Patents

Literature

59results about How to "Fast patching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

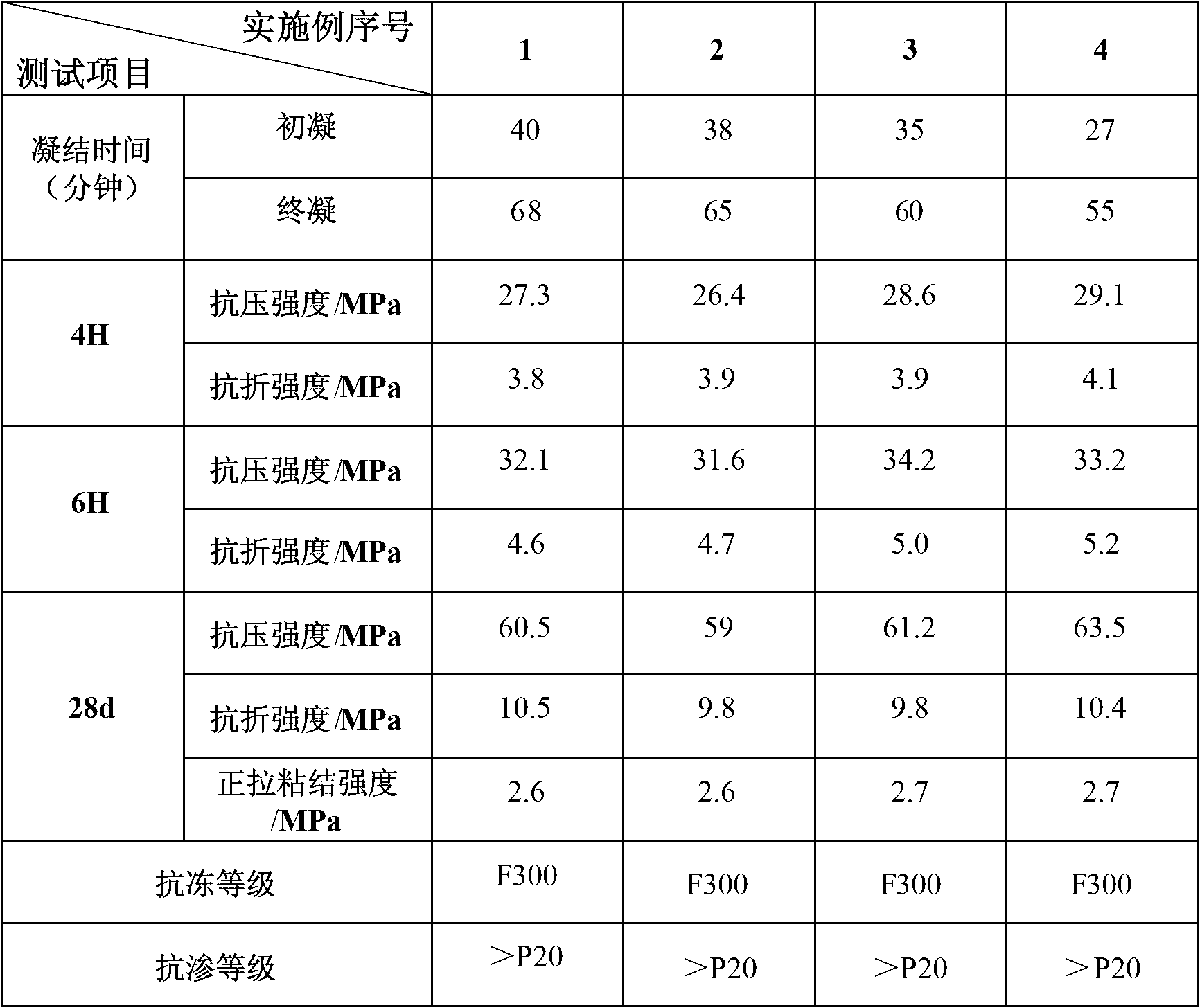

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be openedin 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Process for repairing ancient books, paintings and calligraphy and paper literatures by using paper pulp

ActiveCN1844574AFast patchingEasy to operateNon-fibrous pulp additionPaper/cardboardFiberPulp and paper industry

The invention relates to a pulp repair method of ancient book, painting and calligraphy, which comprises: 1, according to the material of repaired book, painting and calligraphy, selecting pulp material, and adding the raw paper of selected pulp material into mixer, adding water and suspending agent, to mix and break uniformly; the mass ratios between raw paper, suspending agent, and water are: raw paper in 5-20; suspending agent in 5-15; and water in 500-1000, while the mixing time is 30-90s, then getting out the pulp; 2, spreading the book, painting and calligraphy on the repair support that made from paper shade; filling prepared pulp into repair pen to repair them that dropping pulp into the damaged part to use the combine force generated when the pulp becomes paper, the interlace force of fiber, and the adhesive function of suspending agent to complete said process; 3, removing repaired book, painting and calligraphy from the repair support, to be laid on the water-adsorption paper, to be dried.

