Coke oven door smoke sealing material and sealing method thereof

A sealing material and furnace door technology, which is applied to the door/closer of the coke oven, coke oven, coke oven heating, etc., which can solve the problem of poor sealing of the furnace door, lack of sealing effect, smoke and fire from the furnace door and other problems, to achieve the effect of eliminating smoke and fire, reducing chemical yield, and fast repair speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

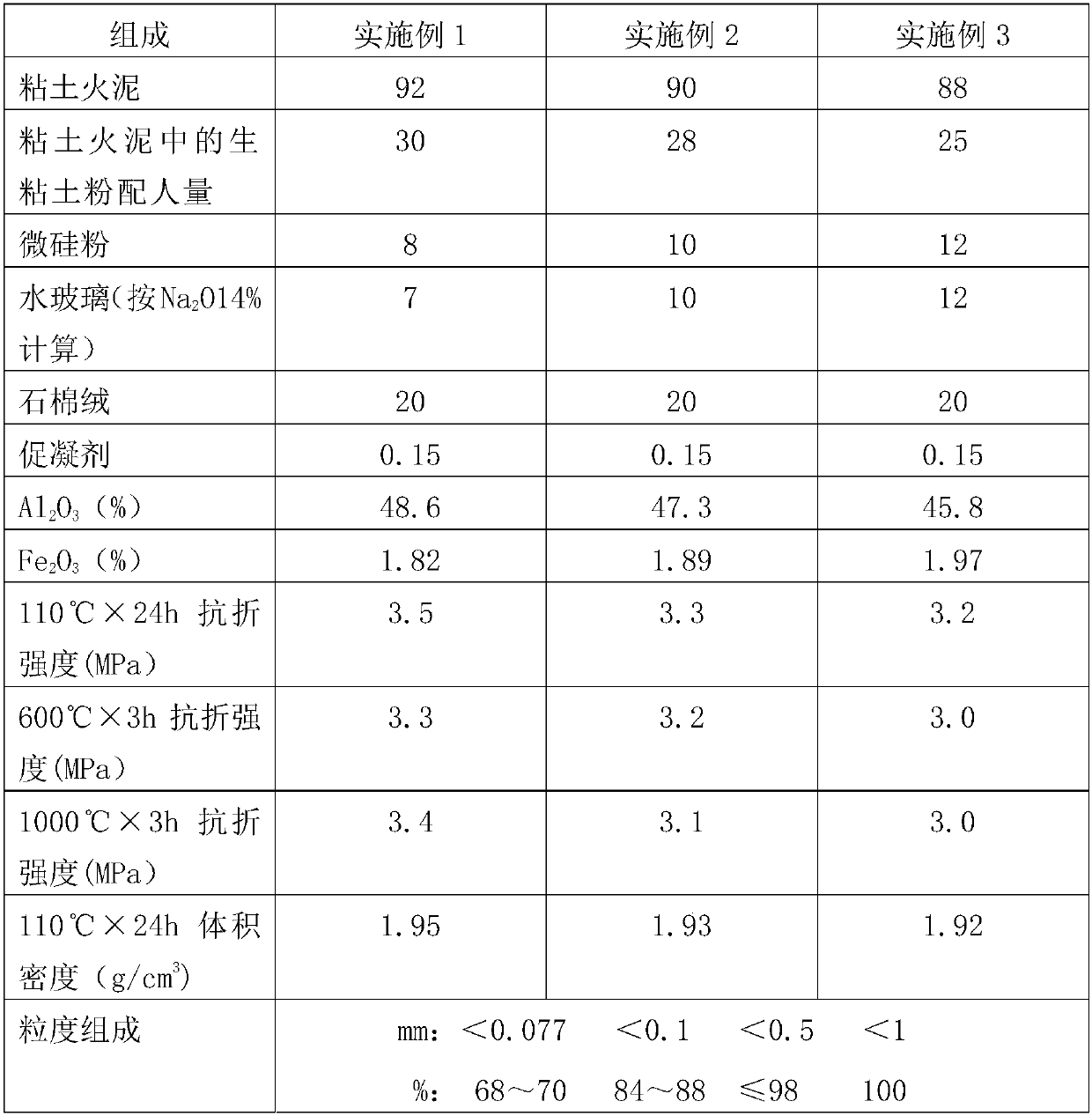

[0031] The specific implementation of the present invention will be further described in detail through the description of the examples below.

[0032] The coke oven door smoke sealing material, including main materials and additive materials;

[0033] The components of the main ingredient are calculated by weight percentage and include:

[0034] Clay fire mud 88-92%;

[0035] Microsilica fume 8-12%;

[0036] Additives are calculated on the basis of the total weight of the above-mentioned main ingredients, including:

[0037] Water glass 7-12%;

[0039] Coagulant 0.1~0.2%.

[0040] Among them, the proportion of raw clay powder in clay fire clay accounts for 25-30%. Water glass by Na 2 O14% calculation. The chemical composition of clay fire clay is Al 2 o 3 ≥45%, Fe 2 o 3 ≤2.00%.

[0041] The particle size of the coke oven door smoke sealing material formed by the above components is controlled at:

[0042] Granularity mm

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com