A secondary coal mining method with strip reverse paste filling

A technology of paste filling and coal mining method, which is applied in filling materials, ground mining, mining equipment and other directions, can solve the problems of coal can not be extracted, waste of resources, surface subsidence, etc., to reduce the occupation of land, reduce environmental pollution, The effect of removing the gangue mountain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

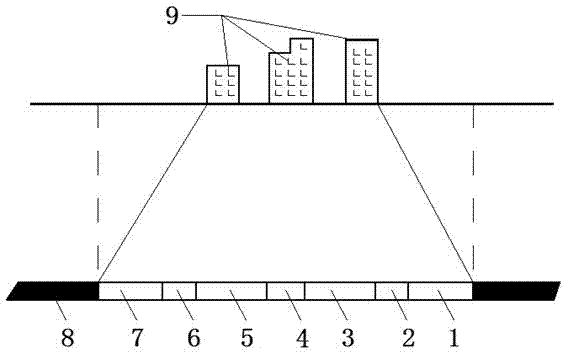

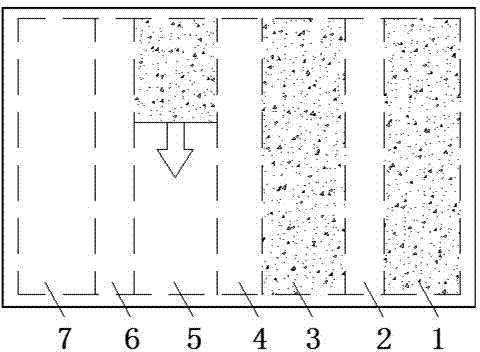

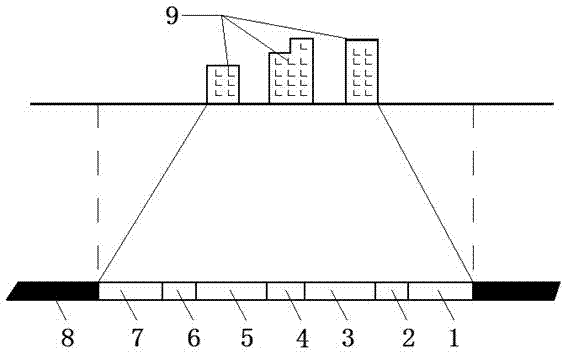

[0019] Secondary coal mining method with strip reverse paste filling of the present invention: first extract the geological information of the area of the surface building group 9 above the coal seam 8, and based on the range and protection level of the surface building group 9, determine the range of the traditional mining area as the basis , so that the surface buildings are within the protection range of the filling strip, and the protection level requirements of the "Buildings, Water Bodies, Railways and Main Shafts and Coal Pillar Retention and Pressure Coal Mining Regulations" are used as the standard to determine the coal filling mining area under the mine ; Then divide the paste filling strip and the mining strip, wherein, the paste filling strip has a width of 80-220m, and the mining strip has a width of 30-70m. The first, second, third, and four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com