Patents

Literature

54results about How to "Guarantee the firmness of the bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

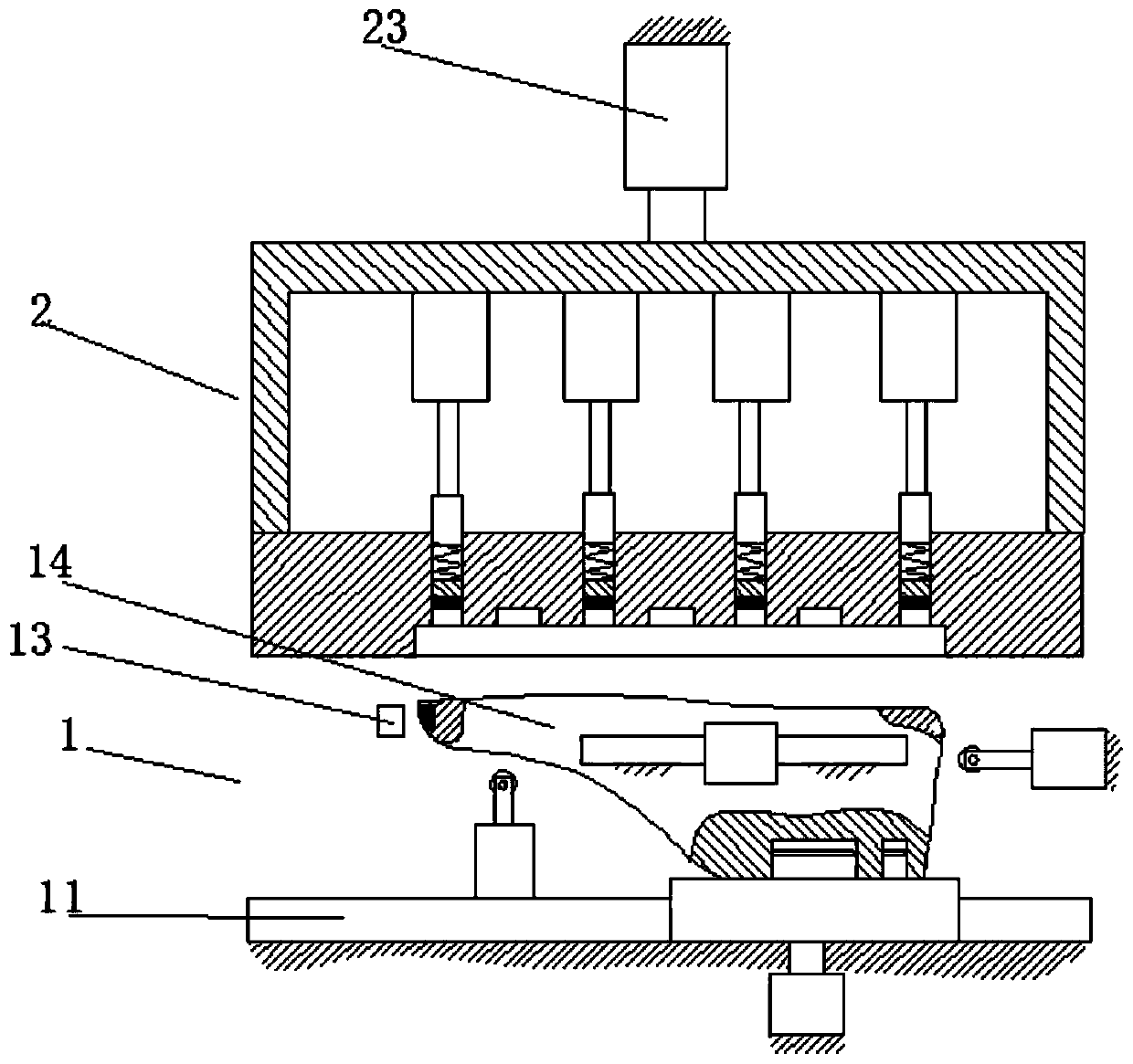

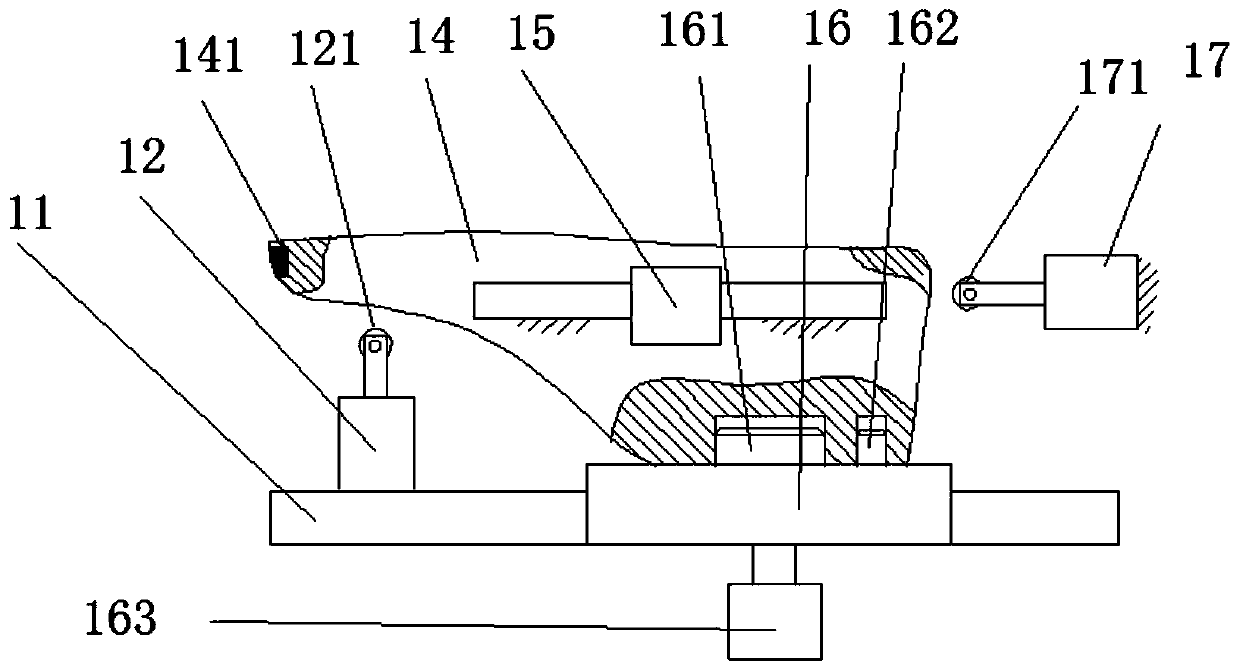

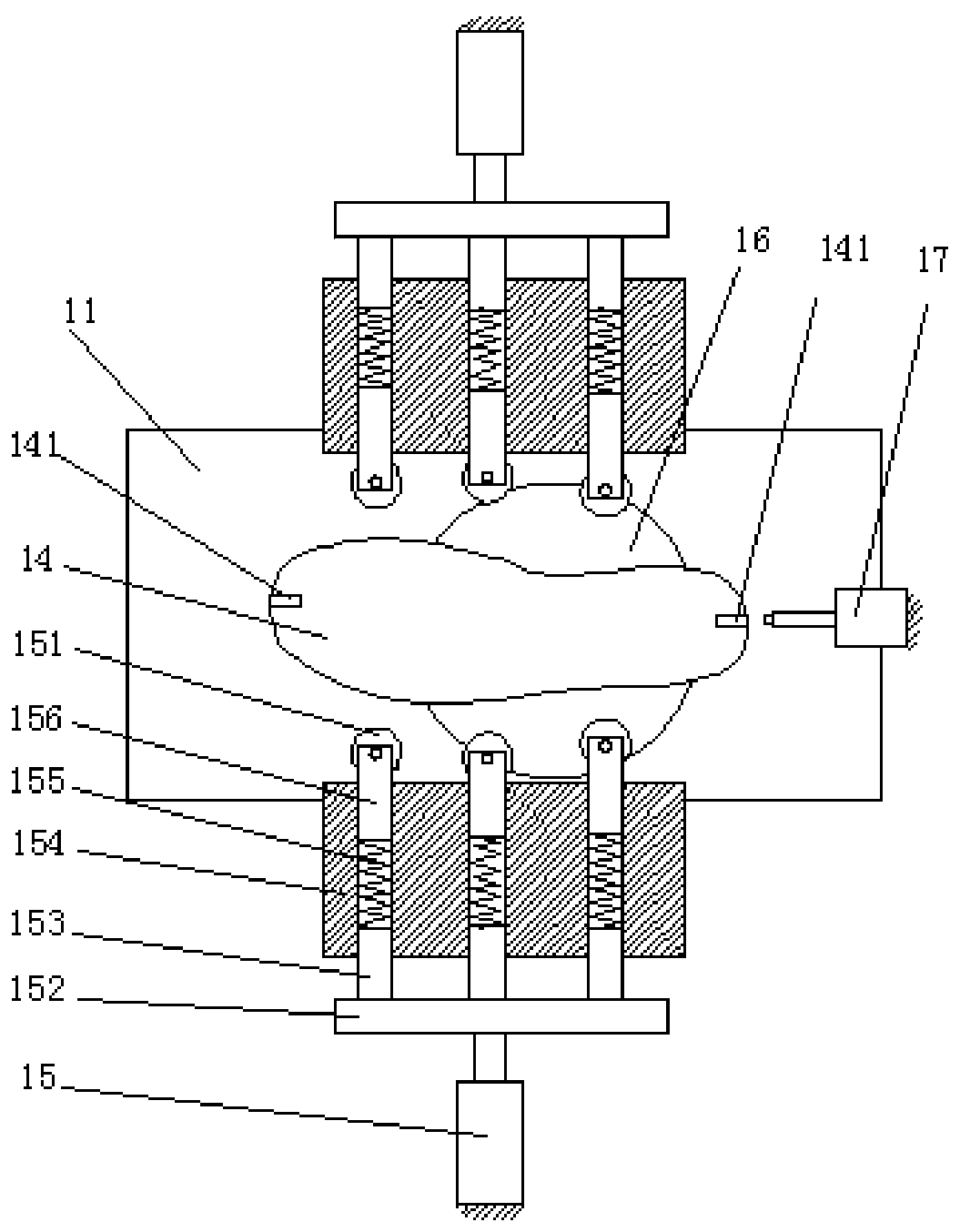

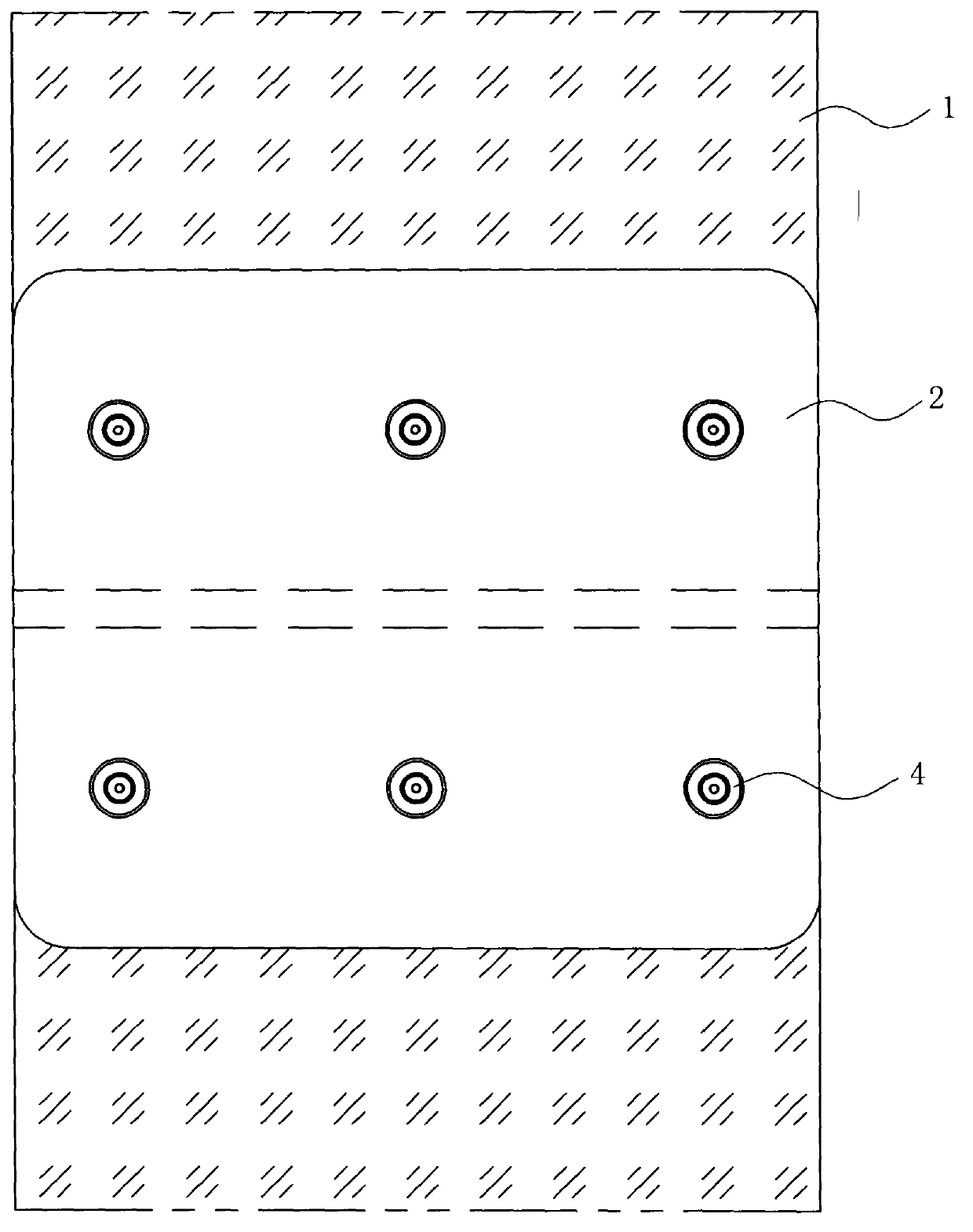

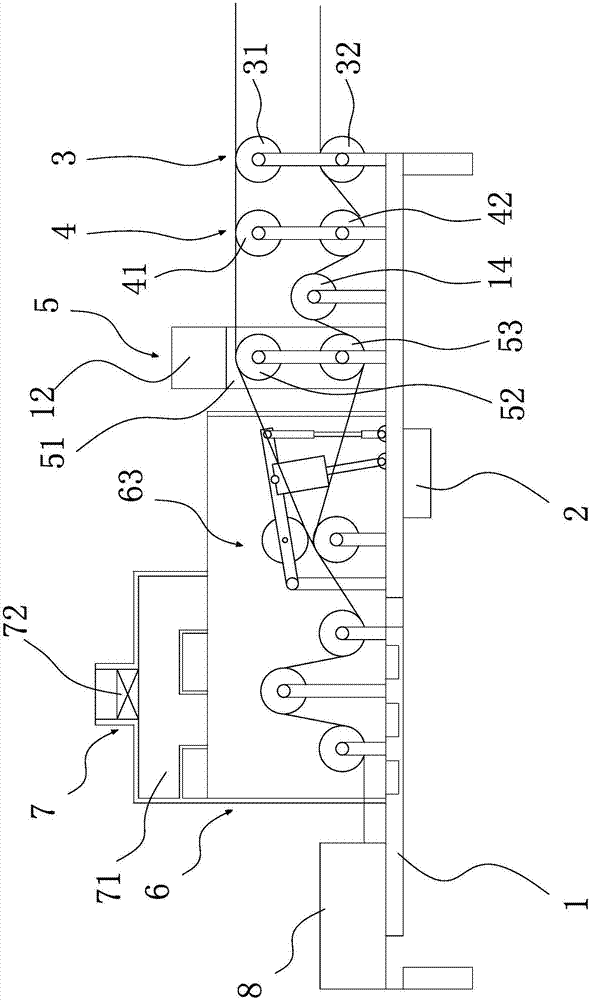

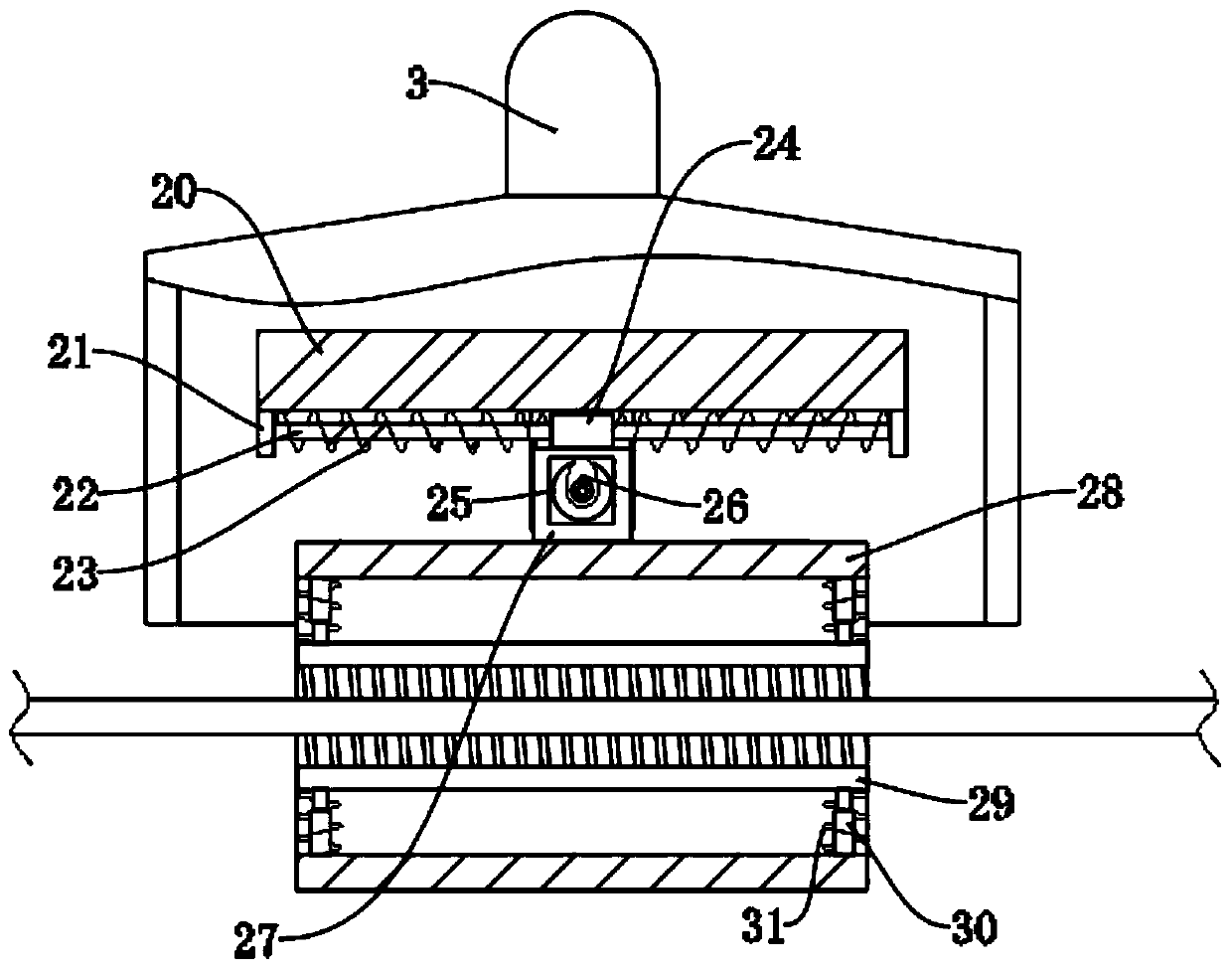

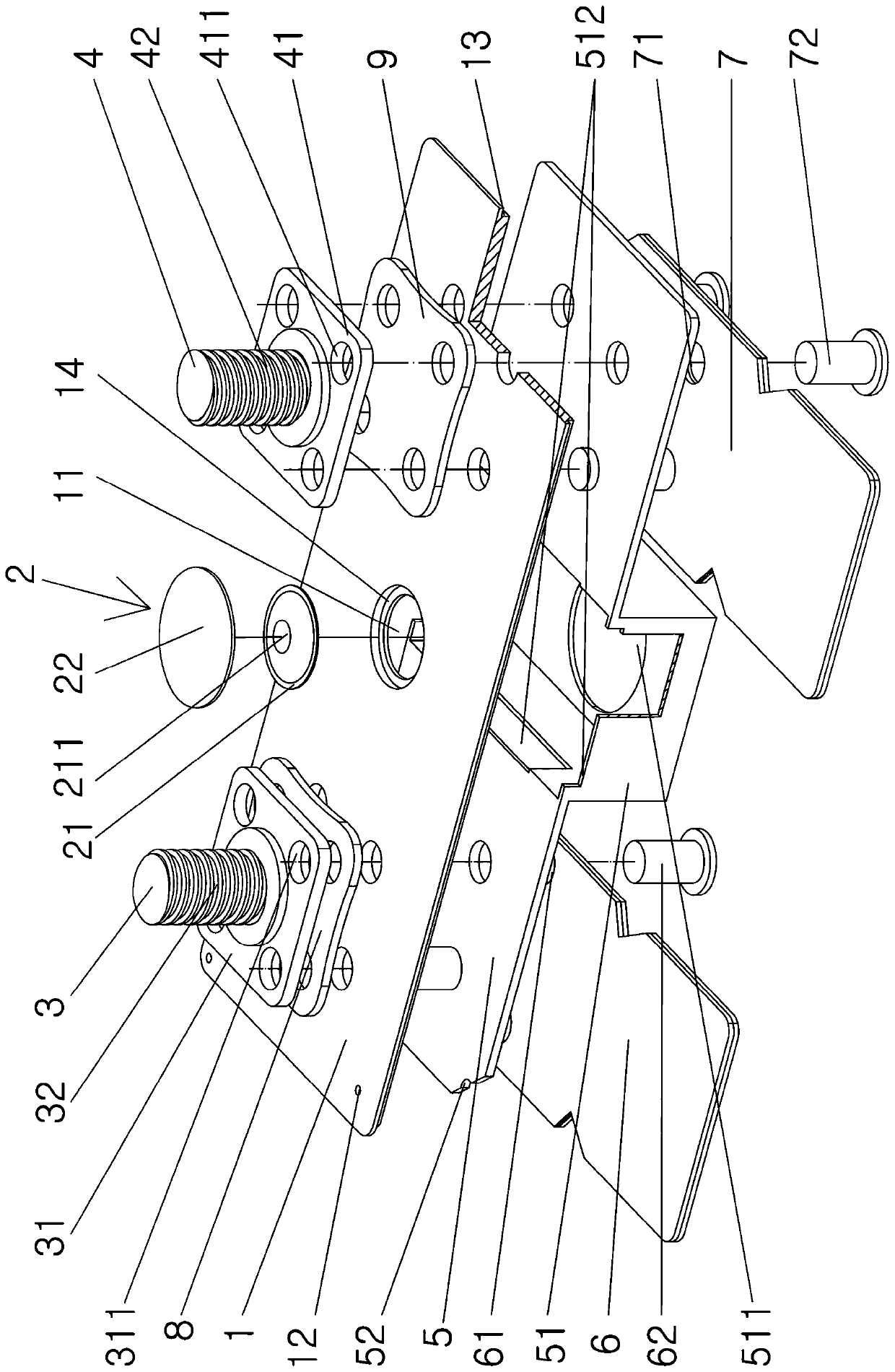

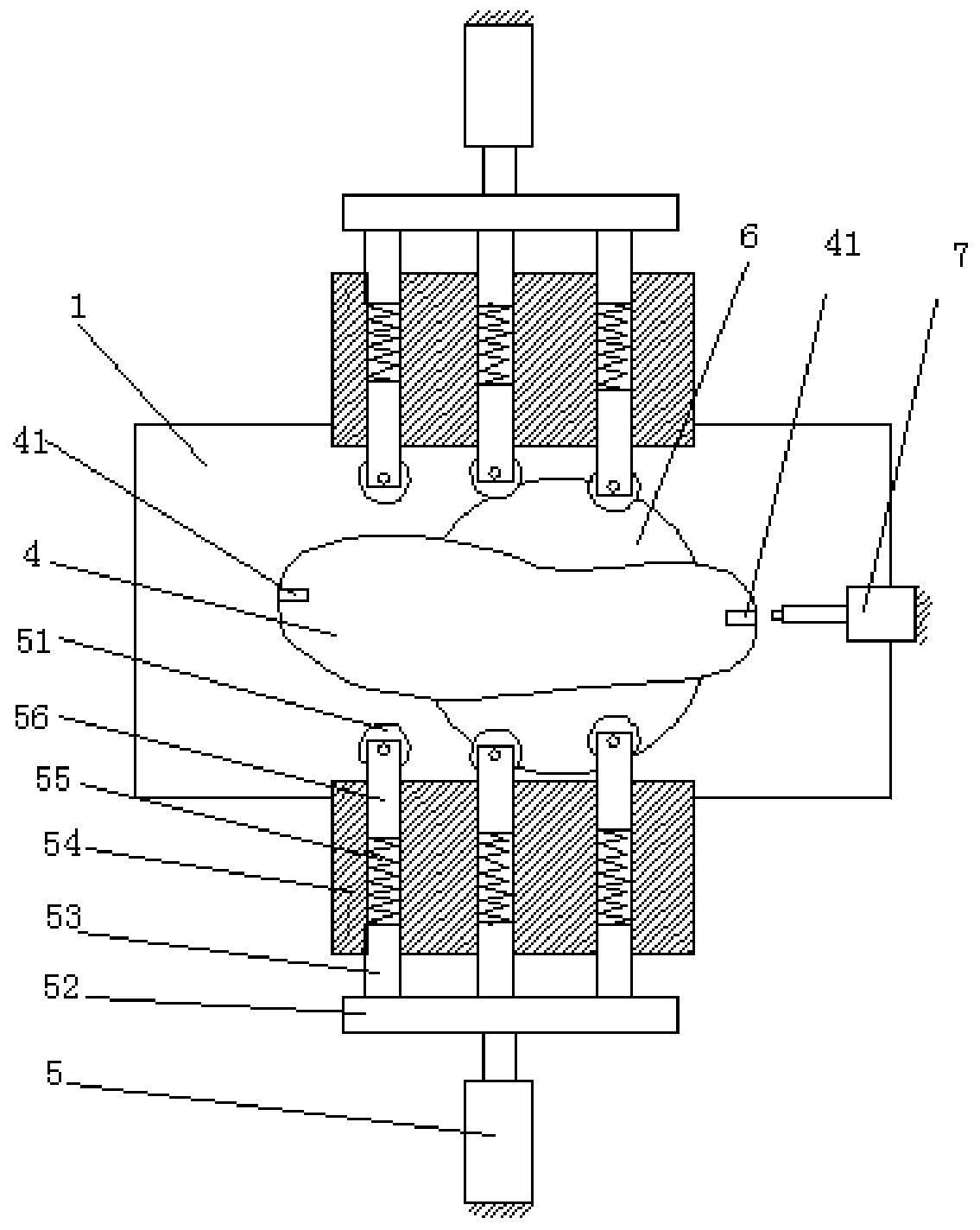

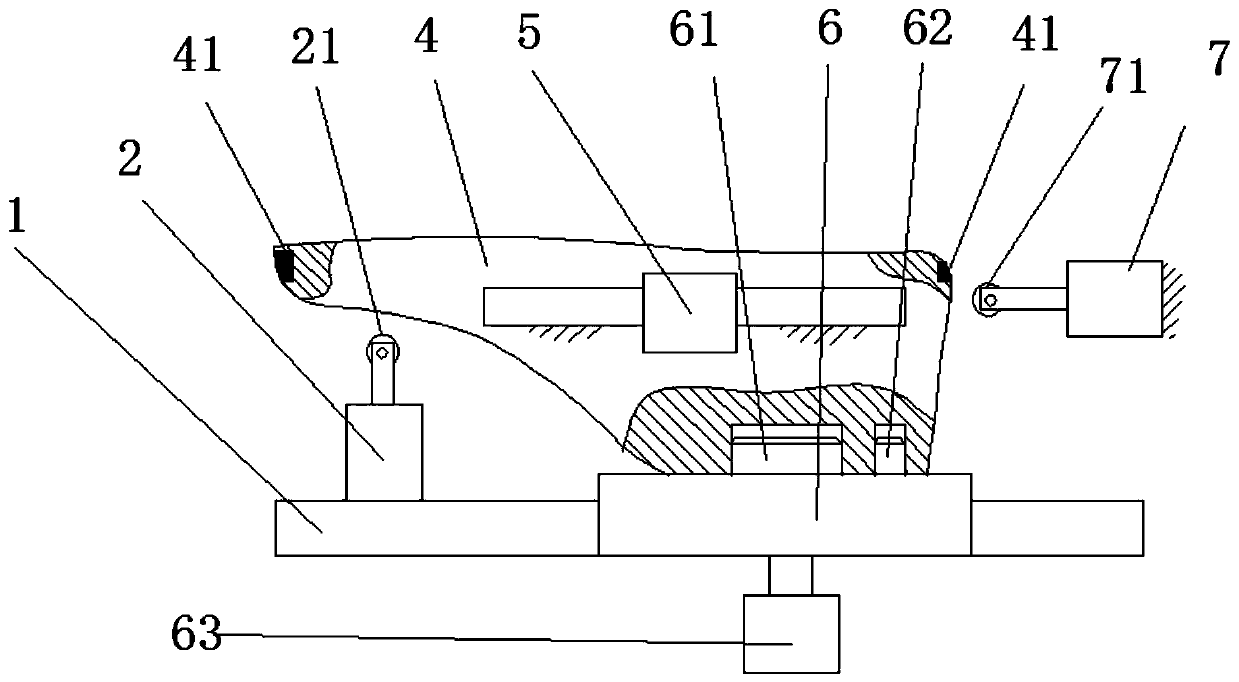

Upper and sole press-fitting equipment

InactiveCN110025083APrevent misalignment or even falling offGuarantee the firmness of the bondShoe gluingStable stateEngineering

