Easy-to-clean three-roll attrition mill for color masterbatch

A color masterbatch and grinding technology, applied in the field of machinery, can solve the problems of overflow of the intermediate roller and the influence of grinding, and achieve the effect of preventing the overflow and helping maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

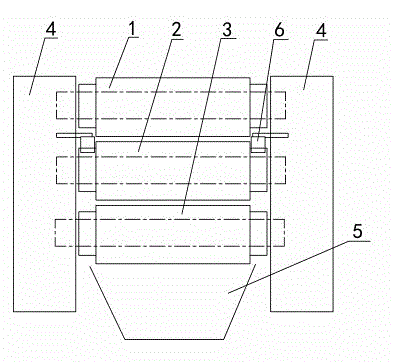

[0012] Such as figure 1 As shown, the present invention provides a three-roller mill for easy-cleaning color masterbatch, which, like the existing mill, includes a milling assembly, a driving device 4 that drives the milling assembly to work, and is arranged on the milling assembly. Collection device below the component.

[0013] The grinding assembly includes a first grinding roller 1, a second grinding roller 2, and a third grinding roller 3. The driving device 4 is arranged on both sides of the grinding assembly, including a motor and a motor housing. The driving device drives the roller shaft of the grinding roller to rotate so as to grind the material. The collection device is a collection frame (not shown in the figure), and the collection device is connected to the third grinding roller 3 through a connecting plate 5 .

[0014] The color masterbatch is viscous and colloidal. During the grinding process, if you do not pay attention to the phenomenon of material overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com