Preparation method of active covering plate for synchronously controlling nitrogen and phosphorus release of bottom mud

A synchronous control, covering plate technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of uneven coverage of granular covering materials, flooding and loss, etc. The effect of utilizing, controlling eutrophication, and simple construction procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

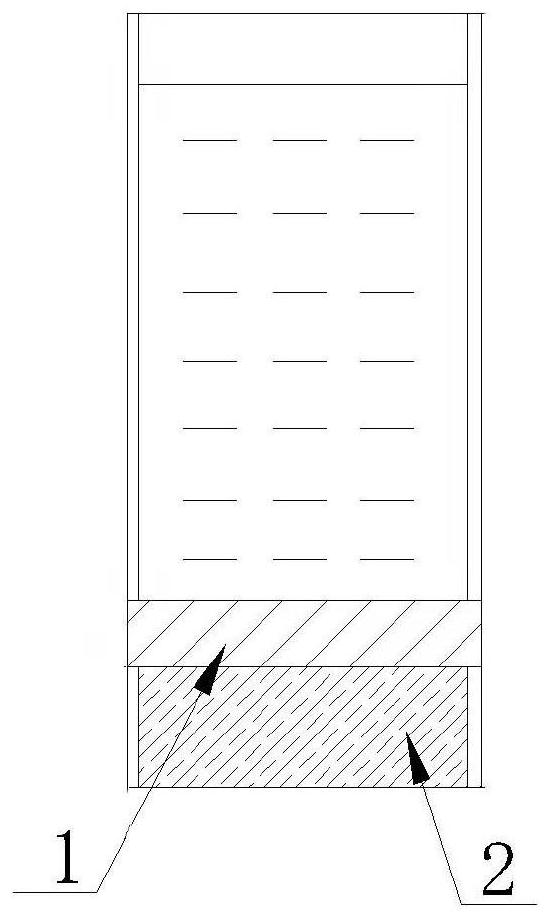

[0033] A method for preparing an active cover plate for synchronously controlling nitrogen and phosphorus release from bottom mud, specifically comprising the following steps:

[0034] (1) Naturally air-drying the collected sludge from a water purification plant or a water supply plant, and calcining to obtain a sludge block;

[0035] (2) the sludge block is subjected to mechanical pulverization and mechanical vibration screening to obtain an aluminum-based phosphorus-locking agent with a particle size of 1-3 mm;

[0036] (3) Add the aluminum-based phosphorus-locking agent, cement, zeolite, and water to the mixer in proportion to stir evenly, and let stand to fully mix the aggregate and the binder;

[0037] (4) adding the above-mentioned stirring base material into the mould frame and pressing;

[0038] (5) After being pressed and formed, the cover plate is obtained by demoulding after standing;

[0039] (6) The finished product of the cover plate can be applied in engineeri...