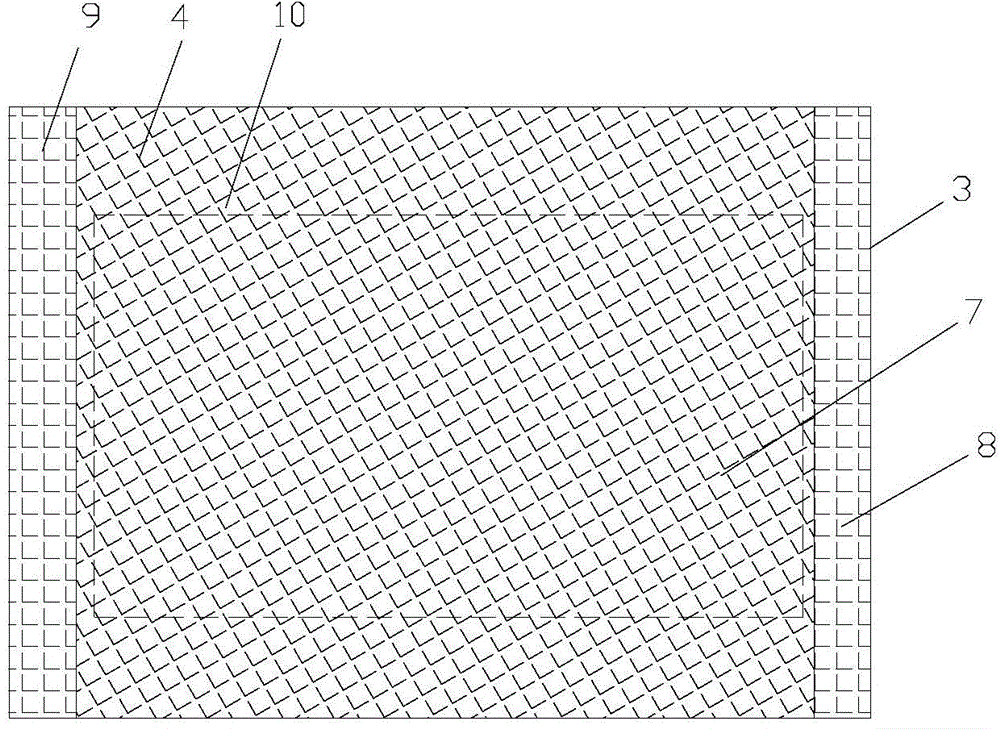

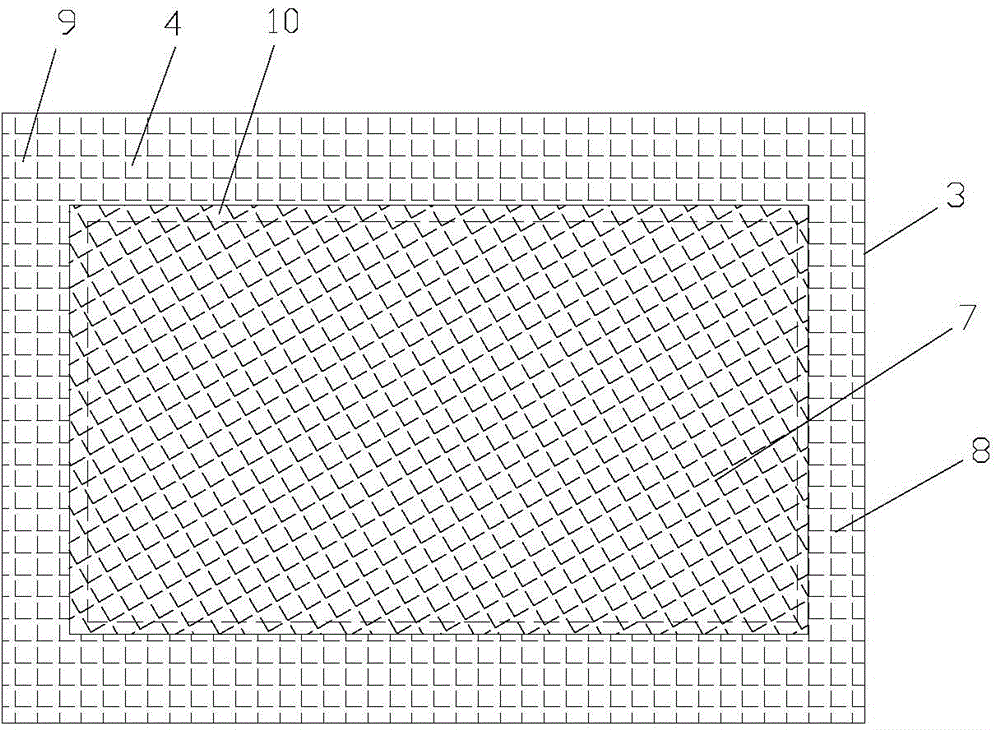

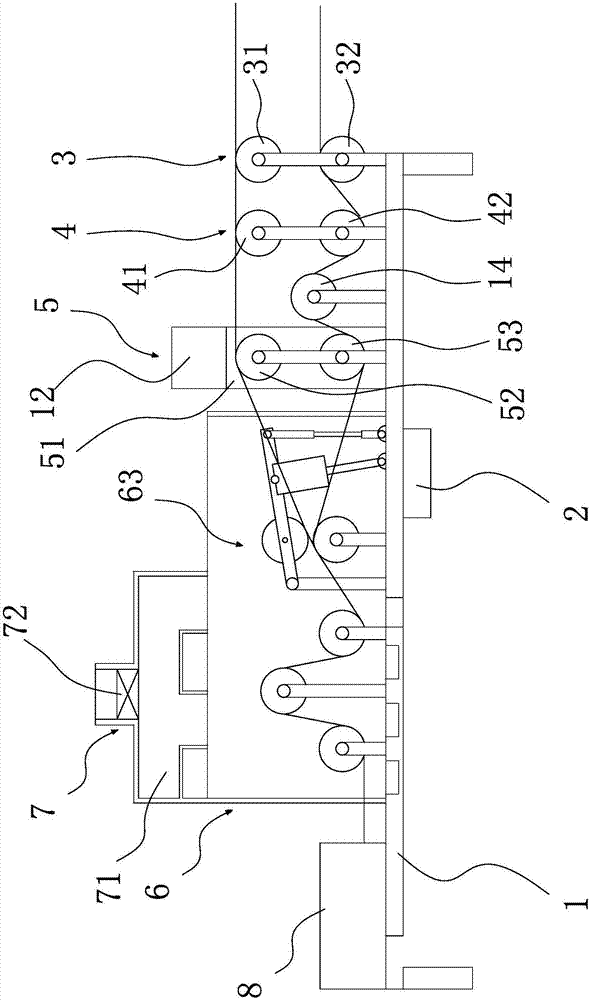

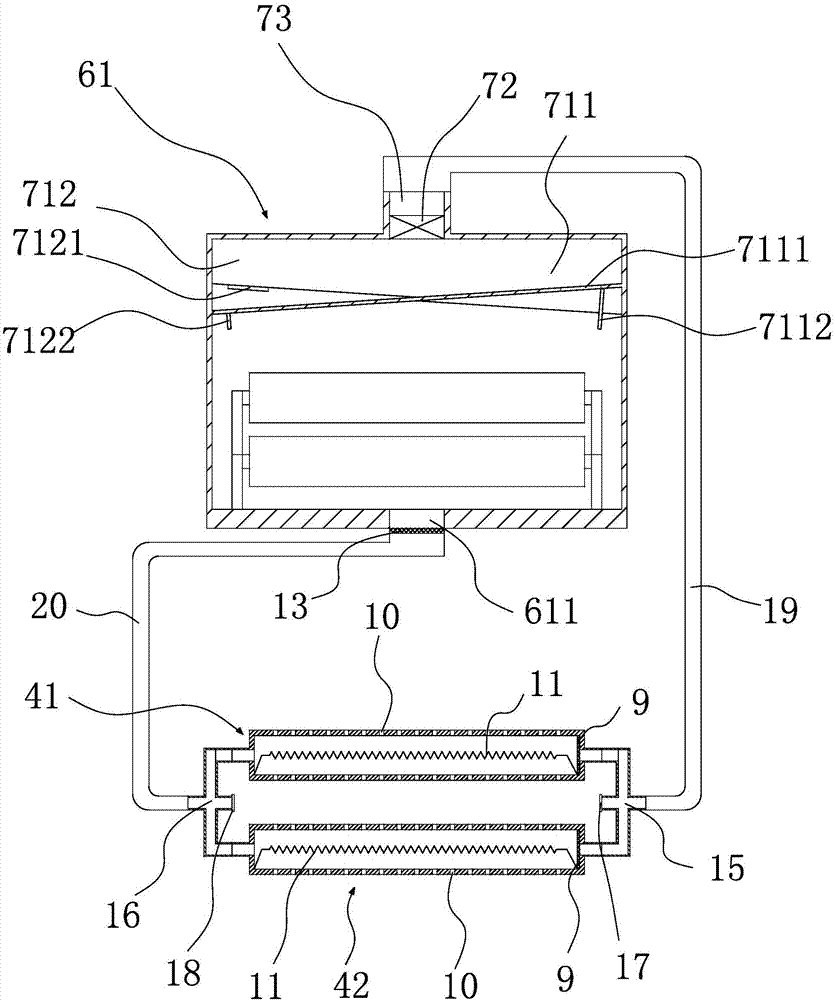

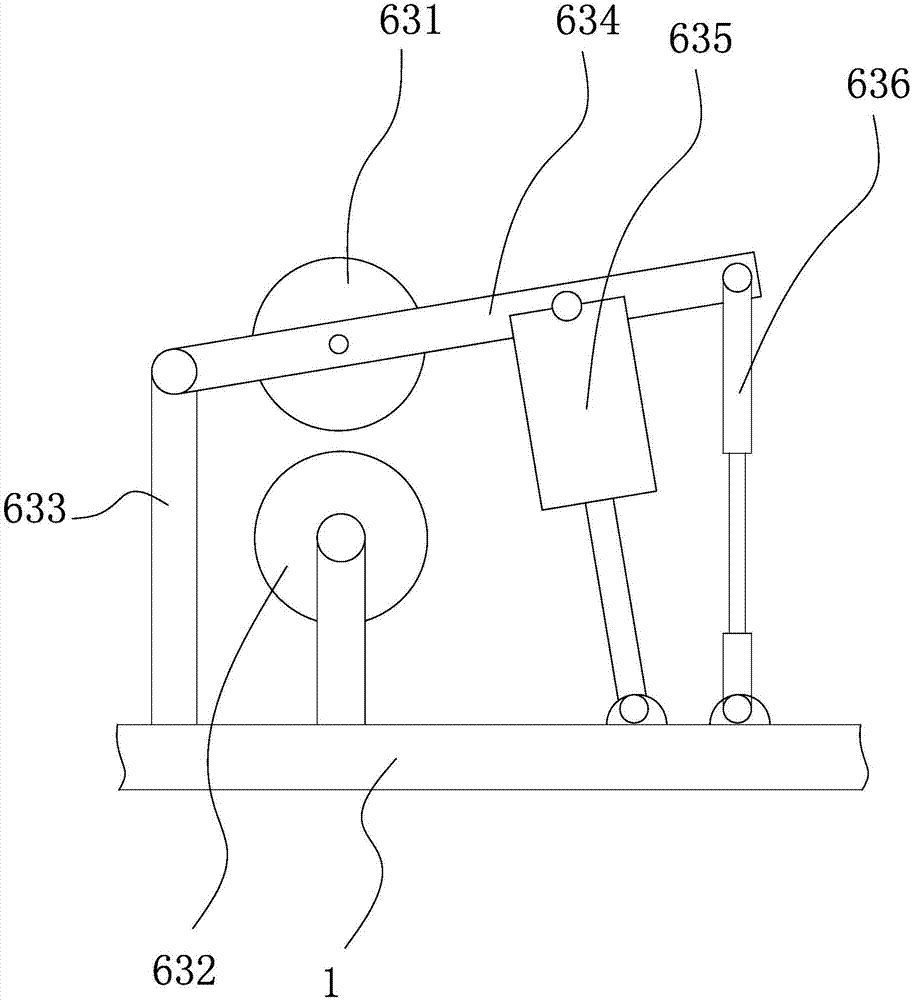

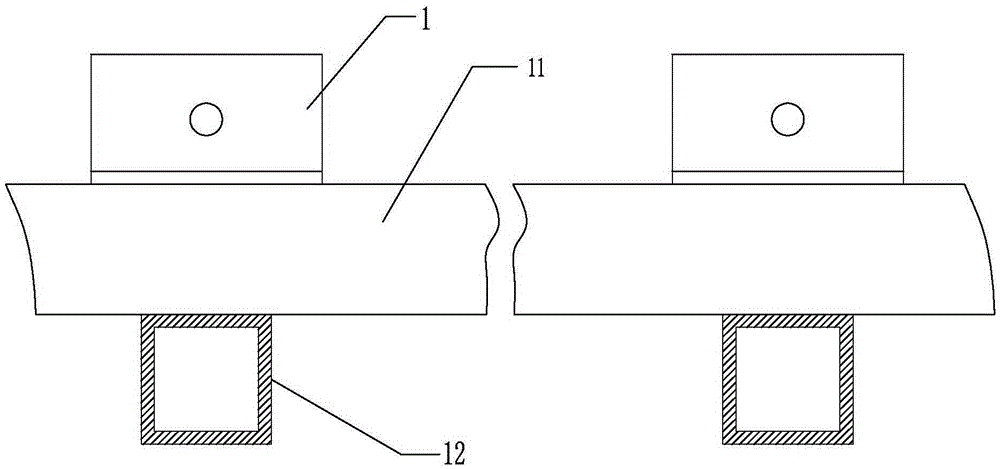

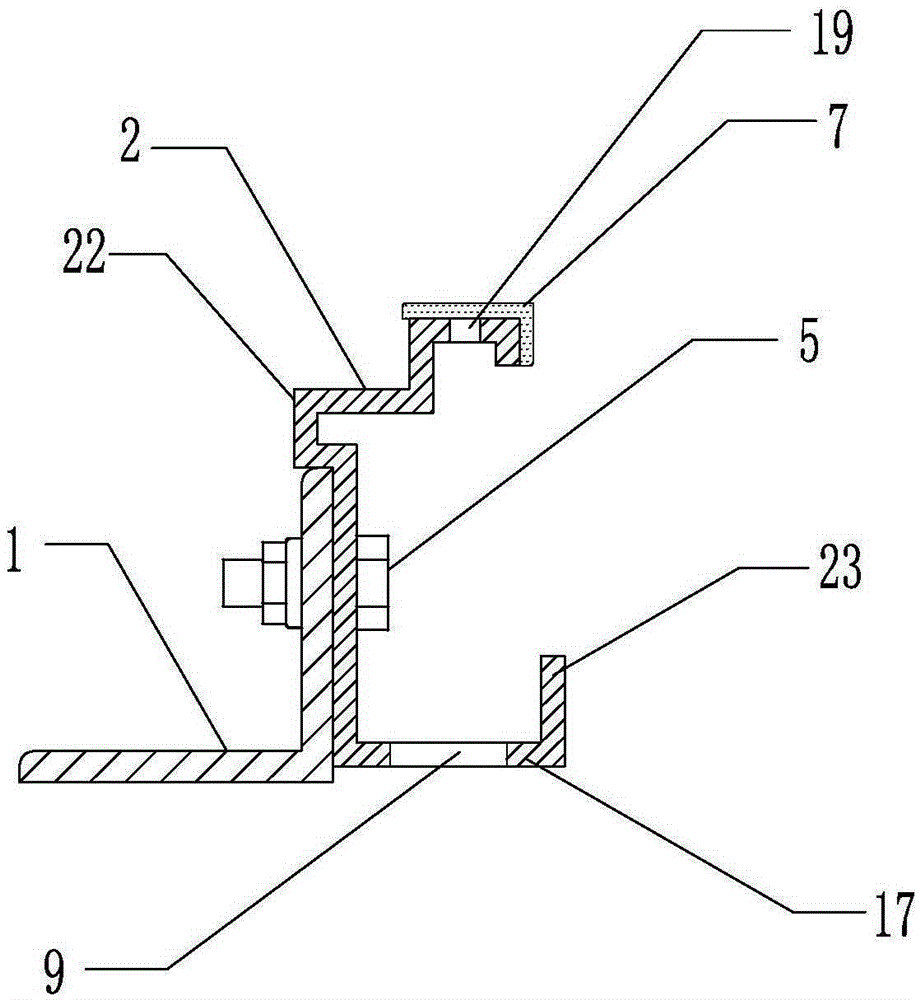

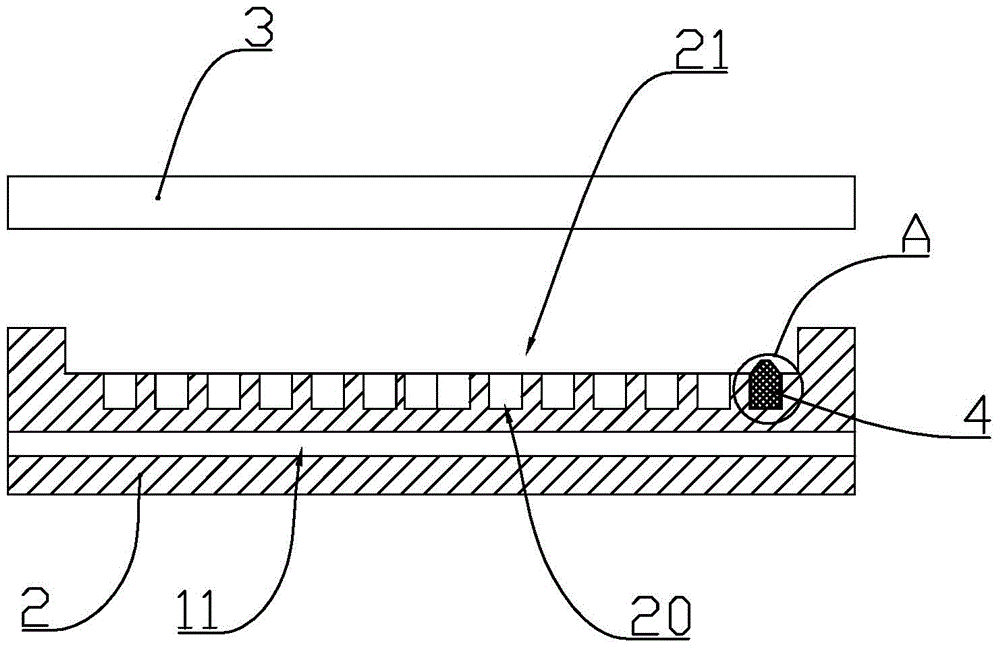

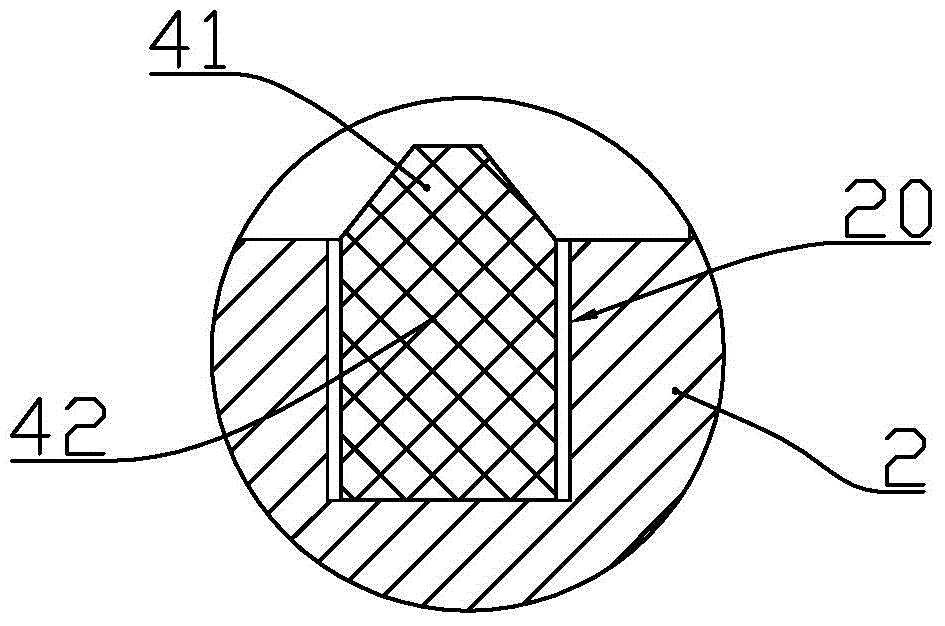

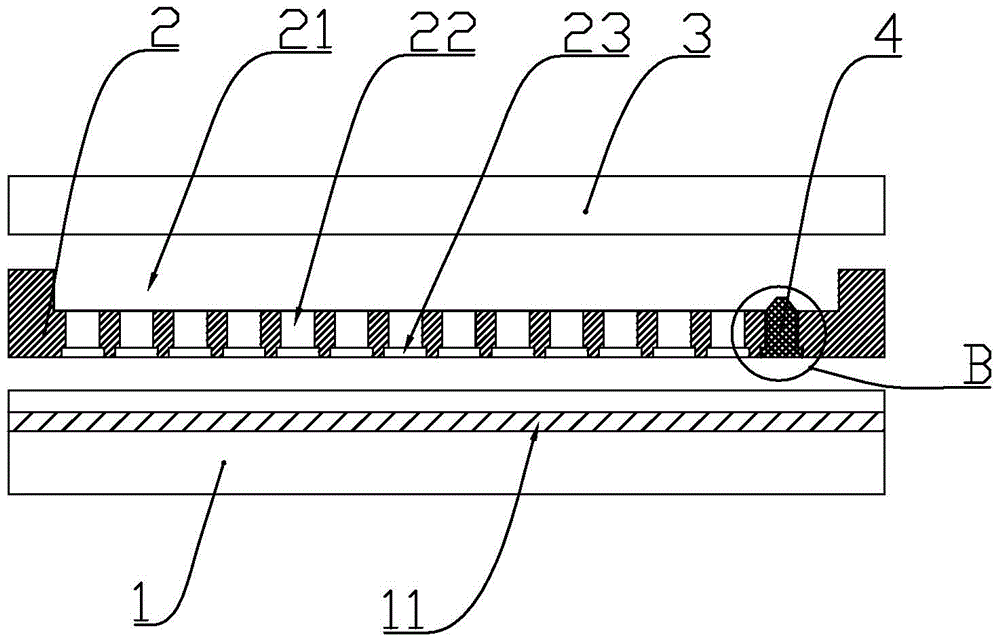

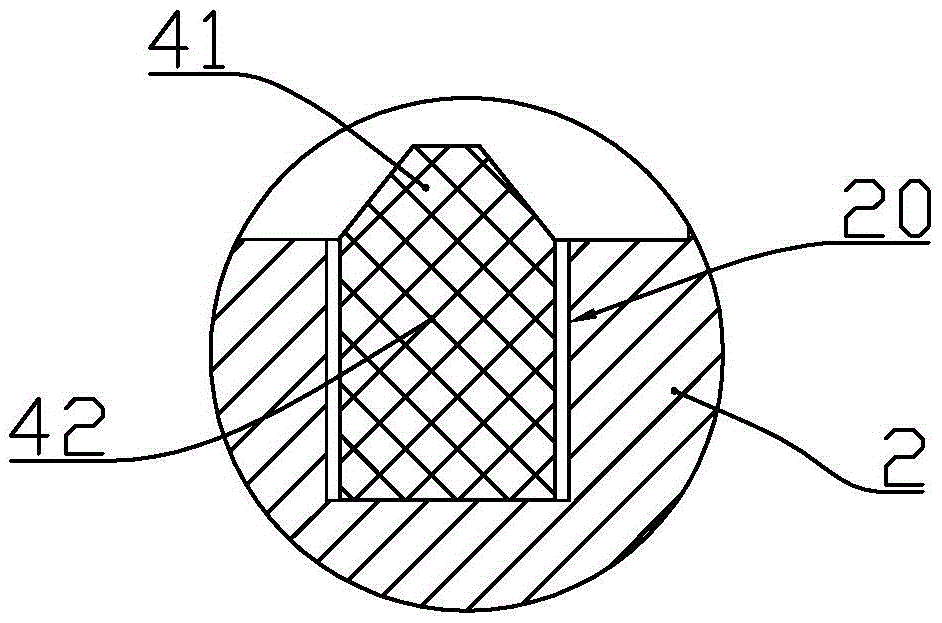

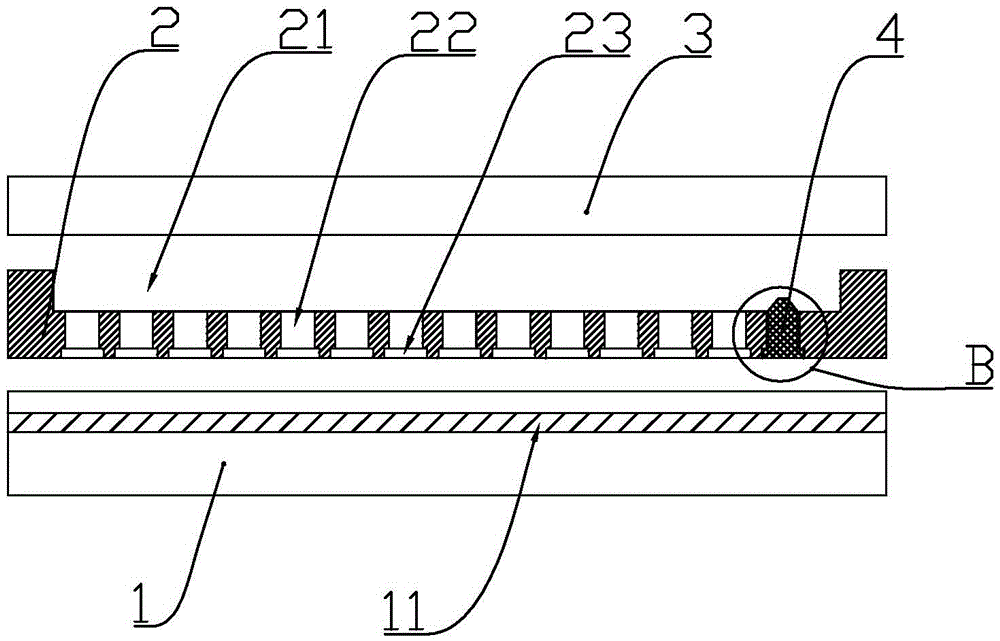

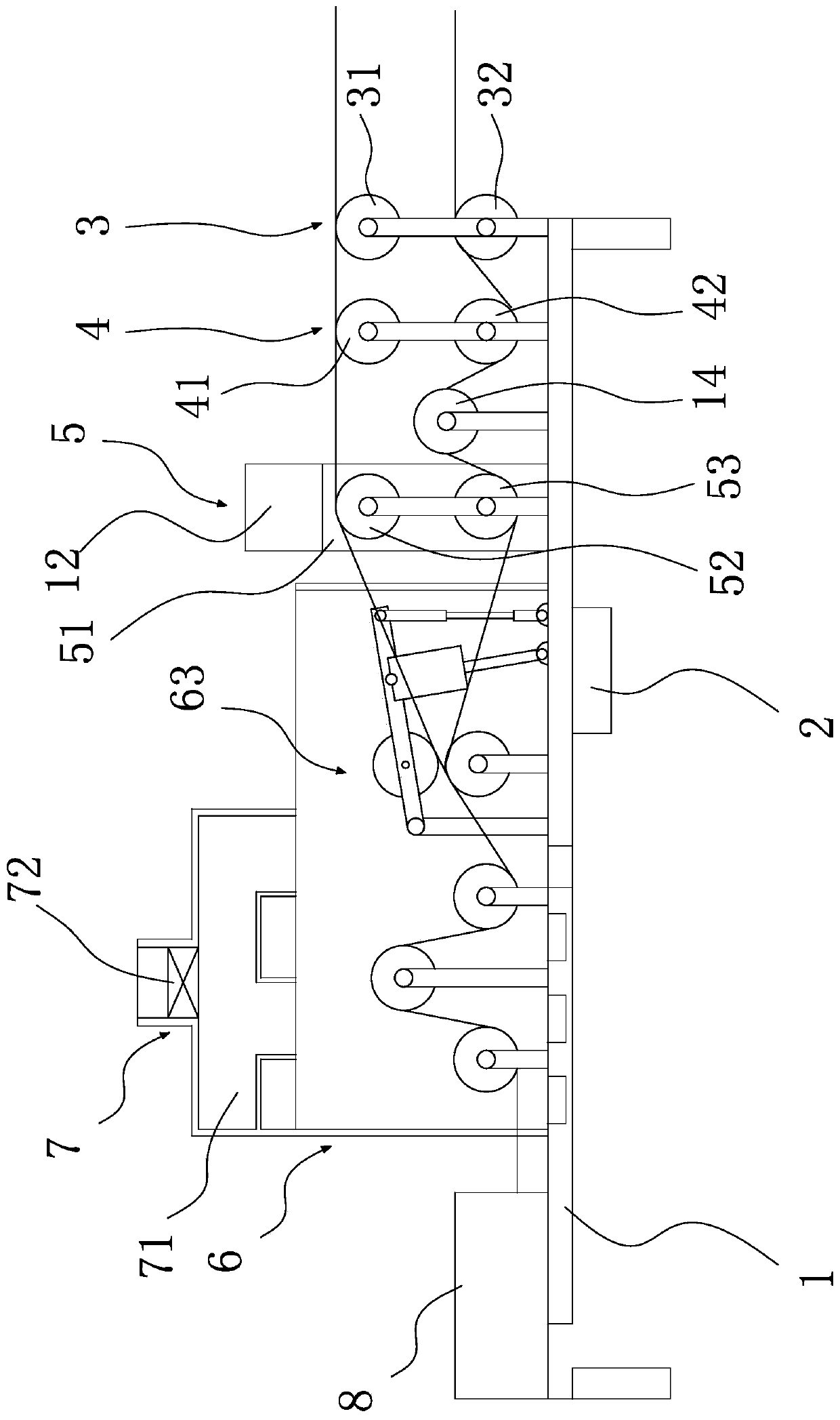

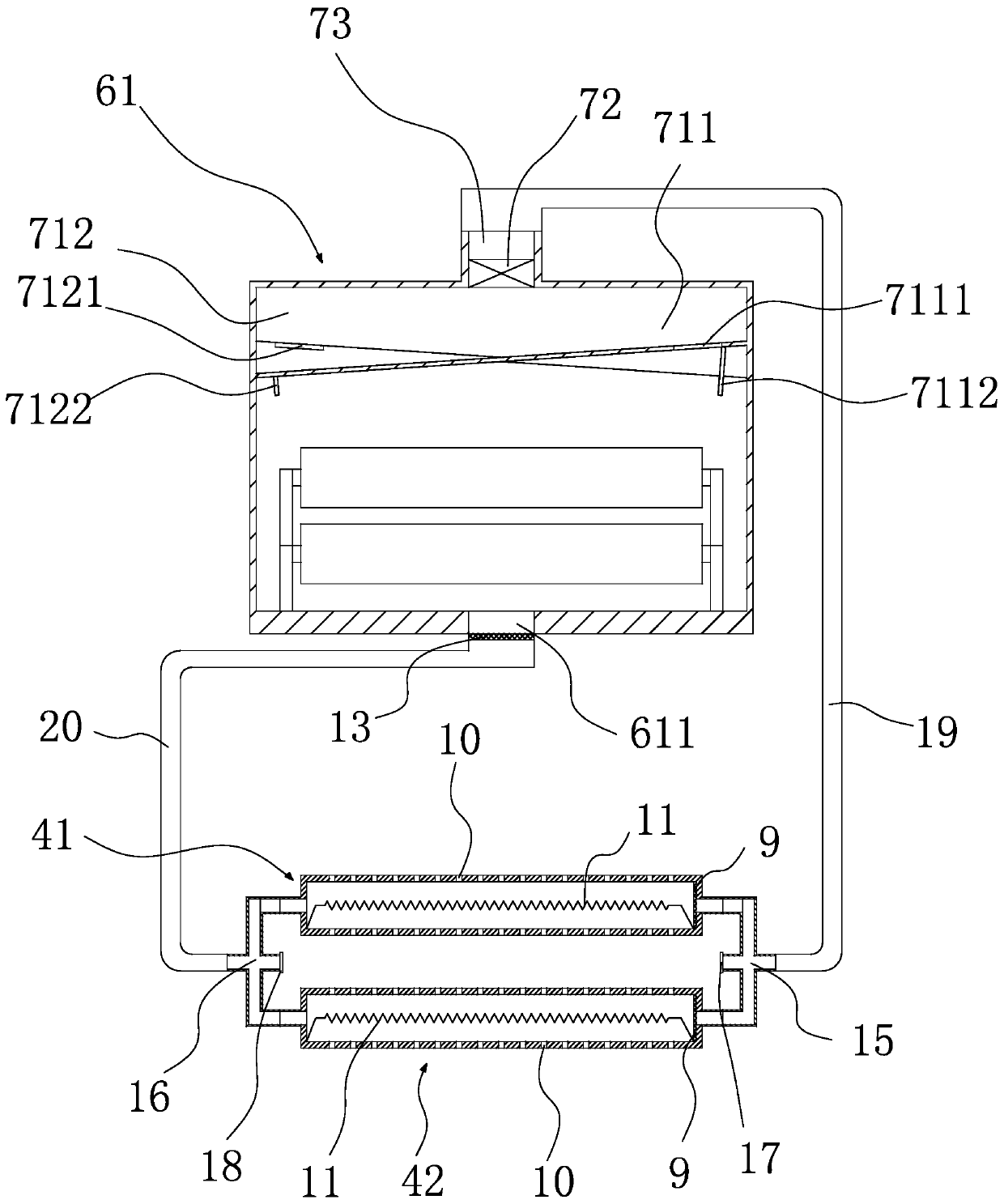

The invention provides upper and sole press-fitting equipment which comprises an upper and shoe tree fixing device and a sole positioning device arranged above the upper and shoe tree fixing device. The upper and shoe tree fixing device comprises a workbench, a turnplate mounted on the workbench, a shoe tree mounted at the center of the turnplate and provided with an upward sole and a compressionmechanism arranged correspondingly to the shoe tree; the sole positioning device comprises a base block, a U-shaped frame with a downward opening, a first push-down element and a press-mounting mechanism, and the base block is fixedly mounted at the bottom end of the U-shaped frame. The shoe tree is arranged on the turnplate, so that position of an upper is ensured to be in a stable state when theupper and the sole are assembled, and bonding firmness of the upper and the sole is ensured; in the sole positioning device, the sole is positioned through a groove formed in the undersurface of thebase block, adsorbed and fixed through a vacuum port and press-fitted on the shoe tree through a press-fitting mechanism to realize close bonding of the upper and the sole.

Owner:JIHUA LAB

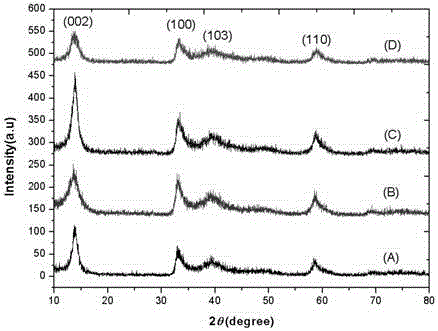

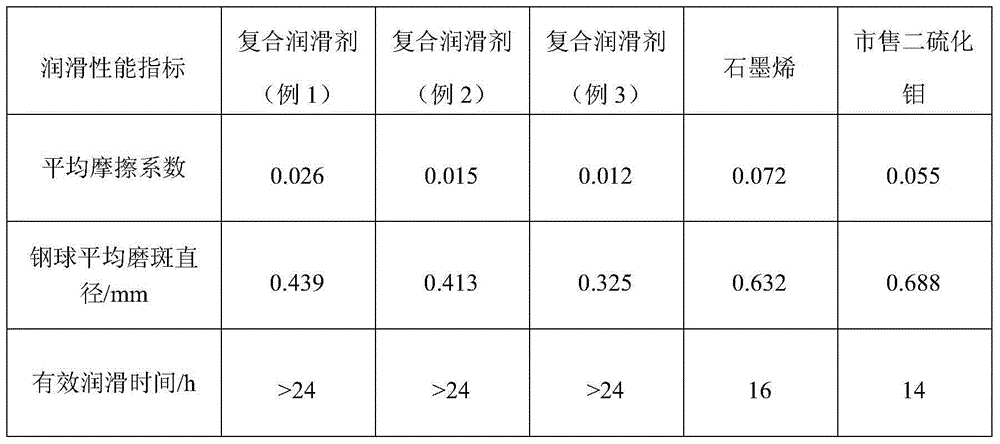

Graphene/molybdenum disulfide composite lubricant and preparation method thereof

InactiveCN106811264AHigh thermal conductivityImprove thermal conductivityAdditivesMass ratioOil additive

The invention discloses a graphene / molybdenum disulfide composite lubricant and preparation and application thereof; the preparation method comprises the steps of 1) mixing in a solvent, graphene oxide solution, a molybdenum source and a surfactant at room temperature according to the mass ratio of 1:(10-20):(20-35), adding a sulfur source, stirring well to obtain a precursor solution having a molar ratio of the sulfur source to the molybdenum source being greater than 2:1; 2) adding the precursor solution of step 1) into a polytetrafluoroethylene reactor at 180-240 DEG C, preferably at 210-240 DEG C, and reacting for 12-36 h, preferably for 24-36 h; 3) washing the suspension and filtered material of step 2) with deionized water 3 times and absolute ethyl alcohol 3 times, and drying in a vacuum oven at 60 DEG C for 12 h; 4) thermally treating the product of step 3) in a quartz boat under the protection of an inert gas to obtain the graphene / molybdenum disulfide composite lubricant. The graphene / molybdenum disulfide composite lubricant of the invention has excellent antifriction property and is an excellent green environment-friendly basic oil additive.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

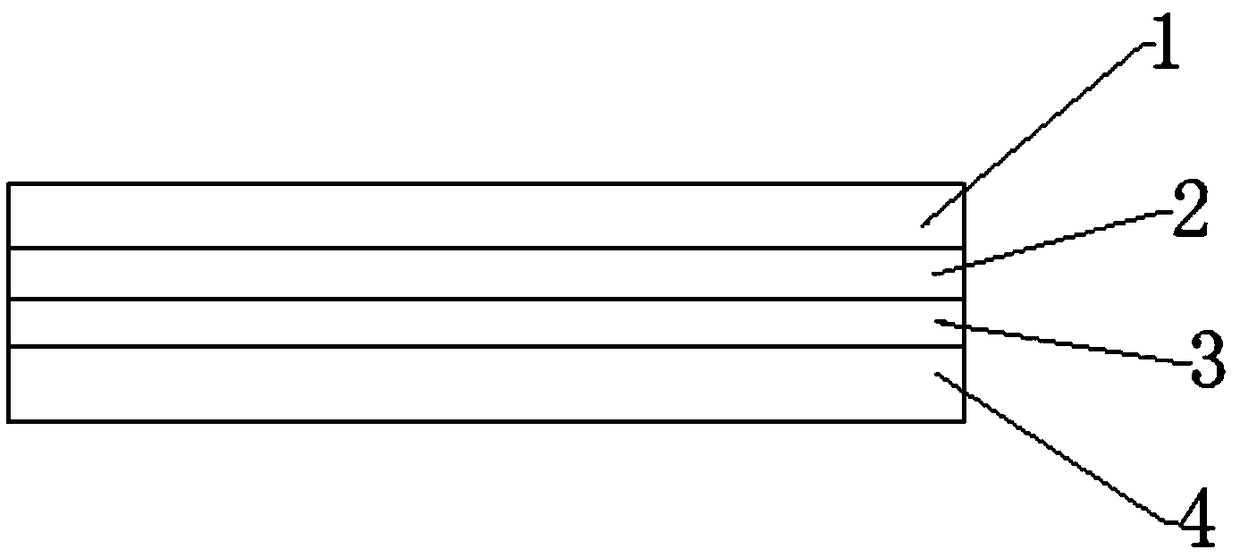

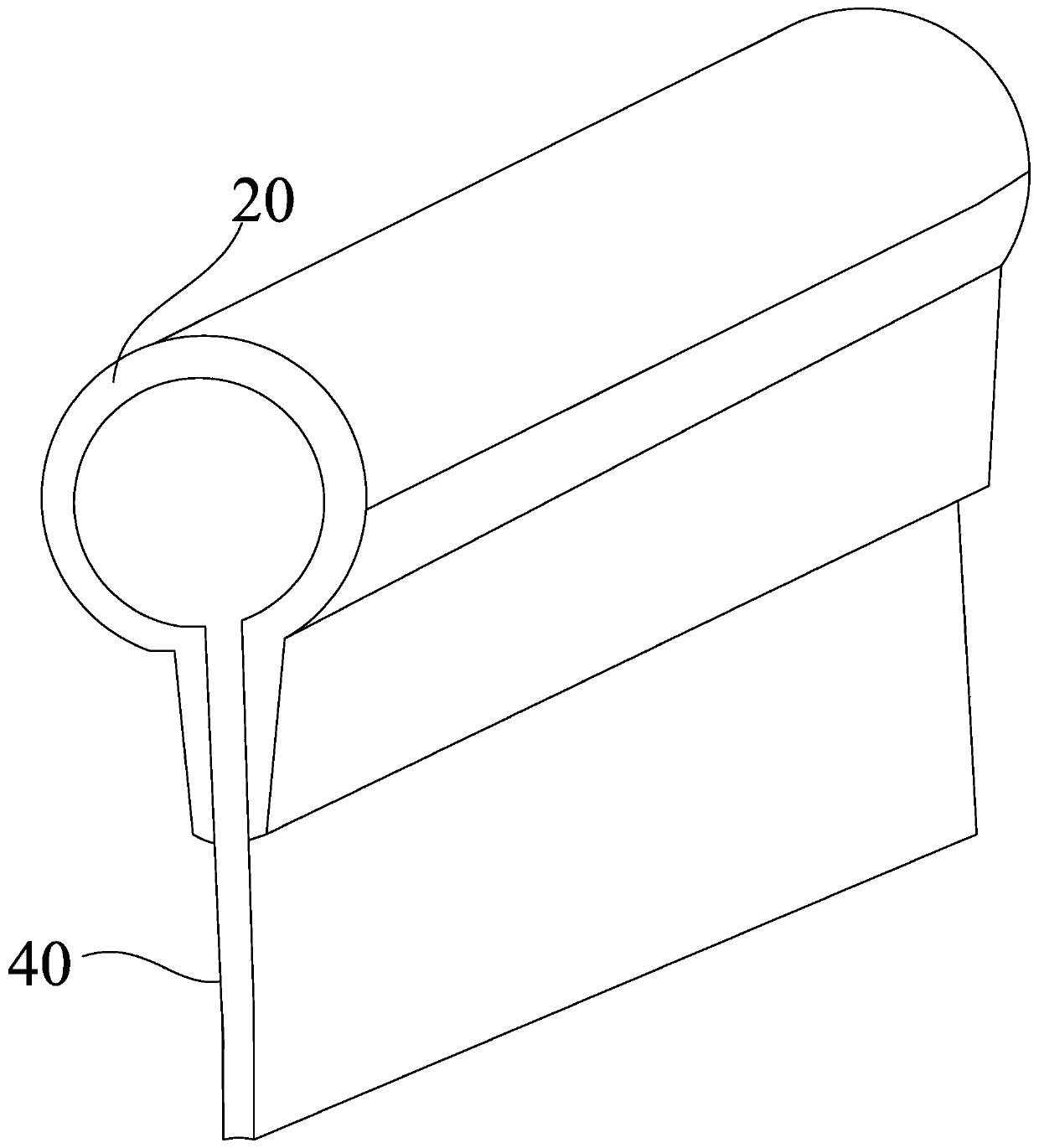

Edge banding strip for waterproof board

InactiveCN104441789AImprove the isolation effectImprove isolationCovering/liningsSynthetic resin layered productsIsolation effectUltimate tensile strength

The invention discloses an edge banding strip for a waterproof board. The edge banding strip comprises a bottom edge and side edges, which are molded into a whole, wherein the two side edges are available, and a U shape is formed by the side edges and the bottom edge; a multi-layer structure which is molded into a whole is formed by the bottom edge and the side edges; an adhesion layer, a carbon fiber layer, a hot melt adhesive layer, a base material layer, a printing layer and a surface waterproof layer are sequentially arranged from inside to outside from the end surface contacted with the waterproof board; a reversed hanging side which is arranged towards the bottom edge is positioned at the inner side of each side edge. The edge banding strip is in the U shape formed by the two side edges and the bottom edge, and the external wrapping structure is better jointed with the cross section of the waterproof board, so that the effect of isolating air from water is improved; the reversed hanging sides which are arranged towards the bottom edge are positioned at the inner sides of the side edges, so that the edge banding strip is good in an isolation effect; the multi-layer structure comprises the carbon fiber layer, and the carbon fiber layer can be used for effectively improving the structural strength of the edge banding strip, so that the mechanical damage to the edge banding strip can be avoided to a certain extent in the using process.

