Method for improving circulating flue gas rate

A technology for circulating flue gas and flue gas, applied in the field of material control, can solve the problems of circulating flue gas escape, etc., and achieve the effects of increasing the circulating flue gas rate, reducing fuel consumption, and increasing total heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

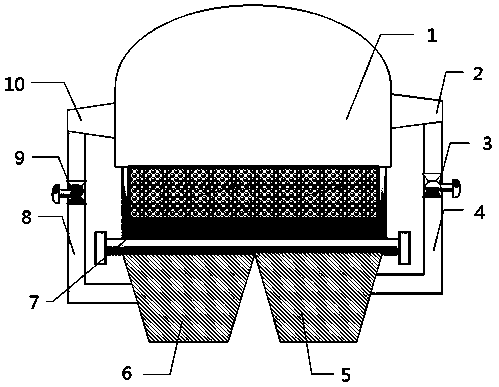

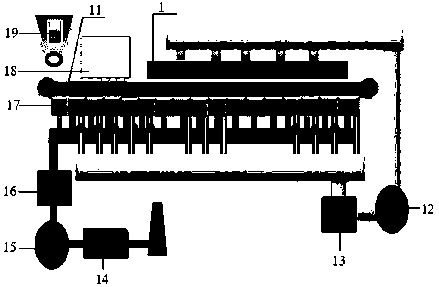

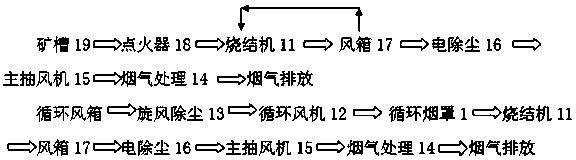

[0024] The present invention is mainly a method for increasing the circulation flue gas rate developed for the sintering flue gas internal circulation production process. A number of pipes are added on both sides of the circulation fume hood installed on the sintering machine to connect with the bellows. A regulating valve is added in the middle of the connecting pipeline. When the negative pressure in the circulating fume hood reaches the condition of flue gas escape, open the regulating valves appropriately to ensure the negative pressure in the circulating fume hood and prevent the fume from escaping, so as to achieve the purpose of increasing the proportion of circulating flue gas.

[0025] Attached below Figure 1~2 And embodiment the present invention is described in further detail:

[0026] Such as figure 2 , 3 As shown, a method for increasing the circulating flue gas rate comprises the following steps:

[0027] S1: Part of the bellows in the bellows 17 of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com