Owner:邱晓刚

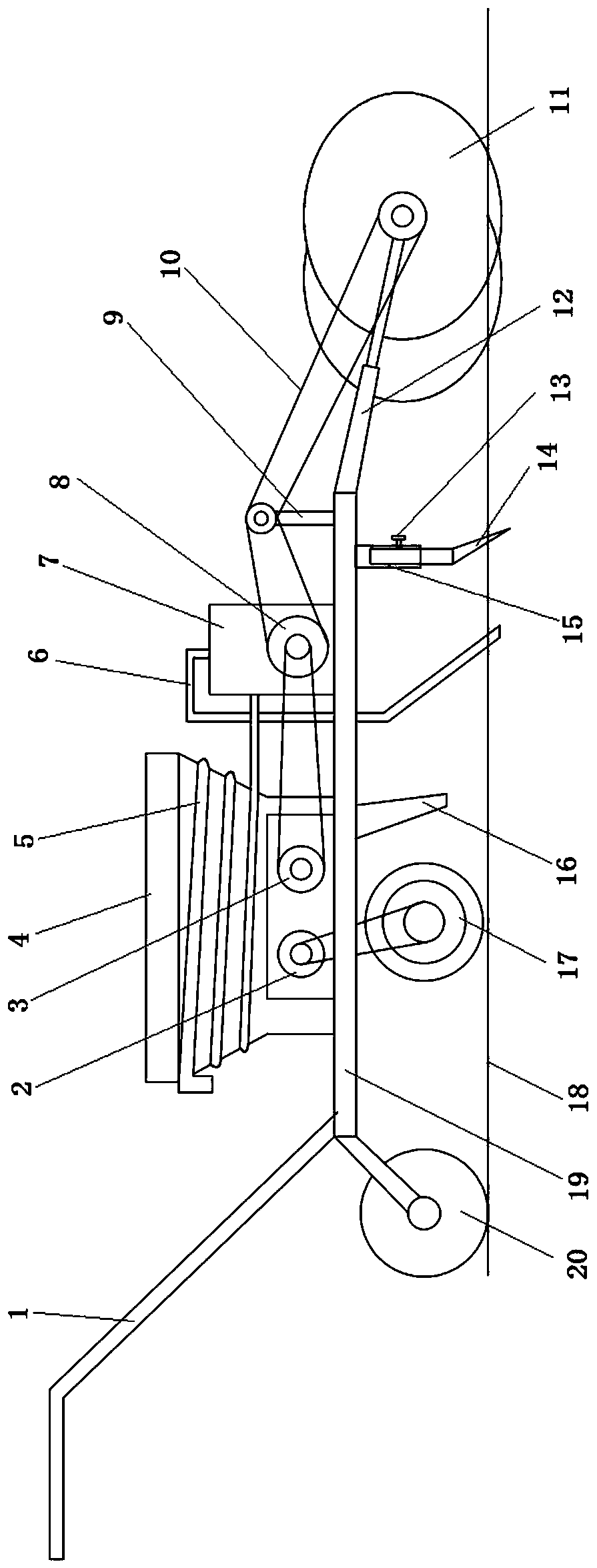

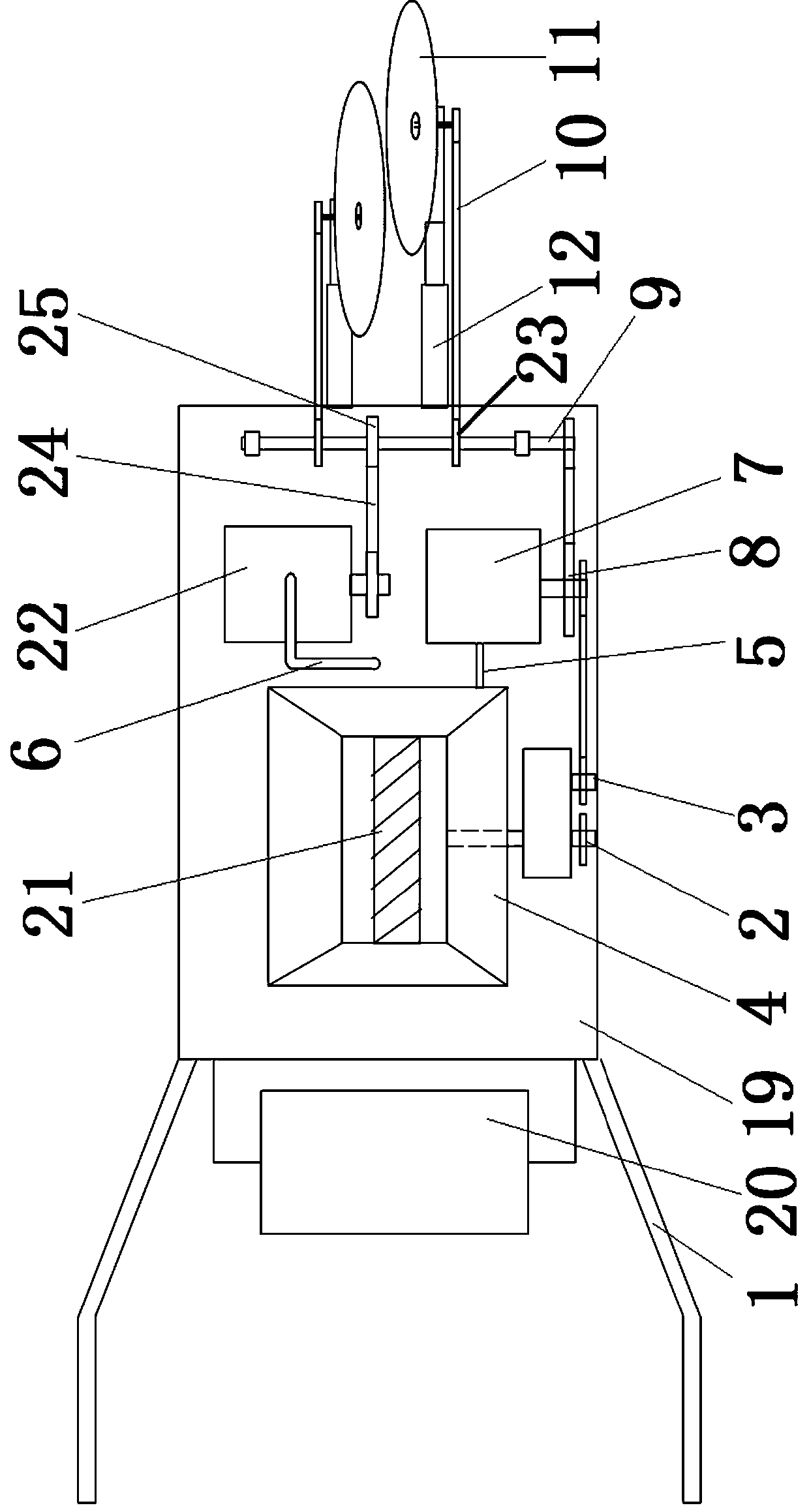

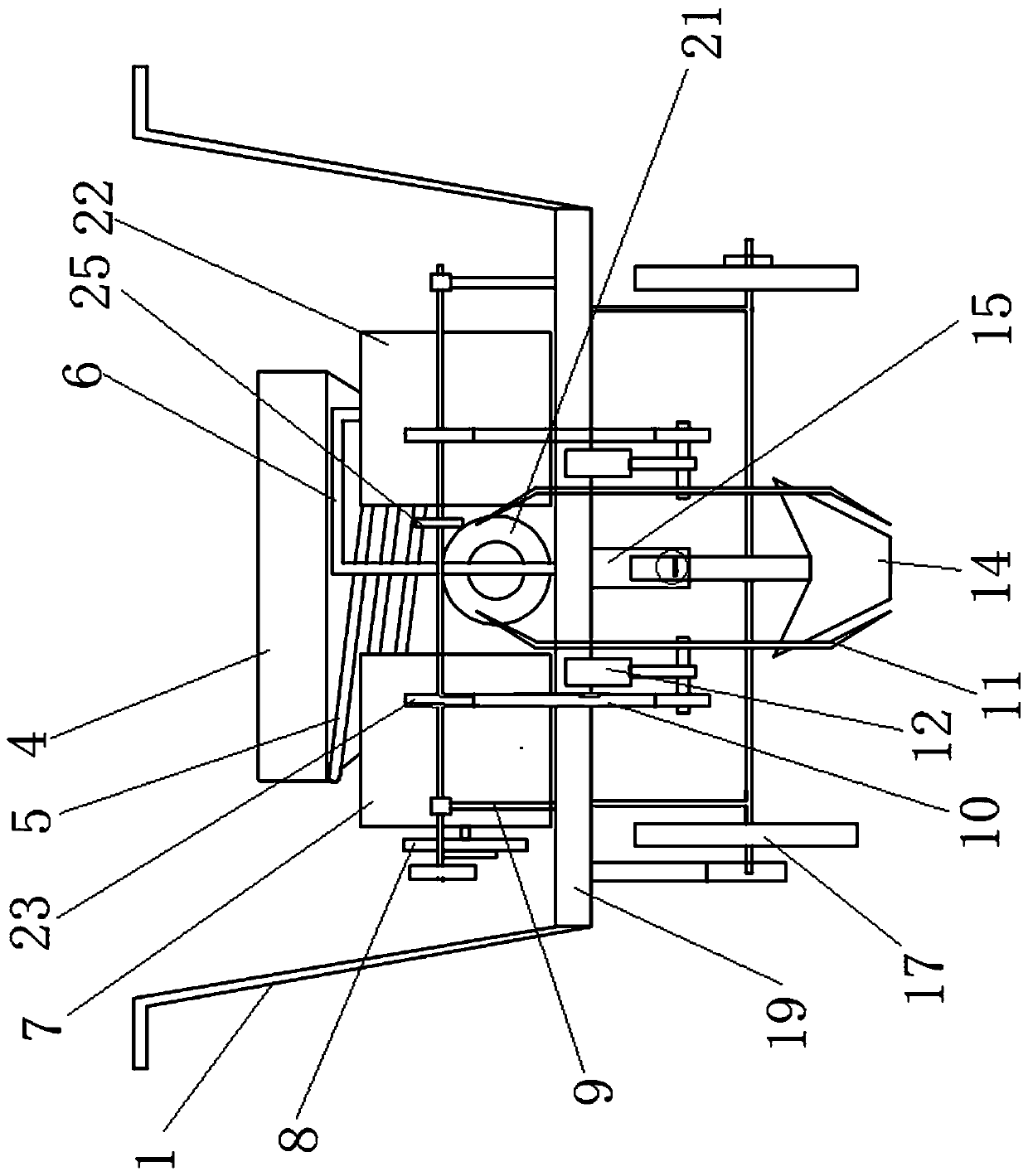

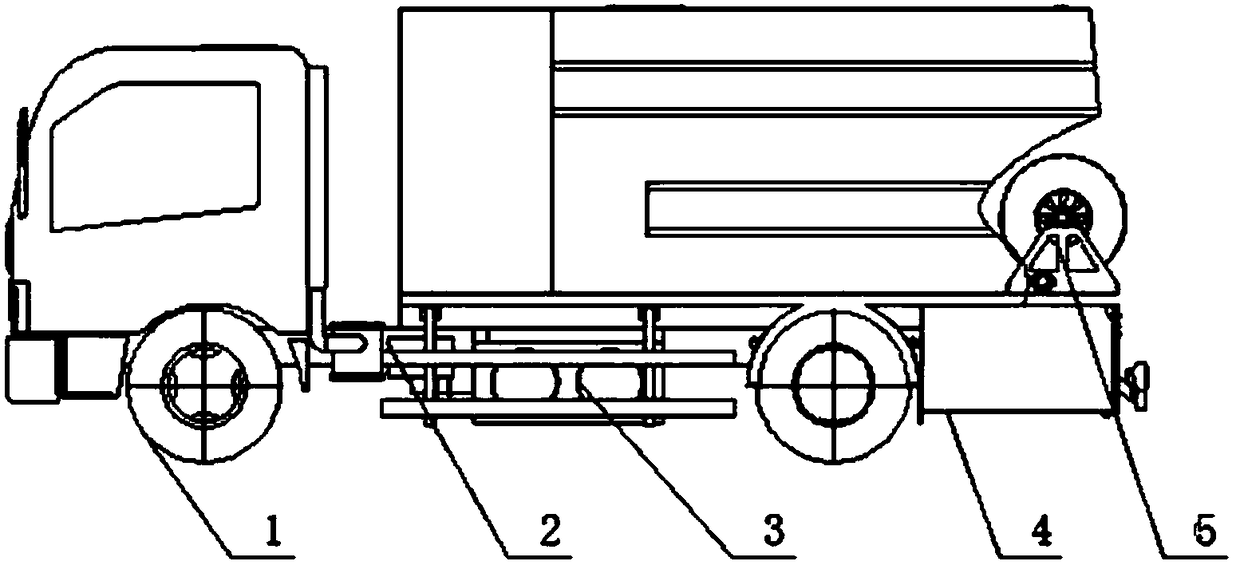

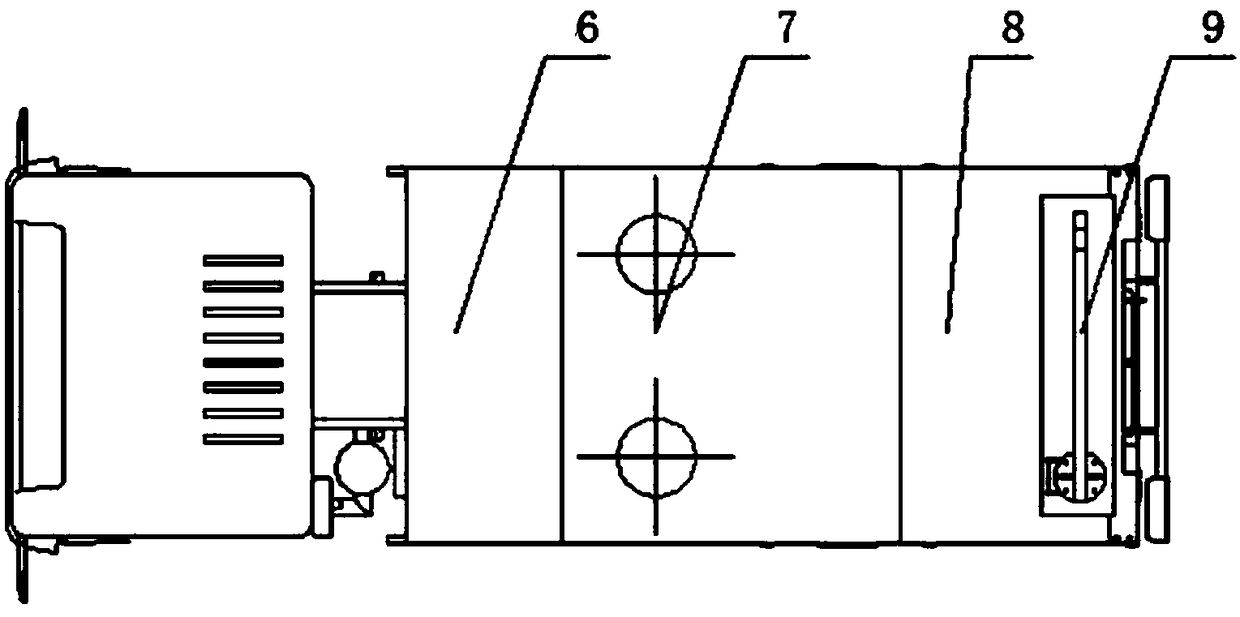

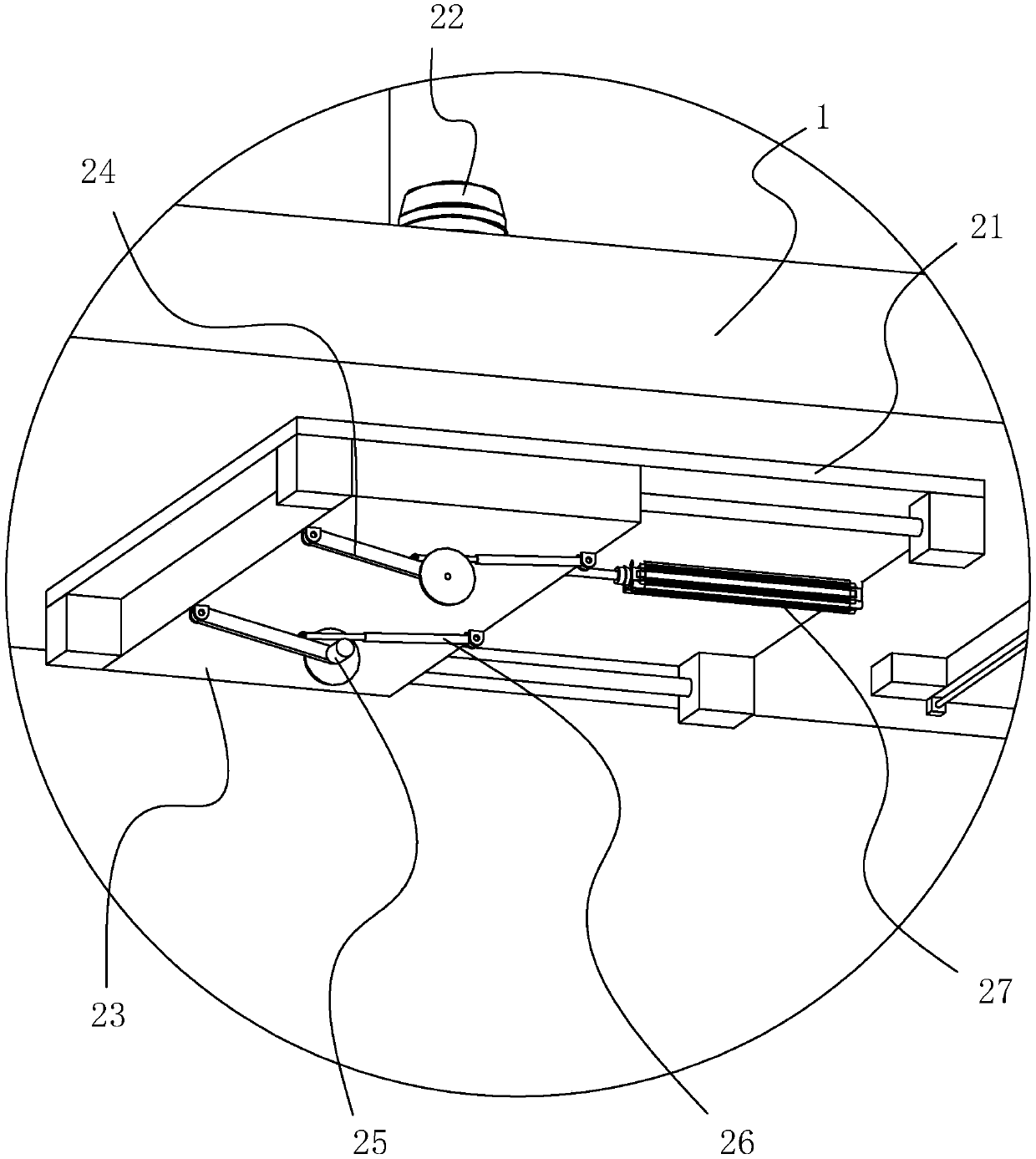

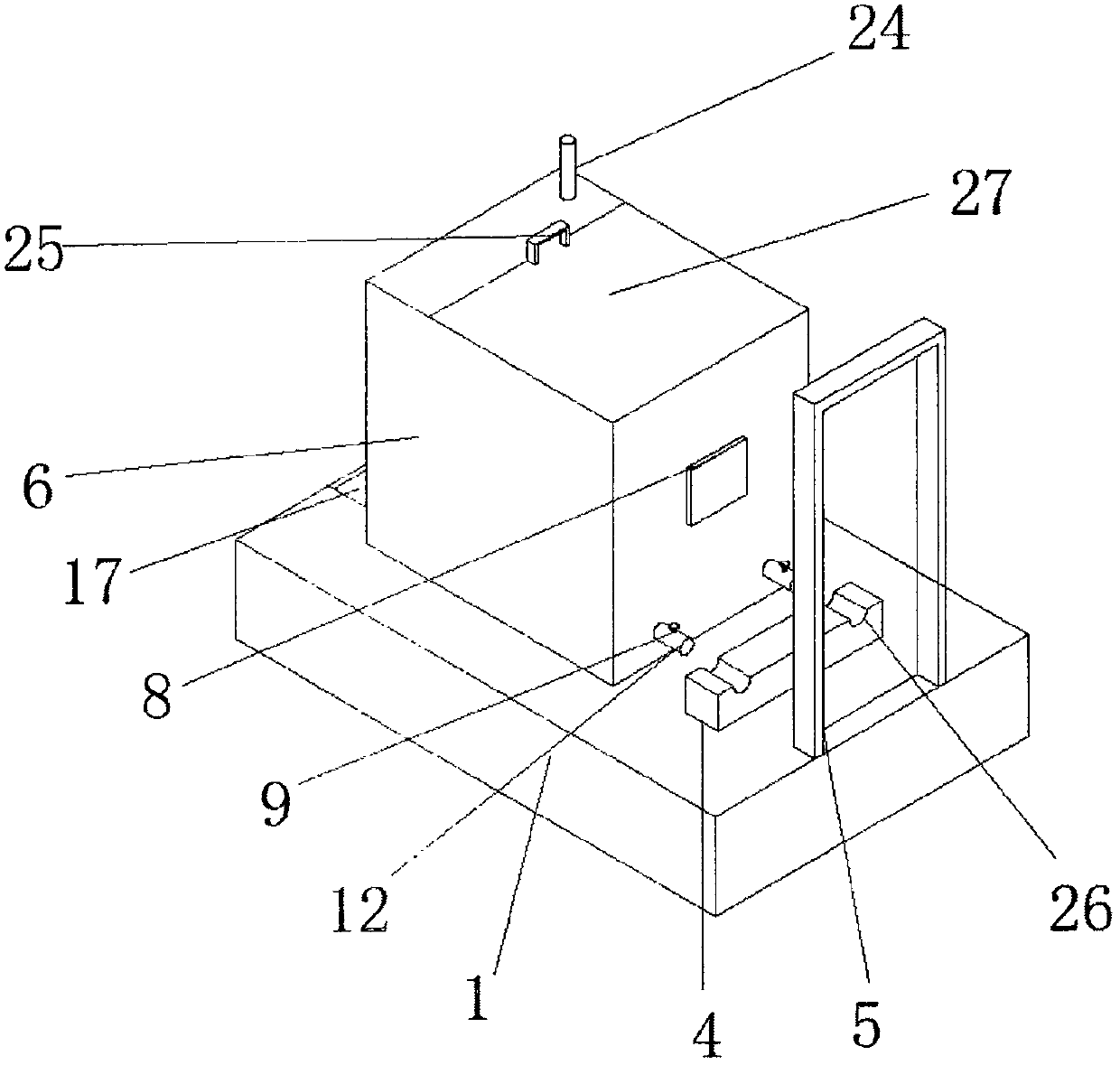

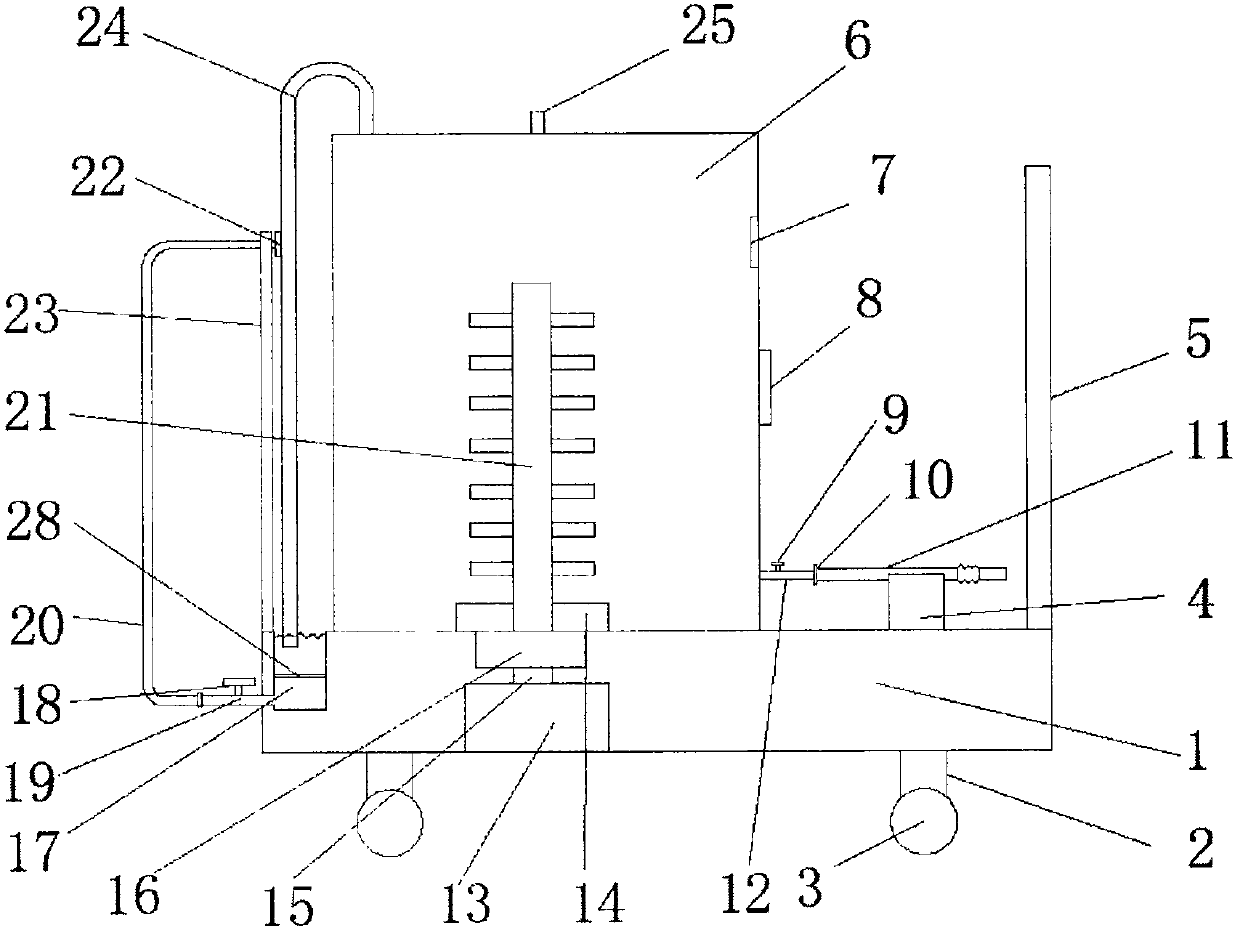

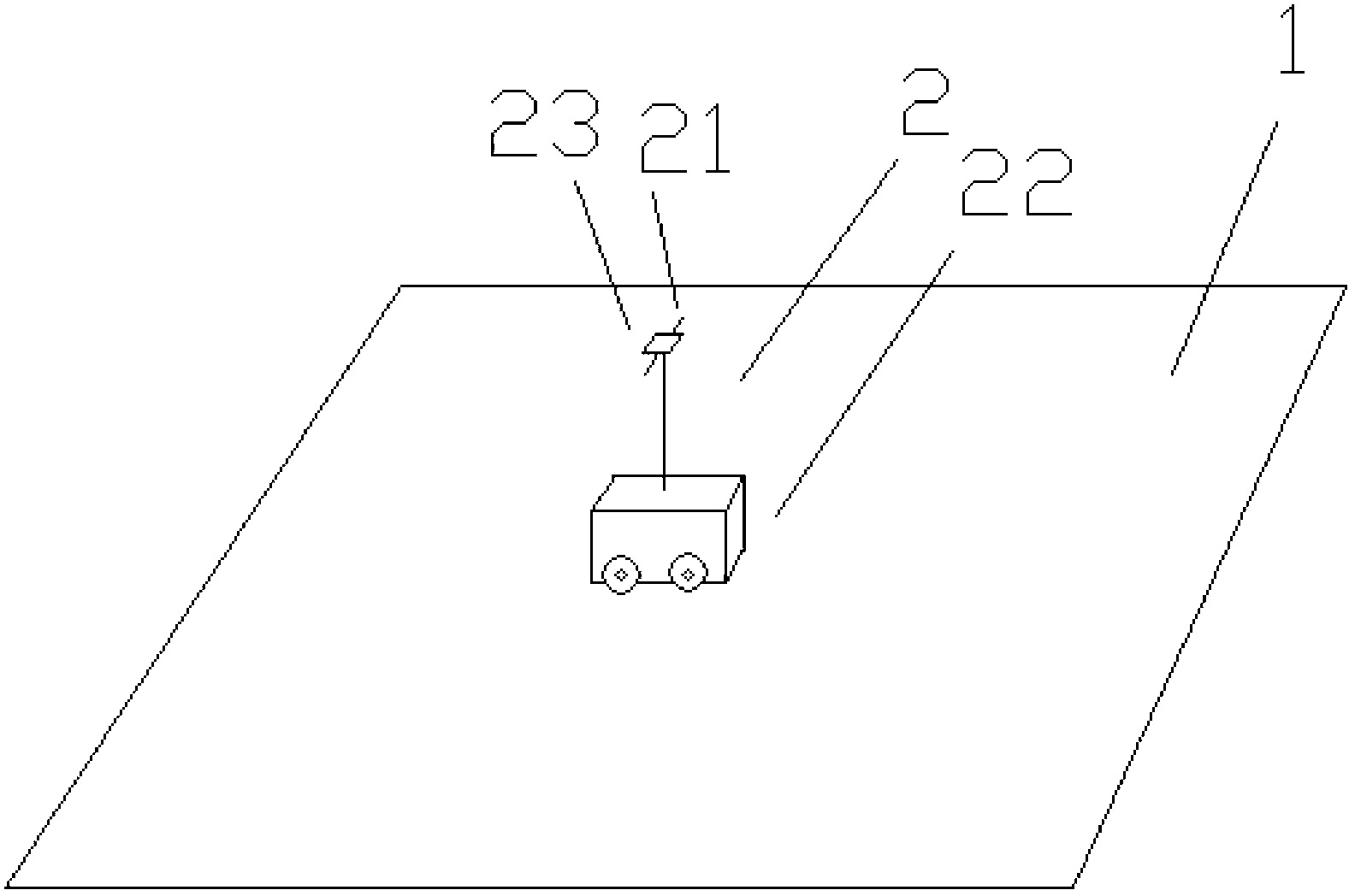

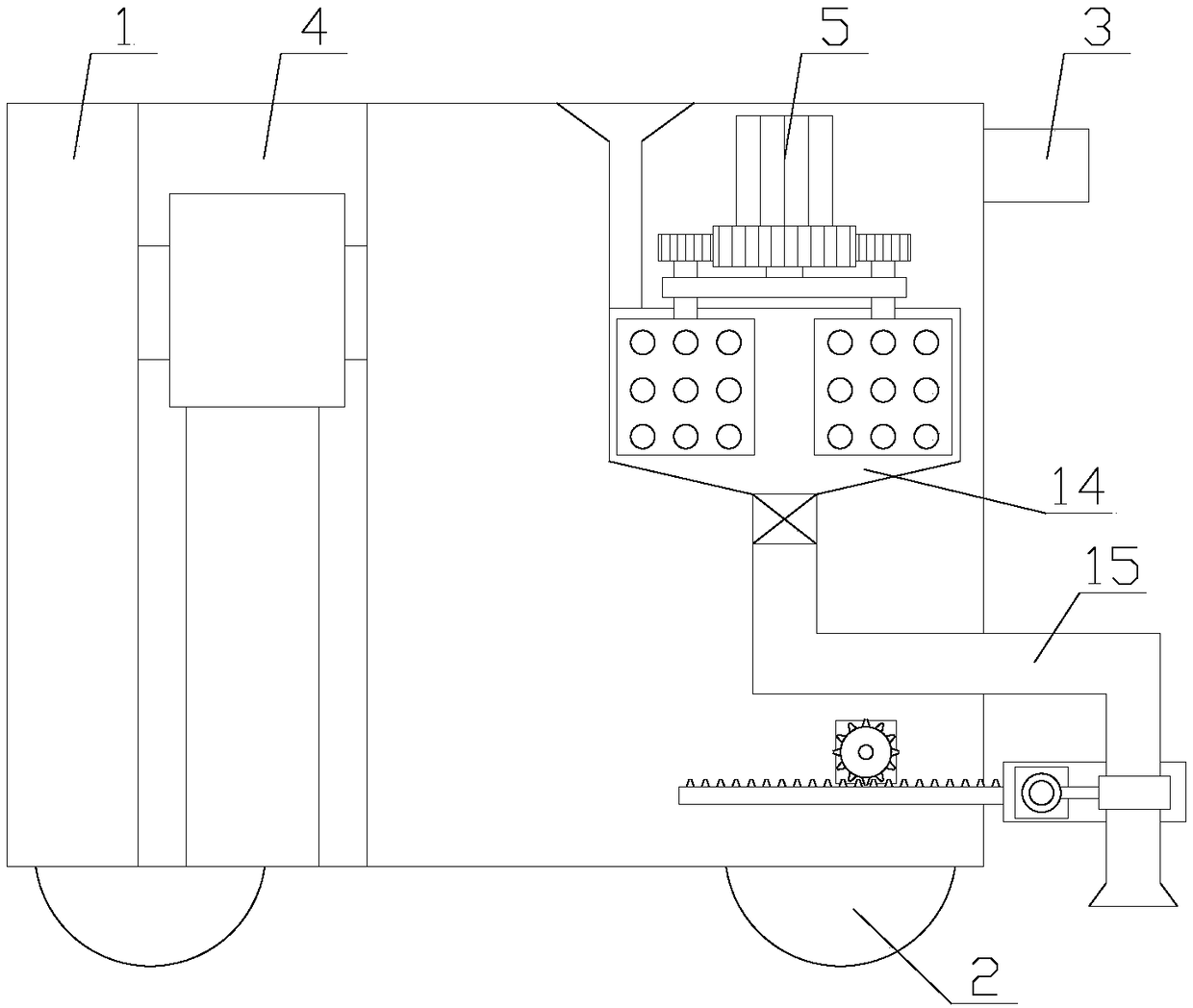

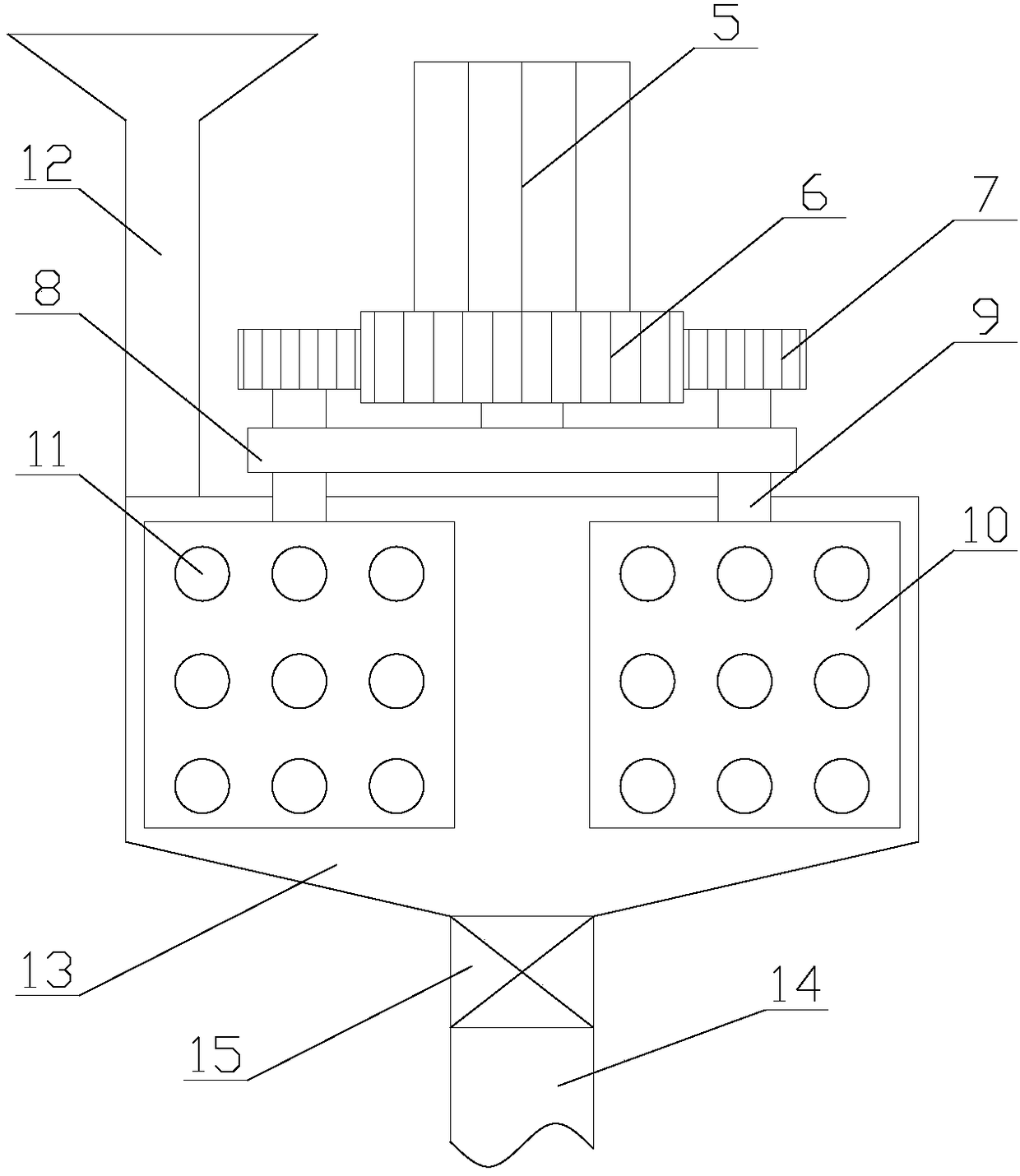

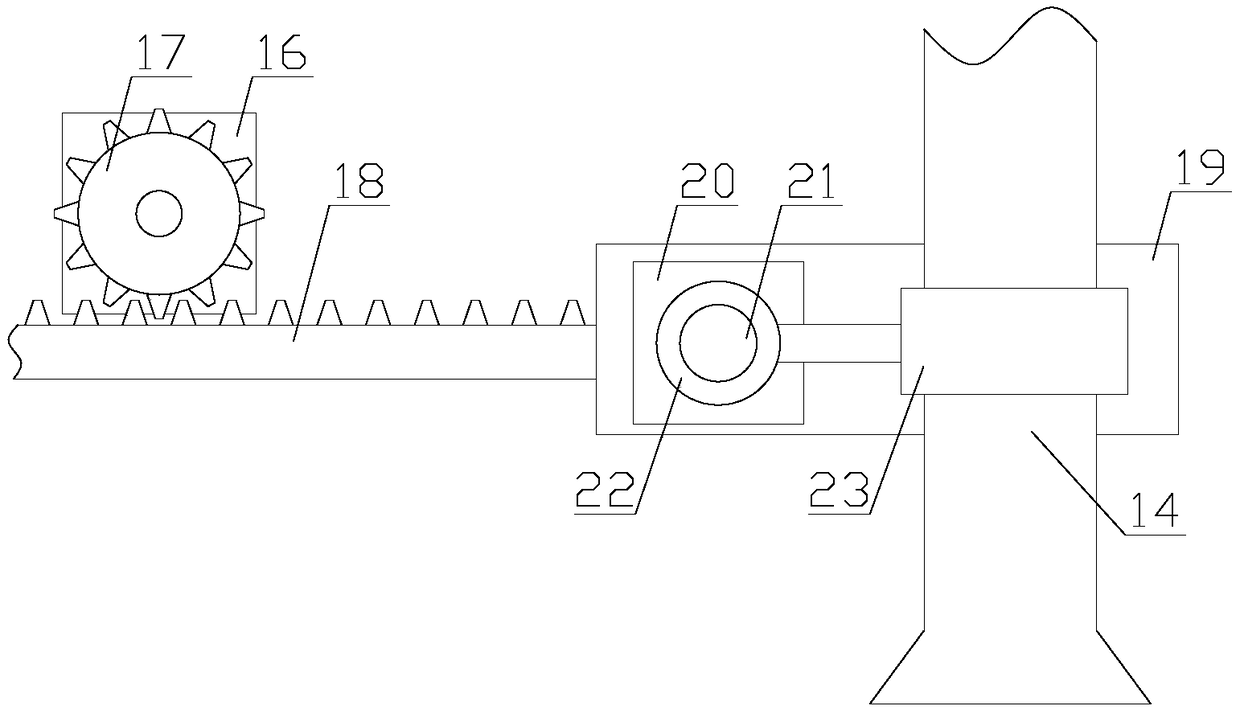

Pavement repairing device and technology

InactiveCN107841925AEasy to useFast patchingRoads maintainenceBuilding insulationsGasolineEngineering

The invention relates to a highway construction technology, and specifically relates to a pavement repairing device and technology. The problem in rapid repair of pavement cracks is solved; the pavement repairing device comprises a bearing platform 19, a gasoline engine 7, an asphalt repairing agent storage tank 4, an air compressor 22, a cleaning shovel 14 and a grooving device; according to thepavement repairing technology, the gasoline engine supplies power to drive the grooving device to cut open the pavement which is then cleaned; after that, a repairing agent in the asphalt repairing agent storage tank is poured into the groove to finish the work of pavement crack repairing. The scheme has the advantages of miniature equipment and convenience in use by road maintainers. Particularlyin remote mountainous areas, construction can be carried out by use of gasoline, and the repairing speed is high; the repaired cracks of different shapes are consistent in width, being neat and beautiful without protruding or sinking; moreover, the color of the repaired pavement is basically kept the same as old pavement.

Owner:蓝婷

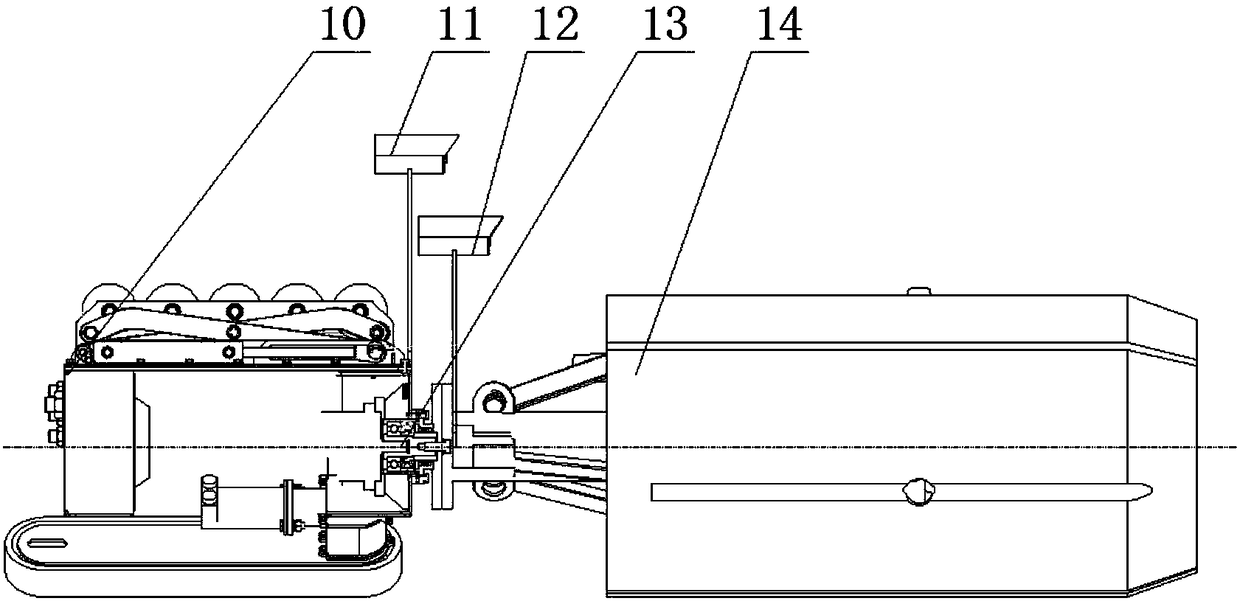

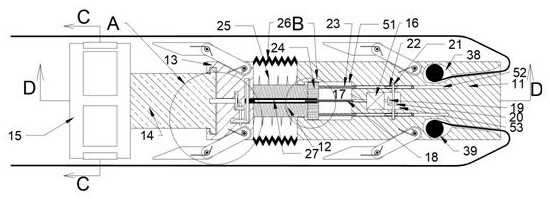

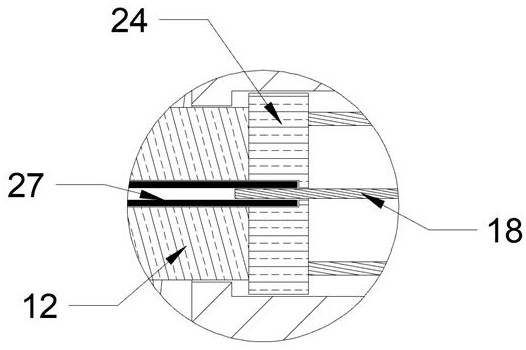

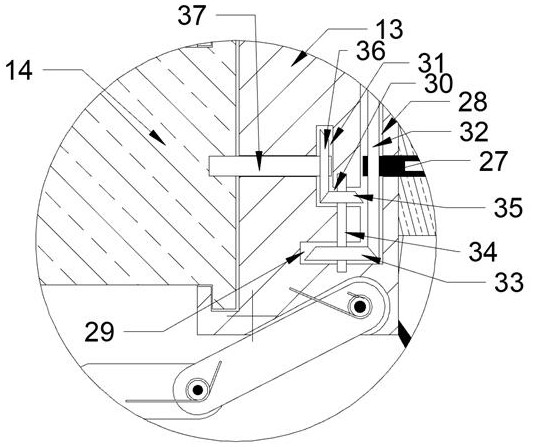

Sewer repairing trolley and sewer pipeline repairing method

InactiveCN108167571AEvenly filledFast patchingPipe elementsItem transportation vehiclesCement slurryEngineering