Owner:常熟市中海塑胶制品有限公司

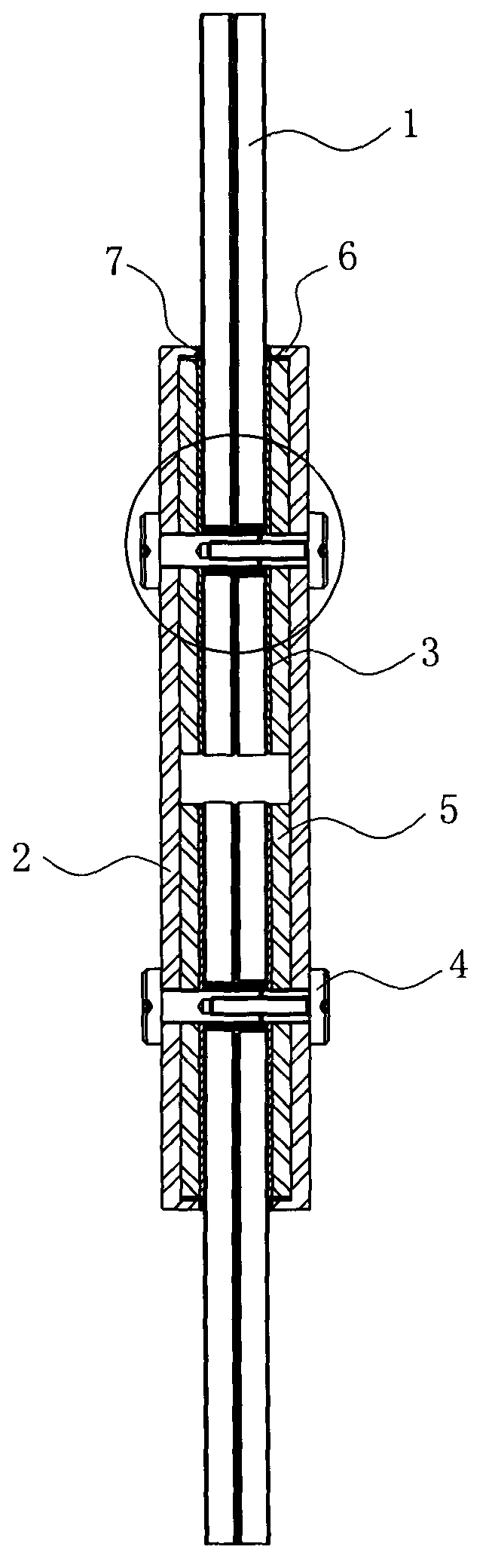

Glass rib splicing structure and construction method thereof

ActiveCN103132637AImprove stabilityReduce temperature stressWallsBuilding material handlingAdhesiveArchitectural engineering

The invention discloses a glass rib splicing structure. The glass rib splicing structure comprises outer connecting plates covered on two sides of spliced ends of adjacent glass ribs, a viscose layer and bolt pins, wherein the viscose layer is positioned between the connecting plates on two sides and a middle glass rib, and the bolt pins penetrate through the glass ribs and the outer connecting plates on two sides. The glass rib splicing structure is characterized in inner steel plates are respectively arranged between the viscose layer and the outer connecting plates and on two sides of a spliced end of every glass rib. A method for the glass rib splicing structure comprises a first step of drilling connecting holes at the spliced end of every glass rib; a second step of respectively arranging bolting holes on the small inner steel plates and the outer connecting plates corresponding to every connecting hole; a third step of adhering the inner steel plates to two sides of the spliced end of every glass rib respectively through adhesive; and a fourth step of respectively enabling the outer connecting plates to be covered on two sides of two adjacent glass ribs with the inner steel plates, and fixing the outer connecting plates by enabling the bolt pins to penetrate through the outer connecting plates, the bolting holes on the inner steel plates and the connecting holes on the glass ribs. By arranging the inner steel plates, splicing firmness of the glass ribs is improved, future maintenance is facilitated, and using cost is reduced.

Owner:苏州苏明装饰股份有限公司

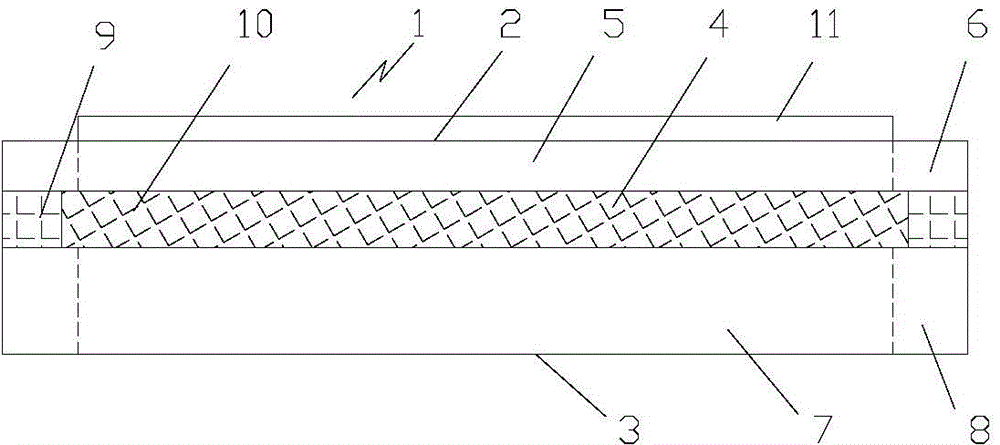

Method for manufacturing flexible substrate and substrate structure

InactiveCN104916550AGuaranteed stabilityAvoid offsetSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMotherboard

The invention provides a method for manufacturing a flexible substrate and a substrate structure. The method comprises: 1) providing a rigid motherboard and a flexible motherboard, wherein a second active region of the rigid motherboard is corresponding to a first active region of the flexible motherboard, and a second non-active region of the rigid motherboard is corresponding to a first non-active region of the flexible motherboard; 2)disposing an adhesive layer on the rigid motherboard, wherein the adhesive layer comprises a strong adhesive layer and a weak adhesive layer, the strong adhesive layer is disposed on at least a part of the second non-active region, and the weak adhesive layer is disposed on the other part of the second non-active region and the second active region; 3) covering the adhesive layer with the flexible motherboard through adhering; and 4) cutting the flexible motherboard along an edge of the first active region. The method enables the flexible motherboard to be subjected to a smaller stress during peeling, thus protecting the internal part of the flexible substrate from being damaged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

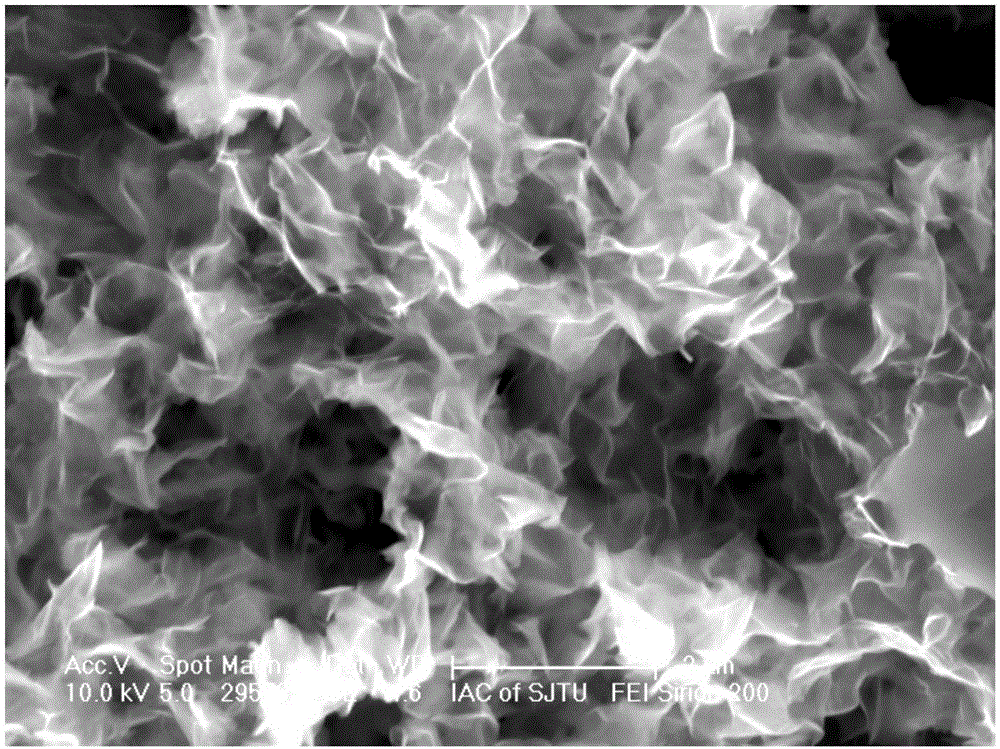

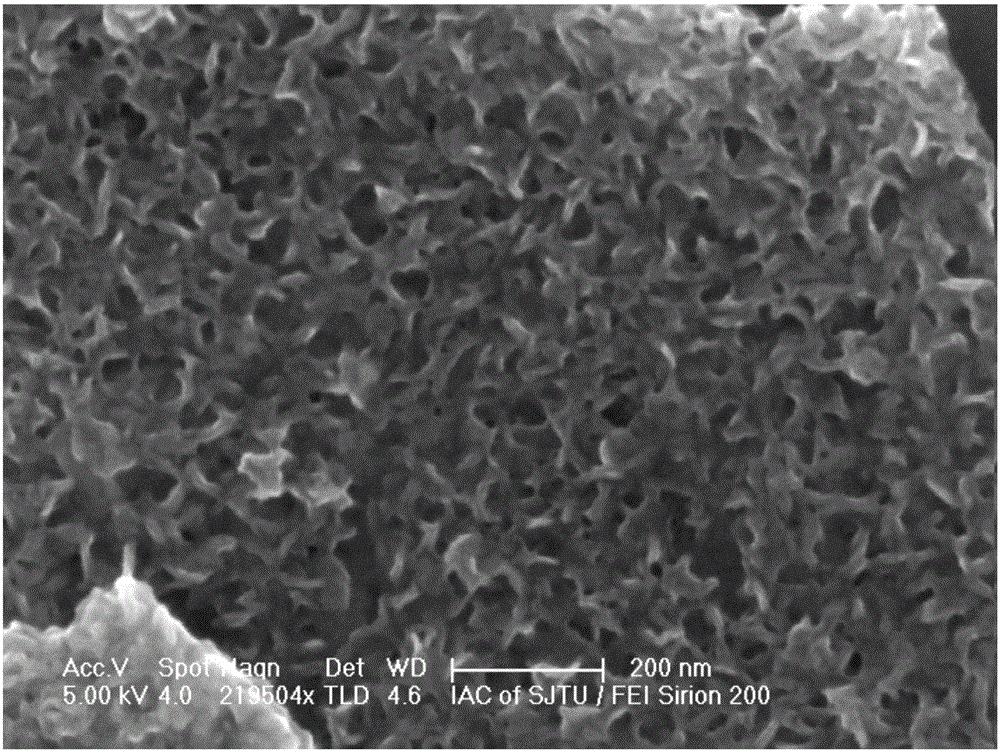

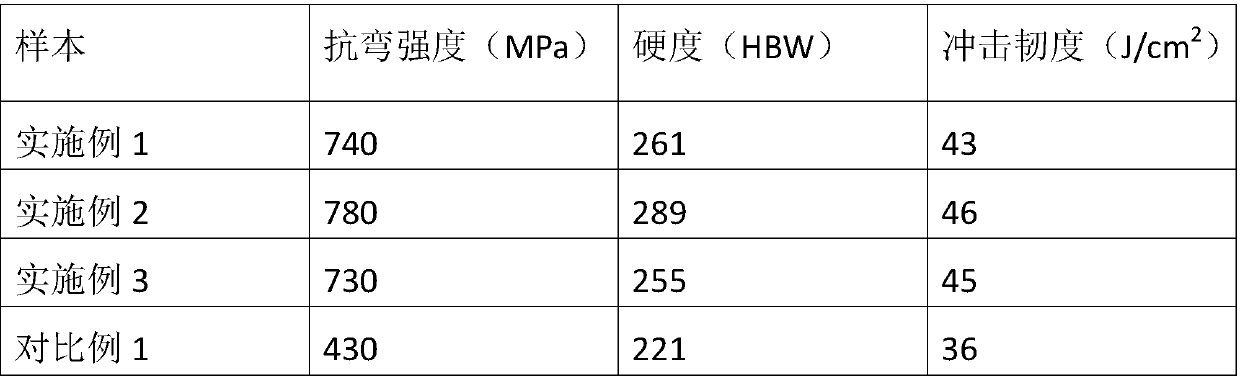

Inorganic fullerene molybdenum disulfide/graphene composite lubricant and preparation method thereof

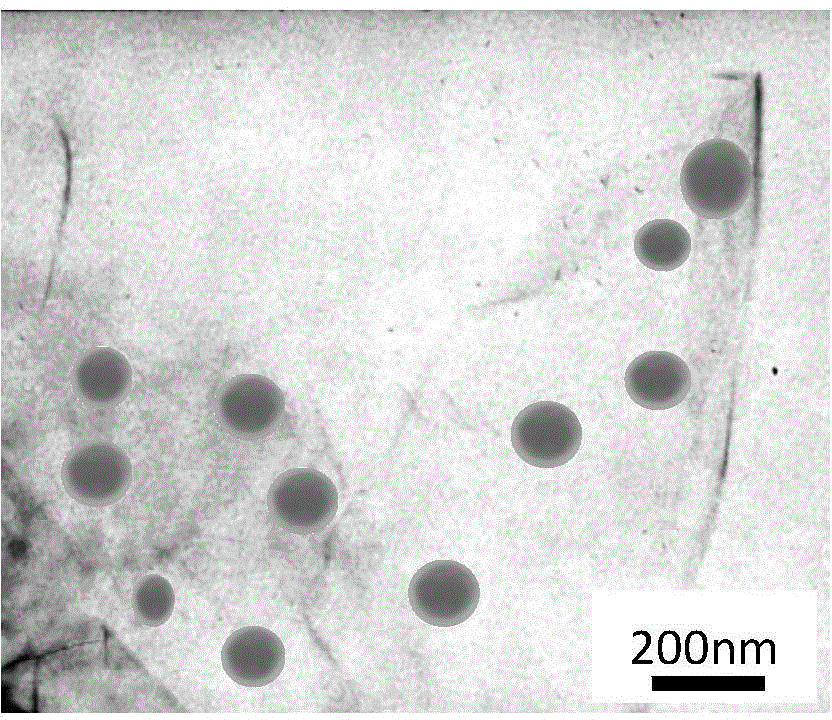

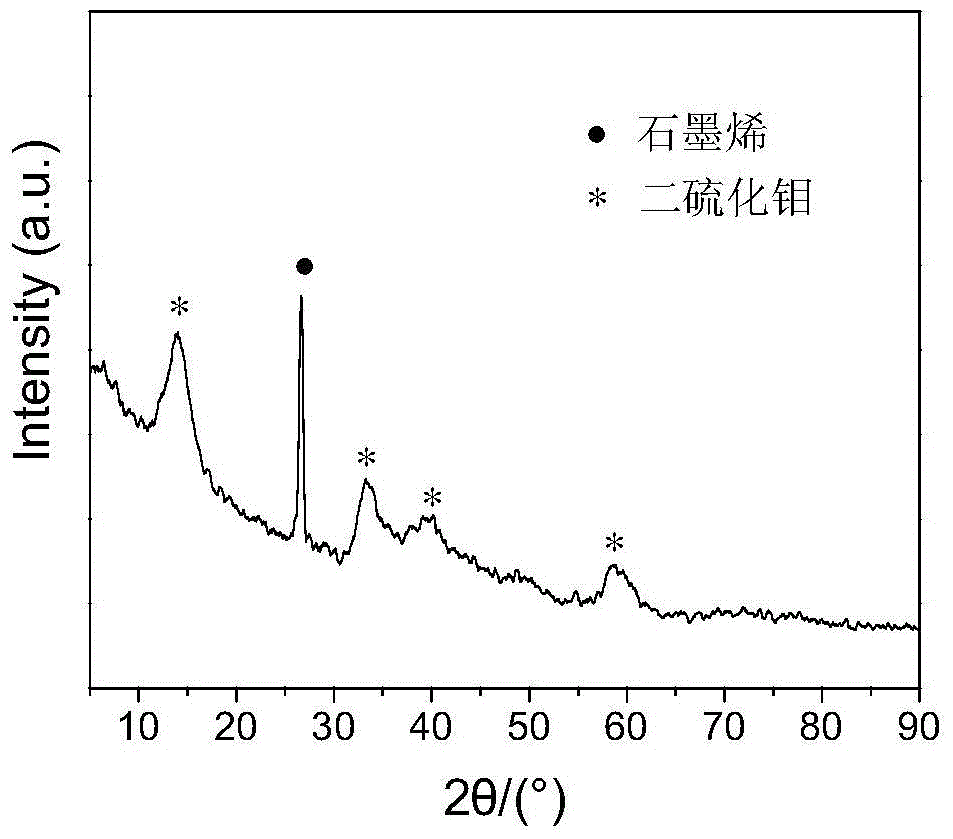

ActiveCN104962340AGuaranteed decentralizationGuarantee the firmness of the bondBase-materialsFullereneCvd graphene

The invention relates to an inorganic fullerene molybdenum disulfide / graphene composite lubricant and a preparation method thereof. The mass ratio of molybdenum disulfide to graphene in the lubricant is 1:(0.0005-0.1), the particle size of the inorganic fullerene molybdenum disulfide is 30-300nm, and the molybdenum disulfide is uniformly dispersed on the graphene surface or in the defect clearances and bonded firmly. The preparation method is convenient and controllable for operation. Under the synergistic actions of the molybdenum disulfide and graphene, the prepared composite lubricant has excellent lubricating property, and has very important application values in the fields of solid lubricating materials, precision machinery, aerospace and the like.

Owner:HEFEI UNIV OF TECH

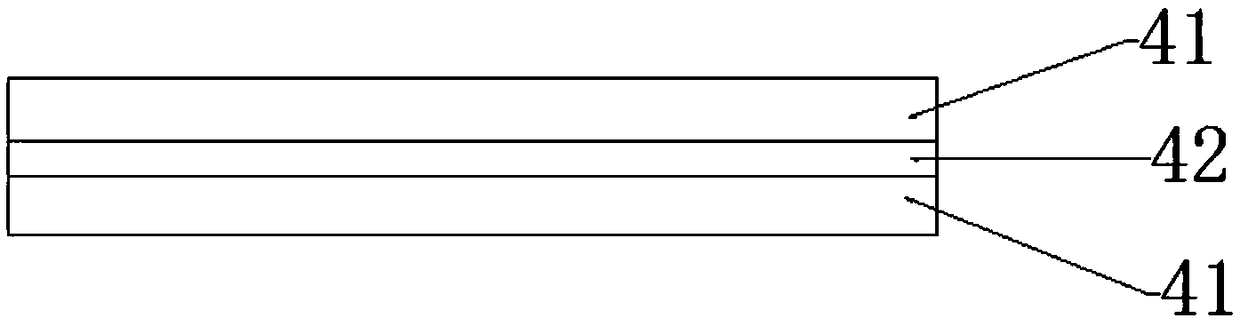

Transparent and high-barrier pesticide packaging film and preparation technology thereof

InactiveCN108973289AHigh transparencyHigh light transmittanceSynthetic resin layered productsDomestic articlesPolyethylene terephthalate glycolPolyurethane adhesive

The invention discloses a transparent and high-barrier pesticide packaging film. The pesticide packaging film sequentially comprises a PET (polyethylene terephthalate) layer, a pattern layer, an adhesion layer and a symmetrical nylon layer, an SiO2 or Al2O3 ceramic film is arranged on the inner side surface of the PET layer, the adhesion layer is formed through solidification of highly anti-corrosion polyurethane glue, and the symmetrical nylon layer is a symmetrical nylon co-extrusion film composed of a PE (poly ethylene) layer, a PA (polyamide) layer and a PE layer which are sequentially arranged. The pesticide packaging film has the good transparency, can visually see the matter state of a content, the packaging film has the good permeating hindering effect on the content, the anti-falling and anti-pressing performance of the packaging film are greatly improved by adding nylon, the packaging film is easy to recycle, and meanwhile, the preparation technology of the transparent and high-barrier pesticide packaging film is simple, and industrialized production implementation is facilitated.

