Preparation method of polycrystalline diamond compact covered by strong-combination chemical vapor deposition (CVD) diamond layer

A polycrystalline diamond and diamond layer technology, applied in the fields of materials, machinery and tools, can solve the problems of lack of effective cooperation, shear stress sensitivity, large diamond particles, etc., to improve service life and work efficiency, prevent cracks and wear resistance The effect of decreasing, improving high temperature resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

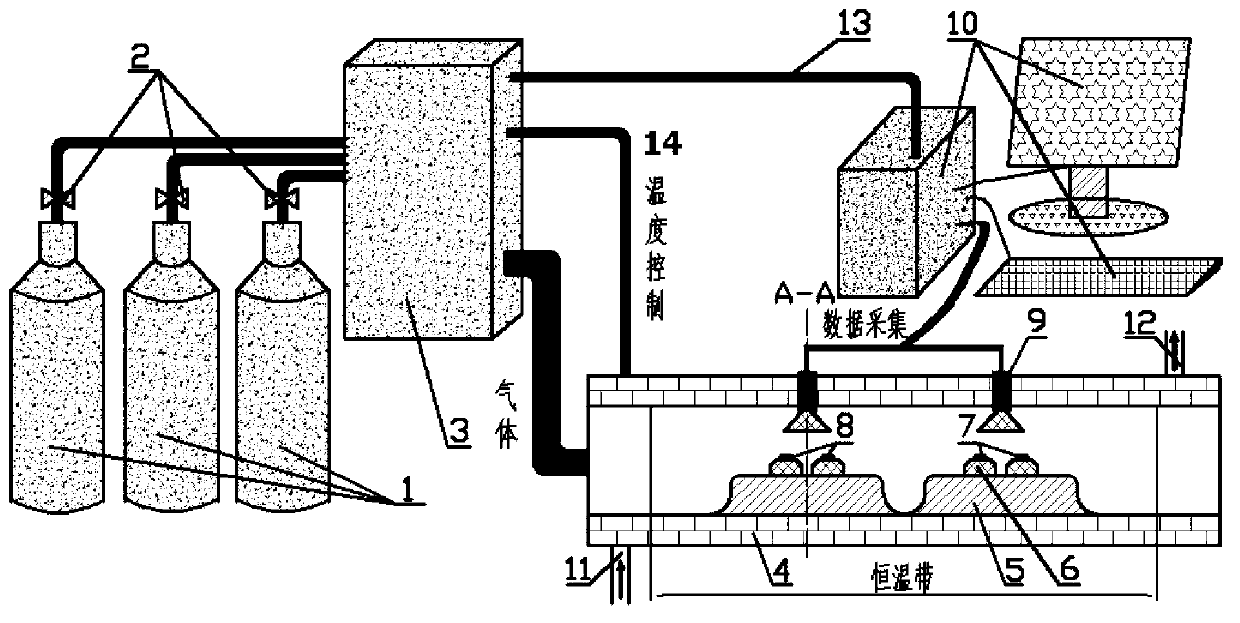

[0031] A method for preparing a polycrystalline diamond composite sheet covered with a strongly bonded CVD diamond layer for drilling. Drill bits for oil drilling have rigid requirements on the service life of the drill teeth (usually it is hoped that the drill bit will not be replaced for one drilling). Pre-PCD must be acid-washed to remove Co and other metal elements.

[0032] Specific steps are as follows:

