Preparing method for resin diamonds

A production method and diamond technology, applied in the field of molds, can solve problems such as falling off, troublesome operation, difficulty in ensuring smooth surface of the wall, etc., to achieve the effect of ensuring the firmness of bonding, ensuring firm connection, and saving mold raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

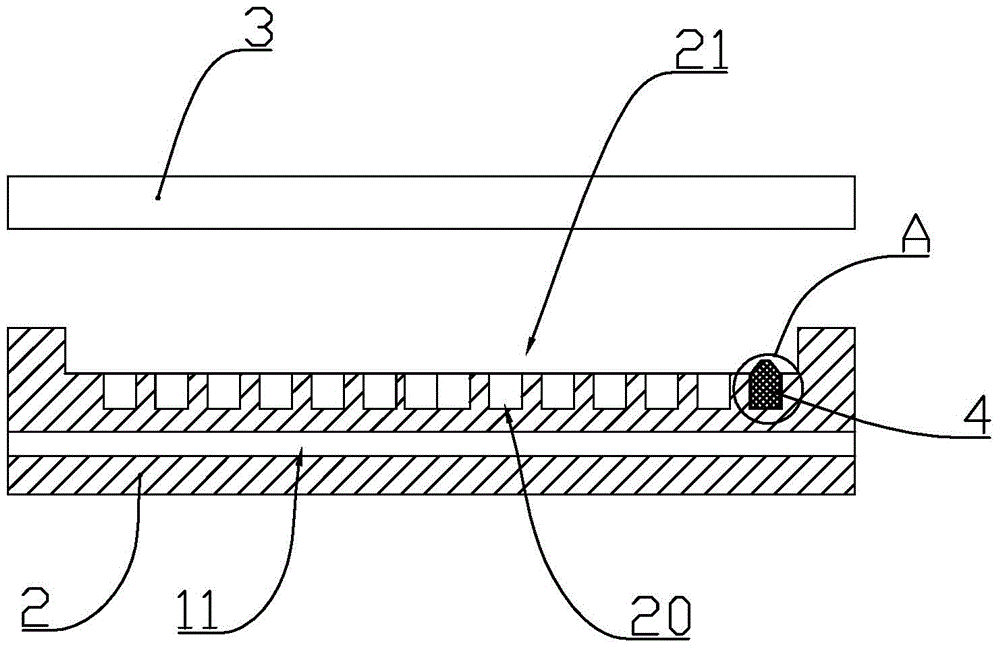

[0042] according to figure 1 , figure 2 As shown, the manufacturing method of a kind of resin diamond described in the present embodiment comprises the following steps successively:

[0043] 1. Preparation of master model:

[0044] ①Provide a diamond-shaped piece with a diamond shape, and the axial section of the diamond-shaped piece is an isosceles trapezoid or an isosceles triangle;

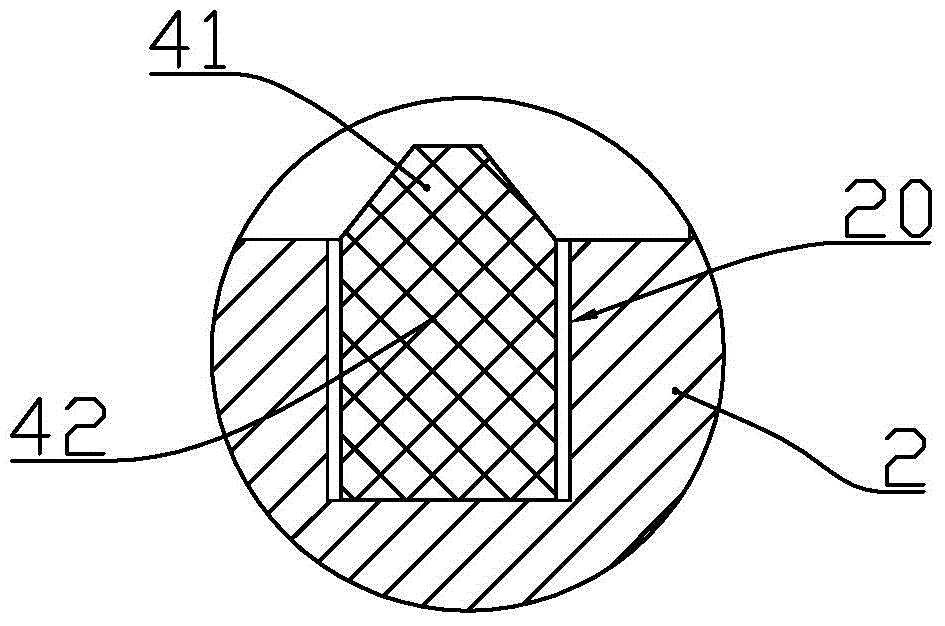

[0045] 2. Prepare the mold 4 according to the diamond shape, the mold adopts zircon or quartz glass as a raw material, one end of the mold is processed into a mold head 41 consistent with the shape of the diamond shape, and the other end of the mold is processed into a cylindrical shape stakes 42;

