Long-distance longitudinal tearing repairing method for steel wire rope core adhesive tape

A technology of longitudinal tearing and steel cord cores, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as belt damage, and achieve the effects of small safety pressure, wide operating range, and obvious social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

[0013] A method for repairing long-distance longitudinal tearing of a steel cord belt. According to the belt repair effect and the length of time required for repair, the damaged part of the belt is the coal transportation surface, and the repair is divided into the following two schemes:

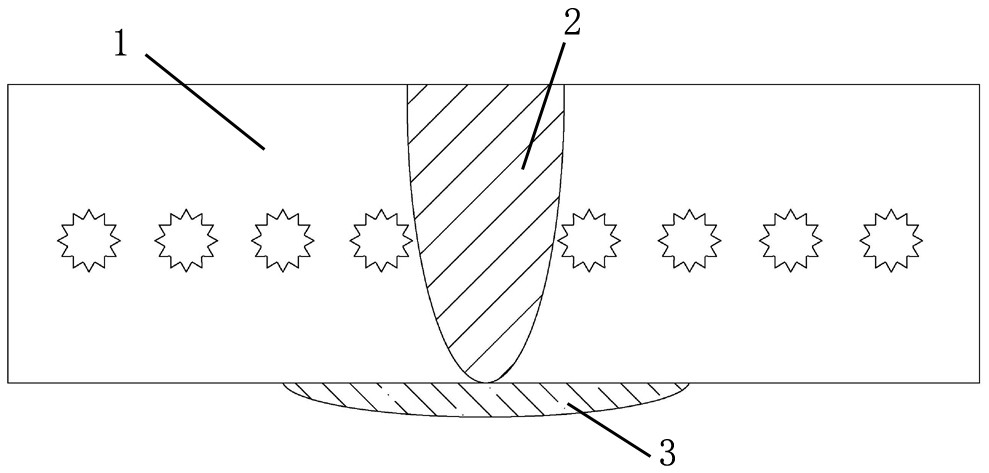

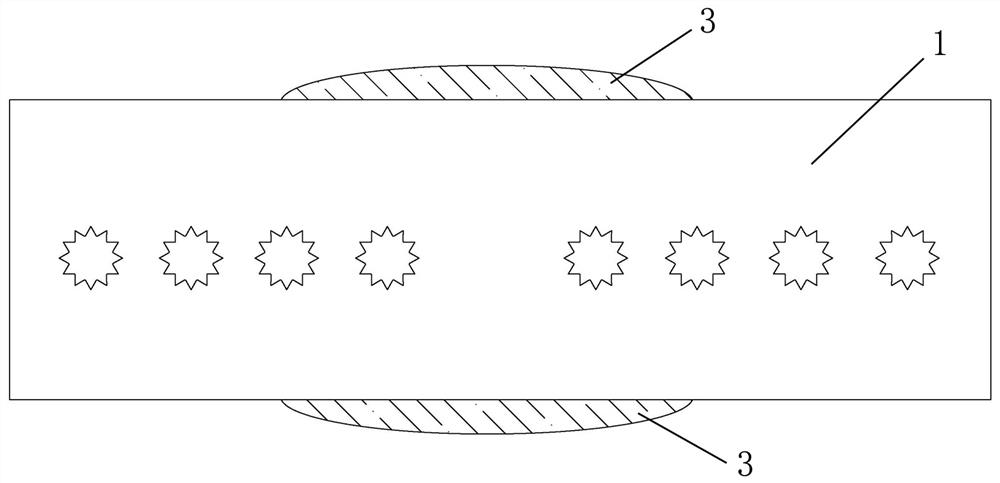

[0014] (1) if figure 1 As shown, if you want to have a good repair effect, use one-sided permanent repair, which takes a long time: use polyurethane material as the repair strip, first cut the torn belt into a V-shaped groove with a width of 2 cm from the torn part of the belt, and then use The hot-filling material is heated by a glue gun and flows into the V-shaped groove for caulking; when the non-coal surface is running to the lower belt position, it is bonded with a repair strip. After the bonding is completed, the belt is permanently bonded. Purpose, it is required to be equal to or l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com