The invention relates to a sewer repairing trolley and a sewer pipeline repairing method. The sewer repairing trolley comprises a chassis and an auxiliary frame installed on the chassis, and further comprises a water tank, a cement slurry preparation system, a pipeline robot and a correcting machine, wherein the water tank and the cement slurry preparation system are installed on the auxiliary frame, and the pipeline robot and the correcting machine can stretch into a sewer; the correcting machine is connected with the pipeline robot, and can rotate and be expanded towards the outer side around a center shaft of the correcting machine; a pipe coiling machine is installed at the rear end of the auxiliary frame; and a power line pipe for controlling the pipeline robot and the correcting machine and used for controlling the pipeline robot to walk and perform grouting is wound on the pipe coiling machine. The sewer repairing trolley can be used for repairing a sewer pipeline, the sewer canbe repaired without the manners of surface exaction or the like, and the construction efficiency is improved.

Owner:CHANGSHA WEINUO ELECTROMECHANICAL

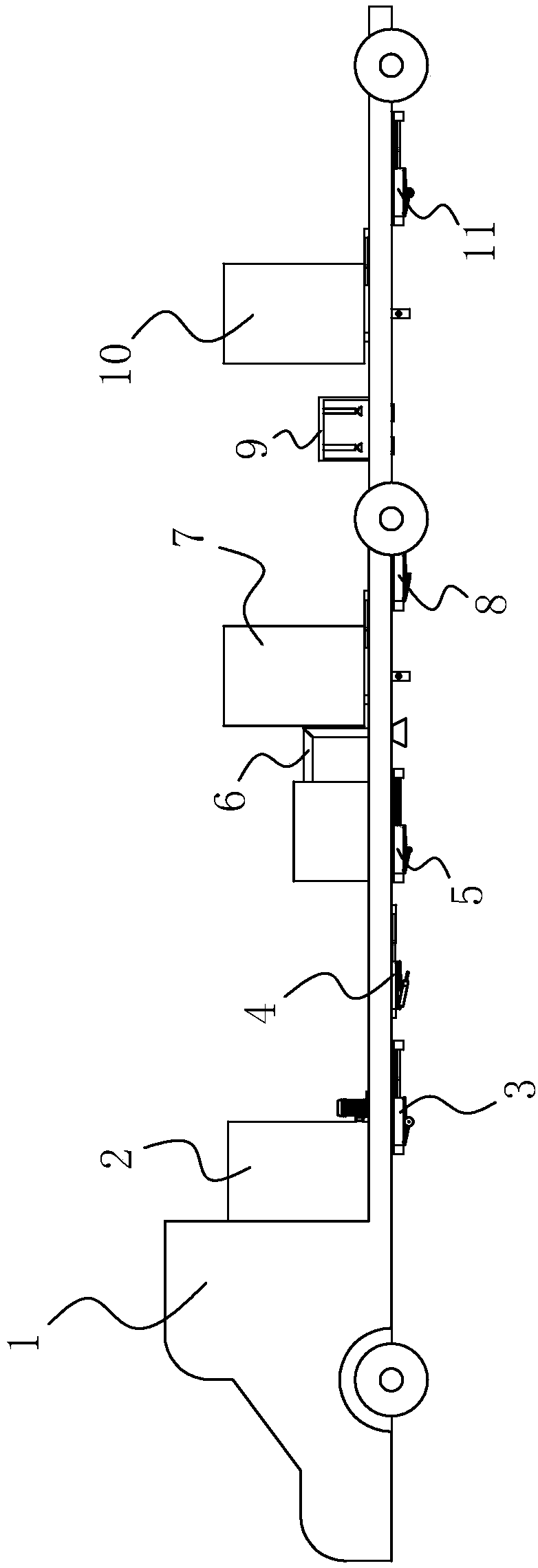

Asphalt pavement repairing device for municipal engineering

The invention discloses an asphalt pavement repairing device for municipal engineering and relates to the technical field of municipal road construction. The technical problem is solved that a large amount of manpower needs to participate in asphalt pavement repairing work. The asphalt pavement repairing device is technically characterized by comprising a vehicle body and further comprising a pavement cutting assembly, a pavement crusher assembly, a cleaning roller assembly, a dust removing assembly, a primary paving assembly, a hot-melting plate assembly, a plate layout assembly, a secondarypaving assembly and a hot press roll assembly sequentially arranged in the length direction of the vehicle body, wherein a power assembly for providing power for each of working assemblies is also arranged in the vehicle body. The asphalt pavement repairing device has the advantage of automatically completing asphalt pavement repair.