Owner:JIANGYIN BAOBO PACKING

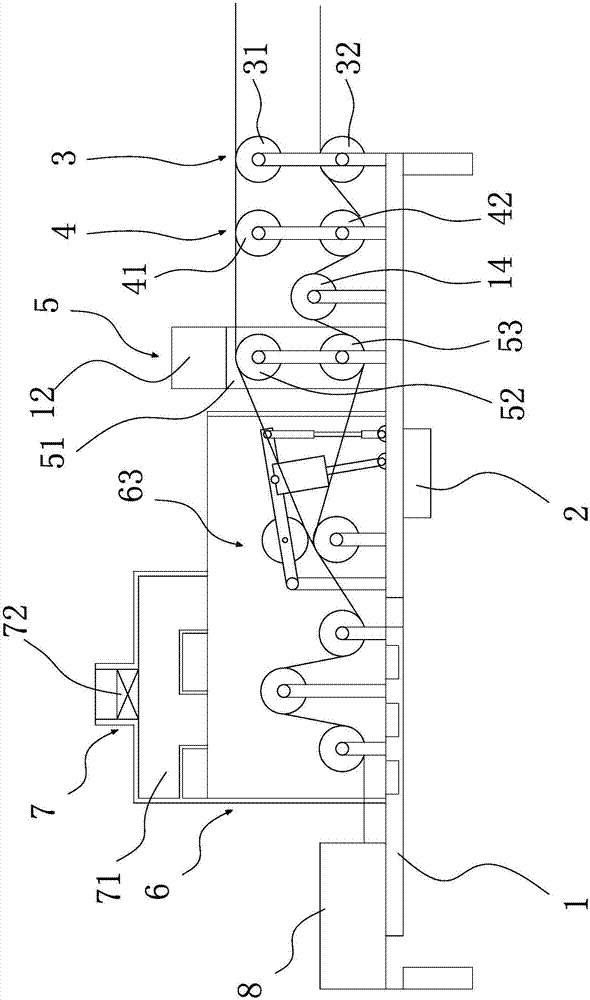

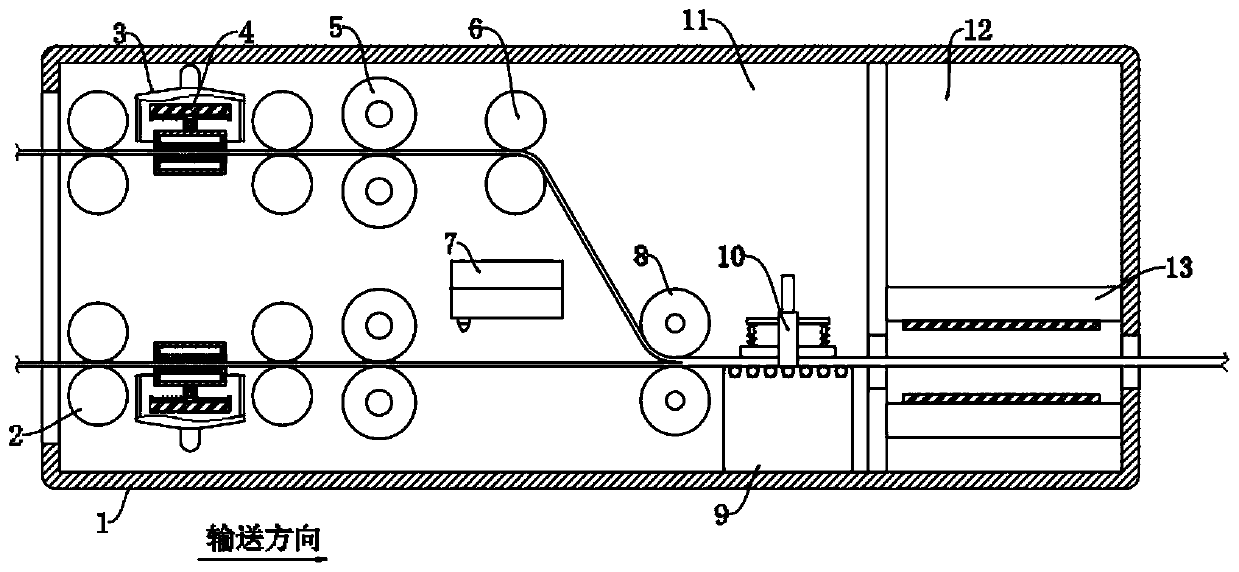

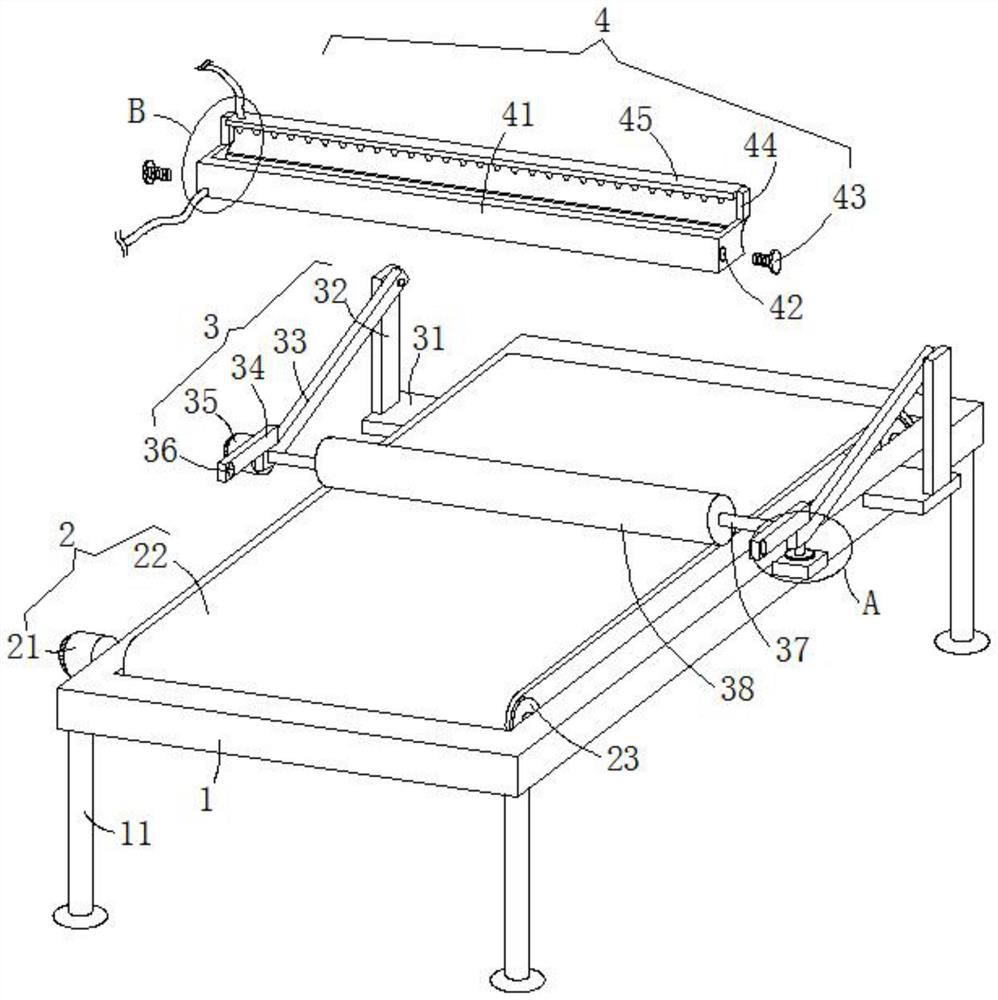

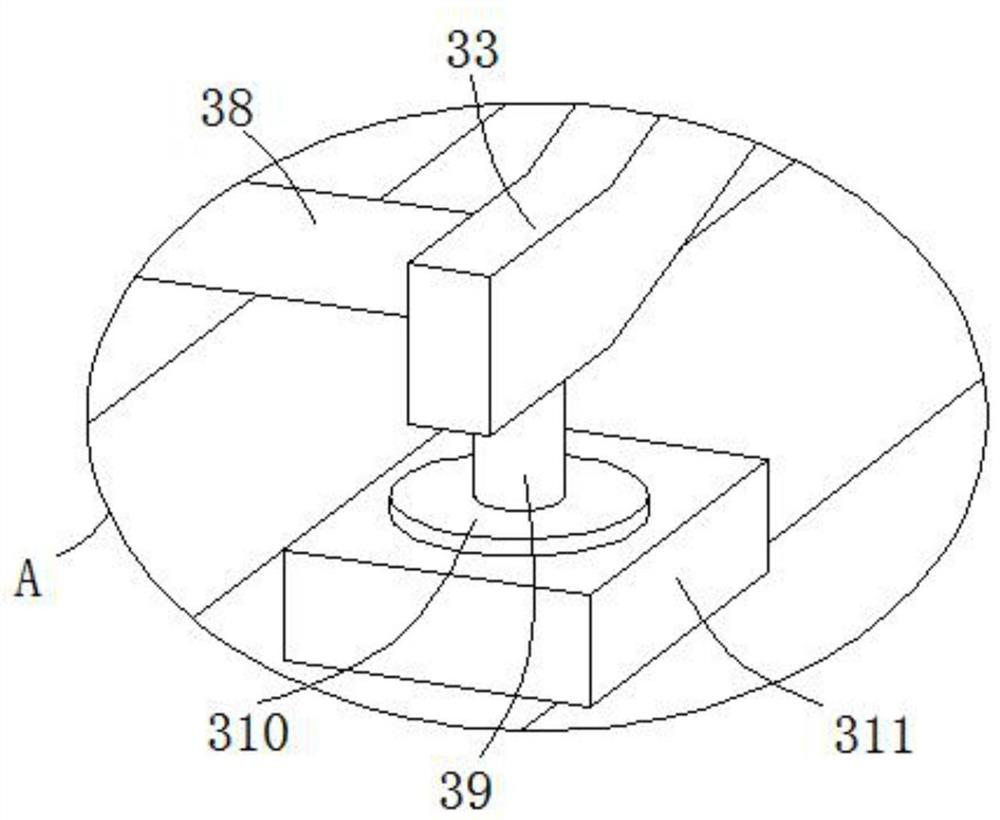

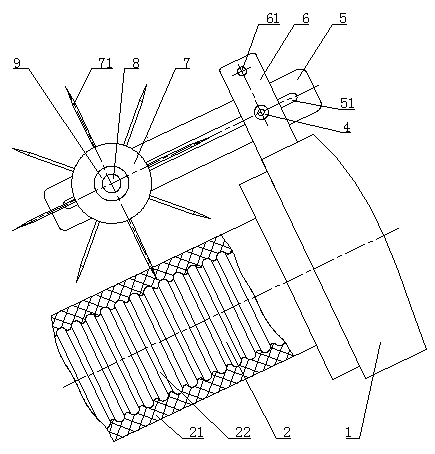

All-in-one machine capable of feeding, drying and compositing fiberglass cloth

ActiveCN107159515AComposite strength adjustableProcessing thickness can be adjustedLamination ancillary operationsLaminationHydraulic cylinderComposite strength

The invention provides an all-in-one machine capable of feeding, drying and compositing fiberglass cloth, and belongs to the technical field of machinery. The all-in-one machine capable of feeding, drying and compositing the fiberglass cloth solves that problem that an existing fiberglass cloth production machine cannot produce the fiberglass cloth with different thicknesses or composite strength, and comprises a rack, wherein a controller is arranged on the bottom surface of the rack, the rack is sequentially provided with a feeding device, a preheating device, a gluing device, a compositing and drying device, a heat dissipation device and a winding rack, the compositing and drying device comprises a drying box, the drying box is internally provided with a plurality of combustors, a composite roller set for pressing the glued fiberglass cloth and a plurality of drying conveying rollers, and the composite roller set comprises a first pressing roller, a second pressing roller and a roller distance adjusting mechanism for adjusting the distance between the first pressing roller and the second pressing roller. According to the all-in-one machine, the distance between the two pressing rollers is adjusted through a hydraulic cylinder, and therefore the composite strength of the fiberglass cloth and the machining thickness of the fiberglass cloth can be adjusted, and the application range is wider.

Owner:浙江凯澳新材料有限公司

Large-specification veneer aluminum plate showing wall installation system and construction method thereof

ActiveCN105401707AAdjust flatnessLarge adjustment rangeCovering/liningsBuilding material handlingEngineeringEdge matching

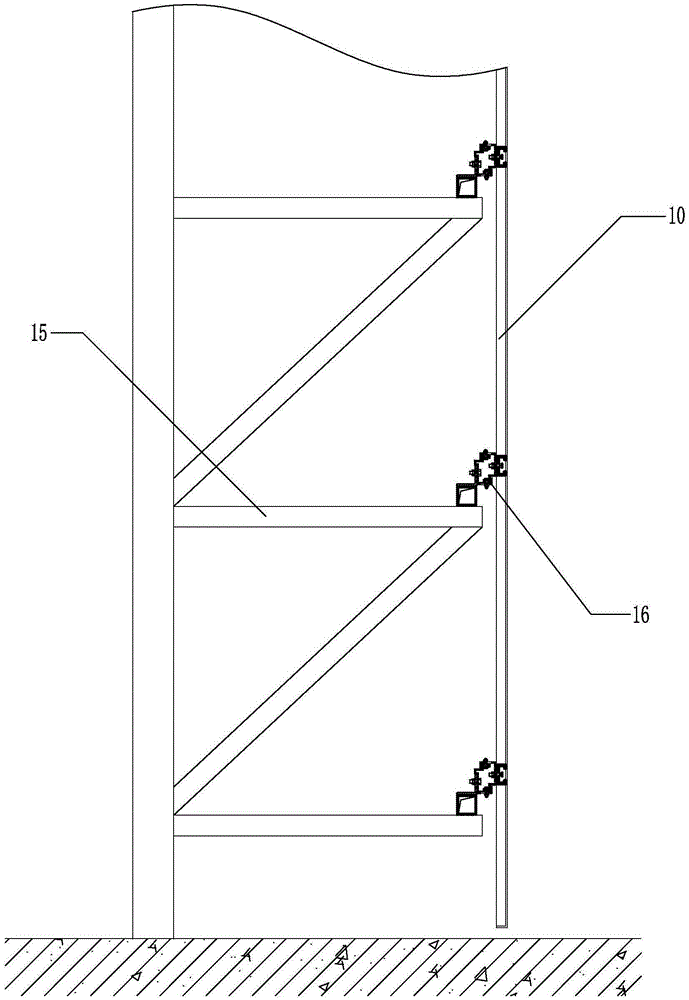

The invention discloses a large-specification veneer aluminum plate showing wall installation system and a construction method thereof. The large-specification veneer aluminum plate showing wall installation system comprises base layer frameworks, a plurality of connecting assemblies and an aluminum plate and is characterized in that the connecting assemblies comprise corner brace connecting fixing pieces and leveling movable fixing pieces; the corner brace connecting fixing pieces are connected with angle steel through anchor bolts; the angle steel is fixed to the base layer frameworks; folded edges are arranged at the upper ends and the lower ends of the corner brace connecting fixing pieces; the folded edges at one ends are provided with fixing holes, and the folded edges at the other ends are provided with adjusting holes; one sides of the leveling movable fixing pieces are fixed to the aluminum plate through aluminum plate fixing pieces, and the upper ends and the lower ends of the other sides of the leveling movable fixing pieces are connected with connecting edges matched with the folded edges of the corner brace connecting fixing pieces; and the corner brace connecting fixing pieces and the leveling movable fixing pieces are fixed through bolts. According to the large-specification veneer aluminum plate showing wall installation system and the construction method thereof, the leveling movable fixing pieces are horizontally moved by a distance relative to the corner brace connecting fixing pieces so that leveling of the flatness of the aluminum plate can be achieved; and operation is convenient, flexibility is high, and the overall effect of a wall face can be easily improved.

Owner:苏州苏明装饰股份有限公司

Glass fiber fabric compounding machine with pre-heating function

ActiveCN107116890AImprove activity stabilityEnsure safetyLamination ancillary operationsLaminationGlass fiberEngineering

The invention provides a glass fiber fabric compounding machine with a pre-heating function and belongs to the technical field of machinery, aiming at solving the problem that an existing glass fiber fabric is easy to degum after being compounded. The glass fiber fabric compounding machine with the pre-heating function comprises a rack which is horizontally and transversely arranged, wherein a controller is arranged on the bottom surface of the rack; the rack is sequentially provided with a feeding device, a pre-heating device, a gumming device, a compound drying device, a heat dissipation device and a winding frame; the feeding device comprises a first feeding roller and a second feeding roller, which are independent to each other; the gumming device comprises a gumming box; the gumming box is internally provided with a first gumming roller and a second gumming roller; the pre-heating device comprises a first pre-heating roller and a second pre-heating roller. The glass fiber fabric compounding machine provided by the invention is used for pre-heating raw materials of the glass fiber fabric, so that glue can completely permeate into the raw materials of the glass fiber fabric in a gumming process, furthermore, the sticking fastness of the glass fiber fabric in a production process is ensured and the quality of the glass fiber fabric is improved.

Owner:浙江凯澳新材料有限公司

Gluing and drying process for fiberglass cloth

ActiveCN107139572AAdvantages of gluing and drying processEmission reductionLamination ancillary operationsLaminationGlass fiberEngineering

The invention provides a gluing and drying process for fiberglass cloth, belongs to the technical field of mechanical engineering, and solves the problem that the existing fiberglass cloth is prone to degumming after bonding. The gluing and drying process is characterized by including the following steps of: A, feeding: simultaneously feeding fiberglass base cloth and nonwoven fabric by traction; B, preheating: preheating the fiberglass base cloth and nonwoven fabric through a preheating device; C, gluing: gluing the fiberglass base cloth and nonwoven fabric; D, bonding: bonding the fiberglass base cloth and the nonwoven fabric glued through a bonding roll set; E, drying: drying the bonded fiberglass cloth in a drying box; F, discharging: rolling the dried fiberglass cloth. The raw materials of the fiberglass cloth are preheated before gluing and bonding, so that glue can completely permeate into the raw materials of the fiberglass cloth during gluing, fastness in bonding during fiberglass cloth production is assured, and quality of fiberglass cloth is improved.

Owner:浙江凯澳新材料有限公司

Preparing method for resin diamonds

The invention discloses a preparing method for resin diamonds. The preparing method comprises the following steps in sequence: 1, preparing a female mold, namely (1) providing a diamond mold piece, (2) preparing mold seeds according to the diamond mold piece, and machining one end of each mold seed into a mold seed head with the same shape as that of the diamond mold piece, and (3) inserting a plurality of mold seeds into a mold cavity of a lower mold, wherein a plurality of slots for allowing insertion columns to be inserted in a matched manner are formed in the mold cavity; 2, preparing a plastic mold, namely arranging the lower mold and an upper mold on an injection molding machine, and performing injection molding on thermoplastic plastics to form the plastic mold; and 3, molding the resin diamonds, namely (1) pouring AB glue into plastic mold cavities formed in the plastic mold by the mold seed heads, and leveling the AB glue by scraping, (2) putting the overall plastic mold with the AB glue in a drying oven and drying at the drying temperature being 110 DEG C for 50 minutes for curing, and (3) taking the cured AB glue blocks out of the plastic mold cavities to obtain resin diamond blanks. The method for preparing the resin diamonds is low in cost.

Owner:王芳华

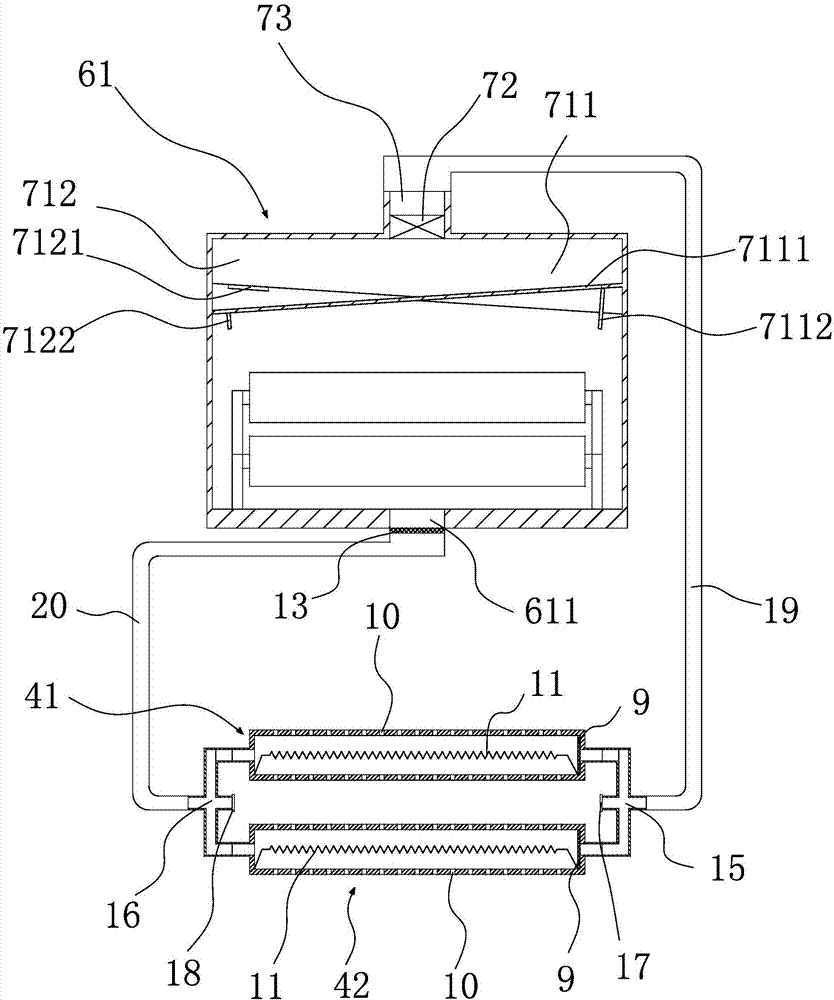

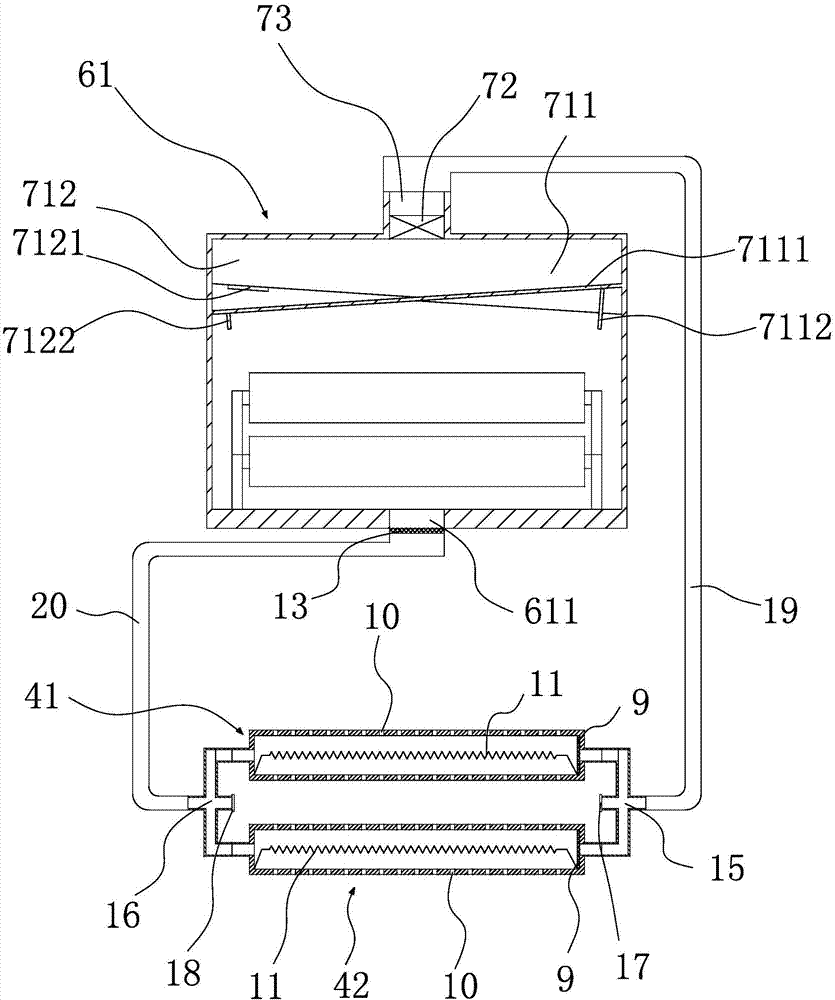

Fabric compounding device with deodorizing and refreshing functions

PendingCN111204112AGuaranteed gluingGuaranteed composite qualityLamination ancillary operationsLaminationAdhesive glueMechanical engineering

The invention discloses a fabric compounding device with deodorizing and refreshing functions. The fabric compounding device comprises a machine shell; a compounding chamber and a deodorizing chamberare sequentially arranged in the machine shell in the material conveying direction; a feeding mechanism, a gluing mechanism, a pair of composite pressing rollers and a re-pressing mechanism are sequentially arranged in the compounding chamber in the material conveying direction; the feeding mechanism comprises an upper feeding line and a lower feeding line which are arranged up and down; the upperfeeding line comprises two pairs of first guide wheels, a pair of heating rollers and a pair of second guide wheels which are arranged in the conveying direction, and a cleaning structure is arrangedbetween the two pairs of first guide wheels; the lower feeding line comprises two pairs of first guide wheels and a pair of heating rollers which are arranged in the conveying direction, and a cleaning structure is arranged between the two pairs of first guide wheels. The fabric can be subjected to dust removal, preheating and softening before compounding, and glue is more uniform and deeply permeates the fabric; meanwhile, the re-pressing mechanism is arranged, the subsequent gluing and compounding quality is guaranteed, and a fragrance fumigator can be used for removing odor and fumigatingthe compounded fabric.

Owner:FUJIAN CHARME TEXTILE

Pre-cleaning device and pre-cleaning method for glass production and processing

InactiveCN112371679AGuarantee the firmness of the bondImprove post-processing efficiencyDirt cleaningFlexible article cleaningDust controlElectric machinery

The invention discloses a pre-cleaning device and a pre-cleaning method for glass production and processing. The pre-cleaning device comprises a supporting frame, a transmission mechanism, a film covering mechanism and a cleaning mechanism, wherein the transmission mechanism is arranged in an inner cavity of the supporting frame; the film covering mechanism comprises two supporting blocks, two supporting columns, two hinge rods, a first driving motor, two transmission rods, a cleaning roller and two extending mounting rods; and the cleaning mechanism comprises a waste liquid collecting box, two supporting rods and a rectangular hollow box. According to the pre-cleaning device and the pre-cleaning method for glass production and processing provided by the invention, manual assistance is conveniently replaced to quickly remove dust from glass to be coated in batches, so that the bonding firmness of glass coating is ensured, and the later processing efficiency of glass coating is improved.

Owner:韩秀忠

Cover plate structure of lithium battery

PendingCN111384318AGuaranteed reliabilityEasy injectionCurrent conducting connectionsCell lids/coversStructural engineeringMechanical engineering

A cover plate structure of a lithium battery belongs to the technical field of lithium battery components. The structure comprises a cover plate body which is provided with a pressure relief explosion-proof hole; a pressure relief explosion-proof mechanism which is arranged on one side, back to the lithium battery shell, of the cover plate body; a positive pole which is arranged at the left end ofthe cover plate body, and a negative pole which is arranged at the right end of the cover plate body. The structure is characterized in that an insulating base plate, anode and cathode lead sheets are arranged below the cover plate body; the insulating base plate is attached to the downward side of the cover plate body, and a lithium battery core positioning protection box is arranged in the middle; an explosion-proof vent hole is formed in the middle of a bottom plate of the lithium battery core positioning protection box, explosion-proof air outlet holes are formed in the periphery, a positive pole column insulation pad is fixed to the left end of the cover plate body and corresponds to the position below a positive pole column, and a negative pole column insulation pad is fixed to theright end and corresponds to the position below a negative pole column. Electrical isolation and insulation are reliable, the lithium battery core is firmly fixed, the service life is long, and electrolyte is prevented from flowing around; the electrical conduction effect is ensured, and the cost is reduced; electrolyte is convenient to inject; and detection and maintenance measures are rapidly taken for the whole lithium battery.

