Patents

Literature

72 results about "Diamond type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond type is a method of scientifically classifying diamonds by the level and type of their chemical impurities. Diamonds are separated into four types: Type Ia, Type Ib, Type IIa, and Type IIb. The impurities measured are at the atomic level within the crystal lattice of carbon atoms and so, unlike inclusions, require an infrared spectrometer to detect.

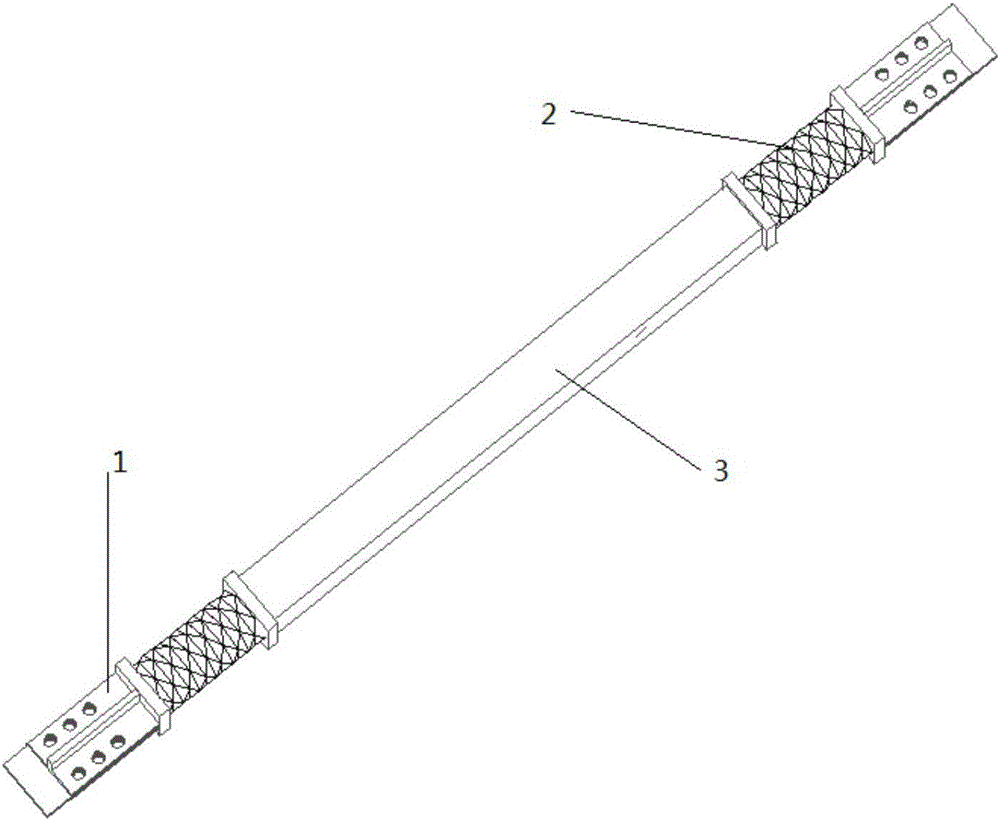

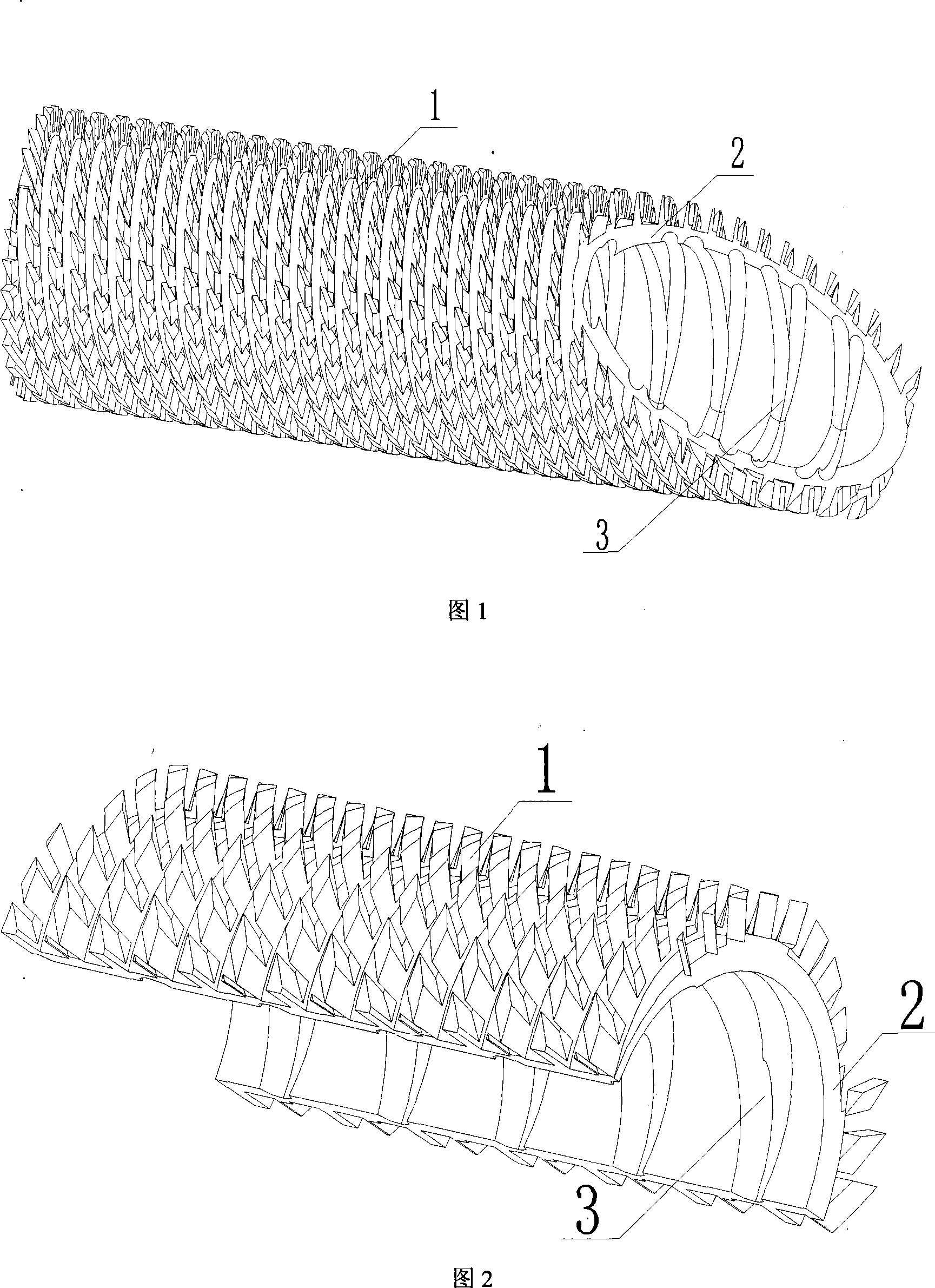

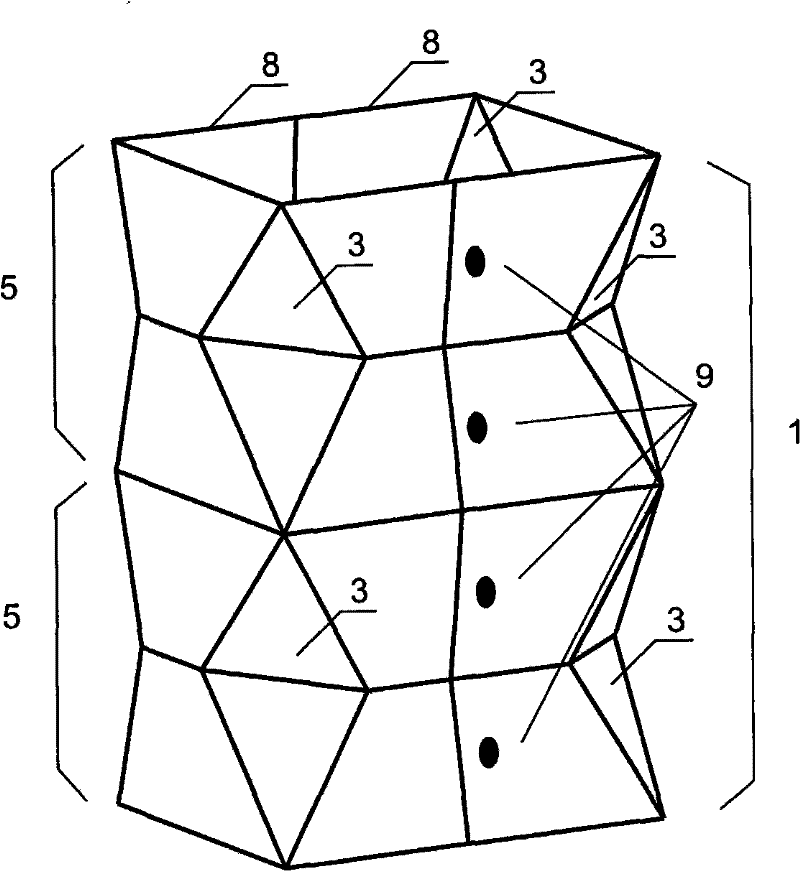

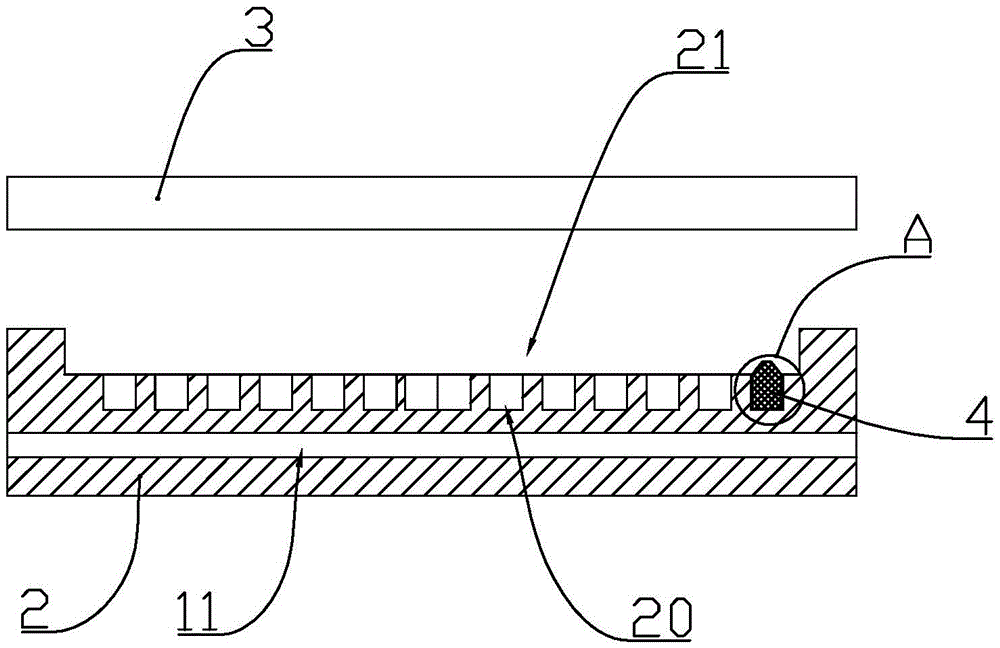

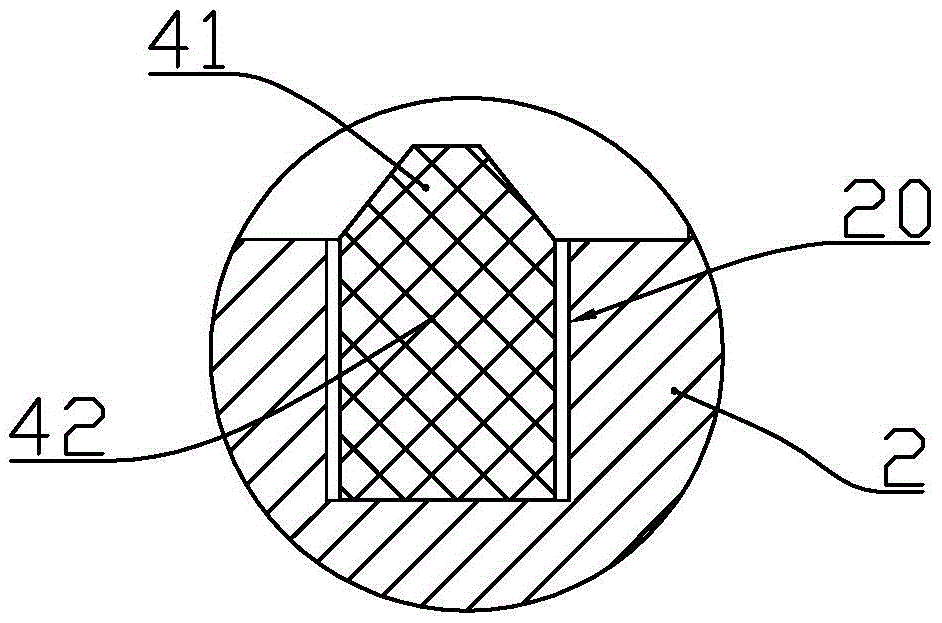

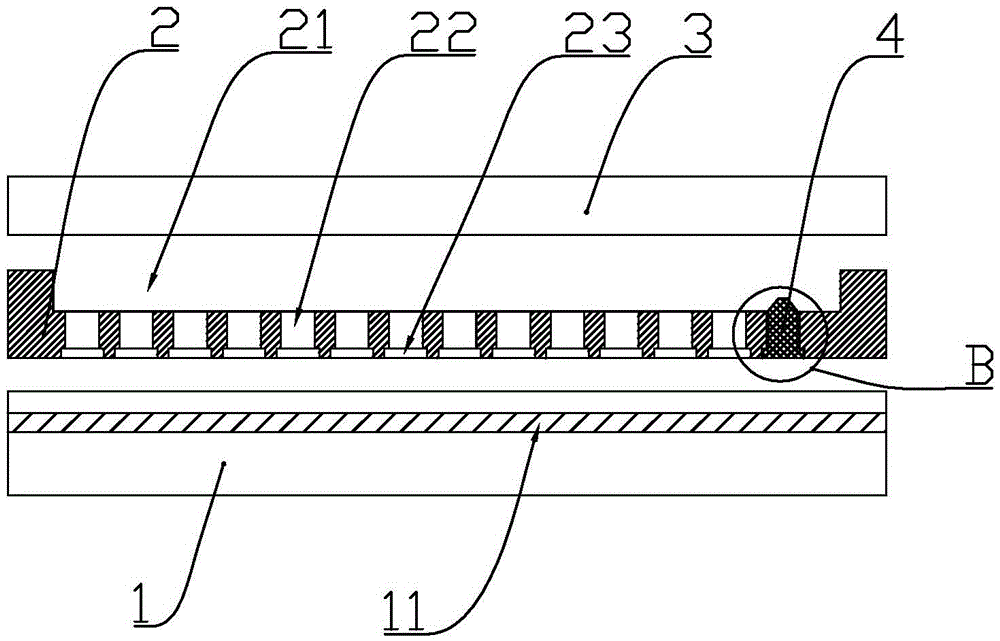

Buckling control support with diamond type energy dissipation units at ends

ActiveCN105888348AImprove protectionQuality assuranceProtective buildings/sheltersShock proofingManufacturing technologyBuckling-restrained brace

The invention discloses a buckling control support with diamond type energy dissipation units at the ends. The buckling control support is characterized by being composed of end restraint sections, energy dissipation sections and a straight supporting section, wherein the two ends of the buckling control support are connected with beam and column members or joints into a whole through high-strength bolts to achieve the purpose of improving the lateral stiffness of the members. The buckling control support with the diamond type energy dissipation units at the ends maintains resilience under the action of a small earthquake and enters a yield stage under the action of a medium earthquake or a major earthquake, and the effect of a damper can be achieved due to the good hystersis energy dissipation performance of the buckling control support. Compared with a traditional buckling control support, the procedures of adding a sleeve outside a core energy dissipation member, performing grouting and the like in the traditional manufacturing process are omitted in the manufacturing technology, and manufacturing is convenient; the support can be prefabricated in a factory, the member quality is guaranteed, the workload of site construction operation is reduced, and energy conservation and environment protection are achieved.

Owner:SOUTHEAST UNIV

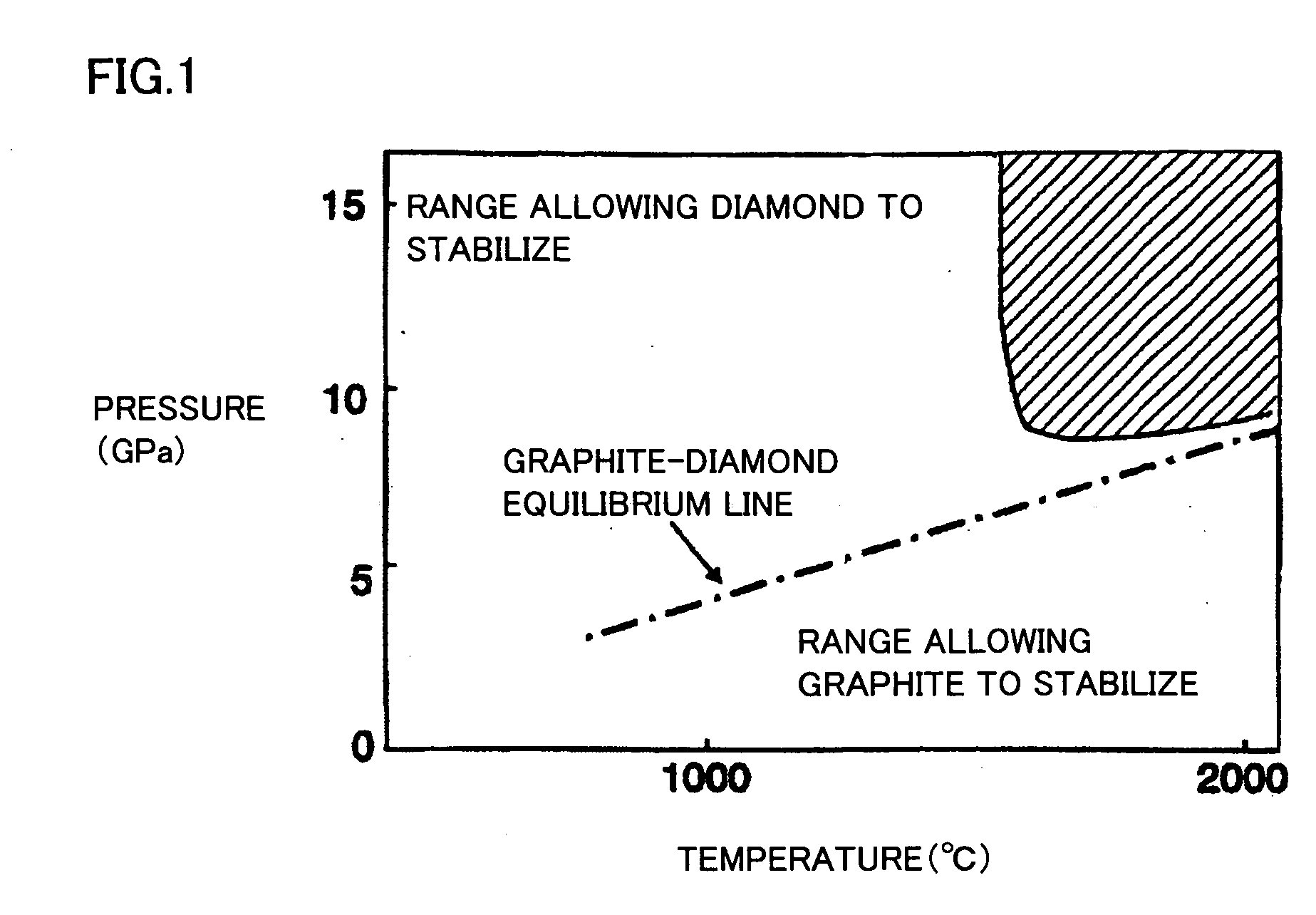

High-hardness polycrystalline diamond and method of preparing the same

ActiveUS20090305039A1Inexpensive and reliableImprove mechanical propertiesMaterial nanotechnologyUltra-high pressure processesUltra high pressurePolycrystalline diamond

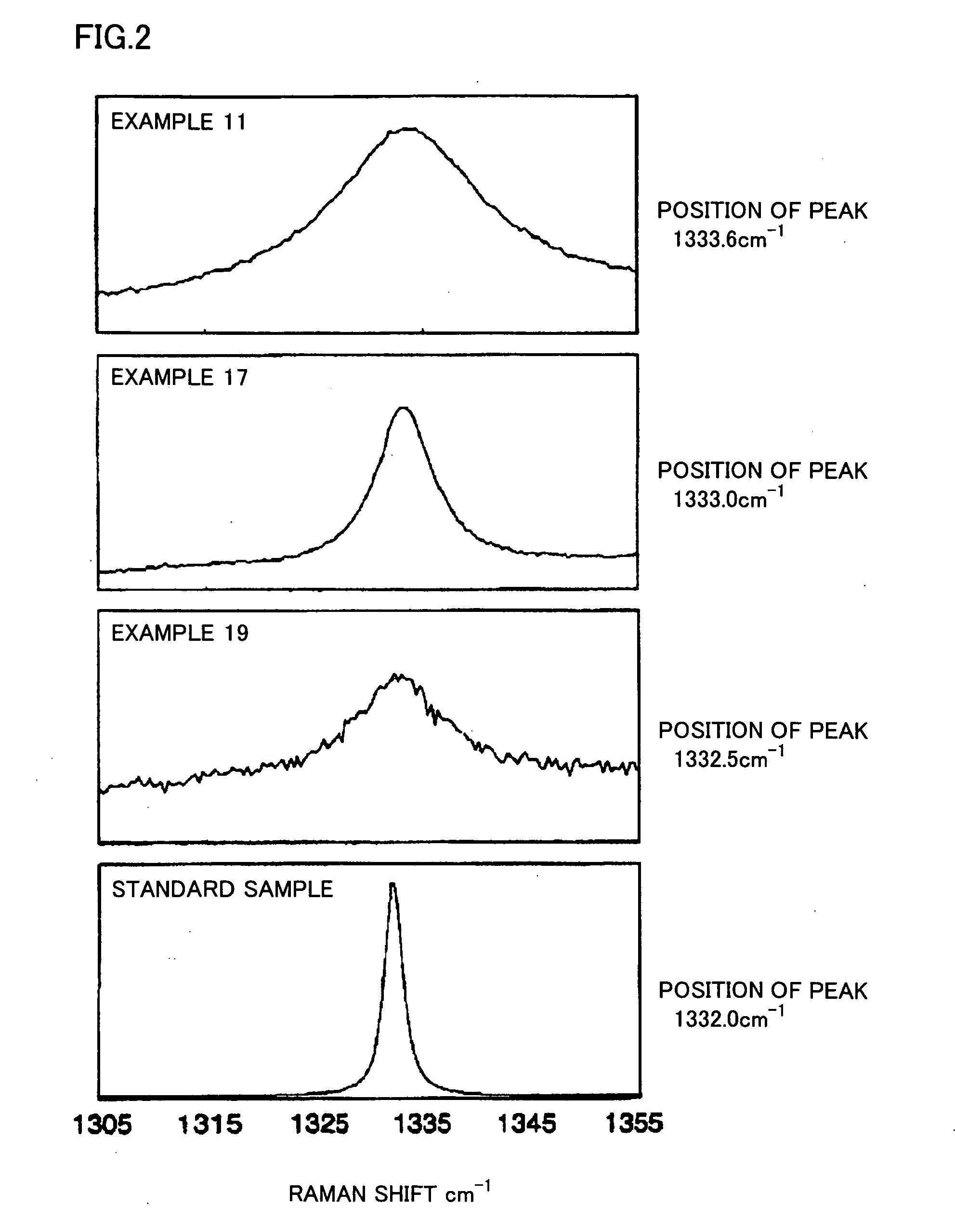

There are provided sufficiently strong, hard, and heat resistant, dense and homogenous polycrystalline diamond applicable to cutting tools, dressers, dies and other working tools and excavation bits and the like, and a cutting tool having a cutting edge of the polycrystalline diamond. The polycrystalline diamond is formed substantially only of diamond formed using a composition of material containing a non diamond type carbon material, the composition of material being converted directly into diamond and sintered at ultra high pressure and ultra high temperature without aid of a sintering aid or a catalyst, and has a mixed microstructure having a fine crystal grain of diamond having a maximal grain size of at most 100 nm and an average grain size of at most 50 nm and a coarse crystal grain of diamond in the form of one of a platelet and a granule having a grain size of at least 50 nm and at most 10,000 nm.

