and resistance meeting is lowered; the casing is communicated with the screen pipe after the colliding pressure is generated, so that the piston effect is removed and the success rate of fishing is increased.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

Prefabricated PCFexternal wall board with window frame and installing method thereof

ActiveCN106436972AReduce in quantityImprove waterproof performanceWallsBuilding material handlingGroutBuilding construction

The invention disclosesa prefabricated PCF external wall board with a window frame and an installing method thereof. The wall board comprises a superposed beamprefabricated portion, the window frame, a window lower wall and a PCF external sash board extending towards the periphery of the window frame, wherein window side edge boards are arranged on the left and right side edges of the window frame, the superposed beam prefabricated portion is located at the upper portion of the window frame, and the PCF external sash board upward extending of the window frame is located on the outer side of the superposed beam prefabricated portion. The window lower wall is located at the lower portion of the window frame, the inner side of the window lower wall is an inner sash board, and the PCF external sash board downward extending of the window frame is located on the outer side of the inner sash board of the window lower wall. A grouted layer is arranged below the window lower wall, the window lower wall is provided with a grouting hole and a grout outlet hole, and the grouting hole and the grout outlet hole are communicated with the grouted layer. A site construction process can be simplified, the site construction time can be shortened, and the advantages of prefabricated parts can be fully played. In addition, connection between the window frame and peripheral members is reliable, the waterproof performance of the window frame is superior, and the water seepagehidden danger of a window can be completely eradicated.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

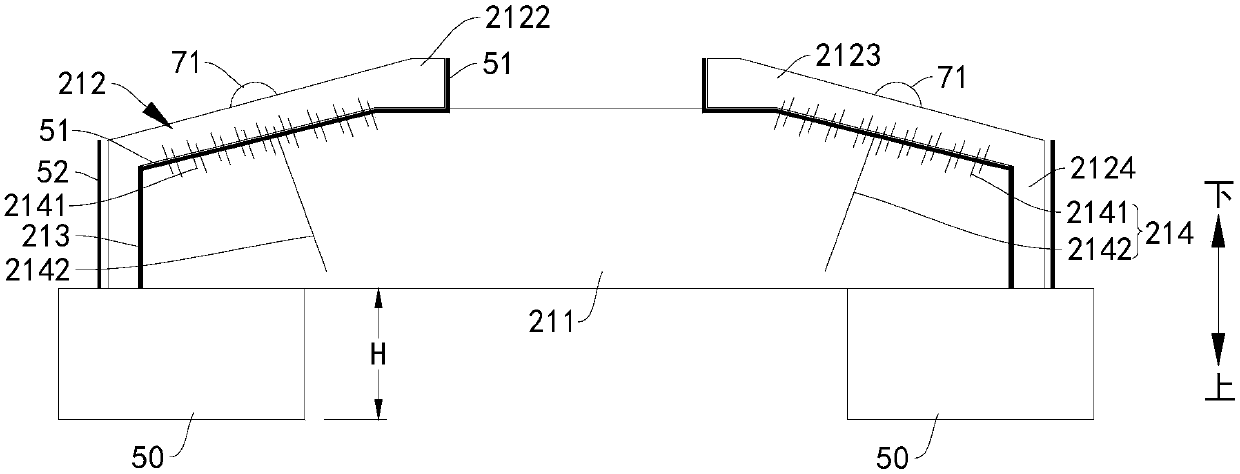

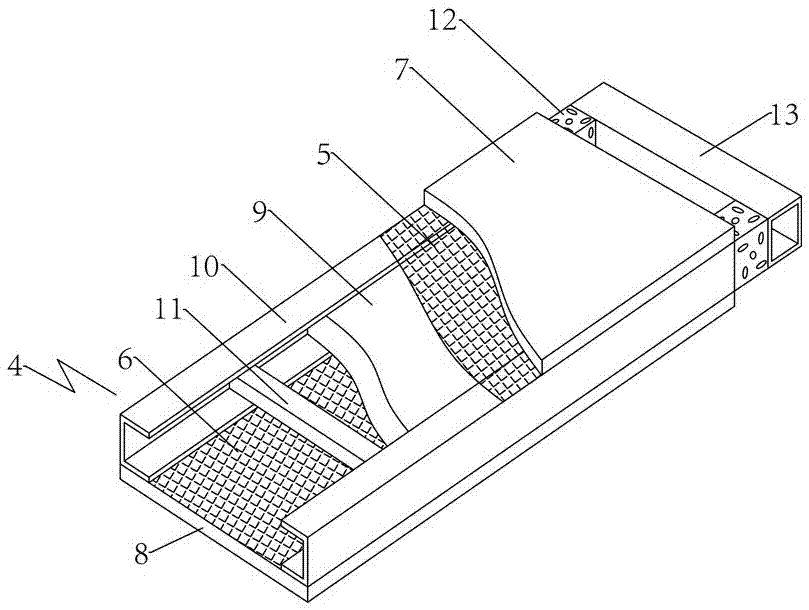

Ultra-high-performance concrete-partial profile steel combined beam unit, ultra-high-performance concrete-profile steel combined beam unit and combined beam

PendingCN110331648AImprove continuityImprove carrying capacityBridge structural detailsConcrete beamsStructural engineering

The invention discloses an ultra-high-performance concrete-partial profile steel combined beam unit. An ultra-high-performance concrete beam comprises a top plate, a web and a bottom plate, half notches are formed in the ends of the top plate, a top plate reinforcing steel plate which is arranged in the longitudinal direction of a bridge is arranged at each of the half notches, one ends of the topplate reinforcing steel plates are fixedly arranged in the top plate, and the other ends of the top plate reinforcing steel plates extend out of the end of the top plate, a web reinforcing steel plate which is arranged in the longitudinal direction of the bridge is arranged in the web, one end of the web reinforcing steel plate is fixedly arranged in the web, and the other end of the web reinforcing steel plate extends out of the end of the web. The invention further provides an ultra-high-performance concrete-profile steel combined beam unit. The invention further provides a combined beam formed by connecting the two beam units. By means of the ultra-high-performance concrete-partial profile steel combined beam unit or the ultra-high-performance concrete-profile steel combined beam unit,the connection structure at the joint of the adjacent beam units is simple and reasonable, and the stress performance is excellent.

Owner:HUNAN UNIV

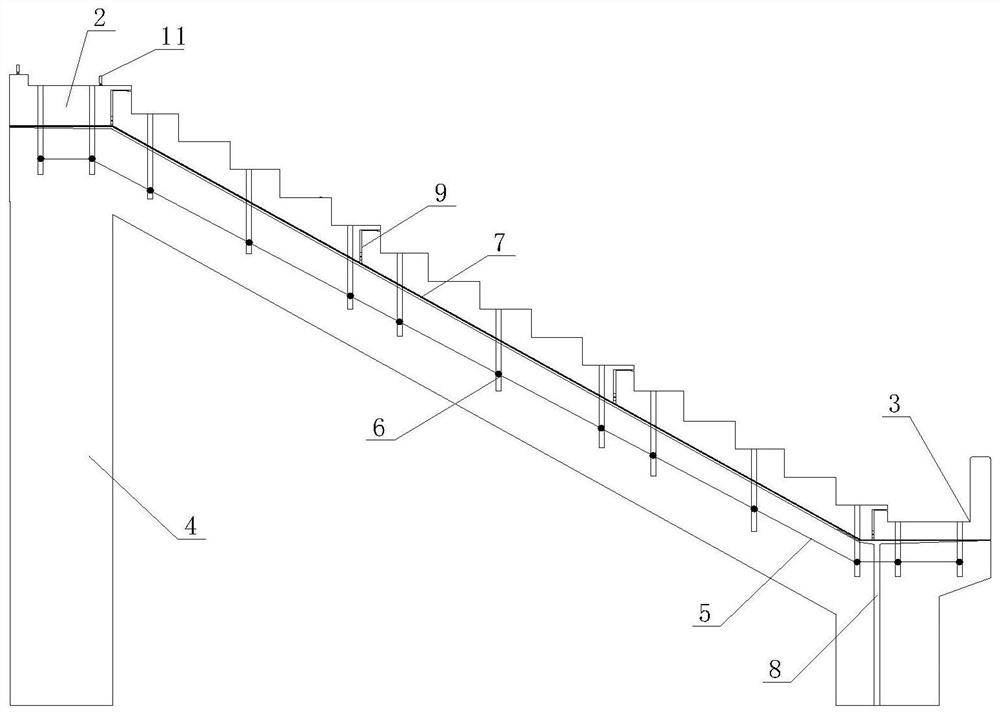

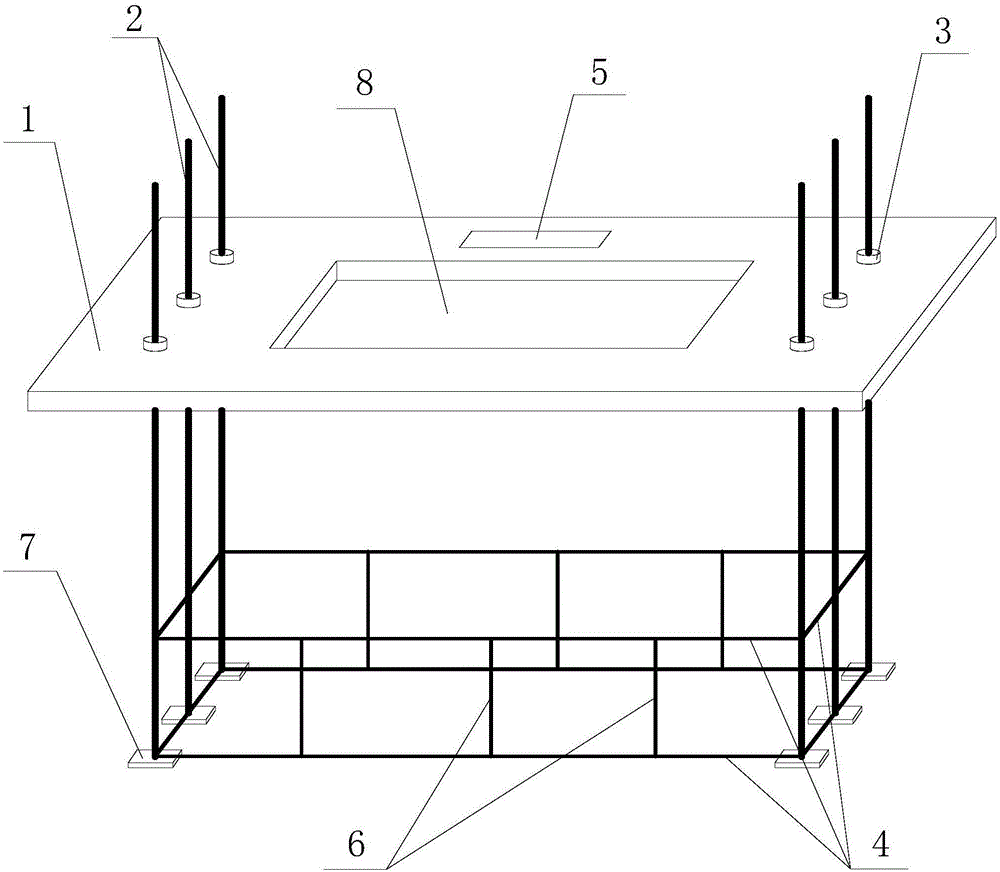

Large-scale venue assembly type combined prefabricated stand

PendingCN111827736AQuality assuranceEnsure safetyDucting arrangementsGrandstandsStructural engineeringMechanical engineering

The invention discloses a large-scale venue assembly type combined prefabricated stand, and belongs to the technical field of large-scale arena construction. The stand comprises a prefabricated stand,a prefabricated middle aisle platform and a prefabricated platform with an apron, and further comprises a lower supporting structure, wherein the prefabricated stand, the prefabricated middle aisle platform and the prefabricated platform with the apron are sequentially connected to the lower supporting structure from top to bottom, the front end of the prefabricated stand is spliced with the prefabricated middle aisle platform, the rear end of the prefabricated stand is spliced with the prefabricated platform with the apron, an air supply system is arranged in the prefabricated stand, the airsupply system comprises rear seat air supply ports, an air supply system main interface and a built-in air supply main ring pipe, the plurality of rear seat air supply ports are arranged at equal intervals, the rear seat air supply ports, the air supply system main interface and the built-in air supply main ring pipe are connected to form a loop, and back reverse ridge beam and prefabricated lifting points are arranged on the prefabricated middle aisle platform and the prefabricated platform with the apron. Construction period is greatly saved, quality and safety of components can be ensured,and quality of pre-burying work can be guaranteed.

