Water stopping device for tunneling machine going in and out of tunnel and water stopping method

A water stop device, technology for entering and exiting holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0082] The difference between this embodiment and embodiment 1 is:

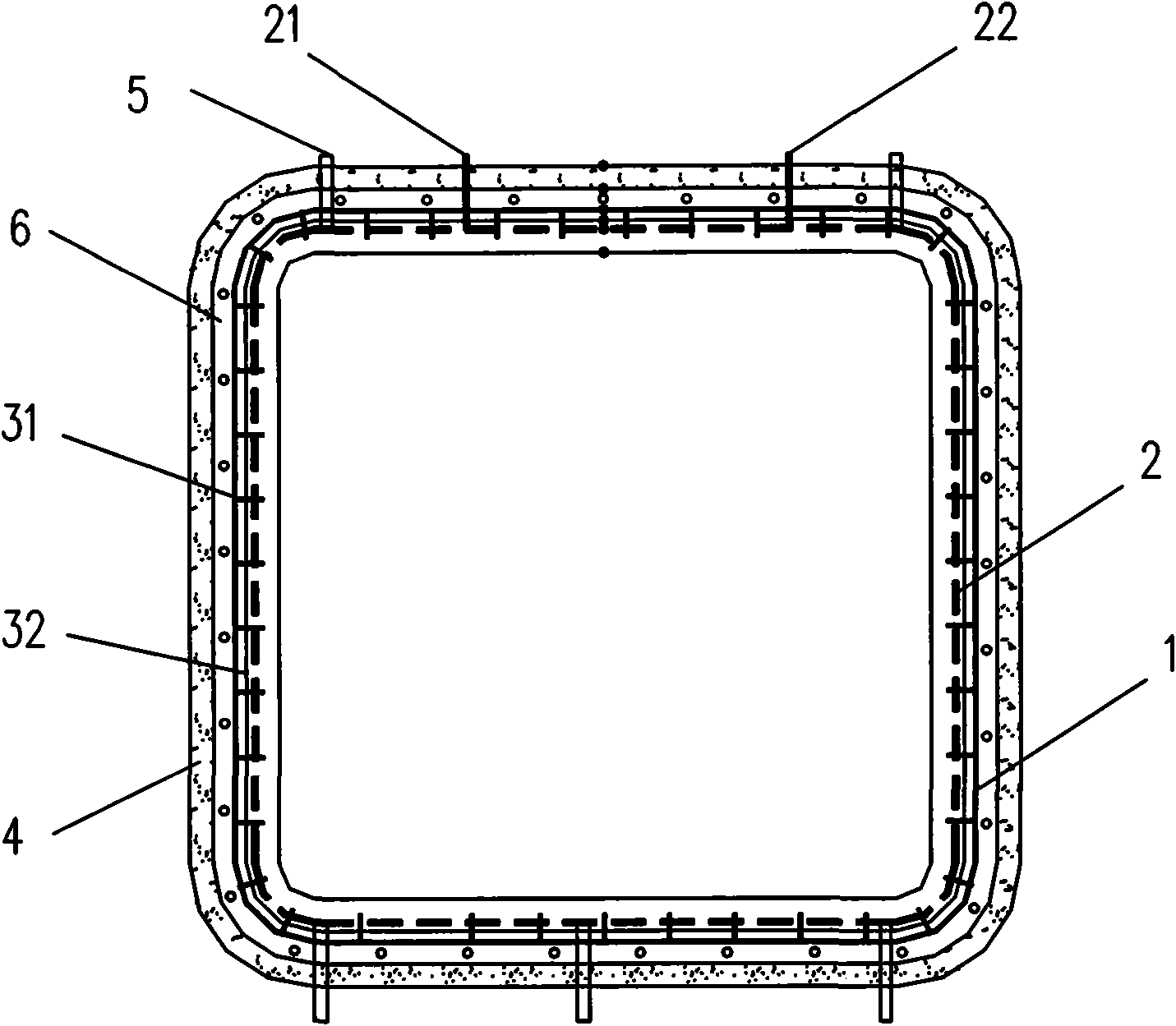

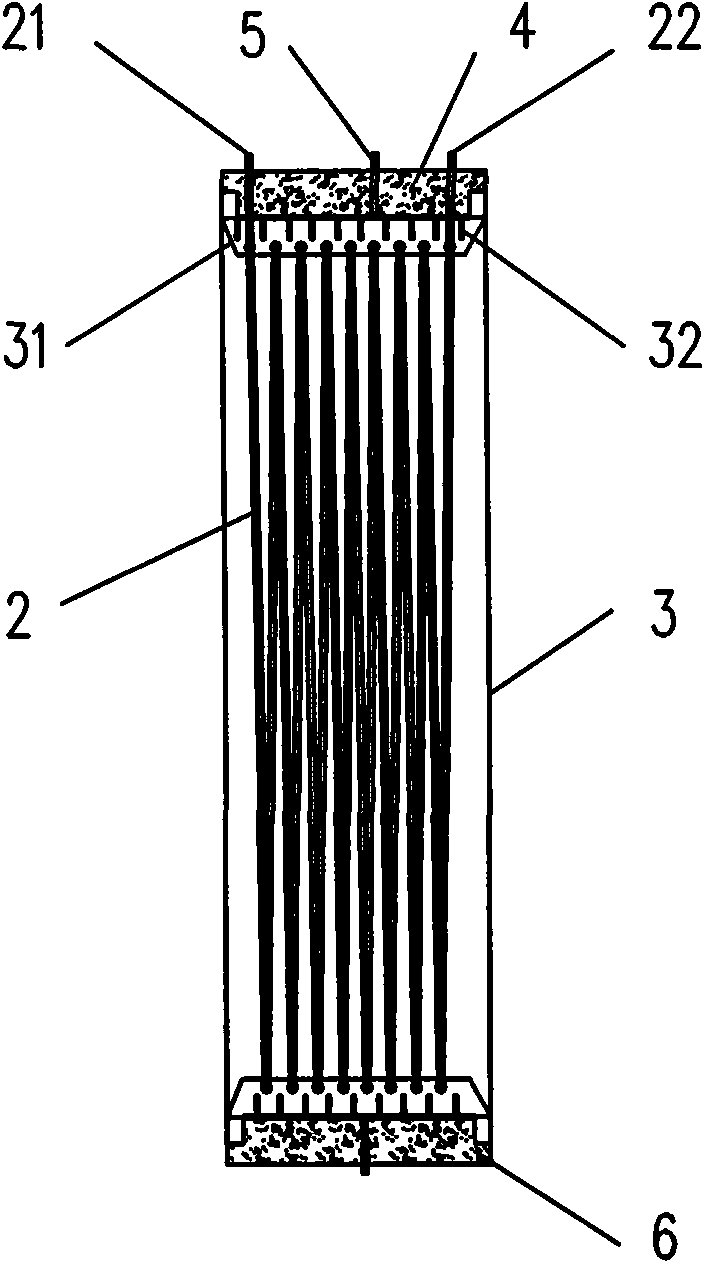

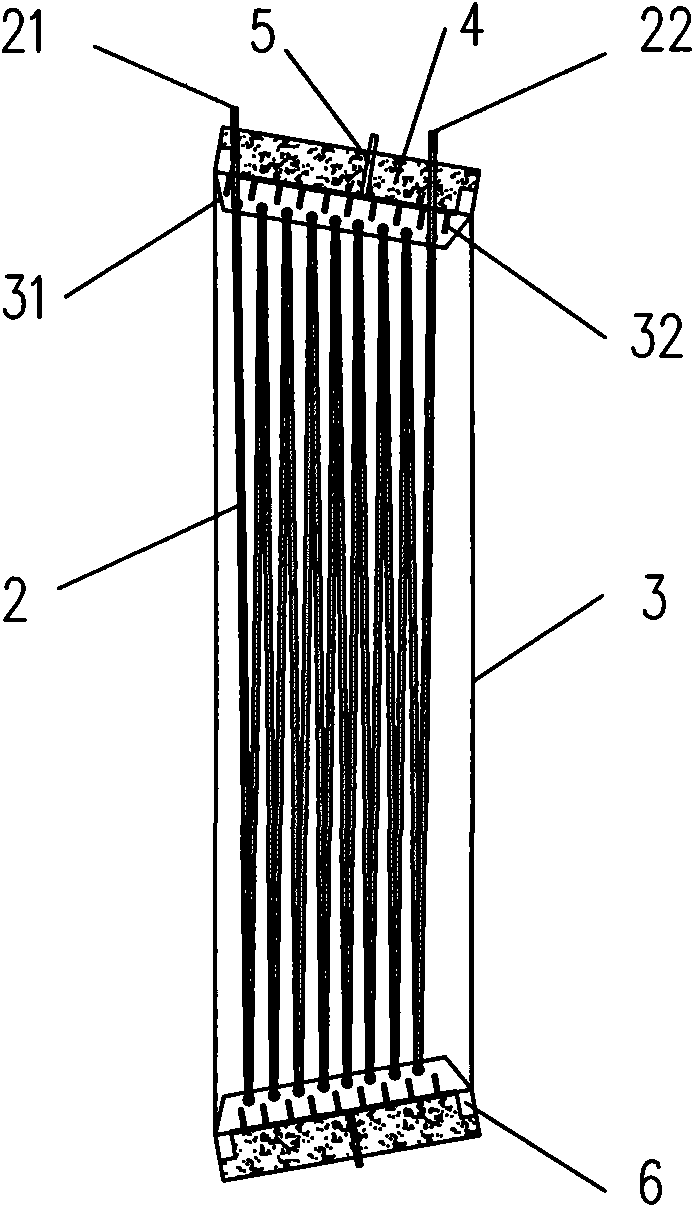

[0083] See image 3 with Figure 4 :The freezing pipe 2 is a pipe arranged in a serpentine shape, such as Figure 5 Shown is an expanded view of a serpentine arrangement of freezing tubes 2. The specific structure is as follows: The freezing pipe is a number of pipes evenly distributed on the inner wall of the sleeve. The head and tail of the pipe are placed in the longitudinal direction of the sleeve, and the adjacent pipes are connected by hoses in turn, thereby forming what is generally called Serpentine pipe. The inner wall of the sleeve 1 is staggered with several transverse stiffeners 31 and several longitudinal stiffeners 32. The transverse stiffeners 31 and the longitudinal stiffeners 32 are welded together. The transverse stiffeners 31 are provided with several small holes, which are frozen. The pipe 2 passes through the small hole, thereby forming a serpentine pipe. In addition, the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com