Intelligent rapid formation flow control method based on line width measurement

A flow control and line width technology, which is applied in the field of intelligently improving the quality of deposition manufacturing, one of the rapid prototyping methods, can solve the problems of solid model preparation errors, extrusion material volume or material volume per unit time that cannot be adjusted in real time Problems such as correction and affecting precision can be improved to improve forming precision, facilitate accurate installation and reduce collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

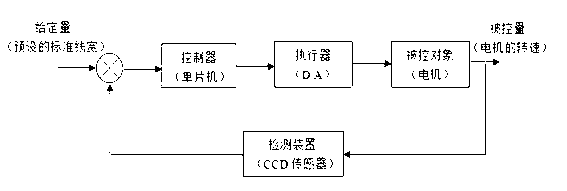

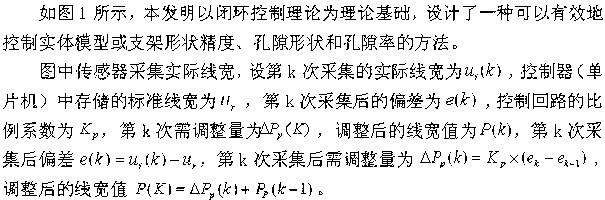

[0017]

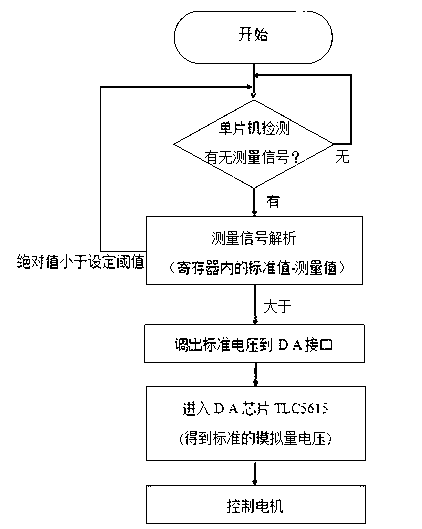

[0018] Such as figure 2 As shown, the control flow of the present invention is as follows.

[0019] Step 1. The slurry extruded by the nozzle is on the workbench of the forming equipment. The linear CCD sensor installed on the nozzle detects the preliminary image of the line width of the extruded material in deposition manufacturing, and processes the obtained image according to the gray value. Get a better quality image, and calculate the line width of the extruded slurry during the movement of the worktable according to the resolution of the CCD;

[0020] Step 2. Send the calculated line width value into the register of the microcontroller, compare it with the preset standard line width value (0.3mm), and calculate the deviation;

[0021] Step 3. If the actual line width is smaller than the standard line width and the absolute value of the difference is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com