Nanometer silicon dioxide, nanometer composite slick water fracturing fluid and preparation method and application of nanometer silicon dioxide and nanometer composite slick water fracturing fluid

A nano-silica and nano-composite technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient sand-carrying capacity, poor shear stability, single function, etc., to simplify construction procedures and investment. The effect of high cost, high drag reduction rate and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A first aspect of the present invention provides a method for preparing nano silicon dioxide, the method comprising:

[0022] (1) In the presence of acid, carry out the first reaction with silicate, ethanol and water to obtain the intermediate product system;

[0023] (2) carry out second reaction with described intermediate product system and dicarboxypolyethylene glycol, and the product that obtains is carried out freeze-drying, obtains nano silicon dioxide.

[0024] According to the present invention, in the preparation method of described nano silica, preferably, silicate: ethanol: water: the molar ratio of dicarboxypolyethylene glycol can be (4-20): (40-100): (40-200): (1-5), more preferably 4: (40-50): (40-50): (1-3), in order to obtain nano silicon dioxide with smaller particle size, and then can be Fracturing fluid brings better seepage and oil discharge effect.

[0025] According to the present invention, in step (1), the acid is used to adjust the pH value o...

Embodiment approach

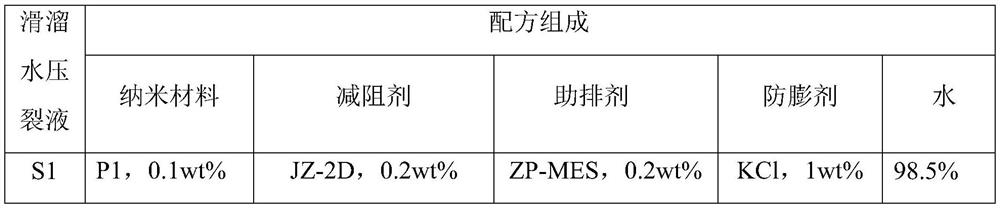

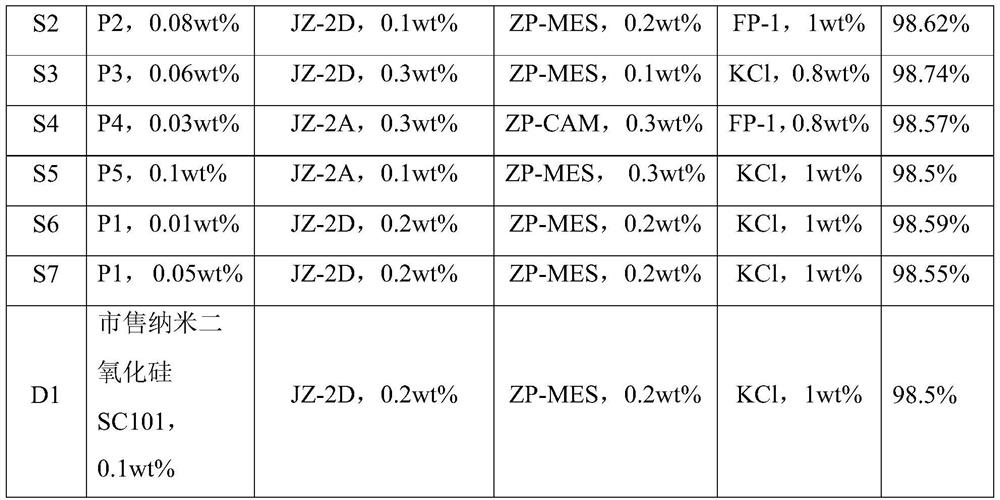

[0045] According to a preferred embodiment of the present invention, the preparation of the nano-composite slick water fracturing fluid can specifically adopt the following operations: prepare the raw materials according to the above-mentioned proportions, mix the drag reducer at a stirring rate of 500-1000 rpm Add water, stir for 1-2 minutes to fully dissolve; then add drainage aid and anti-swelling agent, continue to stir for 1-2 minutes to fully dissolve; finally add nano-silica, continue to stir for 1-2 minutes, so that the system Uniform and stable, the nanocomposite slick water fracturing fluid is prepared.