[0046] ③Insert a plurality of said mold types into the mold cavity 21 of a lower mold, and provide a plurality of slots 20 that are mated with the inserts of the molds in the mold cavity; when inserting the molds, coat the insert surface with Insert after the colloid; the mold cavity is general...

Embodiment 2

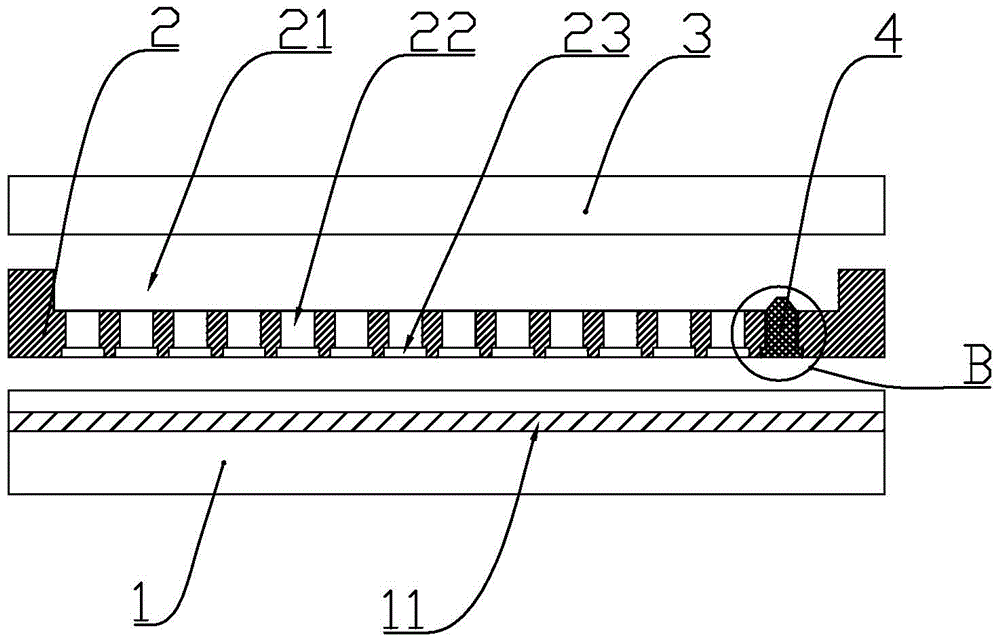

[0061] like image 3 , Figure 4 As shown, the manufacturing method of a kind of resin diamond described in the present embodiment comprises the following steps successively:

[0062] 1. Preparation of master model:

[0063] ①Provide a diamond-shaped piece with a diamond shape, and the axial section of the diamond-shaped piece is an isosceles trapezoid or an isosceles triangle;

[0064] 2. Prepare the mold type 4 according to the diamond shape, the mold type adopts zircon or quartz glass as a raw material, and one end of the mold type is processed into a mold type head 41 consistent with the shape of the diamond type piece, and the middle part of the mold type is processed into a cylindrical Inserting post 42, the other end of mold type is processed into the cylindrical positioning head 43 that diameter is greater than inserting post diameter;

[0065] ③Insert a plurality of mold types into the mold cavity 21 of a lower mold, and a plurality of sockets 22 are provided in t...

Embodiment 3

[0073] like Figure 5 , Figure 9 As shown, two identical lower molds are used as the master mold to form the plastic mold, so that the processed plastic mold has plastic mold cavities on both sides. The service life is doubled, such a piece of plastic mold can be reused 400-500 times, which is 40 to 50 times that of ordinary silicone molds, and there is no way for silicone molds to process a structure with double-sided mold cavities.

[0074] The height of the positioning head is processed to be lower than the depth of the positioning notch, and the height of the positioning head does not need to be very accurate, and then the thermal conductive glue 5 is filled in the positioning notch to be flush with the outer bottom surface of the lower mold. In this way, the processing accuracy of the mold positioning head can be appropriately reduced, and the cost of materials can be reduced. In addition, the use of heat-conducting glue to fill the remaining space in the positioning n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com