Owner:苏州三众新能源科技有限公司

Ultralow-temperature-resistant transparent polyurethane film for laminated glass and preparation method thereof

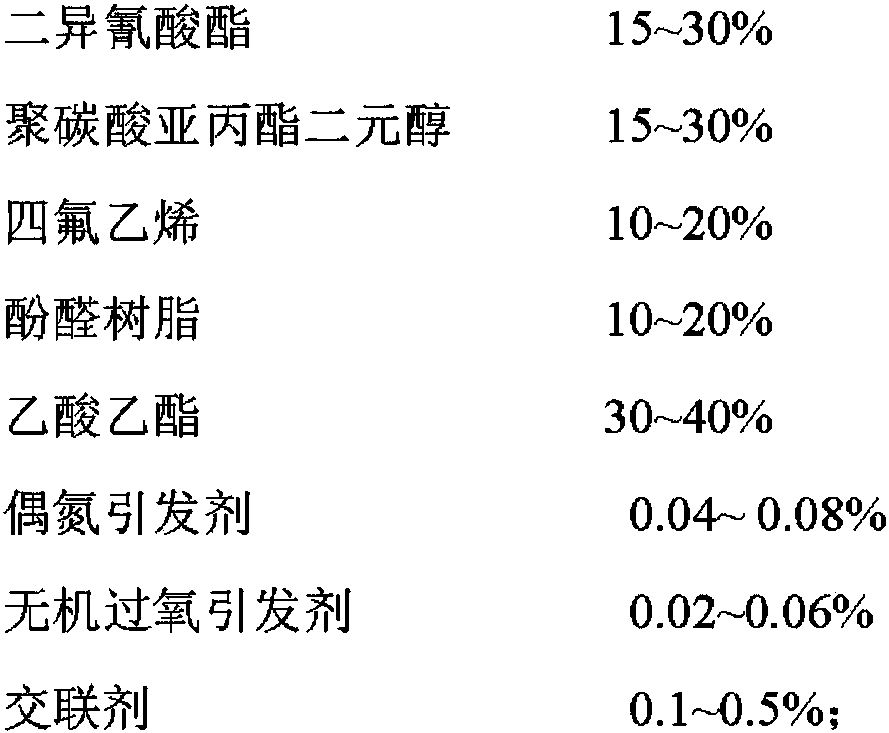

PendingCN113667416AGood optical clarityGuarantee the firmness of the bondPolyureas/polyurethane adhesivesFilm/foil adhesives without carriersPolymer sciencePolyurethane adhesive

The invention discloses an ultralow-temperature-resistant transparent polyurethane film for laminated glass and a preparation method of the ultralow-temperature-resistant transparent polyurethane film, and relates to the technical field of preparation of transparent polyurethane films. The preparation method comprises the following steps: 1, heating polytetrahydrofuran ether diol to 110-120 DEG C, and vacuumizing for 1.5 hours to dehydrate; 2, after dehydration, cooling to 60-80 DEG C, adding a catalyst, a small molecule chain extender and diisocyanate, and carrying out a vacuum-pumping reaction for 5-10 min; and 3, pouring the liquid obtained in the step 2 into a polyfluortetraethylene plate single-sided groove mold, drying for 24 hours in a drying oven at 80-100 DEG C, heating, and continuously drying for 24 hours to prepare the transparent polyurethane film. According to the method, the reaction time is short, the curing speed is high, the prepared polyurethane film is high in optical transparency, high bonding strength can be kept at the low temperature of-65 DEG C, the bonding firmness of laminated glass is guaranteed, and the use safety of the laminated glass is improved.

Owner:锦西化工研究院有限公司

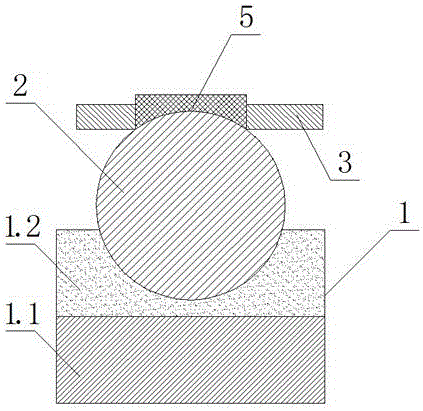

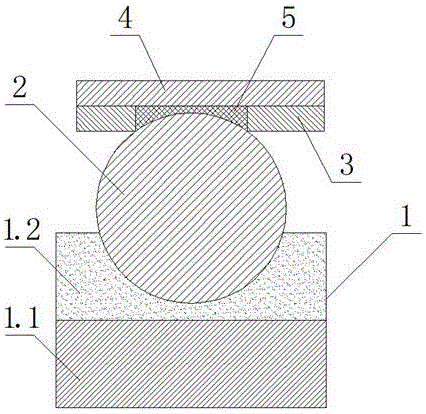

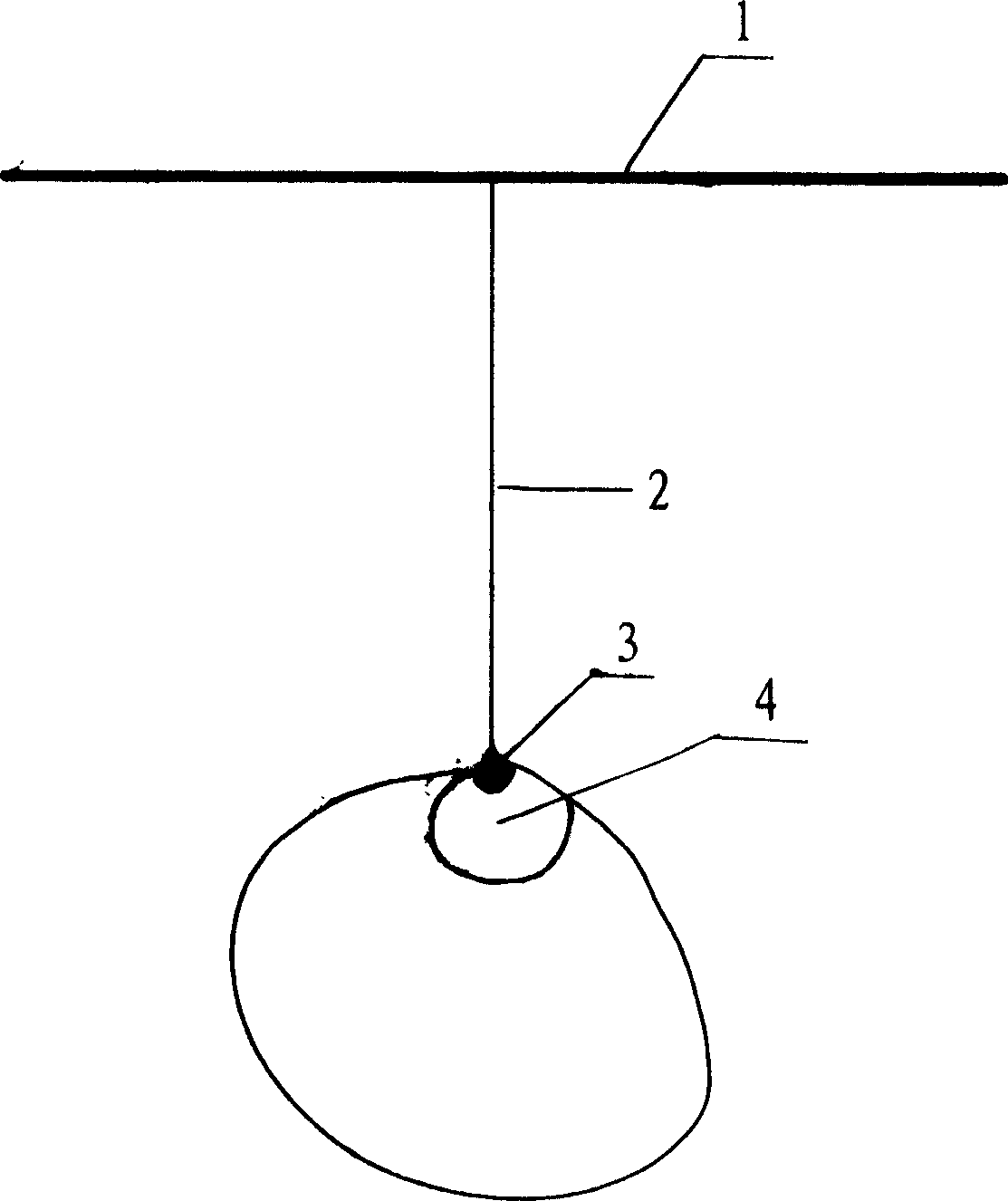

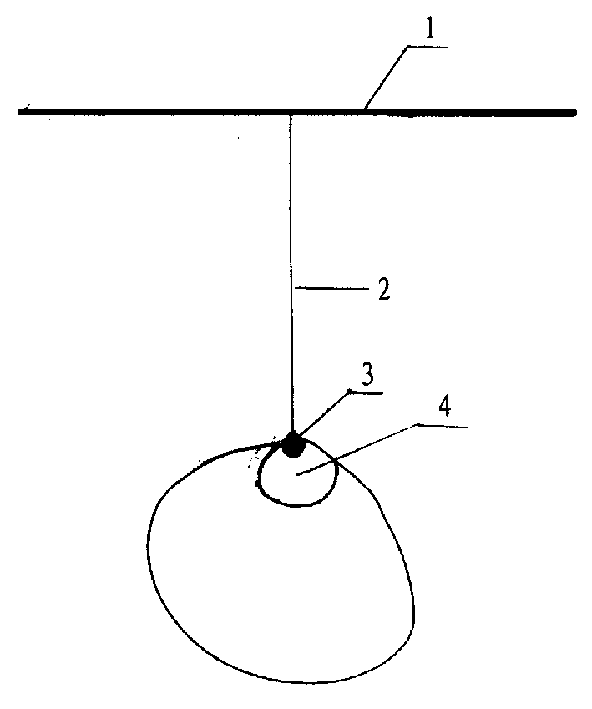

Magnetic type vehicular mobile phone bracket based on universal ball

The invention discloses a magnetic type vehicular mobile phone bracket based on a universal ball. The magnetic type vehicular mobile phone bracket comprises a vehicle body fixing component, a base (1), a ferromagnetic metal universal ball (2) and a permanent magnet suction ring (3), wherein the base (1) is composed of a hard part (1.1) and a soft part (1.2), and the universal ball is in pressed adhesion with an upper surface of the soft part (1.2) by an adhesive; and when the maximum thickness of an outer edge of an elastic gasket (5) is slightly greater than the thickness of the permanent magnet suction ring (3), the elastic gasket (5) is pressed to shrink, and the elastic gasket (5) jacks the surface of a metal magnetic suction piece (4) under the action of an elastic force. According to the magnetic type vehicular mobile phone bracket disclosed by the invention, the adhesion effect of the soft part and the universal ball is good, so that the universal ball is unlikely to fall off. The thickness of the elastic gasket is slightly greater than the thickness of the permanent magnet suction ring, after a mobile phone is mounted, the metal magnetic suction piece sucks the permanent magnet suction ring, the elastic gasket is pressed to shrink and jacks the metal magnetic suction piece under the action of the elastic force, so that the normal pressure of the contact surface is increased, the friction force is increased, and the mobile phone can be placed more stably.

Owner:新昌县大菠萝农业发展有限公司

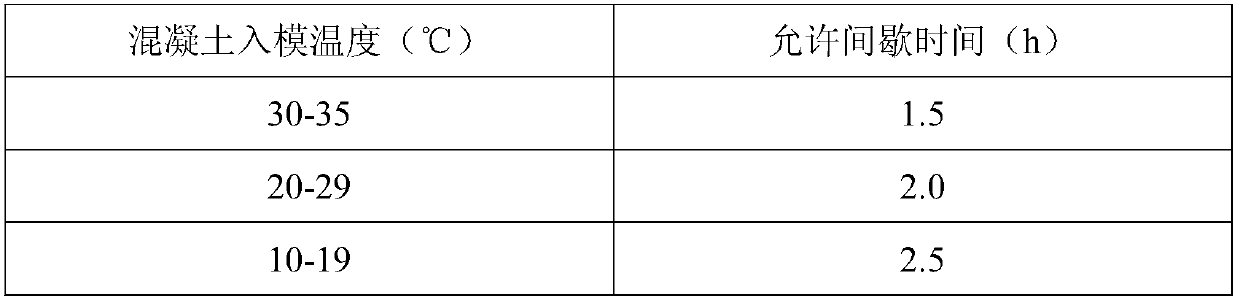

Concrete member water-washed chiseling process

InactiveCN109624066AEffective flushingGuarantee the firmness of the bondCeramic shaping apparatusEnvironmental resistanceHigh pressure water

The invention discloses a concrete member water-washed chiseling process. The process comprises following steps of S1, bottom body treatment; S2, isolation agent painting; S3, mold plate cleaning andchecking; S4, exposed aggregate agent stirring; S5, exposed aggregate agent spraying on the mold plate surface; S6, mold plate supporting; S7, concrete casting; S8, mold plate dismounting; S9, concrete surface checking; S10, high-pressure water gun flushing; S11, flushing result acceptance inspection; and S12, maintenance. The high-pressure water-washed chiseling process is used, concrete laitanceon the side face of a beam plate can be effectively flushed away, aggregate is evenly exposed, bonding firmness of new and old concrete can be effectively ensured, compared with traditional chiseling, water-washed chiseling cannot destroy part corners, finished product protection is facilitated, construction quality is improved, the process is easy to operate, the labor intensity is low, manual work and time can be saved, construction efficiency is greatly improved, cost is saved, in the construction process, noise and dust cannot be generated, and the process is environment-friendly.

Owner:CCCC FIRST HARBOR ENG +1

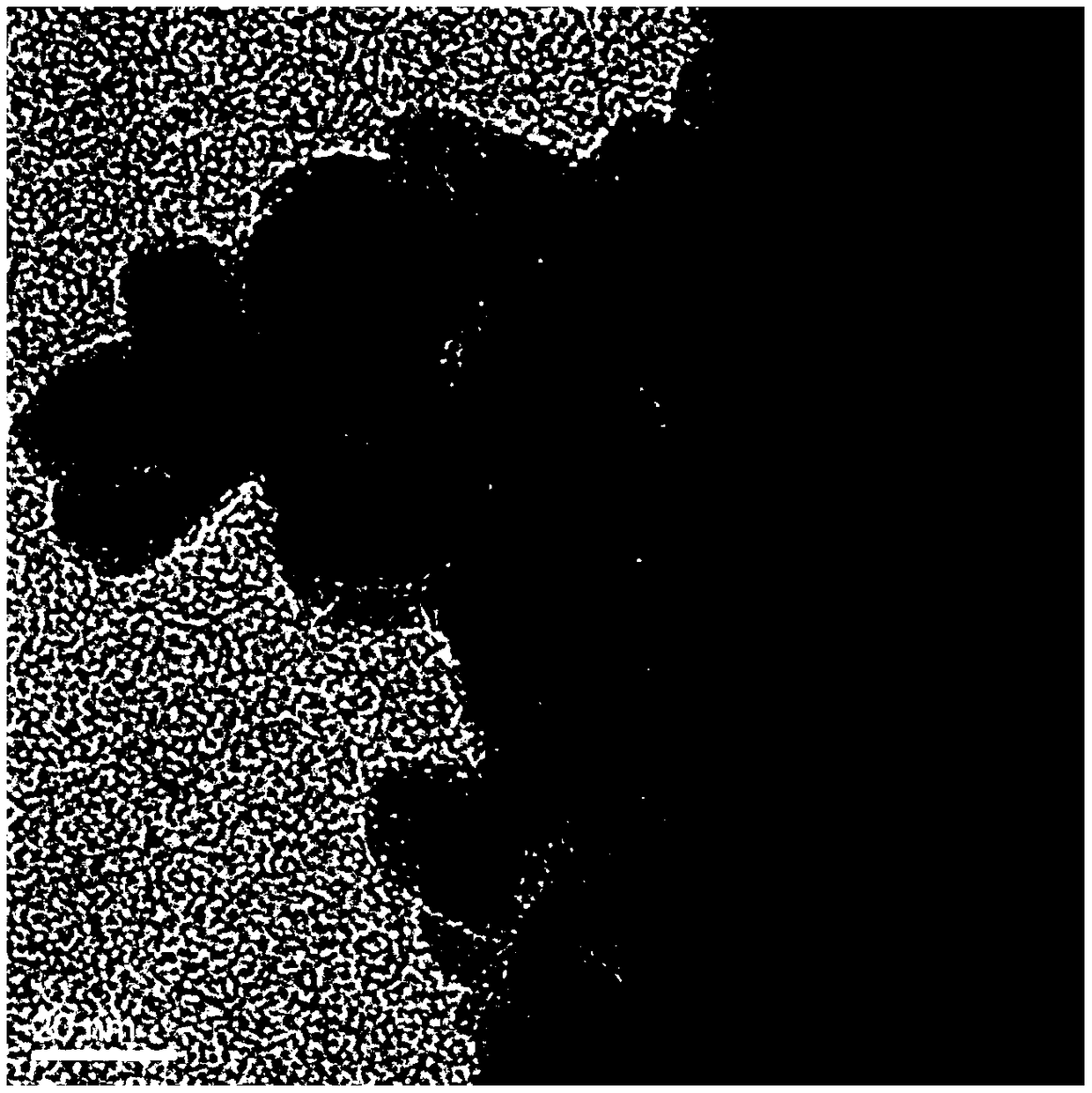

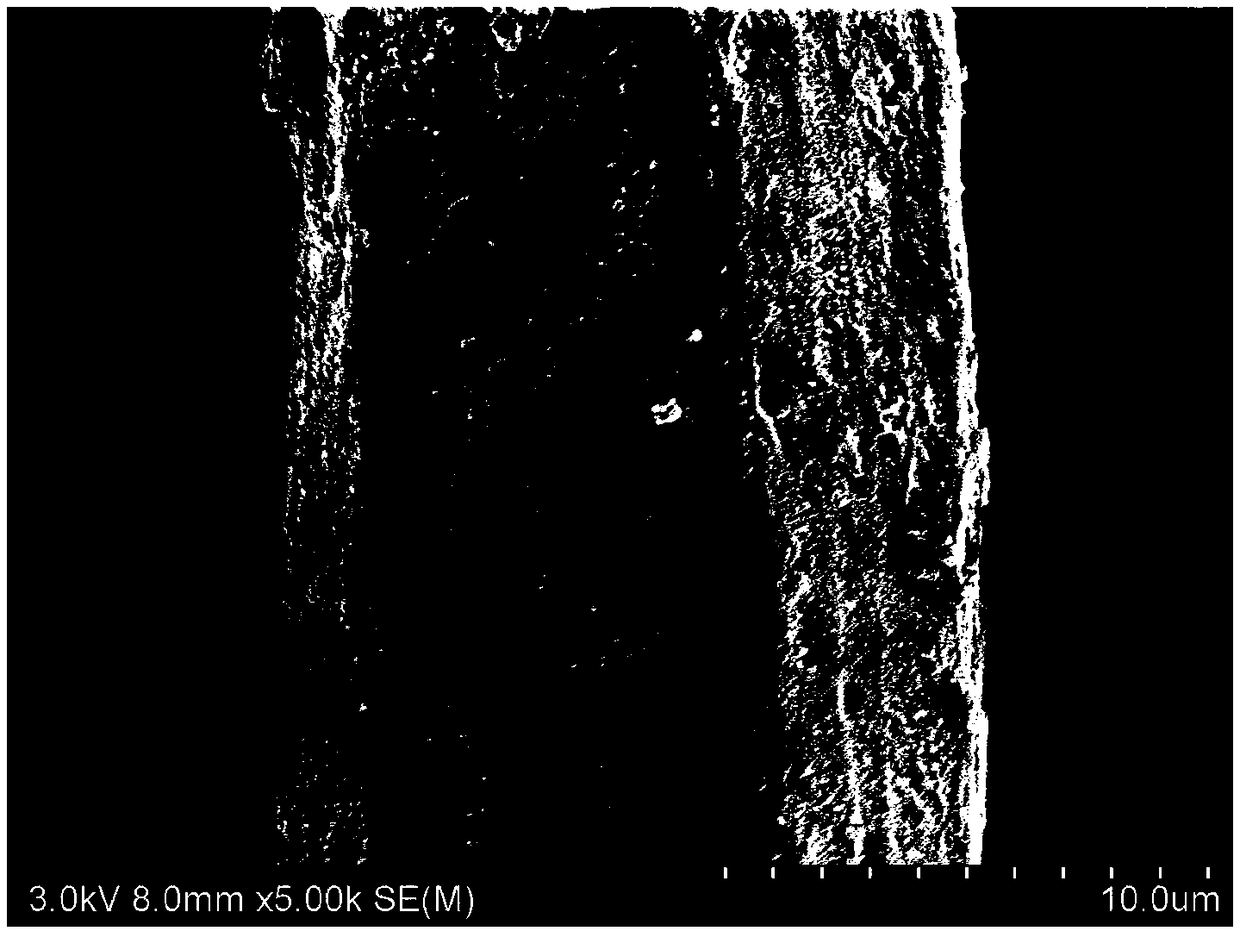

Graphene steel composite material, preparation method and applications thereof

ActiveCN110126378AEvenly distributedReduce the difficulty of dispersionLamination ancillary operationsLaminationPre treatmentCvd graphene

The present invention discloses a graphene steel composite material, which comprises steel layers and graphene layers, wherein the steel layers and the graphene layers are alternately stacked, the uppermost layer and the lowermost layer of the graphene steel composite material in a stacked direction are the steel layers, and the two adjacent steel layers are separated by one graphene layer. The invention further discloses a preparation method of the graphene steel composite material, wherein the preparation method comprises: providing a plurality of steel plates; providing a graphene dispersion liquid, wherein the graphene dispersion liquid comprises a graphene sheet dispersion agent and graphene sheets dispersed in the dispersion liquid; alternately stacking the steel plates and the graphene dispersion liquid to sandwich the graphene dispersion liquid between the two adjacent steel plates to form a sandwich structure, wherein the uppermost layer and the lowermost layer of the sandwichstructure are the steel plates; carrying out pressurizing pre-treatment on the sandwich structure; and sintering the pre-treated sandwich structure at a temperature of 900-1100 DEG C. The invention further discloses applications of the graphene steel composite material.

Owner:北京石墨烯技术研究院有限公司

Printing process for modified titanium dioxide and preparation method of modified titanium dioxide printing material

ActiveCN108855188AHigh catalytic activityEffective size controlPhysical/chemical process catalystsMicro nanoChinese characters

The invention discloses a printing process for modified titanium dioxide and a preparation method of a modified titanium dioxide printing material. The printing process comprises the following steps:1) introducing amino ions and metal elementary substances into titanium dioxide to obtain the printing material at least containing the modified titanium dioxide; 2) printing the printing material onto base cloth by printing equipment, wherein the base cloth is fabric at least containing special-shaped fibers. The printing process and the preparation method have the advantages that the fabric madefrom the special-shaped fibers, especially fibers with shape like Chinese character mi, is adopted, axial slots are formed in microstructures of the fibers, modified titanium dioxide particles in theprinting material enter the slots, and the micro-nano modified titanium dioxide particles can be fastened with the fiber structures; amino positive ions are introduced into titanium dioxide, and accordingly, the bonding fastness between the modified titanium dioxide and shell fabric is guaranteed; metal such as silver is added to expand the spectral range for light absorption, and the fabric hasa good response effect under sunlight; the fibers and the fabric obtained after printing have antibacterial and antistatic performance.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Method for artificial cultivation of mussel on tidal flat and sand shoal

InactiveCN1568673AIn line with living habitsDoes not affect normal growthClimate change adaptationPisciculture and aquariaTidal flatAdhesive

The invention discloses a shellfish artificial breeding method on intertidal zone and sand shoal, which solves the problem of shellfish escape, large scale gathering because of tide, low survival. The inventive method: A segment of thread is picked, one end of thread is fixed to an article, and the other end is adhered to triangular sector of shellfish dorsal border. The method has no harm to shellfish, is reliable in fastness, can be used for breeding hard clam, green clam.