Owner:温州广德建设有限公司

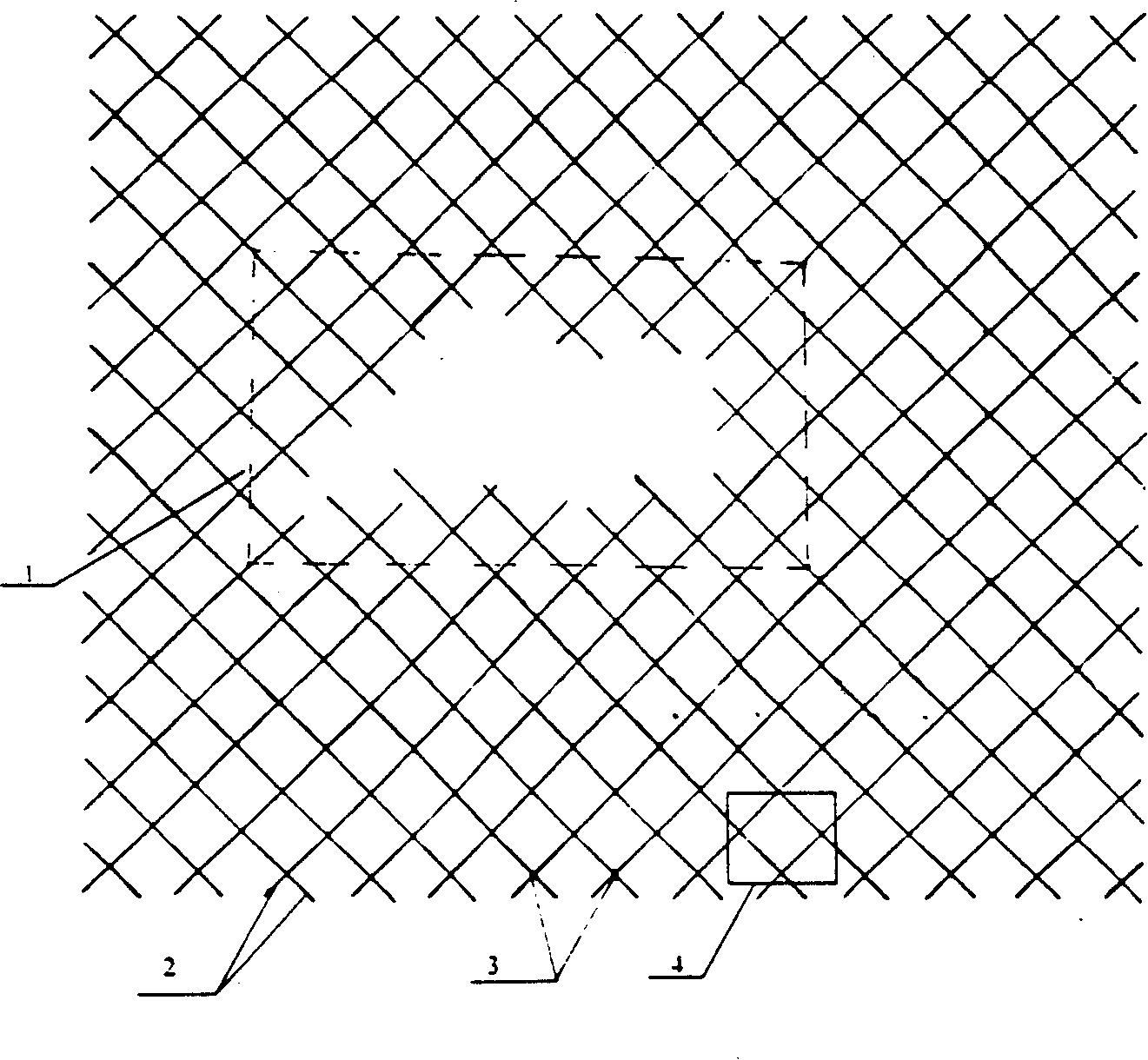

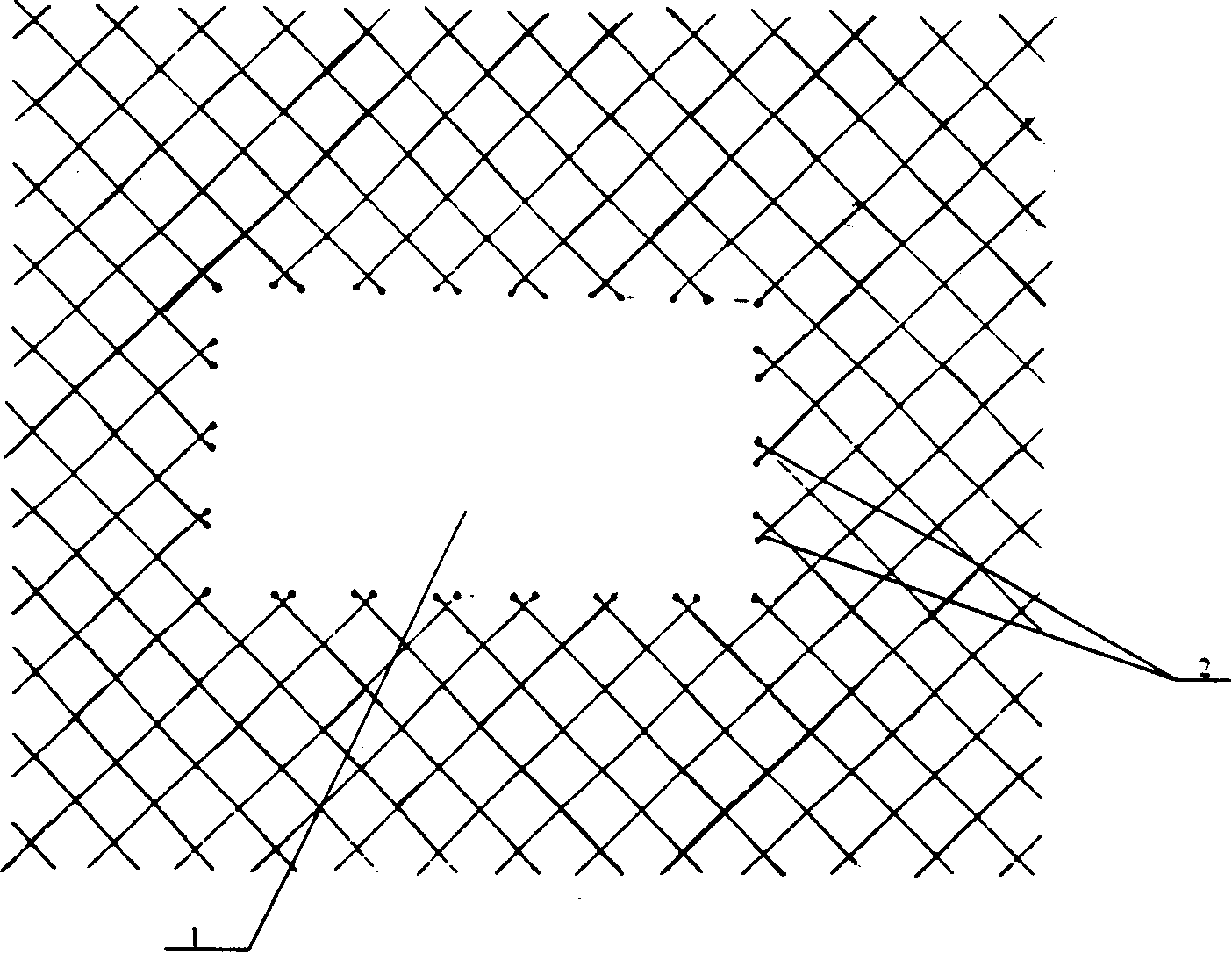

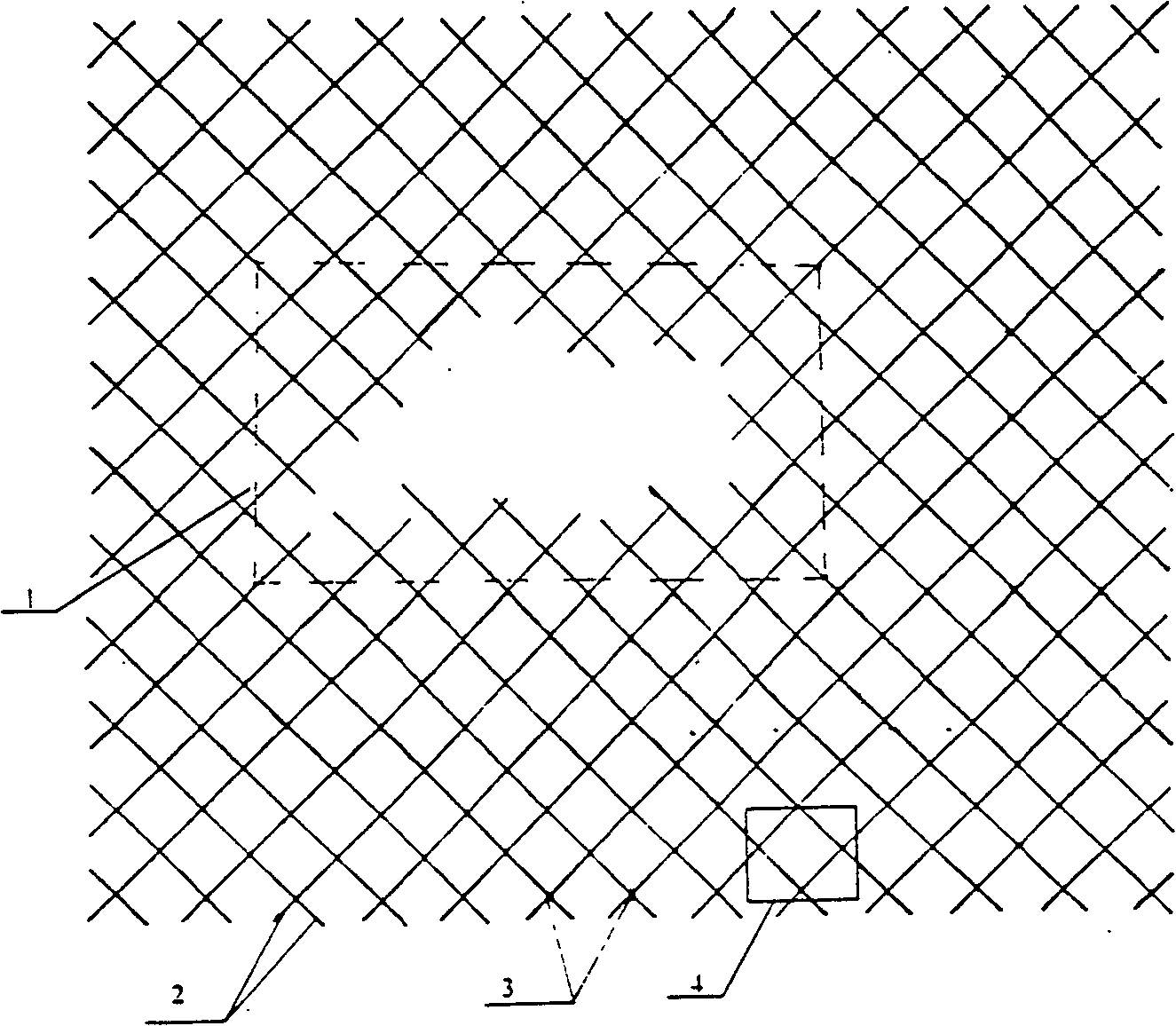

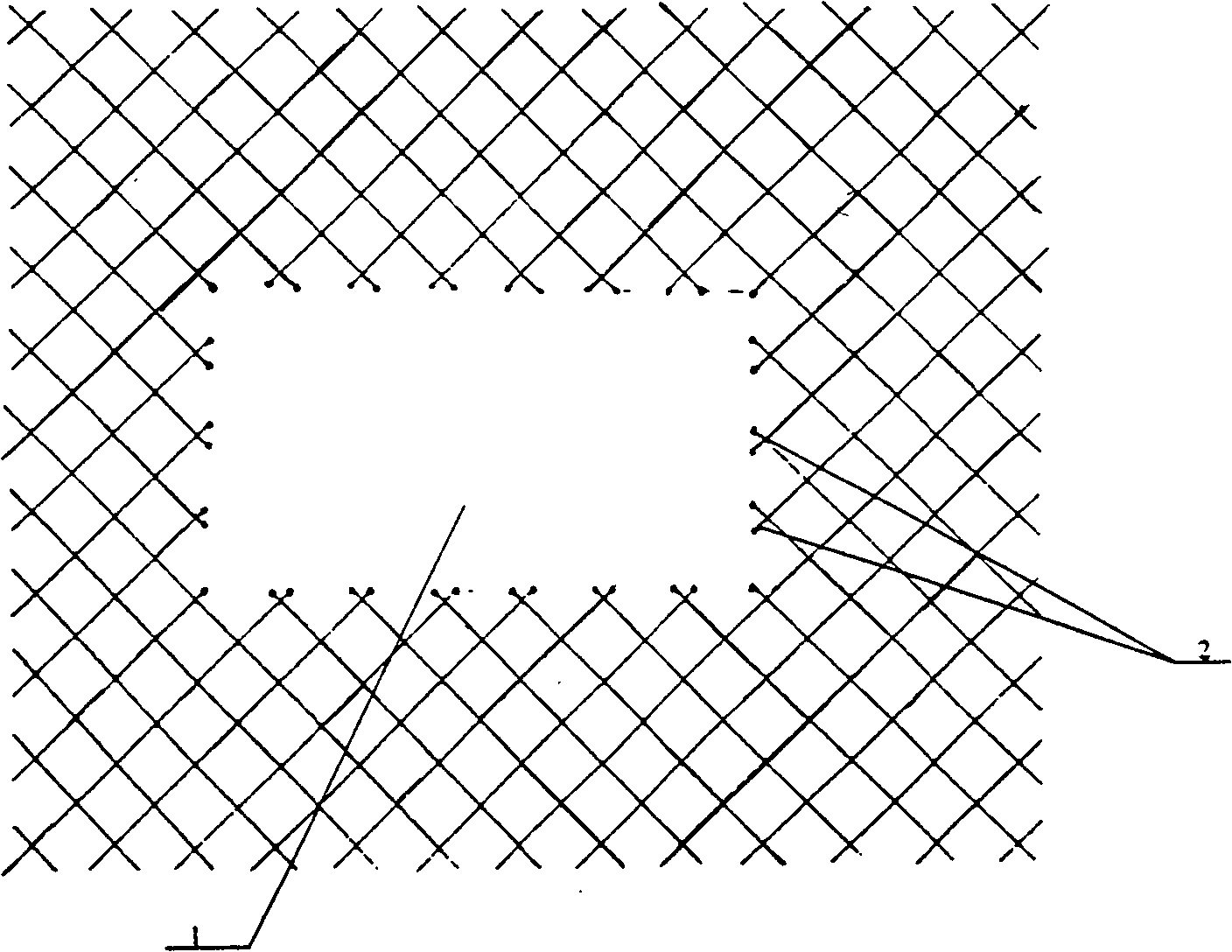

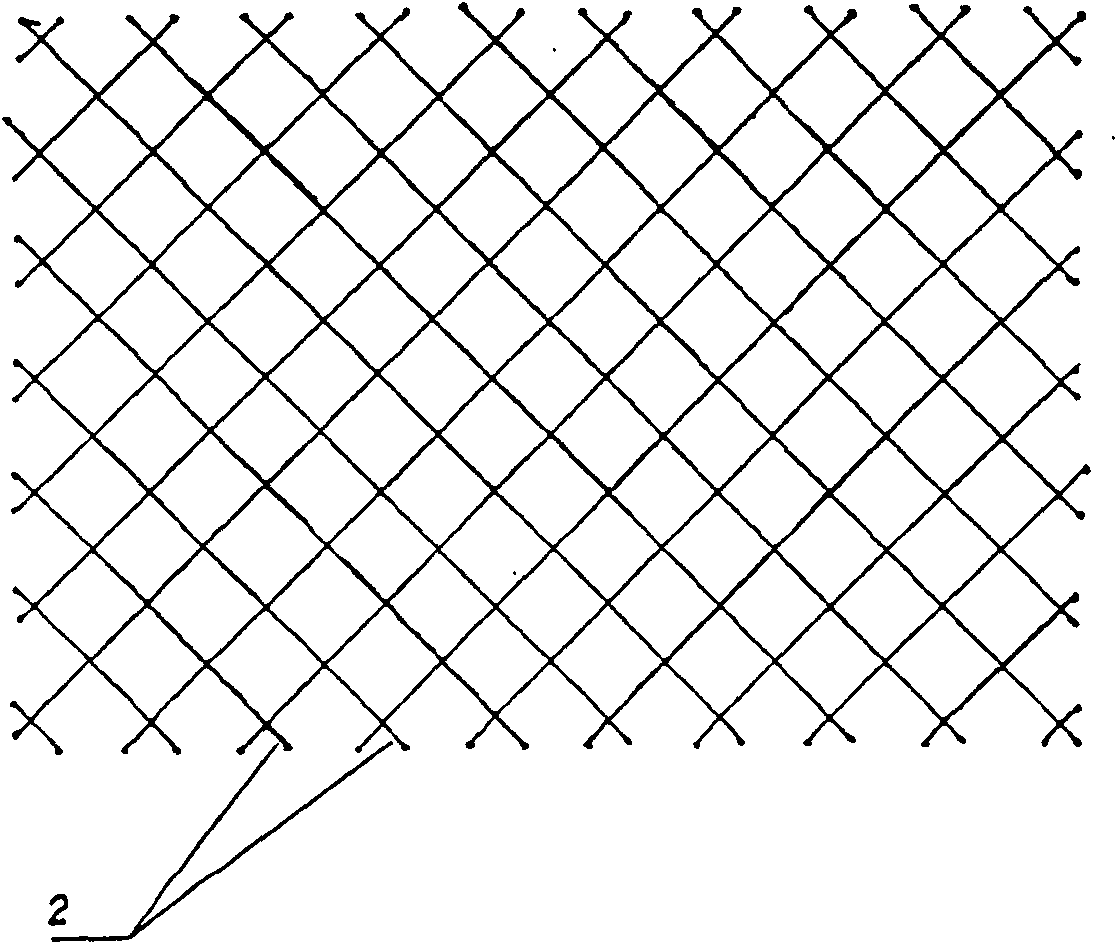

Fishing diamond-type screen tricot knitting net sheet repairing method

A repairing method of a fishery raschel netting with diamond meshes relates to the repairing of fishery raschel netting and provides a repairing method of fishery raschel netting with diamond meshes. The technical proposal of the invention comprises netting clipping and suturing. The invention is characterized in that a hole of a raschel netting with diamond meshes is tailored into a rectangular and the bar end of the clipping boundary of the hole adopts a melting treatment; a piece of netting which is tailored into a rectangular with the latitudinal and longitudinal mesh number at least two more respectively than that of the rectangular hole and with the same specification is selected and the bar end of the clipping boundary of the rectangular netting adopts the melting treatment; a nylon fishing net line or a polyethylene net line with the same diameter as that of the bar end of the repairing netting is taken as a suture; the rectangular netting used for repairing is piled up at the position of the rectangular hole and the meshes of the repairing netting which outnumber the rectangular hole along the latitudinal and longitudinal direction on number are aligned with the meshes around the hole; the suture is rooted at a mesh connecting place which is three meshes away from the hole and is used for equal mesh suturing; and a net knot used for repairing the netting adopts a double dead knot. The method is suitable for the repairing of the fishery raschel netting with diamond meshes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Asphalt pavement repairing device for municipal engineering

InactiveCN107761531AEvenly heatedControl flow rateRoad cleaningRoads maintainenceDisplay deviceRoad surface

The invention discloses an asphalt pavement repairing device for municipal engineering. The asphalt pavement repairing device comprises a base, an asphalt tank, a support frame, a water groove, a support rod and a push rod, wherein the support legs are fixedly connected to four corners of the bottom of the base; the water tank is formed at a left-upper end of the base; a heating sheet is arrangedat an bottom end in the asphalt tank; a stirrer is rotationally arranged on the heating sheet; a temperature sensor is arranged on a right side wall of the asphalt tank; a right side surface of the asphalt tank is provided with a discharging pipe; a display is arranged on a side surface of the asphalt tank above an upper end of the discharging pipe; the support frame is arranged at a position on the right side of the asphalt tank on the base; a push rod is arranged on a right side of the support frame; a stirring motor is arranged in the base; a rotary shaft is arranged at an upper end of thestirring motor; the rotary shaft is rotationally connected with a rotary disk; the rotary disk is rotationally connected with a stirrer. The asphalt pavement repairing device for the municipal engineering is convenient to control, is fast in repairing, is lowered in environment pollution, is convenient to move, and can be widely applied and popularized.