[0046] The fifth aspect of the present invention provides the application of the nanocomposite slickwater fracturing fluid described in the third aspect above in the fracturing of low-permeability tight oil layers.

[0047] The present invention will be described in detail below by way of examples. In the following preparations and examples,

[0048] The particle ...

preparation example 1

[0056] This preparation example is in order to illustrate the preparation method of the nano silicon dioxide provided by the invention

[0057] (1) Methyl silicate, ethanol and water are placed in a reaction vessel and fully stirred and mixed, then acetic acid is added to adjust the pH of the reaction system to 3, heated and carried out at 70°C for the first reaction for 6 hours to obtain an intermediate product system;

[0058] (2) Add dicarboxypolyethylene glycol 400 to the intermediate product system prepared in step (1), and continue the second reaction at 70°C for 12h to obtain a dispersion of nano-silica particles, and then Down freeze-drying 15h, obtain nano-silica powder body (recorded as P1);

[0059] Wherein, the molar ratio of methyl silicate: ethanol: water: dicarboxypolyethylene glycol 400 is 4:40:40:1.

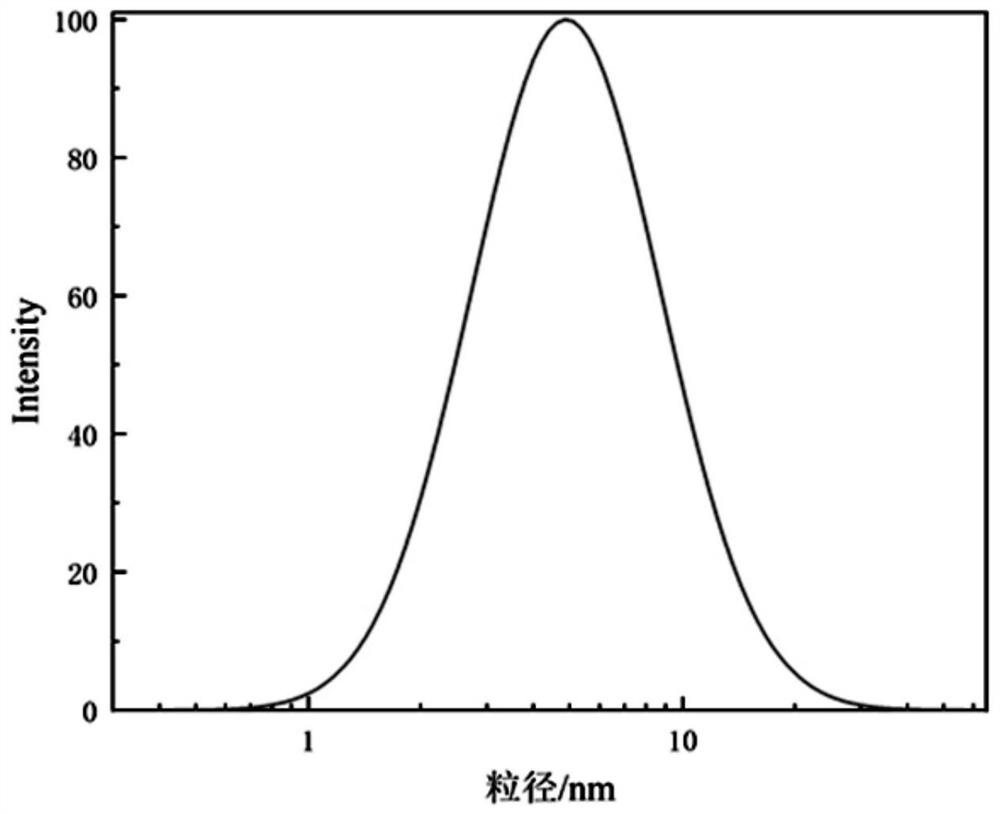

[0060] After testing, the average particle size of P1 is 6nm.

[0061] figure 1 It is the particle size distribution diagram of nano-silica P1 prepared in Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com