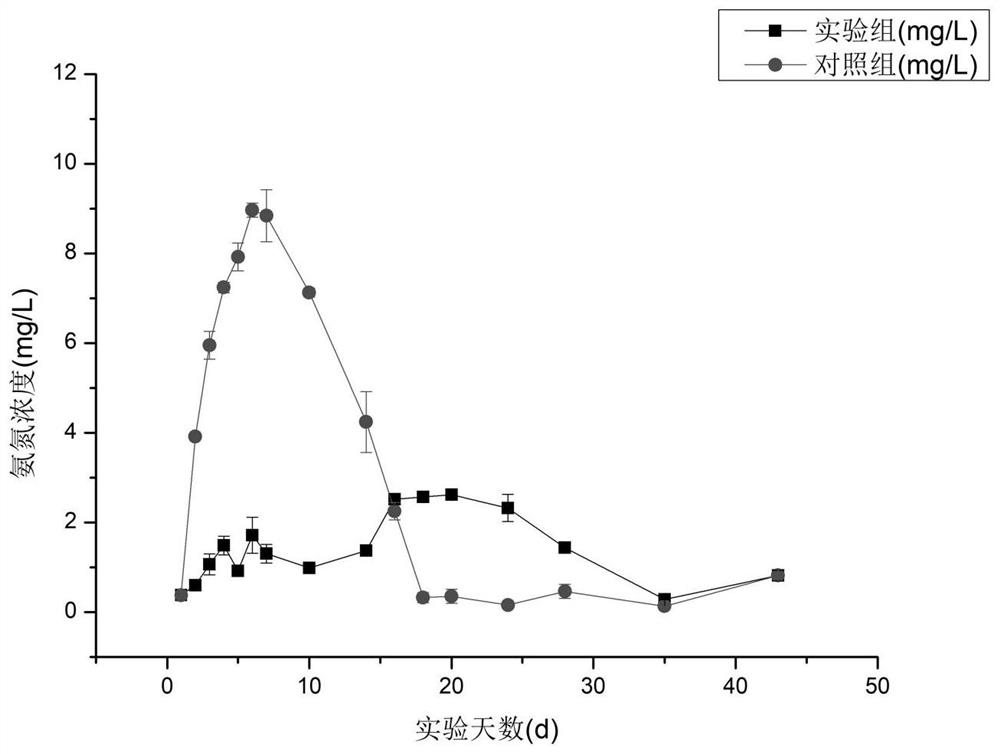

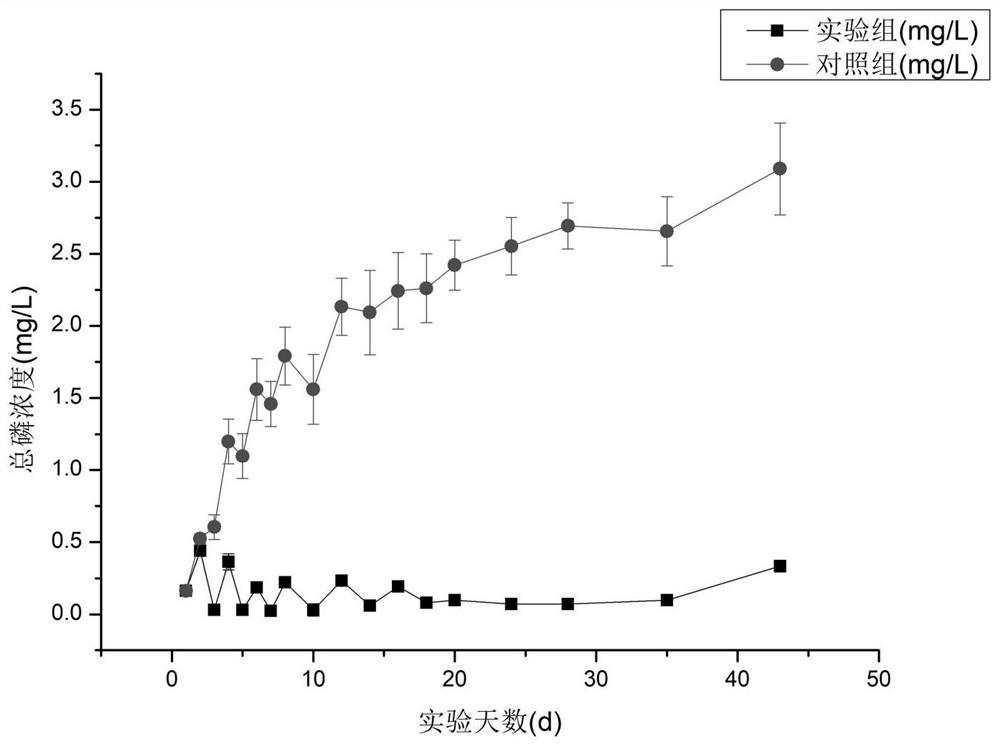

Embodiment 1

[0052] Take the sludge from a water purification plant in Xiamen (sludge components include iron-aluminum compounds, nitrides, organic matter, etc., of which the mass fraction of iron is 2.63%, and the mass fraction of aluminum is 11.77%), and then air-dried and calcined at 400 °C for 3 hours. It is then pulverized by a pulverizer, and then 16-mesh and 50-mesh stainless steel sieves are respectively used to screen out particles with a particle size of 1-3mm, which are aluminum-based phosphorus-locking agents.

[0053] Getting above-mentioned aluminum-based phosphorus-locking agent, cement and zeolite total mass is 100g, and wherein the proportioning of aluminum-based phosphorus-locking agent, cement and zeolite has the following 7 kinds:

[0054](1) 16g of cement, 42g of zeolite, 42g of aluminum-based phosphorus-locking agent;

[0055] (2) 18g of cement, 41g of zeolite, 41g of aluminum-based phosphorus-locking agent;

[0056] (3) 20g of cement, 40g of zeolite, 40g of aluminum...

Embodiment 2

[0064] In this example, the variation range of the porosity and the anti-scour coefficient of the bottom mud active covering board made of aluminum-based phosphorus-locking agent, cement and zeolite with different mass ratios was studied.

[0065] (1) The operation mode and calculation method of the porosity test in this embodiment are as follows:

[0066] (1) Operation method

[0067] ①Measure the side length of the cover plate with a measuring tool, measure each side once, take the average value of the opposite sides, accurate to 0.1cm, and calculate the volume (V) of the cover plate;

[0068] ② Put the cover plate to dry in an oven with a temperature of 100℃±5℃, take out the cover plate and weigh it every 24 hours, until the difference between two consecutive weighings is less than 0.1%, which is regarded as the quality of the dry cover plate (M 2 );

[0069] ③ Cool the cover plate to room temperature and put it into the water tank vertically, inject distilled water with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com