Owner:WENZHOU XINGGONG CONSTR CO LTD

Fast hardening early strength concrete for overall width repair of cement concrete pavement

The invention relates to a fast hardening early strength concrete for overall width repair of a cement concrete pavement. The fast hardening early strength concrete is prepared from the following raw materials in parts by weight: 450-480 parts of cement, 620-660 parts of medium sand, 1120-1140 parts of macadam, 140-160 parts of water and 4-6 parts of additive. The fast hardening early strength concrete has the beneficial effects that (1) the fact repair material for the cement concrete pavement, provided by the invention, has the characteristics of high early strength, high overall width repair speed for the damaged cement concrete pavement, capability of realizing clear road within 24h, convenience for realizing favorable traffic conditions, good working performance and the like; and (2) the cement, the medium sand, the macadam and the additive adopted by the invention are all common base materials on the market, and special materials which have a fast hardening early strength effect, but are high in cost and are not widely applied are not adopted, so that the fast hardening early strength concrete can be favorably popularized and applied in a large scale, and the maintenance and repair cost is reduced.

Owner:CCCC HIGHWAY MAINTENANCE ENG TECH

Roof water leakage detecting system

InactiveCN103175665ARepair marks are smallFast patchingAnalysing solids using sonic/ultrasonic/infrasonic wavesFluid-tightness measurement using electric meansWater leakageReliability engineering

The invention relates to the field of detection, in particular to the field of fault localization. A roof water leakage detecting system comprises a fault localizing system and a working support, wherein the fault localizing system comprises a fault localizing equipment terminal and a fault localizing probe connected with the fault localizing equipment terminal, a handle used for being held is arranged above the working support, a fault localizer is arranged below the working support, and the fault localizing probe is arranged in the fault localizer. On a roof, especially on an outdoor roof, the handle is held by hands, the working support is pushed to move, so that the fault localizing probe is driven to move, cracks on the roof or in the roof can be detected, and a prompt is provided when the cracks are detected.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Automotive windscreen repairing process

InactiveCN109748519ASimple repairLow costLamination ancillary operationsLaminationHigh concentrationEngineering

The invention discloses an automotive windscreen repairing process which is characterized by particularly including the steps: inspecting a damaged position, clearly wiping a windscreen, cleaning scraps at cracks, and dressing and smoothing the cracks by a grinding tool; installing a repair device on the windscreen, adjusting a sealing device, pumping out air at the damaged position; injecting liquid repairing agents at the damaged position, fully filling the damaged position with the repairing agents, irradiating the damaged position by an ultraviolet lamp, and pumping out redundant air at the damaged position by a vacuum syringe again; injecting repairing agents with high concentration in a pressure cylinder of a sealing robot, injecting the liquid repairing agents with the high concentration at the damaged position, repairing a pit in the damaged position, and baking the damaged position by the ultraviolet lamp; scraping off projecting solid glue on the surface of the damaged position by a blade, grinding and polishing a windscreen, and covering the windscreen with a film. By the aid of the technical scheme, a repairing process is simple and rapid, cost is low, replacement of awhole front windscreen is omitted, cost is saved, and prototype repairing success rate is high.

Owner:重庆维车慧科技服务有限公司

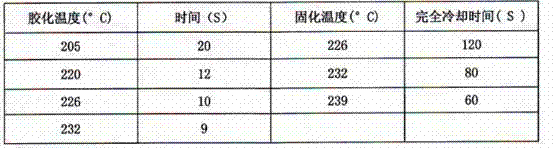

Printing missing word repairing method

The invention relates to a printing missing word repairing method. The printing missing word repairing method comprises the following steps of: (A) preparing a printing plate of words to be repaired, moving out a word missing part of a book, typesetting the word missing part and reserving an appropriate space convenient for operation in the future repairing; (B) making a repairing printing film according to four layers of a transparent film base material, a mold release agent, transfer printing ink and hot melt adhesive in sequence and printing the words needed to be transferred onto the transparent film by using a screen printing method; (C) making a transfer printing iron board according to the range of the repaired words; (D) heating a heating body to 180-200 DEG C and placing the transfer printing iron board on the heating body for 10-20 minutes; (E) placing the machined transfer printing film at a part needed to be repaired, aligning positions of the transfer printing film and the part needed to be repaired, impressing the heated transfer printing iron board onto the words needed to be thermoprinted, and moving out the transfer printing iron board after heated for 2-3 seconds; and (F) cooling the transfer printing film for 10-15 seconds and rapidly uncovering the thermoprinting film with heavy force. The method provided by the invention has the advantages of simplicity and convenience for operation, cost reduction, high repairing speed and the like.

Owner:南京爱德印刷有限公司

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be opened in 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

A baking-free repairing material

The invention provides a baking-free repairing material, particularly a repairing material used for rapid repairing of various kilns in the chemical industry. Bauxitic rock and corundum are adopted as main raw materials. A binder that is aluminum dihydrogen phosphate, a coagulant that is calcium aluminate cement, an agglutinant that is alumina micropowder and a quick-drying agent that is metal aluminum powder are added and mixed with the main raw materials to obtain the repairing material. The repairing material includes, by weight, 61-75 parts of the bauxitic rock and the corundum, 12-15 parts of the binder, 2 parts of the coagulant, 5-10 parts of the agglutinant and 1 part of the quick-drying agent. The repairing speed of the repairing material is high. A structure after being repaired by using the repairing material is solid. Service lifetime is long. The repairing material can be used without kiln shutdown, and does not need baking after repairing, thus greatly shortening the maintenance time of kilns and effectively improving kin strength. The repairing material is an optimal material for repairing kilns.

Owner:河南郑耐新材料有限公司

Anti-leak agent for metal container

InactiveCN1566242ASimple compositionLow costOther chemical processesPolyester coatingsFilling materialsWhite powder

The invention relates to a modified anti-leak agent for metal container which comprises (by weigh percent) alkide resin paint 20-80%, Griffth's white powder 20-80%, and filling material 0-60%.

Owner:王振伟

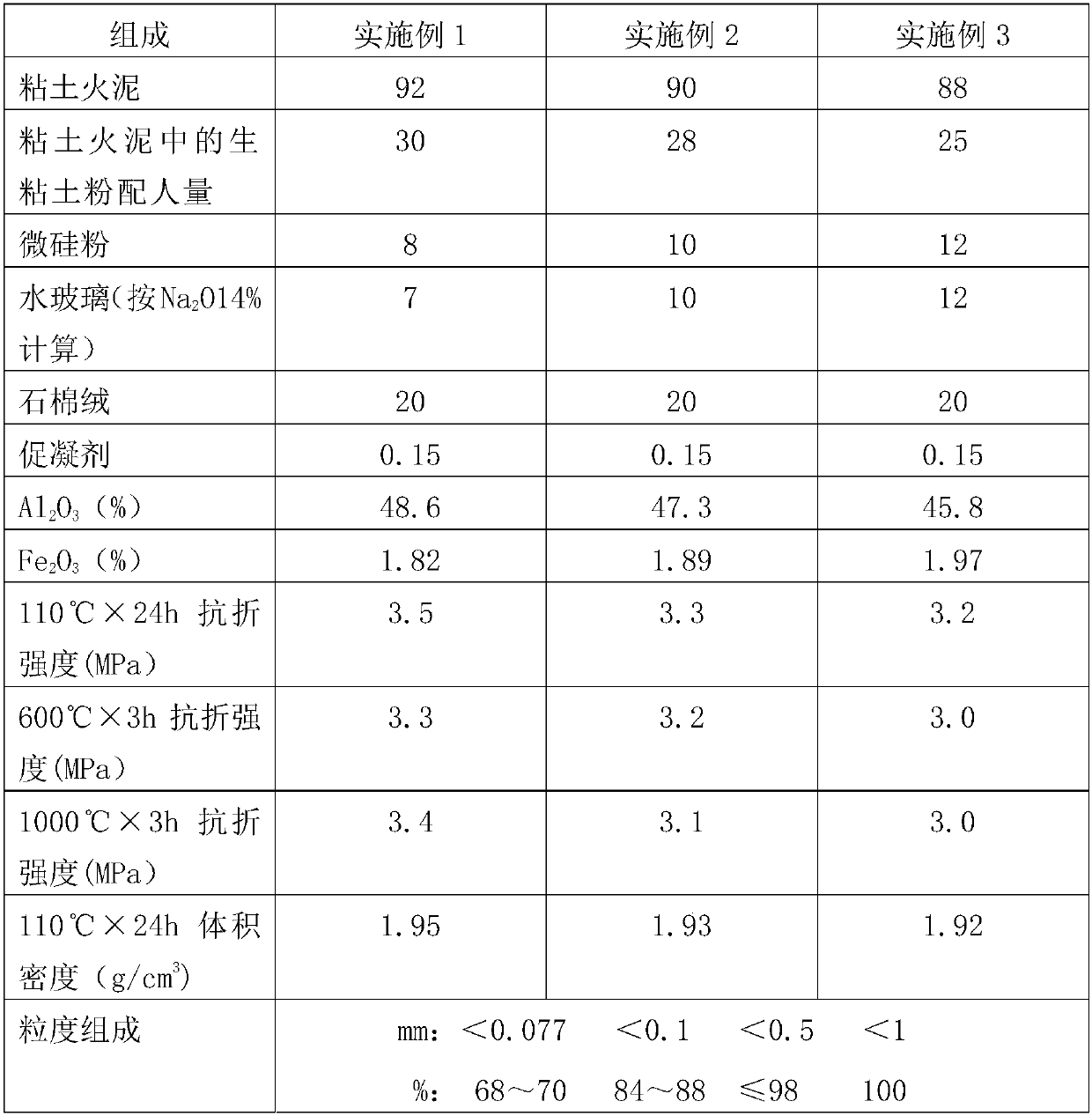

Coke oven door smoke sealing material and sealing method thereof

InactiveCN107674689AImprove adhesionSimple structureCoke oven doors/closuresSurface layerCarbonization

The invention discloses a coke oven door smoke sealing material. The material contains main materials and additive materials, wherein the main materials comprise the following components in percentageby weight: 88%-92% of clay fireclay and 8%-12% of micro silicon powder; the additive materials comprise the following components based on the total weight of the main materials: 7%-12% of water glass, 15%-25% of asbestos wool and 0.1%-0.2% of a coagulant. A sealing method comprises the following steps: after a carbonization chamber of the oven door leakage number is filled with coal and a coal filling pore cover, a bridge tube turning plate and ammonia water pressure are restored to the normal production state, floating ash and impurities at positions of the fire door knife edge and a fire door frame gap are removed firstly, then the prepared sealing material is pressed into the gap by a flat jointing shovel for jointing, after the surface layer is full, the surface of the sealing material is flattened and scraped flat by a shovel, and the sealing material is smoothly connected with the knife edge and an oven door frame joint. The sealing material is reliable in sealing.

