Lightweight assembled steel-structure house and building method thereof

A prefabricated, steel structure technology, applied in the direction of building construction, protective buildings/shelters, buildings, etc., can solve the problems of long construction period, short service life, low construction efficiency, etc., to achieve large assembly operation space, The effect of improving the service life and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

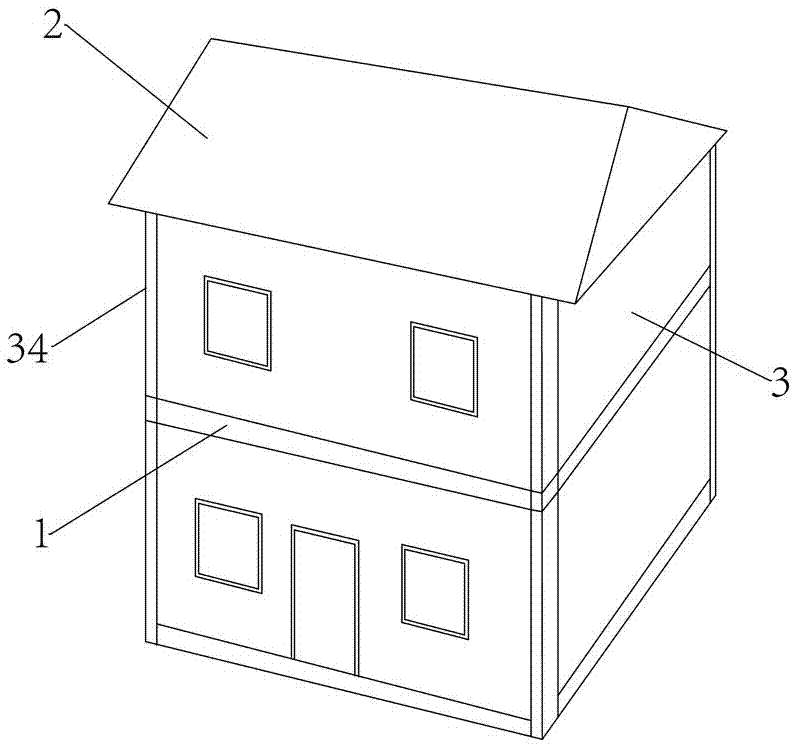

[0035] like figure 1 Shown, the present invention comprises parts such as floor slab 1, roof slab 2, body of wall 3 and doors and windows, wherein, roof slab 2 is the top board that covers on the top floor slab 1 of the house.

