Assembly type house with composite environment-friendly wall boards

A prefabricated and composite technology, applied to walls, building components, buildings, etc., can solve problems such as inability to achieve standardization, mass production, industrialization, uneven technical levels of construction workers, and inconsistent quality of construction operations. The effect of saving labor costs, shortening the construction period, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

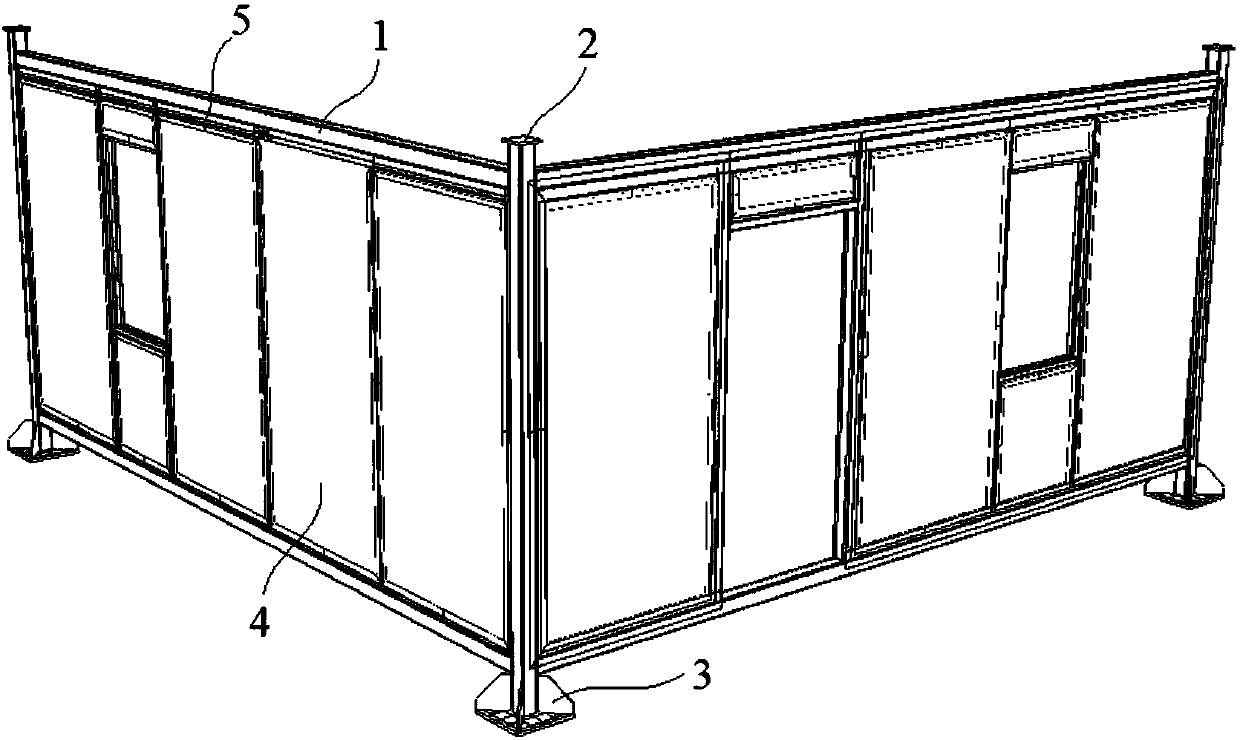

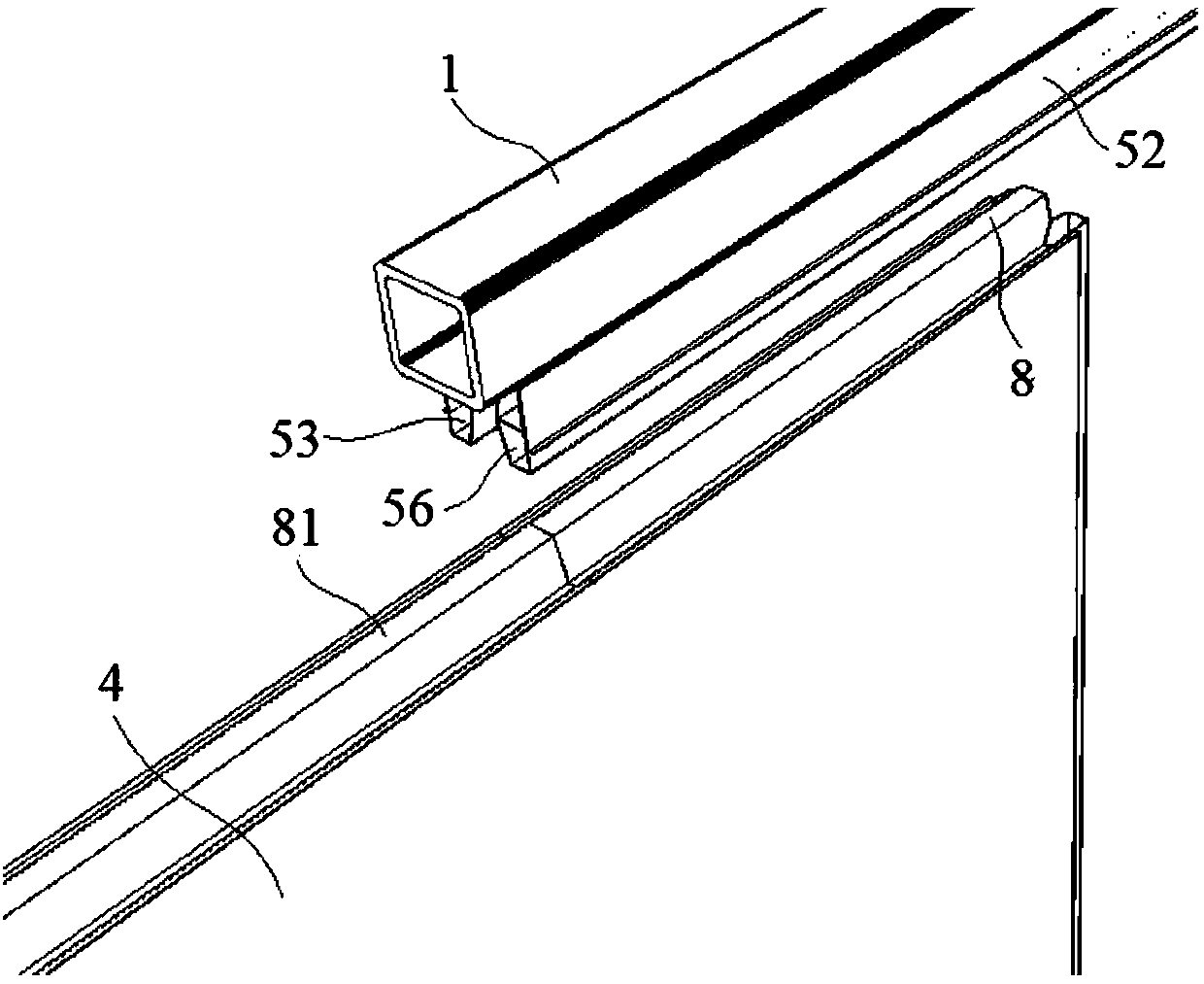

[0028] Embodiment 1: A prefabricated house with composite environmentally friendly wall panels, comprising a steel beam 1, a column 2, a base 3 and a wall panel 4. The column 2 is fixedly connected to the base 3, and the two ends of the steel beam 1 are respectively It is fixedly connected to the upright column 2 and is used to connect two adjacent upright columns 2. The wall panel 4 and the steel beam 1 are fixedly connected by a connecting mechanism 5, and the two adjacent wall panels 4 are arranged separately The left connecting piece 6 and the right connecting piece 7 on both sides of the wall panel 4 are fixedly connected;