Owner:CHINA MCC17 GRP

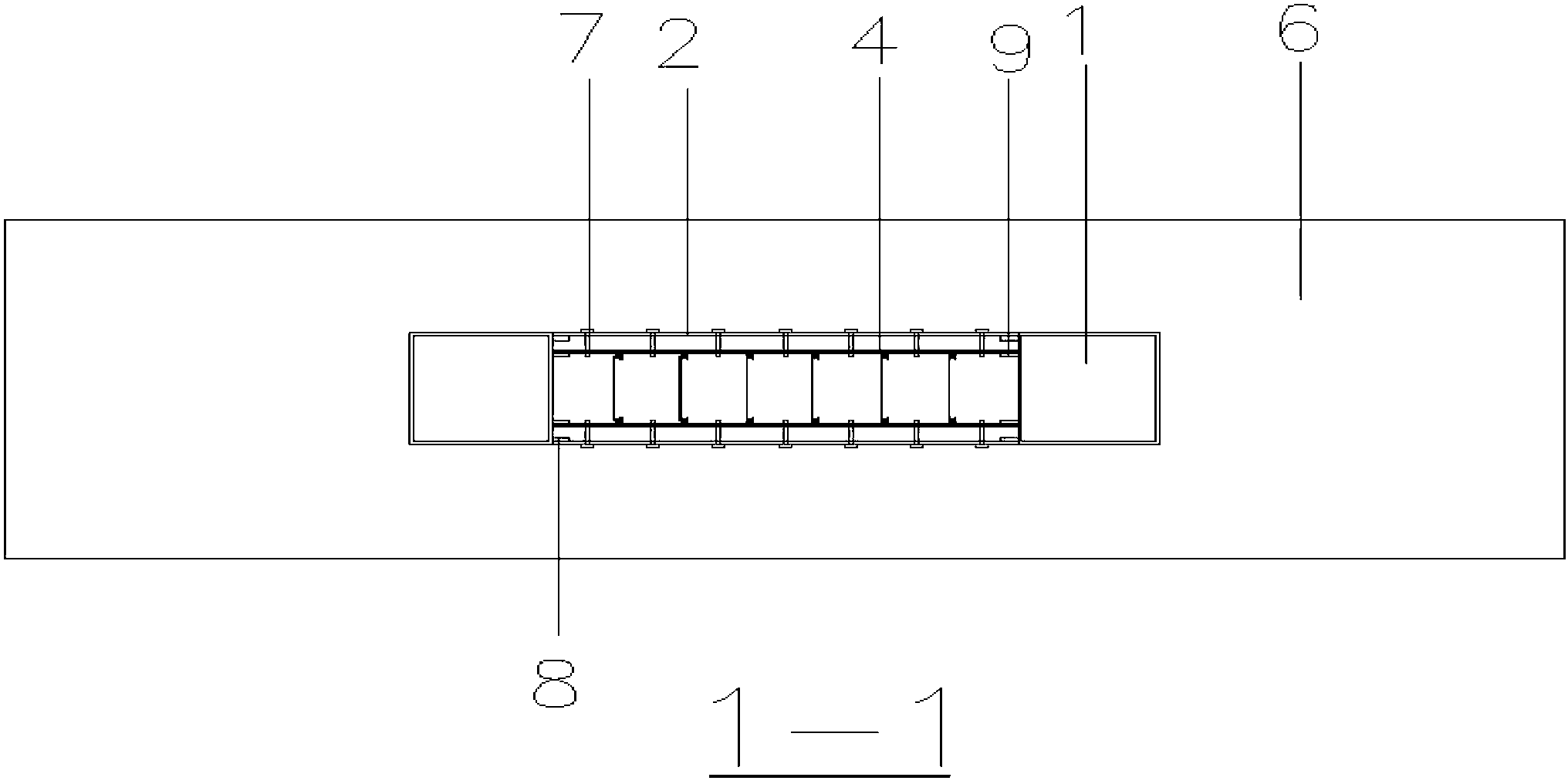

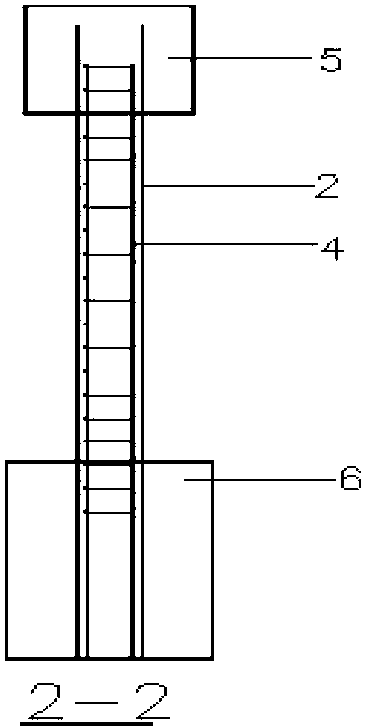

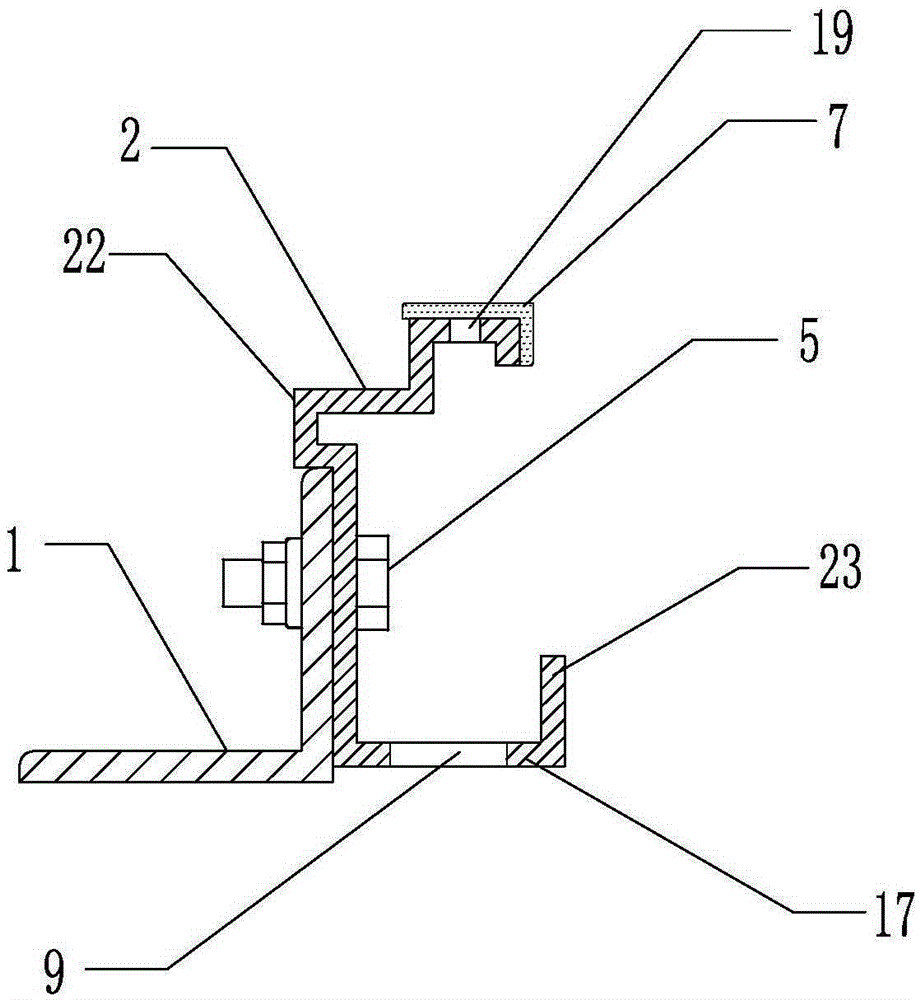

Large-specification veneer aluminum plate showing wall installation system and construction method thereof

ActiveCN105401707AAdjust flatnessLarge adjustment rangeCovering/liningsBuilding material handlingEngineeringEdge matching

The invention discloses a large-specification veneer aluminum plate showing wall installation system and a construction method thereof. The large-specification veneer aluminum plate showing wall installation system comprises base layer frameworks, a plurality of connecting assemblies and an aluminum plate and is characterized in that the connecting assemblies comprise corner brace connecting fixing pieces and leveling movable fixing pieces; the corner brace connecting fixing pieces are connected with angle steel through anchor bolts; the angle steel is fixed to the base layer frameworks; folded edges are arranged at the upper ends and the lower ends of the corner brace connecting fixing pieces; the folded edges at one ends are provided with fixing holes, and the folded edges at the other ends are provided with adjusting holes; one sides of the leveling movable fixing pieces are fixed to the aluminum plate through aluminum plate fixing pieces, and the upper ends and the lower ends of the other sides of the leveling movable fixing pieces are connected with connecting edges matched with the folded edges of the corner brace connecting fixing pieces; and the corner brace connecting fixing pieces and the leveling movable fixing pieces are fixed through bolts. According to the large-specification veneer aluminum plate showing wall installation system and the construction method thereof, the leveling movable fixing pieces are horizontally moved by a distance relative to the corner brace connecting fixing pieces so that leveling of the flatness of the aluminum plate can be achieved; and operation is convenient, flexibility is high, and the overall effect of a wall face can be easily improved.

Owner:苏州苏明装饰股份有限公司

Double-column wave-dissipating body one-time prefabricating construction method

ActiveCN103171052ASimplify on-site construction proceduresImprove work efficiencyBreakwatersQuaysMaterials scienceBuilding construction

The invention discloses a double-column wave-dissipating body one-time prefabricating construction method which comprises the following steps: (1) prefabricating a concrete bottom tire; (2) paying off and bottoming; (3) binding steel bars; (4) erecting a template; (5) hoisting top steel bars; (6) reserving a lifting hole; (7) grouting the template; (8) concrete pouring; (9) removing the template; and (10) maintaining. According to the double-column wave-dissipating body one-time prefabricating construction method, by adoption of the one-time casting molding of set combined spliced steel template, the novel lifting design and the grouting method, the field construction process is simplified, various quality problems in the traditional prefabricating process for the double-column wave-dissipating body are solved, the working efficiency is improved, the cost is saved, and an obvious effect is achieved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

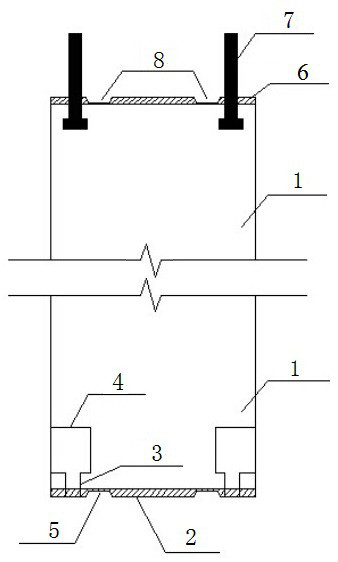

Prefabricated building

PendingCN107700747AImprove integrityImprove seismic performanceBuilding componentsFloor slabArchitectural engineering

The invention provides a prefabricated building which comprises wall assemblies mounted on a building foundation. A floor slab assembly is arranged between every two layers of wall assemblies. A roofboard assembly is arranged at the top end of the wall assembly at the uppermost layer. Each wall assembly comprises an outer wall prefabricated component and inner wall prefabricated components used for dividing the interior of the building into a plurality of rooms. Each floor slab assembly comprises a floor slab prefabricated component arranged corresponding to the top end of each room. Door openings or window openings are reserved in the outer wall prefabricated components or the inner wall prefabricated components corresponding to the positions, where doors and windows need to be arranged,of the building. The wall assemblies, the floor slab assemblies and the roof board assembly all adopt prefabricated components, on-site rapid assembling can be achieved, using reliability is high, durability is good, impact resistance is high, materials are effectively saved, and the weight is reduced; and on-site construction procedures are simplified.