Owner:SUMITOMO ELECTRIC IND LTD

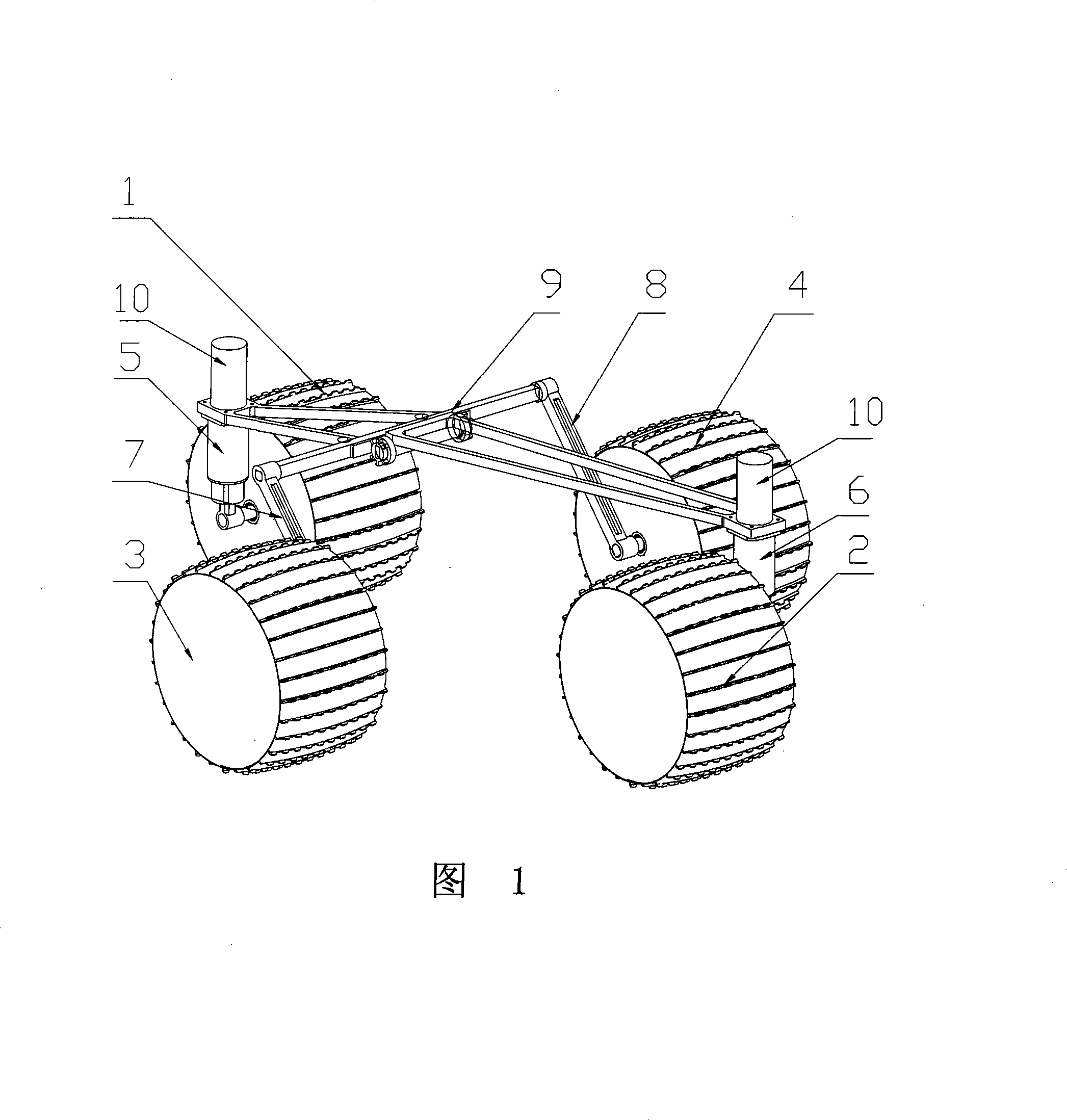

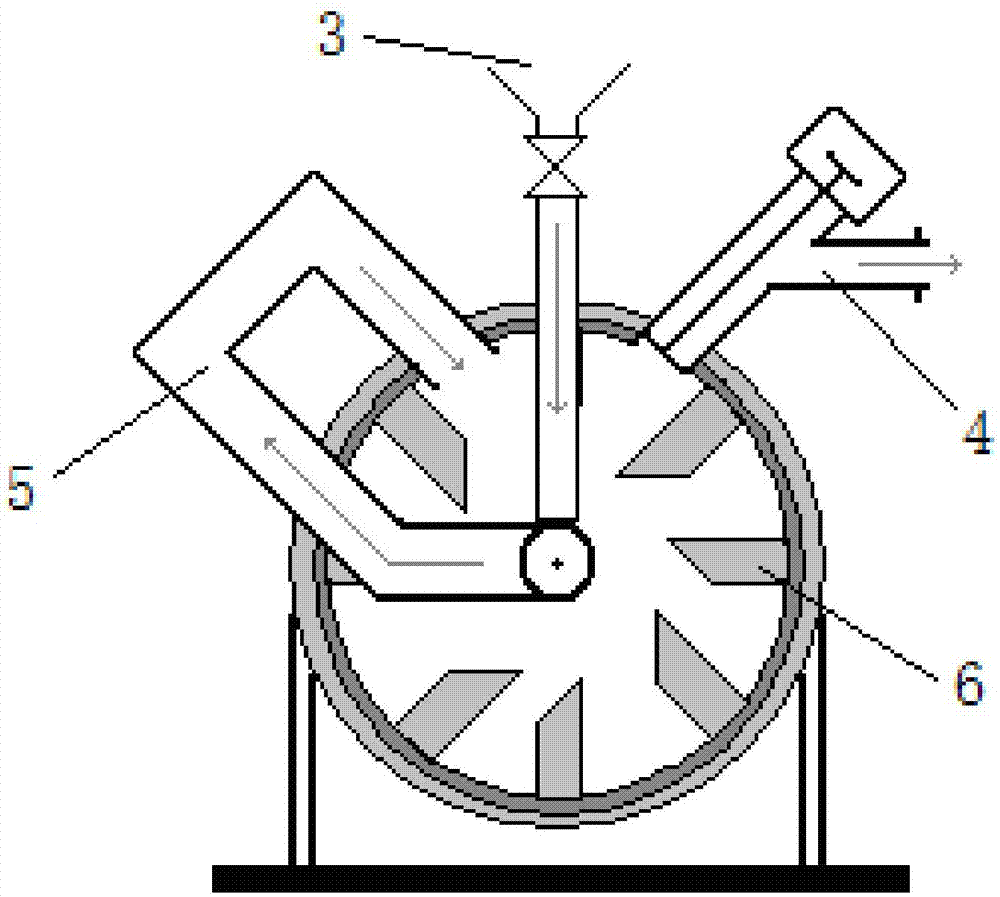

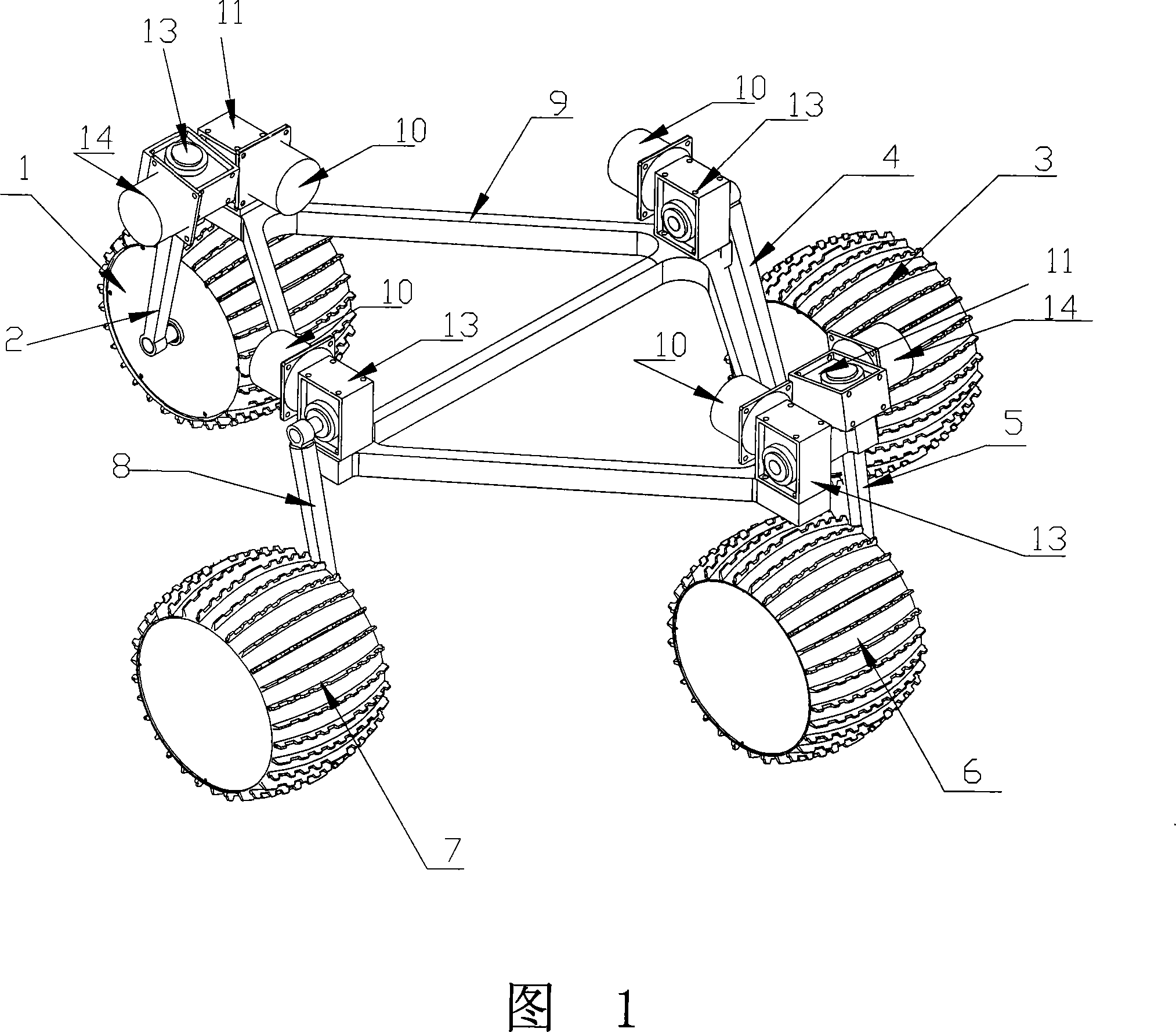

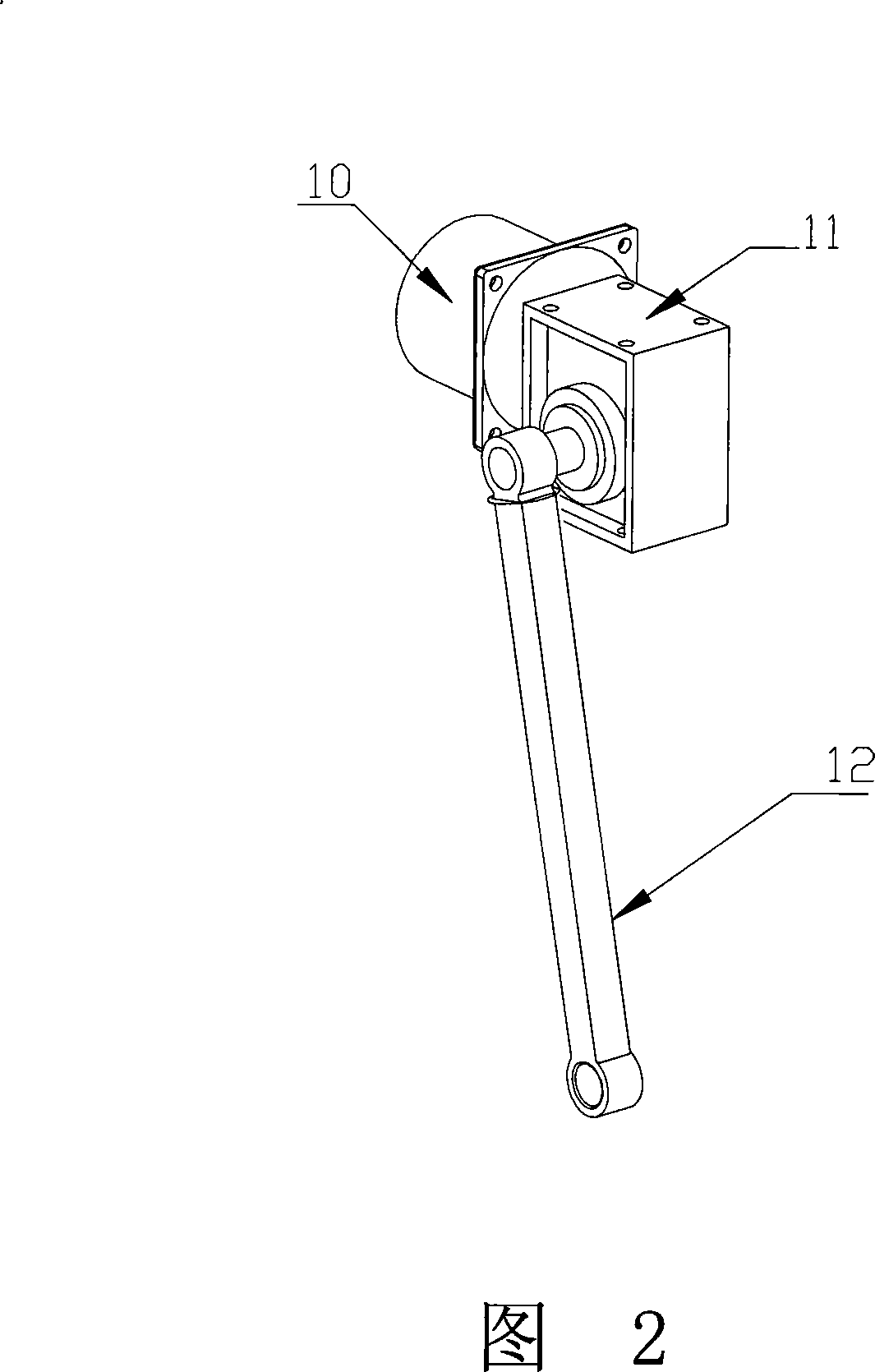

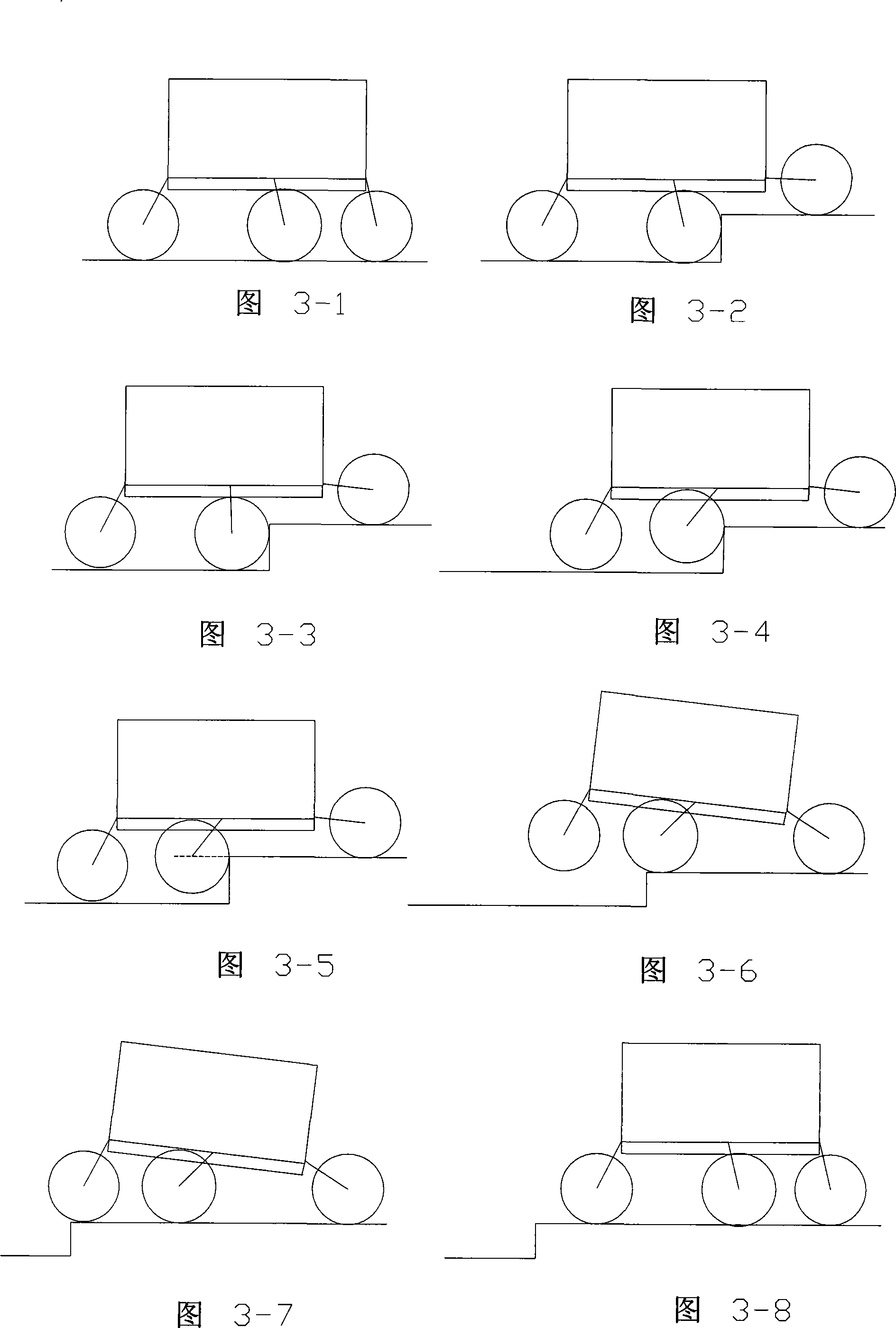

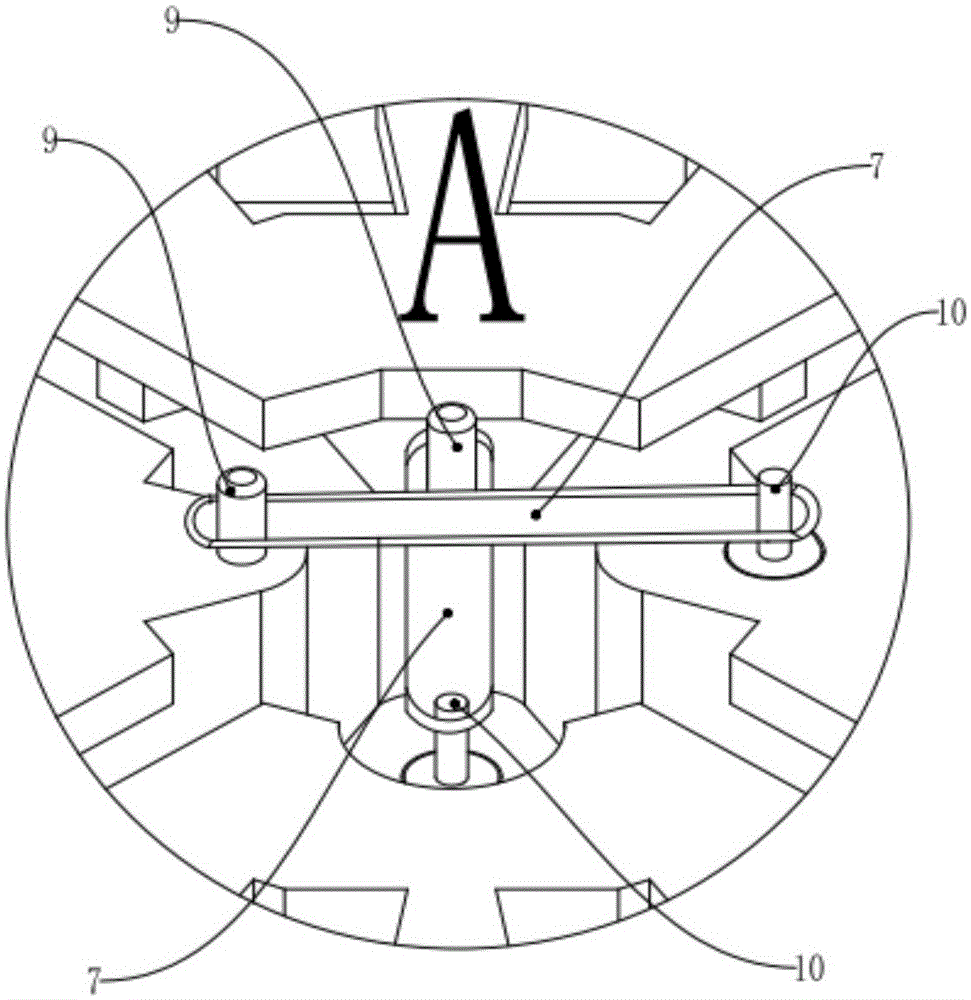

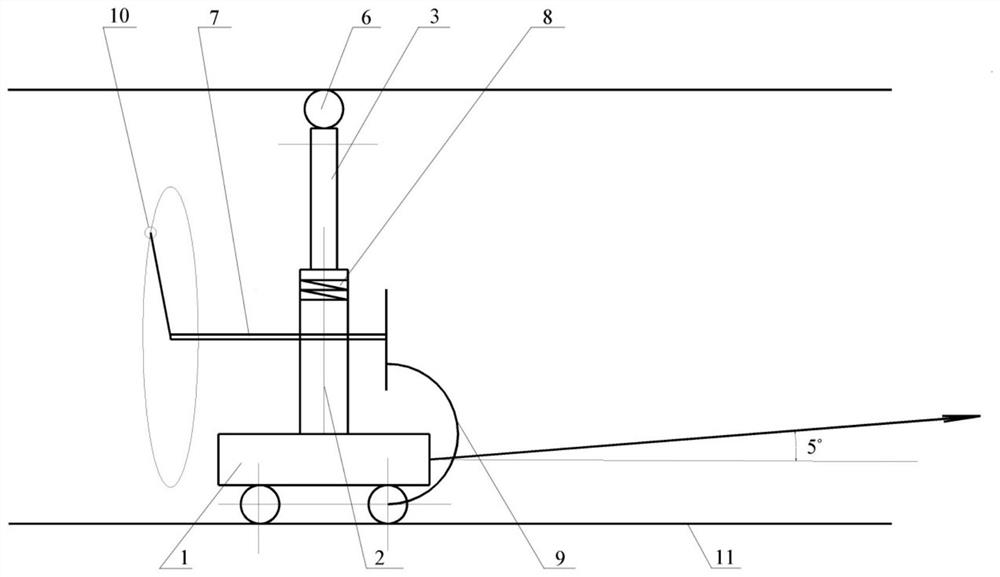

Passive rocking arm diamond-type four-wheel lunar rover moving system

InactiveCN101214783AImprove off-road performanceImprove mobile stabilityExtraterrestrial carsResilient suspensionsVehicle frameBody posture

The invention discloses a rocking arm rhombus four wheels moon vehicle shift system, including a rotary rhombus frame and a front, a rear ,a left and a right wheels with an independent drive system mounted on the frame, the front and the rear wheels are independently fixed on the frame via a front hanger system and a rear hanger system, and the left and the right wheels are independently fixed on the frame via a left hanger system and a right hanger system. The front hanger system and the rear hanger system all consists of a connection mechanism and a steering mechanism. The invent uses a novel type of four wheels three axial rhombus chassis with the advantages of compact structure, high lightness degree, low energy consumption ,big load capacity, good cross country characteristics, convenient posture adjustment, strong land suitability , smooth vehicle body posture and high reliability.