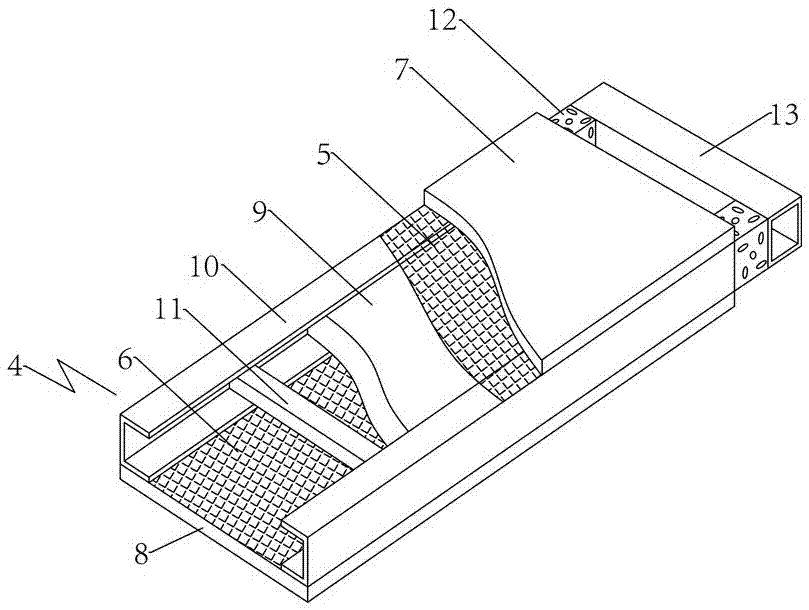

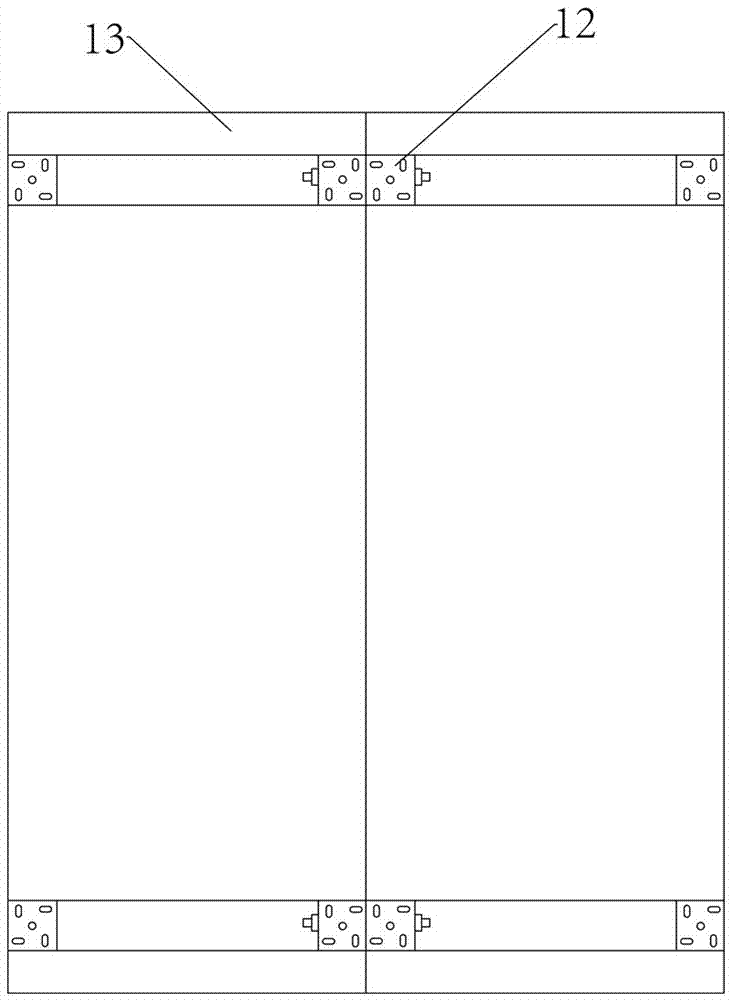

[0036] like figure 2 As shown, the floor slab 1 is a C-shaped steel prefabricated floor slab 1, which uses the first steel structure frame 4 as the skeleton, and a first steel bar grate 5 and a first concrete layer 7 are arranged on one side of the first steel structure frame 4. The other side of the steel structure frame 4 is provided with a second steel bar grate 6 and a second concrete layer 8, and in the first steel structure frame 4, that is, between the first steel bar grate 5 and the second steel bar grate 6, there is a shock-absorbing sound insulation On layer 9, docking frames are respectively arranged at both ends of the steel structure frame.

[0037] The first steel structure frame 4 includes two side beams 10 arranged in parallel and se...

Embodiment 2

[0049] The construction method of the light-weight assembled steel structure house of the present invention comprises the following steps:

[0050]1. Production of docking fittings: a number of installation holes are respectively opened on the four side walls of a section of square-mouth pipe body 14, and the ports and side walls of the square-mouth pipe body 14 are square, and the two opposite side walls The mounting holes are opposite one by one. like Figure 4 As shown, the mounting holes include a circular positioning hole 15 and four assembly holes 16 surrounding the positioning hole 15 . The positioning hole 15 is provided at the center position of the side wall of the square mouth pipe body 14, so as to facilitate quick positioning during docking. The assembly holes 16 are strip holes, and the centers of the four assembly holes 16 are connected in sequence to form a square. The center of the square coincides with the center of the positioning hole 15, and the diagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com