Owner:华声(天津)国际企业有限公司

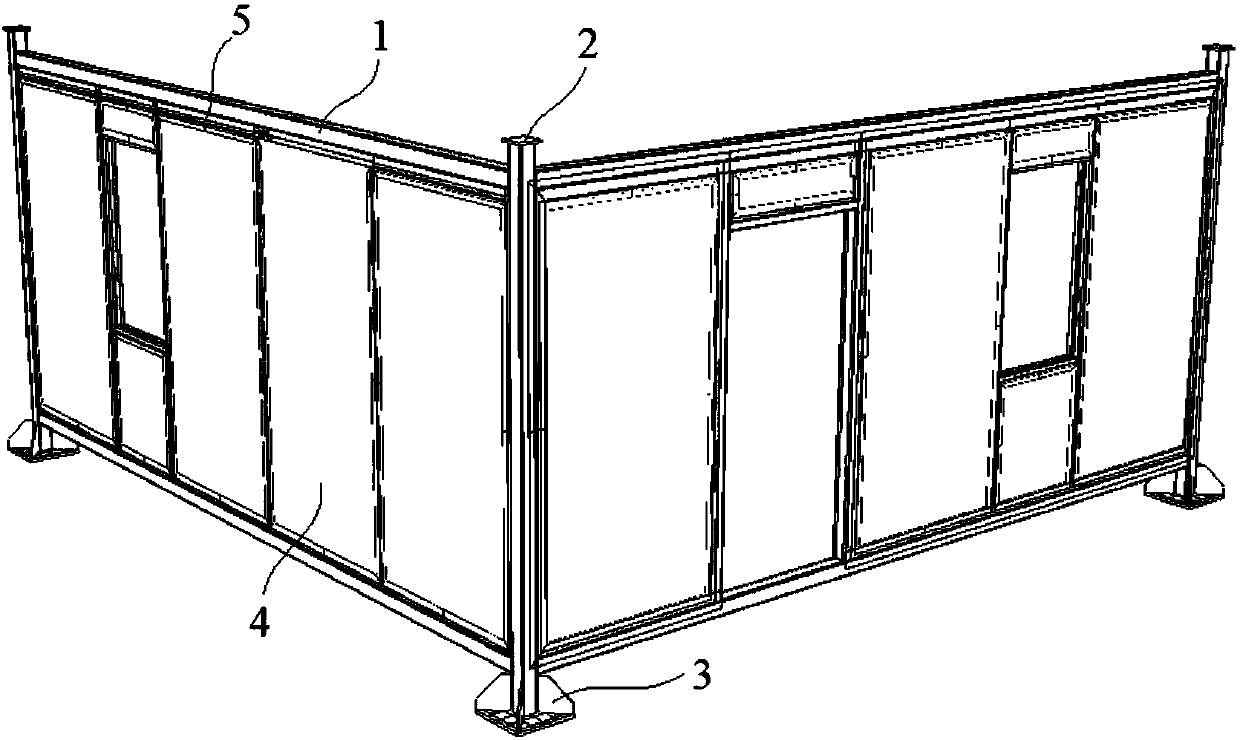

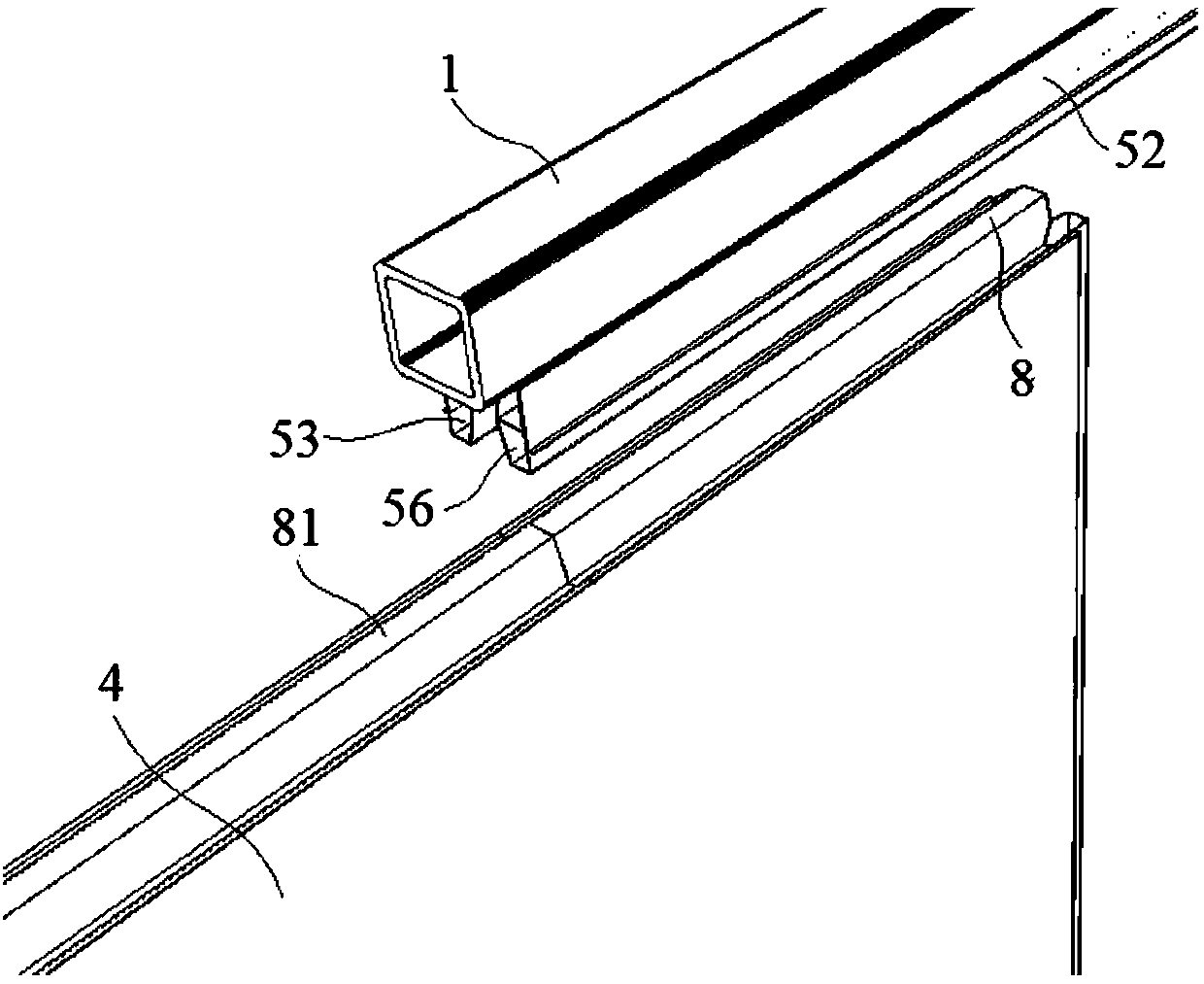

Assembly type house with composite environment-friendly wall boards

The invention discloses an assembly type house with composite environment-friendly wall boards. The assembly type house comprises steel beams, stand columns, bases and the wall boards, the stand columns are fixedly connected with the bases, and the two ends of each steel beam are fixedly connected with the corresponding stand columns respectively so as to make the two adjacent stand columns connected; the upper surface of a U-shaped keel is arched to form a protruding part; the long bottom surface of each steel pipe is a connecting surface, and the short bottom surfaces of the two steel pipesare the upper and lower bottom surfaces of an inner joint or an outer joint respectively; the lower end of each first steel plate is provided with a first stop strip which is bent outwards, and mounting keels used for being connected with connecting mechanisms are arranged on the upper portions of the wall boards; each mounting keel is in an inverted U shape, and the center of the upper surface ofa protruding block of each mounting keel is sunken downwards to form a second filling groove; first filling grooves and the second filling grooves are filled with rubber pads. According to the house,reliable connection between unit systems is achieved through prefabricated parts, the working procedures of field construction are simplified, the construction period is shortened, and a lot of laborcost is reduced.

Owner:苏州阳地钢装配式建筑技术有限公司

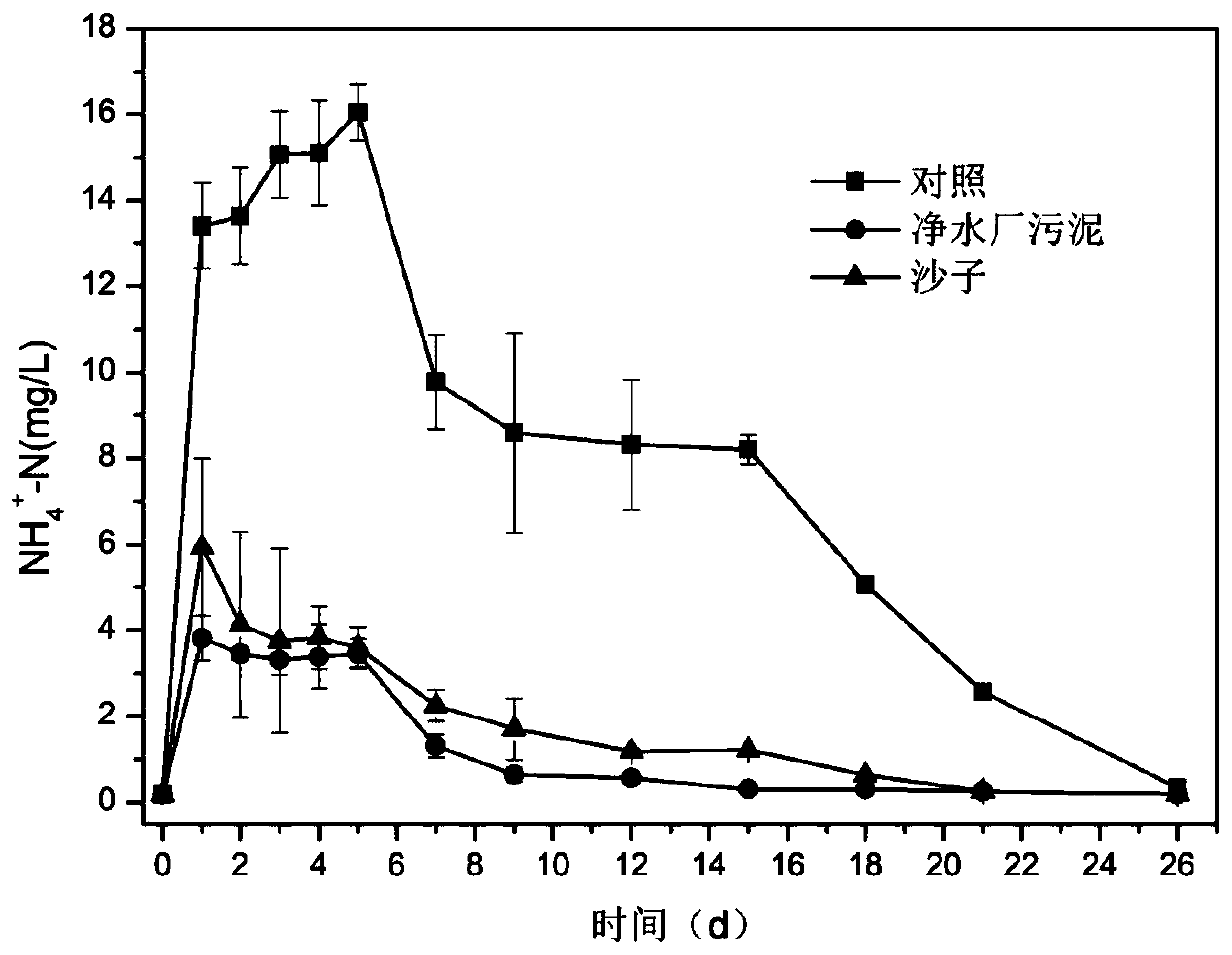

Preparation method of urban river polluted bottom mud active covering plate

ActiveCN110152591AGood water permeabilityImprove water retentionWater treatment parameter controlSludge treatmentMechanical crushingEngineering

The invention discloses a preparation method of an urban river polluted bottom mud active covering plate. The preparation method comprises the following steps: (1) collecting sludge of water purification plants to prepare sludge cakes, and calcining the sludge cakes at 380-450 DEG C for 3.5-4.5 hours to prepare sludge blocks; (2) carrying out mechanical crushing and mechanical vibration screeningon the sludge blocks to prepare the calcining modified sludge particles with a particle size of 1-5 mm; (3) adding 17-18 parts of the calcining modified sludge particles, 4-6 parts of cement and 5-8 parts of fly ash into a stirrer according to a water-cement ratio of 0.26-0.29, uniformly carrying out mixing, and carrying out standing to enable the aggregate and the binder to be fully mixed; (4) adding the stirred bottom material into a mold frame for pressing, wherein the pressing time is 60-80 seconds, and the pressing pressure is 0.75-0.8 MPa; (5) carrying out demolding to obtain a coveringplate 12-16 hours after compression molding; and (6) standing the covering plate finished product under a natural outdoor condition at a temperature of 20-25 DEG C for 12-16 days, wherein the obtainedcovering plate can be used for engineering application. The covering plate prepared by the method has the advantages of good water permeability, high water retention, washing resistance and the like.

