Ultralow-temperature explosion-proof lithium iron phosphate battery

A technology of lithium iron phosphate battery and lithium iron phosphate, which is applied in the direction of battery electrodes, secondary batteries, battery pack components, etc., can solve the problems that hinder the rapid development of lithium iron phosphate batteries, the performance of battery charging and discharging, and the failure of equipment to operate normally. problems, to achieve rapid deployment, improve low-temperature conductivity, and less demanding charging environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

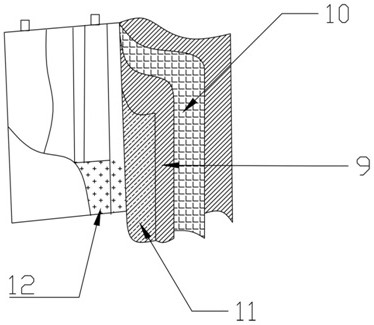

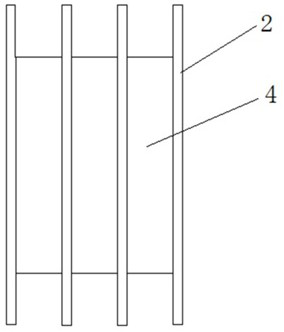

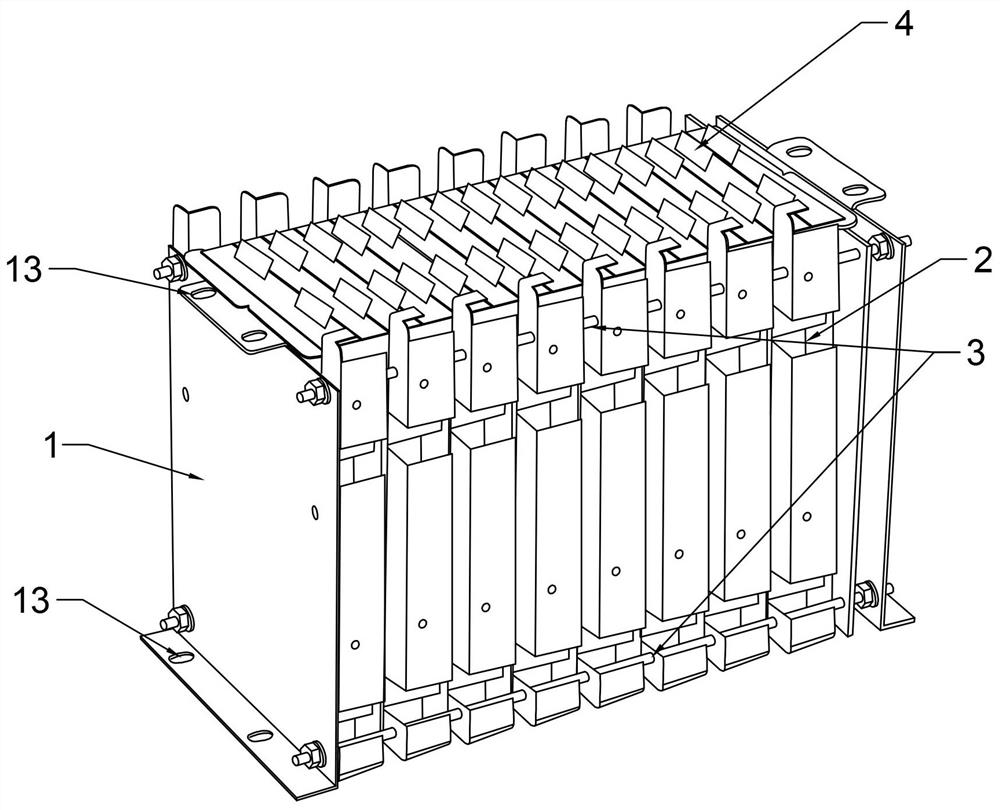

[0030] A kind of ultra-low temperature explosion-proof lithium iron phosphate battery, such as figure 1As shown, it includes a lithium iron phosphate battery cell. The lithium iron phosphate battery cell includes a positive electrode sheet 11, a negative electrode sheet 10, a diaphragm plate 9, and an electrolyte 12. The positive electrode sheet 11 is composed of a positive electrode current collector and a positive electrode active material, wherein the positive electrode The active material adopts the modified nano-scale lithium iron phosphate of more than two kinds of +2 valent elements; the negative plate 10 is composed of a negative electrode current collector and a negative electrode active material, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| critical point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com