Owner:HUNAN UNIV

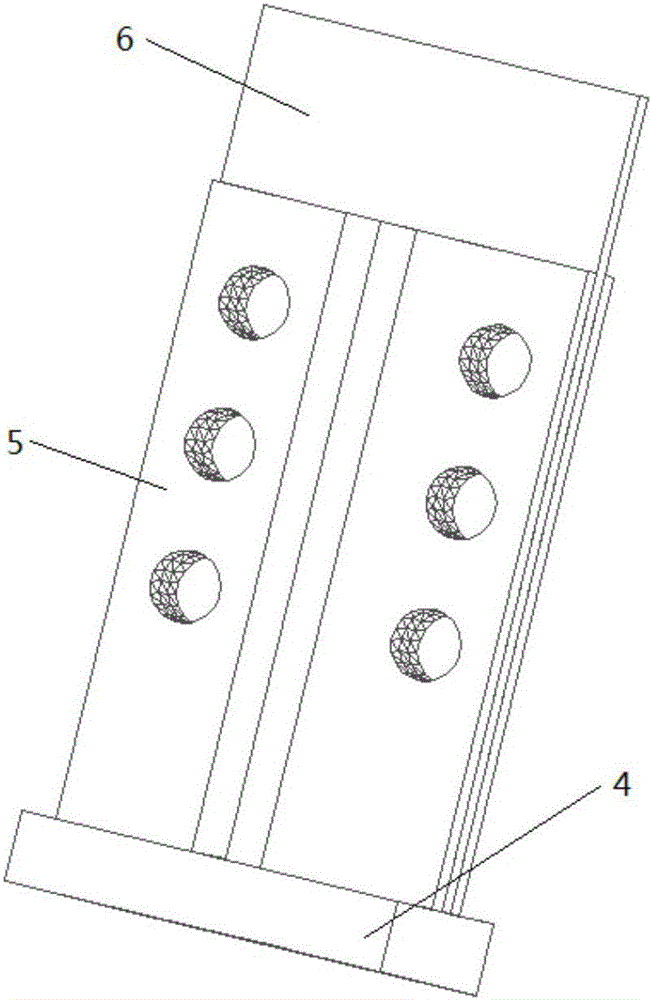

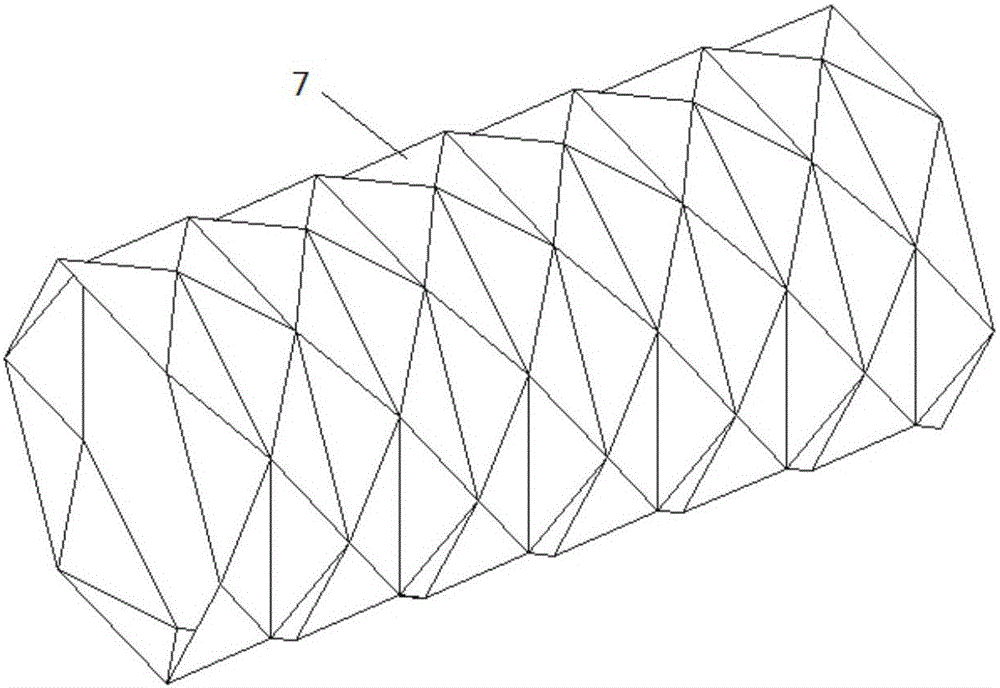

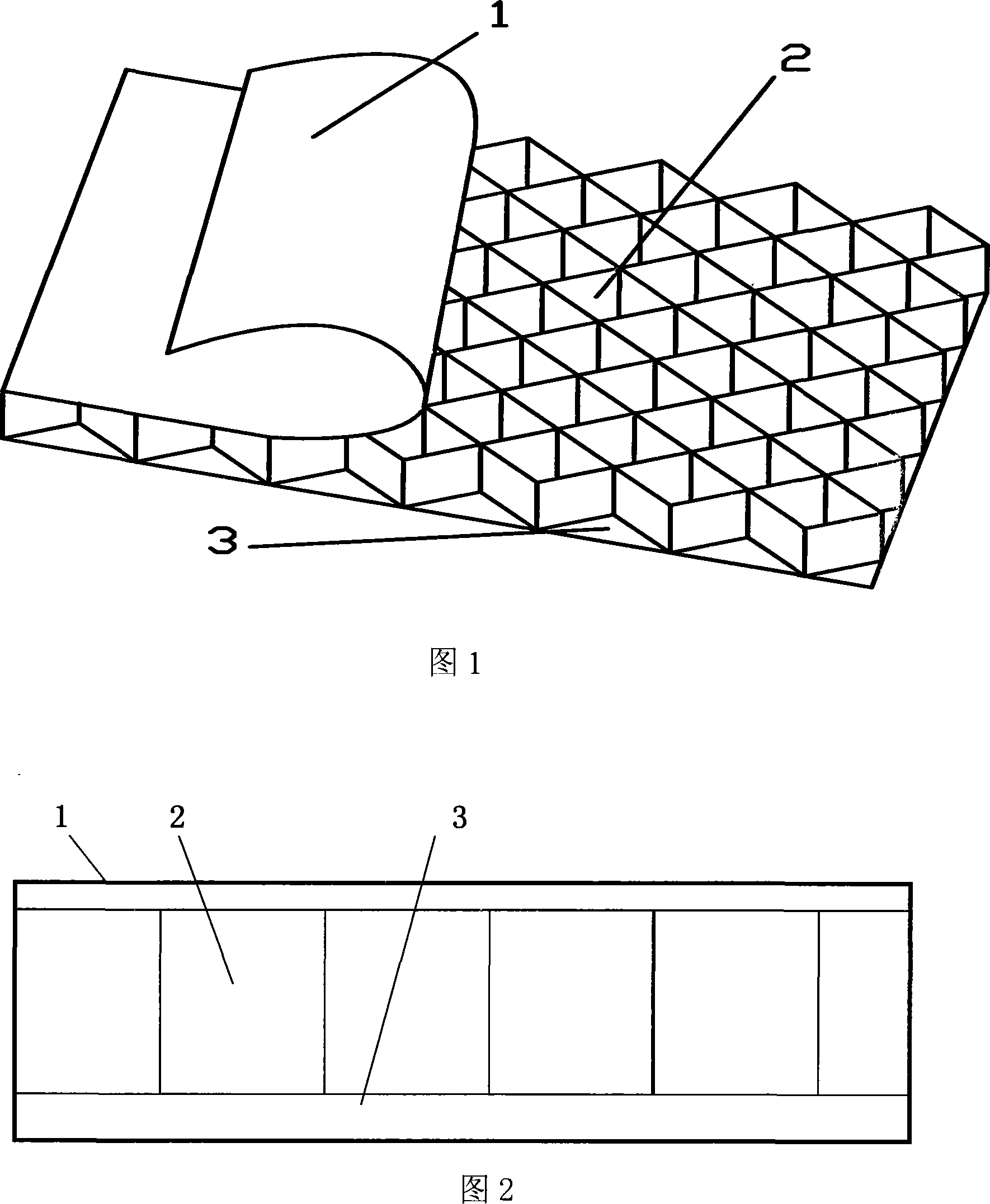

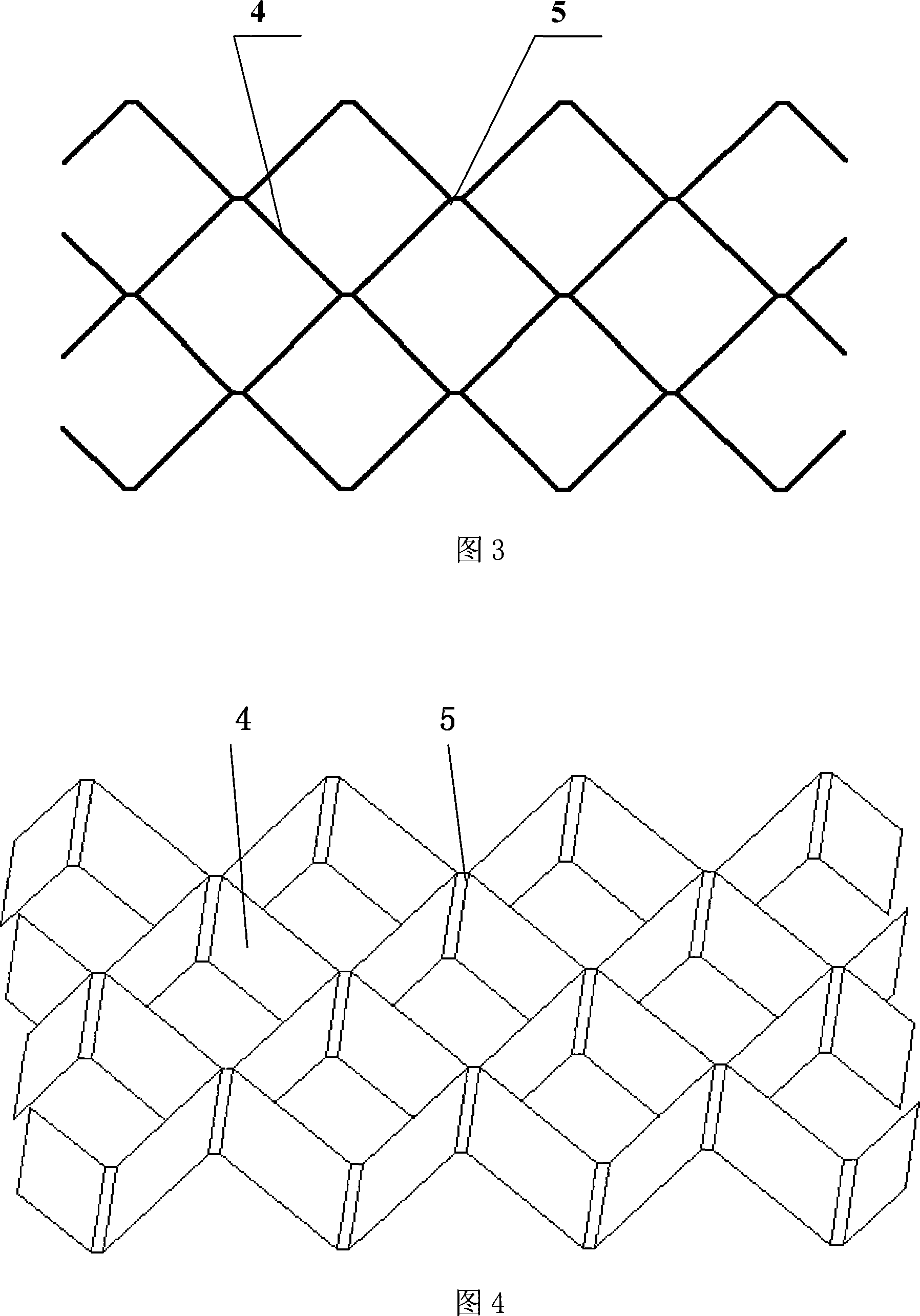

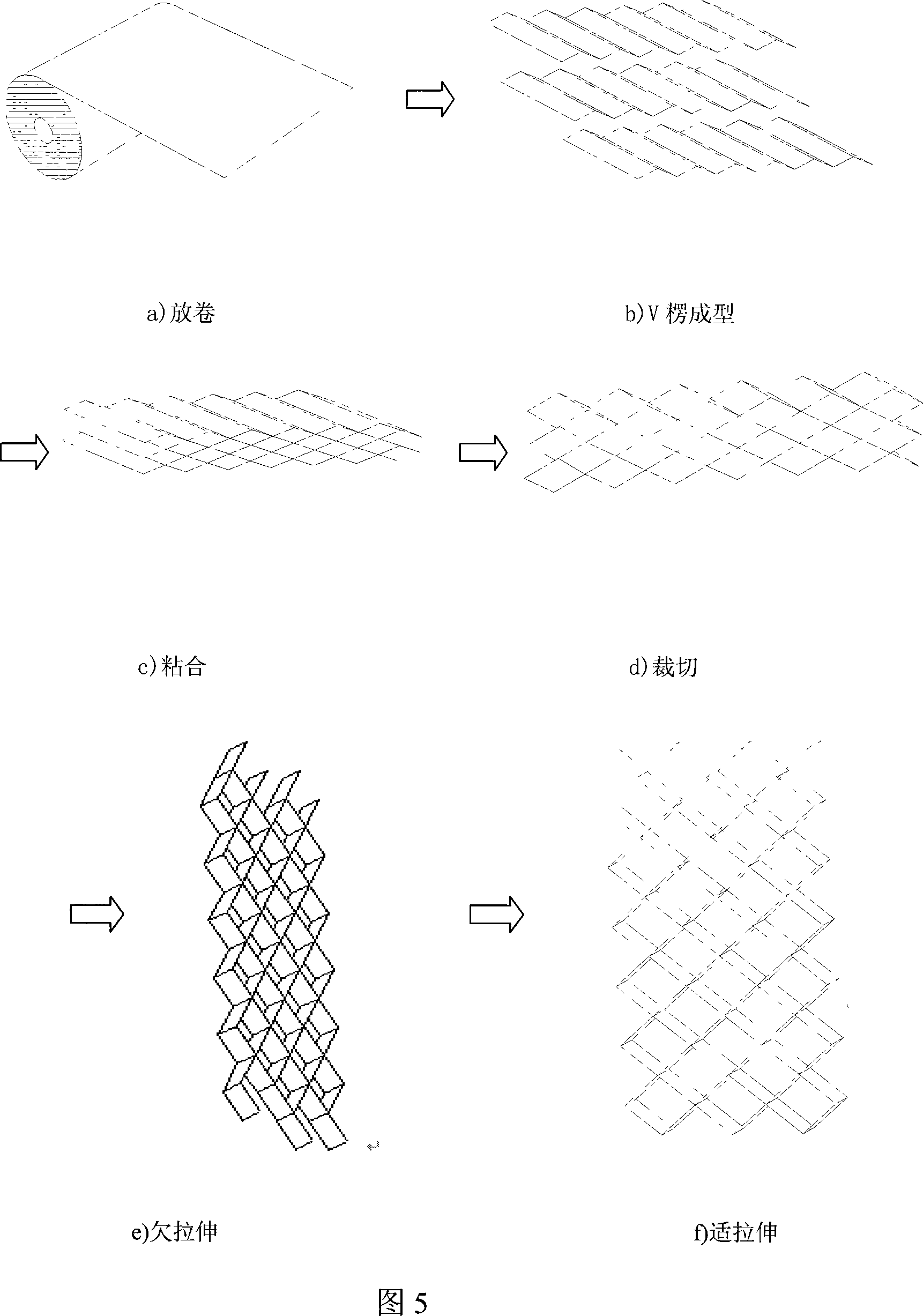

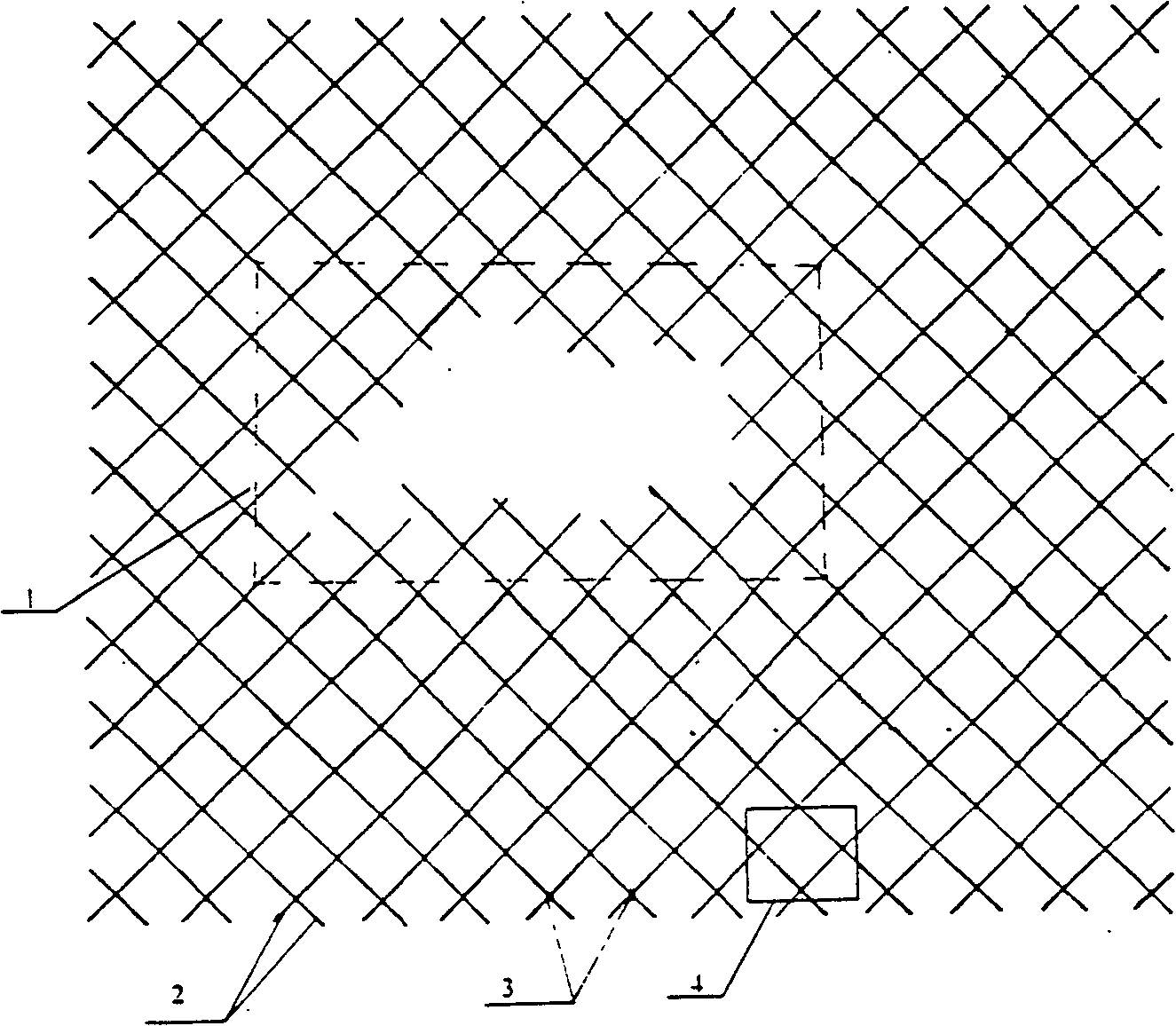

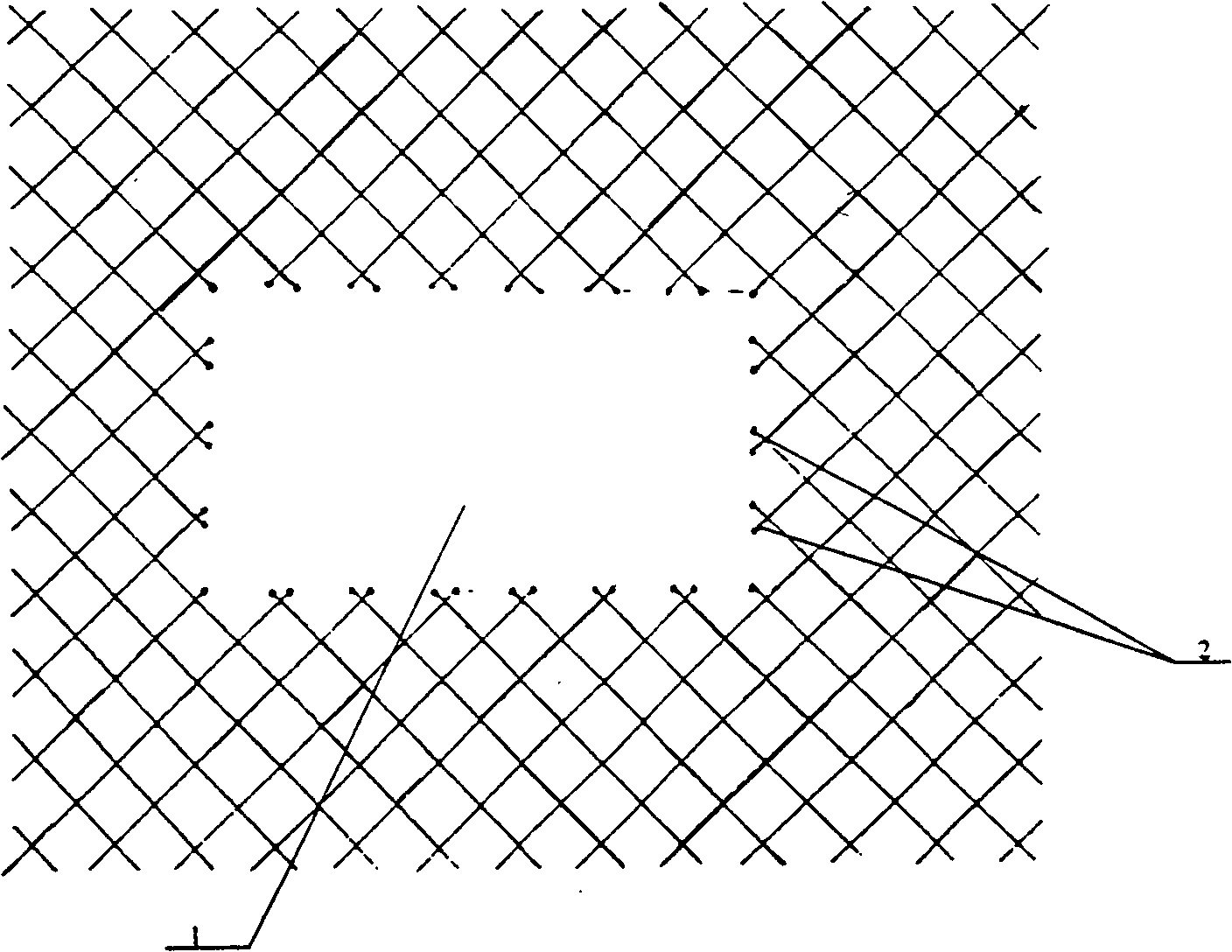

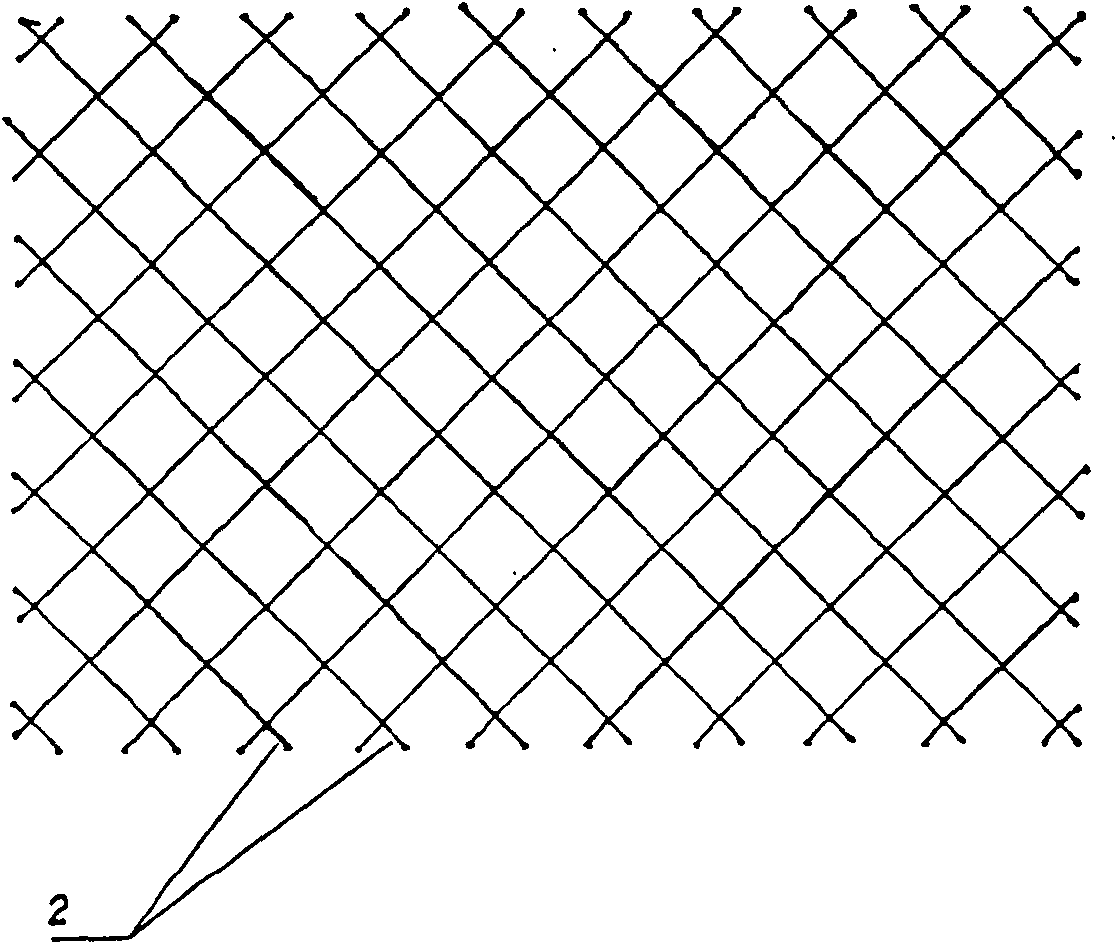

Diamond-type honeycomb sandwich panel and preparation

The invention provides a rhombic honeycomb sandwich and a method to make the sandwich. The rhombic honeycomb sandwich at least comprises an upper surface layer, a lower surface layer and a core layer. The rhombic honeycomb sandwich is characterized in that the core layer is a rhombic grid-shaped layer in the honeycomb structure, which is formed by joining upright flaky base materials. The rhombic layer in the honeycomb structure is formed by erectly and oppositely superposing V-shaped scrip folded. Two pieces of superposed V-shaped scrip form the rhombic grid shape by oppositely superposing the tops of the two pieces of superposed V-shaped scrip. A press mark 1mm to 8mm wide is pressed on the oppositely superposed tops to ensure that the two pieces of superposed V-shaped scrip are bonded together firmly, thus forming a rhombic grid having bonding edges.

Owner:谢勇

Polycrystalline diamond water-based polishing solution and preparation method thereof

InactiveCN106147617AEvenly dispersedImprove dispersion stabilityPolishing compositions with abrasivesWater basedPolycrystalline diamond

The invention discloses a polycrystalline diamond water-based polishing liquid and a preparation method thereof. The polishing liquid contains the following components: special diamond micropowder and the corresponding special suspension liquid. The feature of the present invention is, at first carry out surface wetting and modification to diamond with modifier, then add self-made corresponding special suspension and polish under corresponding polishing process conditions, polycrystalline diamond polishing liquid of the present invention, It can realize high-precision machining on the surface of hard materials such as cemented carbide, ceramics, sapphire, glass, etc. It has the advantages of good stability, high polishing rate, low roughness, and long service life.

Owner:天津诺邦科技有限公司

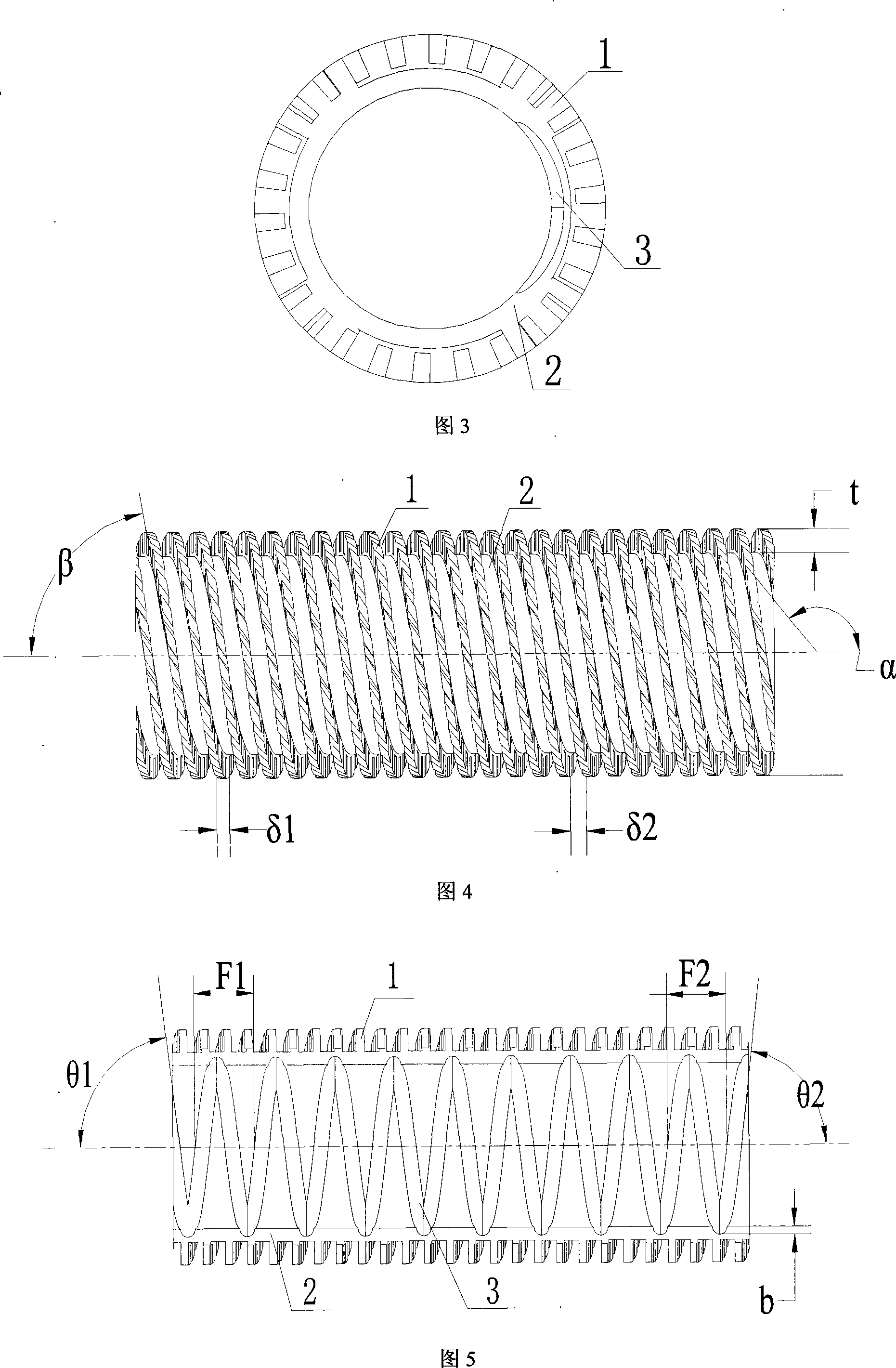

Inner chiasma spiral exterior three-dimensional diamond-type rib double-side intensify heat transfer pipe

InactiveCN101182977AFully taking into account the requirements of enhanced heat transferIncrease heat transfer areaTubular elementsMetallic materialsCondensation heat transfer

Owner:SOUTH CHINA UNIV OF TECH

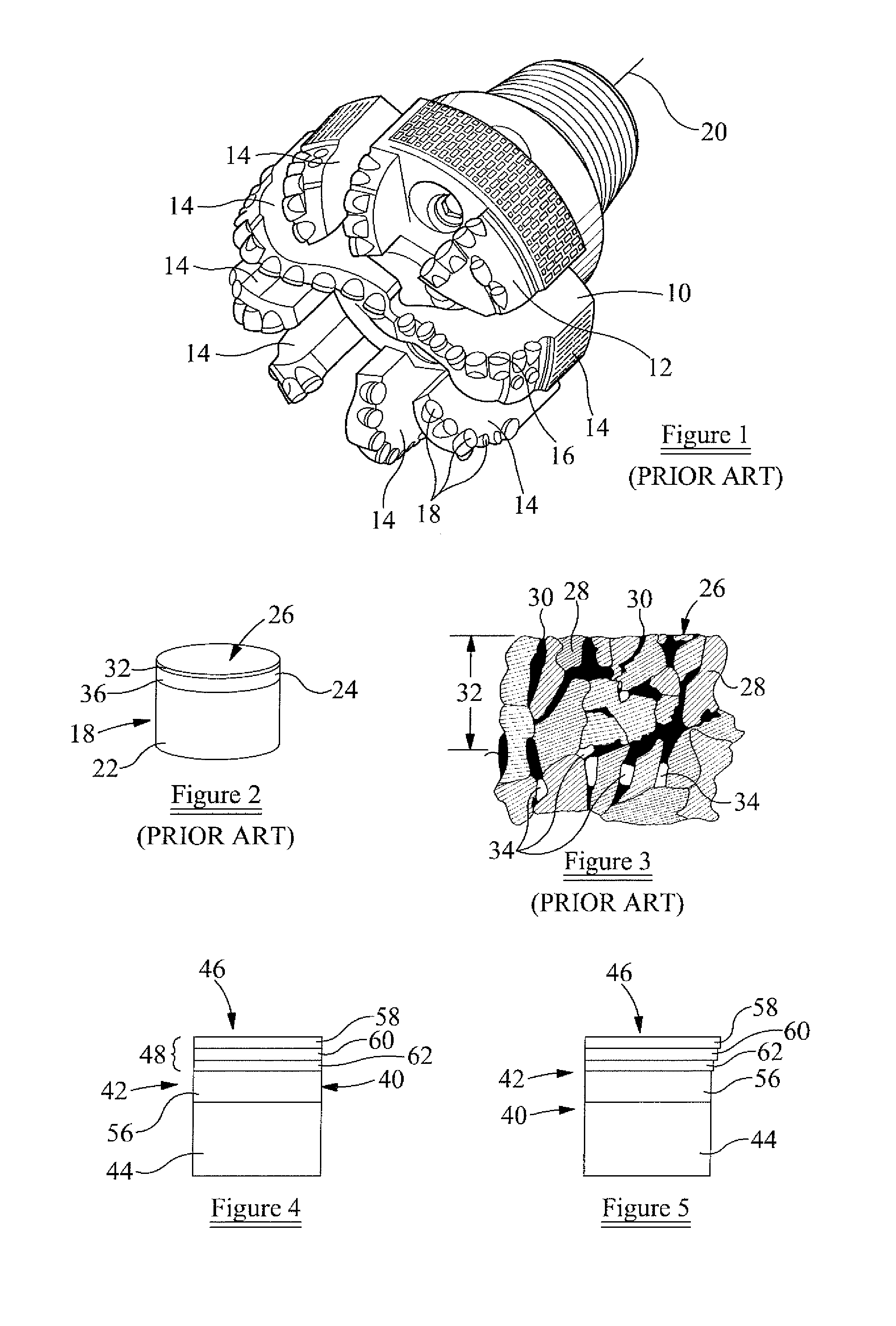

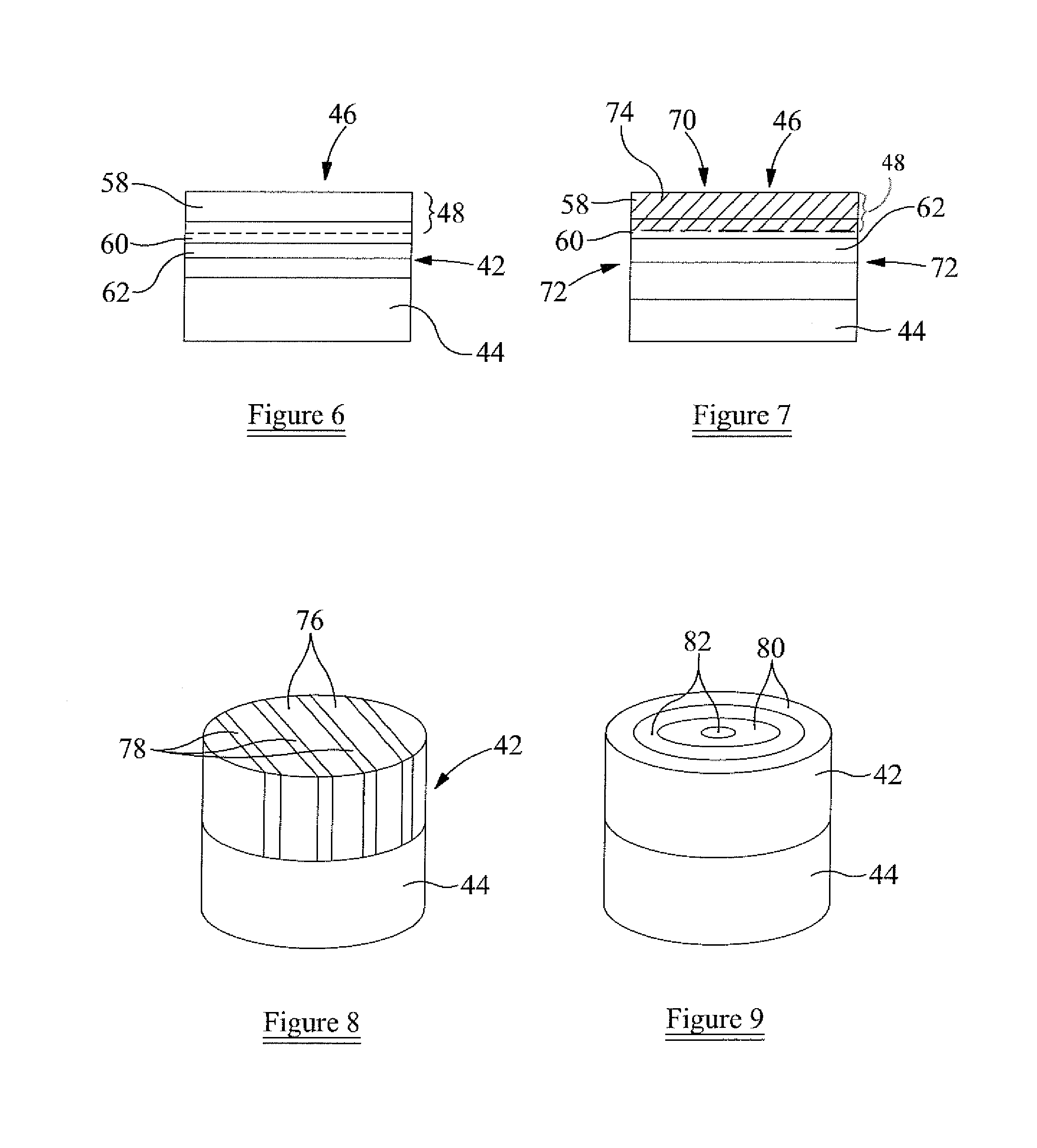

Preparation method of polycrystalline diamond compact covered by strong-combination chemical vapor deposition (CVD) diamond layer

ActiveCN102861917AImprove high temperature resistanceImprove wear resistancePolycrystalline material growthFrom chemically reactive gasesPolycrystalline diamondNucleation

The invention discloses a preparation method of a polycrystalline diamond compact covered by a strong-combination chemical vapor deposition (CVD) diamond layer and belongs to the field of materials, machinery and tools. By means of the method, direct current arc plasma CVD technology can be utilized to precipitate the strong-combination high-quality CVD diamond layer on the surface of the polycrystalline diamond layer by implanting CVD diamond small cylinders with nucleation surface facing outwards in the polycrystalline diamond layer. After the compact is covered by the strong-combination CVD diamond layer, the novel polycrystalline diamond compact greatly improves high temperature resistance and abrasion resistance. The improved polycrystalline diamond compact meets requirements for drilling efficiency and machining efficiency which are higher and higher in the fields of petroleum and geological drilling and machining.

Owner:UNIV OF SCI & TECH BEIJING

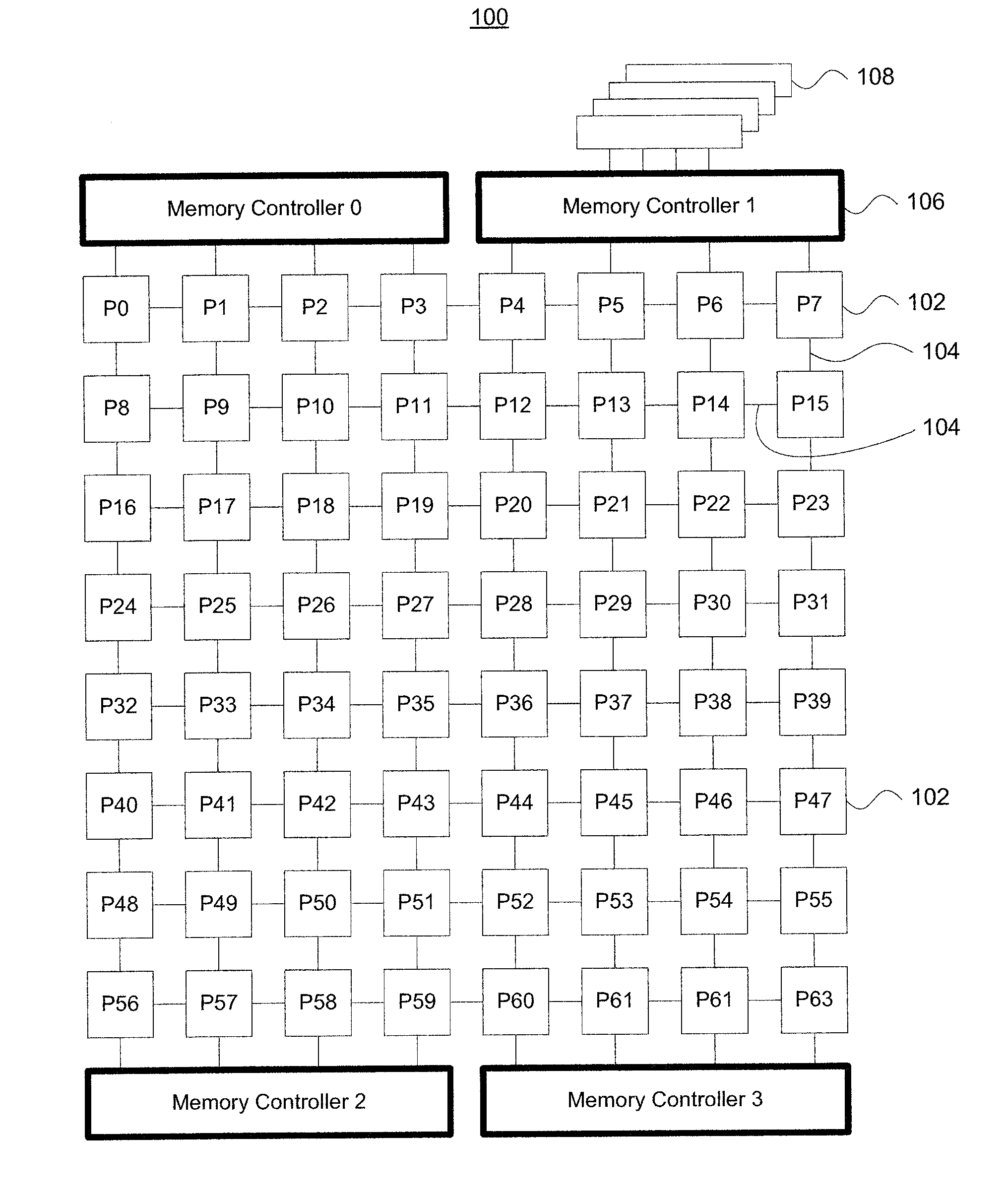

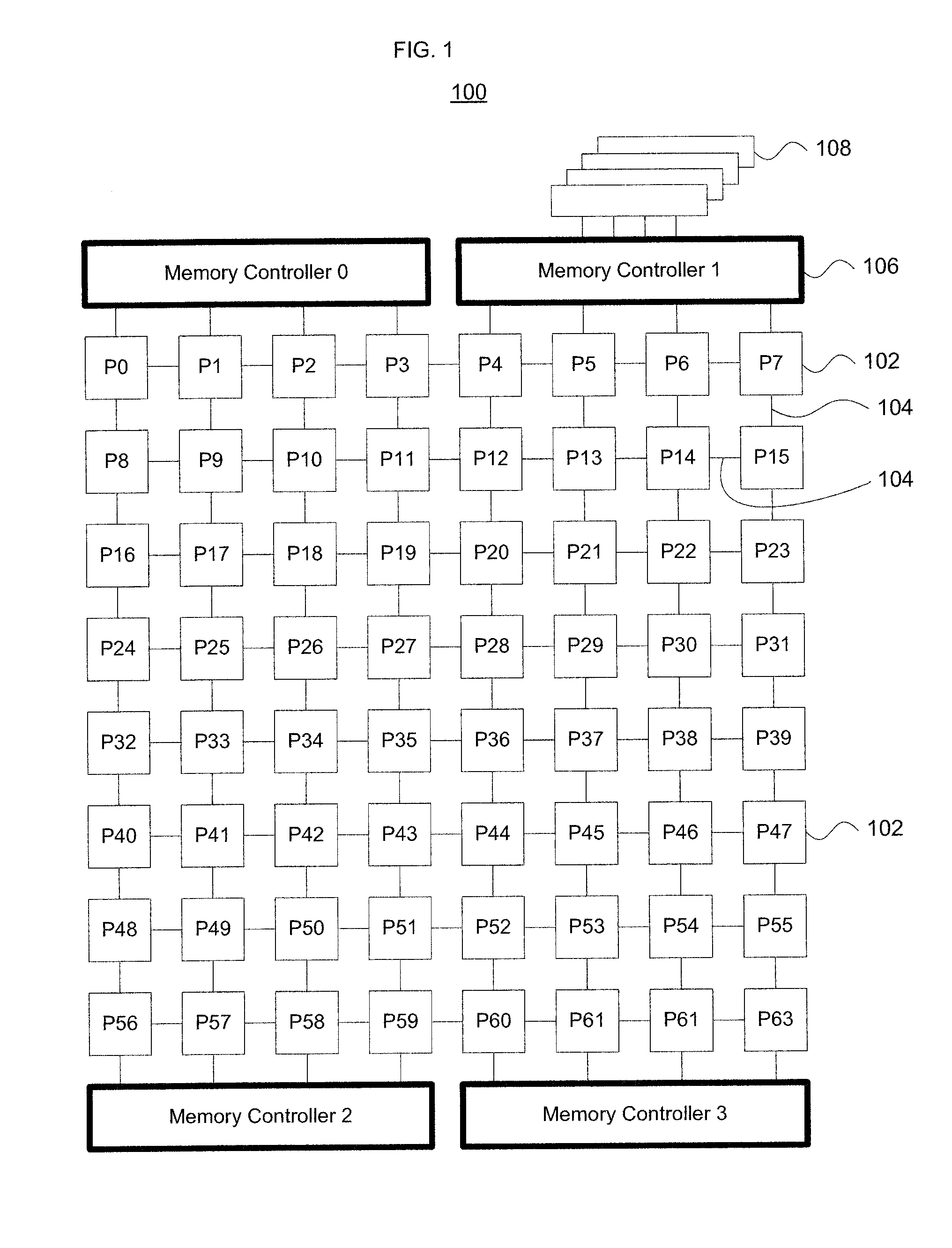

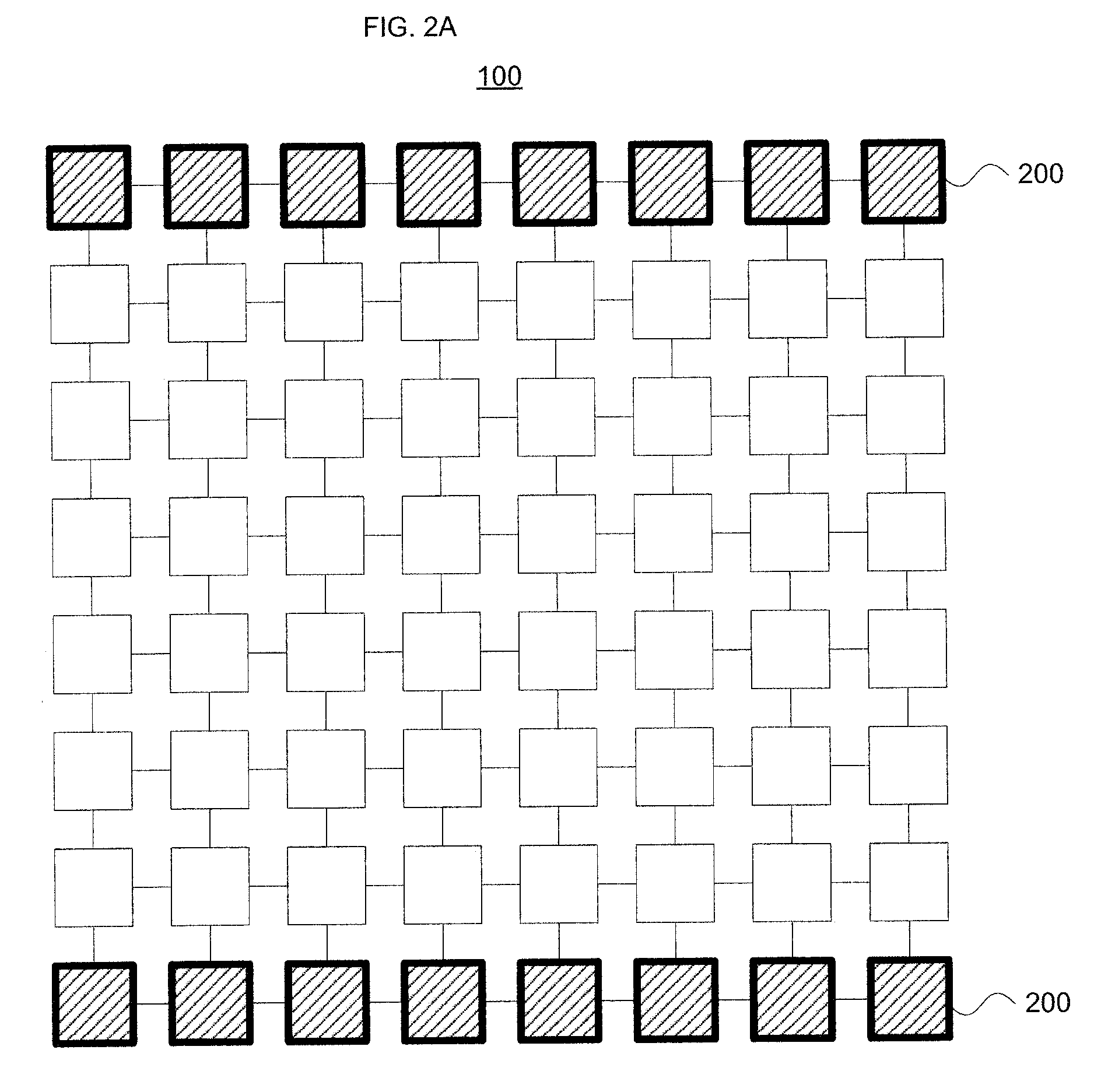

Method for optimizing memory controller configuration in multi-core processors using fitness metrics and channel loads