Owner:HUAQIAO UNIVERSITY

Prefabricated underground diaphragm wall, segmented connector structure and construction method

PendingCN111705783AImprove integrityEasy to tightenBulkheads/pilesSlurry wallArchitectural engineering

The invention belongs to the technical field of foundation pit engineering and particularly relates to a prefabricated underground diaphragm wall. A first embedded steel plate and a second embedded steel plate are laid at the two ends of a prefabricated underground diaphragm wall body correspondingly. Multiple bolt holes are reserved in one end of the prefabricated underground diagram wall body, multiple bolts are embedded in the other end of the prefabricated underground diagram wall body, and one ends of the bolts penetrate the second embedded steel plate. Multiple hand holes are formed in the side wall of the prefabricated underground diagram wall body, and the multiple bolt holes communicate with the multiple hand holes. The invention further provides a segmented connector structure ofthe prefabricated underground diagram wall and a construction method of the segmented connector structure of the prefabricated underground diagram wall. The construction method includes the steps that the above prefabricated underground diaphragm wall is adopted as the previous-constructed prefabricated underground diaphragm wall and the posterior-constructed prefabricated underground diaphragm wall; the bolts on the previous-constructed prefabricated underground diaphragm wall penetrate the corresponding bolt holes of the posterior-constructed prefabricated underground diaphragm wall and then stretch into the corresponding hand holes to be fixed through nuts. A prefabricated assembly manner is adopted, the construction quality can be ensured, the field construction processes are simplified, and the construction efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

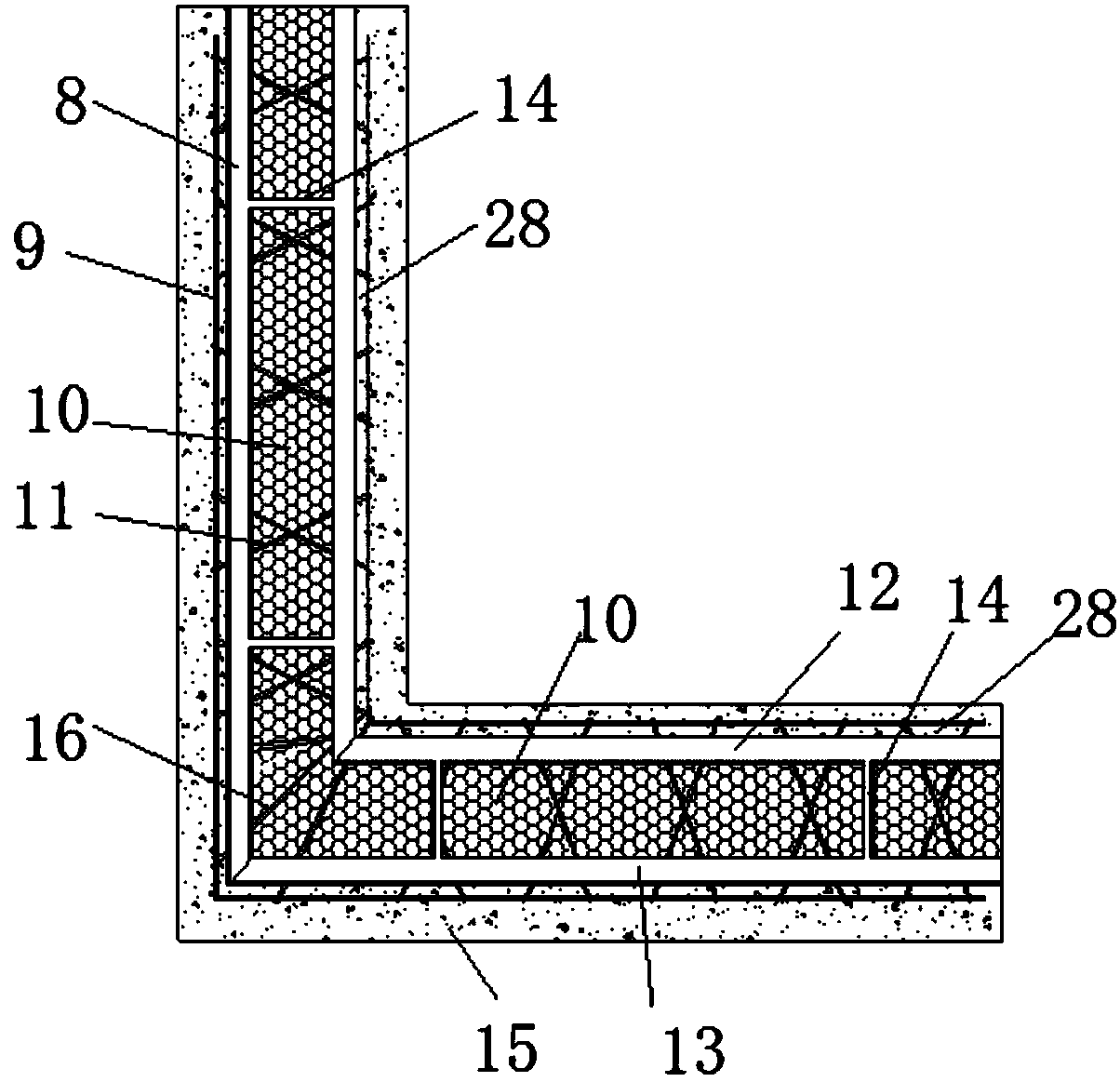

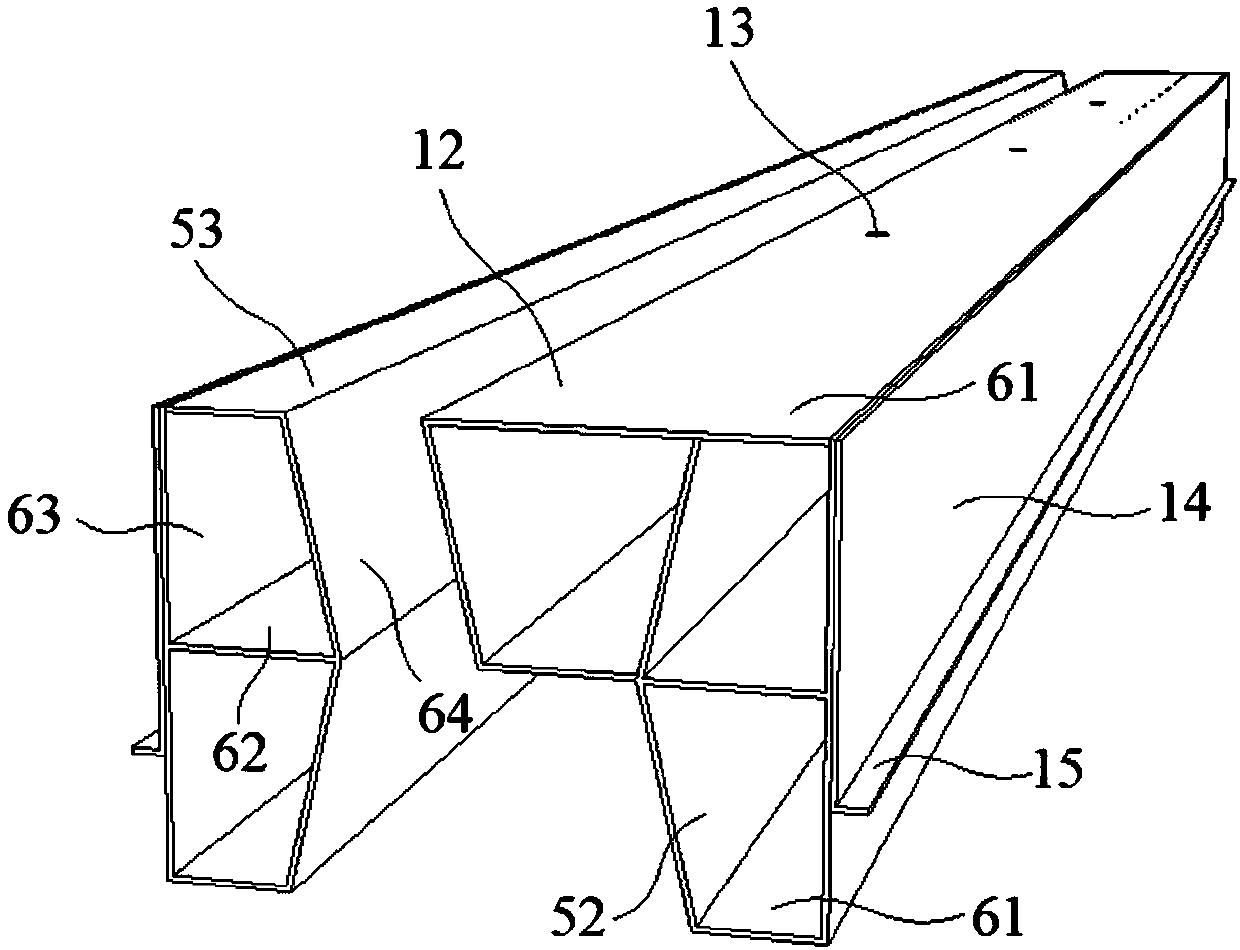

Lightweight assembled steel-structure house and building method thereof

The invention relates to a lightweight assembled steel-structure house and a building method thereof. The house comprises floors, walls, a door and windows, wherein each floor comprises a first steel-structure frame, a first reinforcing steel bar strainer, a first concrete layer, a second reinforcing steel bar strainer, a second concrete layer, a damping and sound-insulation layer and butt joint racks, the first reinforcing steel bar strainer and the first concrete layer are arranged on one side of the first steel-structure frame, the second reinforcing steel bar strainer and the second concrete layer are arranged on the other side of the first steel-structure frame, the damping and sound-insulation layer is arranged between the first reinforcing steel bar strainer and the second reinforcing steel bar strainer, and the butt joint racks are arranged at two ends of the first steel-structure frame; each wall comprises a second steel-structure frame, two layers of parallel reinforcing steel bar strainers arranged in the second steel-structure frame, a thermal-insulation layer arranged between the two layers of parallel reinforcing steel bar strainers, a cement outer wall layer and a fireproof inner wall layer, the cement outer wall layer and the fireproof inner wall layer are poured on two sides of the thermal-insulation layer, and the walls are connected through connecting columns. The lightweight assembled steel-structure house has the advantages that the walls, the floors and the connecting columns are prefabricated in factories, the walls are connected with the connecting columns through bolts, the walls are connected with the floors through bolts, field construction procedures are simplified, and construction efficiency and house quality are increased.

