Top well cementation method and device for self-communicated double-process screen pipe

A screen and general-type technology, which is applied to wellbore/well valve devices, earthwork drilling, wellbore/well components, etc., can solve problems such as re-operation risk, well wall collapse, and inability to circulate mud, etc., to achieve Improve the success rate of salvage, reduce the collapse of the well wall, and eliminate the effect of the piston effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

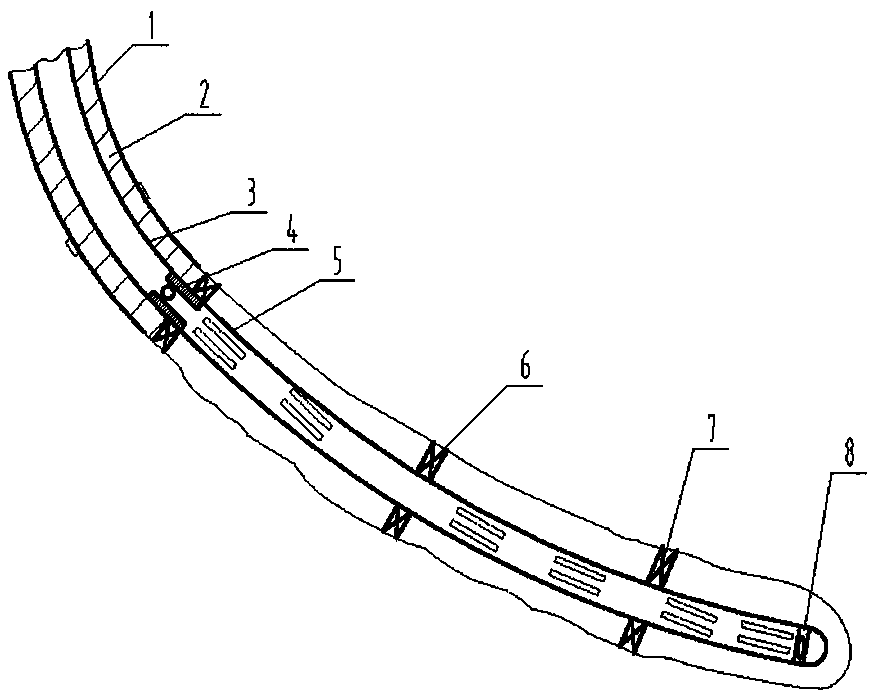

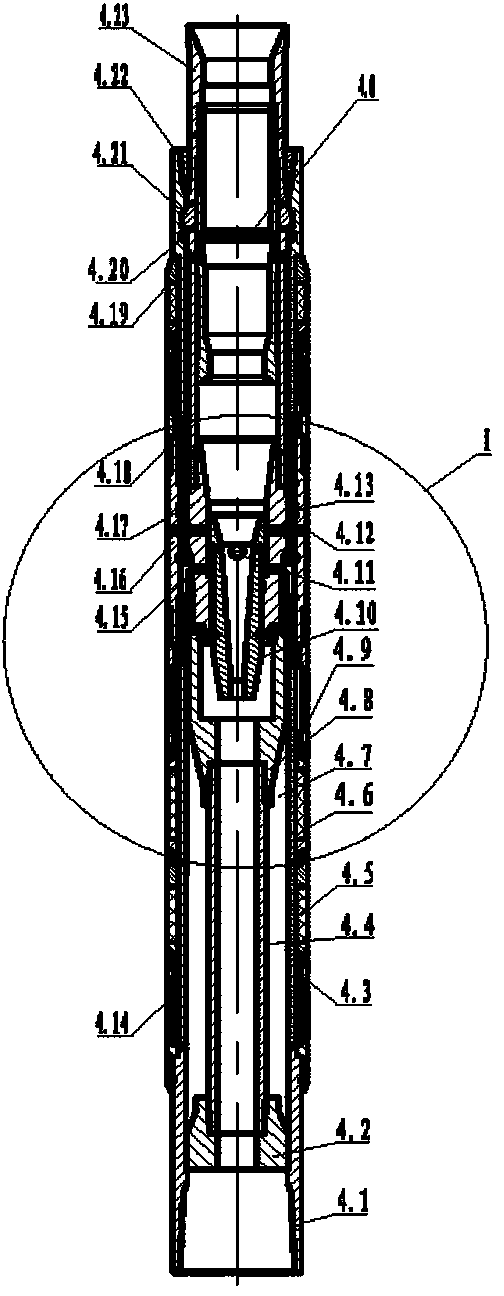

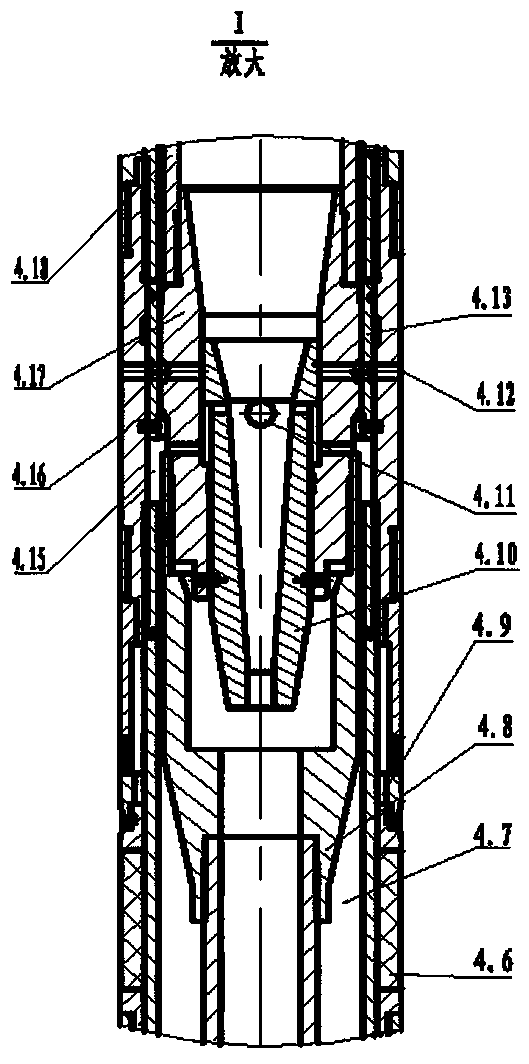

[0010] The present invention is described in detail below in conjunction with accompanying drawing: The method for cementing at the top of the self-passing type double-process screen pipe of the present invention is: the technical casing (1), the screen pipe (3), the casing pipe (2), the self-passing type screen pipe The top cementing device (4), the screen (5), the outer packer of the upper pipe (6), the outer packer of the lower pipe (7), and the pickling circulation valve (8) are connected according to the design, and go downhole with the pipe string. During the casing running process, the mud is circulated at intervals, and the ball is thrown in place to suppress the pressure, so that the packer lower rubber sleeve (4.5) and the packer upper rubber sleeve (4.6) of the self-drilling screen top cementing device (4) are inflated and sealed. Squeeze the pressure again and open the cementing hole (4.12) of the cementing device (4) at the top of the self-passing screen pipe, circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com