ActiveUS8407167B1Genetic modelsDigital computer detailsTraffic capacityStructure of Management Information

The location of the memory controllers within the on-chip fabric of multiprocessor architectures plays a central role in latency bandwidth characteristics of the processor-to-memory traffic. Intelligent placement substantially reduces the maximum channel load depending on the specific memory controller configuration selected. A variety of simulation techniques are used along and in combination to determine optimal memory controller arrangements. Diamond-type and diagonal X-type memory controller configurations that spread network traffic across all rows and columns in a multiprocessor array substantially improve over other arrangements. Such placements reduce interconnect latency by an average of 10% for real workloads, and the small number of memory controllers relative to the number of on-chip cores opens up a rich design space to optimize latency and bandwidth characteristics of the on-chip network.

Owner:GOOGLE LLC

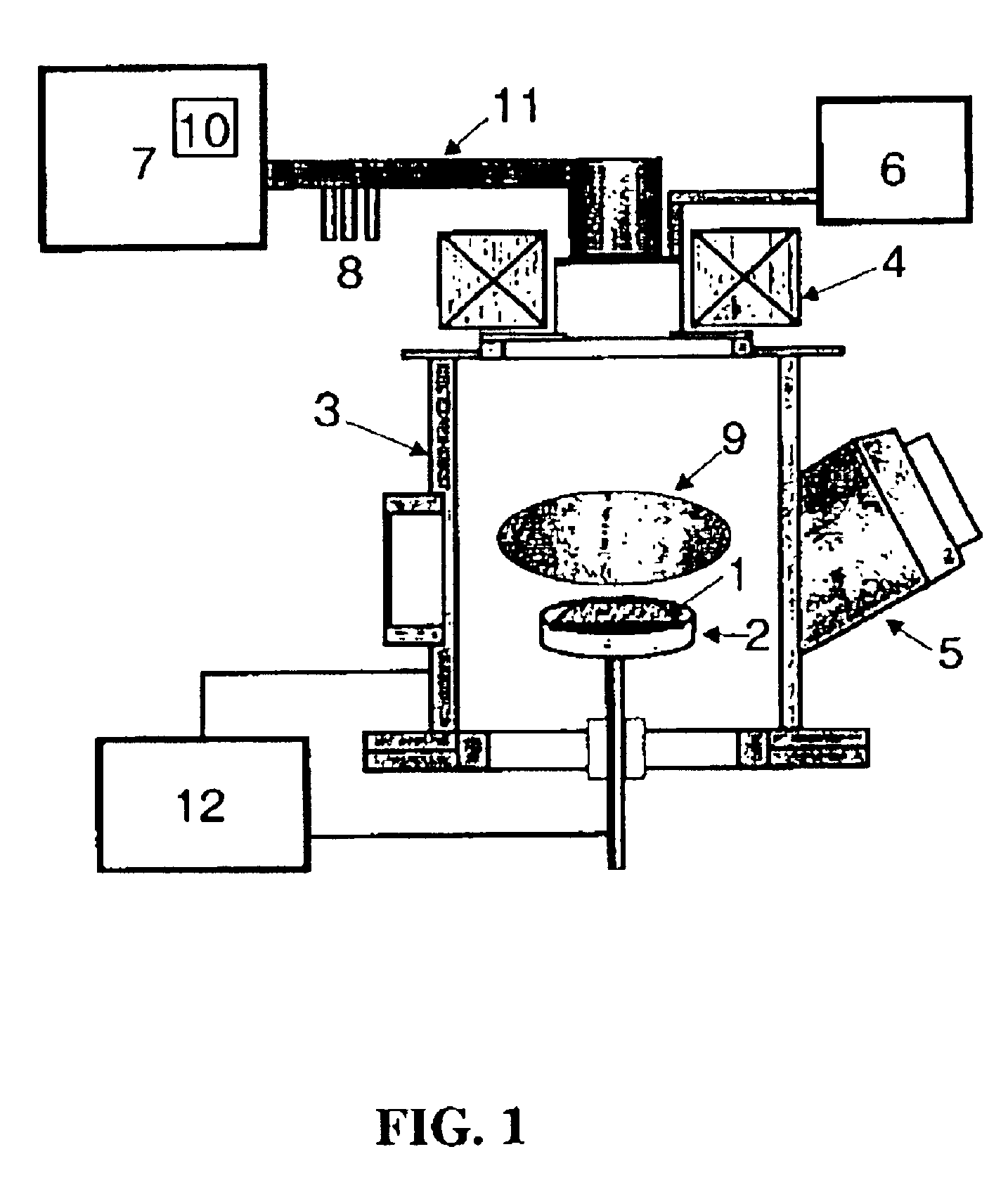

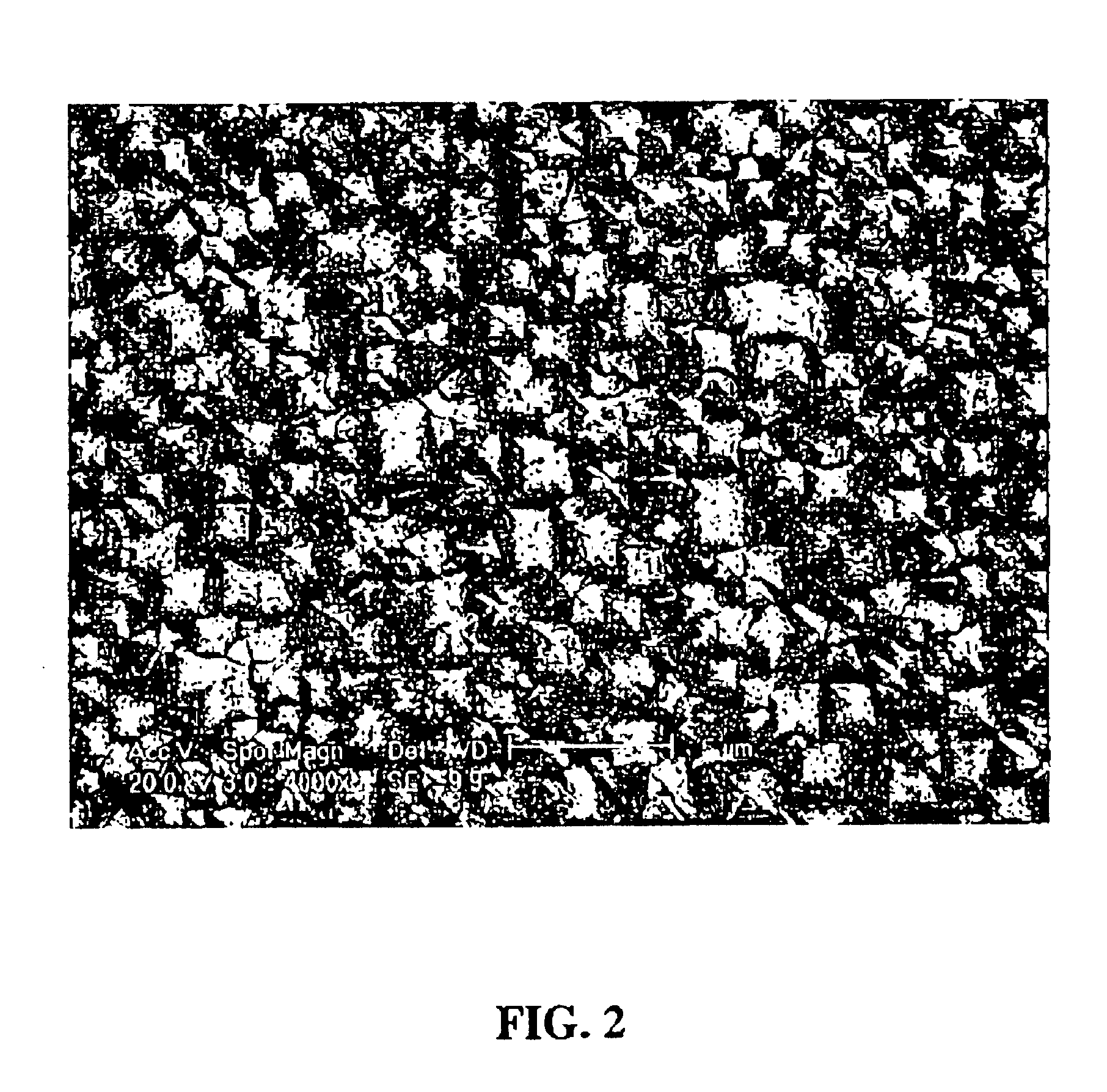

Fabrication of single crystal diamond tips and their arrays

InactiveUS6902716B2Easy to controlPolycrystalline material growthAfter-treatment detailsManufacturing technologySingle crystal

The present invention deals with the generation of sharp single crystal diamond tips and the arrays of these tips, and their fabrication technology. The invention combines the deposition of synthetic diamond films with reactive etching processes. Upon the diamond orientation prepared and reactive etching environment with considerable directivity of ions, single crystal diamond tips with different apical angles can be fabricated. Very sharp diamond tips with an apical angle of no more than about 28° and a tip radius smaller than 50 nm are fabricated on pyramidal-shaped [001]-textured diamond films by subsequent reactive etching., The technology is based on selective etching of sp2- and sp3- hybridized carbons by the activated constituents of an etching environment, in particular based on atomic hydrogen, in a way similar to ion bombardment, which contributes to overall etching and local conversion of diamond to graphitic phase promoting further etching with chemically activated species. This novel method is capable of forming diamond tip arrays over large areas with great uniformity and high reproducibility. The diamond tips prepared are single diamond crystals with their [001] axes parallel each other and normal to the substrate surface. The invented technology enables the control of the apical angle, radius and density of the diamond tips.

Owner:CITY UNIVERSITY OF HONG KONG

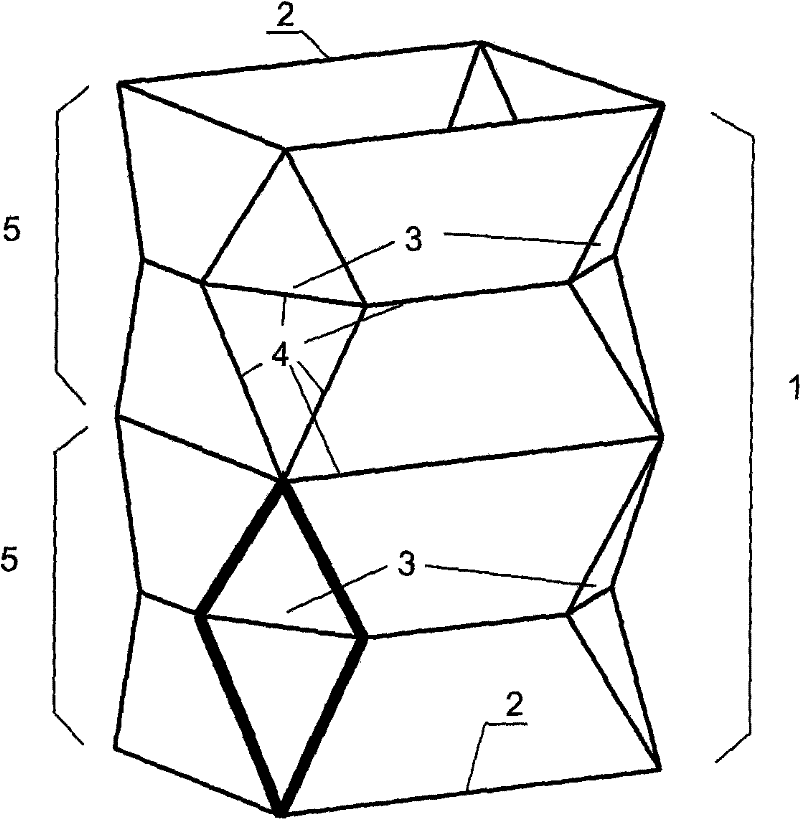

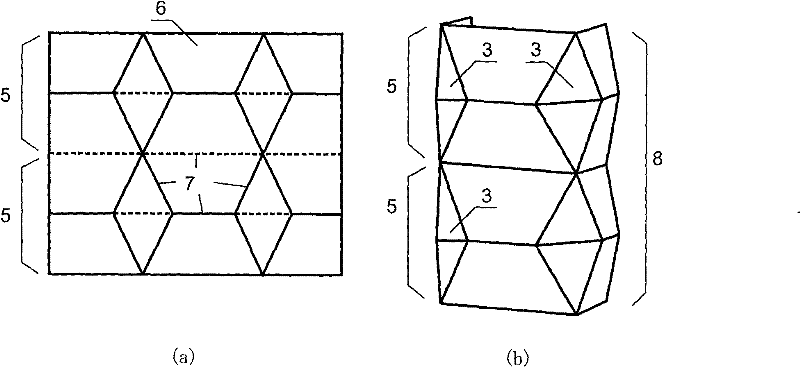

A crease-type crash energy-absorbing box

ActiveCN101638076BHigh specific energy absorption rateImprove processing accuracyBumpersHigh rateEnergy absorption

A crease-type collision energy-absorbing box belongs to the technical field of automobile body structure manufacturing. It is characterized in that the thin-walled pipe fitting introduced with crease lines is used as a crash energy-absorbing box, and the final deformation mode of the collision deformation section is guided by the crease lines. Compared with ordinary thin-walled tubes, the obvious feature of the present invention is that a thin-walled tube is divided into several modules along the axial direction, and each corner area of each module has a diamond-shaped concave corner at a certain distance along the axial direction. A thin-walled pipe with a creased pattern is thus formed. The effect and benefit of the present invention is that by introducing the crease pattern, the crash absorbing box can meet the requirements of high specific energy absorption rate and low load uniformity coefficient at the same time; the crease shape of the invention is easy to form, and the surface of the entire structure is an expandable surface , the advantage is that the whole structure can be directly formed by a thin plate, which makes the processing more convenient, greatly reduces the production cost, and the processing accuracy can also be improved.

Owner:王博 +1

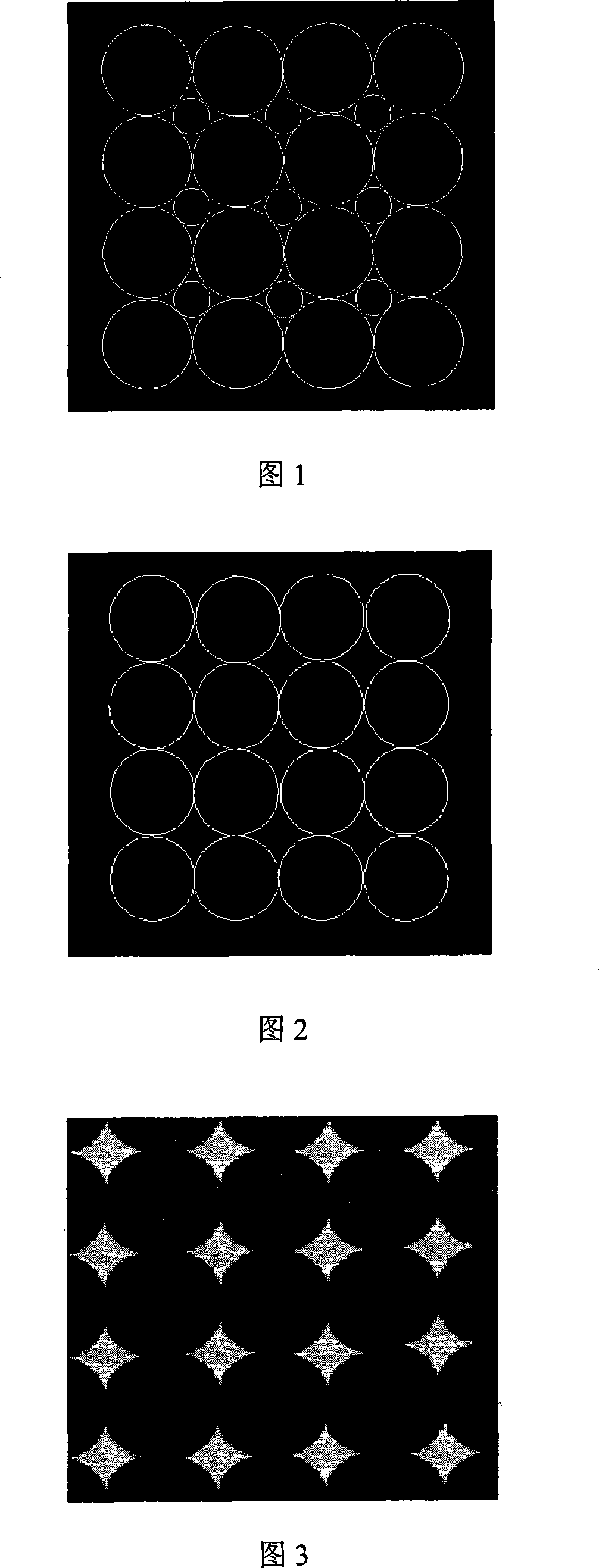

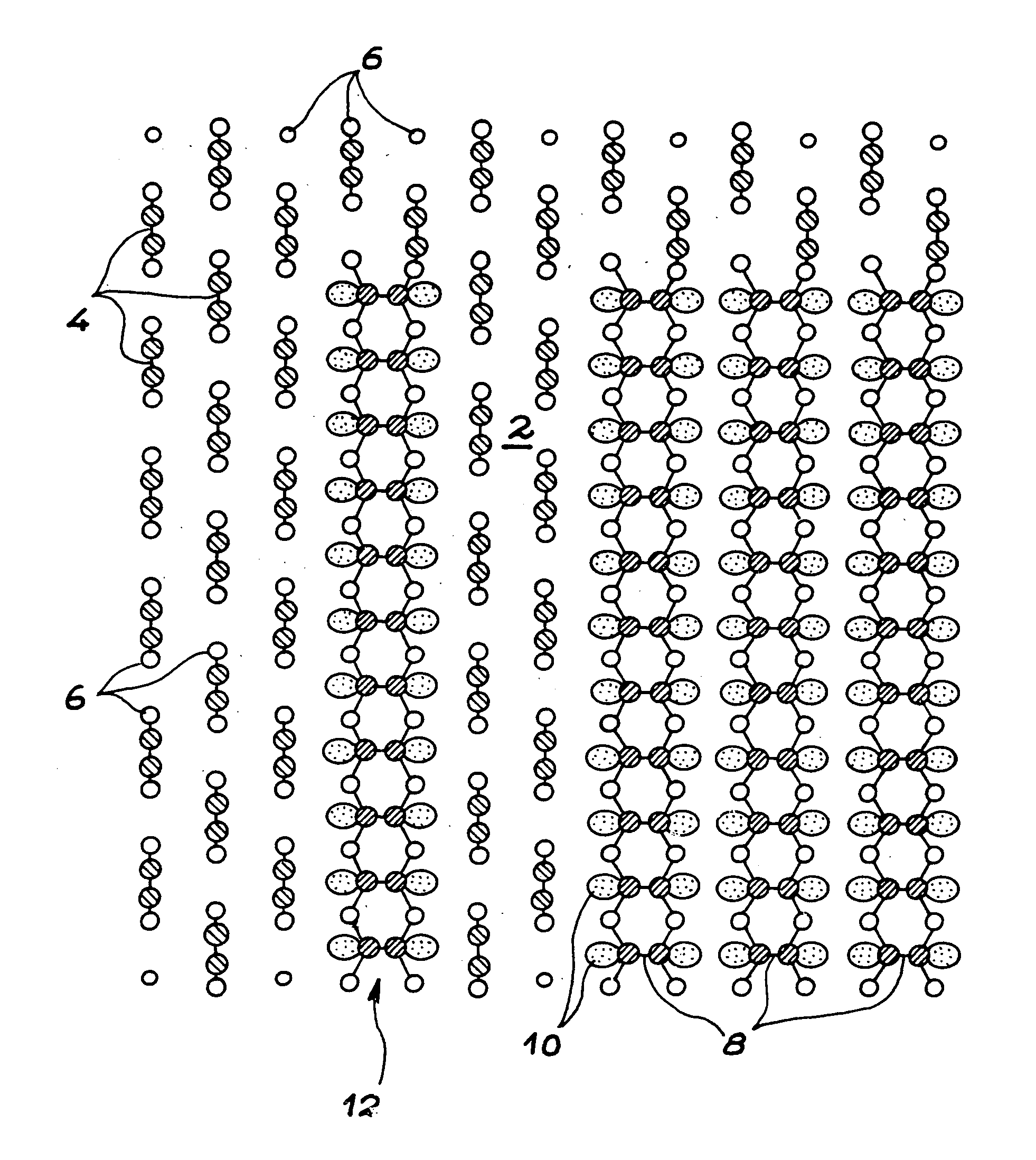

Method for manufacturing diamond-type metal nanometer particle array structure

InactiveCN101143710AHigh sensitivityRealize large areaNanostructure manufactureNano structuringPolystyrene

Fabrication method of rhombic metal nanoparticle array structure: (1) select finely polished silicate glass as the substrate, deposit a layer of chromium with a thickness of several nanometers on the glass surface; The polystyrene nanospheres are mixed in proportion; (3) the chrome-plated glass plate is hydrophilized by chemical method; (4) a layer of mixed polystyrene nanospheres is self-assembled on the surface of the chrome-plated glass plate after the hydrophilization treatment (5) adopt reactive ion etching machine (RIE) to etch the self-assembled layer of polystyrene nanospheres made, and completely etch away the small polystyrene nanospheres in diameter; (6) use the etched polystyrene nanospheres The self-assembled layer of polystyrene nanospheres is used as a mold, and the gap between balls is filled with metal; (7) the self-assembled layer of polystyrene nanospheres is removed to obtain a diamond-shaped metal nanoparticle array structure. The arrayed metal nano-array structure produced by the invention can be applied to the field of biosensing, and realize multi-channel rapid detection of various biomolecules.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

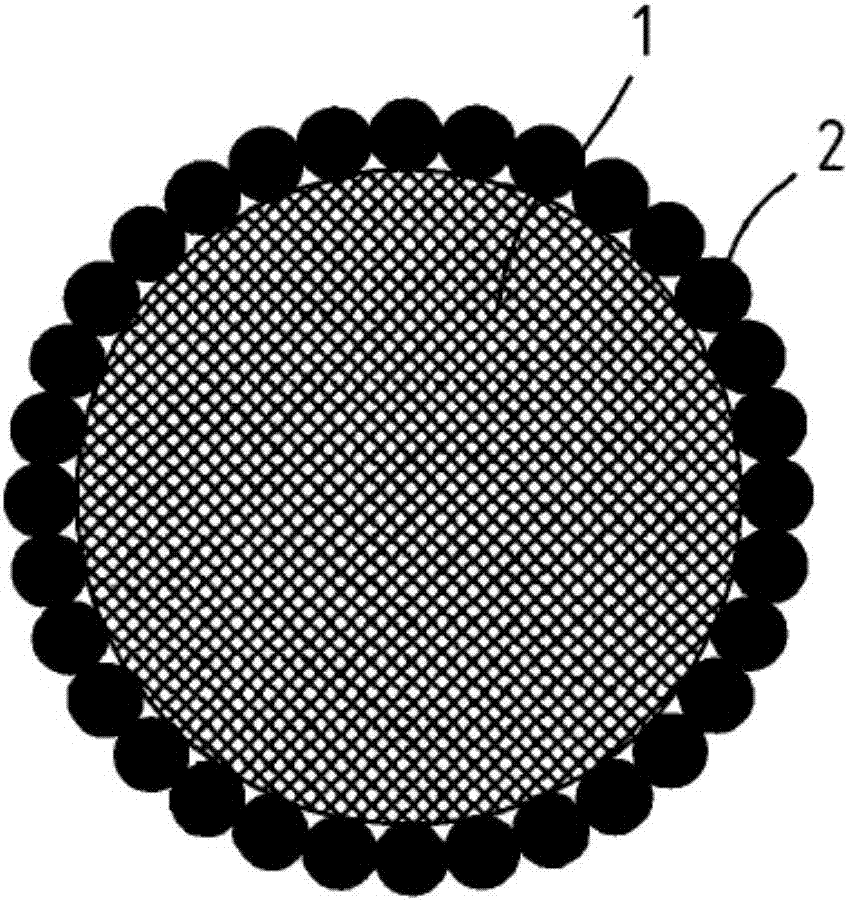

Metal base diamond grinding wheel and preparing method thereof

InactiveCN107186629AEvenly dispersedImprove grinding efficiencyTransportation and packagingAbrasion apparatusMicro nanoMixed materials

The invention discloses a metal base diamond grinding wheel and a preparing method thereof. The preparing method comprises the steps that firstly, raw material pre-mixing is conducted, a diamond type material and a metal material are mixed, and a pre-mixed material is prepared; secondly, grinding material wrapping is conducted, the pre-mixed material prepared in the first step is subjected to micro nano particle shaping wrapping, and composite particles are prepared; and thirdly, forming sintering is conducted, and after the composite particles prepared in the second step are pressed, sintering is conducted, and the metal base diamond grinding wheel is prepared. By means of the above technical scheme, after the diamond type material and the metal material are mixed, micro nano particle shaping wrapping operation is conducted, then pressing and sintering are conducted, the diamond type material can be evenly scattered in the prepared metal base diamond grinding wheel, accordingly, the grinding efficiency of the prepared metal base diamond grinding wheel is improved, and the service life of the prepared metal base diamond grinding wheel is prolonged. Meanwhile, by adoption of the preparing method, the material mixing time can be greatly shortened, the overall production time is shortened, and the production efficiency is improved.