Owner:王立

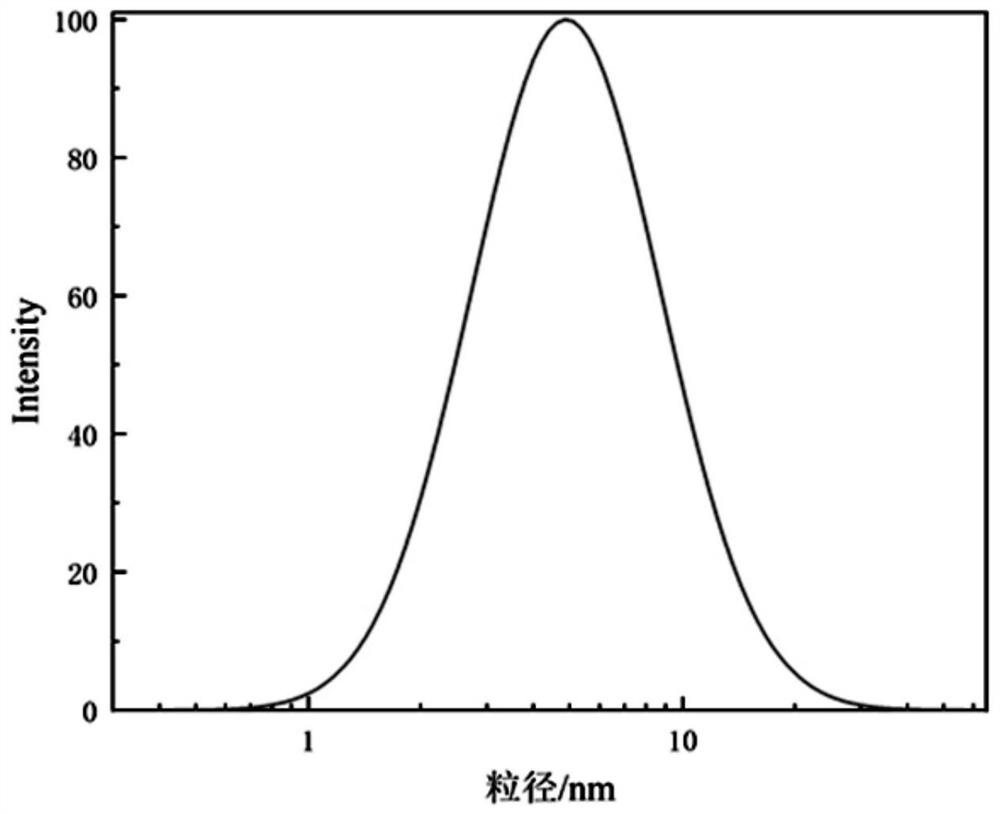

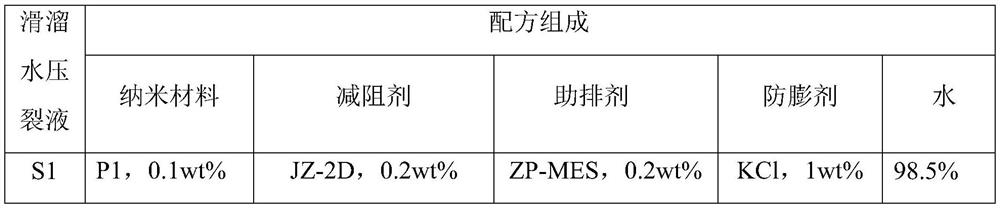

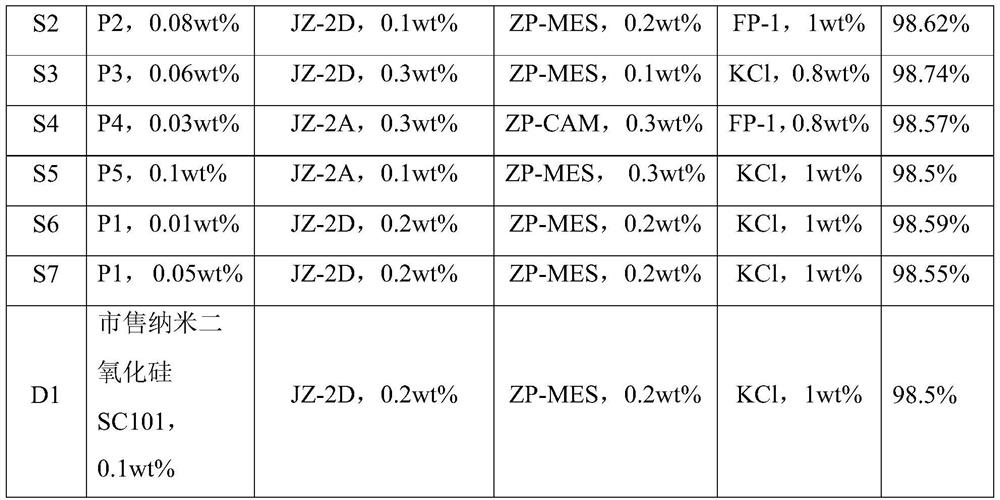

Nanometer silicon dioxide, nanometer composite slick water fracturing fluid and preparation method and application of nanometer silicon dioxide and nanometer composite slick water fracturing fluid

ActiveCN114106810AImprove the transformation effectLow equipment requirementsDrilling compositionFreeze-dryingSilicic acid

The invention relates to the field of oilfield chemistry, and discloses nano-silica, a nano-composite slick water fracturing fluid and a preparation method and application thereof.The preparation method of the nano-silica comprises the steps that 1, silicate ester, ethyl alcohol and water are subjected to a first reaction in the presence of acid, and an intermediate product system is obtained; and (2) carrying out a second reaction on the intermediate product system and dicarboxyl polyethylene glycol, and freeze-drying the obtained product to obtain the nano silicon dioxide. The nano-silica, a drag reducer, a discharge aiding agent, an anti-swelling agent and water are prepared into the nano-composite slickwater fracturing fluid with a specific formula, and the slickwater fracturing fluid has fracturing sand-carrying performance and imbibition oil discharge performance, and is high in drag reduction rate and excellent in temperature resistance and shear resistance.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

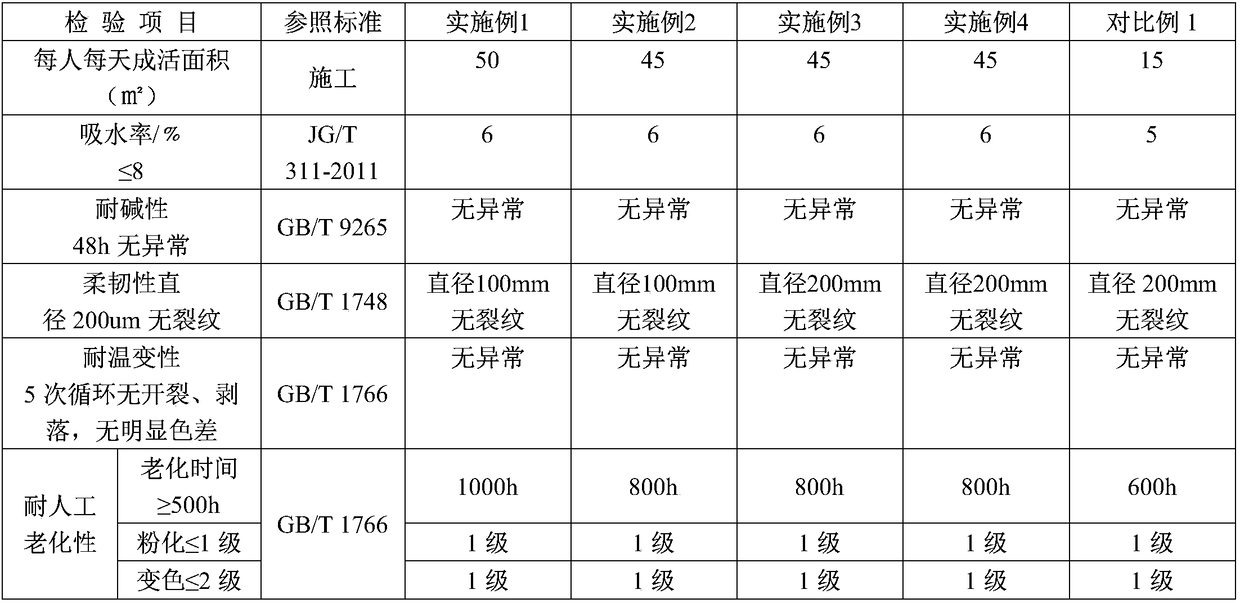

Construction technology for morbidezza soft rock finished product sticker for outer walls

ActiveCN108457389AImprove product qualitySimplify on-site construction proceduresClimate change adaptationHeat proofingPolystyreneRockdust

The invention provides a construction technology for a morbidezza soft rock finished product sticker for outer walls. The construction technology comprises the following processing steps that step a.basic surface preprocessing: dust and dirt which remain on the basic surface of the outer wall are swept, and a leveling putty is used for repairing hole bulges and cracking and dusting portions; stepb. polystyrene boards sticking: adhesive mortar is smeared on the sides of the polystyrene boards, and the sides, smeared by the adhesive mortar, of the polystyrene boards are stuck to the outer wallsurface; step c. fixing piece installation: fixing pieces for outer wall insulation boards are installed on the outer walls on which the polystyrene boards are stuck; step d. paving: the adhesive mortar is put on the inner surface of the morbidezza soft rock finished product sticker placed in alkali-resisting fiberglass grinding cloth, and the side, with the adhesive mortar, of the morbidezza soft rock finished product is stuck to the polystyrene boards. Construction steps in the traditional construction method are reduced, and the construction period of the whole project is one third of thatof the traditional construction technology.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

