Skin repairing method and skin repairing equipment

A repair method and skin technology, applied in the direction of coating, can solve the problems of stress concentration, complex process, increase the weight of components, etc., to achieve the effect of improving repair speed, simplifying process flow, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

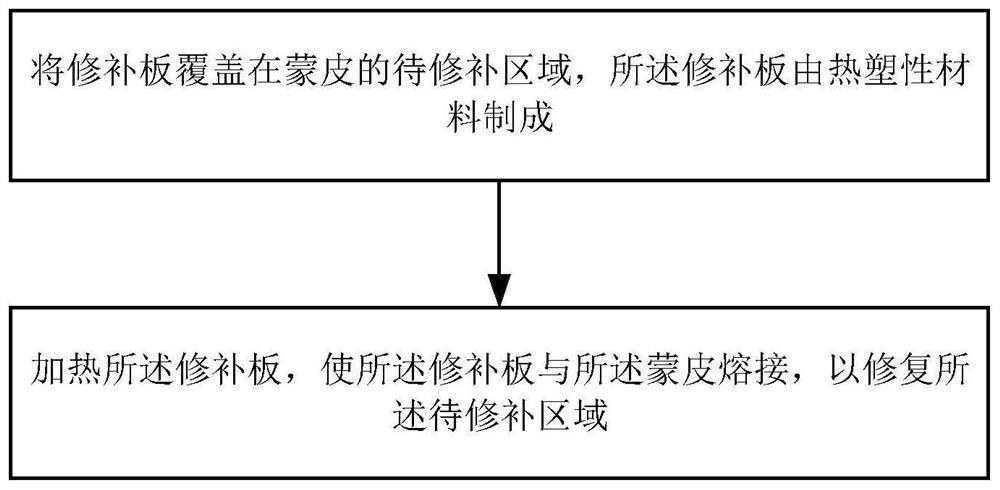

[0061] Such as figure 1As shown, the present invention provides a skin repair method, the skin repair method uses a thermoplastic material to repair the damaged skin 3, the specific steps include: covering the repair plate 1 made of thermoplastic material on the skin On the area to be repaired of the skin 3, then use the heating device 2 to heat the repair plate 1 to melt the thermoplastic material on the surface of the repair plate 1, and the melted thermoplastic material will weld the repair plate 1 and the skin 3 together, that is, complete the repair of the damage. The Skinning 3 was repaired. The skin repair method does not need to make holes on the surface of the skin 3, which simplifies the process flow and improves the repair speed; the thermoplastic material and the damaged skin 3 are welded together by heating, compared with the use of glue The technology can improve the strength of the repaired skin 3, and at the same time make the connection between the repair pla...

Embodiment 2

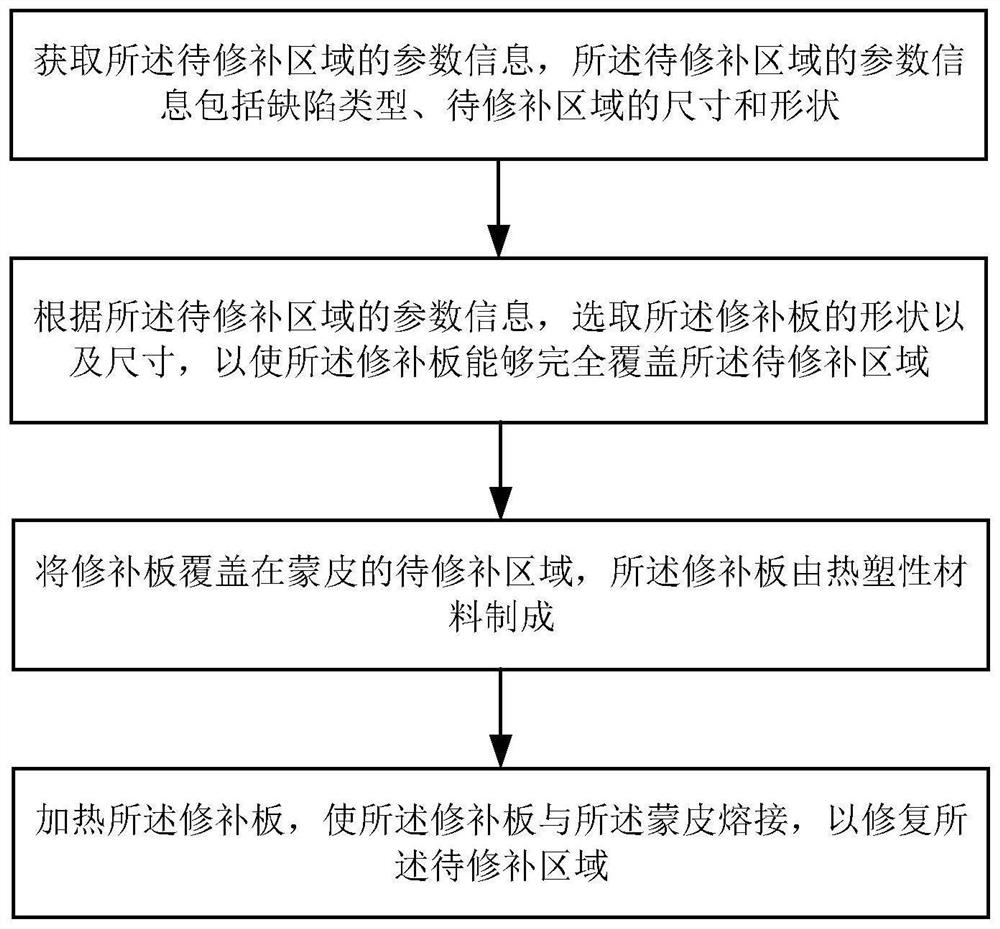

[0068] This embodiment provides a skin repair method, which is further improved on the basis of the first embodiment.