Owner:WUHU ZHEXIN NEW ENERGY

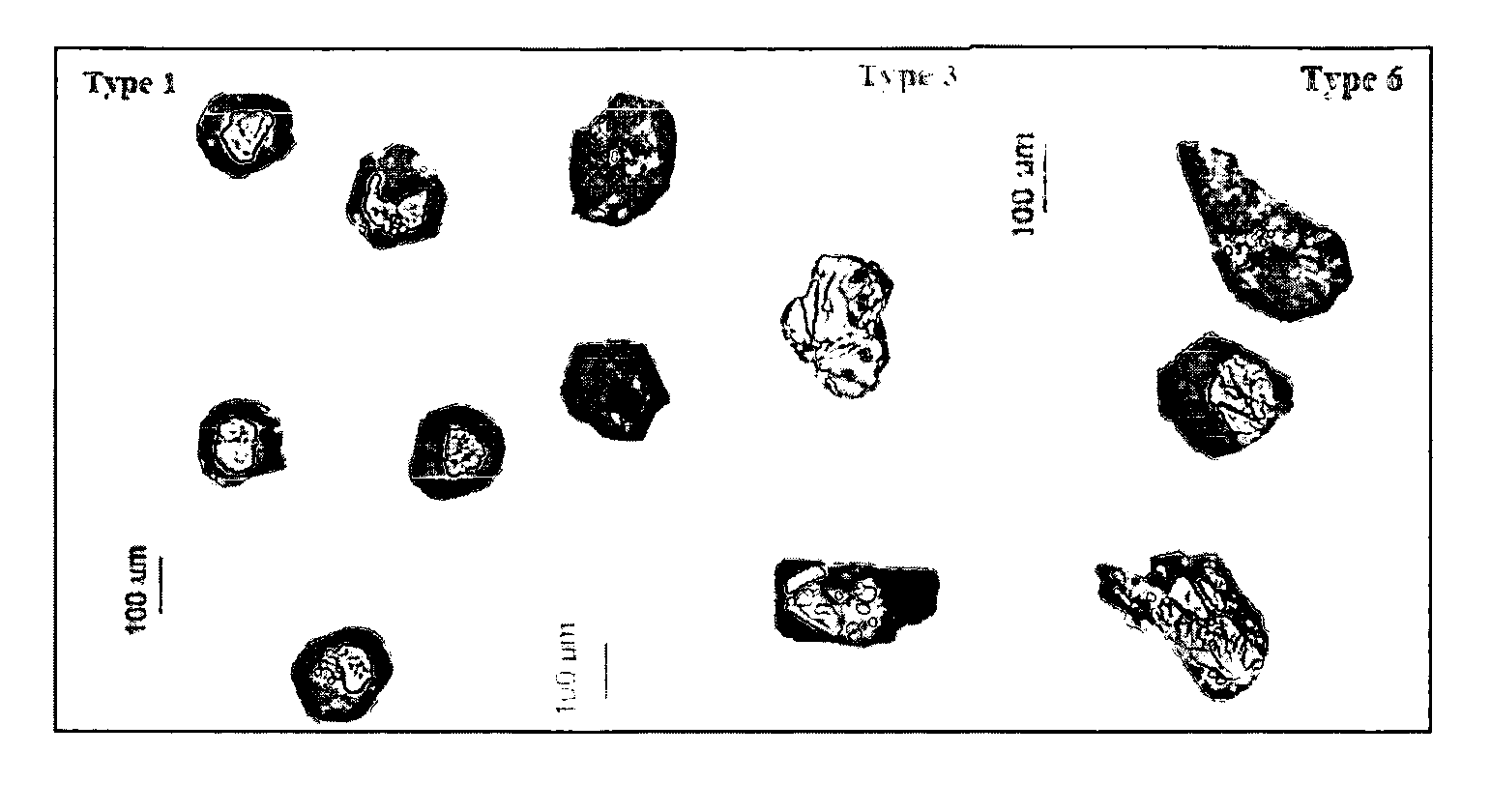

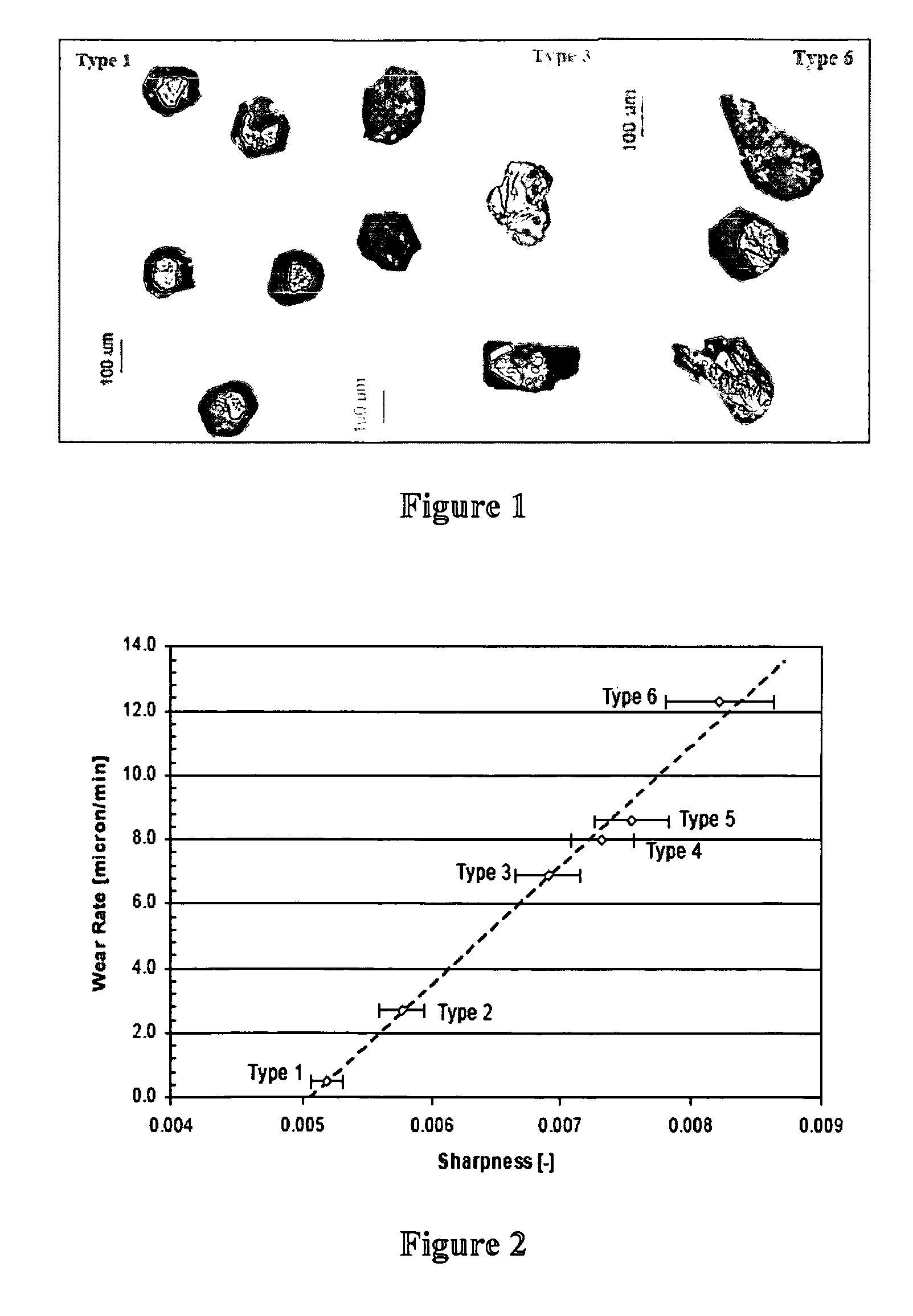

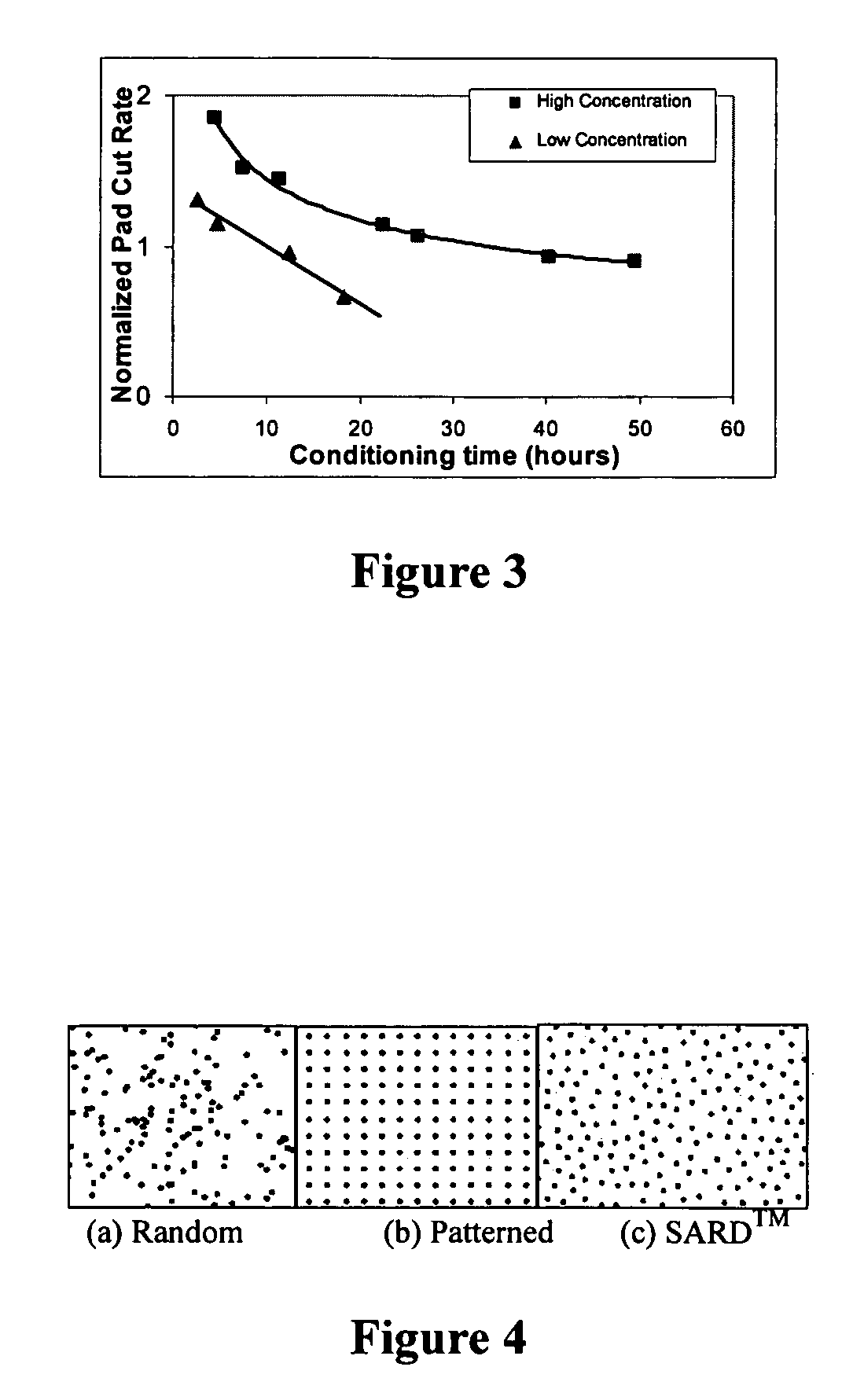

Optimized CMP Conditioner Design for Next Generation Oxide/Metal CMP

InactiveUS20090053980A1Reduce saggingDesirable textureGrinding drivesBelt grinding machinesExperimental validationLife time

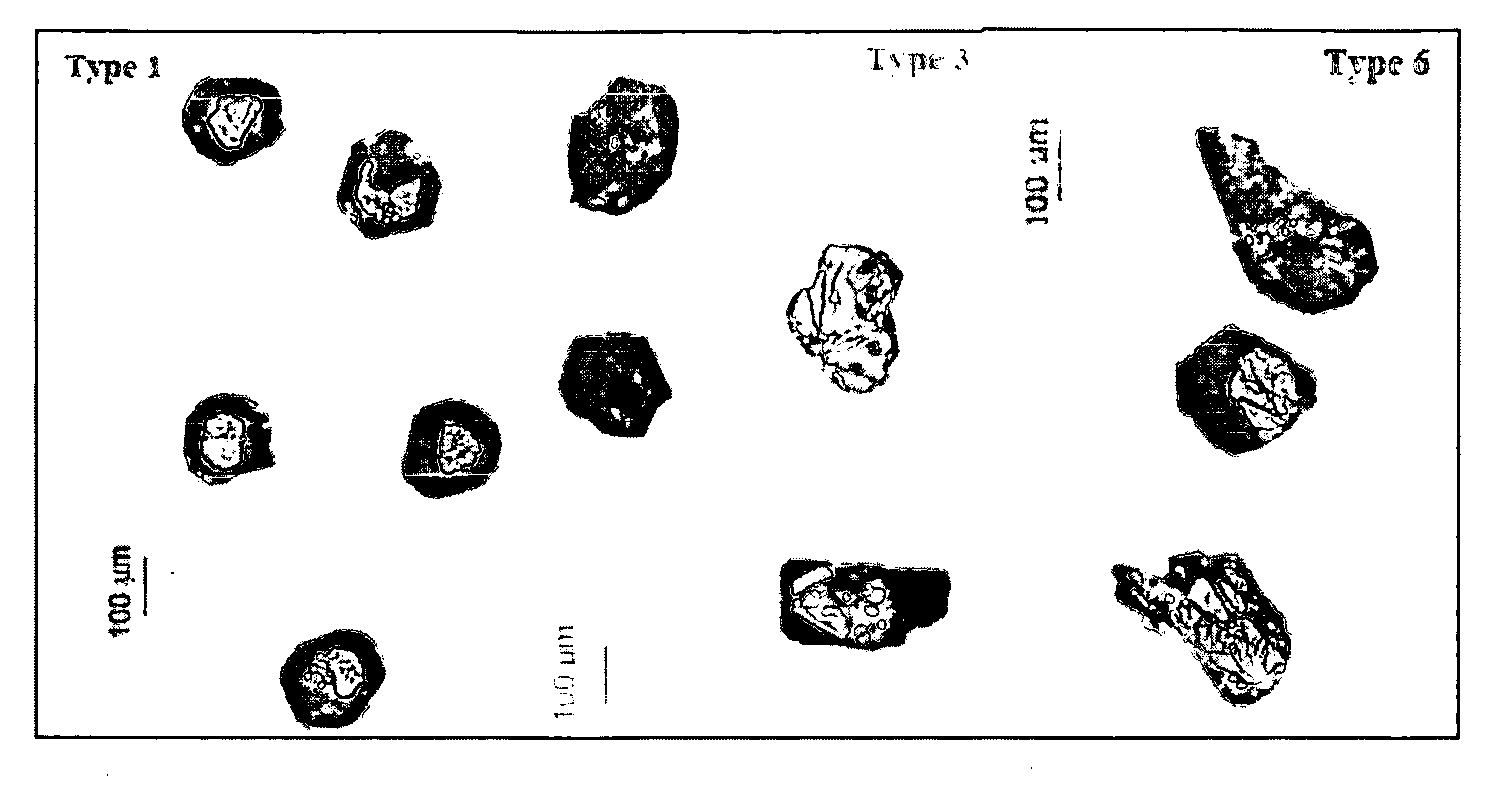

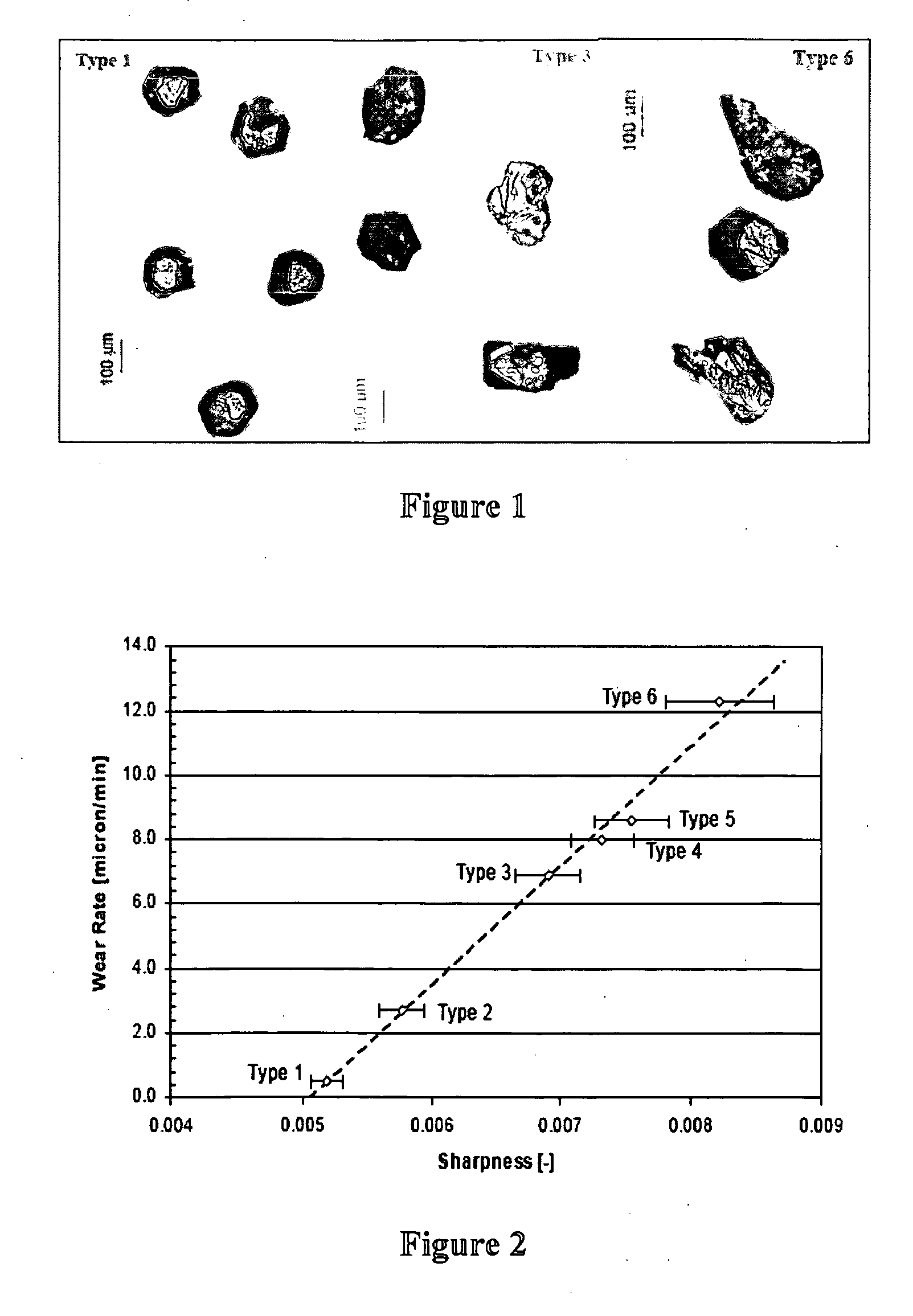

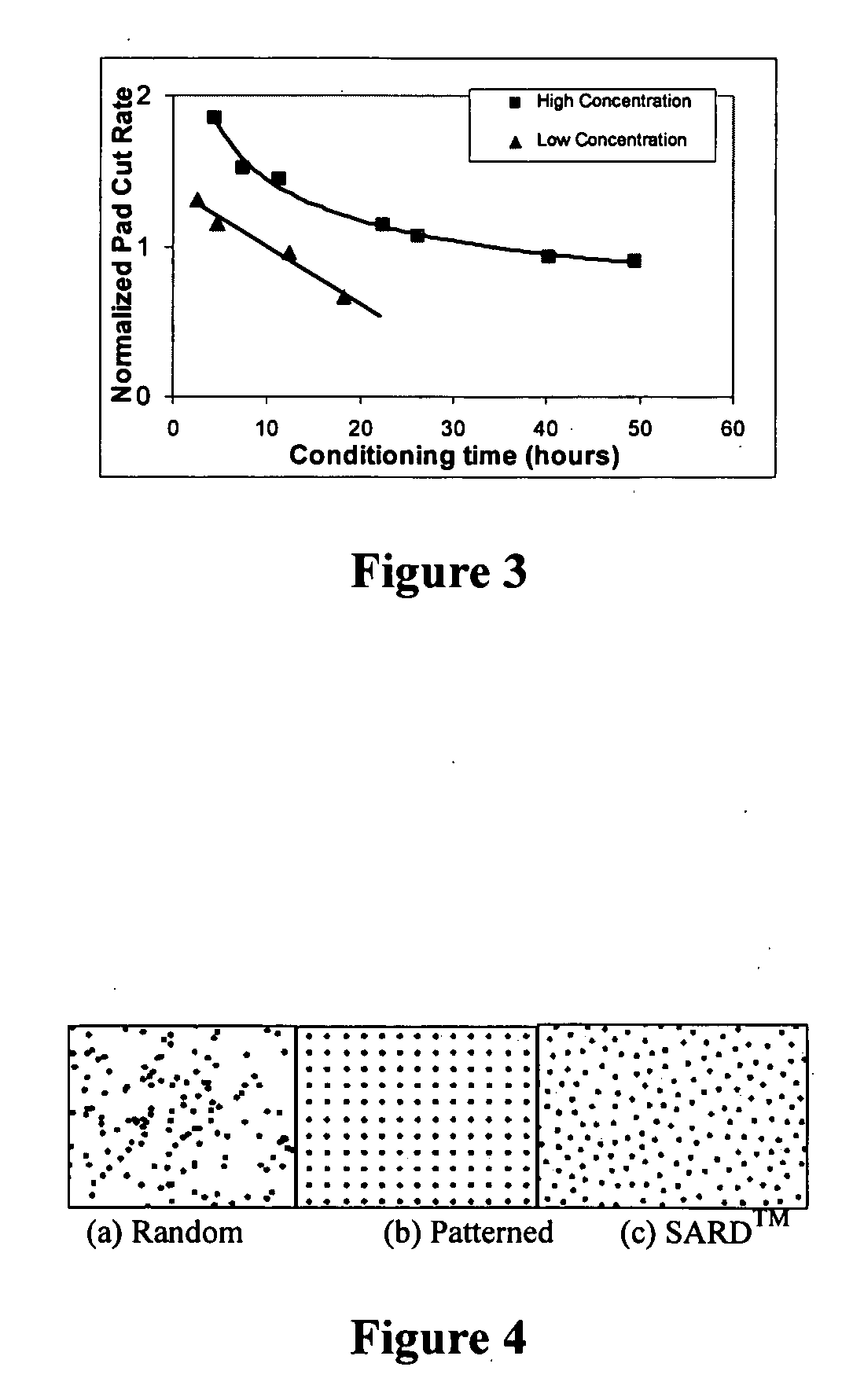

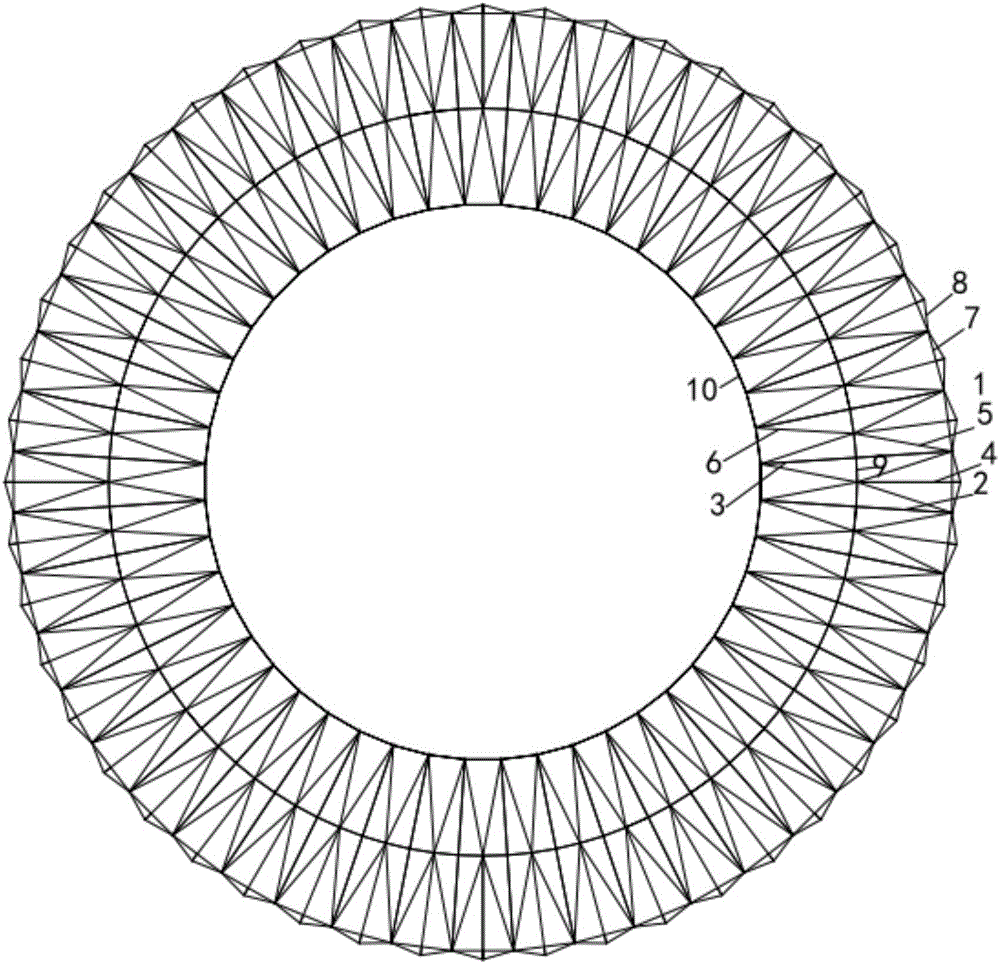

A study of several key conditioner design parameters has been conducted. The purpose was to improve conditioner performance by considering factors such as wafer defects, pad life, and conditioner life. For this study, several key conditioner design parameters such as diamond type, diamond size, diamond shape, diamond concentration and distribution, were selected to determine their effect on CMP performance and process stability. Experimental validations were conducted. Conditioner specifications were matched to each specific CMP environment (intended application) in order to improve process stability and CMP performance particularly for emerging technology nodes. Several conditioner designs were developed and run successfully in the field. Significant planarity improvement for a 300 mm CMP process was achieved in accordance with one embodiment, and an increase of pad life and wafer polish rate was simultaneously achieved with another embodiment.

Owner:SAINT GOBAIN ABRASIVES INC +1

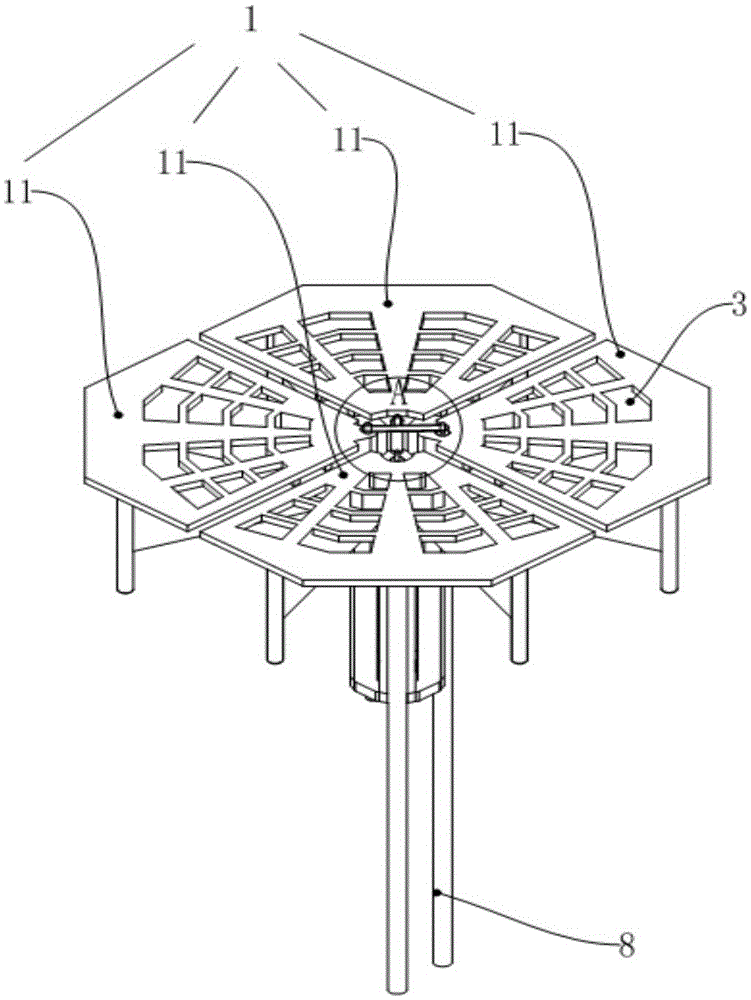

Diamond-type cable dome structure

ActiveCN105804248ARich implementationReduce the impactArched structuresVaulted structuresDiamond typeSpandrel

The invention discloses a diamond-type cable dome structure which comprises an inner ring cable, an outer ring cable, a middle ring cross cable, an outer ring beam, inner ring support rods, outer ring support rods and middle ring support rods. An anchor point of the outer ring cable is arranged between every two outer ring support rods; a cross node of the middle ring cross cable is arranged between every two middle ring support rods; the positions of the inner ring support rods and the middle ring support rods correspond to those of the anchor points, and the positions of the cross nodes correspond to those of the outer ring support rods; outer dorsal cables are arranged between the top ends of the outer ring support rods and the cross nodes, and outer valley cables are arranged between the anchor points and the cross nodes; inner valley cables are arranged between the top ends of the inner ring support rods and the cross nodes, outer radial cables are arranged between the two ends of the middle ring support rods and the anchor points, and inner radial cables are arranged between the top ends of the middle ring support rods and the top ends of the inner ring support rods and between the bottom ends of the middle ring support rods and the bottom ends of the inner ring support rods. The diamond-type cable dome structure is reasonable in structure, exact in force transmission, easy and convenient to construct, stable in structure and high in bearing capacity and is an efficient large-span building structure form.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