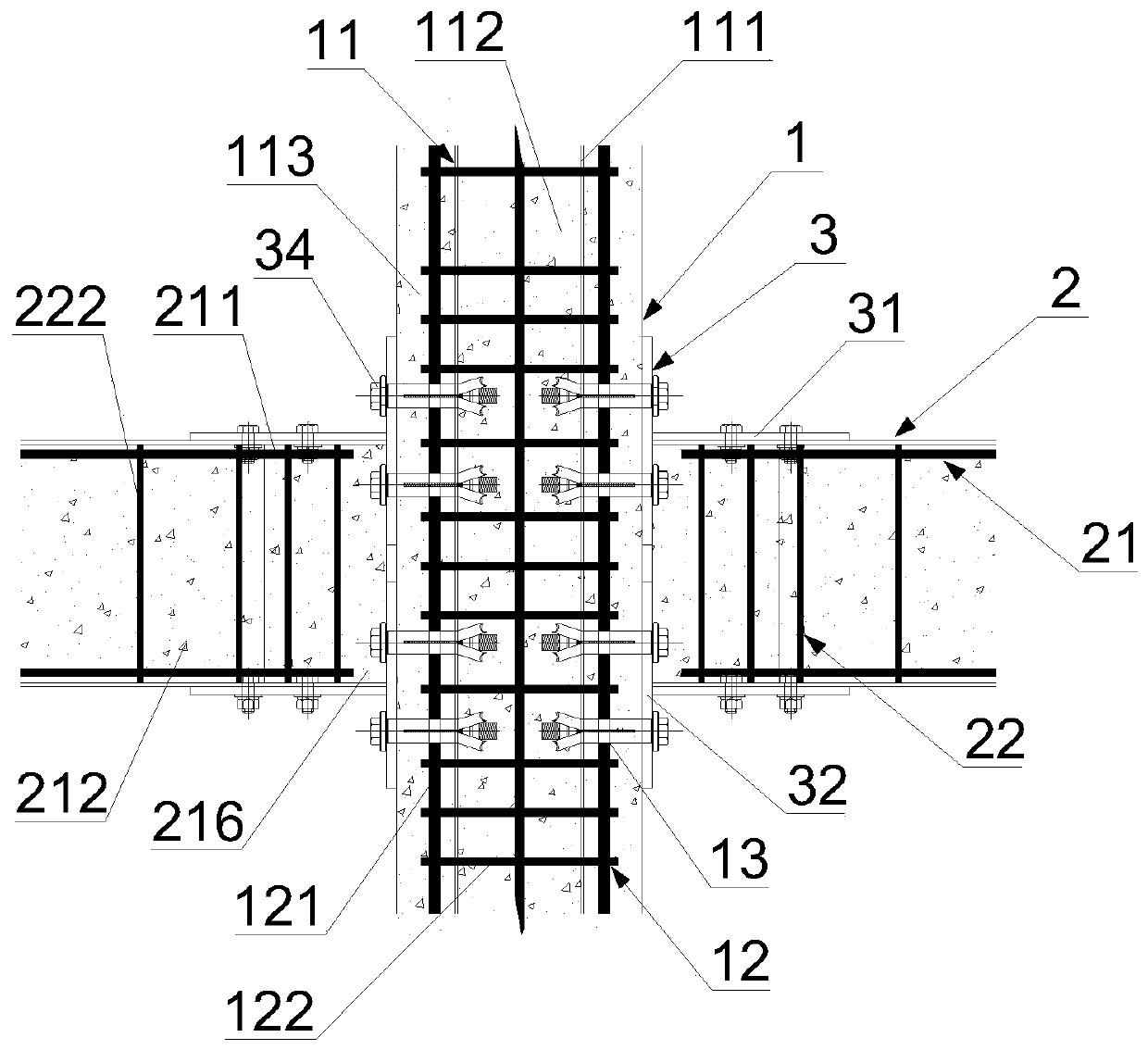

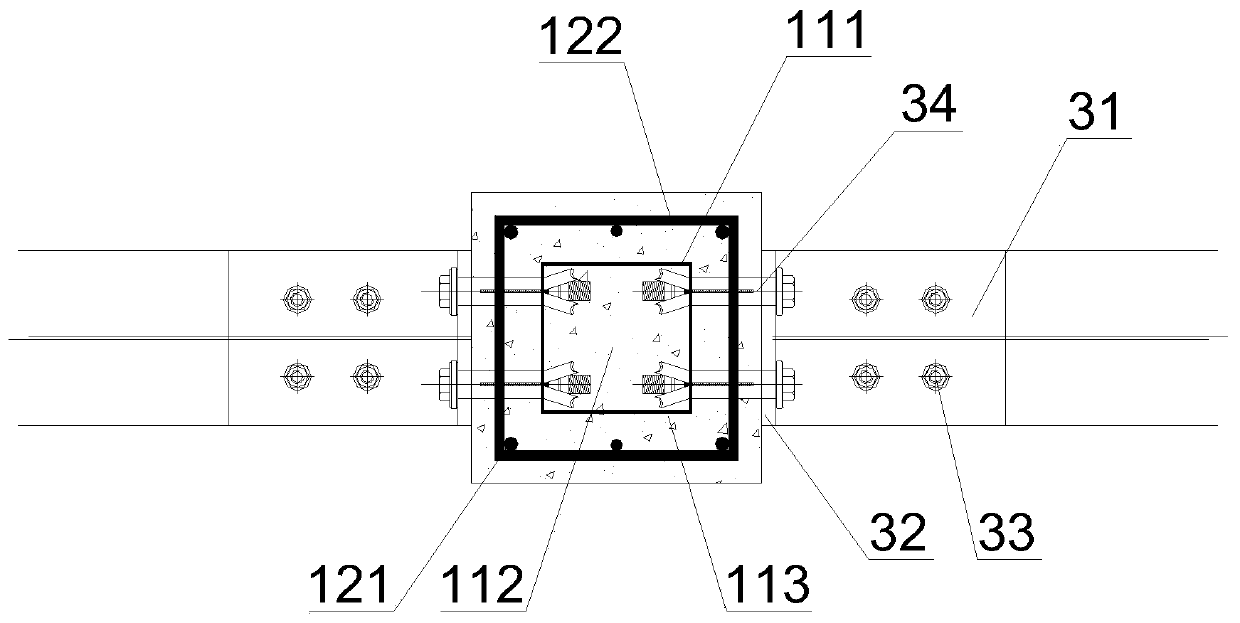

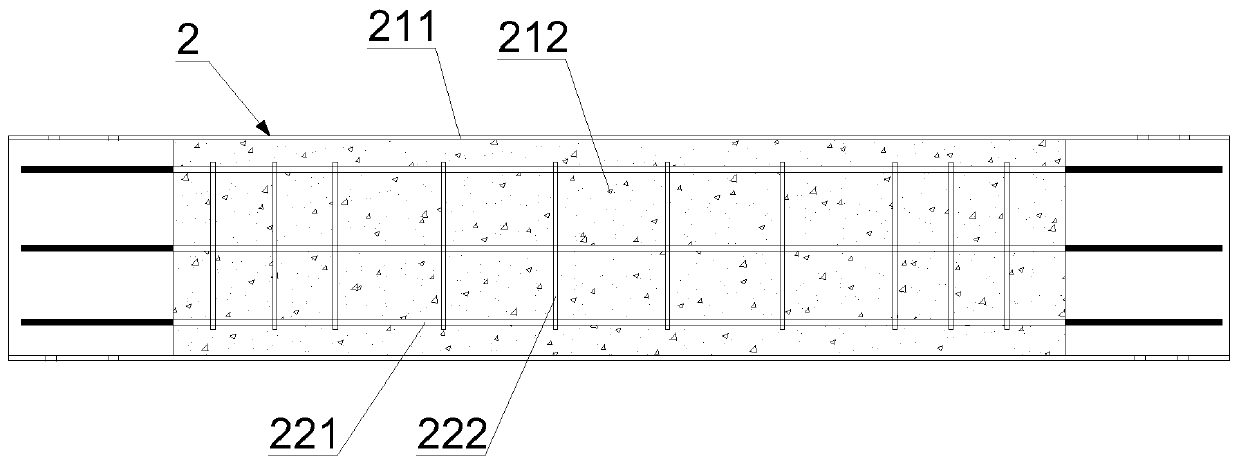

Connecting joint of prefabricated beam and columns

InactiveCN109281399AImprove integrityGood mechanical propertiesBuilding constructionsRebarBeam column

The invention provides a connecting joint of a prefabricated beam and columns. The connecting joint of the prefabricated beam and the columns comprises prefabricated columns, the prefabricated beam and grouting layers, the prefabricated columns are perpendicular to the prefabricated beam, and the grouting layers are arranged at junctions of prefabricated columns and the prefabricated beam, the prefabricated beam comprises beam longitudinal ribs, and the beam longitudinal ribs are arranged in the relative interior of the prefabricated beam. The prefabricated columns comprise column connecting parts, and the column connecting parts are arranged at the junctions of the prefabricated columns and the prefabricated beam. The column connecting parts comprise grouting sleeves, and the grouting sleeves are arranged on the relative outer sides of the beam longitudinal ribs in a sleeving mode. The connecting joint of the prefabricated beam and the columns partially prefabricates beam and column connecting joint area parts into the columns, construction processes are reduced, secondly, the problem of steel interference caused by excessive reinforcing steel bars in the connecting joint of the beam and the columns areas is effectively solved, the construction processes are simple, and the operation is convenient.

Owner:肖忠义

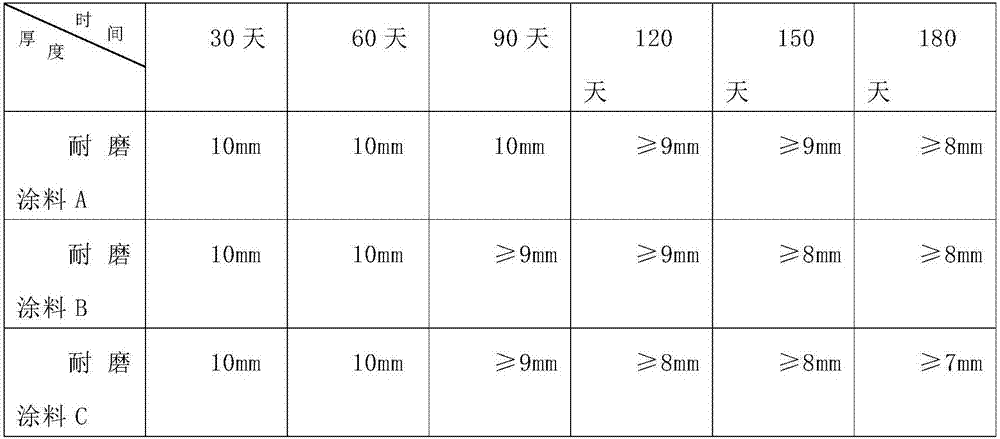

Wear-resistant paint prepared from steel slag, wear-resistant paint coating block and preparation method

ActiveCN107189627ASolve the problem of difficult handling and high cost investmentEasy to useEpoxy resin coatingsEpoxyWear resistant

The invention relates to a wear-resistant paint prepared from steel slag, a wear-resistant paint coating block and a preparation method. The wear-resistant paint is prepared from the raw materials steel slag, epoxy resin and a curing agent, wherein the steel slag are in the two particle size ranges of 1-1.5mm and 3-3.5mm. The wear-resistant paint prepared from steel slag provided by the invention adopts steel slag as the main raw material, has no requirement for steel slag components, only requires the particle size, therefore deep treatment is unnecessary for steel slag, and waste can be turned into things of value, thus fundamentally solving the problems of difficult steel slag treatment and high investment. As a novel functional paint, the wear-resistant paint has large consumption, through popularization of the wear-resistant paint, at least 0.16 ton of steel slag can be treated every year, and because of the low price of steel slag, the cost of the wear-resistant paint mainly lies in cheap epoxy resin and curing agent, the wear resistance is equivalent to that of ceramic wear-resistant paint and silicon carbide wear-resistant paint, however the cost is less than half of the two, therefore the wear-resistant paint prepared from steel slag has broad popularization prospect.