[0069] Such as figure 2 As shown, before covering the area to be repaired with the repair plate 1 , the parameter information of the area to be repaired needs to be obtained, so that the repair plate 1 with an appropriate size can be selected according to the parameter information of the area to be repaired, which can save materials. The parameter information of the area to be repaired specifically includes the defect type of the area to be repaired, the size and shape of the area to be repaired, and the shape and size of the repair board 1 are selected according to these parameter information, so that the repair board 1 can completely cover the area to be repaired , can further improve the repair effect.

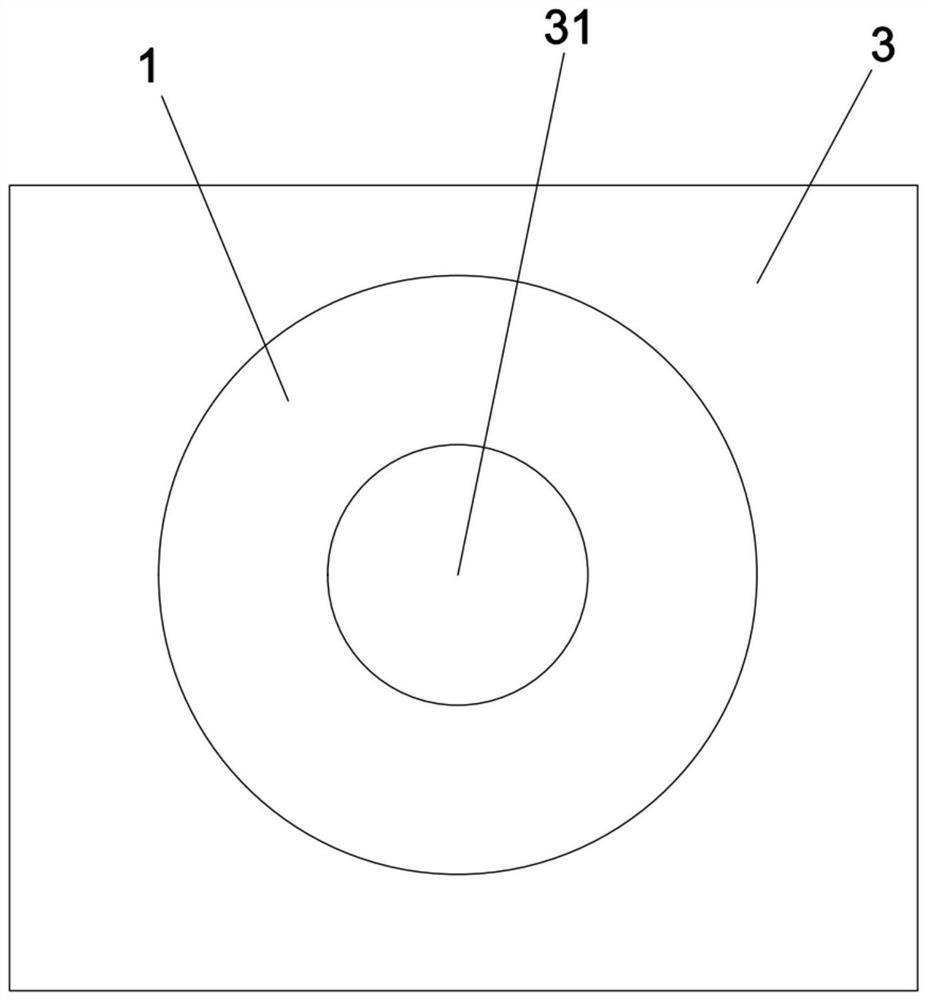

[0070] Such as Figure 3-Figure 4 As shown, common defect types of the skin 3 include hole defects 31 and crack defects 32 .

[0071] Preferably, as ...

Embodiment 3

[0090] This embodiment also provides a skin repairing device, which can be used in the above skin repair method, so as to automatically repair the damaged skin 3, ensure the repair strength and improve the repair speed.

[0091] Specifically, such as Figure 9 As shown, the repairing equipment for the skin 3 includes a mechanical arm 6 and a heating device 2. The end of the mechanical arm 6 is provided with a holding part, and the heating operation end of the heating device 2 is installed on the holding part at the end of the mechanical arm 6 to heat the thermoplastic The repair panel 1 made of material is heated.

[0092] It can be understood that the robot arm 6 in this implementation is a six-axis robot, which can perform multi-degree-of-freedom movements to facilitate the repair of the skin 3 at different positions.

[0093] Preferably, as Figure 9 As shown, the repair equipment for the skin 3 also includes a scanning device 5 and a control device 4, the scanning device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com