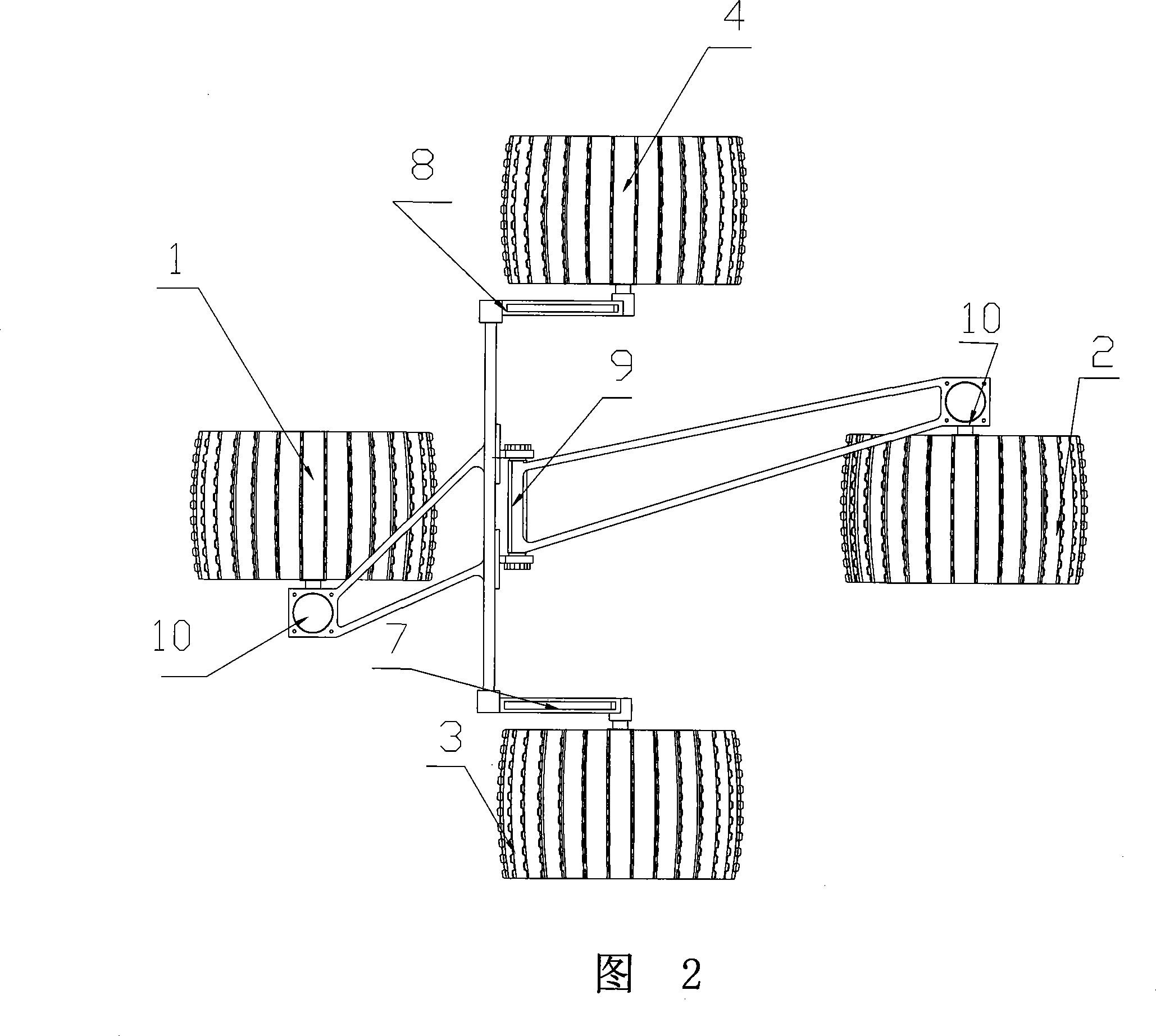

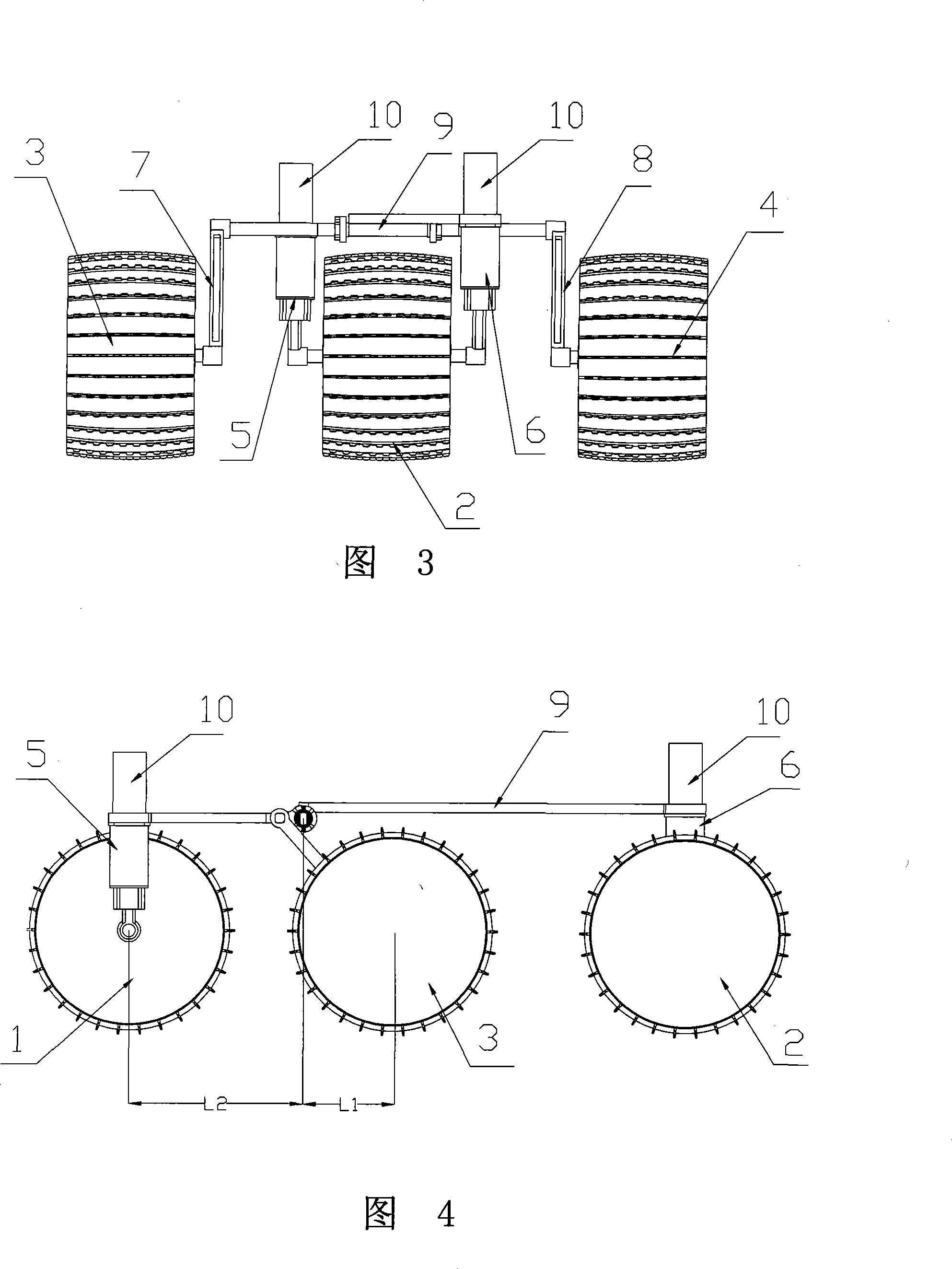

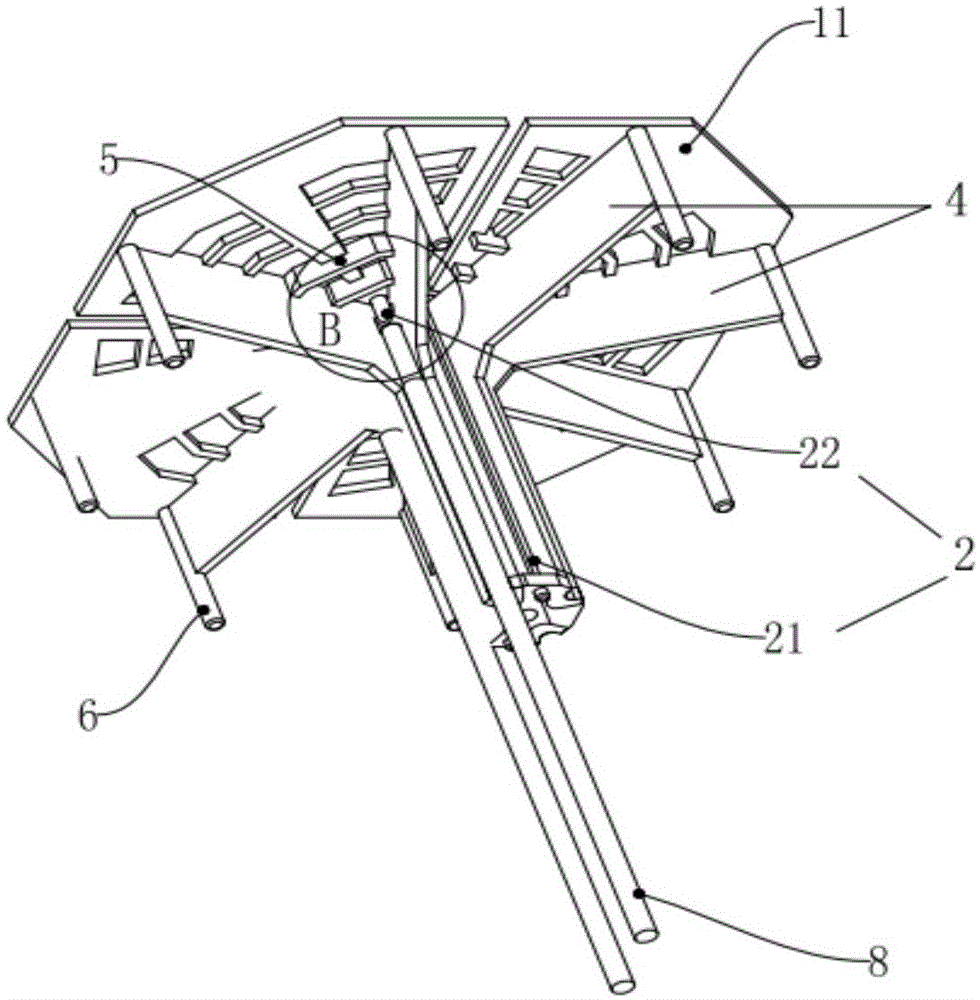

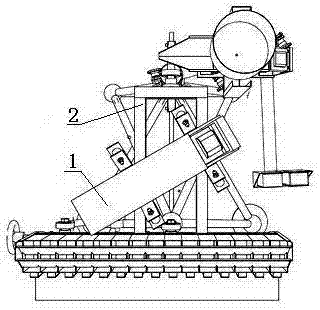

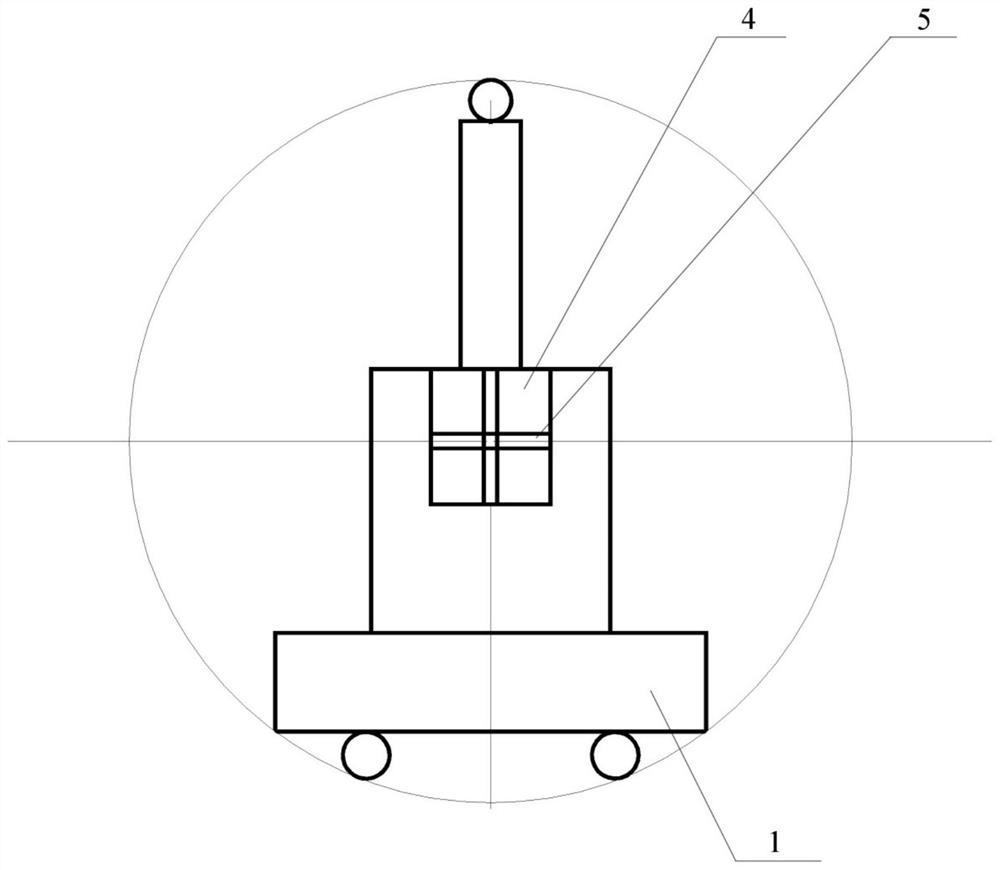

Initiatively rocking arm variable diamond-type four-wheel lunar rover moving system

InactiveCN101214833ATake full advantage of efficient mobilityGive full play to crawling abilityVehiclesVehicle frameEngineering

The invention discloses an active swing arm type variable diamond four-wheel lunar rover moving system. The system comprises a diamond like vehicle frame, a front wheel, a rear wheel, a left wheel and a right wheel with an independent driving system positioned on the vehicle frame. The front wheel and the rear wheel are fixedly positioned on the vehicle frame via a front suspension system and a rear suspension system. The left wheel and the right wheel are fixedly positioned on the vehicle frame via the left suspension system and the right suspension system. The front suspension system and the rear suspension system comprise a swing arm type power mechanism and a steering mechanism. The front wheel and the rear wheel change direction in linkage. The left suspension system and the right suspension system comprise a swing arm type power mechanism. Adopting the structure of the four-wheel three-axis diamond chassis and the active swing arm, the invention initially plays the high-efficient mobility of wheel type driving mode and the crawling ability of foot type moving system, and the invention relates to the active swing arm type variable diamond four-wheel lunar rover moving system with simple and compact structure, low cost, being suitable for operation under various severs environments, wide application, good stability, high reliability and strong flexibility of steering.

Owner:HUNAN UNIV

Optimized CMP conditioner design for next generation oxide/metal CMP

InactiveUS8657652B2Reduce saggingGrinding drivesBelt grinding machinesExperimental validationDiamond type

A study of several key conditioner design parameters has been conducted. The purpose was to improve conditioner performance by considering factors such as wafer defects, pad life, and conditioner life. For this study, several key conditioner design parameters such as diamond type, diamond size, diamond shape, diamond concentration and distribution, were selected to determine their effect on CMP performance and process stability. Experimental validations were conducted. Conditioner specifications were matched to each specific CMP environment (intended application) in order to improve process stability and CMP performance particularly for emerging technology nodes. Several conditioner designs were developed and run successfully in the field. Significant planarity improvement for a 300 mm CMP process was achieved in accordance with one embodiment, and an increase of pad life and wafer polish rate was simultaneously achieved with another embodiment.

Owner:SAINT GOBAIN ABRASIVES INC +1

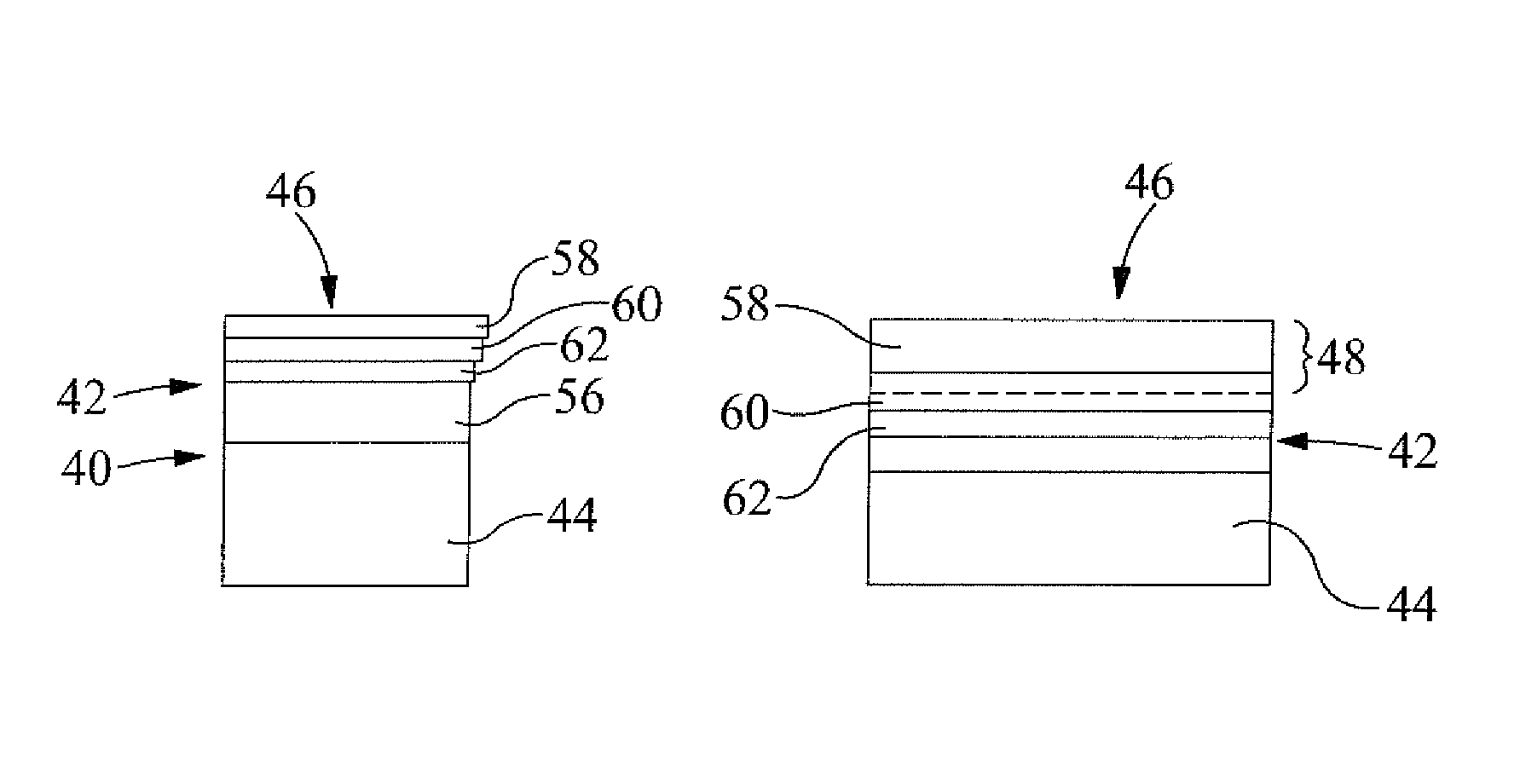

Cutting element

A cutting element includes a multilayer polycrystalline diamond element bonded to a substrate of a less hard material. The polycrystalline diamond element defines a matrix of interstitial volumes. The interstitial volumes of a first region of the diamond layer are adjacent a working surface thereof being substantially free of a catalyzing material. The interstitial volumes of a second region of the diamond layer are remote from the working surface containing the catalyzing material.

Owner:NAT OILWELL VARCO LP

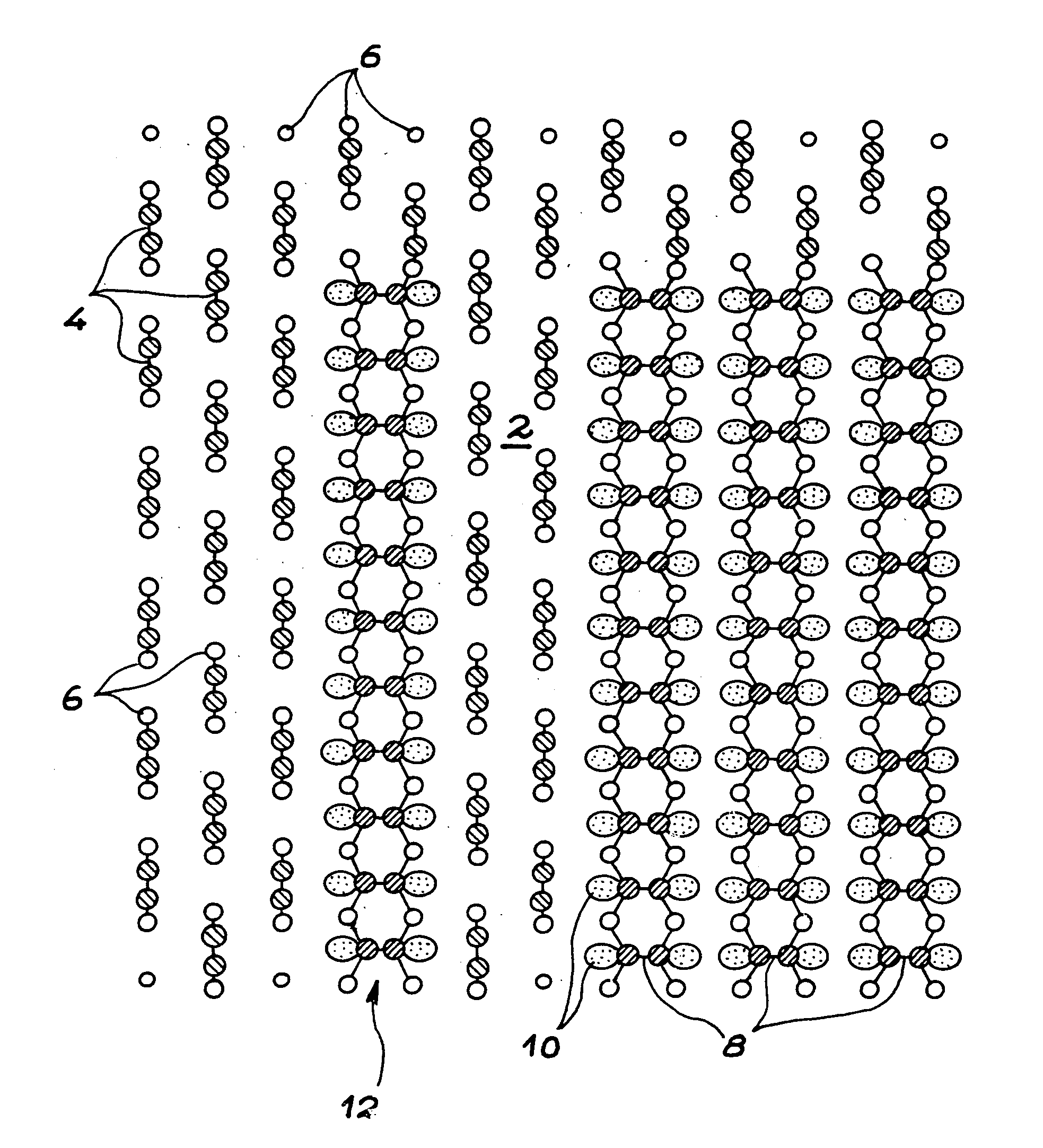

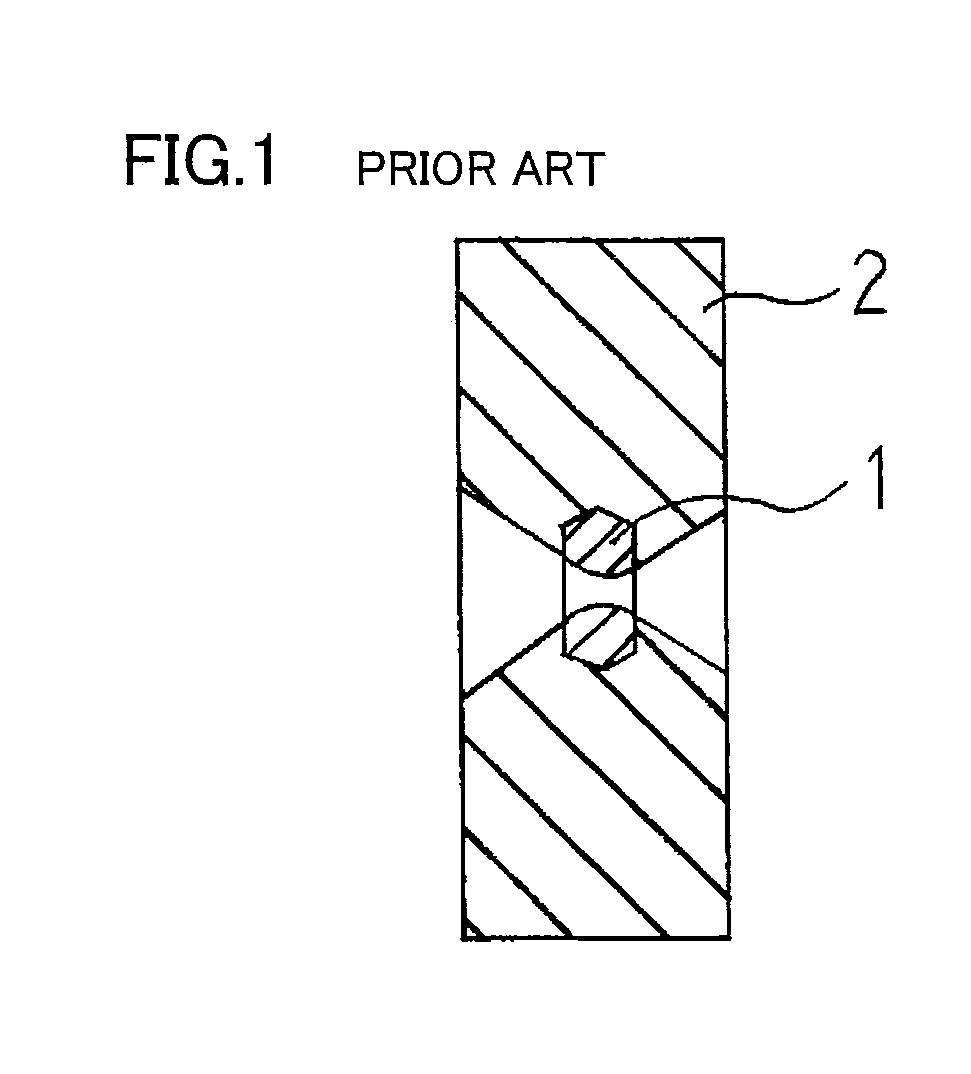

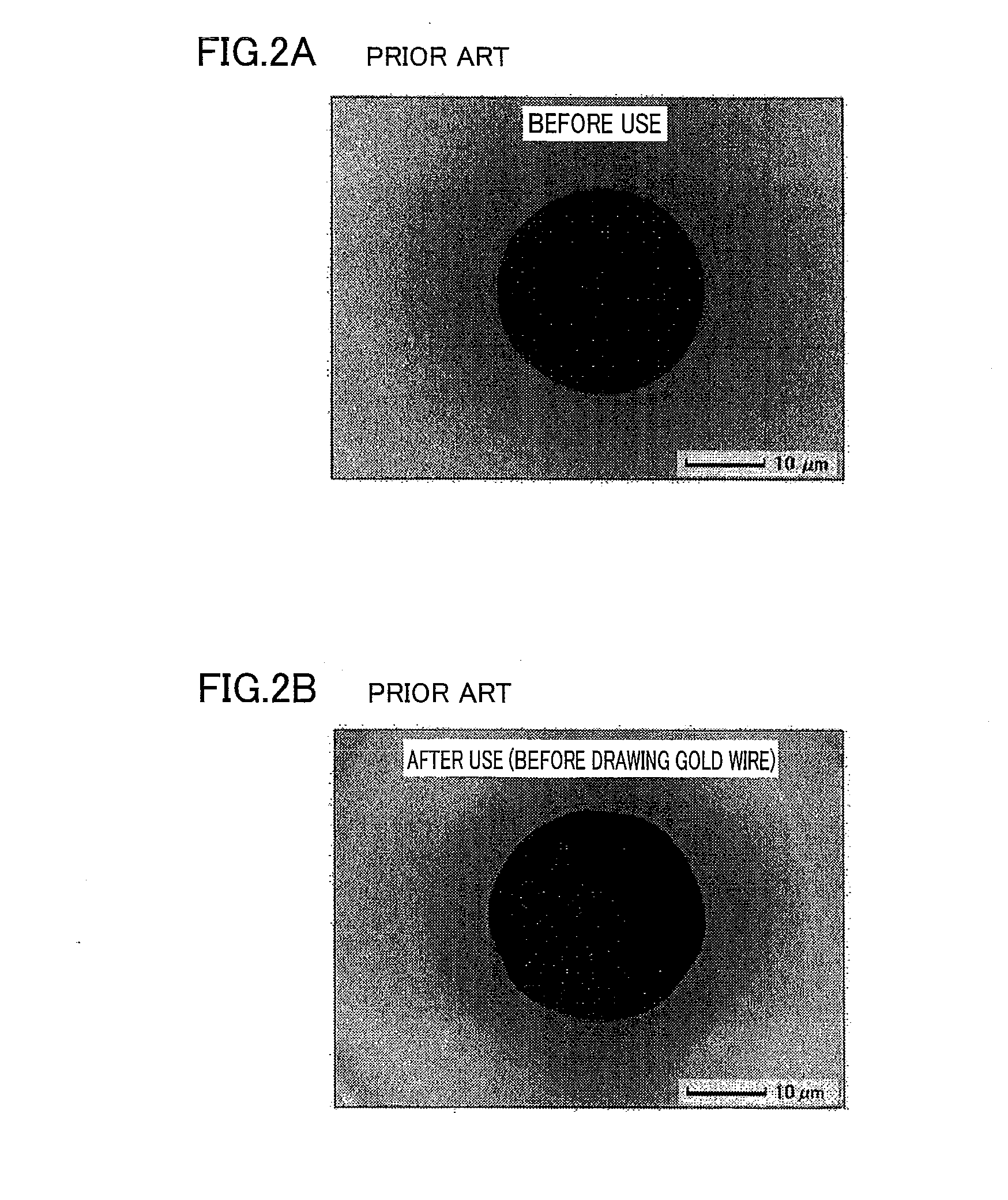

Monoatomic and moncrystalline layer of large size, in diamond type carbon, and method for the manufacture of this layer

InactiveUS20050035380A1Polycrystalline material growthAfter-treatment detailsSingle crystalBiological materials

Monoatomic and monocrystalline layer of large size, in diamond type carbon, and method for the manufacture of this layer. According to the invention, a monocrystalline substrate (2) is formed in SiC terminated by an atomic plane of carbon according to a reconstruction c(2x2) and at least one annealing is carried out, capable of transforming this atomic plane, which is a plane of dimers C≡C (4) of sp configuration, into a plane of dimers C-C (8) of sp3 configuration. Application to microelectronics, optics, optoelectronics, micromechanics and biomaterials.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