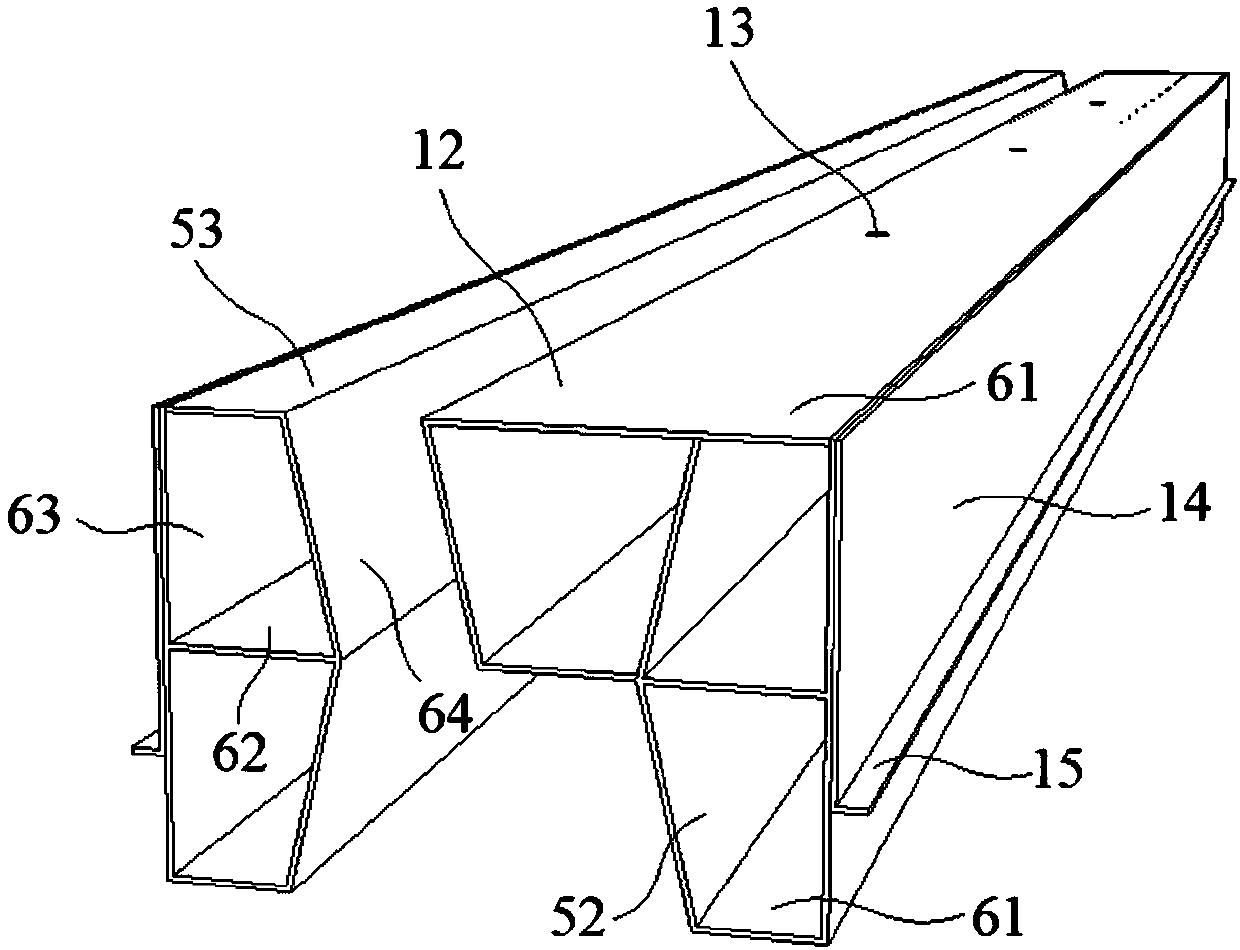

[0029] The left connecting piece 6 is a U-shaped keel, the lower surface of the U-shaped keel is arched to form a groove 21, the right connecting piece 7 is an inverted U-shaped keel relative to the left connecting piece 6, and the upper surface of the U-shaped keel is arched A raised portion 22 is formed together, and the raised portion 22 on the upper ...

Embodiment 2

[0034] Embodiment 2: A prefabricated house with a composite environmentally friendly wall panel, comprising a steel beam 1, a column 2, a base 3 and a wall panel 4. The column 2 is fixedly connected to the base 3, and the two ends of the steel beam 1 are respectively It is fixedly connected with the upright column 2 for connecting two adjacent upright columns 2. The wall panel 4 and the steel beam 1 are fixedly connected by a connecting mechanism 5, and the two adjacent wall panels 4 are arranged separately The left connecting piece 6 and the right connecting piece 7 on both sides of the wall panel 4 are fixedly connected;

[0035] The left connecting piece 6 is a U-shaped keel, the lower surface of the U-shaped keel is arched to form a groove 21, the right connecting piece 7 is an inverted U-shaped keel relative to the left connecting piece 6, and the upper surface of the U-shaped keel is arched A raised portion 22 is formed together, and the raised portion 22 on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com