Owner:王古铨

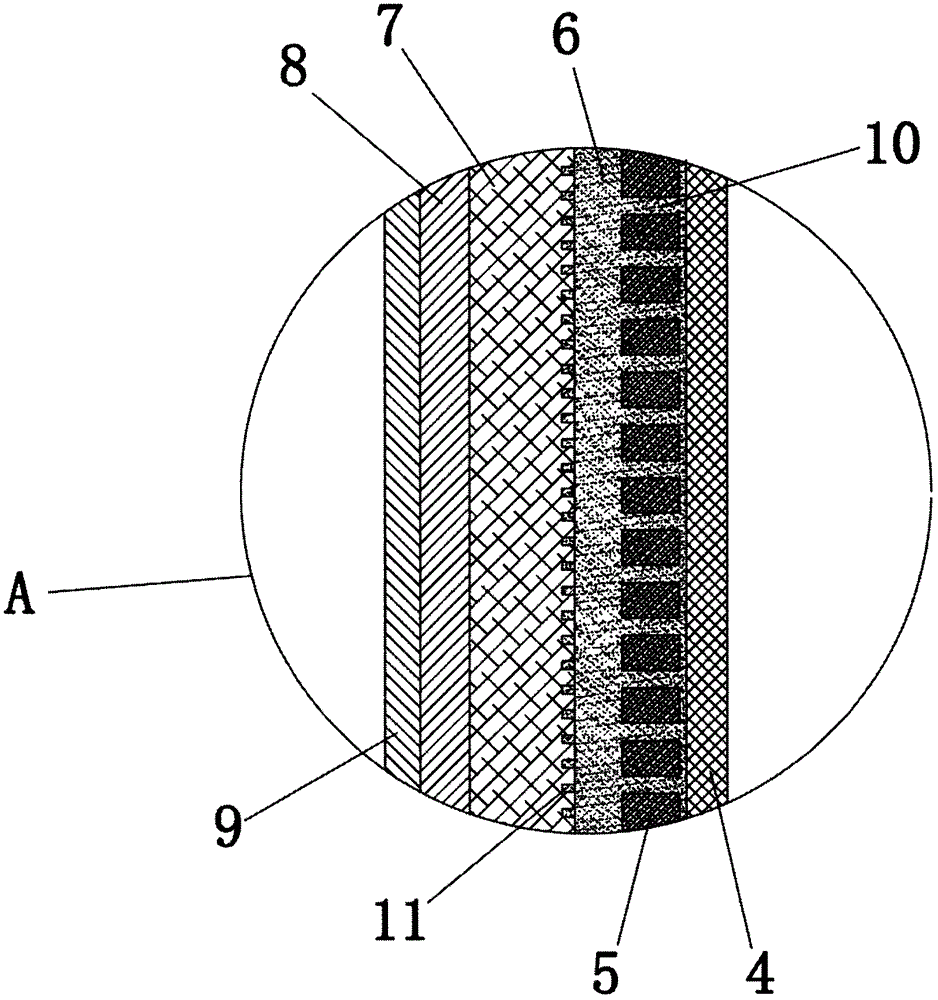

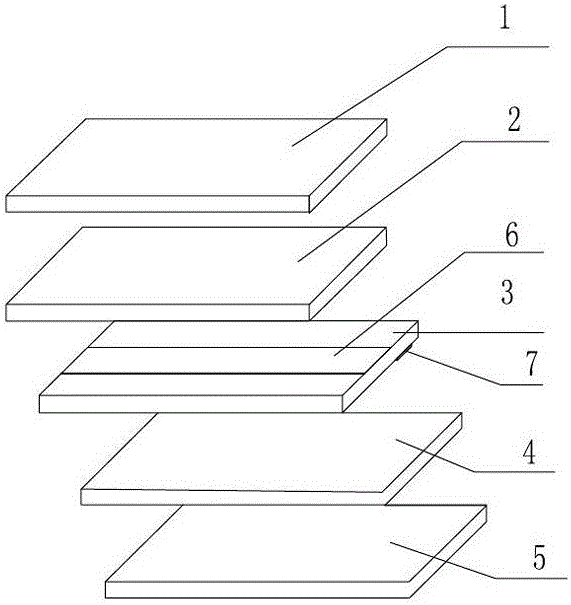

Flexible composite aluminum substrate and preparation method thereof

ActiveCN105101626AGuarantee the firmness of the bondCreate a technical space for storageElectrical equipmentCoatingsInsulation layerSilver bromide

The invention provides a flexible composite aluminum substrate and a preparation method thereof. The flexible composite aluminum substrate comprises a copper foil conducting layer, a first flexible heat conducting glue layer, an insulation layer, a second flexible heat conducting glue layer and a flexible radiating aluminum foil which are connected successively, a first silver bromide photosensitive layer is arranged between the insulation layer and the first flexible heat conducting glue layer, a second silver bromide photosensitive layer is arranged between the insulation layer and the second flexible heat conducting glue layer, and the total area of the first and second silver bromide photosensitive layers is 1 / 5 to 2 / 3 that of the insulation layer. The preparation method is simple, the flexible composite aluminum substrate can be used for information storage innovatively, and the utilization rate of the products is improved.

Owner:DONGGUAN YILIAN ELECTRONICS TECH

How to make resin diamonds

The invention discloses a method for making a resin diamond, which comprises the following steps in turn: 1. Prepare a master mold: ① provide a diamond shape; ② prepare a mold according to the diamond shape, and process one end of the mold into the shape of the diamond shape Consistent mold heads; ③ Insert multiple molds into the mold cavity of a lower mold, and the mold cavity is provided with a plurality of slots that are mated with the plugs of the molds; 2. Prepare plastic molds : Install the lower mold and an upper mold on the injection molding machine, and use thermoplastic injection molding to form a plastic mold; 3. Forming of resin diamonds: ① Pour AB glue into the plastic cavity formed by the mold head on the plastic mold, Squeeze; ②Put the plastic mold with AB glue into the oven to dry and cure, the drying temperature is 110°C, and the drying time is 50min; ③Take the cured and formed AB rubber block out of the plastic mold cavity, that is A resin diamond rough is obtained. The method is low in cost for making resin diamonds.

Owner:王芳华

A glue drying process for glass fiber cloth

ActiveCN107139572BEmission reductionImprove environmental performanceLamination ancillary operationsLaminationGlass fiberEngineering

The invention provides a gluing and drying process for fiberglass cloth, belongs to the technical field of mechanical engineering, and solves the problem that the existing fiberglass cloth is prone to degumming after bonding. The gluing and drying process is characterized by including the following steps of: A, feeding: simultaneously feeding fiberglass base cloth and nonwoven fabric by traction; B, preheating: preheating the fiberglass base cloth and nonwoven fabric through a preheating device; C, gluing: gluing the fiberglass base cloth and nonwoven fabric; D, bonding: bonding the fiberglass base cloth and the nonwoven fabric glued through a bonding roll set; E, drying: drying the bonded fiberglass cloth in a drying box; F, discharging: rolling the dried fiberglass cloth. The raw materials of the fiberglass cloth are preheated before gluing and bonding, so that glue can completely permeate into the raw materials of the fiberglass cloth during gluing, fastness in bonding during fiberglass cloth production is assured, and quality of fiberglass cloth is improved.