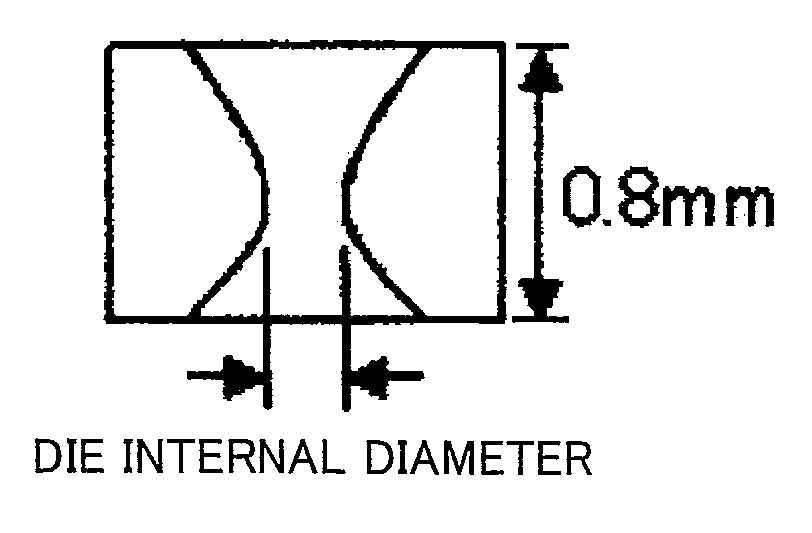

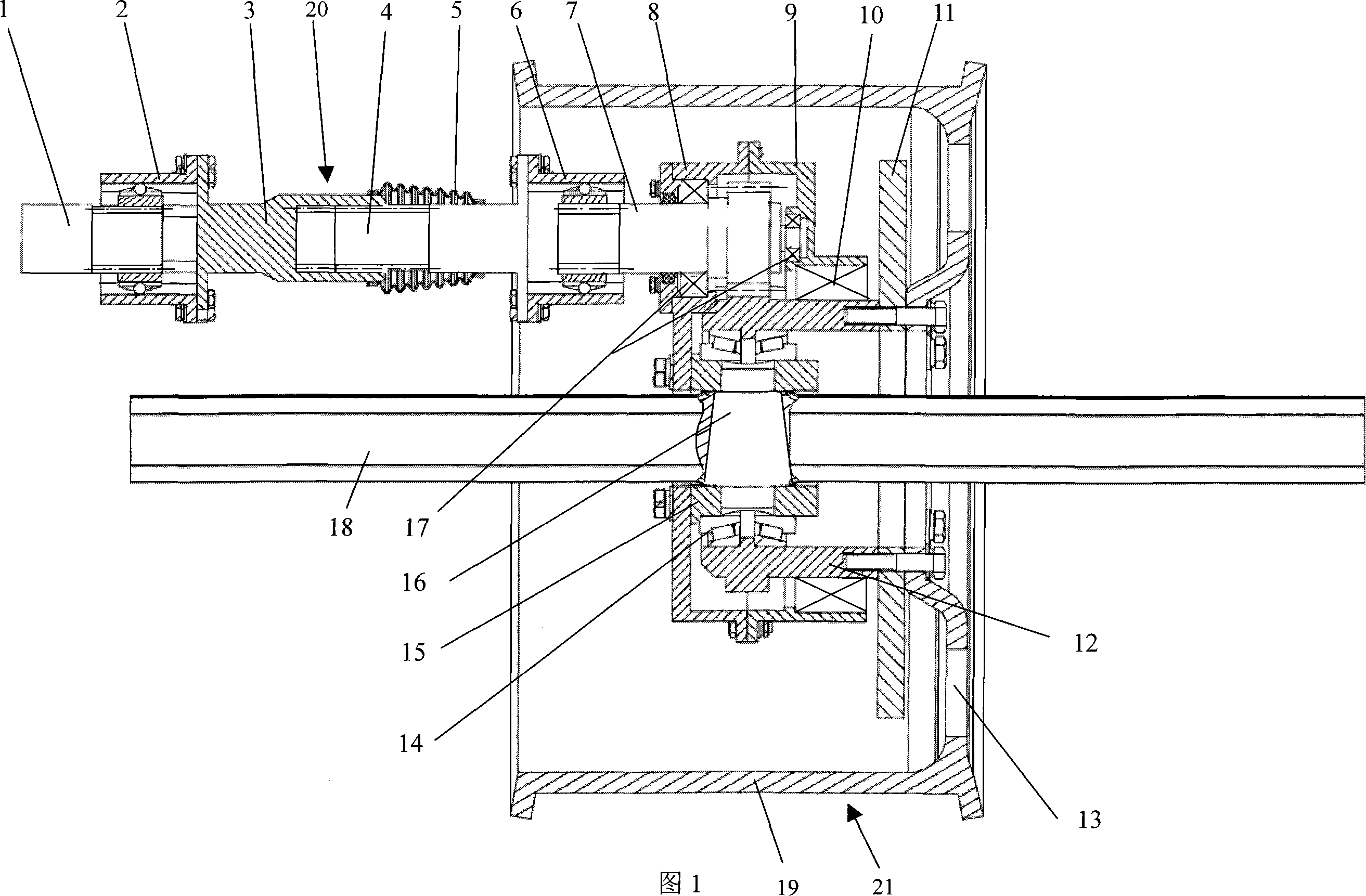

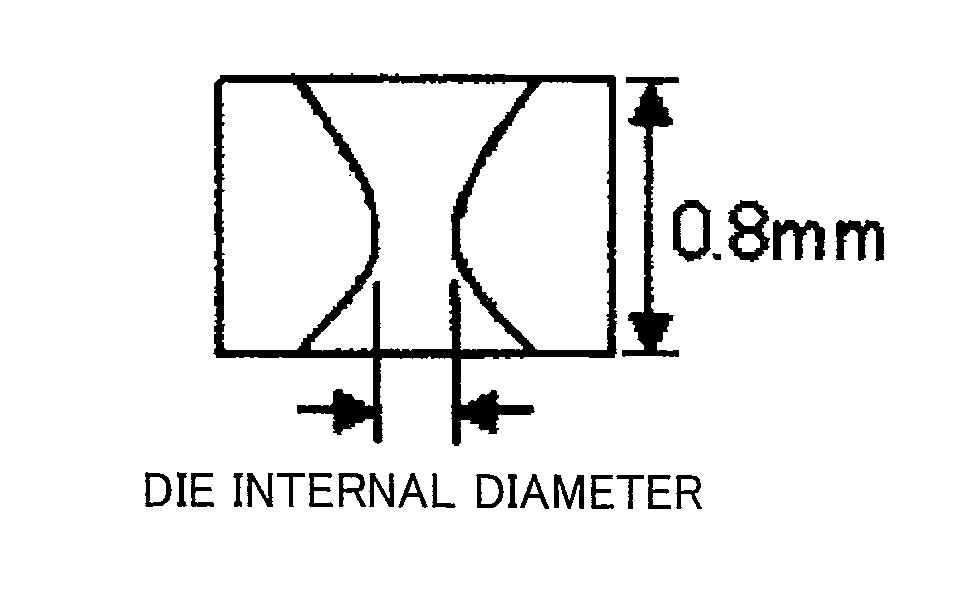

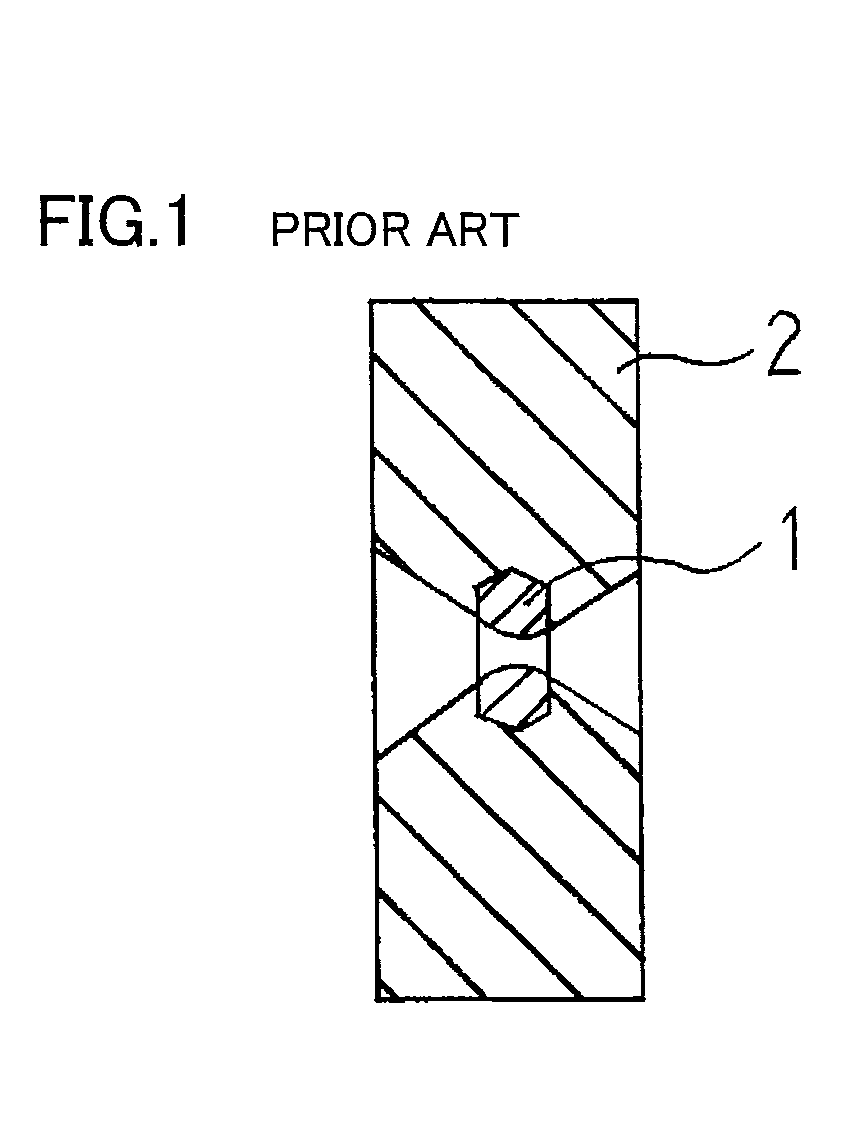

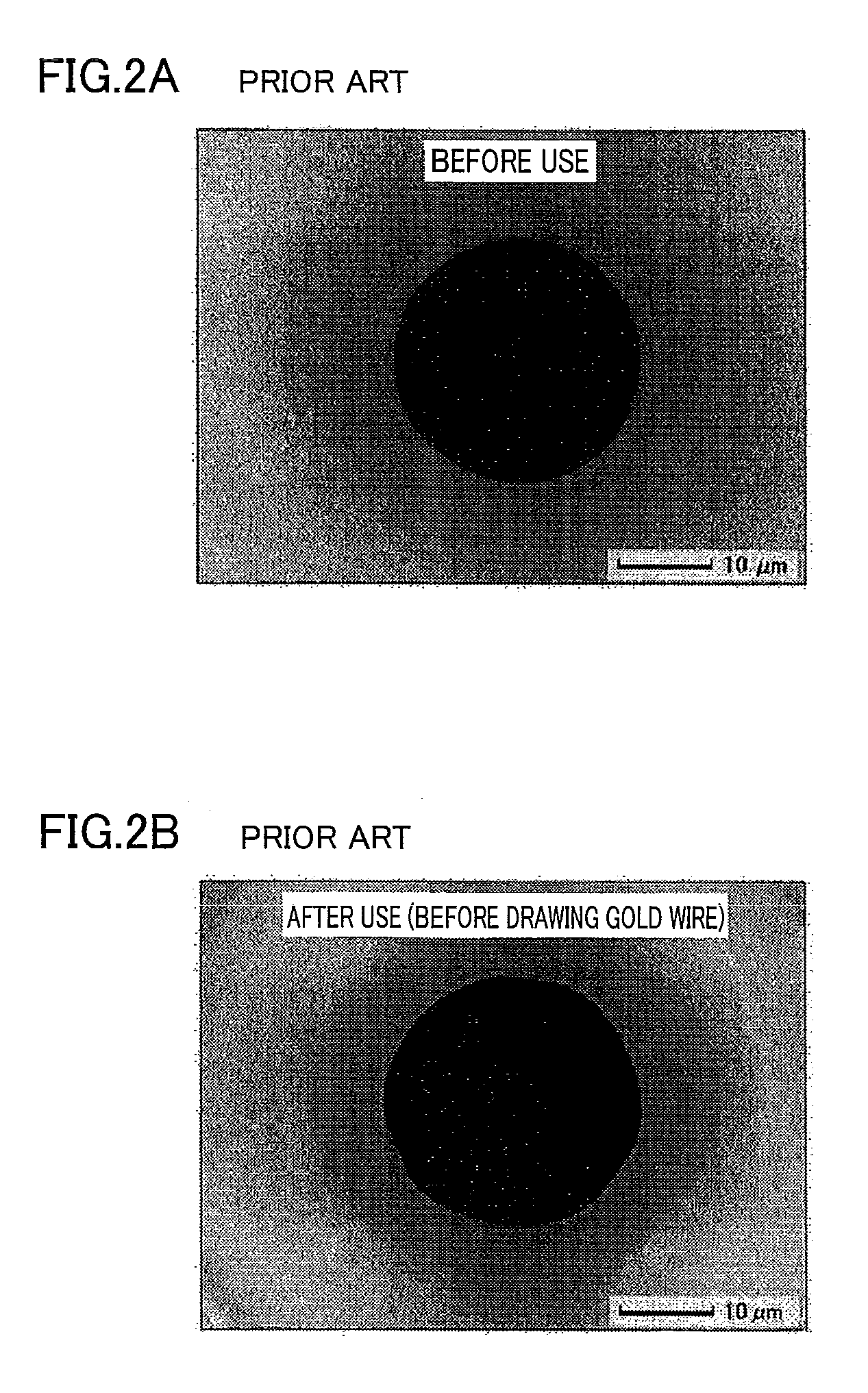

Wire drawing die

ActiveUS20100043520A1Avoid plastic deformationImprove wear resistanceMaterial nanotechnologyPolycrystalline material growthUltra high pressureDiamond crystal

Owner:SUMITOMO ELECTRIC IND LTD +2

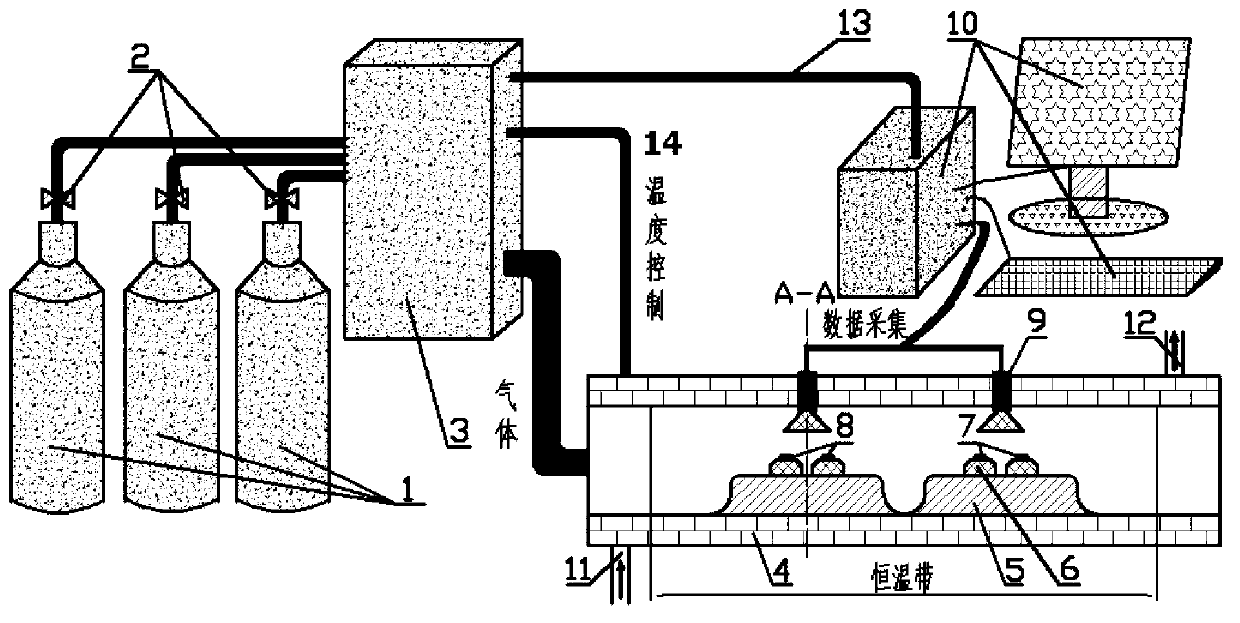

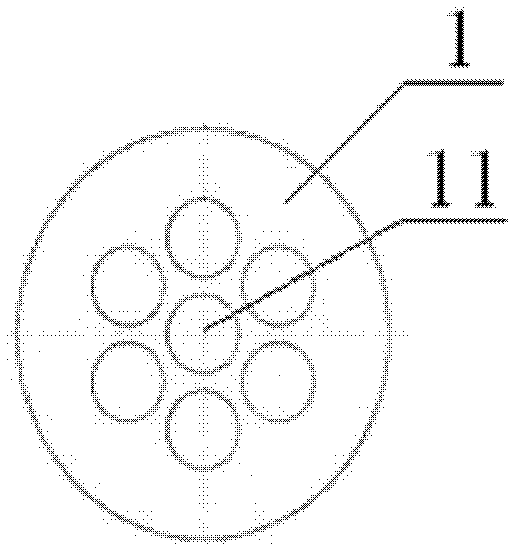

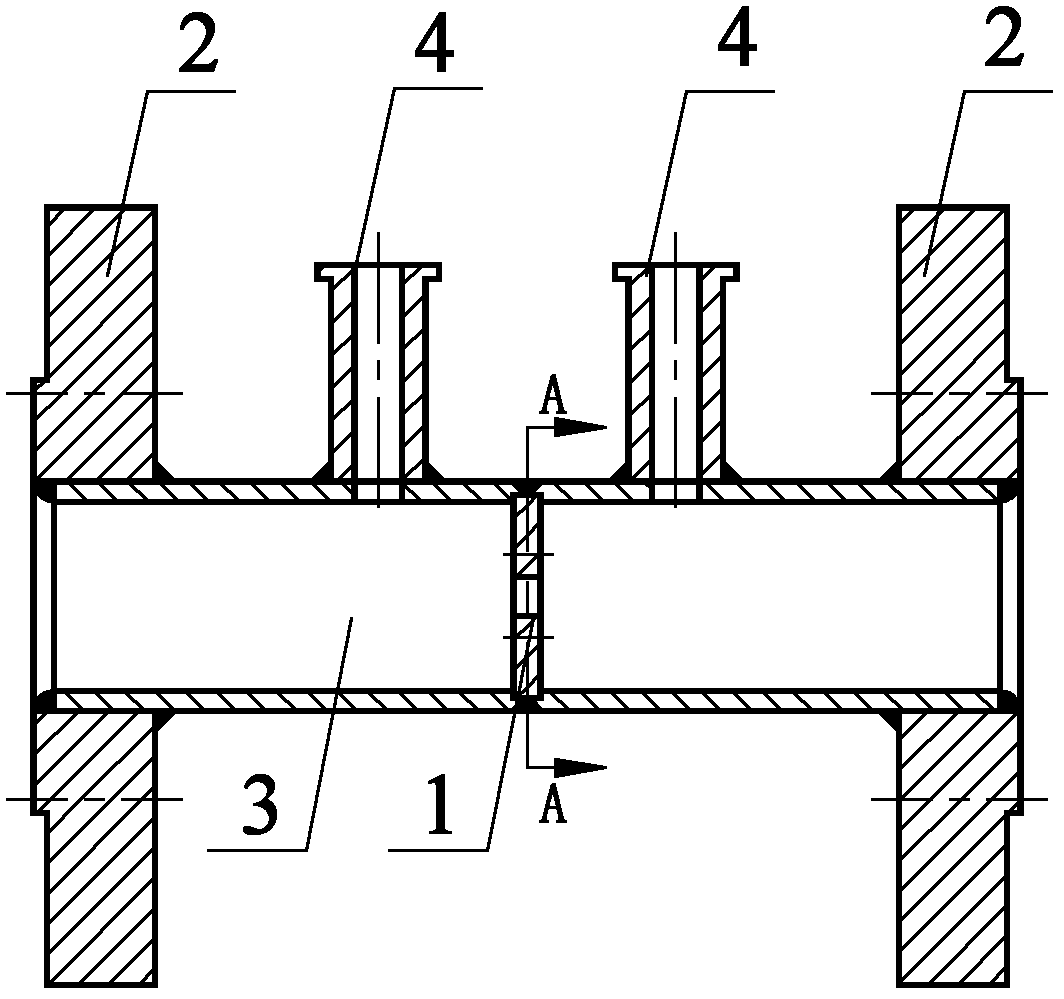

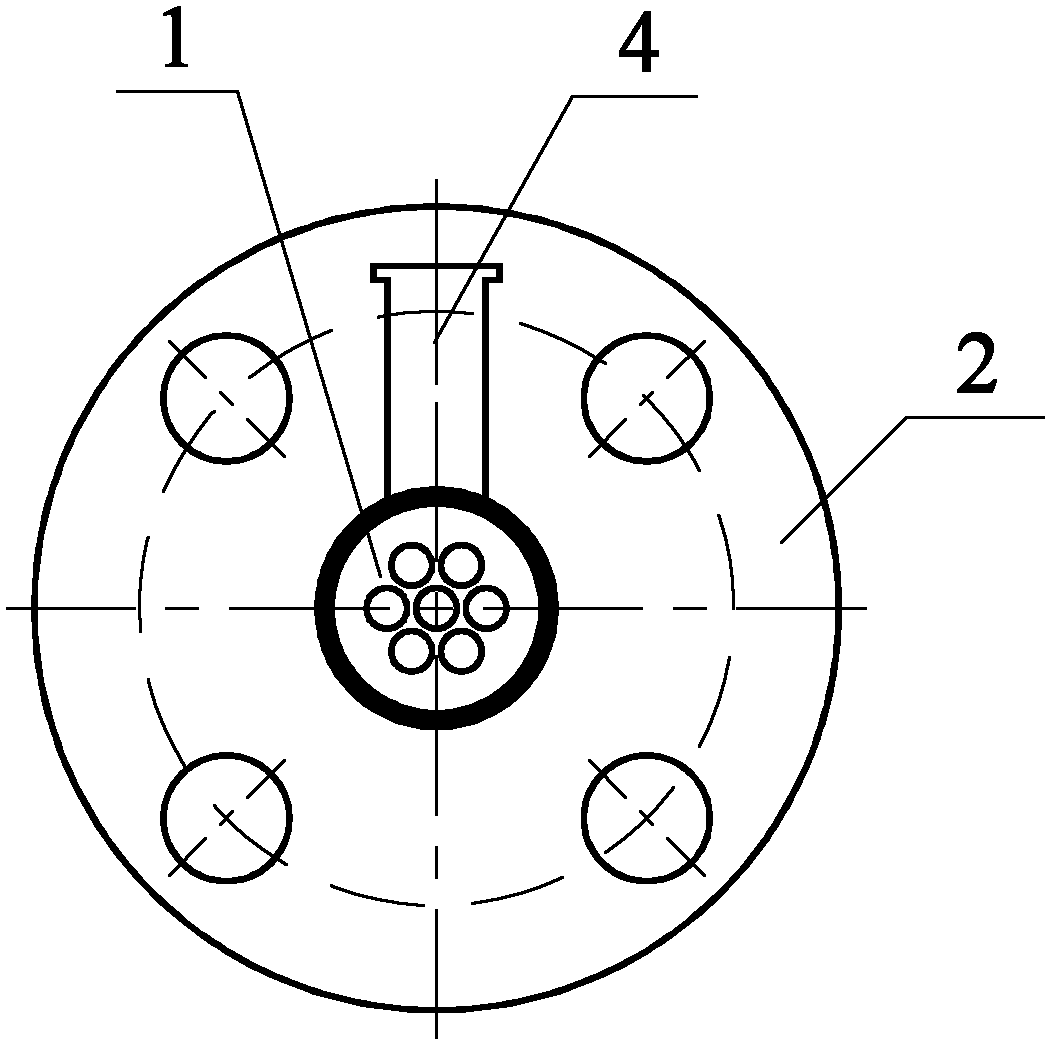

Super-minor-caliber three-diamond-type flowmeter

InactiveCN103033222ACompact structureIngenious designVolume/mass flow by differential pressureStraight tubeDifferential pressure

The invention relates a super-minor-caliber three-diamond-type flowmeter. The super-minor-caliber three-diamond-type flowmeter is installed inside the surface body of a diversion pipe. Differential pressure division pipes are connected on the surface body of the diversion pipe. The three-diamond-type flowmeter is in a circular structure. The diameter of the three-diamond-type flowmeter is in accordance with the inner diameter of the surface body of the diversion pipe. A round hole is formed in the centre of the three-diamond-type flowmeter. Six round holes are symmetrically distributed around the round hole. A regular hexagon shape is formed by the six round holes. Compared with the prior art, the super-minor-caliber three-diamond-type flowmeter is compact in structure and skillful in design. Due to the fact that the rectification and the detection are combined into one, the accuracy and repeatability of a measurement are increased. The super-minor-caliber three-diamond-type flowmeter has the advantages of being wide in measuring range ratio, small in loss of pressure, abrasion resistant, long in service life, short in an installation straight pipe section and the like.

Owner:上海安锐自动化仪表有限公司

Ultra-wideband dual-polarized antenna oscillator employing fractal hollow design

InactiveCN105048110ANice appearanceReduce volumeSimultaneous aerial operationsAntenna supports/mountingsUltra-widebandStructure property

The invention provides an ultra-wideband dual-polarized antenna oscillator employing a fractal hollow design. The ultra-wideband dual-polarized antenna oscillator comprises a reflector plate and an integrally molded main oscillator body, wherein the main oscillator body comprises an oscillator radiation element and a balun bracket; the oscillator radiation element comprises four oscillator radiation sheets; each oscillator radiation sheet is in a diamond-type plane structure; the four oscillator radiation sheets are arranged around the top points as the centers in a coplanar manner; a gap is reserved between the adjacent oscillator radiation sheets; the fractal hollow design is adopted for each oscillator radiation sheet; and the oscillator radiation element is supported by the balun bracket. According to the ultra-wideband dual-polarized antenna oscillator, through the arrangement of the oscillator radiation sheets in the diamond-type plane structure, the voltage standing wave ratio (VSWR) when the ultra-wideband dual-polarized antenna oscillator works within a frequency range of 680-960MHz is smaller than or equal to 1.4; the antenna with a relatively uniform beam width within the width 3dB in the horizontal plane can be realized; the overall oscillator is integrally fabricated and molded by a die-casting technology; and the ultra-wideband dual-polarized antenna oscillator has the characteristics of attractive appearance, small size, low profile, stable structure property and good consistency, and meets the development requirements of mobile communication at present.

Owner:KENBOTONG TECH

Steering wheel driving system of diamond-type vehicle

InactiveCN101219677ATransmission structure without interferenceCapable of large angle steeringMechanical steering gearsTransverse axisSteering wheel

The invention relates to a diamond vehicle steering wheel driving system, comprising that two ends of a steering master pin arranged at the middle part of a lateral axis are connected with a steering knuckle which can rotate around an axis thereof; a wheel hub is arranged on the steering knuckle through a pair of supporting bearings; a spoke on one side of a wheel rim is fixed on one side of the wheel hub; a shell of a decelerator inside a cavity of the wheel rim consists of a left shell and a right shell; the left shell is fixedly connected with the steering knuckle, and the right shell is equipped on an external ring of the wheel hub through a bearing; one end of an inner half shaft inside the shell of the decelerator is linked with the wheel hub through a gear deceleration transmission pair, and the other end of the inner half shaft is connected with an end of a first constant speed universal joint of a ball cage; the other end of the first constant speed universal joint of a ball cage is connected with one end of a retractile outer half shaft; the other end of the retractile outer half shaft is connected with one end of a second constant speed universal joint of a ball cage. The invention can realize constant speed transmission of movement without interference of a transmission structure; the invention has large angle steering capability, beneficial for improving the road clearance of the vehicle.

Owner:HUNAN UNIV

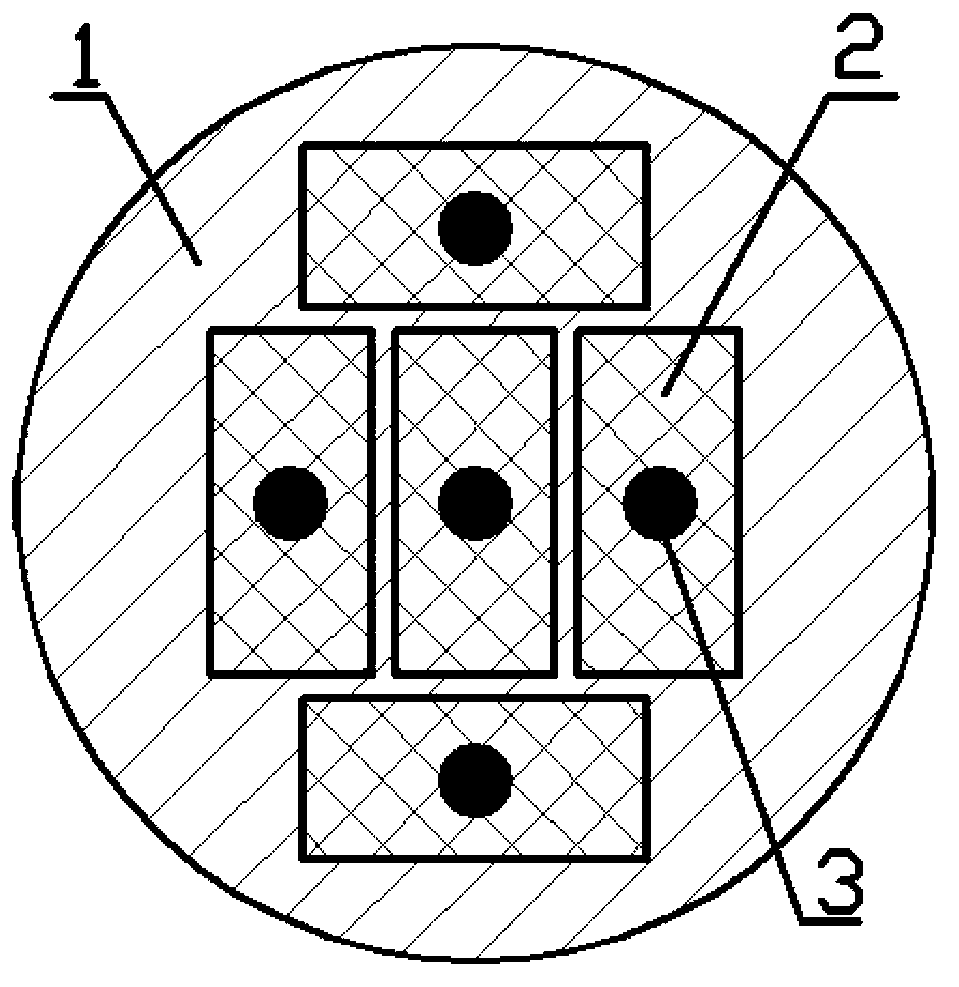

Wire drawing die

ActiveUS9061336B2High strengthImprove heat resistanceMaterial nanotechnologyPolycrystalline material growthDiamond crystalDiamond type

One object of the present invention is to provide a wire drawing die excellent in strength and wear resistance. The wire drawing die has a core formed using highly hard diamond polycrystalline body made substantially only of diamond and produced by directly converting a raw material composition including a non-diamond type carbon material into diamond and sintering the diamond at an ultra high pressure and an ultra high temperature without adding a sintering aid or a catalyst, the polycrystalline body having a mixed construction including fine-grained diamond crystals with a maximum grain size of less than or equal to 100 nm and an average grain size of less than or equal to 50 nm and plate-like or particulate coarse-grained diamond crystals with a minimum grain size of greater than or equal to 50 nm and a maximum grain size of less than or equal to 10000 nm.

