Formwork-detachment-free device for post-cast strip

A technology without dismantling formwork and post-casting belt, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. problems in concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

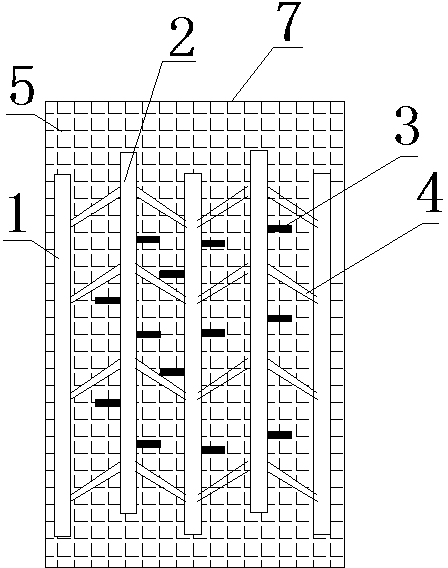

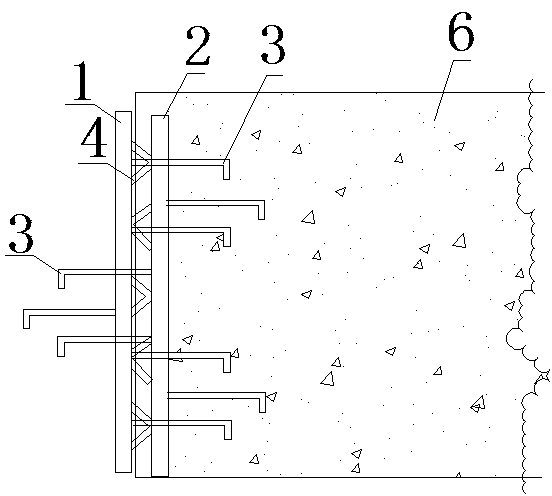

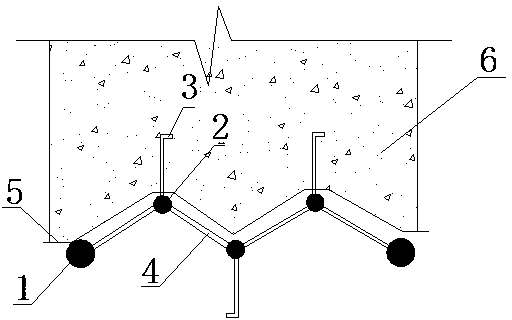

[0013] Below in conjunction with accompanying drawing, the embodiment of the present invention is further elaborated: post-casting belt exempts formwork parts from being dismantled, and it is made formwork body 7 by rectangular cross-section reinforcing steel skeleton, and A-type threaded steel 1, B-type threaded steel 2 and A-type threaded steel 2 are set on formwork body 7 Rebar connecting rod 4 is welded and fixed, and placed under steel mesh sheet 5; tie bars 3 are installed on one side of B-shaped rebar 2, and cast-in-situ concrete 6 is poured into formwork body 7.

[0014] The specific post-casting strip free formwork parts, the A-type rebar and the B-type rebar are welded and fixed in a V-shape in a dislocation and equidistant arrangement.

[0015] The specific post-casting strip free formwork parts, A-type rebar is long strip, 8-30cm long, 1.5-3cm wide.

[0016] The specific post-casting strip free formwork parts, the B-type rebar is cylindrical, 2.8-5.5 in length a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com