Owner:MAANSHAN IRON & STEEL CO LTD

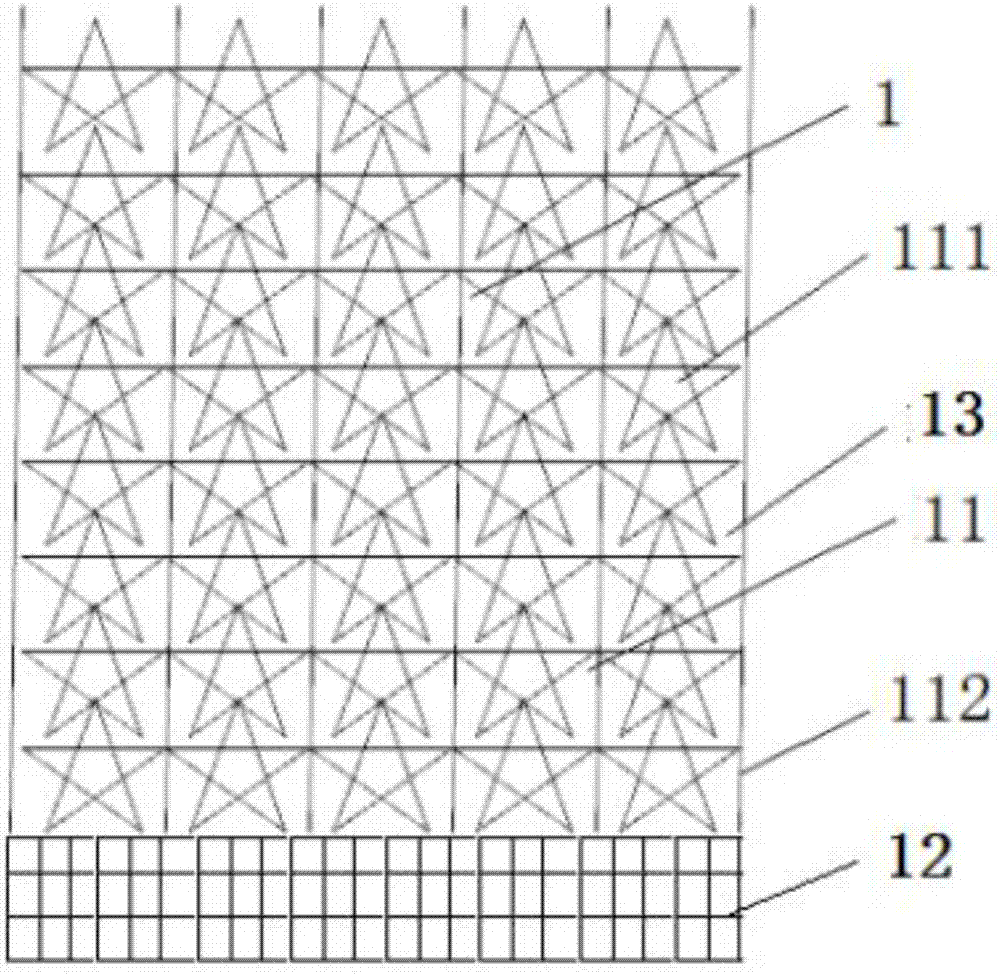

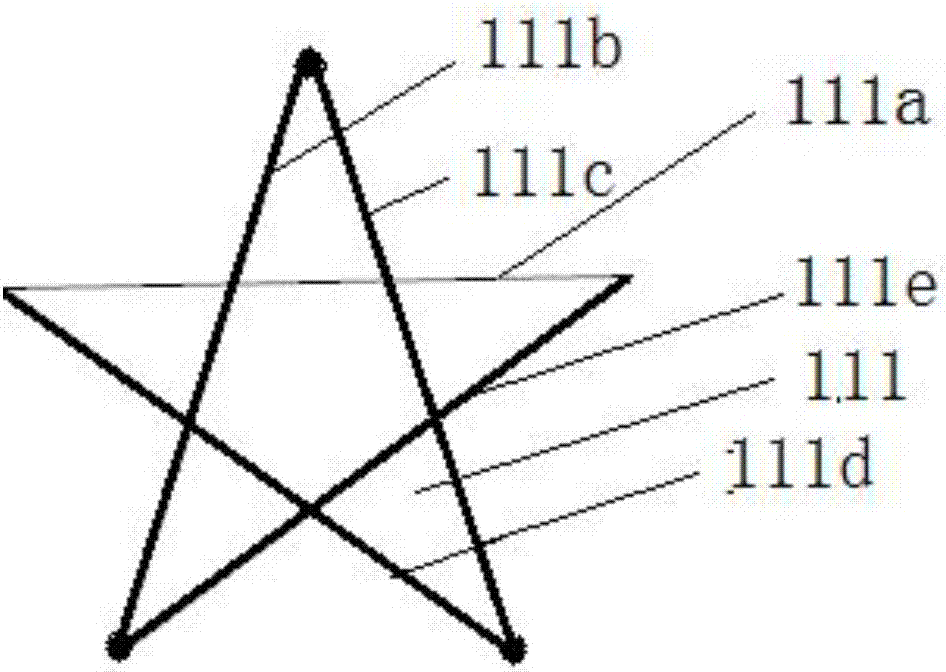

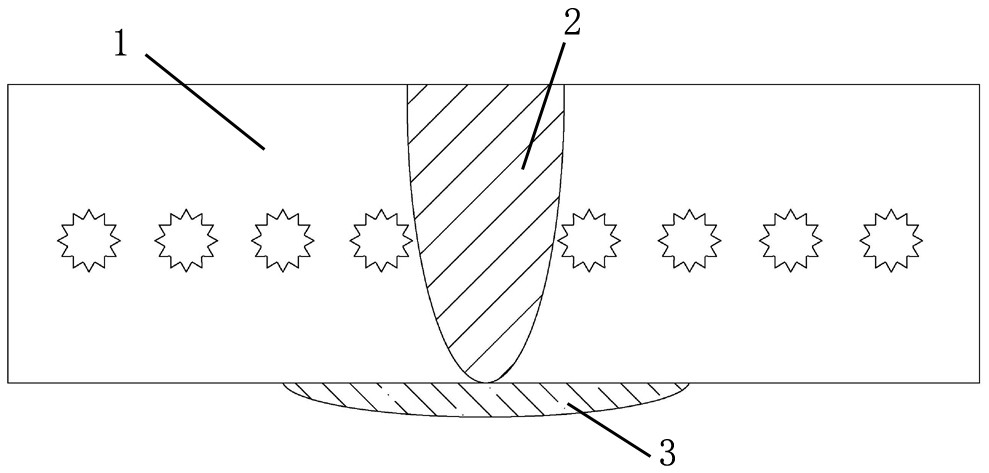

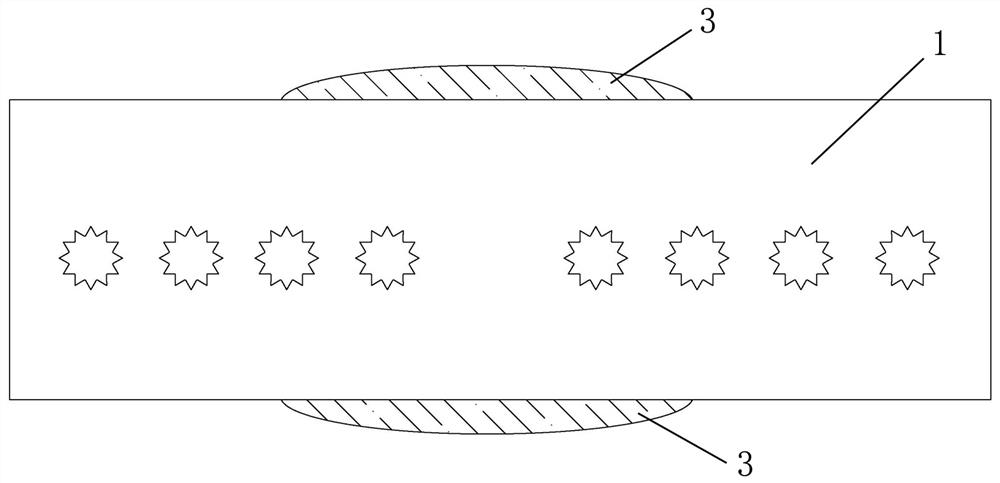

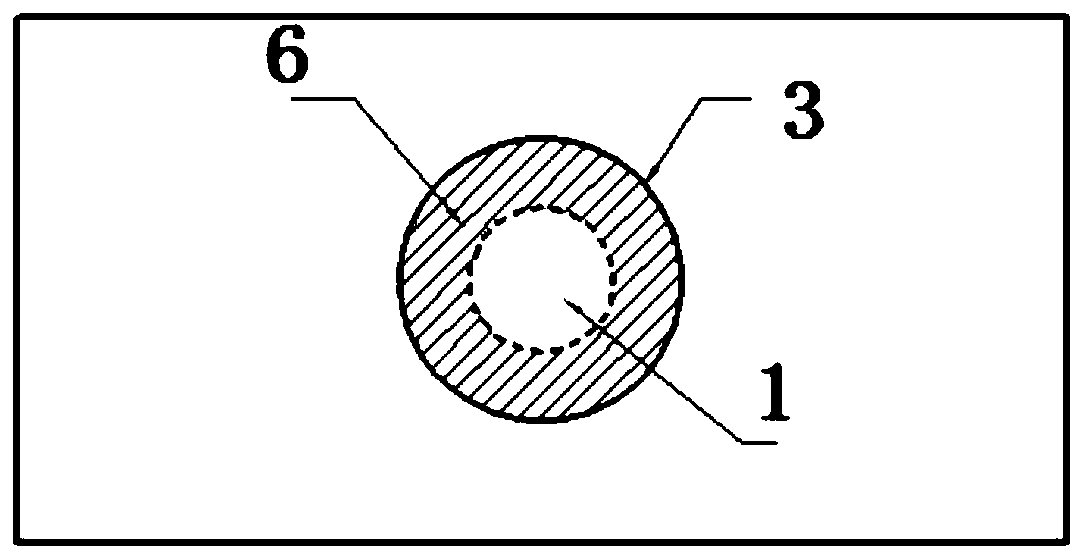

Aortic dissection stent containing chip and monitoring system of aortic dissection stent

The invention discloses an aortic dissection stent containing a chip and a monitoring system of the aortic dissection stent; the aortic dissection stent comprises a stent body, the chip and a covering film; the stent body is composed of a plurality of single stents and a plurality of connection segments; each single stent is of 'star' structure composed of a main segment and four repair segments, and the main segment and the connection segments are connected at 90 degrees; the chip is fixedly mounted at the lower end of the stent body; the covering film covers the stent and the chip and is integrated to the four repair segments. The aortic dissection stent of the invention is a novel medical biomaterial, capable of better improving the repair function of aortic dissection at low recurrence rate, and the dissolved chip in the dissection enables restoration of the aortic dissection to be monitored.

Owner:张天华

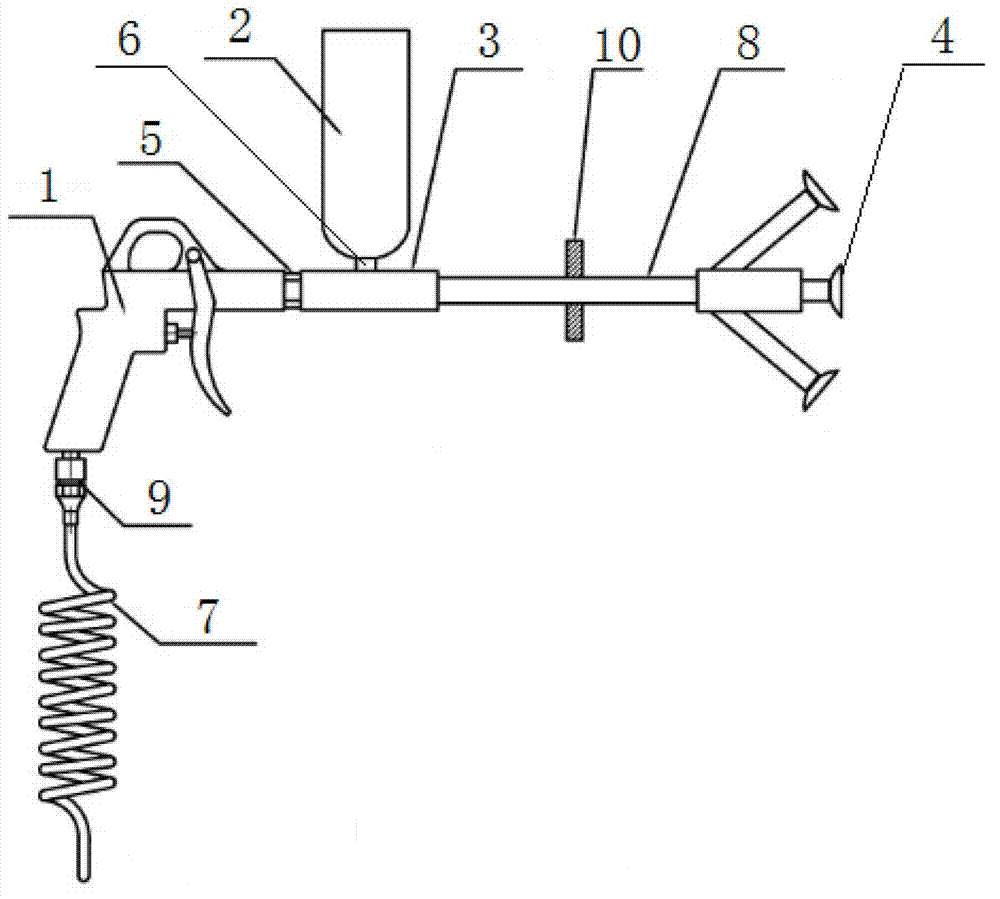

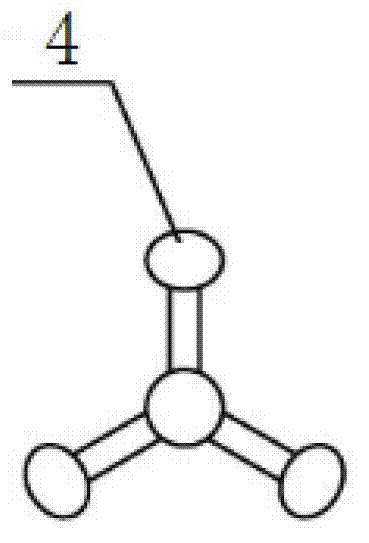

Powder interior repairing machine and repairing method thereof

The invention discloses a powder interior repairing machine which comprises a spray gun, a powder storage tank, a powder pump and a nozzle assembly, wherein the muzzle of the spray gun is communicated with a gas inlet of the powder pump through a straight joint, the powder storage tank is communicated with a powder inlet of the powder pump through a powder outlet pipe, the spray gun is connected with a gas source through a flexible pipe, and a powder outlet of the powder pump is connected with the nozzle assembly through a telescoping tube. The powder interior repairing machine provided by the invention has a simple structure and is convenient to use; with the design of the telescoping tube, the powder interior repairing machine can realize repairing at different crator positions in a steel pipe through adjusting the length of the telescoping tube; and because the nozzle assembly is designed to be composed of three trumpet-shaped nozzles, the jet area of powder is great, the speed of repairing is fast, effective and complete repairing of any crator position at the inner wall of the steel pipe can be realized, and safety in use of an integral pipeline is guaranteed.

Owner:ANHUI HONGYUAN PIPELINE TECH

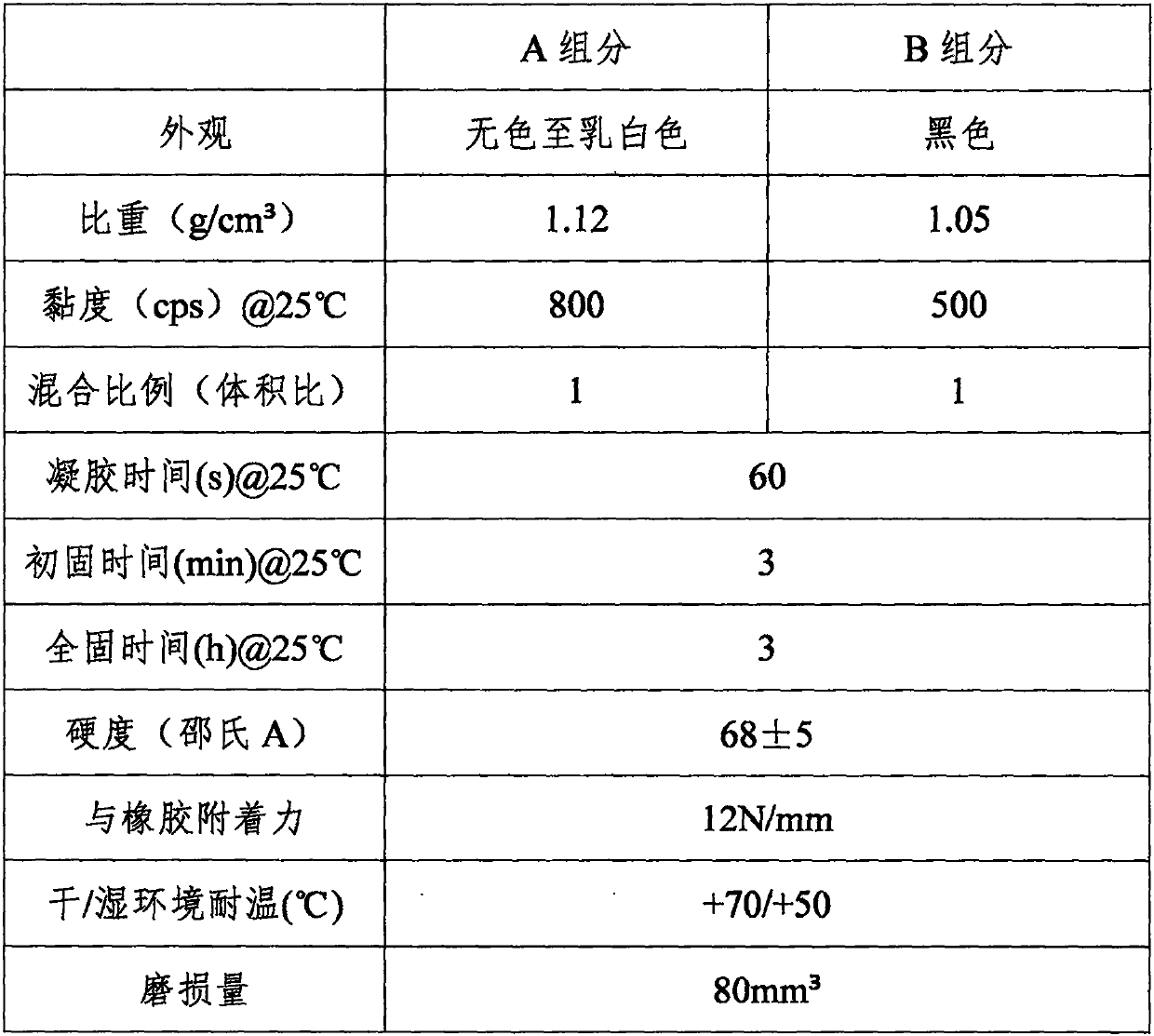

Quick mending agent

InactiveCN102504738BFast patchingEasy to useNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveFuel tank

The invention provides a quick mending agent and a preparation method thereof. The mending agent is a normal-temperature curing dual-component reactive mending agent, and has better comprehensive performances than those of epoxy, anaerobic and other common adhesives; a cured adhesive layer is grey and has the bonding strength of 43MPa; and the temperature for using the mending agent is between 60and 180 DEG C. The quick mending agent is mainly used for sealing and blocking oil tanks, water tanks and gas transmission pipelines.

Owner:北京天诚宇新材料技术有限公司

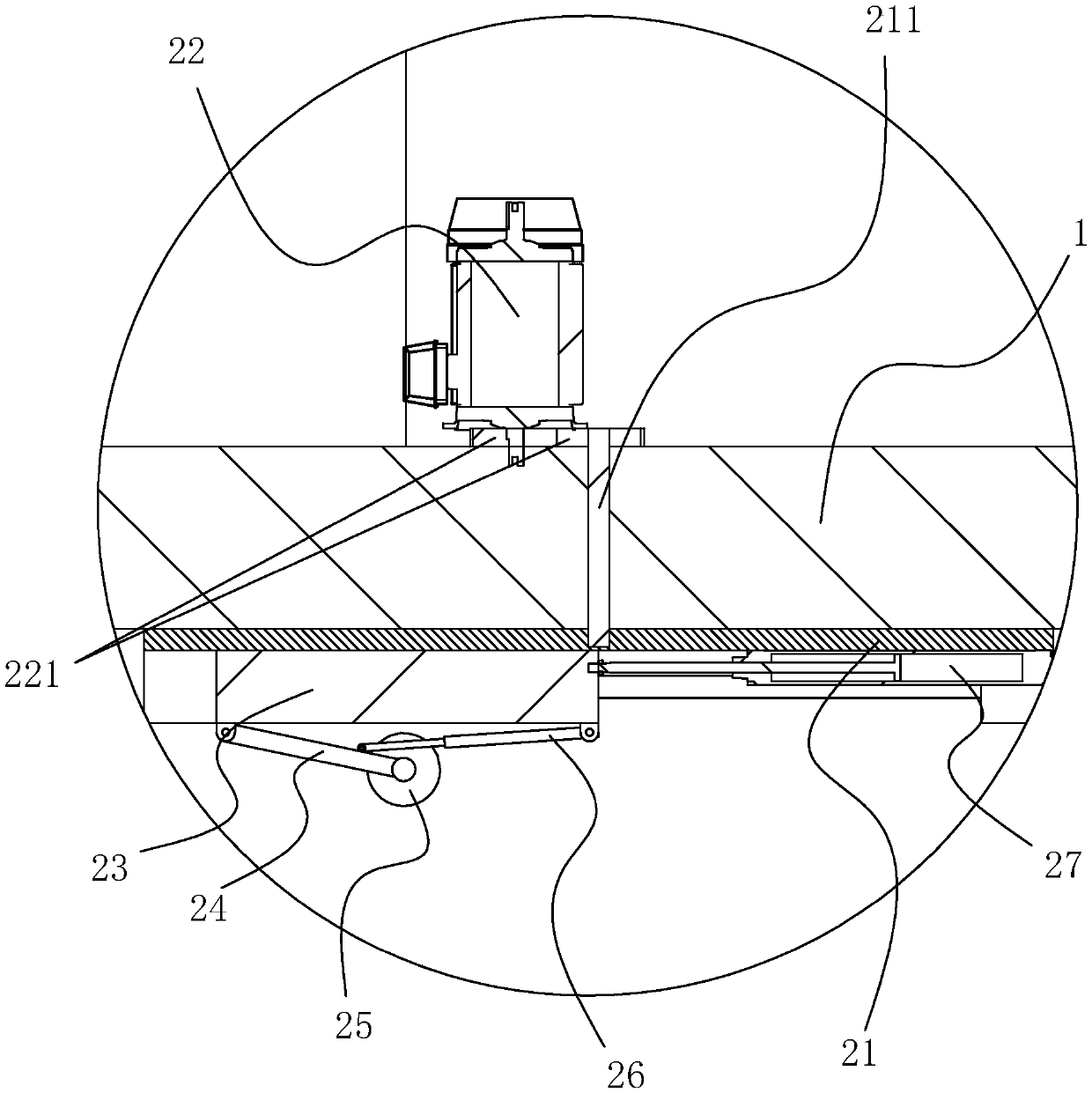

Pipeline installing equipment with ground repairing function

ActiveCN108253194AReduce installation costsFast patchingPipe laying and repairRoads maintainenceEngineeringMechanical engineering

The invention relates to pipeline installing equipment with a ground repairing function. The pipeline installing equipment comprises a shell, a camera, a repairing mechanism and two pressing wheels; an installing mechanism is arranged in a groove; the repairing mechanism comprise a mixing unit and a moving unit; the mixing unit comprises a first motor, a first gear, a rotary plate, a feeding pipe,a stirring box, a discharging pipe, a valve and two stirring assemblies; the installing mechanism comprises a lifting unit, a lifting plate and a telescopic unit; the lifting unit comprises a transmission assembly, a slide block, a slide groove, a telescopic frame, a limiting block and a limiting groove; and the telescopic unit comprises a stretching-out assembly and a lifting block. According tothe pipeline installing equipment with the ground repairing function, through the repairing mechanism, a lot of sunken parts on the ground of the pipe gallery can be filled up, so that other equipment does not shake during working, and the working precision is improved; and in addition, through the installing mechanism, the pipeline installing equipment can lift a pipeline to the higher position,the labor intensity of workers is relieved, and the pipeline installing cost is reduced.

