Thermal insulation decorative composite board and manufacturing method thereof

A technology for composite boards and thermal insulation layers, which is applied in chemical instruments and methods, lamination devices, building structures, etc., can solve problems such as complicated procedures, unstable construction quality, and difficulty in controlling construction flatness, and simplifies on-site construction procedures. , The effect of solving construction quality problems and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

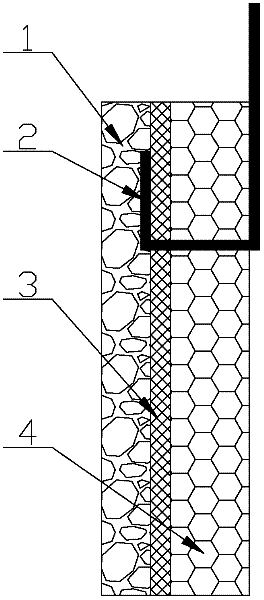

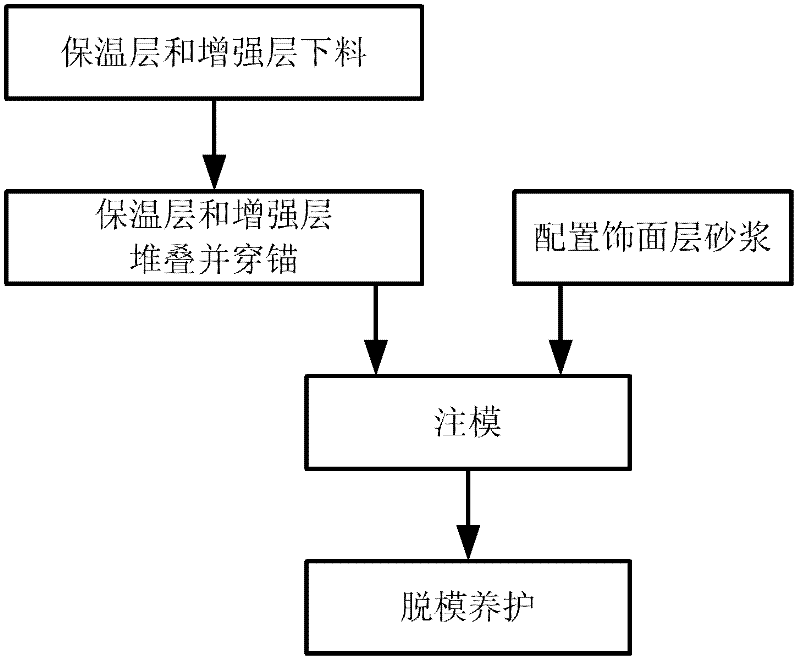

[0039] The overall size of the thermal insulation and decorative composite board is 500*500mm (if you need to change the shape and size, you only need to change the mold). The insulation layer 4 is made of phenolic foam board with good fire resistance, with a thickness of 90mm. The reinforcement layer 3 is made of alkali-resistant glass fiber mesh cloth to assist in enhancing the bonding strength between the finishing layer 1 and the insulation layer 4 . The facing layer 1 is made of solidified fine stone concrete mortar, and pigments can be added according to requirements to make different colors. The anchor bolt 2 is J-shaped, and its hook section is located in the fine stone concrete mortar of the facing layer 1, and is attached to the reinforcement layer 3. The straight section passes through the reinforcement layer 3 and the insulation layer 4, and is connected to the insulation layer 4. fit.

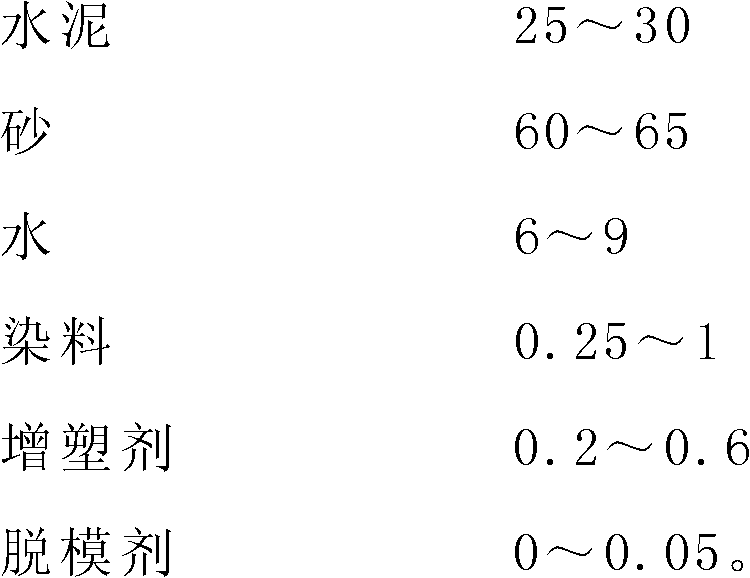

[0040] In the facing layer 1, the percentage by weight of each raw material ...

Embodiment 2

[0043] The overall size of the thermal insulation and decorative composite board is 600*400mm (if you need to change the shape and size, you only need to change the mold). The insulation layer 4 is made of hard foam polyurethane board with a thickness of 90mm. The reinforcement layer 3 is made of alkali-resistant glass fiber mesh cloth to assist in enhancing the bonding strength between the finishing layer 1 and the insulation layer 4 . The facing layer 1 is made of solidified fine stone concrete mortar, and pigments can be added according to requirements to make different colors. Anchor bolt 2 is a percussion type nylon anchor bolt.

[0044] In the facing layer 1, the percentage by weight of each raw material component of the fine stone concrete mortar is:

[0045]

[0046] In the above two product embodiments, the sand is preferably washed sand, the dye is preferably iron oxide dye, the plasticizer is preferably a polycarboxylic acid plasticizer such as a polycarboxylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com