Owner:SUMITOMO ELECTRIC IND LTD +2

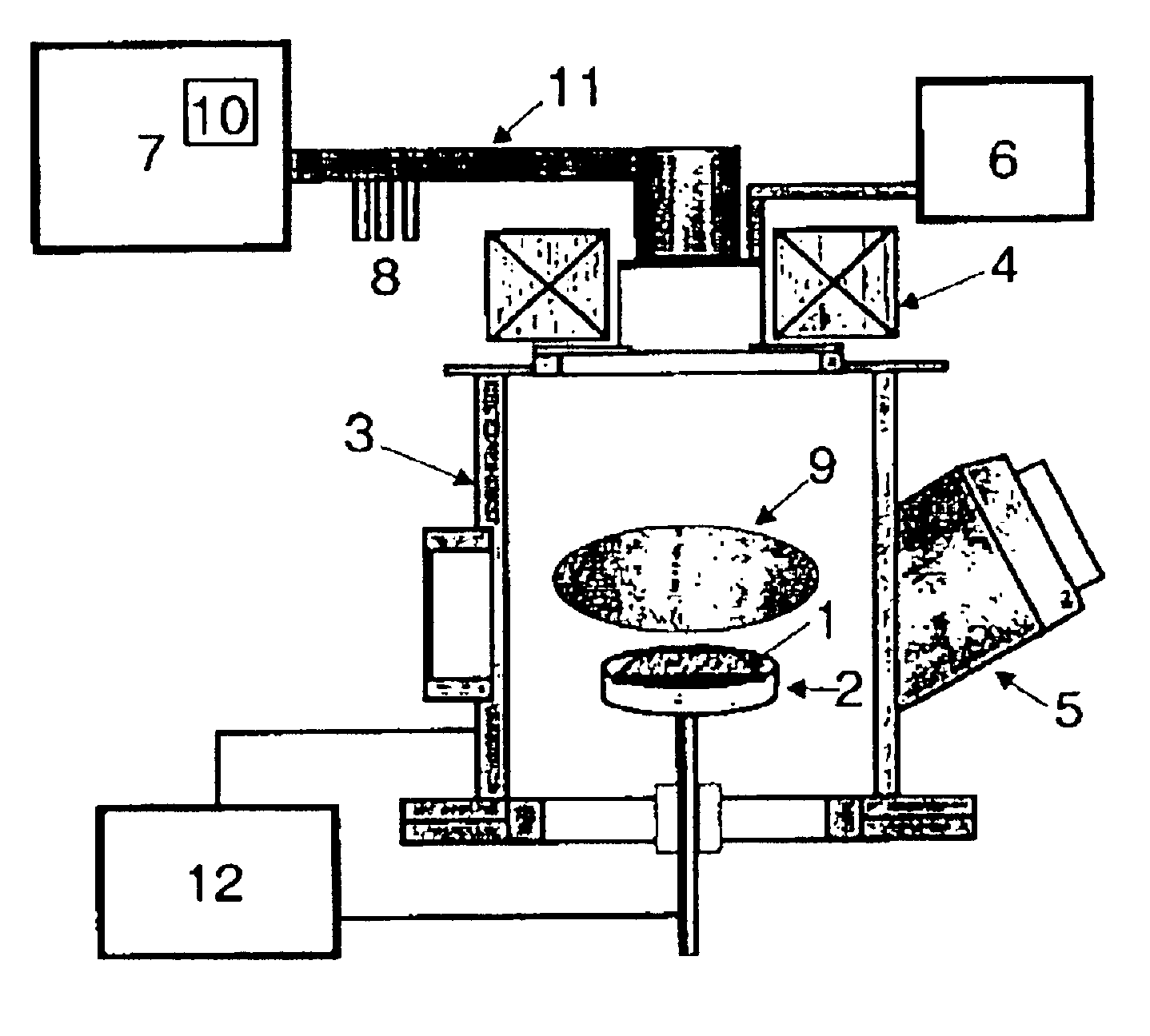

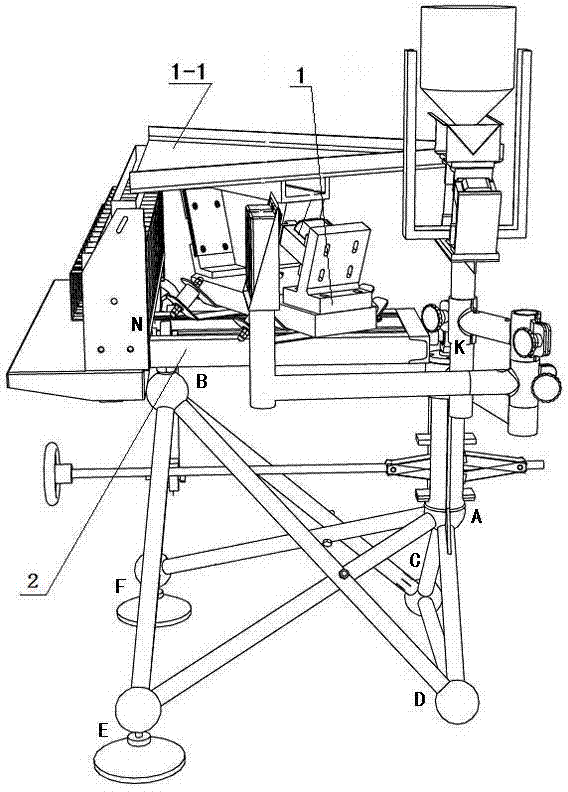

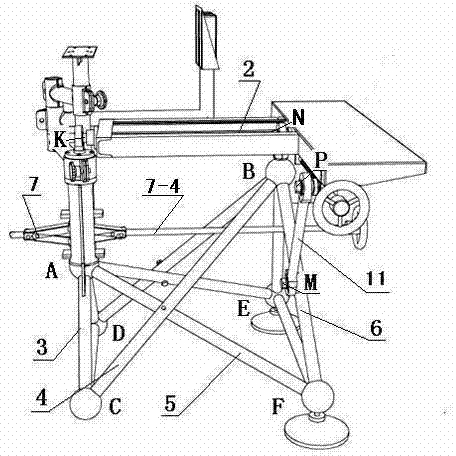

Diamond type selecting machine

The invention discloses a diamond type selecting machine, and relates to the technical field of manufacturing of diamond type selecting machines. The diamond type selecting machine comprises a foot frame, a sorting disc, a sorting disc vibrator and a support frame of the sorting disc vibrator, wherein the support frame is hinged to a forward tilting lifting adjustor and a lateral tilting lifting adjustor connected to the foot frame; the foot frame has two lower front connecting points, two lower back connecting points, an upper front connecting point and an upper back connecting point; one of the upper front connecting point and the upper back connecting point is hinged to one support leg of the support frame, and the other one of the upper front connecting point and the upper back connecting point is connected with the forward tilting lifting adjustor; the sorting disc vibrator is mounted above the connecting line of the upper front connecting point and the upper back connecting point; and a downward vertical projection line of the connecting line of the upper front connecting point and the upper back connecting point is positioned between the two lower front connecting points and the two lower back connecting points. The diamond type selecting machine can solve the problem that a conventional diamond type selecting machine can only sort a small range of diamond monocrystals.

Owner:柳州市威林超硬材料设备有限公司

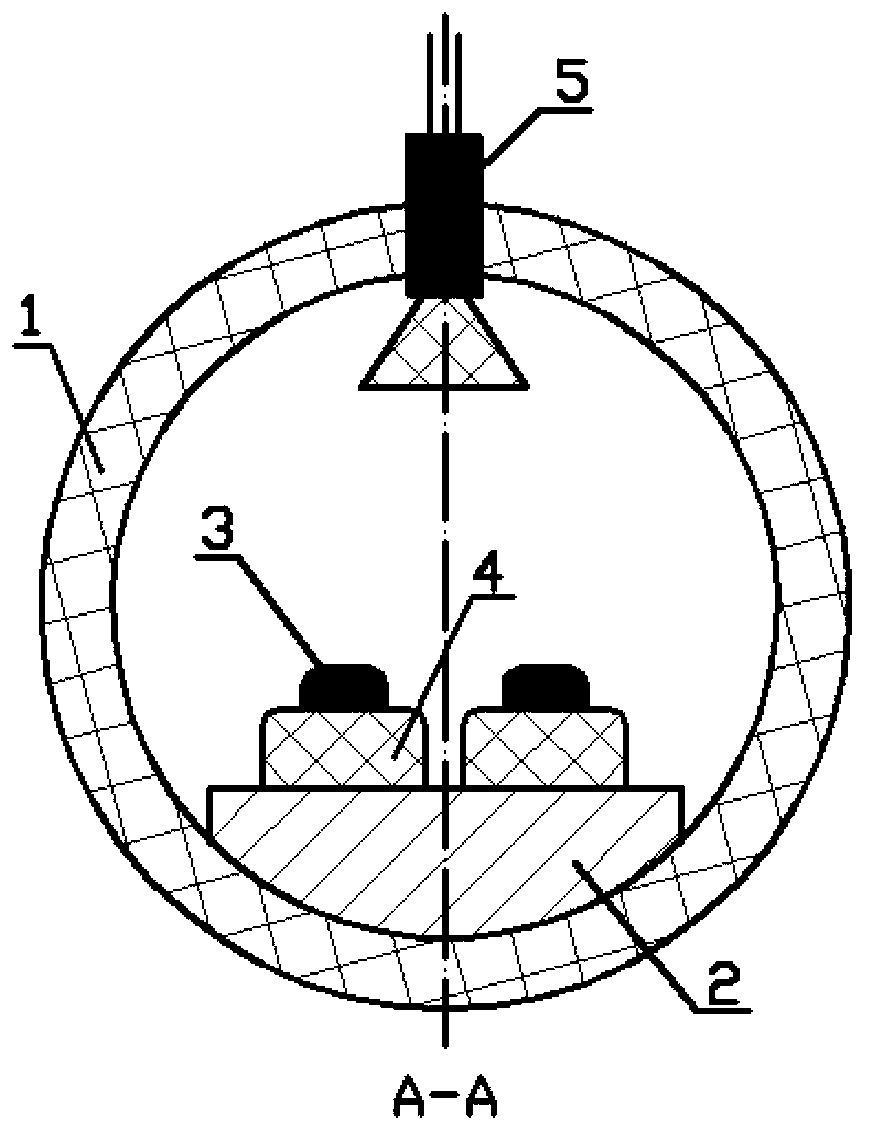

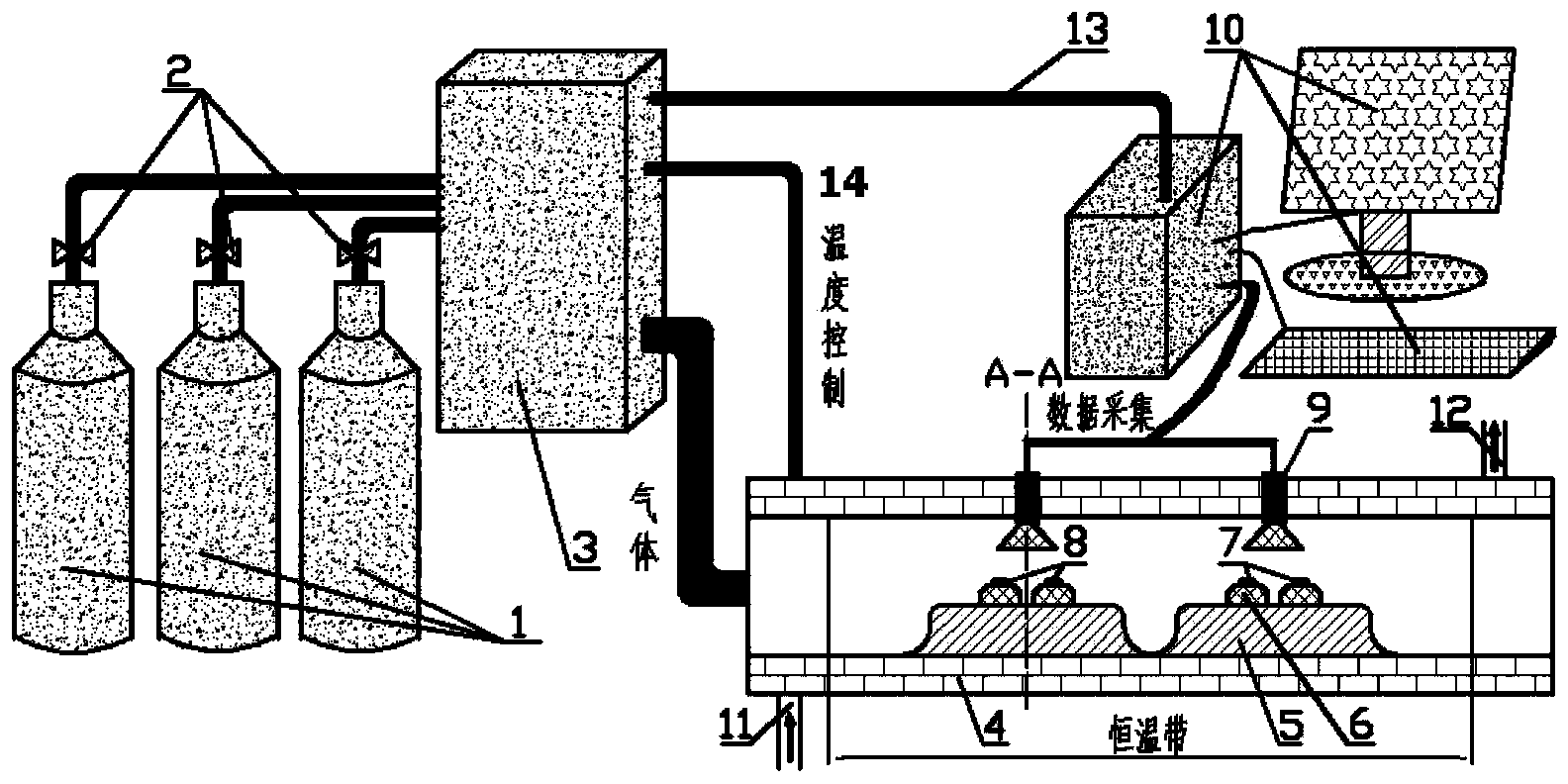

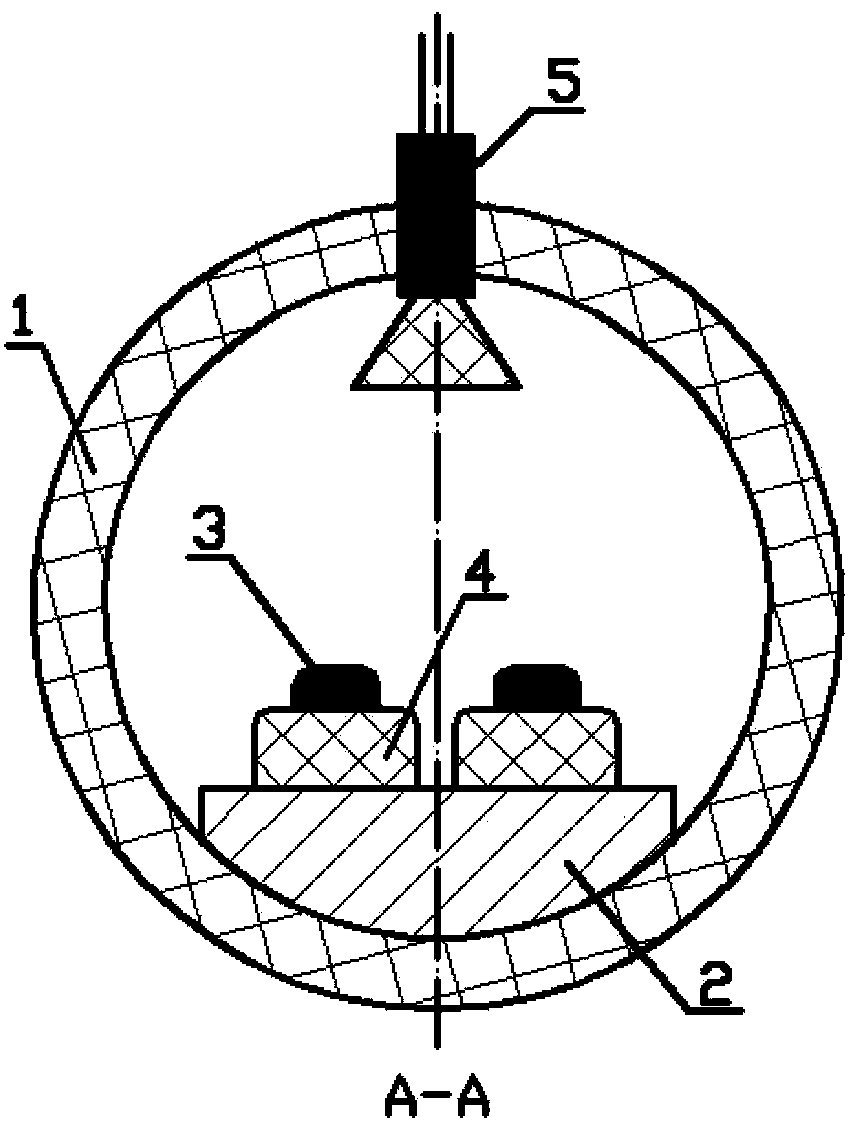

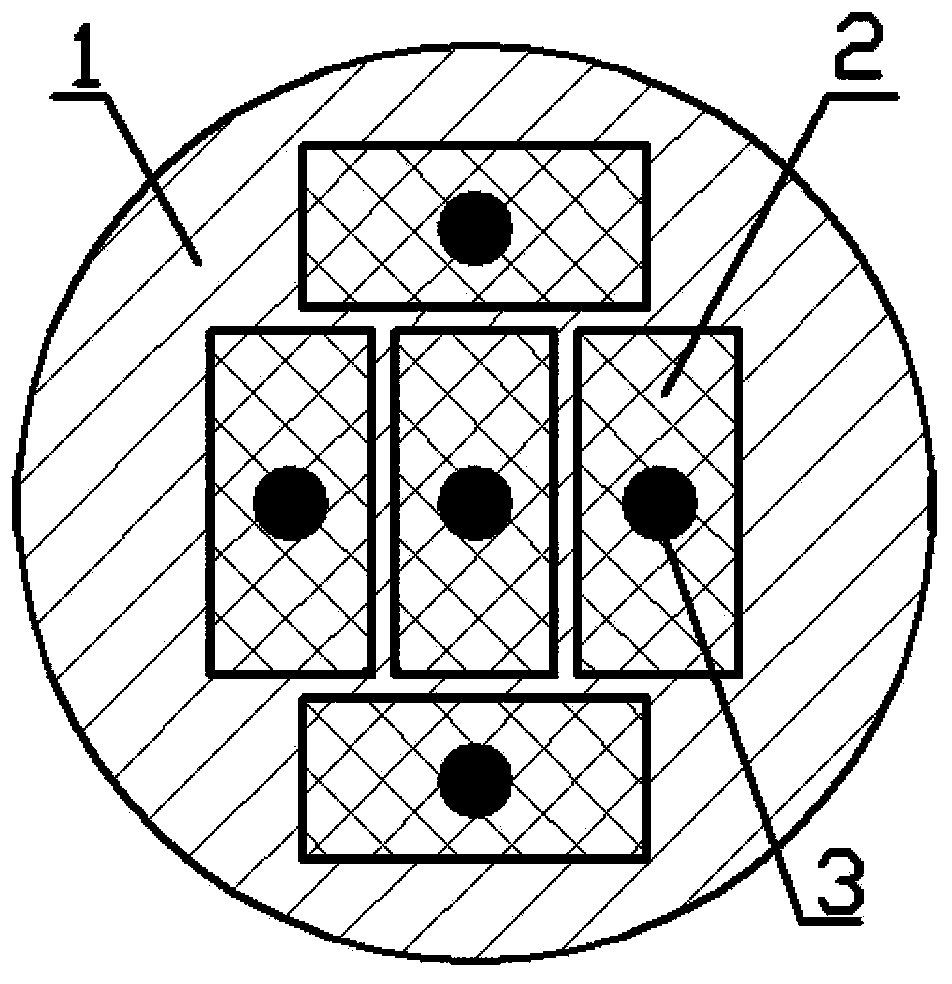

Preparation method of polycrystalline diamond compact covered by strong-combination chemical vapor deposition (CVD) diamond layer

ActiveCN102861917BImprove high temperature resistanceImprove wear resistancePolycrystalline material growthFrom chemically reactive gasesPolycrystalline diamondNucleation

The invention discloses a preparation method of a polycrystalline diamond compact covered by a strong-combination chemical vapor deposition (CVD) diamond layer and belongs to the field of materials, machinery and tools. By means of the method, direct current arc plasma CVD technology can be utilized to precipitate the strong-combination high-quality CVD diamond layer on the surface of the polycrystalline diamond layer by implanting CVD diamond small cylinders with nucleation surface facing outwards in the polycrystalline diamond layer. After the compact is covered by the strong-combination CVD diamond layer, the novel polycrystalline diamond compact greatly improves high temperature resistance and abrasion resistance. The improved polycrystalline diamond compact meets requirements for drilling efficiency and machining efficiency which are higher and higher in the fields of petroleum and geological drilling and machining.

Owner:UNIV OF SCI & TECH BEIJING

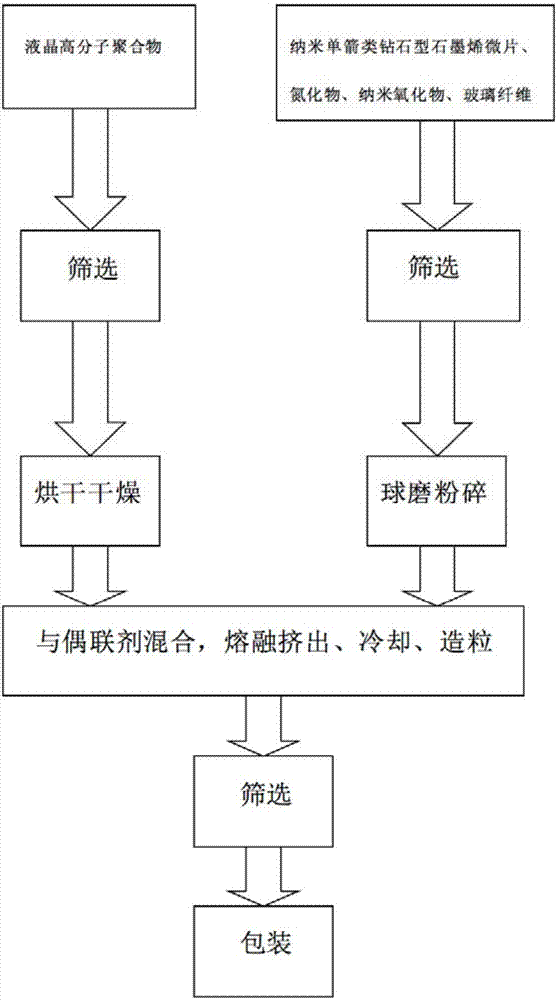

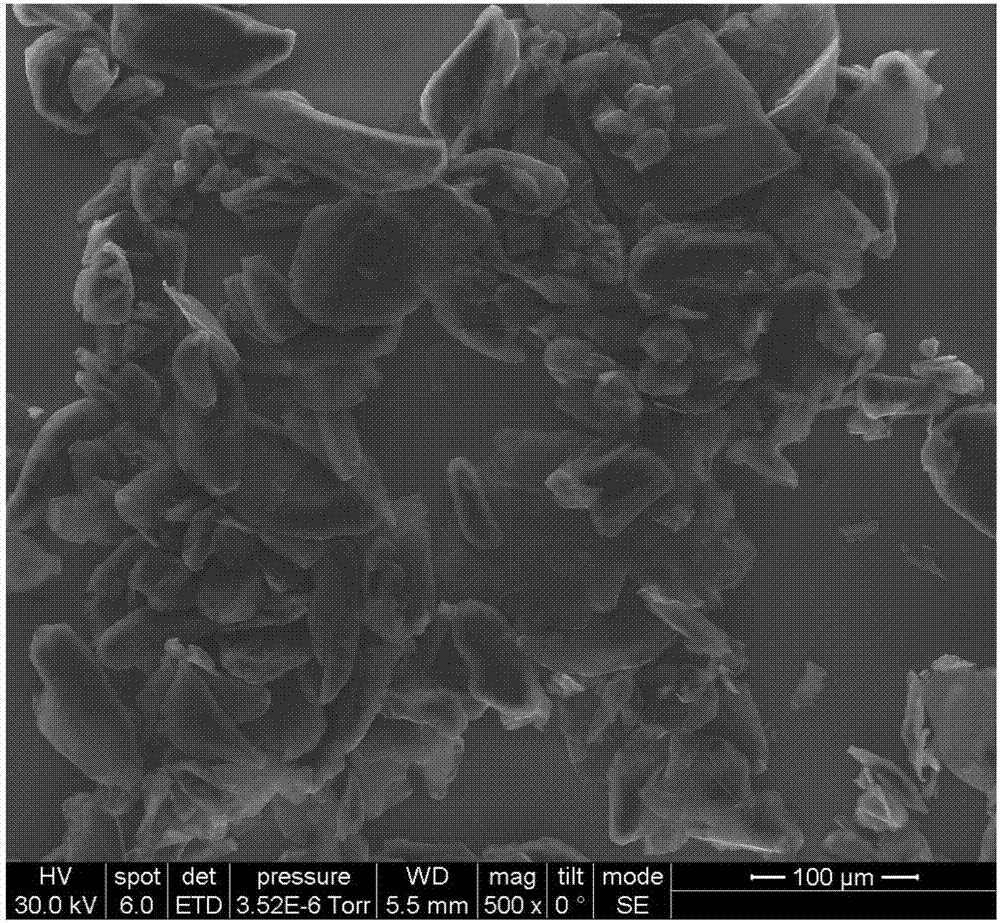

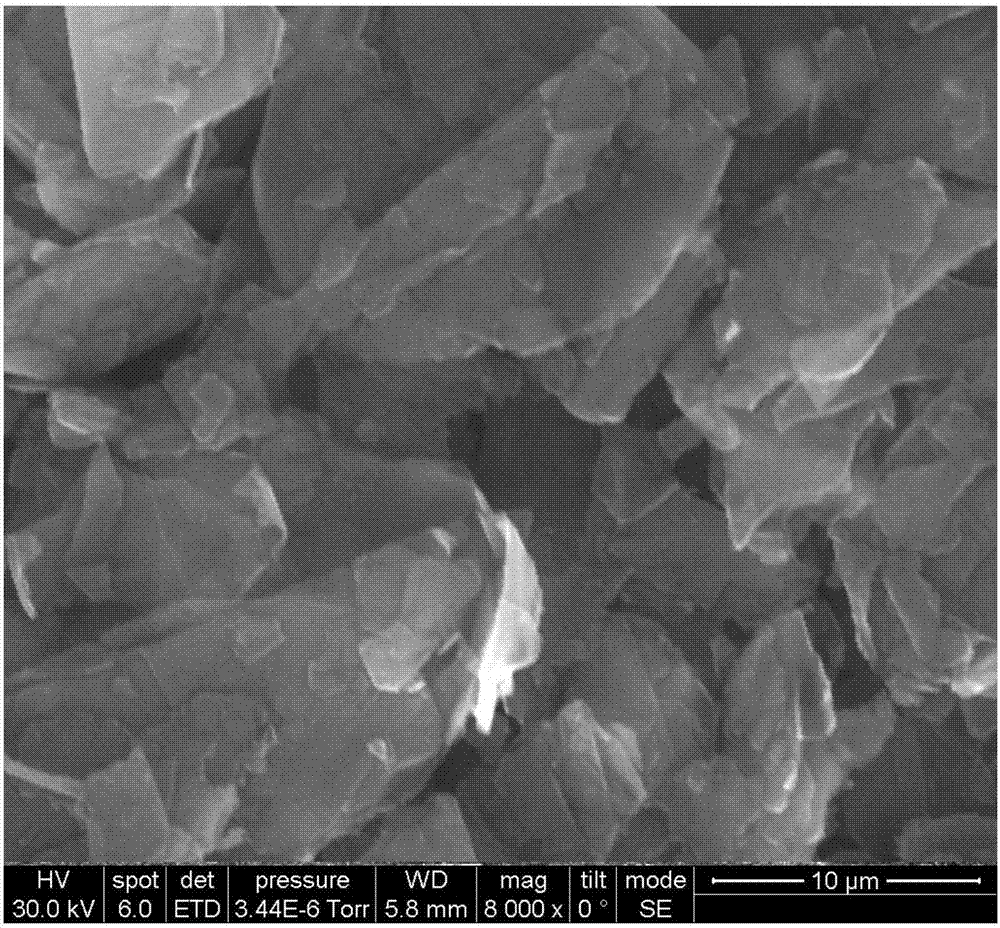

High-radiation heat-radiating and heat-conducting plastics and preparation method thereof

InactiveCN107236325AIncrease productivityImprove mechanical propertiesHeat-exchange elementsGlass fiberHeat conducting

The invention discloses high-radiation heat-radiating and heat-conducting plastics and a preparation method thereof. The high-radiation heat-radiating and heat-conducting plastics are prepared from the following components: 45 to 50 percent of liquid crystal macromolecular polymers, 1 to 2 percent of nano single-arrow diamond-type graphene microsheets, 45 to 50 percent of filler, 1 to 2 percent of glass fibers, and 0.1 to 1 percent of coupling agent, wherein the filler is mixed powder of nitrides and nano oxides. The high-radiation heat-radiating and heat-conducting plastics are good in mechanical performance, high in structural force and adaptive to the market demand.

Owner:段昌荣 +1

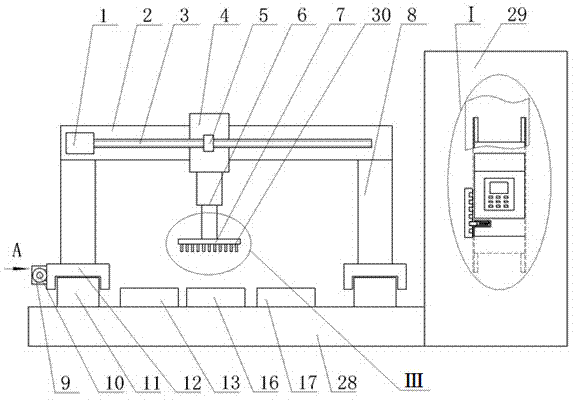

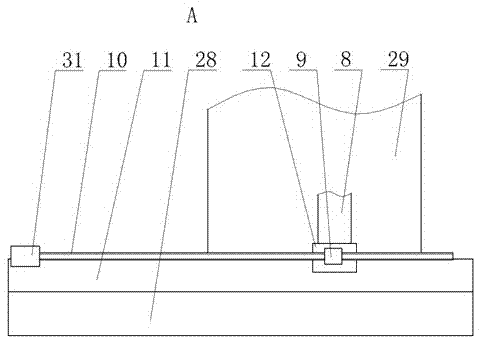

Ultra-small diamond type rectifier bridge adhesive assembly machine

ActiveCN104269367AImprove accuracyAvoid enteringSemiconductor/solid-state device manufacturingAdhesiveSolder paste

The invention discloses an ultra-small diamond type rectifier bridge adhesive assembly machine which comprises a base. Two lower sliding rails are arranged on the upper side of the base in parallel. Sliding blocks are installed on the lower sliding rails. One side of each sliding block is provided with a second nut. One end of each lower sliding rail is provided with a second stepping motor. An output shaft of each second stepping motor is provided with a second screw rod matched with the corresponding second nut. Each sliding block is provided with a support. The second stepping motors enable the sliding blocks to move along the lower sliding rails through cooperation between the second screw rods and the second nuts, a first stepping motor enables a fixing sleeve to slide along an upper sliding rail through a first screw rod and a first nut, and accordingly an adhesive dispensing needle plate can reach any position of the base, the welding process of crystal grains and chips is changed to be the processes of placing a lower framework, pasting solder paste to crystal grains, placing an upper framework, feeding and welding, and the working procedure is simple. A push rod motor can drive the adhesive dispensing needle plate to ascend and descend, and therefore the adhesive dispensing needle plate can achieve the processes of pasting of solder paste, pasting of crystal grains and the like.

Owner:安徽旭特电子科技有限公司

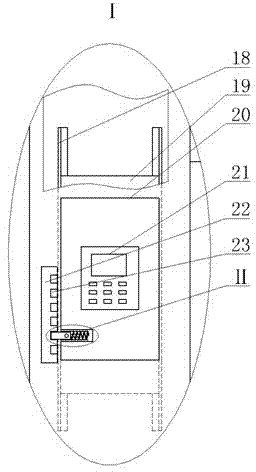

Electricity channel inner surface spraying device used for diamond type power distribution network

PendingCN112808500ADoes not affect bendingDoes not affect bending freedomSpraying apparatusStructural engineeringDiamond type

The invention discloses an electricity channel inner surface spraying device for a diamond type power distribution network. The electricity channel inner surface spraying device comprises a moving trolley and a center fixing frame, a pipe inner circle center adjusting mechanism, a rotating rod and a thermal spraying gun; the center fixing frame is vertically arranged on the moving trolley, the pipe inner circle center adjusting mechanism comprises a movable frame connected to the upper surface portion of the center fixing frame, universal wheels are arranged on the top of the movable frame, the movable frame is provided with a supporting structure; the rotating rod is movably arranged in the central fixing frame and is connected with rolling wheels of the moving trolley; and the thermal spraying gun and the rotating rod are mutually locked.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Diamond-type screen tricot knitting net sheet repairing method for fishing

The invention discloses a method for repairing warp-knitted nets with rhombic meshes for fishing, which relates to the repairing of warp-knitted nets for fishing. The technical solution of the present invention includes mesh cutting and sewing, and is characterized in that the holes of the rhombus mesh warp-knitted mesh are trimmed into rectangles, and the ends of the holes are cut out by melting; There are more than 2 meshes in the rectangular hole, and the same specification is trimmed into a rectangular mesh, and the end of the mesh foot of the cutting edge of the rectangular mesh is melted; use nylon fishing net thread or polyethylene mesh thread with the same diameter as the mesh foot of the repaired mesh as the suture line; Stack the rectangular mesh on the rectangular hole, align the redundant mesh of the repairing mesh with the mesh around the hole; connect the suture line to a mesh more than 3 mesh away from the hole Point the raw feet, use sutures to suture isometrically, and use double dead knots for repairing. This method is suitable for repairing rhombic mesh warp knitted mesh for fishing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

How to make resin diamonds

The invention discloses a method for making a resin diamond, which comprises the following steps in turn: 1. Prepare a master mold: ① provide a diamond shape; ② prepare a mold according to the diamond shape, and process one end of the mold into the shape of the diamond shape Consistent mold heads; ③ Insert multiple molds into the mold cavity of a lower mold, and the mold cavity is provided with a plurality of slots that are mated with the plugs of the molds; 2. Prepare plastic molds : Install the lower mold and an upper mold on the injection molding machine, and use thermoplastic injection molding to form a plastic mold; 3. Forming of resin diamonds: ① Pour AB glue into the plastic cavity formed by the mold head on the plastic mold, Squeeze; ②Put the plastic mold with AB glue into the oven to dry and cure, the drying temperature is 110°C, and the drying time is 50min; ③Take the cured and formed AB rubber block out of the plastic mold cavity, that is A resin diamond rough is obtained. The method is low in cost for making resin diamonds.

Owner:王芳华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com