Owner:融创达科技成果转化(江苏)有限公司

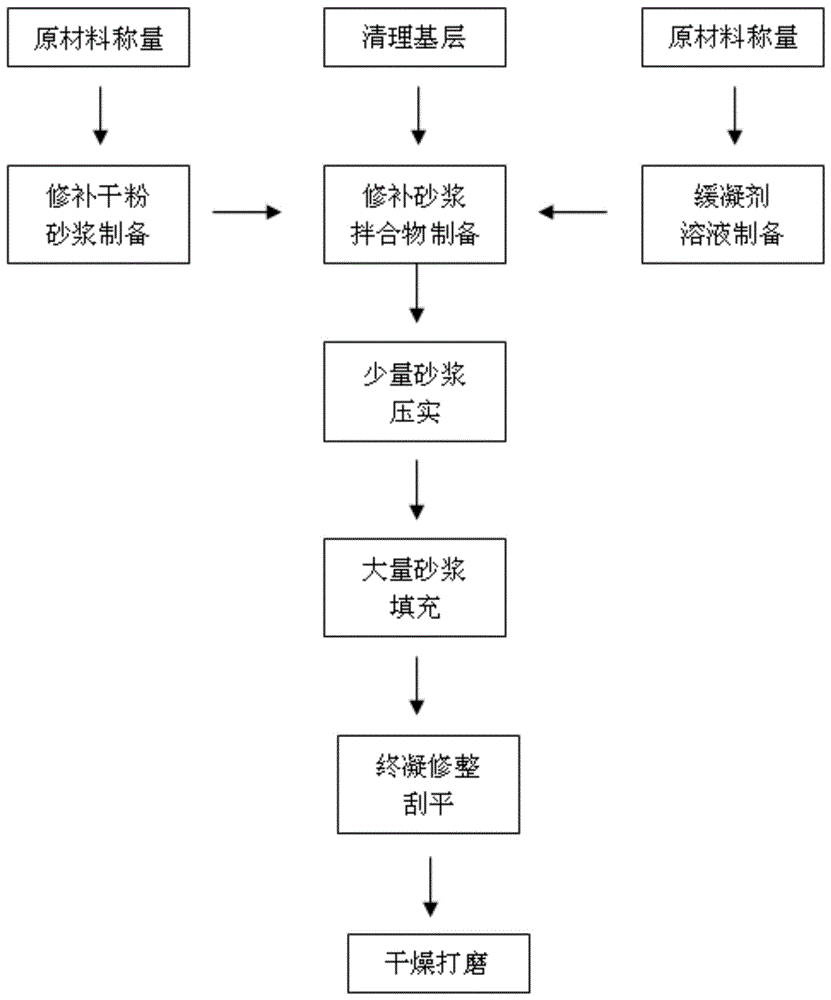

Rapid repair mortar and repair process special for autoclaved aerated concrete slab

InactiveCN105859234AGood qualityRepair cycle reductionSolid waste managementGypsumAutoclaved aerated concrete

The invention discloses a rapid repair mortar and a repair process for an autoclaved aerated concrete slab. The repair mortar takes gypsum mortar as a substrate material doped with a functional admixture, and is characterized by comprising the following components in parts by weight: 90-100 parts of gypsum mortar, 0.5-1.5 parts of an additive, and 25-30 parts of a retarder aqueous solution. The repair process comprises the following steps: cleaning a damaged surface, mixing the repair mortar, smearing a small amount of the mortar on the damaged surface and squeezing and compacting the mortar at first, then filling a damaged part compactly with a large amount of the mortar, trimming and flattening the mortar after final set of the mortar, and finally, performing polishing. The repair technology has the characteristics of convenience in operation, high repair speed, basically no chromatic aberration, and firm agglutination between the repair mortar and an autoclaved aerated concrete base, and the like, so that the repair efficiency can be greatly improved, and the damage rate is reduced.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

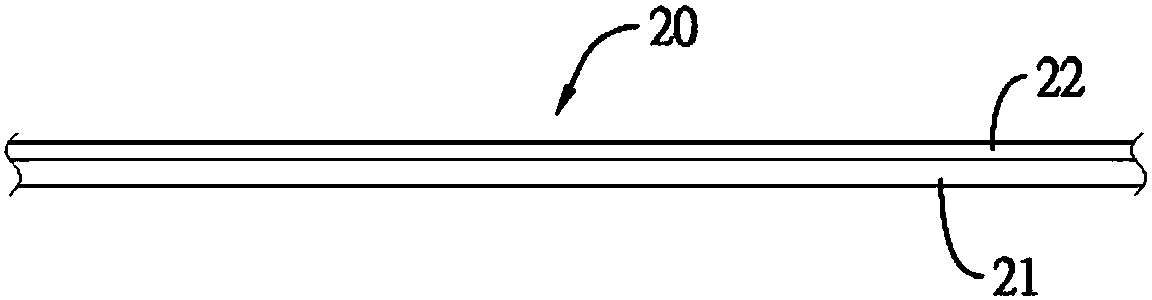

Conveyor belt repair method

The invention relates to a conveyor belt repair method comprising the following step (1) of grinding; the step (2) of primer coating: the primer is composed of first components and second components and the mass ratio of the first components to the second components is 100:3; when the primer is coated, the first components and the second components are mixed uniformly, and the primer is coated ona polished conveyor belt with a brush; the primer is uniformly coated on the conveyor belt without missing points for forming a primer coating; the step (3) of drying; the step (4) of coating of repair agents: the repair agents are composed of components A and components B and the mass ratio of the components A to the components B is 1:1; when the repair agents are coated, the components A and thecomponents B are mixed uniformly, and then the repair agents uniformly mixed through a spray gun are uniformly coated on the primer coating; and the step (5) of curing. The conveyor belt repair method is simple in process and wide in application range, and can be widely applied to different conveyor belts; and the repair effect is good.

Owner:济宁联能工贸有限公司

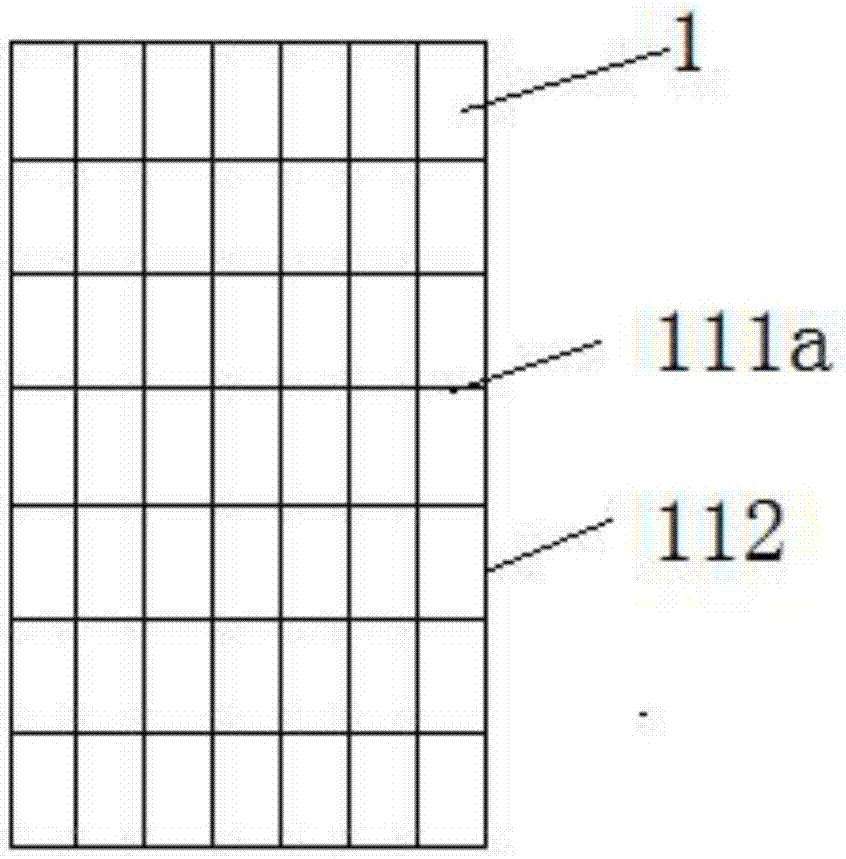

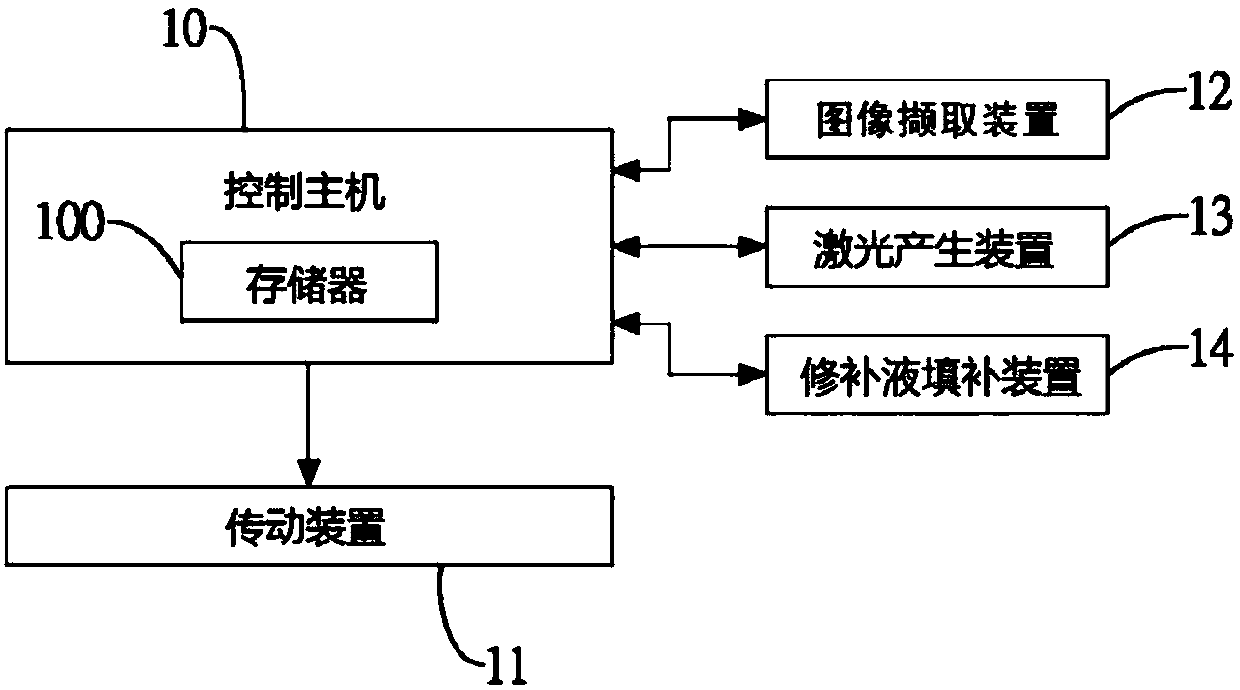

Alignment film repairing method capable of saving repairing cost

An alignment film repairing method capable of saving the repairing cost includes: establishing a visual image of an object to be tested, defining a defect frame option area after it is determined thatan alignment film has defects, and defining a plurality of removing designated areas according to the defect frame option area; generating an binaryzation image of the visual image so as to find a block corresponding to the defects; comparing if each removing designated area is overlapped with the block or not so as to retain the removing designated areas overlapped with the block, and then performing laser removing and repairing solution filling on the removing designated areas overlapped with the block, wherein removing designated areas separating from the block are corresponding to normalparts of the alignment film and can be excluded, and later laser removing and repairing solution filling of the removing designated areas separating from the block can be avoided. The alignment film repairing method can effectively reduce and shorten the area and the time of laser removing and repairing solution filling, and can save the repairing cost.

Owner:MARKETECH INT

Process for repairing ancient books, paintings and calligraphy and paper literatures by using paper pulp

ActiveCN100510257CFast patchingEasy to operateNon-fibrous pulp additionPaper/cardboardAdhesion forceFiber

The ancient book, calligraphy and painting pulp repairing process of the present invention relates to a kind of ancient book, calligraphy and painting, paper document repairing process method using pulp. The process is as follows: (1) Select the pulp material according to the quality of the restored ancient books, calligraphy and painting paper, put the base paper of the pulp material into the mixer, add water and suspending agent, stir and pulverize evenly; the weight ratio of base paper, suspending agent and water is: Base paper 5-20, suspending agent 5-15, water 500-1000; stirring time 30-90 seconds, take out the pulp for later use. (2) Put the ancient books, calligraphy and paintings to be repaired flat on the repair frame made by handmade paper curtains, put the prepared pulp in the repair pen for repair, and repair the damaged parts of ancient books, calligraphy and paintings, and use When the pulp is made into paper, the bonding force, the interweaving force of the fibers and the adhesion of the suspending agent are automatically repaired; (3) the above-mentioned repaired ancient books, calligraphy and paintings are removed from the repair rack, placed flat on the absorbent paper, and absorbed. Let it dry naturally, remove the binding, and the repair work is complete.

