Main beam unit with UHPC formwork structure, main beam structure and construction method of main beam structure

A formwork and main beam technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of low strength of prefabricated bridges, complicated on-site construction procedures, inconvenient transportation and installation, etc., and achieve simplified construction procedures, simple construction methods, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

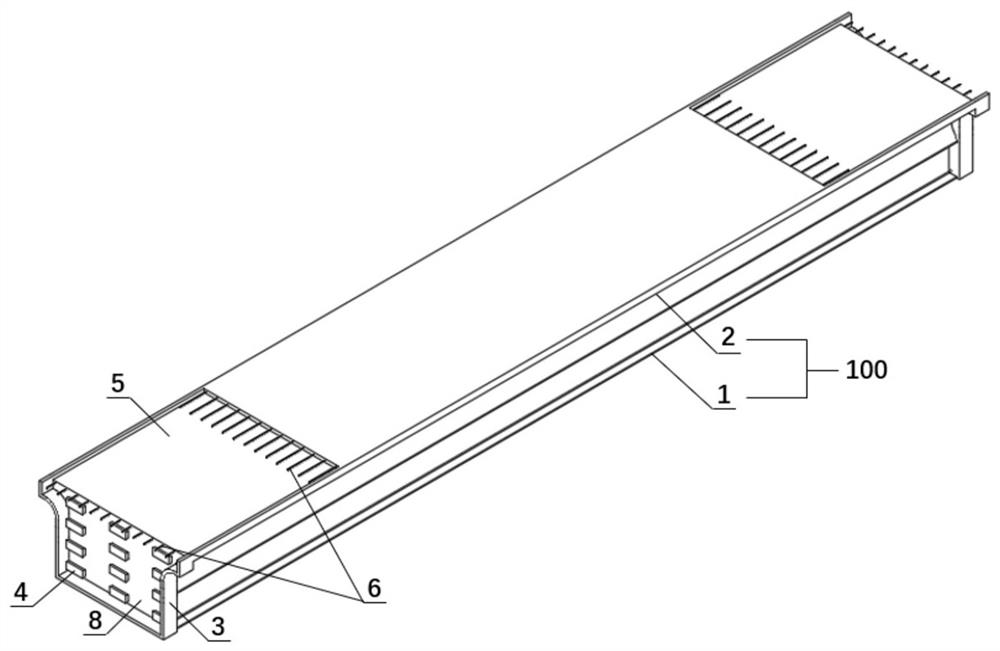

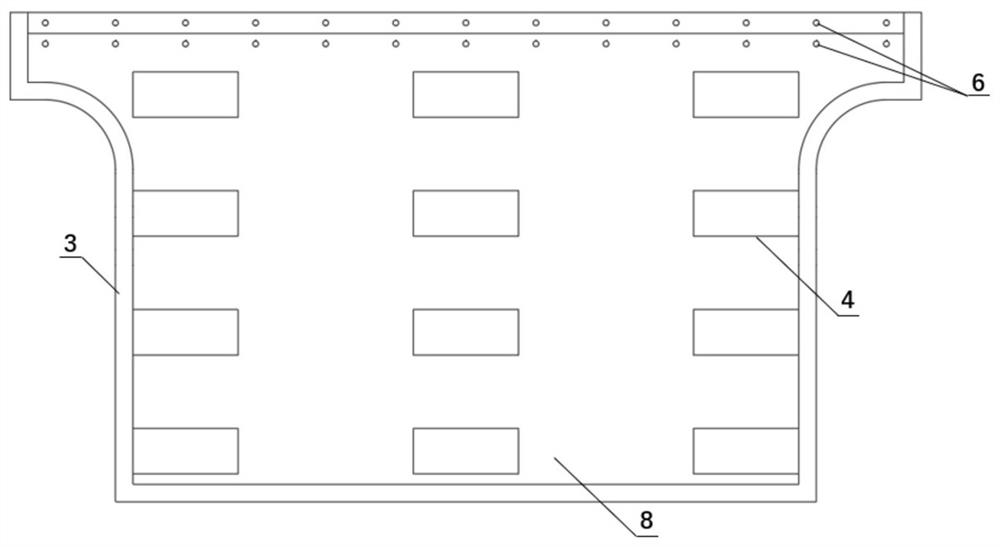

[0050] Such as Figure 1-Figure 6 As shown, the main beam unit (type I) with UHPC formwork structure of this embodiment includes a main beam body 100, at least one longitudinal bridge end of the main beam body 100 is provided with a UHPC formwork structure, and the UHPC formwork structure It includes a riser 8 located at the end of the girder body 100 , and the side and bottom of the riser 8 extend away from the girder body 100 to form a longitudinal bridge extension plate 3 .

[0051] In this embodiment, the riser 8 is provided with a plurality of tooth keys 4 on the surface away from the main girder body 100 . Specifically, the trapezoidal tooth key includes an upper top surface and a lower bottom surface, the area of the upper top surface is larger than the area of the lower bottom surface, the lower bottom surface is close to the vertical plate, and the upper top surface is away from the vertical plate; the distance between adjacent trapezoidal tooth keys in the height...

Embodiment 2

[0063] Such as Figure 8-Figure 12 As shown, the main beam unit (Type II) with UHPC formwork structure in this embodiment includes a main beam body 100, at least one longitudinal bridge end of the main beam body 100 is provided with a UHPC formwork structure, and the UHPC formwork structure It includes a riser 8 located at the end of the girder body 100 , and the side and bottom of the riser 8 extend away from the girder body 100 to form a longitudinal bridge extension plate 3 .

[0064] In this embodiment, the riser 8 is provided with a plurality of tooth keys 4 on the surface away from the main girder body 100 , and its specific arrangement can be the same as that of the first embodiment.

[0065] In this embodiment, the main beam body 100 is a steel-UHPC composite beam, and the steel-UHPC composite beam includes a steel beam and a UHPC beam, the steel beam is a welded I-beam 10, and the UHPC beam is a rectangular flat beam 9; the welded I-beam The upper flange of 10 is pro...

Embodiment 3

[0070] Such as Figure 13-Figure 16 As shown, the main beam unit (Type III) with UHPC formwork structure in this embodiment includes a main beam body 100, at least one longitudinal bridge end of the main beam body 100 is provided with a UHPC formwork structure, and the UHPC formwork structure It includes a riser 8 located at the end of the girder body 100 , and the side and bottom of the riser 8 extend away from the girder body 100 to form a longitudinal bridge extension plate 3 .

[0071]In this embodiment, the riser 8 is provided with a plurality of tooth keys 4 on the surface away from the main girder body 100 , and its specific arrangement can be the same as that of the first embodiment.

[0072] In this embodiment, the main beam body 100 is a UHPC single beam, and the UHPC single beam is a π-shaped beam 2 . Specifically, the π-shaped beam 2 includes a top plate 21, a pair of arc-shaped webs 22 and a pair of bottom plates 23, the bottom plate 23 is arranged at the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com