A filling and repairing method for adhesive repair

A technology of bonding and repairing pieces, which is applied in the field of filling and repairing for bonding repairs, can solve problems such as difficult control of digging and repairing angle accuracy, unfavorable engineering application, and affecting repairing effects, so as to overcome difficult control, improve repairing speed, reduce The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the present application.

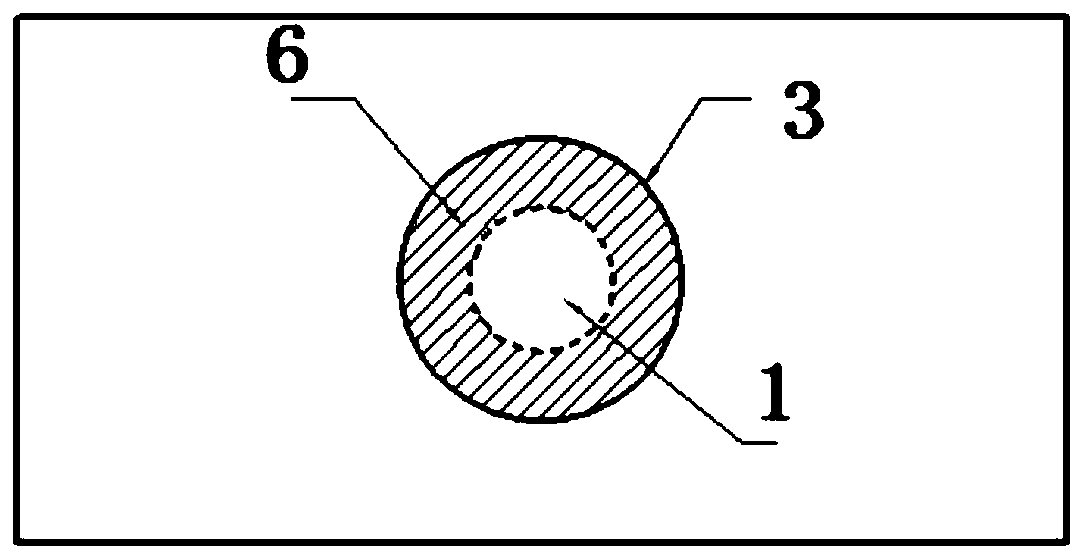

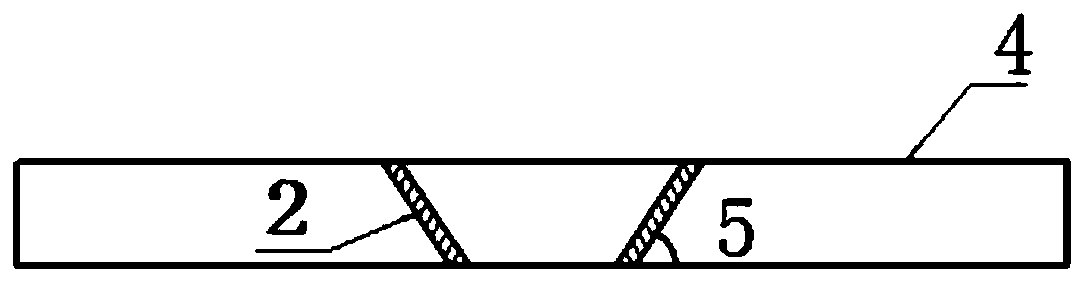

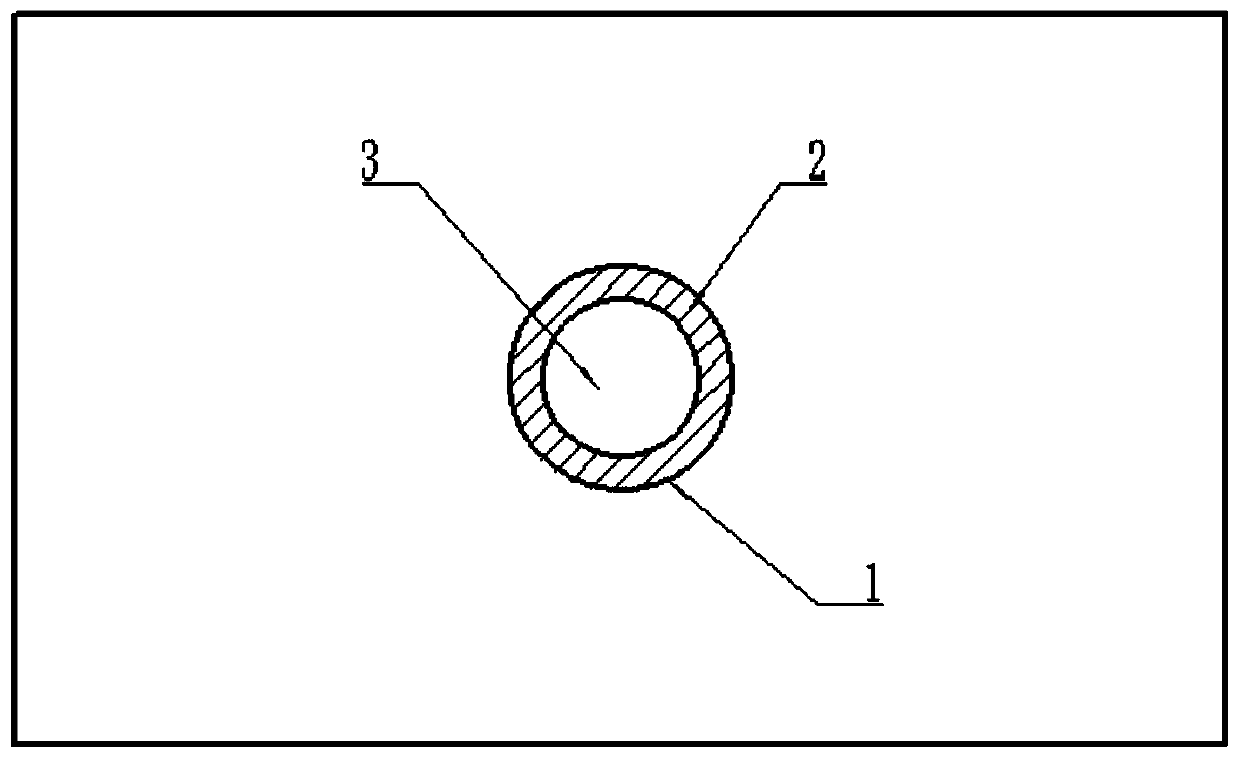

[0023] The present invention is a filling and repairing method (method for short, see Figure 2-3 ), the steps of this method are:

[0024] 1) Surface cleaning of the damaged area;

[0025] 2) According to the shape of the damaged area, use a rotary grinder to process the damaged area into a shape with a smooth boundary, no sharp corners and no stress singularity, so as to eliminate possible stress singularity, and the damaged area will be columnar after treatment. shape structure, determine the aspect ratio of the damaged area, and the smooth boundary refers to the boundary generated by rounded corner transition;

[0026] 3) Prepare a patch made of the same material as the motherboard. The thickness of the patch is the same as that of the damaged sunken ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com