Owner:邱晓刚

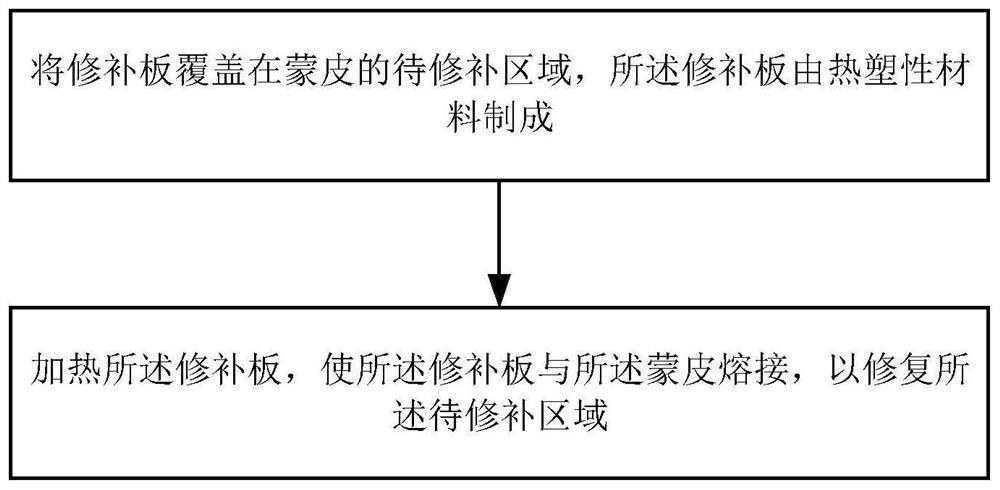

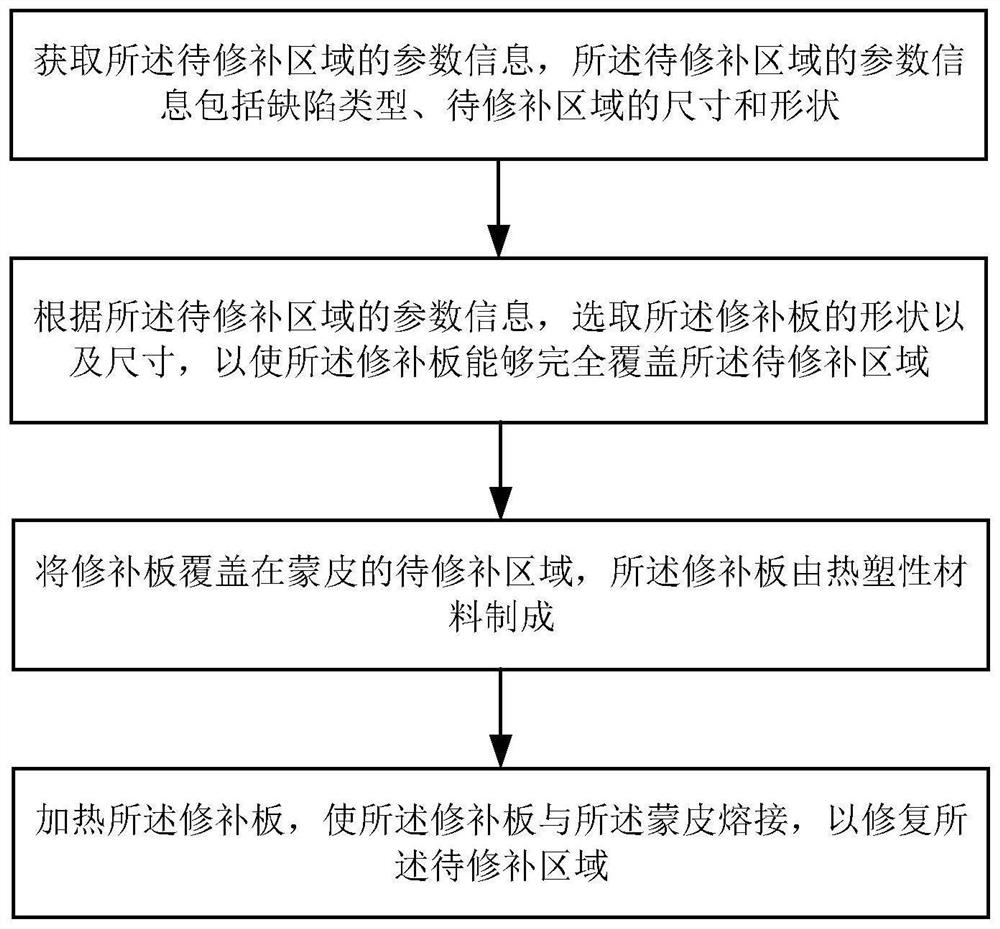

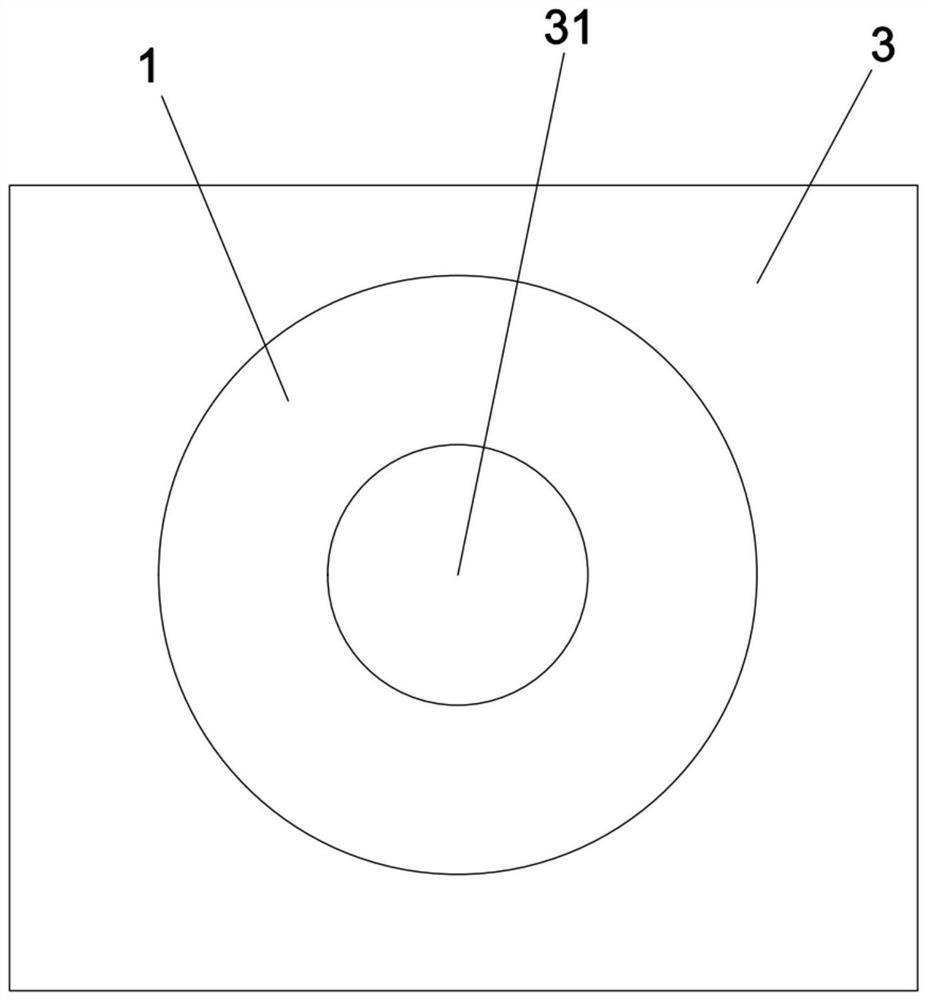

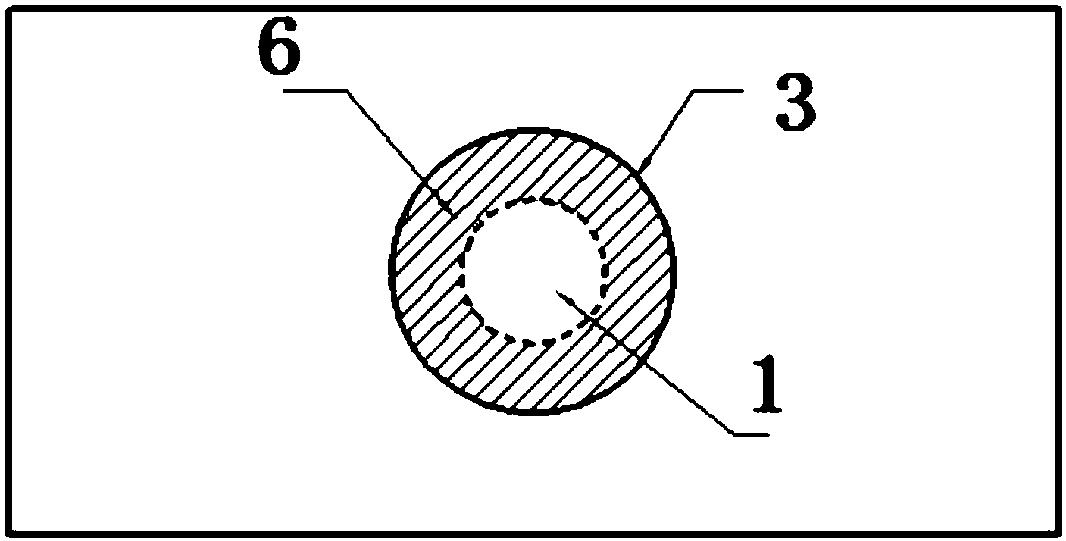

Skin repairing method and skin repairing equipment

The invention belongs to the technical field of plate repairing, and discloses a skin repairing method and skin repairing equipment. The skin repairing method comprises the steps of covering a to-be-repaired area of skin with a repairing plate made of a thermoplastic material, and heating the repairing plate to be welded to the skin so as to repair the to-be-repaired area. The skin repairing method is simple to operate, the repairing speed of the skin can be increased, meanwhile, the service life of the skin can be effectively prolonged, and the cost is saved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

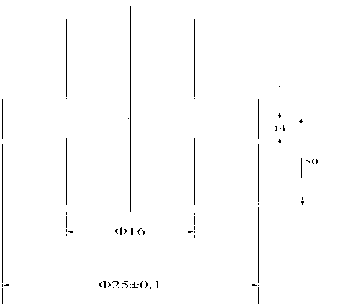

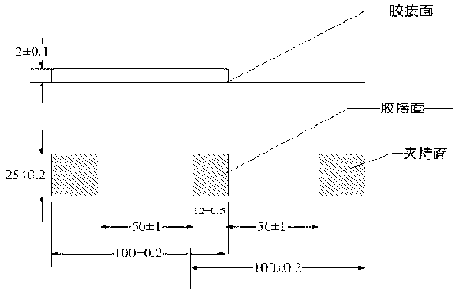

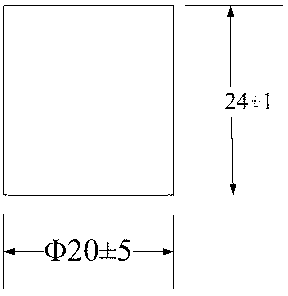

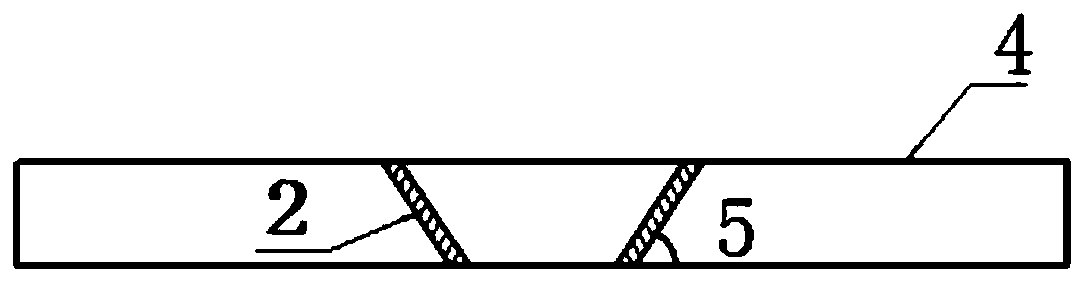

Filling repair method used for adhesive bonding repair

The invention relates to a filling repair method used for adhesive bonding repair. According to the method, structure repair is completed by filling a clearance between a repair patch and a to-be-repaired material with an adhesive, the repaired structure is kept basically consistent with a structure not damaged in shape, no residual obstacle is formed near the repair region, the method is especially applicable to a structure with relatively high requirement on appearance, and the problem of patching angle does not need to be considered during filing repair, and therefore, damage to a mother board material and the difficulty of repair patch processing are reduced, and the repair work is simpler and faster.

Owner:HEBEI UNIV OF TECH

Diamond-type screen tricot knitting net sheet repairing method for fishing

The invention discloses a method for repairing warp-knitted nets with rhombic meshes for fishing, which relates to the repairing of warp-knitted nets for fishing. The technical solution of the present invention includes mesh cutting and sewing, and is characterized in that the holes of the rhombus mesh warp-knitted mesh are trimmed into rectangles, and the ends of the holes are cut out by melting; There are more than 2 meshes in the rectangular hole, and the same specification is trimmed into a rectangular mesh, and the end of the mesh foot of the cutting edge of the rectangular mesh is melted; use nylon fishing net thread or polyethylene mesh thread with the same diameter as the mesh foot of the repaired mesh as the suture line; Stack the rectangular mesh on the rectangular hole, align the redundant mesh of the repairing mesh with the mesh around the hole; connect the suture line to a mesh more than 3 mesh away from the hole Point the raw feet, use sutures to suture isometrically, and use double dead knots for repairing. This method is suitable for repairing rhombic mesh warp knitted mesh for fishing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

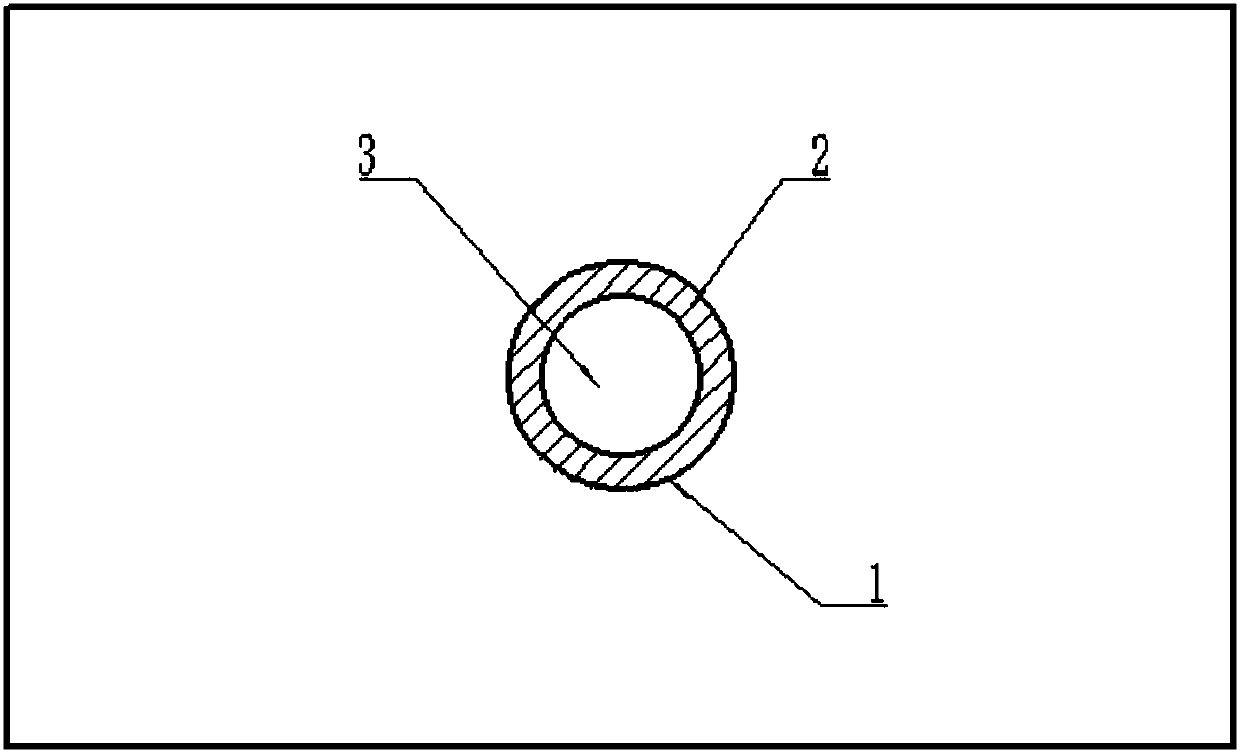

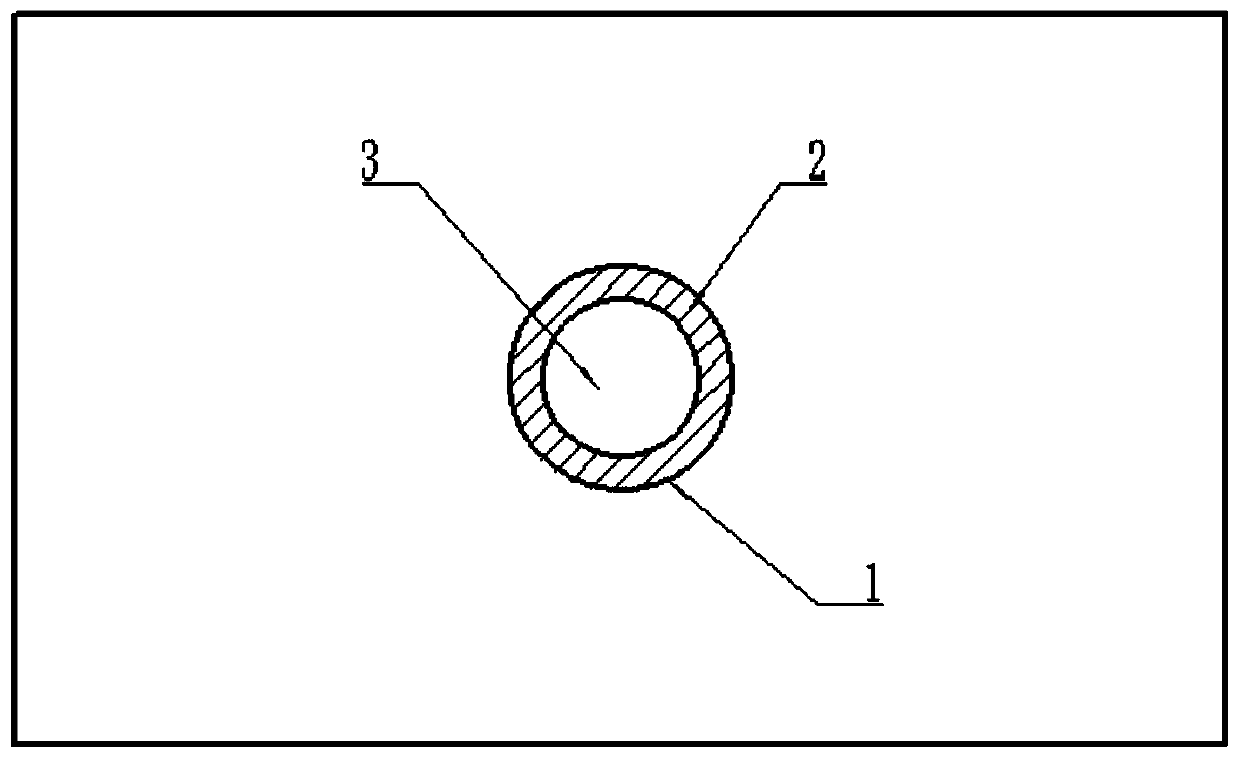

Plastic pipe inner ring leakage repairing device

InactiveCN112268159ALarge opening rangeCause secondary damagePigs/molesElectric machineryThin membrane

The invention discloses a plastic pipe inner ring leakage repairing device which comprises a head. A moving cavity, reciprocating cavities and a main transmission cavity are formed in the head, the reciprocating cavities are located at the right end of the moving cavity, distributed in the front-back direction, completely symmetrical and connected with the moving cavity, and the main transmissioncavity is located between the two reciprocating cavities. A motor is fixedly connected into the left cavity wall of the main transmission cavity. The motor is in power connection with a motor shaft, the right end of the motor shaft extends into the main transmission cavity and is fixedly connected with a motor bevel gear, and an incomplete gear shaft is rotationally connected between the upper cavity wall and the lower cavity wall of the main transmission cavity. The two ends of the incomplete gear shaft penetrate through the reciprocating cavities in the two sides and are rotationally connected into the cavity walls of the sides, away from the symmetry axis, of the reciprocating cavities, a thin film material needed for pipe repairing only needs to be put into the corresponding cavity, the device is started to be plugged into a pipe, the device can automatically drill into the pipe, drilling and film pasting repairing are conducted at the same time, the repairing speed is high, and the repairing efficiency is high.

Owner:杭州容旗科技有限公司

Quick leakage repairing method for anticorrosive pipeline

The invention discloses a quick leakage repairing method for an anticorrosive pipeline. The quick leakage repairing method is characterized in that a mode of digging out and repairing again is adopted; the method is simple and effective, and is high in repairing speed, can complete leakage repairing by only needing more than half an hour, and is high in efficiency, so that the anticorrosive pipeline is long in service time and can be continuously used for 8-16 months; and an anticorrosive layer is good in quality and is wide in applicability. According to the quick leakage repairing method disclosed by the invention, ABS powder and PFA powder with a special proportion are taken as raw materials, any additive and plastic filler are not added during production, two raw materials are complementary in performance in a heating melting process, and are good in integration with the original anticorrosive layer; and leakage repairing points tightly fit to the original anticorrosive layer in the pipeline and the inner wall of the pipeline, and adhesive force is strong, so that the leakage repairing points, the original anticorrosive layer and the inner wall of the pipeline do not get loose and separate within a very long time, and therefore, impact resistance is improved, quality of the anticorrosive layer is improved, and the service life of the anticorrosive layer is greatly prolonged.

Owner:丁冲

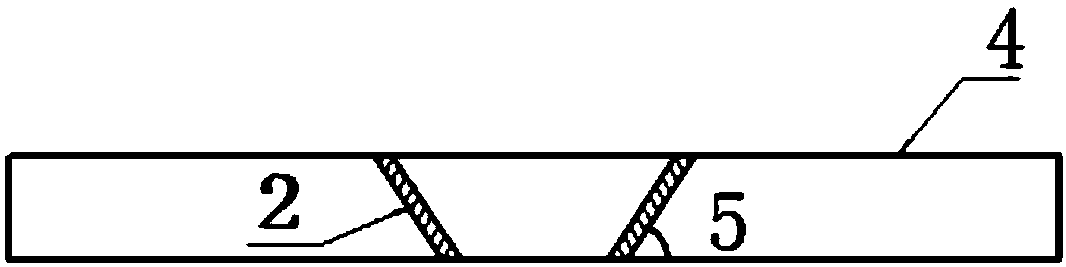

Long-distance longitudinal tearing repairing method for steel wire rope core adhesive tape

InactiveCN112374080AAvoid full mine shutdownShort recovery timeControl devices for conveyorsAdhesive beltMaterials science

The invention discloses a long-distance longitudinal tearing repairing method for a steel wire rope core adhesive tape. According to the belt repairing effect and the time length required by repairing, repairing is divided into the following two schemes that (1) single-face permanent repairing is adopted, specifically, a polyurethane manufacturing material is used as a repairing strip, a torn beltis firstly formed into a V-shaped groove with the width being 2cm from the belt tearing part, then a hot repairing filling material is heated through a glue gun and then flows into the V-shaped groove, and joint filling is conducted; and when a non-coal-conveying face is transferred to the lower belt position, the repairing strip is used for bonding, after bonding is completed, the purpose of belt permanent bonding is achieved, the requirement is equal to or lower than the belt surface, then a belt conveyor operates normally, the consumed time is long, and the effect is good; and (2) the twofaces of the belt are bonded through the repairing strip, the polyurethane manufacturing material is used as the repairing strip, the non-coal-conveying face of the torn belt is firstly transferred tothe return lower belt position and bonded through the repairing strip, then the damaged belt coal conveying face is transferred to the top plate face, and then the upper repairing strip is bonded. The consumed time is short, and the production benefits are good.

Owner:DATONG COAL MINE GRP

A filling and repairing method for adhesive repair

ActiveCN107738497BAvoid damageSimple wayLayered productsMaterial gluingRepair materialMechanical engineering

The invention relates to a filling repair method used for adhesive bonding repair. According to the method, structure repair is completed by filling a clearance between a repair patch and a to-be-repaired material with an adhesive, the repaired structure is kept basically consistent with a structure not damaged in shape, no residual obstacle is formed near the repair region, the method is especially applicable to a structure with relatively high requirement on appearance, and the problem of patching angle does not need to be considered during filing repair, and therefore, damage to a mother board material and the difficulty of repair patch processing are reduced, and the repair work is simpler and faster.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com