Owner:浙江凯澳新材料有限公司

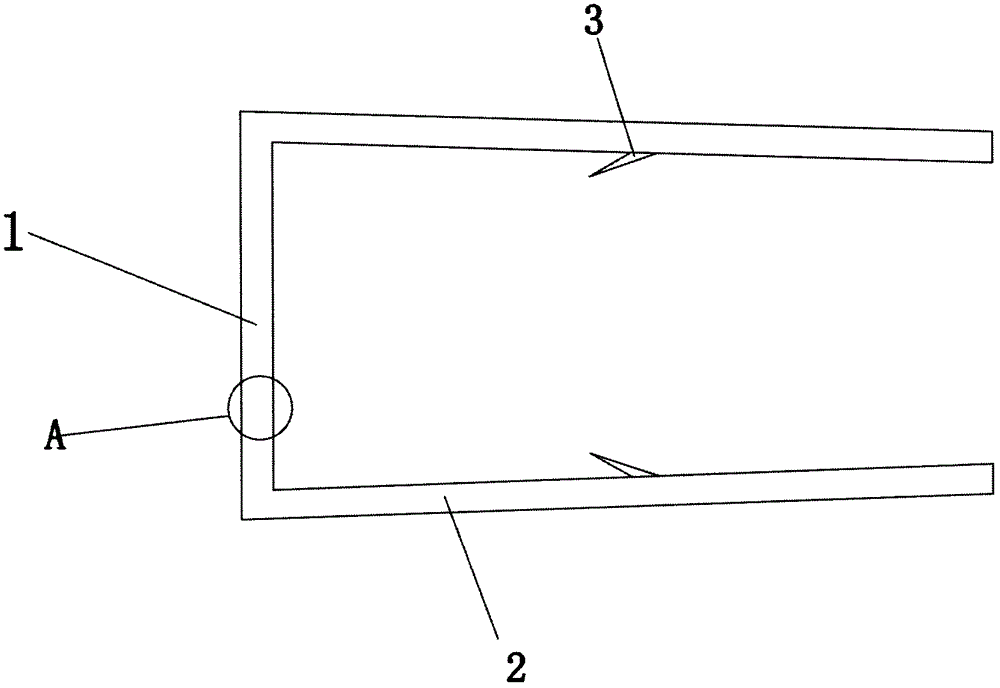

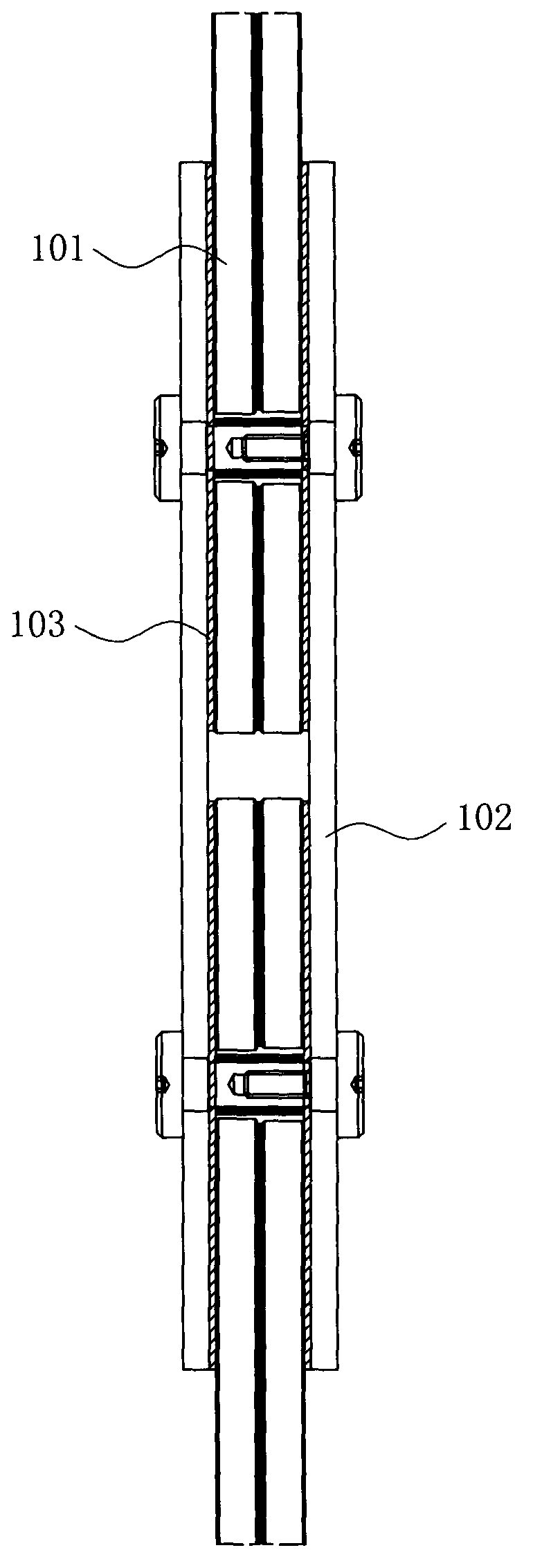

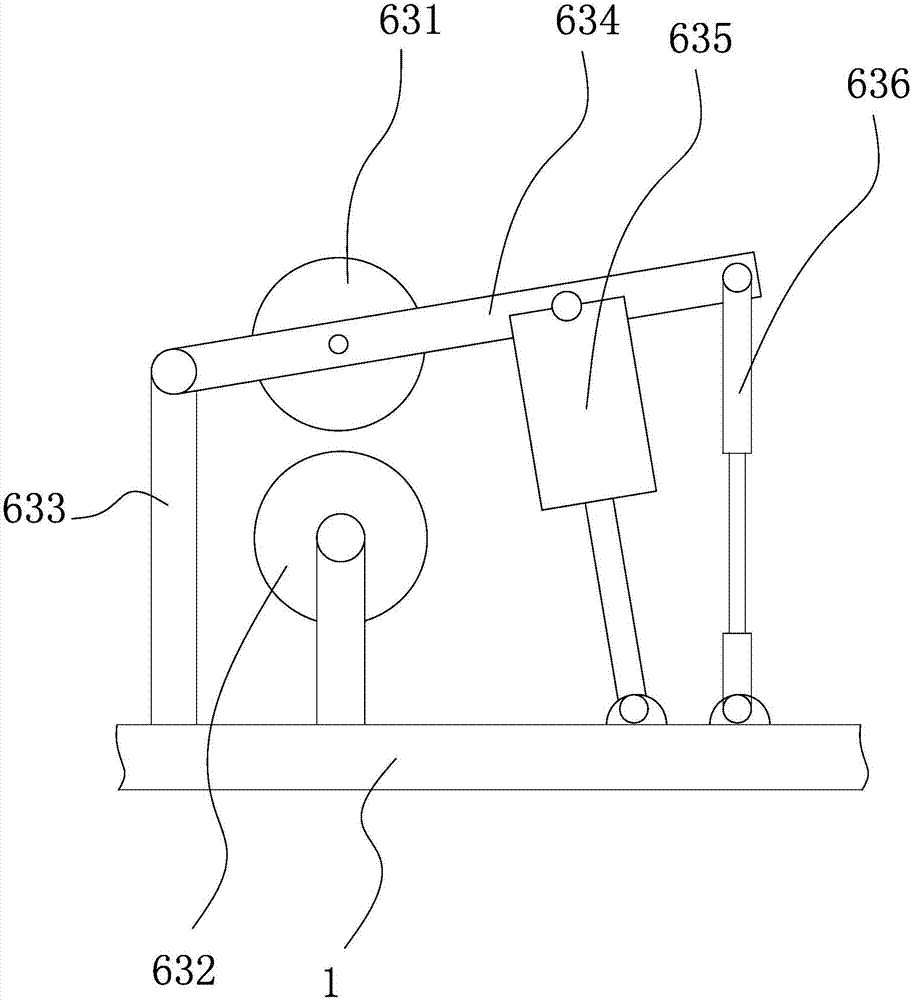

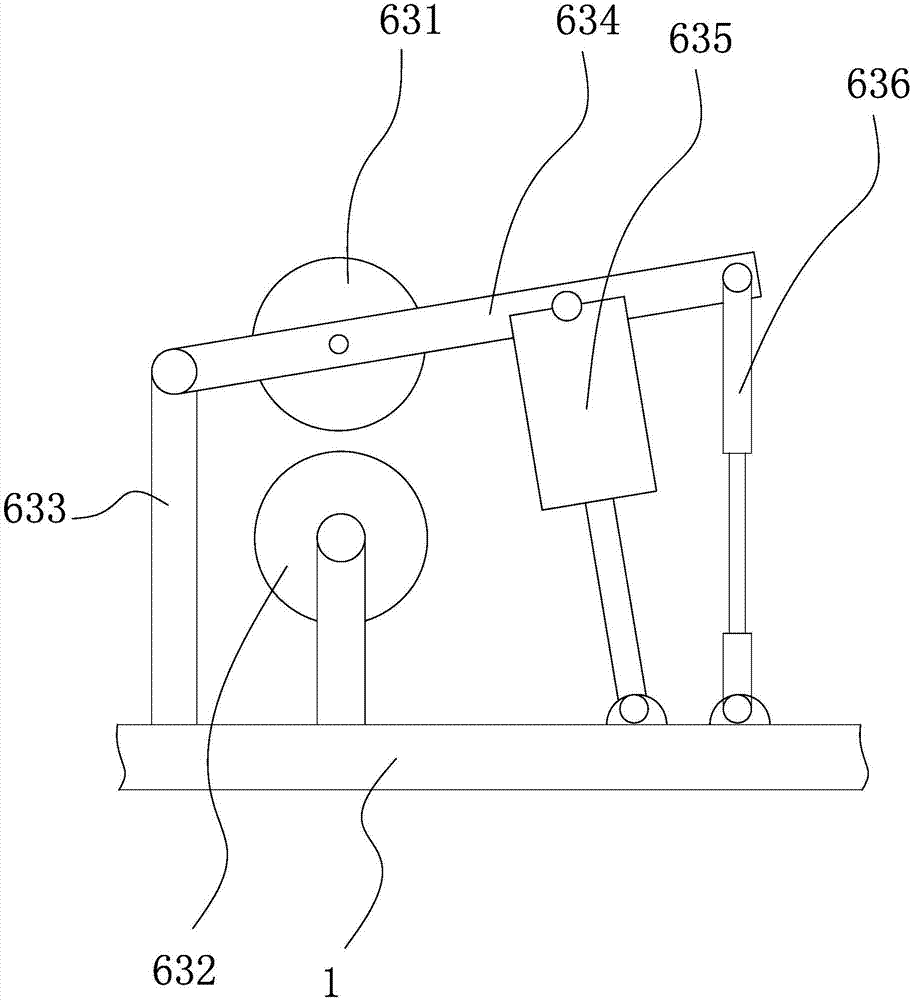

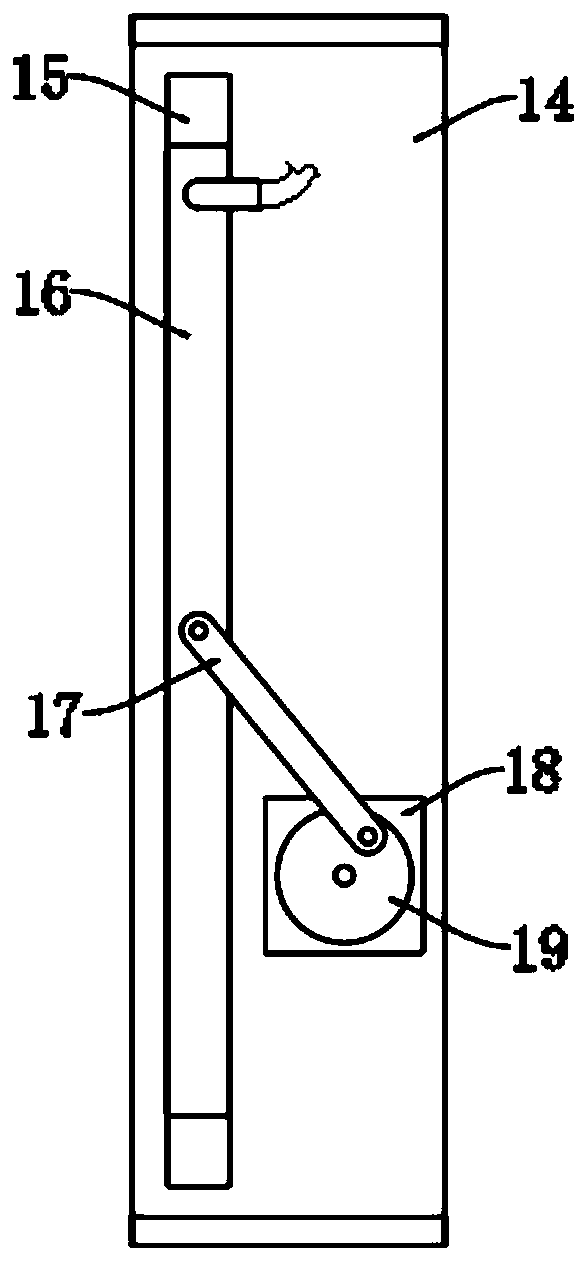

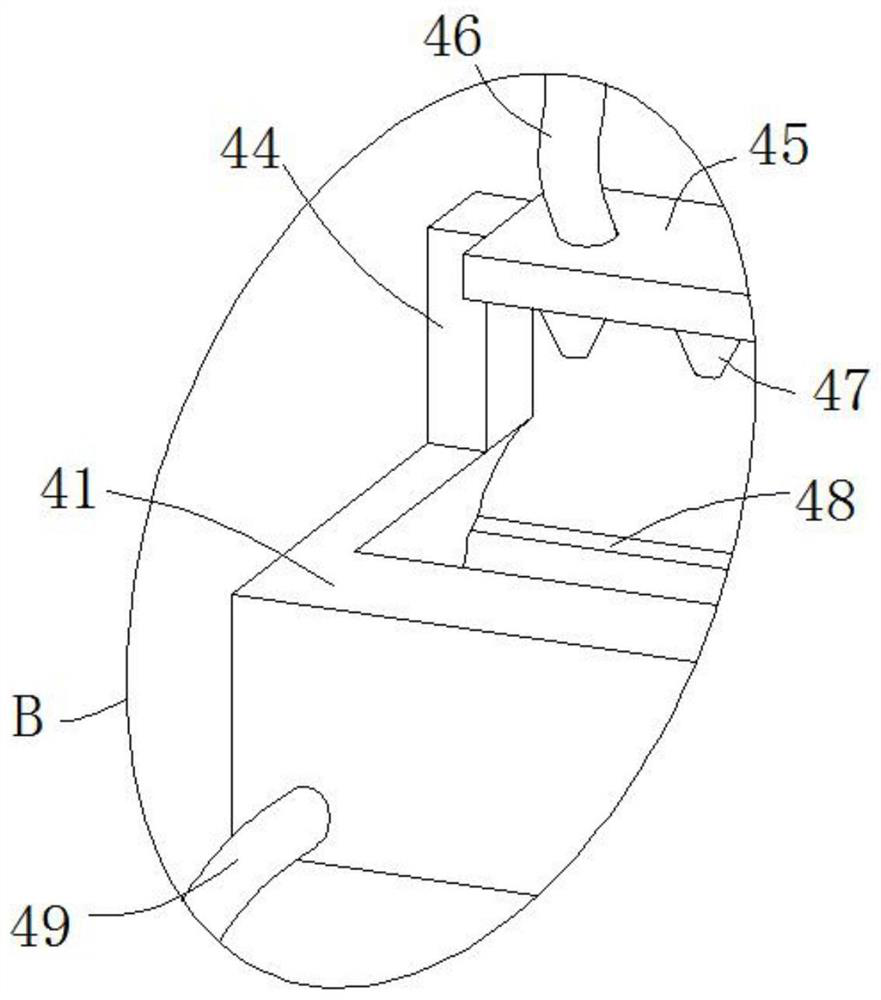

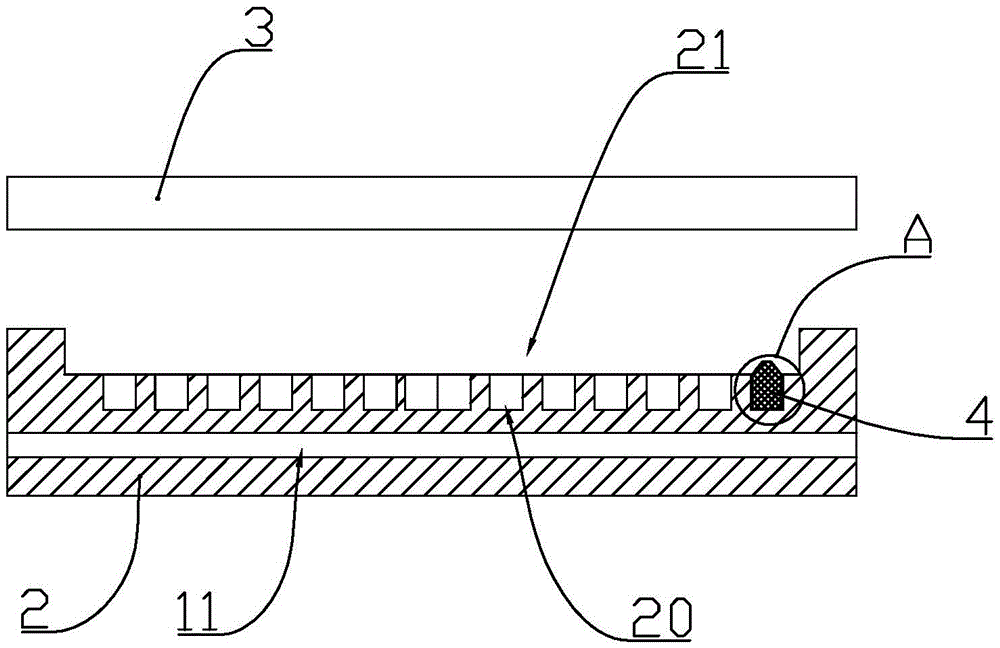

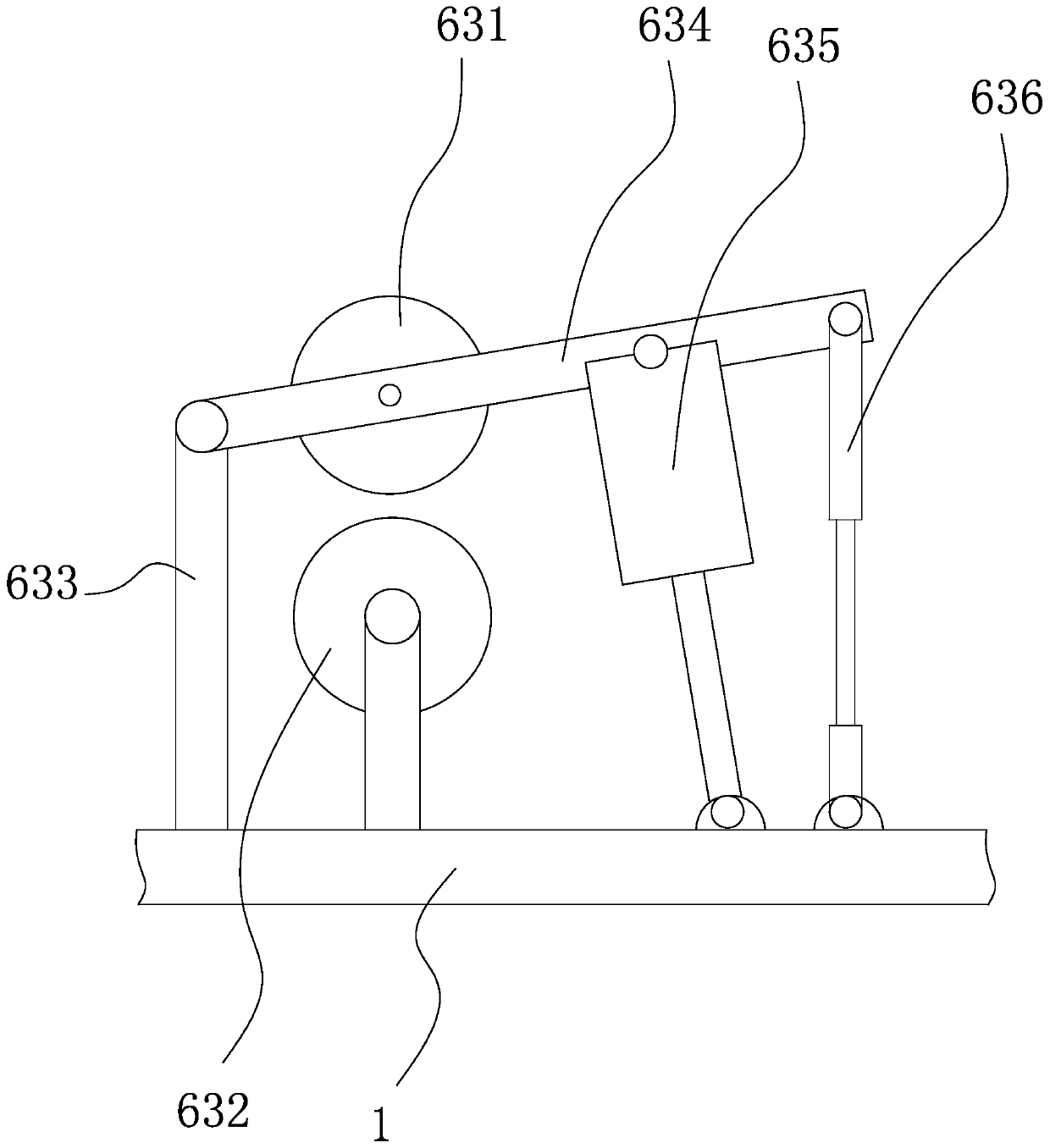

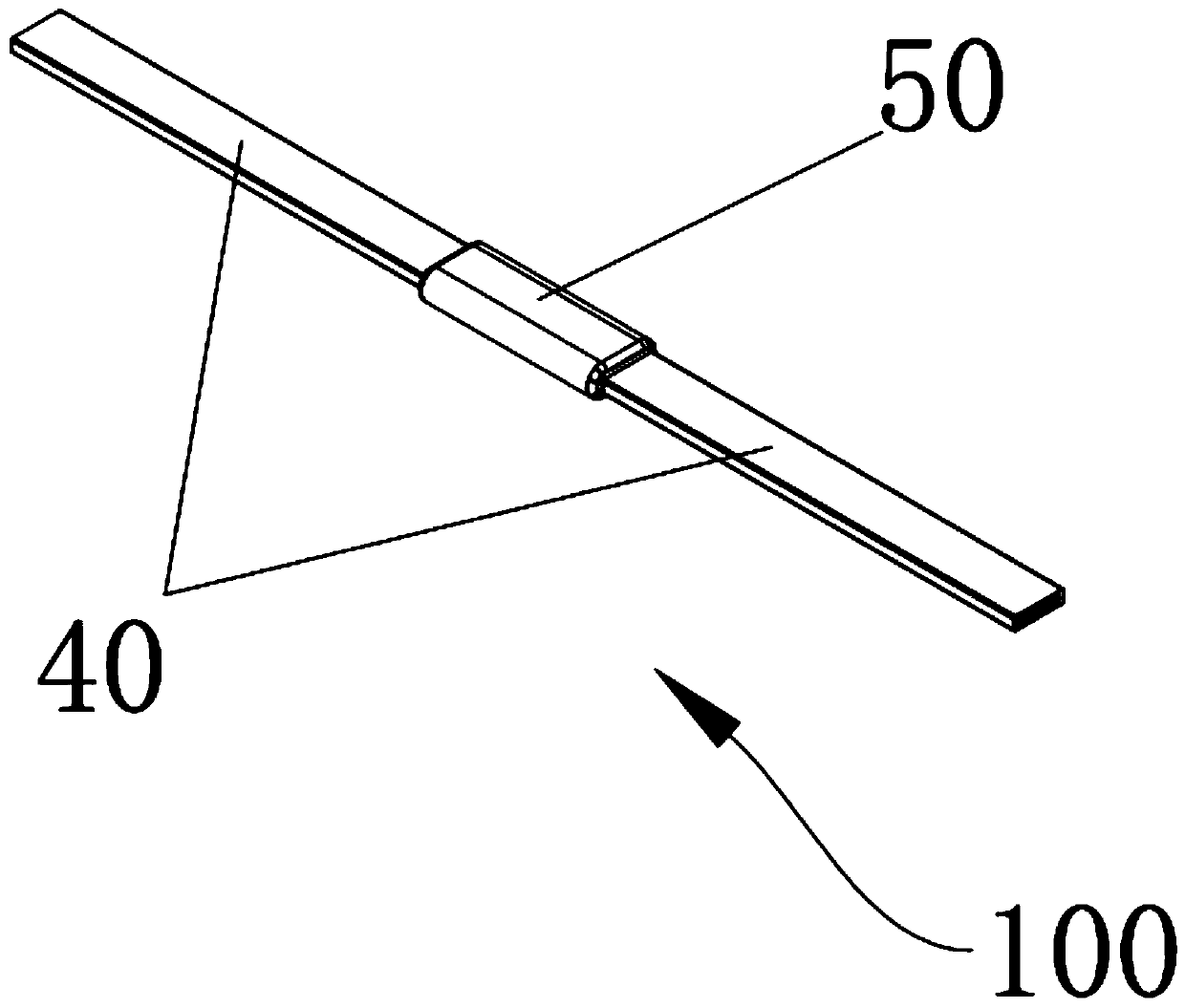

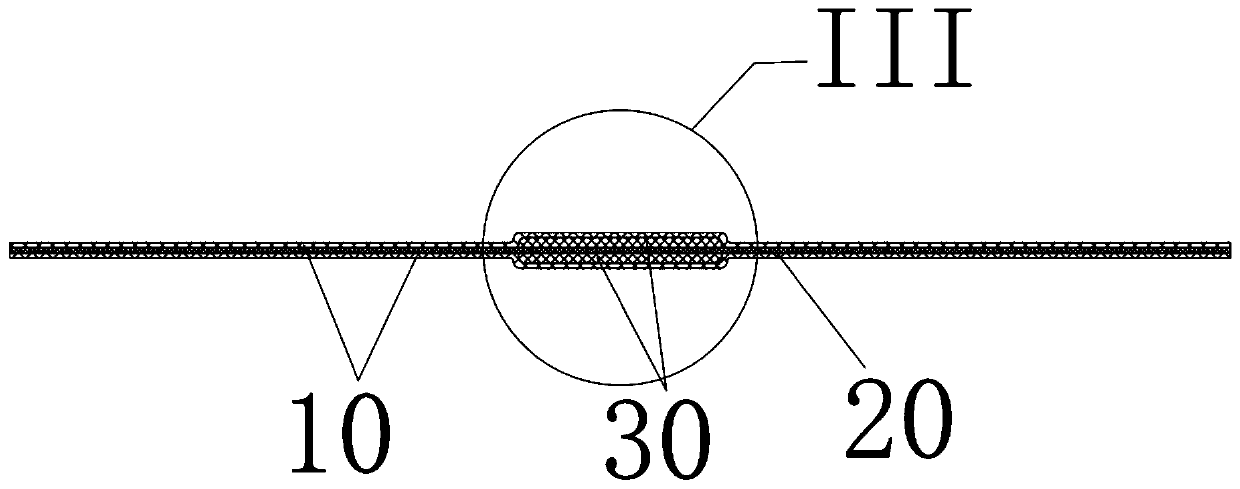

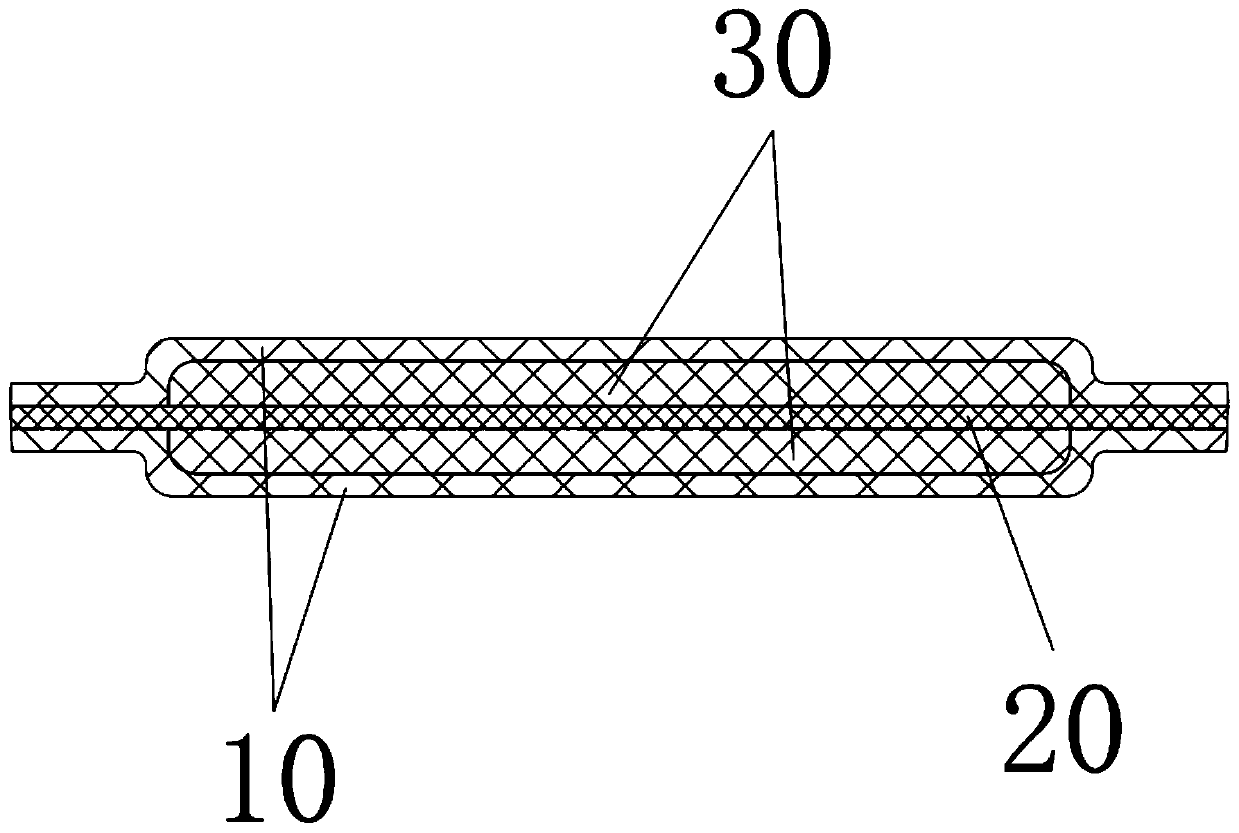

Shoe upper and shoe tree fixing device

InactiveCN110037386APrevent misalignment or even falling offGuarantee the firmness of the bondLastingStable stateEngineering

The invention provides a shoe upper and shoe tree fixing device. The shoe upper and shoe tree fixing device comprises a working table, a rotary disc, a shoe tree, a shoe vamp compression mechanism, ashoe heel compression mechanism and shoe upper side face compression mechanisms, wherein the shoe upper side face compression mechanisms are arranged on the left side and the right side of the shoe tree respectively; the shoe vamp compression mechanism is arranged below the front end of the shoe tree, the shoe heel compression mechanism is arranged on the rear side of the shoe tree, each shoe upper side face compression mechanism comprises third pressure heads and a third pushing element matched with the third pressure heads, and the third pressure heads are used for making the middle of a shoe upper and the shoe vamp parts corresponding to the third pressure heads compressed onto parts, corresponding to the third pressure heads, of the shoe tree. In the shoe upper and shoe tree fixing device, the shoe tree is arranged on the rotary disc, the compression mechanisms are arranged around the shoe tree, the shoe upper is fixed to the shoe tree through the compression mechanisms, and the phenomenon that due to the foot shape structure of the shoe tree, the shoe upper is staggered with the shoe tree, and even the shoe upper falls off is avoided. It is ensured that when the shoe upper anda shoe sole are assembled, the position of the shoe upper is in a stable state, and then it is ensured that the shoe upper is firmly stuck to the shoe sole.

Owner:JIHUA LAB

Winding pipe coating film exhausting device

The invention discloses a winding pipe coating film exhausting device. The winding pipe coating film exhausting device comprises a handpiece, and further comprises a connecting plate, a support plate, a pin wheel, a rotating shaft and a bearing, wherein the support plate is connected with the handpiece; the connecting plate is connected with the support plate through bolts; the bearing is installed into an inner hole of the pin wheel; the rotating shaft is installed into an inner hole of the bearing; the pin wheel is connected with the connecting plate through the rotating shaft; 8 steel pins which are uniformly distributed circumferentially are arranged on the excircular surface of the pin wheel; a long waist-shaped hole is formed in the connecting plate; two screw holes are formed in the support plate; the inner hole of the pin wheel is in transition fit with the excircular surface of the bearing; the inner hole of the bearing is in transition fit with the excircular surface of the rotating shaft. The winding pipe coating film exhausting device is simple in structure, convenient to adjust, good in exhausting effect, good in processing quality, low in cost and long in service life.

Owner:武汉纳川管材有限公司

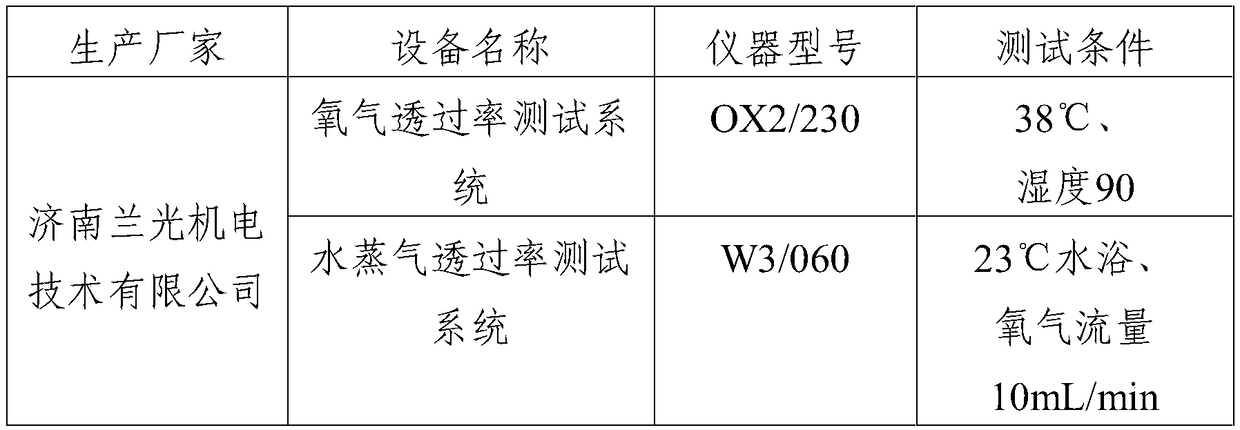

Isolating film, top-emitting photoelectric device and manufacturing method and application thereof

InactiveCN110752308AImprove mechanical propertiesGood chemical stabilitySolid-state devicesSemiconductor/solid-state device manufacturingMetal membraneLight emission

The present invention relates to the technical field of photoelectric devices, and specifically provides an isolating film, a top-emitting photoelectric device and a manufacturing method and an application thereof. The isolating film includes a first oxide film and a metal film, a second oxide film and a third oxide film that are stacked outward from the surface of the first oxide film. The top-emitting photoelectric device includes a top electrode and a packaging layer stacked on the surface of the top electrode. The packaging layer is the isolating film. The isolating film of the invention has good mechanical properties and chemical stability, plays a good isolation effect on water vapor and oxygen and can effectively prevent penetration of water vapor and / or oxygen. When the isolating film is used as the packaging layer of the top-emitting photoelectric device, the light emission efficiency and light purity of the top-emitting photoelectric device are greatly improved, so it is conducive to improving the stability, service life and efficiency of the photoelectric device.