Owner:杨嵩 +2

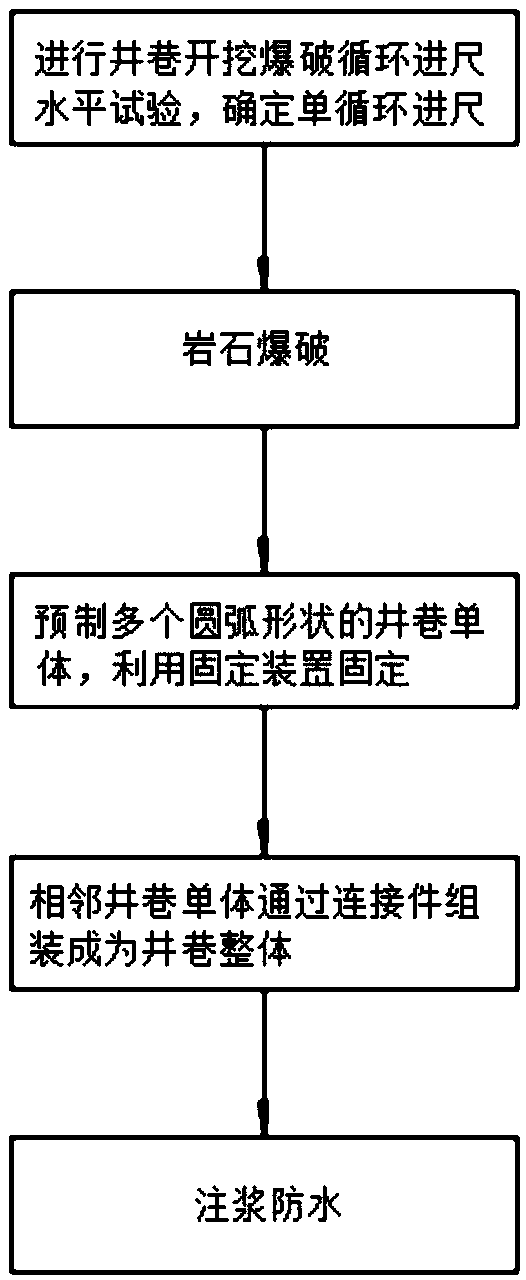

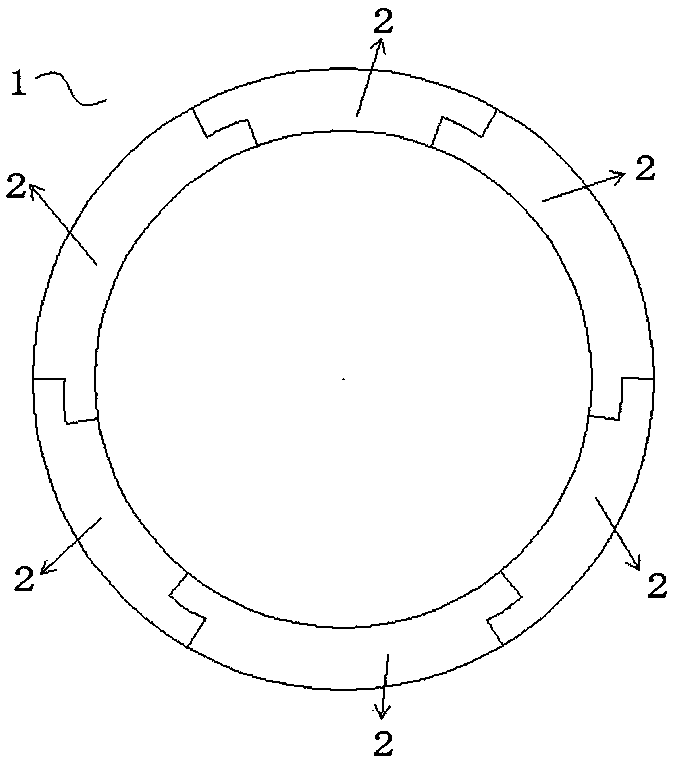

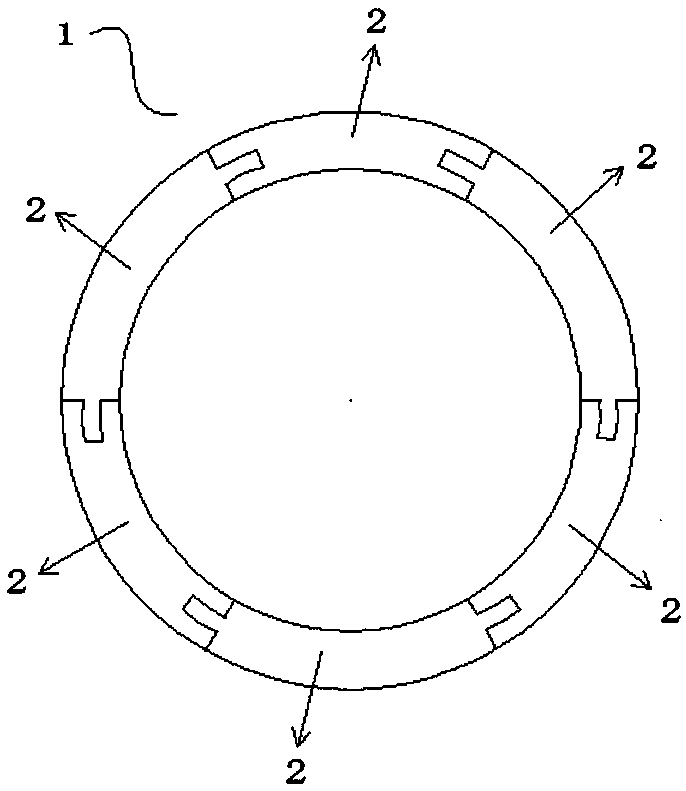

Assembled-type well lane construction method

InactiveCN109098718AEnsure safetySimplify on-site construction proceduresUnderground chambersShaft sinkingWhole bodyRebar

The invention relates to the field of the mine construction, and discloses an assembled-type well lane construction method. The method comprises the following steps: performing a well lane excavatingand blasting cyclical footage horizontal test, and determining single cyclical footage; blasting rock; prefabricating multiple arc-shaped well lane single bodies, and fixing by using a fixing device;assembling the neighboring well lane single bodies as a well lane whole body through a connecting piece; and grouting and resisting water. The provided assembled-type well lane construction method iscapable of using the prefabricated well lane single bodies to be assembled as the well lane whole body through the connecting piece without performing in-site steel bar binding and concrete pouring work, and simplifying site construction working process, wherein the working process is simplified as follows: blasting; installing the well lane single bodies, constructing through the connecting piece; and grouting and resisting the water. The construction method is capable of reaching design strength while a shaft or a lane is installed, reducing work time, and improving a construction speed.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

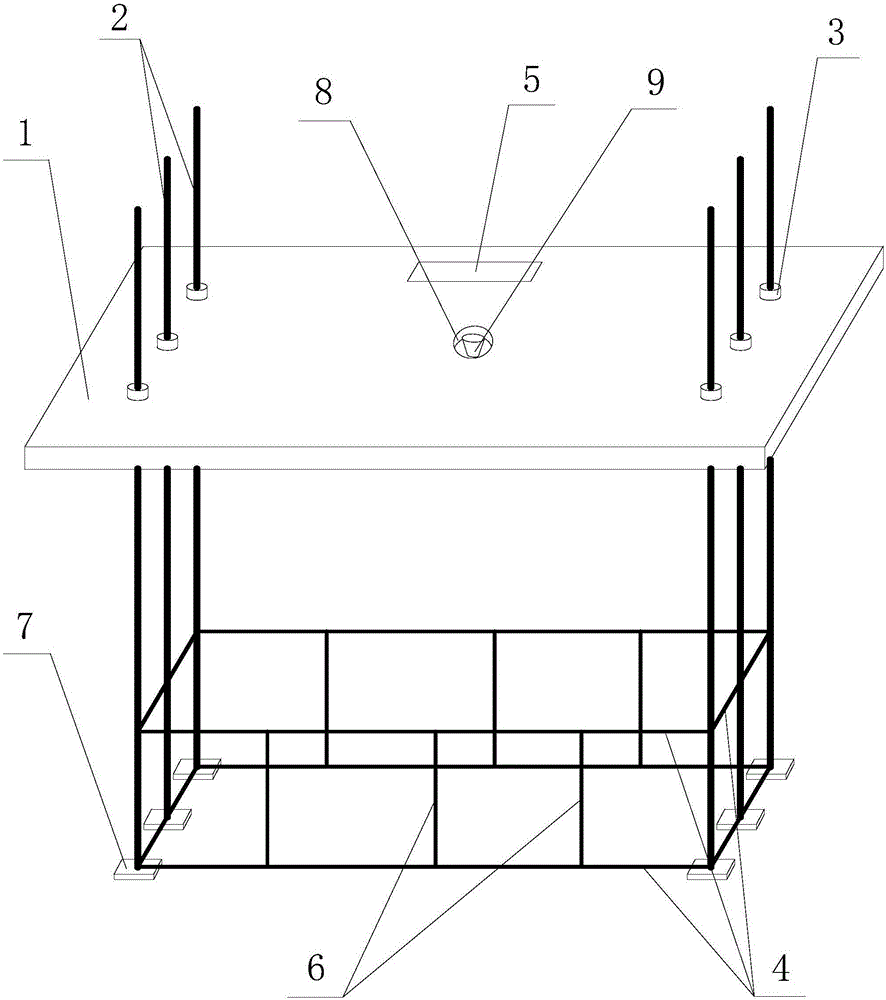

Pre-assembled steel column base anchor bolt structure

PendingCN106759943AAvoid disassemblyBarrier disassemblyBuilding material handlingSteel columnsAnchor bolt

The invention discloses a pre-assembled steel column base anchor bolt structure, comprising a positioning form which is provided with anchor bolt holes, anchor bolts are inserted into the anchor bolt holes, the positioning form is fixed to the anchor bolts through nuts, the axes of the anchor bolts are parallel, a transverse bar is fixedly connected between every two adjacent anchor bolts and is positioned below the positioning form, the transverse bars are perpendicular to the axes of the anchor bolts, and the upper surface of the positioning form is provided with a level. The invention is intended to provide the pre-assembled steel column base anchor bolt structure to solve the problem that steel column base positioning in the prior is slow and ineffective, field construction procedure of a steel column base in positioning is simplified, and construction efficiency is improved.

Owner:CHINA MCC5 GROUP CORP

Prefabricated part composite beam-prefabricated superposed composite column T-shaped fabricated joint

ActiveCN110016966AQuality assuranceSimplify on-site construction proceduresBuilding constructionsInternal stressComposite beams

The invention belongs to the field of structural engineering in civil engineering, in particular to a prefabricated part composite beam-prefabricated superposed composite column T-shaped fabricated joint, comprising a superposed combination column and a part composite beam that are prefabricated. The end part of the part composite beam is fixedly connected with the superposed combination column through a steel joint, internal stress assemblies and external stress assemblies are arranged in the part composite beam in a staggered mode, a core firmware and a peripheral firmware are arranged in the superposed combination column, and the core firmware is located inside the peripheral firmware, one fixed end of the steel joint is fixedly connected with the internal stress assemblies, and the other fixed end of the steel joint is fixedly connected with the core firmware and the peripheral firmware. By adopting the fabricated joint, connection between the components is convenient and rapid, fastening is reliable, and the workload of on-site mold making, installation and welding is reduced.

Owner:HEFEI UNIV OF TECH

Main beam unit with UHPC formwork structure, main beam structure and construction method of main beam structure

ActiveCN114319065AEasy constructionQuality improvementBridge structural detailsBridge erection/assemblyPierHigh performance concrete

The invention discloses a main beam unit with UHPC (Ultra High Performance Concrete) formwork structures, which comprises a main beam body, at least one longitudinal bridge direction end part of the main beam body is provided with the UHPC formwork structures, and each UHPC formwork structure comprises a vertical plate positioned at the end part of the main beam body; the side edges and the bottom edges of the vertical plates extend in the direction away from the main beam body to be provided with longitudinal-bridge-direction extension plates. The invention further provides a main beam structure and a construction method of the main beam structure. The UHPC formwork structure is arranged at the end of the main beam body, a ready-made formwork is provided for a pier top cast-in-place joint structure, the formwork of the joint structure does not need to be erected on a construction site, ultra-high performance concrete can be directly cast in place at the joint, construction is convenient, and rapid construction of a bridge structure is facilitated.

Owner:HUNAN UNIV

Rapidly positioned column foot anchor bolt structure

PendingCN106801470AStable structureStrong and stable structureBuilding material handlingLight beamSteel columns

The invention discloses a rapidly positioned column foot anchor bolt structure which comprises a positioning mold plate, wherein anchor bolt holes are formed in the positioning mold plate; anchor bolts are inserted into the anchor bolt holes; the positioning mold plate is fixed with the anchor bolts through screw nuts; the axes of the anchor bolts are parallel to one another; N transverse ribs which are distributed up and down in the direction of the axes of the anchor bolts are fixedly connected between the every two adjacent anchor bolts; the transverse ribs are all positioned on the lower side of the positioning mold plate; the transverse ribs are perpendicular to the axes of the anchor bolts; longitudinal ribs are fixedly connected between every two adjacent transverse ribs up and down; a gradienter is arranged on the upper surface of the positioning mold plate; a through hole is formed in the center of the positioning mold plate; a light beam emission device is arranged on the positioning mold plate; the emitting end of the light beam emission device is positioned inside the through hole; light beams are emitted to the lower side of the positioning mold plate; and the emitted light beams are parallel to the axes of the anchor bolts. By adopting the rapidly positioned column foot anchor bolt structure, the problems that in the prior art, a steel column foot is low in positioning construction speed and low in efficiency can be solved, and the purposes that on-site construction procedures of steel column foot positioning are simplified and the construction efficiency is improved can be achieved.

