Large-specification veneer aluminum plate showing wall installation system and construction method thereof

An installation system and large-scale technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems of aluminum plate hanging buckle correspondence, high installation accuracy requirements, and limited adjustment tolerance, so as to avoid sticking The effect of fastness, reduction of construction process, reduction of parts and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

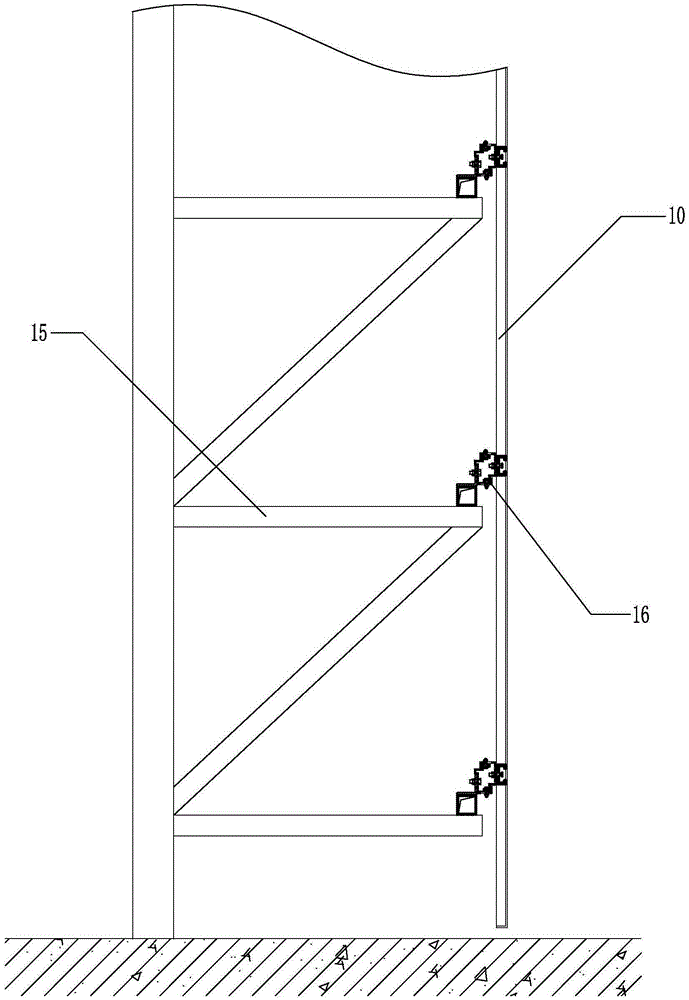

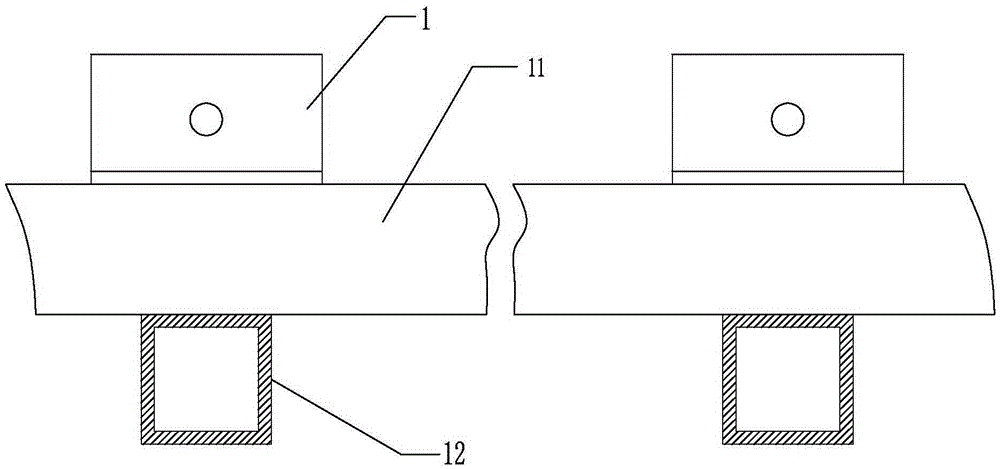

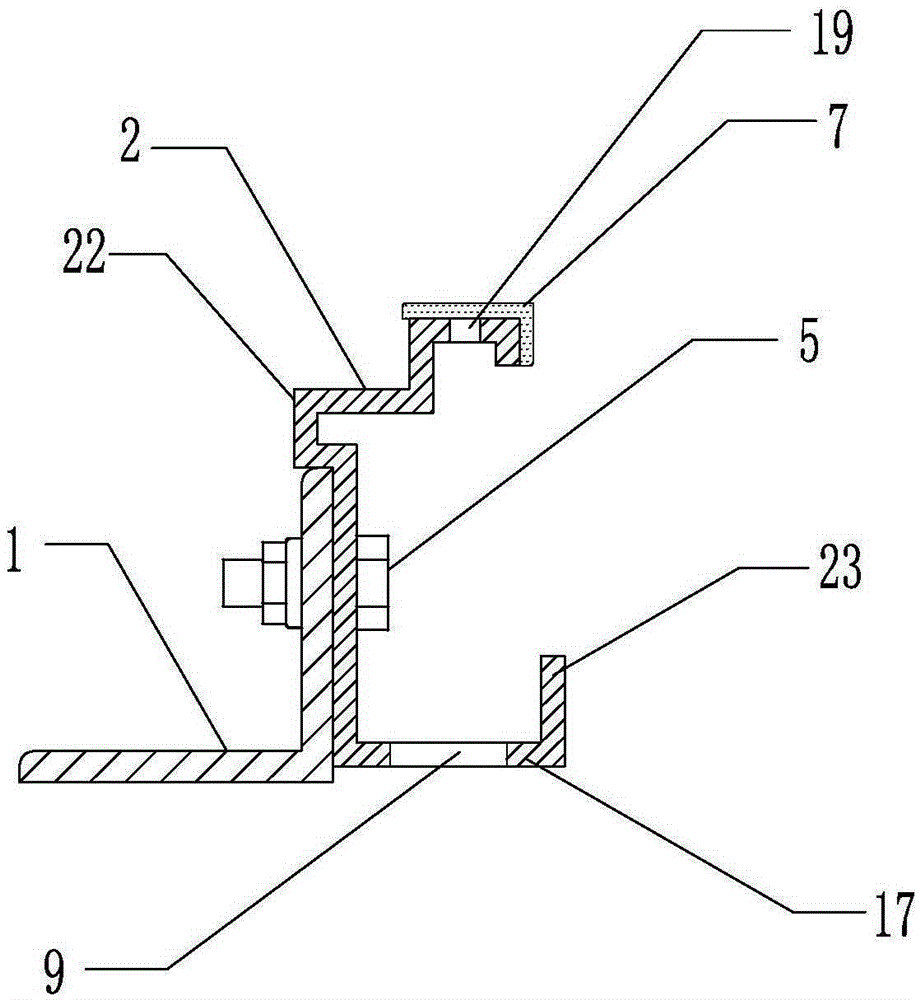

[0034] Embodiment one: see Figure 1-7 As shown, a large-scale decorative display aluminum panel wall installation system includes a base frame 15, a number of connecting components 16 and an aluminum plate 10, and the aluminum plate 10 is installed on the base frame 15 through the connecting components 16. The connection assembly 16 includes a corner code connecting piece 2 and a leveling movable piece 3. The corner piece connecting piece 2 is connected to the angle steel 1 through the anchor bolt 5, and the angle steel 1 is fixed on the base frame 15. The upper and lower ends of the firmware 2 are respectively provided with flanges 17, the flange 17 at one end is provided with a fixing hole 19, and the flange 17 at the other end is provided with an adjustment hole 9, and one side of the leveling movable firmware 3 The aluminum plate fixture is fixed to the aluminum plate 10, and the upper and lower ends of the other side are respectively provided with a connecting edge 18 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com