Owner:TCL CORPORATION

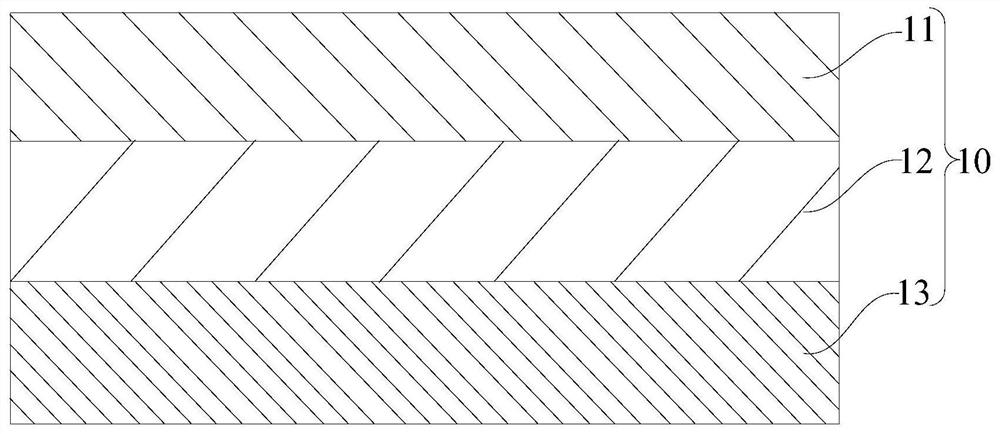

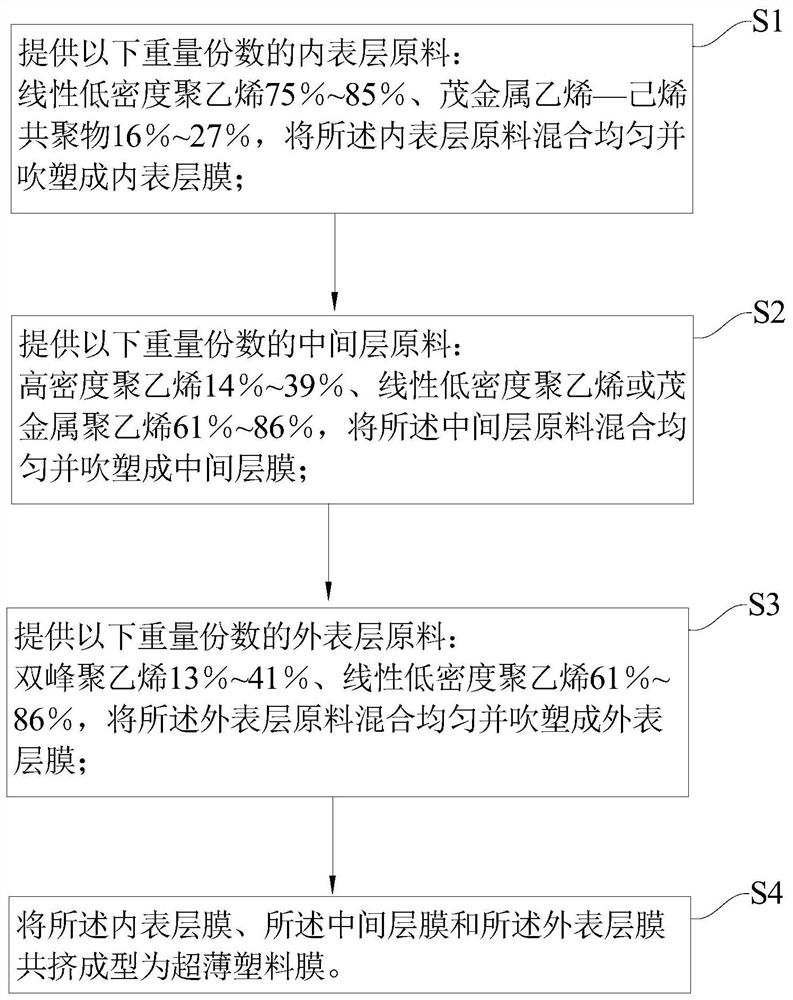

Ultrathin plastic film, preparation method of ultrathin plastic film and express bag

PendingCN112406228AGuaranteed StrengthGuaranteed mechanical propertiesSynthetic resin layered productsBagsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of plastic products, and particularly relates to an ultrathin plastic film, a preparation method of the ultrathin plastic film and an express bag. The ultrathin plastic film includes an inner surface layer, a middle layer and an outer surface layer that are sequentially combined. The inner surface layer is prepared from the following raw materials in percentage by weight: 75%-85% of linear low-density polyethylene and 12%-27% of metallocene ethylene-hexene copolymer; the middle layer is prepared from the following raw materials in percentage by weight: 14%-33% of high-density polyethylene and 56%-87% of linear low-density polyethylene or metallocene polyethylene; the outer surface layer is prepared from the following raw materials in percentageby weight: 15 to 37 percent of bimodal polyethylene and 46 to 86 percent of linear low-density polyethylene. The thickness of the ultrathin plastic film is successfully reduced to about 0.04 mm by repeatedly testing the raw material composition and the weight ratio of the inner surface layer, the middle layer and the outer surface layer for multiple times, and meanwhile, the mechanical property ofthe ultrathin plastic film is ensured.

Owner:SHENZHEN S F TAISEN HLDG (GRP) CO LTD

Rope belt and production method thereof

PendingCN110077064AGuarantee the firmness of the bondIncrease pulling forceLamination ancillary operationsSynthetic resin layered productsPull forceEngineering

The invention relates to a rope belt. The rope belt comprises outer skin fiber layers, an inner core layer and high-molecular polymer layers, wherein the high-molecular polymer layers are wrapped outside the inner core layer at an interval or in a continuous sticking manner, and the outer skin fiber layers are wrapped outside the inner core layer or the high-molecular polymer layers in the lengthdirection and matched with the wrapped layer in shape. The inner core layer is continuous and uninterrupted and guides weaving of the outer skin fiber layers, continuous weaving and coating of the outer skin fiber layers are guaranteed, and automation is easy to realize; shape support is provided for weaving deformation of the outer skin fiber layers in the presence of the high-molecular polymer layers, and deformation weaving difficulty is reduced, so that the shape which cannot be obtained by weaving with an existing weaving process is realized; the inner core layer is embedded in the high-molecular polymer layers, therefore, bonding firmness between the inner core layer and the high-molecular polymer layers is guaranteed, and pull force borne by the rope belt is substantially increased;with the adoption of a positioning impregnation technology, the rope belt keeps non-deformation after being cut and can be directly used.

Owner:YILIAN PLASTICS SHENZHEN CO LTD

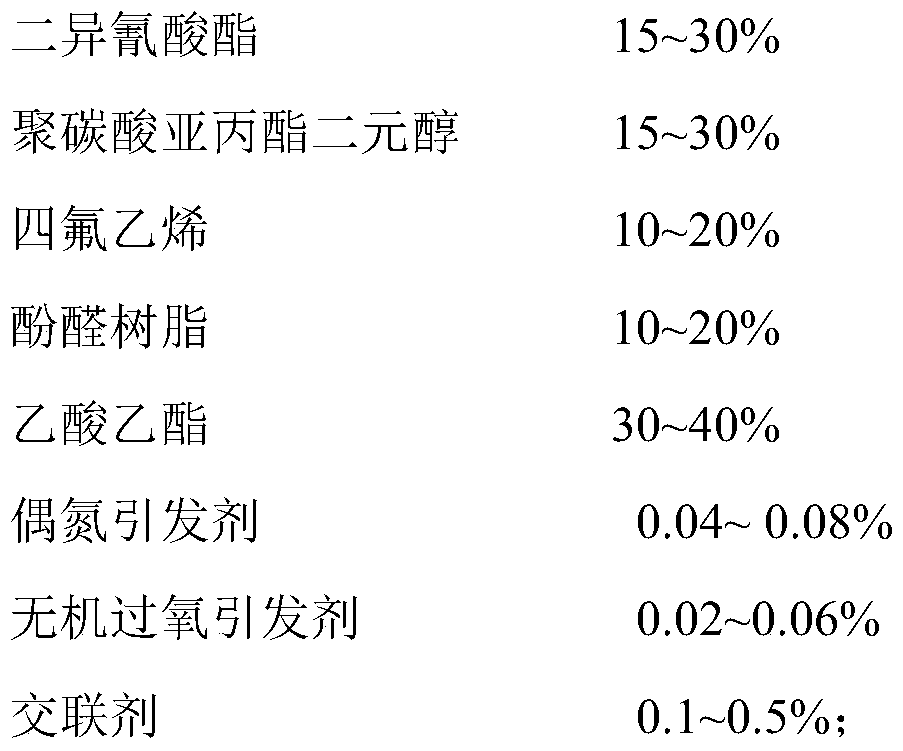

A kind of preparation method of corrosion-resistant polyurethane press roll

ActiveCN108316042BImprove corrosion resistanceGuarantee the firmness of the bondPress sectionDomestic articlesPolymer scienceChemical agent

The invention relates to the technical field of press rolls, and particularly relates to a preparation method of a corrosion-resistant polyurethane press roll. The preparation method comprises the following steps: preparing modified polyurethane resin by using raw materials of formula ratios, and then carrying out laminating coating on the modified polyurethane resin with a steel material, so as to obtain the chemical agent corrosion-resistant press roll. The preparation method has a simple process and is suitable for large-scale production and application.

Owner:东莞理文造纸厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com