Owner:CHINA MCC5 GROUP CORP

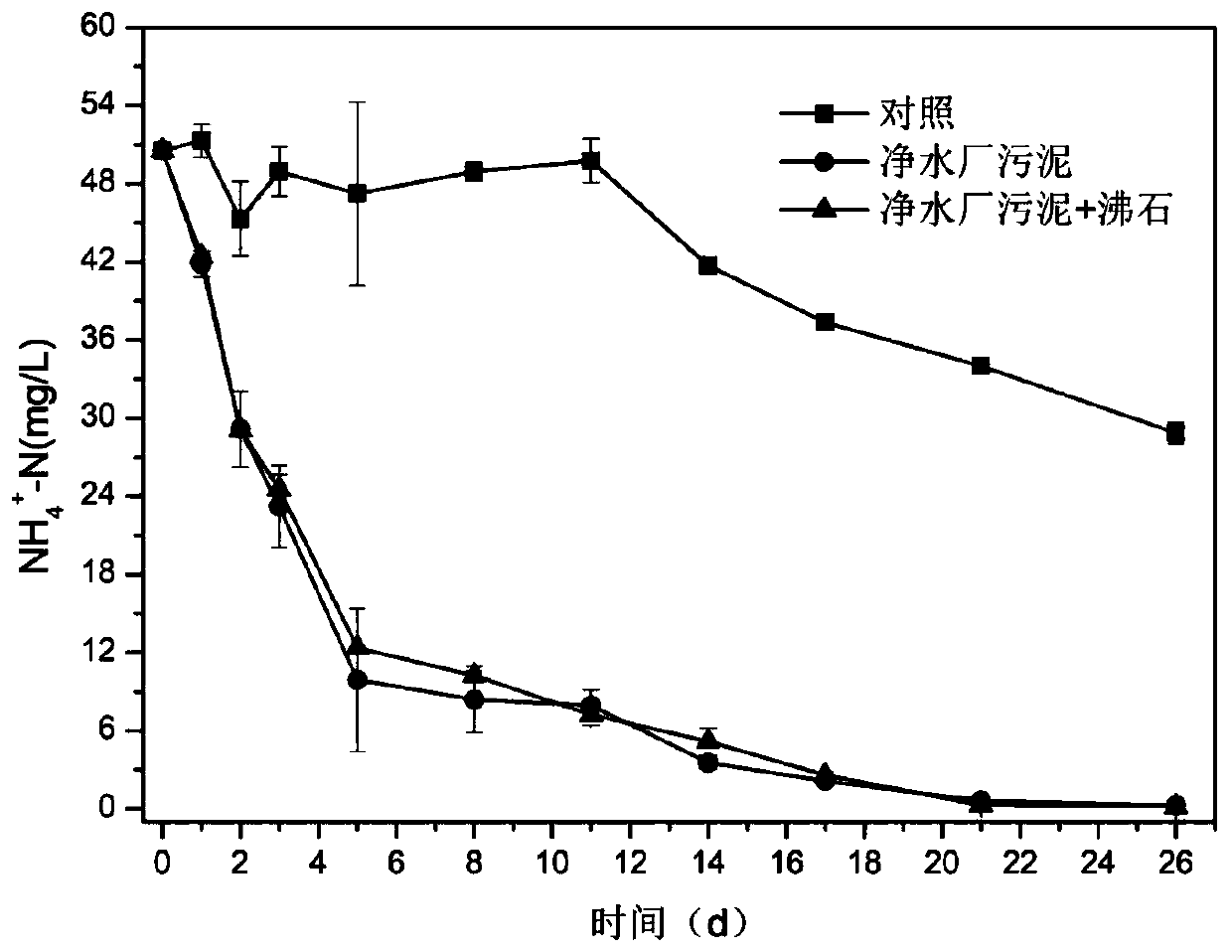

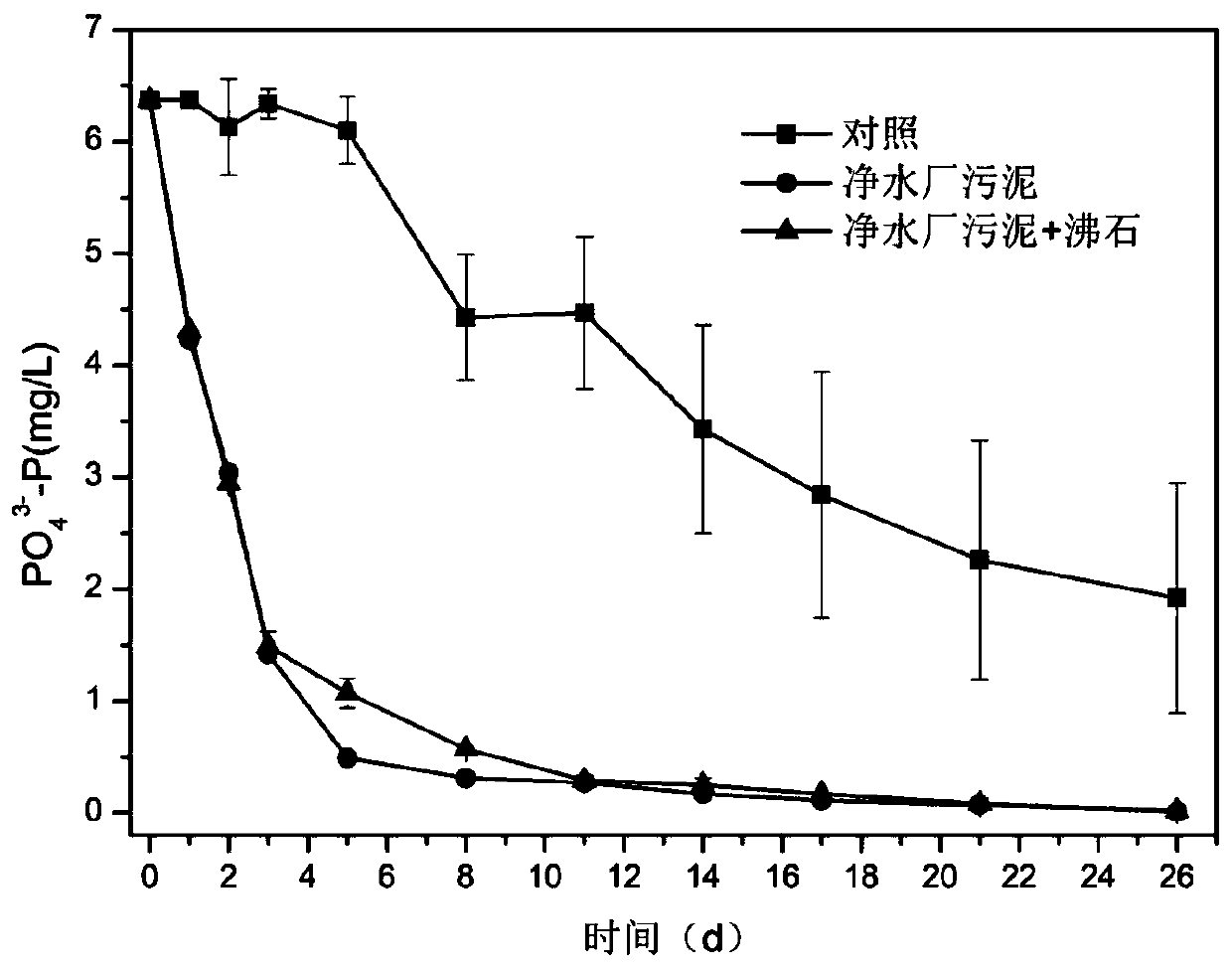

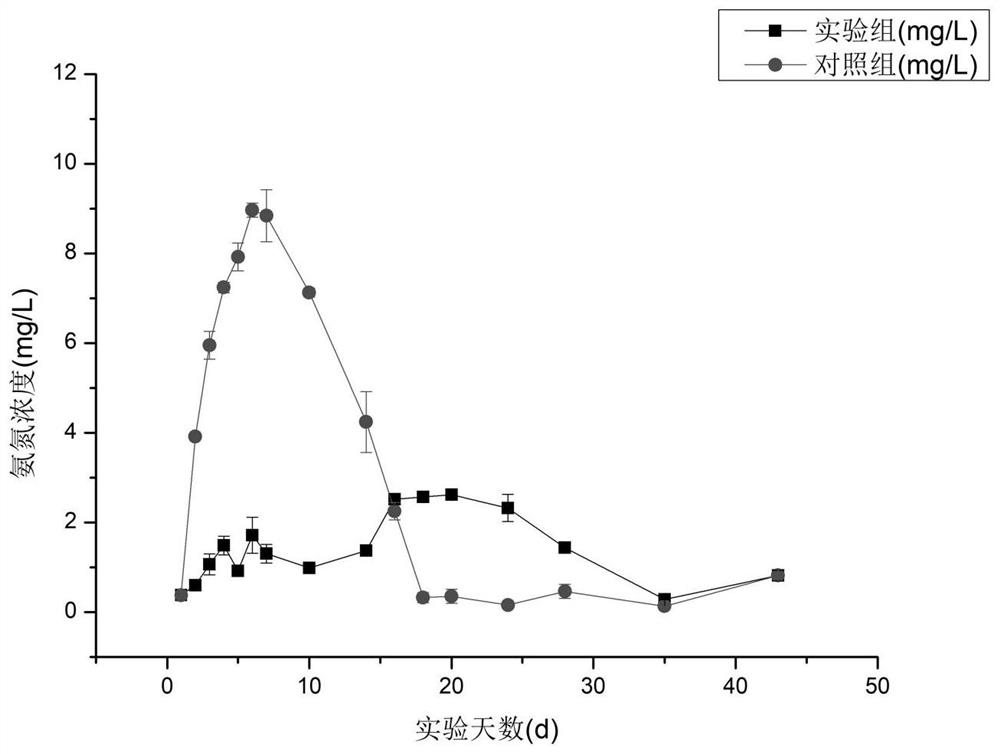

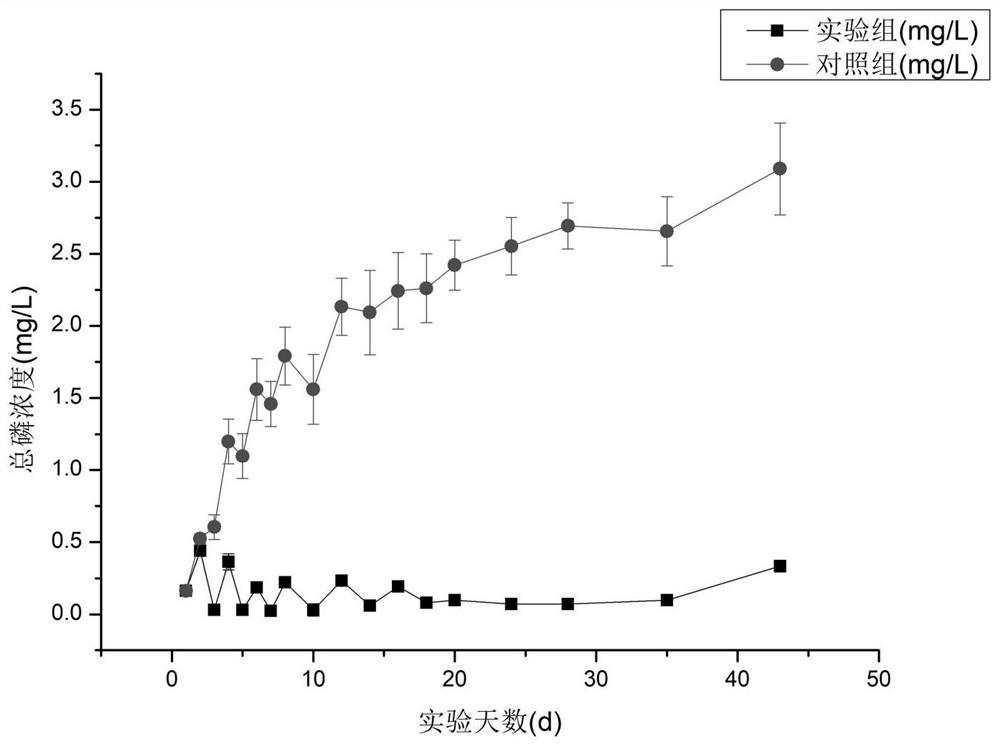

Preparation method of active covering plate for synchronously controlling nitrogen and phosphorus release of bottom mud

The invention discloses a preparation method of an active covering plate for synchronously controlling nitrogen and phosphorus release of bottom mud. The preparation method comprises the following steps: (1) naturally air-drying sludge of a water purification plant, and calcining to obtain a sludge block; (2) the sludge blocks are subjected to mechanical crushing and mechanical vibration screening, and the aluminum-based phosphorus locking agent is prepared; (3) adding the aluminum-based phosphorus locking agent, cement, zeolite and water into a stirrer according to a ratio, uniformly mixing, and standing to obtain a base material; (4) the base material is added into a mold frame to be pressed; (5) after compression molding, standing and demolding to obtain a cover plate; and (6) standing the cover plate finished product under a natural open air condition for engineering application. The active covering plate prepared by the invention not only can synchronously control the release of nitrogen and phosphorus in bottom mud, but also has the advantages of washing resistance, good water permeability, high water retention and the like, and solves the problems of non-uniform covering, flood washing loss and the like of a granular covering material; the prepared active covering plate can be recycled, cyclic utilization of resources is promoted, meanwhile, the process is simple, operation is convenient, and the cost is low.

Owner:HUAQIAO UNIVERSITY

Formwork-detachment-free device for post-cast strip

InactiveCN104005557APrevent spilloverChange structureForms/shuttering/falseworksSteel barOperational safety

The invention aims to provide a formwork-detachment-free device for a post-cast strip. According to the formwork-detachment-free device, a formwork body is formed by a steel reinforcement framework with a rectangular cross section. A-type threaded steel, B-type threaded steel and a reinforcing steel bar connection rod are arranged on the formwork body, combined and fixed through welding and placed below a steel wire screen. A tie bar is installed on one side of the B-type threaded steel and cast-in-place concrete is poured into the formwork body. Multiple times of trail show that the formwork-detachment-free device has the advantages that an original structure is changed, overflowing of the concrete is effectively prevented in the pouring process, labor and force are saved in the process of cleaning, waste is completely eradicated, the pouring quality is not influenced, an on-site construction procedure is simplified, labor force is lowered, waste reinforcing steel bars are fully used for manufacturing, materials are conveniently obtained, cost is reduced, practicability is high, cost is low, operation is safe and convenient, and the formwork-detachment-free device is suitable for application and popularization.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com