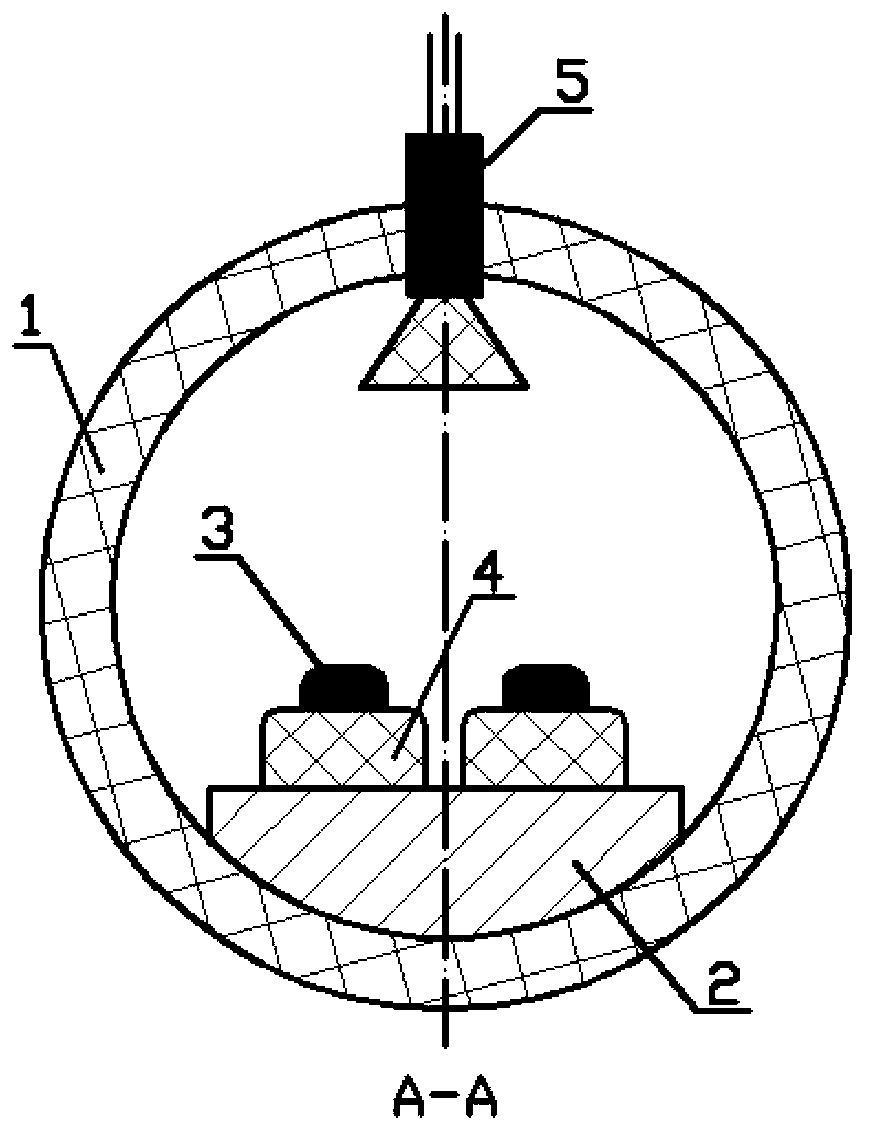

[0033] (1) Prepare a CVD diamond self-supporting film with a diameter of 60 mm and a thickness of 2.3 mm using DC arc plasma CVD technology, and remove the film;

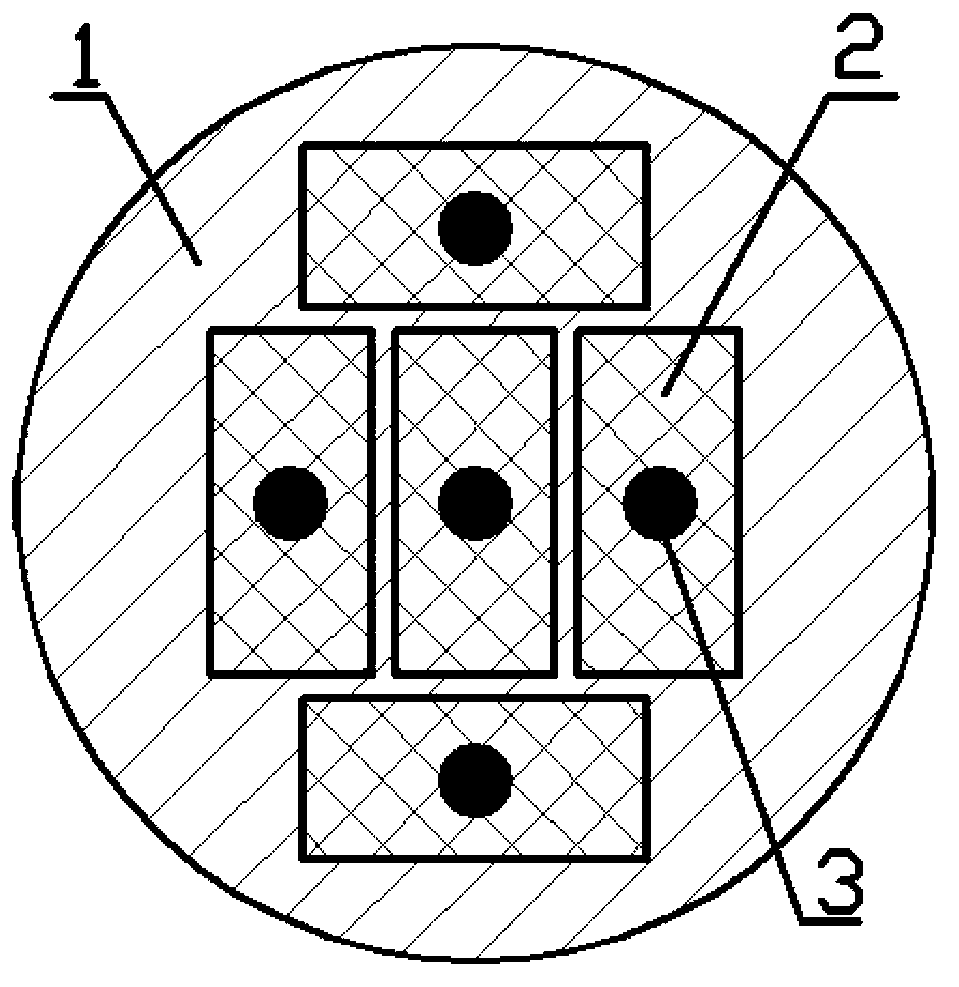

[0034] (2) Use a laser cutting machine to cut the CVD diamond self-supporting film into small cylinders with a diameter of 1mm and a height of 2.3mm along its growth direction;

[0035] (3) Embed 10-1000 CVD diamond small cylindrical cores facing outward into diamond powder and press them together with the cemented carbide substrate to form a blank, then hot-press sinter in a hydrogen-reducing atmosphere, a...

Embodiment 2

[0041] A method for preparing a polycrystalline diamond composite sheet covered with a strongly bonded CVD diamond layer for cutting tools. Knives are consumable and can be coated with thinner CVD diamond layers, so there is an option to deposit CVD diamond films at lower temperatures and slower deposition rates, eliminating the need for pickling of the PCD.

[0042] Specific steps are as follows:

[0043] (1) Prepare a CVD diamond self-supporting film with a diameter of 100 mm and a thickness of 3 mm using DC arc plasma CVD technology, and remove the film;

[0044] (2) Use a laser cutting machine to cut the CVD diamond self-supporting film into small cylinders with a diameter of 1.5mm and a height of 3mm along its growth direction;

[0045] (3) Embed 10-1000 CVD diamond small cylindrical cores facing outward into diamond powder and press them together with the cemented carbide substrate to form a blank, then hot-press sinter in a hydrogen-reducing atmosphere, and anneal to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com